WO2017163871A1 - Vehicle drive device - Google Patents

Vehicle drive device Download PDFInfo

- Publication number

- WO2017163871A1 WO2017163871A1 PCT/JP2017/009156 JP2017009156W WO2017163871A1 WO 2017163871 A1 WO2017163871 A1 WO 2017163871A1 JP 2017009156 W JP2017009156 W JP 2017009156W WO 2017163871 A1 WO2017163871 A1 WO 2017163871A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- gear

- bearing

- drive device

- planetary

- vehicle drive

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/02—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows

- F16C19/14—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load

- F16C19/18—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/22—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings

- F16C19/24—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for radial load mainly

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/58—Raceways; Race rings

- F16C33/64—Special methods of manufacture

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16H—GEARING

- F16H48/00—Differential gearings

- F16H48/06—Differential gearings with gears having orbital motion

- F16H48/10—Differential gearings with gears having orbital motion with orbital spur gears

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16H—GEARING

- F16H48/00—Differential gearings

- F16H48/38—Constructional details

Definitions

- the present invention relates to a vehicle drive device capable of amplifying a torque difference and transmitting drive torque from two independent drive sources to left and right drive wheels.

- electric motors are arranged on the left and right drive wheels, respectively, and each electric motor is controlled independently to give an appropriate drive torque difference between the left and right wheels, thereby controlling the turning moment of the vehicle It is known to do.

- it is effective to generate a large difference in driving torque between the left and right drive wheels in order to achieve smooth turning of the vehicle and to suppress changes in vehicle behavior such as extreme understeer and extreme oversteer There is. For this reason, it is desirable to amplify the difference between the torques output from the two electric motors and transmit them to the left and right drive wheels.

- Patent Document 1 a differential that is a torque difference amplifying mechanism in which two planetary gear structures with three elements and two degrees of freedom are coaxially arranged between two drive sources and left and right drive wheels.

- a vehicle drive device comprising the device is disclosed.

- the vehicle driving device disclosed in FIG. 5A of Patent Document 1 (hereinafter referred to as Conventional Technology 1) has a configuration as shown in the skeleton diagram shown in FIG.

- the vehicle drive device 100 includes left and right electric motors 102L and 102R mounted on the vehicle, left drive wheels 104L and right drive wheels 104R, a differential device 105 and reduction gear trains 106L and 106R provided therebetween. , 107L, 107R.

- the electric motor 102L and the electric motor 102R operate with electric power from a battery (not shown) mounted on the vehicle, are individually controlled by an electronic control device (not shown), and can generate and output different torques. .

- the output shaft 102aL of the electric motor 102L and the output shaft 102aR of the electric motor 102R are connected to the coupling members 111 and 112 of the differential device 105 through the reduction gear trains 106L and 106R, respectively.

- the output from the differential device 105 is given to the left and right drive wheels 104L, 104R via the reduction gear trains 107L, 107R.

- the differential device 105 is configured by combining two identical planetary gear mechanisms 110L and 110R with three elements and two degrees of freedom on the same axis.

- the single-pinion type planetary gear mechanism includes a sun gear S L , S R and internal gears R L , R R provided on the same axis, and these sun gears S L , S R and internal gears R L , R R.

- a plurality of planetary gears P L and P R and planetary gears P L and P R are rotatably supported, and are provided coaxially with the sun gears S L and S R and the internal gears R L and R R.

- was planet carrier C L is composed of a C R

- the planetary gear P L, P R is engaged the sun gear S L, S R and the internal gear R L, in the R R.

- the sun gear S L, S R and the planetary gears P L, P R is the external gear having gear teeth on the outer circumference

- the internal gear R L, R R is the internal gear having gear teeth on the inner peripheral is there.

- the differential 105 includes a first planetary gear mechanism 110L having a sun gear S L , a planet carrier C L , a planetary gear P L, and an internal gear RL , as well as a sun gear S R , a planetary gear.

- carrier C R, and a second planetary gear mechanism 110R having a planetary gear P R and the internal gear R R is configured by combining coaxially.

- the sun gear S L of the first planetary gear mechanism 110L and the internal gear R R of the second planetary gear mechanism 110R is coupled by a first coupling member 111, and the internal gear R L of the first planetary gear mechanism 110L second

- the sun gear S R of the planetary gear mechanism 110R is coupled by the second coupling member 112.

- the torque TM1 generated by the electric motor 102L is input to the first coupling member 111 via the reduction gear train 106L, and the torque TM2 generated by the electric motor 102R is input to the second coupling member 112 by the reduction gear train 106R. Is input through. Further, the planet carrier C R of the planetary carrier C L and the second planetary gear mechanism 110R of the first planetary gear mechanism 110L, respectively reduction gear train 107L, through 107R left and right drive wheels 104L, the output is connected to the 104R It is taken out.

- Patent Document 2 (hereinafter referred to as Conventional Technology 2) has a configuration as shown in the skeleton diagram shown in FIG.

- the vehicle drive device 100 is provided between a first electric motor 102L and a second electric motor 102R mounted on the vehicle, a left drive wheel 104L and a right drive wheel 104R, and these.

- a differential device 105 and reduction gear trains 106L and 106R are provided.

- the first electric motor 102L and the second electric motor 102R operate with electric power from a battery (not shown) mounted on the vehicle, and are individually controlled by an electronic control device (not shown) to generate different torques. Can be output.

- the output shaft 102aL of the first electric motor 102L and the output shaft 102aR of the second electric motor 102R are connected to the sun gears S L and S R of the differential device 105 via reduction gear trains 106L and 106R, respectively.

- the output from the differential device 105 is given to the left and right drive wheels 104L, 104R.

- the differential device 105 of the prior art 2 is configured by combining two identical planetary gear mechanisms 110L and 110R with three elements and two degrees of freedom on the same axis.

- the planetary gear mechanisms 110L and 110R for example, single-pinion type planetary gear mechanisms are employed.

- the first electric motor 102L torque TM1 generated in is input to the sun gear S L of the first planetary gear mechanism 110L via a reduction gear train 106L, torque TM2 generated by the second electric motor 102R is decelerated It is input to the sun gear S R of the second planetary gear mechanism 110R through a gear train 106R.

- first coupling member 111 and the second coupling member 112 are connected to the left and right drive wheels 104L and 104R, respectively, and outputs are taken out.

- the electric motor 102L input from 102R, the sun gear S L, the sun gear S R, and the drive wheels 104L, output to 104R, the carrier C L and the internal gear R R, and the carrier C R It becomes an internal gear R L.

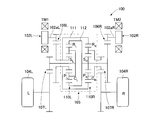

- the vehicle drive device (prior application example 1) for which the applicant of this application has applied for a patent has the configuration shown in FIGS.

