WO2018168389A1 - Vehicle control apparatus - Google Patents

Vehicle control apparatus Download PDFInfo

- Publication number

- WO2018168389A1 WO2018168389A1 PCT/JP2018/006568 JP2018006568W WO2018168389A1 WO 2018168389 A1 WO2018168389 A1 WO 2018168389A1 JP 2018006568 W JP2018006568 W JP 2018006568W WO 2018168389 A1 WO2018168389 A1 WO 2018168389A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- regenerative

- energy

- vehicle

- engine

- traveling

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L50/00—Electric propulsion with power supplied within the vehicle

- B60L50/10—Electric propulsion with power supplied within the vehicle using propulsion power supplied by engine-driven generators, e.g. generators driven by combustion engines

- B60L50/16—Electric propulsion with power supplied within the vehicle using propulsion power supplied by engine-driven generators, e.g. generators driven by combustion engines with provision for separate direct mechanical propulsion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K6/00—Arrangement or mounting of plural diverse prime-movers for mutual or common propulsion, e.g. hybrid propulsion systems comprising electric motors and internal combustion engines ; Control systems therefor, i.e. systems controlling two or more prime movers, or controlling one of these prime movers and any of the transmission, drive or drive units Informative references: mechanical gearings with secondary electric drive F16H3/72; arrangements for handling mechanical energy structurally associated with the dynamo-electric machine H02K7/00; machines comprising structurally interrelated motor and generator parts H02K51/00; dynamo-electric machines not otherwise provided for in H02K see H02K99/00

- B60K6/20—Arrangement or mounting of plural diverse prime-movers for mutual or common propulsion, e.g. hybrid propulsion systems comprising electric motors and internal combustion engines ; Control systems therefor, i.e. systems controlling two or more prime movers, or controlling one of these prime movers and any of the transmission, drive or drive units Informative references: mechanical gearings with secondary electric drive F16H3/72; arrangements for handling mechanical energy structurally associated with the dynamo-electric machine H02K7/00; machines comprising structurally interrelated motor and generator parts H02K51/00; dynamo-electric machines not otherwise provided for in H02K see H02K99/00 the prime-movers consisting of electric motors and internal combustion engines, e.g. HEVs

- B60K6/42—Arrangement or mounting of plural diverse prime-movers for mutual or common propulsion, e.g. hybrid propulsion systems comprising electric motors and internal combustion engines ; Control systems therefor, i.e. systems controlling two or more prime movers, or controlling one of these prime movers and any of the transmission, drive or drive units Informative references: mechanical gearings with secondary electric drive F16H3/72; arrangements for handling mechanical energy structurally associated with the dynamo-electric machine H02K7/00; machines comprising structurally interrelated motor and generator parts H02K51/00; dynamo-electric machines not otherwise provided for in H02K see H02K99/00 the prime-movers consisting of electric motors and internal combustion engines, e.g. HEVs characterised by the architecture of the hybrid electric vehicle

- B60K6/48—Parallel type

- B60K6/485—Motor-assist type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L50/00—Electric propulsion with power supplied within the vehicle

- B60L50/50—Electric propulsion with power supplied within the vehicle using propulsion power supplied by batteries or fuel cells

- B60L50/60—Electric propulsion with power supplied within the vehicle using propulsion power supplied by batteries or fuel cells using power supplied by batteries

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/10—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries

- B60L58/12—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries responding to state of charge [SoC]

- B60L58/13—Maintaining the SoC within a determined range

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W10/00—Conjoint control of vehicle sub-units of different type or different function

- B60W10/02—Conjoint control of vehicle sub-units of different type or different function including control of driveline clutches

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W10/00—Conjoint control of vehicle sub-units of different type or different function

- B60W10/04—Conjoint control of vehicle sub-units of different type or different function including control of propulsion units

- B60W10/06—Conjoint control of vehicle sub-units of different type or different function including control of propulsion units including control of combustion engines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W10/00—Conjoint control of vehicle sub-units of different type or different function

- B60W10/04—Conjoint control of vehicle sub-units of different type or different function including control of propulsion units

- B60W10/08—Conjoint control of vehicle sub-units of different type or different function including control of propulsion units including control of electric propulsion units, e.g. motors or generators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W10/00—Conjoint control of vehicle sub-units of different type or different function

- B60W10/10—Conjoint control of vehicle sub-units of different type or different function including control of change-speed gearings

- B60W10/11—Stepped gearings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W20/00—Control systems specially adapted for hybrid vehicles

- B60W20/10—Controlling the power contribution of each of the prime movers to meet required power demand

- B60W20/11—Controlling the power contribution of each of the prime movers to meet required power demand using model predictive control [MPC] strategies, i.e. control methods based on models predicting performance

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W20/00—Control systems specially adapted for hybrid vehicles

- B60W20/10—Controlling the power contribution of each of the prime movers to meet required power demand

- B60W20/13—Controlling the power contribution of each of the prime movers to meet required power demand in order to stay within battery power input or output limits; in order to prevent overcharging or battery depletion

- B60W20/14—Controlling the power contribution of each of the prime movers to meet required power demand in order to stay within battery power input or output limits; in order to prevent overcharging or battery depletion in conjunction with braking regeneration

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W30/00—Purposes of road vehicle drive control systems not related to the control of a particular sub-unit, e.g. of systems using conjoint control of vehicle sub-units, or advanced driver assistance systems for ensuring comfort, stability and safety or drive control systems for propelling or retarding the vehicle

- B60W30/18—Propelling the vehicle

- B60W30/18009—Propelling the vehicle related to particular drive situations

- B60W30/18109—Braking

- B60W30/18127—Regenerative braking

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W30/00—Purposes of road vehicle drive control systems not related to the control of a particular sub-unit, e.g. of systems using conjoint control of vehicle sub-units, or advanced driver assistance systems for ensuring comfort, stability and safety or drive control systems for propelling or retarding the vehicle

- B60W30/18—Propelling the vehicle

- B60W30/18009—Propelling the vehicle related to particular drive situations

- B60W30/18072—Coasting

- B60W2030/1809—Without torque flow between driveshaft and engine, e.g. with clutch disengaged or transmission in neutral

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W50/00—Details of control systems for road vehicle drive control not related to the control of a particular sub-unit, e.g. process diagnostic or vehicle driver interfaces

- B60W2050/0062—Adapting control system settings

- B60W2050/0075—Automatic parameter input, automatic initialising or calibrating means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W2510/00—Input parameters relating to a particular sub-units

- B60W2510/08—Electric propulsion units

- B60W2510/081—Speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W2520/00—Input parameters relating to overall vehicle dynamics

- B60W2520/10—Longitudinal speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W2540/00—Input parameters relating to occupants

- B60W2540/12—Brake pedal position

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W2556/00—Input parameters relating to data

- B60W2556/10—Historical data

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W2710/00—Output or target parameters relating to a particular sub-units

- B60W2710/08—Electric propulsion units

- B60W2710/081—Speed

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/62—Hybrid vehicles

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/70—Energy storage systems for electromobility, e.g. batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/7072—Electromobility specific charging systems or methods for batteries, ultracapacitors, supercapacitors or double-layer capacitors

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/80—Technologies aiming to reduce greenhouse gasses emissions common to all road transportation technologies

- Y02T10/92—Energy efficient charging or discharging systems for batteries, ultracapacitors, supercapacitors or double-layer capacitors specially adapted for vehicles

Definitions

- This disclosure relates to a vehicle control device.

- Patent Document 1 a technology for putting a vehicle in an inertial running state by disengaging a clutch device provided between an engine and a transmission when an accelerator is off while the vehicle is running has been put into practical use.

- This inertial traveling is a technology that uses the kinetic energy of a vehicle as it is for traveling, and it is possible to improve fuel efficiency by extending the traveling distance of the vehicle.

- regenerative travel in which kinetic energy at the time of deceleration of the vehicle is recovered as regenerative energy to improve the energy efficiency of the vehicle.

- the motor functions as a generator by the rotation of an engine output shaft or the like, and the electrical energy generated by the power generation is stored in a battery.

- the present disclosure has been made in view of the above circumstances, and a main purpose thereof is to provide a vehicle control device capable of appropriately switching between inertial traveling and regenerative traveling.

- the clutch device In response to the establishment of predetermined inertial running conditions, the clutch device is disengaged to perform inertial running of the vehicle, and in accordance with the establishment of predetermined regeneration execution conditions during inertial running, the engine rotation speed is adjusted.

- a travel control unit that performs connection to the regenerative travel using the regenerative device from the inertia travel by performing connection of the clutch device; In the case where a braking operation is performed as the regeneration execution condition during the inertia traveling, an estimation is performed for estimating the energy consumed by adjusting the engine rotation speed and estimating the regeneration energy recovered by the regeneration traveling. And With The traveling control unit performs a transition from the inertia traveling to the regenerative traveling based on a comparison between the consumed energy and the regenerative energy.

- the energy consumption consumed by adjusting the engine speed is estimated, and the regeneration recovered by the regenerative traveling is estimated.

- Estimate energy is estimated.

- the transition from the inertia travel to the regenerative travel is performed.

- the shift to the regenerative travel can be suppressed from the viewpoint of energy efficiency, for example, by shifting to the regenerative travel in consideration of the energy consumption.

- the frequency of switching from coasting to regenerative traveling can be suppressed, leading to improved drivability. Thereby, inertial running and regenerative running can be switched appropriately.

- the brake operation as the regeneration execution condition may be a brake pedal operation by a driver or a deceleration determination by a vehicle operation control unit (for example, an automatic operation control unit).

- a vehicle operation control unit for example, an automatic operation control unit.

- the engine rotational speed is adjusted by driving the rotating machine, and the electrical energy required to drive the rotating machine is estimated as consumed energy. Good.

- the second means includes a determination unit that determines that the regenerative energy estimated by the estimation unit is greater than the consumed energy, and the travel control unit has the regenerative energy greater than the consumed energy. When it is determined, a transition from the inertia traveling to the regenerative traveling is performed, and when it is determined that the regenerative energy is smaller than the consumed energy, the inertia traveling is maintained.

- the transition from the inertial running to the regenerative running is performed, so that the energy more than the consumed energy can be recovered by the regenerative running.

- coasting since coasting is maintained when it is determined that the regenerative energy is smaller than the consumed energy, the fuel efficiency effect by coasting can be obtained, and the shift to unfavorable regeneration from the viewpoint of energy efficiency is suppressed. be able to.

- the estimation unit estimates the energy consumption based on the vehicle speed when the brake operation as the regeneration execution condition is performed during the inertial traveling.

- the energy consumption is energy required to rotate the output shaft of the engine up to the target engine speed, and is considered to correlate with the vehicle speed. That is, when the vehicle speed is high, the target engine rotation speed increases, and energy consumption increases accordingly. Considering this point, the energy consumption is estimated based on the vehicle speed, so that the energy consumption can be accurately estimated. As a result, it is possible to appropriately determine the transition from inertial travel to regenerative travel.

- the estimation unit estimates the regenerative energy based on the amount of brake operation when the brake operation is performed as the regeneration execution condition during the inertia traveling.

- Regenerative energy is considered to correlate with the amount of brake operation. For example, when the brake operation amount is large, the driver's request for deceleration is large and the regenerative energy is also large. Considering this point, the regenerative energy is estimated based on the brake operation amount, so that the regenerative energy can be estimated with high accuracy. As a result, it is possible to appropriately determine the transition from inertial travel to regenerative travel.

- the fifth means includes a setting unit that sets a duration of the regenerative travel when the brake operation is performed during the inertia travel, and the estimation unit determines the brake operation amount and the duration. Based on this, the regenerative energy is estimated.

- Regenerative energy is considered to correlate with the duration of regenerative travel. For example, the longer the duration of regenerative travel, the greater the regenerative energy. Considering this point, when the braking operation is performed during coasting, the duration of regenerative travel is set, and the regenerative energy is estimated based on the set duration and the amount of brake operation. Energy can be estimated accurately.

- the sixth means includes a storage unit that stores the duration when the regenerative travel is performed, and the setting unit is configured to perform the duration based on the history of the duration stored in the storage unit. Set.

- the duration is stored, and the duration is set based on the history of the stored duration, so the duration is set according to the tendency of the regenerative driving for each vehicle. be able to. Thereby, a continuation time can be set suitably.

- the storage unit stores the duration for each of a plurality of vehicle driving conditions, and the setting unit, when the brake operation is performed during the inertia running, The history is acquired according to the traveling condition of the vehicle, and the duration is set based on the history.

- the regeneration time of regenerative driving is thought to affect the driving conditions in each case. For example, it is considered that the regeneration time becomes longer as the vehicle speed increases.

- a history of duration is acquired according to the traveling condition of the vehicle, and the duration is set based on the history.

- the duration can be set in consideration of the conditions affecting the regeneration time.

- the duration time can be set with high accuracy in accordance with each operating condition.

- the regenerative device is a rotating electrical machine that performs regenerative power generation that recovers kinetic energy of the vehicle as electrical energy, and based on a state of a storage battery that stores power generated by the rotating electrical machine, A correction unit that corrects the regenerative energy estimated by the estimation unit is provided.

- the regenerative energy is corrected based on the state of the storage battery.

- the shift to the regenerative travel that is disadvantageous from the viewpoint of energy efficiency can be suitably suppressed by taking into account the state on the energy storage side.

- the regenerative device is a rotating electrical machine that performs regenerative power generation that recovers kinetic energy of the vehicle as electrical energy, and the regenerator estimated by the estimation unit based on a state of the rotating electrical machine.