- Gear 300 one of the planet carrier C L and the other of the first coupling member 231 for coupling the sun gear S R, a second coupling member for coupling one of the sun gear S L and the other planet carrier C R 232, the first coupling member 231 and the second coupling member 232 are arranged coaxially, and among the first coupling member 231 and the second coupling member 232, the second coupling member 232 is a hollow shaft,

- the coupling member 231 has a shaft inserted through the hollow shaft, and the shaft passing between the two planetary gear mechanisms 300L and 300R has a double structure, and the internal gear R L of the planetary gear mechanisms 300L and 300R. , R R and the input gear 213 of the speed reduction mechanism are engaged with and connected to external gears 217 provided on the internal gears R L , R R.

- Patent Document 3 discloses a vehicle drive device (prior art 3) provided with a differential device that is a torque difference amplification mechanism.

- the vehicle drive device of Prior Art 3 includes first and second drive sources M 1 and M 2, left and right drive wheels WL and WR, both drive sources M 1 and M 2, A differential device 302 interposed between the drive wheels WL and WR.

- the differential device 302 includes a continuous pinion 320 having a plurality of planetary gears connected to one shaft, and a continuous pinion.

- the rotating mechanism includes sun gears 324 and 325 that mesh with the planetary gears 321 and 322 of 320, a carrier 323 that pivotally supports the continuous pinion 320, and an internal gear 327 that meshes with the planetary gear 322 of the continuous pinion 320. .

- a drive source M1, a drive source M2, and left and right drive wheels WL, WR are connected to the differential device 302.

- the drive source M1 is connected to the internal gear 327 via the hollow shaft 311, and the drive source M2 is connected to the hollow shaft 312.

- the left driving wheel WL is connected to the carrier 323 via the shaft 313L

- the right driving wheel WR is connected to the first sun gear 324 via the shaft 313R.

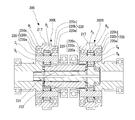

- the deep groove ball bearing 220 is disposed between the internal gears R L and R R and the planetary carriers C L and C R.

- the deep groove ball bearing 220 includes an inner ring 220a, a rolling element 220b, and an outer ring 220c.

- the bearing elements such as the inner ring 220a, the rolling element 220b, and the outer ring 220c are arranged between the inner gears R L and R R and the planetary carriers C L and C R. Since it is necessary to arrange them, the radial dimension increases by the thickness of the inner ring 220a and the outer ring 220c.

- the vehicle drive device is mounted on the vehicle body, it is advantageous to reduce the mounting space and secure a wide cabin space, and it is essential to reduce the size and weight of the gear device that amplifies the torque difference.

- an object of the present invention is to reduce the size in the radial direction of a torque difference amplification mechanism incorporated in a vehicle drive device.

- the present invention provides a three-element and two-degree-of-freedom planetary gear mechanism coaxially between two drive sources mounted on a vehicle and independently controllable and left and right drive wheels. Two combinations, a specific element of one planetary gear mechanism and a specific element of the other planetary gear mechanism are connected to each other by a first coupling member and a second coupling member to drive left and right from two driving sources.

- a differential device for amplifying and outputting a torque difference is provided on the ring, and the planetary gear mechanism is provided with an internal gear, a planet carrier provided coaxially with the internal gear, and provided coaxially with the internal gear.

- a vehicle drive device having a sun gear and a planetary gear as a revolving gear, an external gear as a speed reduction mechanism connected to the internal gear, and the internal gear supported by the planet carrier via a bearing

- the opposing surface of the internal gear and the planet carrier On at least one side, characterized in that the formation of the raceway surface of the bearing that is hardened.

- the bearing surface of the hardened bearing may be formed on the inner diameter surface of the internal gear, or the raceway surface of the hardened bearing may be formed on the outer diameter surface of the planet carrier.

- the material of the internal gear or planetary carrier is case-hardened steel, and the raceway surface of the bearing can be formed by carburizing and quenching.

- the material of the internal gear or planet carrier may be medium carbon steel, and the raceway surface of the bearing may be formed by induction hardening.

- the teeth of the internal gear may also be induction hardened.

- the bearing can be a deep groove ball bearing, and the cage of the deep groove ball bearing can be a resin crown.

- a cylindrical roller bearing with a cage may be used as the bearing, and a thrust washer may be disposed near the outer end of the raceway surface.

- a slide bearing may be used, and a stepped portion for arranging the slide bearing on the raceway surface may be provided.

- At least one of the outer ring and the inner ring is formed by directly forming the hardened raceway surface of the bearing on at least one of the opposing surfaces of the inner gear and the planetary carrier. Since it can be omitted, the radial dimension can be reduced by the thickness of the inner ring or the outer ring.

- FIG. 5 is an enlarged view showing another embodiment of the gear device surrounded by a two-dot chain line in FIG. 1.

- FIG. 6B is a partially enlarged view of the plain bearing taken along line bb in FIG. 6A.

- FIG. 10 is a skeleton diagram showing a gear configuration of a vehicle drive device according to Prior Art 3.

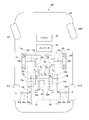

- the electric vehicle AM shown in FIG. 7 is a rear wheel drive system, and includes a chassis 60, drive wheels 61L and 61R as rear wheels, front wheels 62L and 62R, and a two-motor vehicle drive device 1 according to the present invention.

- a battery 63, an inverter 64, and the like are provided.

- the gear structure of the vehicle drive device 1 is shown with the skeleton figure.

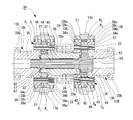

- a vehicle drive device 1 shown in FIG. 1 includes two electric motors 2L and 2R that are mounted on a vehicle and can be controlled independently, and left and right drive wheels 61L and 61R and two electric motors 2L and 2R. 2 left and right reduction gears 3L and 3R provided between them.

- the driving torque of the two-motor type vehicle drive device 1 is transmitted to the left and right drive wheels 61L and 61R via a drive shaft composed of constant velocity joints 65a and 65b and an intermediate shaft 65c.

- a front wheel drive system or a four wheel drive system may be used in addition to the rear wheel drive system shown in FIG.

- the vehicle drive device shown in FIG. 1 may be mounted on both the front wheels or the rear wheels, or may be mounted on one of them, and the other may be another device such as an engine-driven gear device. It may be a drive device.

- the left and right electric motors 2L and 2R in the two-motor type vehicle drive device 1 use electric motors having the same maximum output and the same output characteristics, and are housed in motor housings 4L and 4R as shown in FIG. Has been.

- the motor housings 4L and 4R include cylindrical motor housing bodies 4aL and 4aR, outer walls 4bL and 4bR that close the outer surfaces of the motor housing bodies 4aL and 4aR, and reduction gears on the inner surfaces of the motor housing bodies 4aL and 4aR. It consists of inner walls 4cL and 4cR separated from 3L and 3R. The inner walls 4cL and 4cR are provided with openings through which the motor shaft 5a is drawn.

- the electric motors 2 ⁇ / b> L and 2 ⁇ / b> R are of a radial gap type in which a stator 6 is provided on the inner peripheral surface of the motor housing main body 4 aL and 4 aR, and a rotor 5 is provided with a gap in the inner periphery of the stator 6. I am using something.

- the electric motors 2L and 2R may be axial gap types.

- the rotor 5 has a motor shaft 5a in the center, and the motor shaft 5a is drawn from the openings of the inner walls 4cL and 4cR of the motor housing main bodies 4aL and 4aR to the reduction gears 3L and 3R, respectively.

- a seal member 7 is provided between the periphery of the inner side walls 4cL and 4cR of the motor housing bodies 4aL and 4aR and the motor shaft 5a.

- the motor shaft 5a is rotatably supported by the rolling bearings 8a and 8b on the inner walls 4cL and 4cR and the outer walls 4bL and 4bR of the motor housing bodies 4aL and 4aR (see FIG. 1).

- the bearings 8a and 8b are the same, but different sizes may be combined.

- a reduction gear housing 9 that accommodates two reduction gears 3L and 3R provided in parallel on the left and right is divided into three pieces in a direction perpendicular to the gear shafts of the reduction gears 3L and 3R, as shown in FIG.

- the housing 9a has a three-piece structure including left and right side housings 9bL and 9bR fixed to both side surfaces of the central housing 9a.

- the left and right side housings 9bL and 9bR are fixed to the openings on both sides of the central housing 9a by a plurality of bolts (not shown).

- a plurality of bolts 10 are used to fix side faces 9bL and 9bR of the reduction gear housing 9 on the side of the outboard side (outside the vehicle body) and the inner side walls 4cL and 4cR of the motor housing bodies 4aL and 4aR of the electric motors 2L and 2R.

- the two electric motors 2L and 2R are fixedly arranged on the left and right sides of the reduction gear housing 9 (see FIG. 1).

- the central housing 9a is provided with a partition wall 11 in the center.

- the speed reducer housing 9 is divided into left and right parts by the partition wall 11, and independent left and right accommodation chambers for accommodating the two speed reducers 3L and 3R are provided in parallel.

- the reduction gears 3L and 3R are provided symmetrically and have large input gear shafts 12L and 12R having an input gear 12a to which power is transmitted from the motor shaft 5a, and the input gear 12a.

- Intermediate gear shafts 13L and 13R having both an output side small gear 13b meshing with an input side external gear 13a and an output gear 14a, and an output gear 14a.

- the constant velocity joint 65a is pulled out from the speed reducer housing 9.

- 65 is a parallel shaft gear reducer including output gear shafts 14L and 14R that transmit torque to drive wheels 61L and 61R (see FIG. 7) via an intermediate shaft 65c (see FIG. 7).

- the input gear shafts 12L and 12R, the intermediate gear shafts 13L and 13R, and the output gear shafts 14L and 14R of the left and right reduction gears 3L and 3R are coaxially arranged.

- Both ends of the input gear shafts 12L and 12R of the reduction gears 3L and 3R are respectively connected to bearing fitting holes 16a formed on both left and right sides of the partition wall 11 of the central housing 9a and bearing fitting holes 16b formed on the side housings 9bL and 9bR. It is rotatably supported via rolling bearings 17a and 17b.

- the bearing fitting holes 16a and 16b have a stepped shape having a wall portion with which the outer rings of the rolling bearings 17a and 17b abut. In FIG. 1, the rolling bearings 17a and 17b are the same, but they may be combined in different sizes.

- the end portions on the outboard side of the input gear shafts 12L, 12R are drawn outward from the openings provided in the side housings 9bL, 9bR, and between the openings and the outer ends of the input gear shafts 12L, 12R. Is provided with an oil seal 18 to prevent leakage of the lubricating oil sealed in the speed reducer housing 9.

- the input gear shafts 12L and 12R have a hollow structure, and end portions of the motor shaft 5a are inserted into the hollow input gear shafts 12L and 12R.

- the input gear shafts 12L, 12R and the motor shaft 5a are coupled by splines (including serrations, the same applies hereinafter).

- At least one or more intermediate gear shafts 13L and 13R are arranged.

- the intermediate gear shafts 13L and 13R have a pair of intermediate gear shafts 13L and 13R.

- the intermediate gear shafts 13L and 13R constitute a stepped gear shaft having an input side external gear 13a meshing with the input gear 12a on the outer peripheral surface and an output side small gear 13b meshing with the output gear 14a.

- rolling bearings 20a and 20b are fitted into bearing fitting holes 19a formed on both surfaces of the partition wall 11 of the central housing 9a and bearing fitting holes 19b formed on the side housings 9bL and 9bR. Is supported through.

- the bearing fitting holes 19a and 19b have a stepped shape with a wall portion with which the outer rings of the rolling bearings 20a and 20b come into contact.

- the bearing fitting hole 19a has a first coupling member 31 and a second coupling which will be described later. It penetrates so that member 32 may pass.

- the rolling bearings 20a and 20b have different sizes, but they may be combined with each other.

- the intermediate gear shafts 13L and 13R arranged on the same axis are connected to the intermediate gear shafts 13L and 13R so that the drive torque applied from the two electric motors 2L and 2R is a torque difference between the left and right drive wheels 61L and 61R.

- a gear device 30 for amplifying and distributing the signal is incorporated.

- the gear device 30 is composed of two planetary gear mechanisms 30L and 30R with three elements and two degrees of freedom, which are coaxially combined with a pair of left and right intermediate gear shafts 13L and 13R arranged coaxially.

- the planetary gear mechanisms 30L and 30R constituting the gear device 30 include internal gears R L and R R and internal gears R L and R R incorporated in the large-diameter input side external gear 13a of the intermediate gear shafts 13L and 13R, respectively.

- a plurality of planetary gears P L arranged equally in the circumferential direction as revolving gears meshed with the sun gears S L , S R and the internal gears R L , R R and the sun gears S L , S R provided coaxially with each other.

- a first coupling member 31 that couples the other sun gear S R (the right side of the figure in FIG. 1) with one sun gear S L (the left side of the figure in FIG. 1) and the other sun gear S R a planet carrier C R second coupling member 32 for coupling the (right side in FIG. in FIG.

- the planetary gear mechanisms 30L and 30R constituting the gear device 30 are incorporated only in any one of the pair of intermediate gear shafts 13L and 13R.

- the input-side external gear 13a connected to the internal gears R L , R R is an output-side small gear 13b provided on the drive-side intermediate gear shafts 13L, 13R among the plural pairs of intermediate gear shafts 13L, 13R, or

- An output-side small-diameter gear 13b that is arranged so as to mesh with the input gear 12a of the input gear shafts 12L and 12R and is coaxial with the planetary gear mechanisms 30L and 30R is formed of a plurality of pairs of intermediate gear shafts 13L and 13R.