- a correction unit for correcting energy is provided.

- the traveling control unit changes the engine rotational speed when shifting from the inertia traveling to the regenerative traveling. Is less than a predetermined value, the rotating machine is operated to increase the engine rotation speed, and if the engine rotation speed is equal to or higher than a predetermined value, the engine rotation speed is increased by combustion of the engine.

- the combustion efficiency of the engine is poor in the low rotation speed range, so it is considered that driving by a rotating machine is more efficient than engine combustion.

- the combustion efficiency of the engine is good in the high rotation speed region.

- the regenerative device is a rotating machine, and is applied to a vehicle in which a transmission gear ratio between the output shaft and a rotating shaft of the rotating machine is variable.

- a shift control unit for changing the engine rotation speed to the side that suppresses the decrease is provided.

- the speed ratio is a ratio of a rotational speed of the rotary shaft of the rotating machine to a rotational speed of the output shaft, and the speed change control unit is configured to execute the predetermined inertial running condition.

- the speed ratio is made larger than before, and the speed ratio is made smaller when the inertia running is released.

- the transmission ratio is a ratio of a rotational speed of the rotary shaft of the rotating machine to a rotational speed of the output shaft, and the shift control unit is configured to satisfy the predetermined inertial running condition.

- the speed ratio is made larger than before, and the speed ratio is made smaller when the engine speed becomes equal to or higher than a predetermined speed as the engine speed is adjusted.

- the regenerative device is a rotating electrical machine that performs regenerative power generation that collects kinetic energy of the vehicle as electric energy, and the regenerative power generation by the rotating electrical machine is performed at a predetermined output or less.

- a setting unit that sets a duration of the regenerative traveling and a request output for requesting the regenerative traveling, and the duration is a predetermined time or less, And when the said request

- Regenerative power generation by a rotating electrical machine is performed at a predetermined output or less (output is limited) in consideration of heat associated with the power generation operation. For this reason, for example, even when the amount of brake operation is large and the required output for regenerative travel is large, the regenerative energy may not be sufficiently recovered due to the output restriction.

- the output is larger than the predetermined output. Allowed regenerative power generation.

- the duration of regenerative travel is extremely short and the required output is large, regenerative power generation with an output larger than a predetermined output is possible. That is, in this case, if the regenerative power generation time is extremely short, the temperature rise of the rotating electrical machine can be suppressed even if the regenerative power generation is performed at or above the output limit. Thereby, the regenerative energy according to the required output can be efficiently recovered while suppressing an excessive temperature rise of the rotating electrical machine.

- FIG. 1 is a configuration diagram showing an outline of a vehicle control system

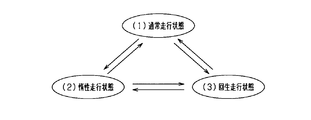

- FIG. 2 is an explanatory diagram showing an outline of each traveling state.

- FIG. 3 is a timing chart when transitioning from the inertia running state to the regenerative running state

- FIG. 4 is a flowchart showing the travel control process.

- FIG. 5 is a correlation diagram showing the relationship between the SOC and the coefficient ⁇ .

- FIG. 6 is a flowchart showing a travel control process in the second embodiment.

- FIG. 7 is a flowchart showing a regenerative energy estimation process in the third embodiment.

- FIG. 1 is a configuration diagram showing an outline of a vehicle control system

- FIG. 2 is an explanatory diagram showing an outline of each traveling state.

- FIG. 3 is a timing chart when transitioning from the inertia running state to the regenerative running state

- FIG. 4 is a flowchart showing the travel control process.

- FIG. 5 is a correlation diagram showing the relationship between the SOC and

- FIG. 8 is a correlation diagram showing the relationship between the vehicle speed, the road surface gradient, and the regeneration duration time.

- FIG. 9 is a configuration diagram showing an outline of the vehicle control system in the fourth embodiment.

- FIG. 10 is a flowchart showing a processing procedure of shift control in the fourth embodiment.

- FIG. 11 is a timing chart during inertial running in the fourth embodiment.

- FIG. 12 is a flowchart showing a processing procedure of regenerative power generation in the fifth embodiment.

- FIG. 13 is a correlation diagram illustrating the relationship among the brake operation amount, the road surface gradient, and the regeneration request output.

- an engine 11 is a multi-cylinder internal combustion engine driven by combustion of fuel such as gasoline or light oil, and appropriately includes a fuel injection valve, an ignition device, and the like as is well known.

- the engine 11 is integrally provided with an ISG 13 as a generator and an electric motor.

- a rotating shaft 14 of the ISG 13 is drivingly connected to the engine output shaft 12 by a belt or the like. In this case, the rotation shaft 14 of the ISG 13 is rotated by the rotation of the engine output shaft 12, while the engine output shaft 12 is rotated by the rotation of the rotation shaft 14 of the ISG 13.

- the ISG 13 has a power generation function for generating power (regenerative power generation) by rotation of the engine output shaft 12 and a power output function for applying a rotational force to the engine output shaft 12.

- a power generation function for generating power (regenerative power generation) by rotation of the engine output shaft 12

- a power output function for applying a rotational force to the engine output shaft 12.

- An in-vehicle battery 15 as a storage battery is electrically connected to the ISG 13.

- the power is supplied from the battery 15 to drive the ISG 13 and the battery 15 is charged by the generated power of the ISG 13.

- the electric power of the battery 15 is used to drive various electric loads mounted on the vehicle.

- an auxiliary device 16 such as a water pump or a fuel pump is mounted on the vehicle 10 as a driven device that is driven by the rotation of the engine output shaft 12.

- an air conditioner compressor may be included as the driven device.

- Driven devices include those directly coupled to the engine output shaft 12 and those coupled to the engine output shaft 12 by the clutch means in addition to those coupled to the engine 11 by a belt or the like. .

- a transmission 18 is connected to the engine output shaft 12 via a clutch device 17 having a power transmission function.

- the clutch device 17 is, for example, a friction clutch, and includes a disk (flywheel or the like) on the engine 11 side connected to the engine output shaft 12 and a disk (clutch disk) on the transmission 18 side connected to the transmission input shaft 21. Etc.) and a set of clutch mechanisms. When both disks come into contact with each other in the clutch device 17, the power is transmitted between the engine 11 and the transmission 18 (clutch connection state), and both the disks are separated from each other. Then, a power cut-off state (clutch cut-off state) is established in which power transmission between the engine 11 and the transmission 18 is cut off.

- the clutch device 17 of the present embodiment is configured as an automatic clutch that performs switching between a clutch engagement state / clutch disengagement state by an actuator such as a motor.

- the clutch device 17 may be provided inside the transmission 18.

- the transmission 18 is, for example, a continuously variable transmission (CVT) or a multi-stage transmission having a plurality of shift stages.

- the transmission 18 shifts the motive power of the engine 11 input from the transmission input shaft 21 at a gear ratio according to the vehicle speed V and the engine rotation speed, and outputs it to the transmission output shaft 22.