- the planetary carriers C L and C R are composed of a carrier pin 33 that supports the planetary gears P L and P R , and an outboard side carrier flange that is connected to the outboard side end of the carrier pin 33. 34a and an inboard carrier flange 34b connected to the inboard side end.

- the carrier flange 34a on the outboard side includes a hollow shaft portion 35 extending toward the outboard side, and the end portion on the outboard side of the hollow shaft portion 35 is formed on the side housings 9bL and 9bR of the speed reducer housing 9. It is supported by the fitting hole 19b via the rolling bearing 20b (refer FIG. 1).

- the carrier flange 34b on the inboard side includes a hollow shaft portion 36 extending toward the inboard side, and an end portion on the inboard side of the hollow shaft portion 36 is formed in a bearing fitting hole formed in the partition wall 11 of the central housing 9a. It is supported by 19a via the rolling bearing 20a (refer FIG. 1).

- the output-side small-diameter gear 13b is integrally formed on the outer peripheral surface of the hollow shaft portion 35 of the carrier flange 34a.

- the planetary gears P L and P R are supported by the carrier pin 33 via the needle roller bearing 37.

- each of the carrier flanges 34a, 34b facing surface and a planetary gear P L of, inserting the thrust plate (not shown) between the P R, the planetary gear P L, even working to smooth rotation of the P R Good.

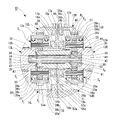

- a bearing 39 is disposed between the outer peripheral surfaces of the carrier flanges 34a and 34b and the internal gears R L and R R.

- a deep groove ball bearing is adopted as the bearing 39 for supporting the internal gears R L and R R on the carrier flanges 34a and 34b.

- the deep groove ball bearing includes an outer ring 39a, an inner ring 39b, and a rolling element 39c.

- the raceway surface of the outer ring 39a is used as the inner diameter surface of the internal gears R L and R R. Formed directly.

- the outer ring 39a By forming the raceway surface of the outer ring 39a directly on the inner diameter surface of the inner gears R L and R R , the outer ring 39a has a thickness corresponding to the thickness of the outer ring than when the outer ring of a separate part is incorporated in the inner diameter surface of the inner gears R L and R R The radial dimension can be reduced.

- gears such as the internal gears R L and R R

- a case-hardened steel that has been subjected to surface hardening and quenching is used in order to sufficiently secure the tooth surface strength and tooth root strength of the teeth.

- bearings that support the rotation of gears also need to withstand high surface pressure generated on the rolling elements and raceways by the load.

- high-carbon chromium alloy steel that has been subjected to core quenching or surface-hardened steel Hardened and hardened. That is, both the gear and the bearing need to have sufficient hardness (for example, a surface hardness of 58 HRC or more) by quenching.

- the internal gears R L and R R are, for example, case-hardened steel, and carburized and quenched as a heat treatment, and the surface hardness of the tooth portion and the bearing raceway surface is It is secured at 58HRC or higher.

- a deep groove ball bearing is adopted as the bearing 39 for supporting the internal gears R L and R R on the carrier flanges 34a and 34b, as in the embodiment shown in FIGS.

- the raceway surface corresponding to the inner ring 39b of the bearing is formed directly on the outer diameter surfaces of the carrier flanges 34a and 34b.

- the planetary carriers C L and C R provided with the carrier flanges 34a and 34b are, for example, medium carbon steel, and the bearing raceway surface is subjected to induction hardening as a heat treatment, and the surface hardness is secured to 58 HRC or more. Yes.

- the teeth of the output-side small-diameter gear 13b formed on the planetary carriers C L and C R are also heat-treated in the same manner. A portion to be induction-hardened is indicated by a thick dashed line in FIG.

- the rolling bearing 39 is the same on the outboard side and the inboard side, but a combination of different forms may be used. That is, the bearing on the outboard side directly forms the raceway surface of the outer ring 39a on the inner diameter surface of the internal gears R L and R R as shown in FIGS. 1 and 2, and the bearing on the inboard side is the inner ring 39a as shown in FIG.

- the raceway surface may be formed directly on the outer diameter surface of the carrier flanges 34a, 34b.

- the bearing on the inboard side directly forms the raceway surface of the outer ring 39a on the inner diameter surface of the internal gears R L and R R

- the bearing on the outboard side forms the raceway surface of the inner ring 39a on the carrier flanges 34a and 34b. You may form directly on an outer diameter surface.

- the size of the bearing may be different between the bearing on the outboard side and the bearing on the inboard side.

- FIG. 4 employs a cylindrical roller bearing with a cage as the bearing 39 for supporting the internal gears R L and R R on the carrier flanges 34a and 34b.

- the raceway surface of the outer ring 39a is an internal gear R L, are directly formed on the inner diameter surface of the R R, further, the raceway surface of the inner ring 39b is also directly formed on the outer peripheral surface of the carrier flange 34a, 34b Has been.

- a step is provided at the inner end of the raceway surface of the outer ring 39a to restrict the rolling element 39c from moving.

- a thrust ring 39d is provided in the vicinity of the outside of the raceway surface of the inner ring 39b. The thrust ring 39d is regulated so as not to drop off by a retaining ring 39e provided further outside. As a result, the rolling element 39c is restricted from moving in the axial direction by the step and the thrust ring 39d, and is prevented from falling off the bearing 39.

- the embodiment shown in FIG. 5 employs a deep groove ball bearing as the bearing 39 for supporting the internal gears R L and R R on the carrier flanges 34a and 34b as in the embodiment shown in FIGS.

- the bearings 39 are provided on both the outboard side and the inboard side.

- the cantilever is supported only by the bearing 39 on the board side.

- the raceway surface of the outer ring 39a is formed directly on the inner diameter surface of the internal gears R L and R R

- the raceway surface of the inner ring 39b is formed on the carrier flange 34b on the inboard side. It is formed directly on the outer peripheral surface.

- the bearings 39 are provided in a single row, but may be in a double row (not shown).

- a cylindrical roller bearing can be adopted as in the embodiment shown in FIG.

- the outboard side bearing 39 is abolished and is cantilevered only by the inboard side bearing 39, but the inboard side bearing 39 is abolished and the outboard side bearing 39 is supported. You may make it cantilever-support only by 39 (illustration omitted).

- FIG. 6AB employs a plain bearing as the bearing 39 for supporting the internal gears R L and R R on the carrier flanges 34a and 34b.

- the sliding bearing is attached by fitting to the stepped portion provided on the outer peripheral surface of the carrier flanges 34a, 34b, and the sliding surface of the sliding bearing is attached to the inner diameter surface of the internal gears R L , R R. Is formed directly.

- the sliding surfaces of the inner diameter surfaces of the internal gears R L and R R are secured by heat treatment.

- axial and circumferential oil grooves 39f are formed on the outer peripheral surface of the slide bearing so that lubricating oil can be supplied to the sliding surface.

- the collar 40 is disposed between the inboard carrier flange 34b and the rolling bearing 20a that supports the hollow shaft portion 36 of the inboard carrier flange 34b.

- the first coupling member 31 and the second coupling member 32 that couple the two planetary gear mechanisms 30L and 30R that constitute the gear device 30 of the vehicle drive device 1 are the speed reducer housing 9.

- the central housing 9a is incorporated through the partition wall 11 that partitions the left and right.

- the first coupling member 31 and the second coupling member 32 are arranged coaxially, and one coupling member (the second coupling member 32 in each embodiment of FIGS. 1 to 6) is a hollow shaft and the other coupling

- the member (the first coupling member 31 in each embodiment of FIGS. 1 to 6) has a double structure composed of a shaft inserted through the hollow shaft.

- the end portion of the right side of the planetary gear mechanism 30R side in the second coupling member 32 consists of a hollow shaft, and the hollow shaft portion 36 of the carrier flange 34b on the inboard side of the planet carrier C R the spline 41 is provided, it is connected by spline fitting to the second coupling member 32 the planet carrier C R.

- the end portion of the left planetary gear mechanism 30L side of the first coupling member 31, the spline 42 in the hollow shaft portion 35 of the carrier flange 34a on the outboard side of the planet carrier C L provided, the first coupling member 31 to the planet carrier C L are connected by spline fitting.

- the two planetary gear mechanisms 30L, first coupling member 31 of the 30R and a second binding member 32 by connecting the splined to the planet carrier C L and the planet carrier C R, two The planetary gear mechanism can be divided into left and right, and can be incorporated into the three-piece reduction gear housing 9 from the left and right in the same manner as other reduction gear shafts.

- End of the planet carrier C L of the second coupling member 32 has, on its outer peripheral surface, the external gear meshing with the planetary gears P L of the left planetary gear mechanism is formed, the sun the external gear of the left planetary gear mechanism A gear S L is configured.

- the first coupling member 31 inserted through the second coupling member 32 constituted by a hollow shaft has a large diameter portion 43 at an end portion on the right planetary gear mechanism 30R side, and an outer peripheral surface of the large diameter portion 43 is provided. , external gear meshing with the planetary gears P R of the right planetary gear mechanism 30R is formed, the outer gear constitutes the sun gear S R of the right planetary gear mechanism 30R.

- the maximum diameter of the sun gear S R which (in each embodiment the coupling member 31) coupling members on the inner diameter side are connected with the outer diameter side coupling member by (in the embodiments in which the second coupling member 32) is set smaller than the minimum diameter of the spline hole of the inner surface of the hollow shaft portion 36 of the carrier flange 34b on the inboard side of the planet carrier C R for mating is the inner diameter side It is possible to easily incorporate the coupling member (the first coupling member 31 in each embodiment).

- a collar 44 and a collar 44 are provided between the outer peripheral surface of the inner diameter side coupling member (first coupling member 31 in each embodiment) and the inner peripheral surface of the outer diameter side coupling member (second coupling member 32). Needle roller bearings 45 and 46 are interposed at both ends.

- the first coupling member 31 and the second coupling member 32 and the planetary carriers C L and C R are fitted (splines 42 and 41) with a fitting tolerance that can be slid in the axial direction.

- the axial movement of the first coupling member 31 and the second coupling member 32 and the planetary carriers C L and C R due to the sliding movement of the spline (splines 42 and 41) is caused by the outer diameter side coupling member (each implementation).

- the load is supported by providing thrust bearings 47 and 48 at both ends of the second coupling member 32).

- the coupling member (the first coupling member 31 in each embodiment) on the inner diameter side of the dual-structure shaft that couples the two planetary gear mechanisms 30L and 30R is a coupling member (the first coupling member 31 in each embodiment) and the planet.

- the coupling member (the first coupling member 31 in each embodiment) on the inner diameter side of the double-structure shaft that couples the two planetary gear mechanisms 30L and 30R includes the tooth surfaces of the sun gears S L and S R , the planetary gear P L, the tooth surfaces of the P R, in order to supply the lubricating oil, etc, is provided an oil supply hole 50 to the axis.

- the thrust bearings 47 and 48 at both ends of the outer diameter side coupling member (second coupling member 32 in each embodiment) are positioned. Radial oil supply passages 51 and 52 are provided.

- the output gear shafts 14L and 14R have a large-diameter output gear 14a, and are formed in bearing fitting holes 53a formed on both surfaces of the partition wall 11 of the central housing 9a and bearing fitting holes 53b formed on the side housings 9bL and 9bR. It is supported by rolling bearings 54a and 54b.

- the bearing fitting holes 53a and 53b have a stepped shape having a wall portion with which the outer rings of the rolling bearings 54a and 54b come into contact. In FIG. 1, the rolling bearings 54a and 54b are the same, but they may be combined in different sizes.

- Outboard side ends of the output gear shafts 14L and 14R are drawn out of the reduction gear housing 9 from openings formed in the side housings 9bL and 9bR, and are pulled out to the outboard side of the output gear shafts 14L and 14R.

- the outer joint portion of the constant velocity joint 65a is splined to the outer peripheral surface of the end portion.

- the constant velocity joint 65a coupled to the output gear shafts 14L and 14R is connected to the drive wheels 61L and 61R via the intermediate shaft 65c and the constant velocity joint 65b (see FIG. 7).

- An oil seal 55 is provided between the end of the output gear shafts 14L and 14R on the outboard side and the opening formed in the side housings 9bL and 9bR, and leakage of the lubricating oil sealed in the speed reducer housing 9 and the outside Intrusion of muddy water from

- the gear configuration of the two-motor type vehicle drive device 1 of the embodiment shown in FIG. 1 is as shown in the skeleton diagram shown in FIG.

- the left and right electric motors 2 ⁇ / b> L and 2 ⁇ / b> R are operated by electric power supplied via an inverter 64 from a battery 63 mounted on the vehicle.

- the electric motors 2L and 2R are individually controlled by an electronic control device (not shown), and can generate and output different torques.

- the torque of the motor shaft 5a of the electric motors 2L and 2R is the gear ratio between the input gear shaft 12a of the input gear shafts 12L and 12R of the reduction gears 3L and 3R and the large-diameter input side external gear 13a of the intermediate gear shafts 13L and 13R. And transmitted to the internal gears R L and R R of the gear device 30.

- the output side small gear 13b of the intermediate gear shafts 13L and 13R meshes with the large diameter output gear 14a of the output gear shafts 14L and 14R via the gear device 30, and the number of teeth of the output side small gear 13b and the output gear 14a.