- Wheels 27 are connected to the transmission output shaft 22 via a differential gear 25 and a drive shaft 26 (vehicle drive shaft).

- Each wheel 27 is provided with a brake device 28 that applies a braking force to each wheel 27 by being driven by a hydraulic circuit (not shown) or the like.

- the brake device 28 adjusts the braking force for each wheel 27 in accordance with the pressure of a master cylinder (not shown) that transmits the depression force of the brake pedal to the hydraulic oil.

- the present system includes an engine ECU 31 that controls the operating state of the engine 11 and a transmission ECU 32 that controls the clutch device 17 and the transmission 18 as on-vehicle control means.

- Each of these ECUs 31 and 32 is a well-known electronic control device including a microcomputer or the like, and controls the engine 11, the transmission 18 and the like based on detection results of various sensors provided in this system. Are implemented as appropriate.

- the ECUs 31 and 32 are communicably connected to each other, and can share control signals, data signals, and the like.

- the ECU 31 includes two ECUs 31 and 32, and the engine ECU 31 constitutes a “vehicle control device”.

- the present invention is not limited to this, and two or more ECUs constitute a vehicle control device. May be.

- an accelerator sensor 41 that detects an operation amount (accelerator operation amount) of an accelerator pedal as an accelerator operation member

- a brake sensor 42 that detects an operation amount (brake operation amount) of a brake pedal as a brake operation member.

- a vehicle speed sensor 43 for detecting the vehicle speed V

- an inclination angle sensor 44 for detecting the inclination angle of the road surface of the vehicle 10

- a rotation speed sensor 45 for detecting the engine rotation speed

- a battery sensor 46 for detecting the state of the battery 15, and the like.

- the detection signals of these sensors are sequentially input to the engine ECU 31.

- the system is provided with a load sensor (air flow meter, intake pressure sensor) for detecting engine load, a cooling water temperature sensor, an outside air temperature sensor, an atmospheric pressure sensor, and the like, which are not shown.

- the engine ECU 31 performs various engine controls such as fuel injection amount control by a fuel injection valve and ignition control by an ignition device based on detection results of various sensors, engine start by ISG 13, engine torque assist and power generation control, brake device Brake control by 28 is performed. Further, the transmission ECU 32 performs intermittent control of the clutch device 17 and shift control of the transmission 18 based on detection results of various sensors.

- the vehicle 10 has a function of performing inertial running while the clutch device 17 is in a disconnected state under the situation where the vehicle 10 is running by driving the engine 11. Moreover, it has the function to perform the regenerative driving

- FIG. 2 is an explanatory diagram showing an outline of each traveling state of the vehicle 10.

- the normal running state is a state in which the vehicle 10 is caused to travel with the engine 11 in an operating state and the clutch device 17 in a connected state (specifically, a state corresponding to a shift operation position by a driver).

- the inertia traveling state is a state in which the vehicle 10 is coasted with the engine 11 stopped and the clutch device 17 disconnected.

- the regenerative travel state is a state in which the engine 11 is in an operating state (no fuel injection), the clutch device 17 is in a connected state, regenerative power generation is performed by the ISG 13, and the vehicle 10 travels.

- (1) the transition from the normal traveling state to (2) the inertial traveling state and (2) the transition from the inertial traveling state to (1) the normal traveling state are each performed according to the establishment of known conditions.

- the engine ECU 31 shifts the vehicle 10 to (2) the inertial traveling state in accordance with establishment of predetermined coasting conditions including the accelerator condition and the brake condition.

- the predetermined coasting conditions include that the engine rotational speed is stable at a predetermined value or higher (for example, idle rotational speed or higher), the vehicle speed V is within a predetermined range (for example, 20 to 120 km / h), road surface It may be included that the gradient (tilt) is within a predetermined range.

- the engine ECU 31 shifts the vehicle 10 to (1) the normal traveling state in accordance with establishment of predetermined coast release conditions including the accelerator condition and the brake condition. .

- the inertial running state may be canceled as the predetermined coast implementation condition is not established.

- (1) transition from the normal travel state to (3) regenerative travel state, and (3) transition from the regenerative travel state to (1) normal travel state are each performed according to the establishment of a known condition.

- the engine ECU 31 (3) in the regenerative running state according to the establishment of predetermined regeneration execution conditions including the brake condition and the storage state of the battery 15.

- regenerative power generation is performed by the ISG 13, and kinetic energy is stored in the battery 15 as electric energy.

- the engine ECU 31 shifts to (1) the normal travel state in accordance with the establishment of a predetermined regenerative release condition including the accelerator condition.

- (2) the transition from the inertia traveling state to (3) the regenerative traveling state and (3) the transition from the regenerative traveling state to (2) the inertia traveling state can be performed.

- the energy (energy consumption) consumed for increasing the engine rotation speed may be larger than the energy recovered by the regenerative travel (regenerative energy). In such a case, it is not preferable from the viewpoint of improving fuel consumption.

- the relationship between energy consumption and regenerative energy will be described with reference to FIG.

- a predetermined brake operation is performed during coasting based on a known coast release condition (for example, when the amount of braking operation is greater than a predetermined threshold Th)

- the brake operation is included in the predetermined regeneration execution condition during inertial running.

- the brake operation here may be a brake operation by a driver or a deceleration control (automatic brake or the like) by a vehicle operation control unit.

- the vehicle 10 is in the coasting state before the timing t12 and at the timings t13 to t14, is in the regenerative traveling state at the timings t12 to t13 and the timings t15 to t16, and is in the normal traveling state after the timing t16. .

- the energy consumed when shifting to the regenerative traveling at timing t12 to t13 is A1

- the energy recovered by the regenerative traveling at timing t12 to t13 is B1

- shifting to the regenerative traveling at timing t15 to t16 is A2

- the energy recovered by regenerative travel at timings t15 to t16 is B2.

- the regenerative energy B2 is larger than the consumed energy A2, and the fuel efficiency effect by the regenerative travel is obtained.

- the consumed energy A1 is larger than the regenerative energy B1, and the consumed energy cannot be recovered by the regenerative energy. That is, in the regenerative travel at the timing t12 to t13, energy is lost by shifting from the inertia travel to the regenerative travel, which is considered disadvantageous from the viewpoint of energy efficiency.

- the transition from the inertia travel to the regenerative travel is performed. Specifically, when it is determined that the regenerative energy is larger than the consumed energy, the inertial traveling is canceled and the regenerative traveling is performed, and when it is determined that the regenerative energy is smaller than the consumed energy, the inertial traveling is maintained. . That is, the transition from the inertia traveling to the regenerative traveling is enabled, and the transition to the disadvantageous regenerative traveling from the viewpoint of energy efficiency is suppressed.