- the torque of the motor shafts 5a of the electric motors 2L and 2R is further increased by the ratio and output to the drive wheels 61L and 61R.

- the gear device 30 is configured by combining two planetary gear mechanisms 30L and 30R having the same three-element and two-degree-of-freedom with coaxial intermediate gear shafts 13L and 13R.

- the planetary gear mechanisms 30L and 30R are of a single pinion type.

- a planetary gear mechanism is used.

- the planetary gear mechanisms 30L and 30R are coaxially provided with sun gears S L and S R and internal gears R L and R R, and between these sun gears S L and S R and the internal gears R L and R R.

- a plurality of planetary gears P L, P R is close to the planetary gear P L, provided the P R rotatably supported by the sun gear S L, S R and the internal gear R L, on R R coaxial It is composed of planetary carriers C L and C R.

- the sun gear S L, S R and the planetary gears P L, P R is the external gear having gear teeth on the outer circumference

- the internal gear R L, R R is the internal gear having gear teeth on the inner peripheral is there.

- the planetary gears P L and P R mesh with the sun gears S L and S R and the internal gears R L and R.

- the gear device 30 includes the first planetary gear mechanism 30L having the sun gear S L , the planet carrier C L , the planet gear P L and the internal gear RL , and the sun gear S R and the planet carrier C.

- a second planetary gear mechanism 30R having a planetary gear P R and the internal gear R R is configured by combining coaxially.

- the torque TM1 generated by the electric motor 2L is transmitted to the intermediate gear shaft 13L by meshing the input gear 12a of the input gear shaft 12L and the input side external gear 13a, and the torque transmitted to the intermediate gear shaft 13L is It is transmitted to the output-side small gear 13b of the intermediate gear shaft 13L via the first planetary gear mechanism 30L, and the output-side small gear 13b of the intermediate gear shaft 13L and the output gear 14a of the output gear shaft 14L are engaged with each other to produce an output gear shaft.

- Drive torque TR is output from 14L to drive wheel 61L.

- the torque TM2 generated by the electric motor 2R is transmitted to the intermediate gear shaft 13R when the input gear 12a of the input gear shaft 12R and the input side external gear 13a are meshed, and the torque transmitted to the intermediate gear shaft 13R is the second torque. It is transmitted to the output-side small gear 13b of the intermediate gear shaft 13R via the planetary gear mechanism 30R, and the output-side small gear 13b of the intermediate gear shaft 13R and the output gear 14a of the output gear shaft 14R are meshed to drive from the output gear shaft 14R.

- a driving torque TR is output to the wheel 61R.

- the outputs from the electric motors 2L and 2R are also given to the internal gears R L and R R of the two planetary gear mechanisms 30L and 30R, respectively, and the outputs from the first coupling member 31 and the second coupling member 32 are drive wheels. It is given to 61L and 61R.

- the 2nd coupling member 32 is comprised by the hollow shaft, the 1st coupling member 31 is penetrated in the inside, and the axis

- the first coupling member 31 has one end a rotation shaft of the (right end in the drawing) is the sun gear S R, the other end (left end in the drawing) are provided through the sun gear S L, connected to the planet carrier C L Has been.

- the second coupling member 32 is a hollow shaft, one end (left end in the drawing) has a rotation shaft of the sun gear S L, the other end (right end in the drawing) is connected to the planet carrier C R.

- the first planetary gear mechanisms 30L and 30R are coupled by the first coupling member 31 and the second coupling member 32.

- the gear unit 30 is configured by combining two identical single pinion type planetary gear mechanisms 30L and 30R, it can be represented by two velocity diagrams as shown in FIG.

- the two speed diagrams are shifted up and down, the speed diagram of the left planetary gear mechanism 30L is shown on the upper side, and the speed diagram of the right planetary gear mechanism 30R is shown on the lower side.

- the torques TM1 and TM2 output from the electric motors 2L and 2R are respectively connected to the internal gears via the input side external gears 13a meshing with the input gears 12a of the input gear shafts 12L and 12R.

- the inputs from the electric motors 2L and 2R are the internal gears R L and R R

- the outputs to the drive wheels 61L and 61R are the sun gear S R and the carrier C L

- the sun gear S L and the carrier C R Become.

- the torque difference distributing mechanism is a gear unit 30 two planetary gear mechanism 30L which constitutes the connection of 30R the sun gear S L and the planet carrier C R, the sun gear S R And the planetary carrier C L , a connecting member having a larger diameter than the internal gears R L and R R is not required.

- the torque difference distribution mechanism can be made smaller than those of the prior art 1 and the prior art 2

- the vehicle drive device 1 for an electric vehicle incorporating the torque difference distribution mechanism can be made smaller and lighter.

- the vehicle on which the vehicle drive device 1 is mounted is not limited to an electric vehicle or a hybrid electric vehicle, but may be, for example, a fuel cell vehicle that uses the first electric motor 2L and the second electric motor 2R as driving sources. Good.

- the present invention is not limited to the embodiment described above, and can be implemented in various forms without departing from the gist of the present invention.

Abstract

The present invention addresses the problem of reducing the radial dimension of a gear device 30 mounted in a vehicle drive device 1. In a vehicle drive device, planetary gear mechanisms 30L, 30R which constitute a gear device 30 for distributing, to left and right wheels, power supplied from two electric motors 2L, 2R have: internally toothed gears RL, RR; planetary carriers CL, CR provided coaxially with the internally toothed gears RL, RR; sun gears SL, SR provided coaxially with the internally toothed gears RL, RR; and planetary gears PL, PR as revolving gears. Externally toothed gears 13a as speed reduction mechanisms are connected to the internally toothed gears RL, RR, and the internally toothed gears RL, RR are supported by the planetary carriers CL, CR through bearings 39. The vehicle drive device is characterized in that a hardened raceway surface of the bearing 39 is formed on at least one of the facing surfaces of the internally toothed gear RL, RR and the planetary carrier CL, CR.

Description

この発明は、独立した二つの駆動源からの駆動トルクを左右の駆動輪にトルク差を増幅して伝達することができる車両駆動装置に関するものである。

The present invention relates to a vehicle drive device capable of amplifying a torque difference and transmitting drive torque from two independent drive sources to left and right drive wheels.

電気自動車等の車両において、左右の駆動輪にそれぞれ電動モータを配置して、各電動モータを独立して制御することにより左右輪に適宜駆動トルク差を与えて、これにより車両の旋回モーメントを制御することが知られている。車両のスムーズな旋回走行の実現や、極端なアンダーステア、極端なオーバーステア等の車両の挙動変化を抑制するために、左右の駆動輪の間に大きな駆動トルクの差を発生させることが有効な場合がある。そのため、二つの電動モータから出力されるトルクの差を増幅し、左右の駆動輪に伝達することが望まれる。

In vehicles such as electric cars, electric motors are arranged on the left and right drive wheels, respectively, and each electric motor is controlled independently to give an appropriate drive torque difference between the left and right wheels, thereby controlling the turning moment of the vehicle It is known to do. When it is effective to generate a large difference in driving torque between the left and right drive wheels in order to achieve smooth turning of the vehicle and to suppress changes in vehicle behavior such as extreme understeer and extreme oversteer There is. For this reason, it is desirable to amplify the difference between the torques output from the two electric motors and transmit them to the left and right drive wheels.

特許文献1及び特許文献2には、二つの駆動源と左右の駆動輪との間に、3要素2自由度の遊星歯車構造体を同軸上に二つ組み合わせたトルク差増幅機構である差動装置を備えた車両駆動装置が開示されている。

In Patent Document 1 and Patent Document 2, a differential that is a torque difference amplifying mechanism in which two planetary gear structures with three elements and two degrees of freedom are coaxially arranged between two drive sources and left and right drive wheels. A vehicle drive device comprising the device is disclosed.

特許文献1の図5(a)に開示された車両駆動装置(以下、従来技術1という。)は、図9に示すスケルトン図のような構成になっている。

The vehicle driving device disclosed in FIG. 5A of Patent Document 1 (hereinafter referred to as Conventional Technology 1) has a configuration as shown in the skeleton diagram shown in FIG.

車両駆動装置100は、車両に搭載された左右の電動モータ102L及び電動モータ102Rと、左駆動輪104L及び右駆動輪104Rと、これらの間に設けられる差動装置105と減速ギヤ列106L、106R、107L、107Rとを備えている。

The vehicle drive device 100 includes left and right electric motors 102L and 102R mounted on the vehicle, left drive wheels 104L and right drive wheels 104R, a differential device 105 and reduction gear trains 106L and 106R provided therebetween. , 107L, 107R.

電動モータ102L及び電動モータ102Rは、車両に搭載されたバッテリ(図示省略)からの電力により動作し、電子制御装置(図示省略)により個別に制御され、異なるトルクを発生させて出力することができる。

The electric motor 102L and the electric motor 102R operate with electric power from a battery (not shown) mounted on the vehicle, are individually controlled by an electronic control device (not shown), and can generate and output different torques. .

電動モータ102Lの出力軸102aL、電動モータ102Rの出力軸102aRは、それぞれ減速ギヤ列106L、106Rを介して差動装置105の各結合部材111、112に接続される。差動装置105からの出力は減速ギヤ列107L、107Rを介して左右の駆動輪104L、104Rに与えられる。

The output shaft 102aL of the electric motor 102L and the output shaft 102aR of the electric motor 102R are connected to the coupling members 111 and 112 of the differential device 105 through the reduction gear trains 106L and 106R, respectively. The output from the differential device 105 is given to the left and right drive wheels 104L, 104R via the reduction gear trains 107L, 107R.

差動装置105は、3要素2自由度の同一の遊星歯車機構110L、110Rが同軸上に二つ組み合わされて構成されている。

The differential device 105 is configured by combining two identical planetary gear mechanisms 110L and 110R with three elements and two degrees of freedom on the same axis.

遊星歯車機構110L、110Rには、例えば、シングルピニオン形式の遊星歯車機構が採用されている。シングルピニオン形式の遊星歯車機構は、同軸上に設けられた太陽歯車SL、SR及び内歯車RL、RRと、これら太陽歯車SL、SRと内歯車RL、RRとの間に位置する複数の遊星歯車PL、PRと、遊星歯車PL、PRを回動可能に支持し、太陽歯車SL、SR及び内歯車RL、RRと同軸上に設けられた遊星キャリヤCL、CRとから構成され、遊星歯車PL、PRは太陽歯車SL、SRと内歯車RL、RRとに噛み合っている。ここで、太陽歯車SL、SRと遊星歯車PL、PRは外周にギヤ歯を有する外歯歯車であり、内歯車RL、RRは内周にギヤ歯を有する内歯歯車である。

As the planetary gear mechanisms 110L and 110R, for example, single-pinion type planetary gear mechanisms are employed. The single-pinion type planetary gear mechanism includes a sun gear S L , S R and internal gears R L , R R provided on the same axis, and these sun gears S L , S R and internal gears R L , R R. A plurality of planetary gears P L and P R and planetary gears P L and P R are rotatably supported, and are provided coaxially with the sun gears S L and S R and the internal gears R L and R R. was planet carrier C L, is composed of a C R, the planetary gear P L, P R is engaged the sun gear S L, S R and the internal gear R L, in the R R. Here, the sun gear S L, S R and the planetary gears P L, P R is the external gear having gear teeth on the outer circumference, the internal gear R L, R R is the internal gear having gear teeth on the inner peripheral is there.

この差動装置105は、図9に示すように、太陽歯車SL、遊星キャリヤCL、遊星歯車PL及び内歯車RLを有する第1遊星歯車機構110Lと、同じく太陽歯車SR、遊星キャリヤCR、遊星歯車PR及び内歯車RRを有する第2遊星歯車機構110Rとが同軸上に組み合わされて構成されている。

As shown in FIG. 9, the differential 105 includes a first planetary gear mechanism 110L having a sun gear S L , a planet carrier C L , a planetary gear P L, and an internal gear RL , as well as a sun gear S R , a planetary gear. carrier C R, and a second planetary gear mechanism 110R having a planetary gear P R and the internal gear R R is configured by combining coaxially.

そして、第1遊星歯車機構110Lの太陽歯車SLと第2遊星歯車機構110Rの内歯車RRとが第1結合部材111によって結合され、第1遊星歯車機構110Lの内歯車RLと第2遊星歯車機構110Rの太陽歯車SRとが第2結合部材112によって結合されている。

Then, the sun gear S L of the first planetary gear mechanism 110L and the internal gear R R of the second planetary gear mechanism 110R is coupled by a first coupling member 111, and the internal gear R L of the first planetary gear mechanism 110L second The sun gear S R of the planetary gear mechanism 110R is coupled by the second coupling member 112.

第1結合部材111には、電動モータ102Lで発生されたトルクTM1が減速ギヤ列106Lを介して入力され、第2結合部材112には、電動モータ102Rで発生されたトルクTM2が減速ギヤ列106Rを介して入力される。また、第1遊星歯車機構110Lの遊星キャリヤCL及び第2遊星歯車機構110Rの遊星キャリヤCRは、それぞれ減速ギヤ列107L、107Rを介して左右の駆動輪104L、104Rに接続されて出力が取り出される。

The torque TM1 generated by the electric motor 102L is input to the first coupling member 111 via the reduction gear train 106L, and the torque TM2 generated by the electric motor 102R is input to the second coupling member 112 by the reduction gear train 106R. Is input through. Further, the planet carrier C R of the planetary carrier C L and the second planetary gear mechanism 110R of the first planetary gear mechanism 110L, respectively reduction gear train 107L, through 107R left and right drive wheels 104L, the output is connected to the 104R It is taken out.