- the engine ECU 31 estimates the consumed energy A1 and the regenerative energy B1. If it is determined that the consumed energy A1 is larger than the regenerative energy B1, the inertia traveling is maintained without shifting from the inertia traveling to the regeneration traveling. In other words, in this case, the clutch is kept off (disengaged) at timings t12 to t13, and neither energy consumption A1 nor regenerative energy B1 is generated.

- the regenerative travel at the timings t12 to t13 which is disadvantageous from the viewpoint of energy efficiency, is not performed in FIG. 3, but the regenerative travel at the advantageous timings t15 to t16 is performed.

- the engine ECU 31 estimates the energy consumption Erec and the regenerative energy Eregen, respectively, when a brake operation is performed during inertial running.

- the energy consumption Erec refers to the energy required to rotate the engine output shaft 12 by the ISG 13. Specifically, the energy consumption Erec is estimated based on the sum of the required rotational energy calculated from the vehicle speed V and the loss energy including friction loss. More specifically, it is estimated based on the following formula (1).

- j represents the inertia (moment of inertia) of the engine 11

- ⁇ t represents the target rotational speed of the engine 11

- ⁇ 0 represents the current engine rotational speed

- Ploss represents the loss output

- Tst represents the return target time

- Effmot represents the output efficiency in the power running drive of the ISG 13

- Effbatt_out represents the output efficiency of the battery 15.

- the loss output is engine friction or the like and can be calculated by a known method.

- ⁇ t is calculated based on the vehicle speed V. In this case, ⁇ t is calculated as a larger value as the vehicle speed V increases.

- ⁇ 0 is considered to be zero in many cases. Further, it is considered that other parameters do not fluctuate greatly in each coasting. Then, it is considered that the energy consumption Erec greatly depends on the vehicle speed V.

- regenerative energy Eregen refers to energy that can be recovered by regenerative travel.

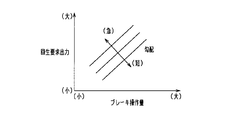

- the regenerative energy Eregen is estimated using a regenerative output Pregen calculated based on the brake operation amount and a regenerative duration Tgen that is predicted to continue regenerative travel. More specifically, it is estimated based on the following formula (2).

- Effgen represents the output efficiency in the power generation of the ISG 13, and Effbatt_in represents the input efficiency of the battery 15.

- the regeneration continuation time Tgen is a predetermined value determined in advance by adaptation or the like, and is, for example, 10 seconds.

- the engine ECU 31 controls the transition from inertial running to regenerative running by comparing the estimated energy consumption Erec and regenerative energy Eregen, respectively.

- step S11 it is determined whether or not the vehicle 10 is currently in an inertia running state with the clutch off. If YES, the process proceeds to step S12, and if NO, the process proceeds to step S21.

- step S12 it is determined whether or not the brake is on. Whether or not the brake is on is determined based on, for example, that the amount of brake operation detected by the brake sensor 42 is greater than zero. If step S12 is YES, the process proceeds to step S13.

- step S13 energy consumption Erec is estimated.

- the consumed energy Erec is estimated based on the above-described equation (1), for example.

- step S14 the regenerative energy Eregen is estimated.

- the regenerative energy Eregen is estimated based on the above-described equation (2), for example.

- step S15 it is determined whether or not the estimated regenerative energy Eregen is larger than the consumed energy Erec.

- step S15 is YES, that is, when the regenerative energy Eregen is larger than the consumed energy Erec, the inertia traveling is canceled and the transition to the regenerative traveling is performed (step S16). If step S15 is NO, that is, if the consumed energy Erec is larger than the regenerative energy Eregen, coasting is maintained (step S17).

- step S12 when step S12 is NO, it progresses to step S18 and it is determined whether it is in the accelerator-on state. Whether or not the accelerator is on is determined based on, for example, that the accelerator operation amount detected by the accelerator sensor 41 is greater than zero. If step S18 is YES, the inertia traveling is canceled and the transition to the normal traveling is performed (step S19). If step S18 is NO, this process is ended as it is. That is, the vehicle 10 maintains the coasting state.

- step S21 it is determined whether or not the vehicle 10 is currently in a regenerative running state. If YES, the process proceeds to step S22. If NO, the process is terminated. In step S22, it is determined whether or not the accelerator is on. When step S22 is YES, that is, when the accelerator is turned on during the regenerative travel, the regenerative travel is canceled and the shift to the normal travel is performed (step S23).

- step S22 when step S22 is NO, it progresses to step S24, and it is determined whether it is in a brake-off state.

- the brake-off state is determined based on, for example, that the brake operation amount detected by the brake sensor 42 is zero.

- step S24 in addition to the brake off state, for example, the SOC of the battery 15 is equal to or higher than a predetermined value (for example, a value close to full charge), or the vehicle speed V is equal to or lower than a predetermined value (for example, 30 km / h). The following may be determined. If step S24 is YES, a transition from regenerative travel to inertial travel is performed (step S25). If step S24 is NO, this process is ended as it is. That is, the vehicle 10 maintains the regenerative travel state.

- a predetermined value for example, a value close to full charge

- a predetermined value for example, 30 km / h

- Steps S13 and S14 correspond to an “estimator”

- step S15 corresponds to a “determination unit”

- steps S16 and S17 correspond to a “travel controller”.

- the energy consumption Erec consumed by adjusting the engine speed is estimated, and the regenerative energy Eregen recovered by the regenerative traveling is estimated. To do. Then, based on the comparison between the consumed energy Erec and the regenerative energy Eregen, the transition from the inertia traveling to the regenerative traveling is performed. Specifically, when it is determined that the regenerative energy Eregen is larger than the consumed energy Erec, the transition from the inertia traveling to the regenerative traveling is performed. Therefore, the energy exceeding the consumed energy Erec can be recovered by the regenerative traveling.

- coasting is maintained when it is determined that the regenerative energy Eregen is smaller than the energy consumption Erec, so that the fuel efficiency effect by coasting can be obtained, and the shift to unfavorable regeneration from the viewpoint of energy efficiency can be achieved. Can be suppressed. Furthermore, the frequency of switching from coasting to regenerative driving can be suppressed, leading to improved drivability. Thereby, inertial running and regenerative running can be switched appropriately.

- the consumed energy Erec is energy required for rotating the engine output shaft 12 to the target engine speed, and is considered to correlate with the vehicle speed V. That is, when the vehicle speed V is high, the target engine speed increases, and the energy consumption Erec increases accordingly. In consideration of this point, the energy consumption Erec is estimated based on the vehicle speed V, so that the energy consumption Erec can be estimated with high accuracy. As a result, it is possible to appropriately determine the transition from inertial travel to regenerative travel.

- Regenerative energy Eregen is considered to correlate with the amount of brake operation. For example, when the brake operation amount is large, the driver's request for deceleration is large, and the regenerative energy Eregen is also large. Considering this point, the regenerative energy Eregen is estimated based on the brake operation amount, so that the regenerative energy Eregen can be estimated with high accuracy. As a result, it is possible to appropriately determine the transition from inertial travel to regenerative travel.

- the engine 11 is stopped during inertial running, but this may be changed.

- the engine rotation speed may be maintained at an idle rotation speed (for example, 700 rpm) without stopping the engine 11 during inertial traveling.

- the range in which the engine rotation speed is increased by driving the ISG 13 is smaller than the configuration in which the engine 11 is stopped. Therefore, energy consumption Erec when shifting from inertial traveling to regenerative traveling is reduced.

- the engine rotation speed is maintained at the idle rotation speed, the responsiveness at the time of releasing the inertial running is improved as compared with the case where the engine 11 is stopped.

- the engine rotation speed may be adjusted by means other than driving the ISG 13.

- the engine rotation speed is adjusted by the operation (combustion) of the engine 11.

- the energy required for operating the engine 11 may be estimated as the consumed energy Erec.

- the engine rotation speed is increased by combining the driving of the ISG 13 and the combustion of the engine 11 may be employed.

- the combustion efficiency of the engine 11 is poor in the low rotation speed region, so that the driving by the ISG 13 is considered to be more efficient than the combustion of the engine 11.

- the combustion efficiency of the engine 11 is good. Considering this point, it is preferable to select driving of the ISG 13 and combustion of the engine 11 according to the engine rotation speed.

- the engine rotational speed is increased by driving the ISG 13, and in a high rotational speed range where the engine rotational speed is equal to or higher than the predetermined value K, combustion of the engine 11 occurs. It is good to increase the engine speed.

- the predetermined value K is, for example, an idle rotation speed. In this case, for example, if the energy consumption Erec is estimated as energy consumed by driving the ISG 13, the energy consumption Erec when shifting from inertia traveling to regenerative traveling is reduced.

- the engine rotation speed may be increased by a combination of a starter (not shown) and the combustion of the engine 11 instead of the combination of the drive of the ISG 13 and the combustion of the engine 11.

- the ISG 13 is used as the regeneration device, but the regeneration device is not limited to this.

- an alternator having only a power generation function may be used as the regeneration device, and a flywheel may be used as the regeneration device.

- the kinetic energy of the vehicle 10 is stored as rotational energy in the flywheel.

- a starter may be used as a device for starting the engine 11.

- the SOC is acquired as a parameter indicating the storage state of the battery 15, and the regenerative energy Eregen estimated based on the SOC is corrected.

- the recovery of regenerative energy Eregen is limited depending on the SOC of the battery 15. For example, when the SOC of the battery 15 is close to full charge, the power that can be charged to the battery 15 is small, and even if regenerative power generation is performed, the regenerative energy Eregen that is recovered may be limited. is there.

- the engine ECU 31 acquires the SOC of the battery 15 and corrects the regenerative energy Eregen estimated based on the SOC. Then, the regenerated energy Eregen after correction is used to compare with the consumed energy Erec.

- the correction for example, when the SOC of the battery 15 is close to full charge, the electric energy that can be charged in the battery 15 becomes small, so that the estimated regenerative energy Eregen is corrected to be reduced.

- the correction method is not particularly limited, for example, there is a method of multiplying the estimated regenerative energy Eregen by a coefficient ⁇ .

- the SOC within the usage range of the battery 15 and the coefficient ⁇ have a correlation as shown in FIG. 5, for example.

- the coefficient ⁇ is 1 when the SOC is equal to or less than the predetermined value P.

- the regenerative energy Eregen does not change before and after the correction.

- the coefficient ⁇ decreases as the SOC increases.

- FIG. 6 is a flowchart showing a processing procedure of the travel control process in the second embodiment, and this process is repeatedly performed by the engine ECU 31 at a predetermined period in place of FIG. 4 described above.

- the same processes as those in FIG. 4 are the addition of steps S31 and S32 and the change of the processing content of step S15.

- step S13 when the vehicle 10 is coasting and the brake is on (when both steps S11 and S12 are YES), the consumed energy Erec is estimated (step S13), and the regenerative energy Eregen is estimated. Is estimated (step S14).

- step S31 the engine ECU 31 acquires the SOC of the battery 15.

- step S32 the regenerative energy Eregen is corrected based on the acquired SOC. Specifically, the regenerative energy Eregen is corrected based on the above-described correlation between the SOC and the coefficient ⁇ .

- step S15 it is determined whether the corrected regenerative energy Eregen is larger than the consumed energy Erec. If step S15 is YES, it will progress to step S16 and will transfer to regeneration driving

- the state on the side where the regenerative energy Eregen is stored can be considered.

- the transition to the regenerative travel that is disadvantageous from the viewpoint of energy efficiency can be suitably suppressed.

- the regenerative energy Eregen is corrected based on the SOC of the battery 15.

- the regenerative energy Eregen may be corrected based on other parameters indicating the state of the battery 15.

- the regenerative energy Eregen may be corrected based on the temperature of the battery 15.

- the regenerative energy Eregen may be corrected based on a parameter indicating the state of the ISG 13. That is, in this case, the regenerative energy Eregen is corrected in consideration of the state on the energy recovery side. For example, in the configuration in which the regenerative energy Eregen is corrected based on the temperature of the ISG 13, the temperature of the ISG 13 (for example, the temperature of the switching element of the inverter unit or the temperature of the stator of the motor unit) is acquired in step S31 in FIG. In step S32, the regenerative energy Eregen is corrected based on the temperature.

- the method of multiplying the coefficient ⁇ is used as a method for correcting the regenerative energy Eregen, but the present invention is not limited to this.

- the battery acceptable energy is calculated based on the SOC of the battery 15 and the battery capacity, and a smaller value of the calculated battery acceptable energy and the estimated regenerative energy Eregen is used as the corrected regenerative energy Eregen. Good.

- the regenerative energy Eregen is corrected based on the SOC.

- the SOC is a predetermined value or more

- the transition from inertial running to regenerative running may be prohibited.

- the predetermined value is set to, for example, an SOC close to full charge.

- a transition from inertia traveling to regenerative traveling may be prohibited.

- the transition to the regenerative traveling is prohibited and the inertia traveling is maintained. You may make it do.

- the past duration is acquired according to the traveling condition of the vehicle 10, and the current duration (regeneration is based on the duration).

- the duration Tgen

- the regeneration energy Eregen is estimated using the set regeneration duration Tgen.

- the engine ECU 31 stores the duration of regenerative travel as a history in a memory or the like in the engine ECU 31 for each travel condition in each regenerative travel in the past.

- the traveling conditions include, for example, vehicle speed V, road surface gradient, and the like. In this case, it is considered that the longer the vehicle speed V is, the longer the duration of regenerative travel is. In addition, it is considered that the longer the road gradient, the longer the duration of regenerative travel.

- FIG. 7 describes the processing procedure for estimating the regenerative energy Eregen in step S14 of FIG. This process is performed by the engine ECU 31 as a subroutine process when step S14 of FIG. 4 is performed. That is, in FIG. 4, when the vehicle 10 is in an inertia running state and the brake is on (when both steps S11 and S12 are YES), the consumed energy Erec is estimated (step S13). Then, the process proceeds to step S101 in FIG.

- step S101 the traveling condition of the vehicle 10 is acquired.

- the vehicle speed V is acquired based on the detection value by the vehicle speed sensor 43

- the road surface gradient is acquired based on the detection value by the inclination angle sensor 44.

- step S102 the duration of past regenerative travel is acquired according to the acquired travel conditions. For example, the duration of regenerative travel that has been performed in the past at a vehicle speed V that is approximately the same as the current vehicle speed V is acquired. In addition, you may consider a road surface gradient.

- the current regeneration duration Tgen is set based on the obtained duration.

- the average value of the duration of regenerative travel for the past 10 times under the same travel conditions is set as the regeneration duration Tgen.

- step S104 the regenerative energy Eregen is estimated based on the set regeneration continuation time Tgen, and the process returns to step S15 in FIG.

- step S103 corresponds to a “setting unit”

- step S104 corresponds to an “estimating unit”.

- Regenerative energy Eregen is considered to correlate with the duration of regenerative travel.

- the regeneration duration Tgen is set as the current duration, and based on the set regeneration duration Tgen and the brake operation amount. Therefore, the regenerative energy Eregen can be estimated with high accuracy.

- the duration time is stored each time, and the regeneration duration time Tgen is set based on the stored history of the continuous time. Therefore, according to the tendency of the regenerative travel for each vehicle 10.

- the regeneration duration Tgen can be set appropriately.

- the history of the past duration is acquired according to the driving conditions of the vehicle 10 and the regeneration duration Tgen is set based on the history, the conditions affecting the duration of the regeneration running are taken into account.

- the regeneration duration Tgen can be set.

- the regeneration continuation time Tgen can be appropriately set according to the operating conditions at each time, and as a result, the regenerative energy Eregen can be estimated with high accuracy.

- the regeneration duration Tgen is set based on the past regeneration travel duration stored in a memory or the like. However, this may be changed.

- the regeneration duration Tgen may be set each time based on the traveling conditions of the vehicle 10. In such a configuration, for example, a correlation map as shown in FIG. 8 can be used. In FIG. 8, the regeneration duration Tgen is longer as the vehicle speed V is higher, and the regeneration duration Tgen is longer as the road gradient is steeper.

- the regeneration duration time Tgen may be set using traffic information such as traffic lights and traffic congestion on the road. In this case, for example, if the traffic light that exists in the traveling direction of the vehicle 10 is a red signal, the vehicle 10 needs to stop, so the regeneration duration Tgen is set short.

- FIG. 9 schematic structure of the vehicle control system in 4th Embodiment is shown.

- the fourth embodiment is directed to a vehicle control system including a transmission 51 between the engine output shaft 12 and the rotating shaft 14 of the ISG 13.

- the transmission 51 can change the speed ratio of the rotational power by the ISG 13 (the rotational speed of the rotary shaft 14 / the rotational speed of the engine output shaft 12).

- the gear ratio is N2 / N1.

- the engine ECU 31 controls the gear ratio of the transmission 51 according to the state of the vehicle 10. Except that this transmission 51 is provided, it is the same as the configuration diagram of FIG.

- the control when shifting from (2) the inertia running state to (3) the regenerative running state is shown in FIG. 2, but in the fourth embodiment, (2) in the inertia running state, in particular.

- the control will be described.

- the gear ratio of the transmission 51 in inertial running, is changed to a side that suppresses the decrease in engine rotation speed. Specifically, when the vehicle 10 is in a normal running state and a predetermined coasting condition is satisfied, the gear ratio (the rotational speed of the rotary shaft 14 / the rotational speed of the engine output shaft 12) is set to be higher than the previous gear ratio. Enlarge. Then, the vehicle 10 is switched to coasting with the gear ratio increased, and coasting is performed. Then, the gear ratio is reduced when shifting from inertia traveling to normal traveling. That is, the increased gear ratio is restored.

- the gear ratio before shifting to inertial running by increasing the gear ratio before shifting to inertial running, the kinetic energy at the time of deceleration can be recovered as rotational energy by the ISG 13, and after recovering, it is possible to shift to inertial driving.

- the inertia of the engine 11 during inertial traveling is increased, a decrease in engine rotation speed during inertial traveling is suppressed, and the period during which the engine output shaft 12 rotates during inertial traveling can be extended.

- the rotation of the engine output shaft 12 is ensured to reduce the energy consumption Erec associated with the transition.

- the transition between the normal traveling and the inertia traveling is shown, but the same applies to the transition between the regenerative traveling and the inertia traveling.

- step S41 it is determined whether or not the vehicle 10 is currently in the non-inertial traveling state (normal traveling state or regenerative traveling state). If step S41 is YES, the process proceeds to step S42, and if step S41 is NO, the process proceeds to step S46. In step S42, it is determined whether or not the coast execution condition is satisfied. For example, regarding the transition from normal travel to inertial travel, it is determined that the accelerator is off and the brake is off. If step S42 is YES, it will progress to step S43, and if step S42 is NO, this process will be complete

- step S43 the gear ratio of the transmission 51 is increased. Specifically, the gear ratio is changed so that the rotation speed of the rotation shaft 14 of the ISG 13 is larger than the rotation speed of the engine output shaft 12.

- step S44 it is determined whether or not a predetermined time T has elapsed since the gear ratio of the transmission 51 was changed. While this predetermined time T elapses, the kinetic energy is recovered as rotational energy by the ISG 13. Then, when the predetermined time T has elapsed (S44: YES), the process proceeds to step S45, where the clutch is turned off (disengaged) and the vehicle shifts to coasting.

- step S47 it is determined whether a coast release condition is satisfied. For example, regarding the transition to normal travel, it is determined whether or not the accelerator is turned on. Regarding the transition to regenerative travel, it is determined whether the brake is turned on and the regenerative energy Eregen is greater than the consumed energy Erec. If step S47 is YES, it will progress to step S48 and will start drive of ISG13.

- step S49 it is determined whether or not it is a transition timing to normal driving or regenerative driving. Specifically, the engine ECU 31 determines whether or not the engine rotational speed has increased to a rotational speed corresponding to the vehicle speed V by driving the ISG 13. If it is determined that it is the transition timing (step S49: YES), the process proceeds to step S50. In step S50, the transmission ratio of the transmission 51 is reduced. That is, the gear ratio is returned to the state before the coast execution condition is established. In step S51, inertial running is canceled and the routine proceeds to normal running or regenerative running. On the other hand, if step S46 and step S47 are NO, this process will be complete

- FIG. 11 shows a timing chart showing the processing of FIG. 10 more specifically.

- reference control control that does not change the transmission ratio of the transmission 51

- control in this embodiment control that changes the transmission ratio of the transmission 51

- the control in this embodiment is indicated by a solid line.

- FIG. 11 shows a scene in which the vehicle 10 shifts from the normal driving state to the inertial driving state and then shifts from the inertial driving state to the regenerative driving state.

- the transmission gear ratio of the transmission 51 is changed from LOW to HIGH at the timing t21 when the coast execution condition is satisfied. That is, in this case, the gear ratio is made larger than the gear ratio in the reference control. Then, the kinetic energy is recovered, and at a timing t22 after a predetermined time T has elapsed, the clutch is turned off and switched to inertial running. That is, in this case, the predetermined time T is a delay time from the establishment of the coast execution condition until the coasting is actually started. Thereafter, the engine rotation speed decreases, but the decrease speed becomes slower than that in the reference control.

- the range of increase in the engine rotation speed by driving the ISG 13 is smaller than that in the reference control ( ⁇ NE2 ⁇ NE1). That is, by increasing the gear ratio in inertia traveling, it is possible to reduce the energy consumption Erec when shifting from inertia traveling to non-inert inertia traveling.

- the gear ratio was changed to the side that suppresses the decrease in engine speed during inertial running. Specifically, the gear ratio is changed from LOW to HIGH when the coast execution condition is satisfied, and coasting is performed in the state of HIGH. In this case, by setting the gear ratio to HIGH, it is possible to suppress a decrease in the engine rotation speed as compared with a case where coasting is performed with LOW. Thereby, the period during which the engine output shaft 12 rotates can be extended, and as a result, it is possible to reduce the energy consumption Erec when shifting from inertia traveling to non-inert inertia traveling.

- the ISG 13 When traveling by the combustion of the engine 11, the ISG 13 is rotated, and a sliding loss occurs with the rotation. Considering this point, when the inertia traveling is canceled, that is, when the transition from the inertia traveling to the non-inert inertia traveling (normal traveling and regenerative traveling) is performed, the gear ratio is changed from HIGH to LOW. In this case, the rotational speed of the ISG 13 with respect to the engine rotational speed in non-inertial travel is smaller than that during inertial travel. Thereby, the sliding loss accompanying the rotation of the ISG 13 can be reduced in the non-inertial traveling, and accordingly the traveling by the combustion of the engine 11 can be suitably performed. Further, in the configuration in which the cooling fan is drivingly connected to the rotating shaft 14 of the ISG 13, the rotation speed of the ISG 13 is reduced, so that the rotation sound of the cooling fan can be reduced.

- the gear ratio is reduced when releasing the inertia running (the state before the coast execution condition is satisfied), but the timing for reducing the gear ratio is not limited to this.

- the gear ratio may be reduced when the engine rotation speed reaches a predetermined threshold value NEth during a period in which the engine rotation speed is increased by driving the ISG 13 at the time of transition from inertial running to regenerative running.

- a step of determining whether or not the engine speed is equal to or higher than the threshold NEth is provided as a step that proceeds when step S49 of FIG. 10 is NO. If the engine speed is equal to or higher than the threshold value NEth, the process proceeds to step S50, and the gear ratio is reduced. That is, the gear ratio is reduced before the inertia running is released. On the other hand, if the engine speed is less than the threshold value NEth, the present process is terminated as it is.

- the threshold value NEth is set to a value larger than the engine rotation speed range where a large torque (passing torque) at the time of starting the engine is required.

- the sliding loss of the ISG 13 can be reduced before the inertia traveling is canceled by reducing the gear ratio at a timing when a large torque is not required at the time of starting the engine. It is possible to reduce the energy consumption Erec associated with the transition to.

- the transmission 51 is provided between the engine output shaft 12 and the rotating shaft 14 of the ISG 13.

- the present invention is limited to this as long as the gear ratio of the rotational power by the ISG 13 is variable. Not. For example, it is good also as a structure which provides a speed change function to ISG13 and changes a gear ratio by ISG13.

- an alternator having only a power generation function or a rotating machine (flywheel or the like) having no power generation function may be used instead of the ISG 13, for example.

- a transmission is provided between the engine output shaft 12 and a rotation shaft such as an alternator, and the gear ratio of the transmission is changed to a side that suppresses a decrease in engine rotation speed during inertial running.

- the engine ECU 31 When performing regenerative power generation, the engine ECU 31 transmits a power generation command to the ISG 13. At this time, the engine ECU 31 sets the regeneration request output based on the brake operation amount, the storage state of the battery 15, and the like. Then, based on the regeneration request output, the ISG 13 is caused to perform regenerative power generation. Thereby, the electric power according to the state of the vehicle 10 is obtained by regenerative power generation.

- an output limit may be provided for the regenerative power generation of the ISG 13. Therefore, even when the regenerative request output is large, regenerative power generation may be suppressed to a predetermined output value Wth or less due to the output limitation, and in this case, recovery of the regenerative energy Eregen is limited.

- the output limit of regenerative power generation is set in consideration of the duration of regenerative travel, and is set assuming regenerative travel of about 30 seconds, for example.

- the engine ECU 31 sets the regeneration duration Tgen and the regeneration request output when the regeneration execution condition is satisfied. And if regeneration continuation time Tgen is below predetermined threshold TA and regeneration required output is above predetermined threshold WA, regenerative power generation with an output larger than output value Wth is permitted.

- the threshold value TA is a determination value for determining regenerative travel for an extremely short time, and is set to 3 seconds, for example.

- the threshold value WA is set to a value corresponding to the output limit of regenerative power generation. That is, in this case, regenerative power generation with a large output (output exceeding the output limit of regenerative power generation) is performed in an extremely short time. Thereby, the regenerative energy Eregen can be efficiently recovered.

- step S61 it is determined whether or not the vehicle 10 is currently in a non-regenerative traveling state (normal traveling state or inertial traveling state). If step S61 is YES, the process proceeds to step S62. If step S61 is NO, the process is terminated. In step S62, it is determined whether or not a regeneration execution condition is satisfied. For example, regarding the transition from inertial running to regenerative running, it is determined whether the brake is turned on and the regenerative energy Eregen is greater than the consumed energy Erec. If step S62 is YES, the process proceeds to step S63, and if step S62 is NO, the process ends.

- a regeneration execution condition For example, regarding the transition from inertial running to regenerative running, it is determined whether the brake is turned on and the regenerative energy Eregen is greater than the consumed energy Erec.

- step S63 the regeneration duration Tgen is set.

- the regeneration continuation time Tgen is set in the same manner as the process of step S103 in FIG.

- a regeneration request output is set.

- the regeneration request output is set by applying the brake operation amount and the road surface gradient to the map shown in FIG. In the map of FIG. 13, the regeneration request output increases as the brake operation amount increases, and the regeneration request output increases as the road surface gradient increases.