次に、特許文献2に開示された車両駆動装置(以下、従来技術2という。)は、図10に示すスケルトン図のような構成になっている。

Next, the vehicle drive device disclosed in Patent Document 2 (hereinafter referred to as Conventional Technology 2) has a configuration as shown in the skeleton diagram shown in FIG.

なお、図10においては、従来技術1との差を分かりやすくするために、左右に電動モータ102L、102Rを配置して従来技術1と同様の図にし、同一構成部分には同一符号を付している。

In FIG. 10, in order to make the difference from the prior art 1 easier to understand, the electric motors 102L and 102R are arranged on the left and right to make the same figure as in the prior art 1, and the same components are denoted by the same reference numerals. ing.

図10に示すように、車両駆動装置100は、車両に搭載された第1の電動モータ102L及び第2の電動モータ102Rと、左駆動輪104L及び右駆動輪104Rと、これらの間に設けられる差動装置105と減速ギヤ列106L、106Rとを備えている。

As shown in FIG. 10, the vehicle drive device 100 is provided between a first electric motor 102L and a second electric motor 102R mounted on the vehicle, a left drive wheel 104L and a right drive wheel 104R, and these. A differential device 105 and reduction gear trains 106L and 106R are provided.

第1の電動モータ102L及び第2の電動モータ102Rは、車両に搭載されたバッテリ(図示省略)からの電力により動作し、電子制御装置(図示省略)により個別に制御され、異なるトルクを発生させて出力することができる。第1の電動モータ102Lの出力軸102aL、第2の電動モータ102Rの出力軸102aRは、それぞれ減速ギヤ列106L、106Rを介して差動装置105の太陽歯車SL、SRに接続される。差動装置105からの出力は左右の駆動輪104L、104Rに与えられる。

The first electric motor 102L and the second electric motor 102R operate with electric power from a battery (not shown) mounted on the vehicle, and are individually controlled by an electronic control device (not shown) to generate different torques. Can be output. The output shaft 102aL of the first electric motor 102L and the output shaft 102aR of the second electric motor 102R are connected to the sun gears S L and S R of the differential device 105 via reduction gear trains 106L and 106R, respectively. The output from the differential device 105 is given to the left and right drive wheels 104L, 104R.

従来技術1と同様に従来技術2の差動装置105は、3要素2自由度の同一の遊星歯車機構110L、110Rが同軸上に二つ組み合わされて構成されている。遊星歯車機構110L、110Rには、例えば、シングルピニオン形式の遊星歯車機構が採用されている。

Like the prior art 1, the differential device 105 of the prior art 2 is configured by combining two identical planetary gear mechanisms 110L and 110R with three elements and two degrees of freedom on the same axis. As the planetary gear mechanisms 110L and 110R, for example, single-pinion type planetary gear mechanisms are employed.

そして、第1の遊星歯車機構110Lの遊星キャリヤCLと第2の遊星歯車機構110Rの内歯車RRとが第1結合部材111によって結合され、第1の遊星歯車機構110Lの内歯車RLと第2の遊星歯車機構110Rの遊星キャリヤCRとが第2結合部材112によって結合されている。

Then, the planet carrier C L of the first planetary gear mechanism 110L and the internal gear R R of the second planetary gear mechanism 110R is coupled by a first coupling member 111, the internal gear R L of the first planetary gear mechanism 110L When the planet carrier C R of the second planetary gear mechanism 110R is coupled by the second coupling member 112.

第1の電動モータ102Lで発生されたトルクTM1が減速ギヤ列106Lを介して第1の遊星歯車機構110Lの太陽歯車SLに入力され、第2の電動モータ102Rで発生されたトルクTM2が減速ギヤ列106Rを介して第2の遊星歯車機構110Rの太陽歯車SRに入力される。

The first electric motor 102L torque TM1 generated in is input to the sun gear S L of the first planetary gear mechanism 110L via a reduction gear train 106L, torque TM2 generated by the second electric motor 102R is decelerated It is input to the sun gear S R of the second planetary gear mechanism 110R through a gear train 106R.

また、第1結合部材111、第2の結合部材112は、それぞれ左右の駆動輪104L、104Rに接続されて出力が取り出される。

Also, the first coupling member 111 and the second coupling member 112 are connected to the left and right drive wheels 104L and 104R, respectively, and outputs are taken out.

この従来技術2では、電動モータ102L、102Rからの入力は、太陽歯車SL、太陽歯車SRとなり、駆動輪104L、104Rへの出力は、キャリヤCLと内歯車RR、キャリヤCRと内歯車RLとなる。

In the prior art 2, the electric motor 102L, input from 102R, the sun gear S L, the sun gear S R, and the drive wheels 104L, output to 104R, the carrier C L and the internal gear R R, and the carrier C R It becomes an internal gear R L.

上記のように、従来技術1及び従来技術2に記載のものにおいては、二つの電動モータ102L、102Rで異なるトルクTM1、TM2を発生させて入力トルク差ΔTINを与えると、差動装置105において入力トルク差ΔTINが増幅され、入力トルク差ΔTINよりも大きな駆動トルク差ΔTOUTを得ることができる。

As described above, in the conventional techniques 1 and 2 described above, when the two electric motors 102 </ b> L and 102 </ b> R generate different torques TM <b> 1 and TM <b> 2 and give the input torque difference ΔTIN, the input is performed in the differential device 105. The torque difference ΔTIN is amplified, and a driving torque difference ΔTOUT larger than the input torque difference ΔTIN can be obtained.

前記従来技術1及び従来技術2では、2つの遊星歯車機構を構成する内歯車RL、RRと結合部材とを接続することによりトルク差を増幅するようにしているため、左右どちらかの内歯車RL、RRと別部材を繋ぐ結合部材の1つが、必ず他方の内歯車RL、RRより大径になるため、装置が大型化するという問題がある。

In the prior art 1 and the prior art 2, since the torque difference is amplified by connecting the internal gears R L and R R constituting the two planetary gear mechanisms and the coupling member, either the right or left inner gear is used. Since one of the coupling members that connect the gears R L and R R to another member always has a larger diameter than the other internal gears R L and R R , there is a problem that the apparatus becomes large.

このため、本願の出願人は、従来技術1と従来技術2におけるトルク差を増幅する歯車装置よりも小型、軽量化を図った車両駆動装置を、既に特許出願を行っている(特願2016-023529号)。

For this reason, the applicant of the present application has already filed a patent application for a vehicle drive device that is smaller and lighter than the gear device that amplifies the torque difference between the prior art 1 and the prior art 2 (Japanese Patent Application No. 2016- No. 023529).

この本願の出願人が特許出願している車両駆動装置(先願例1)は、図11及び図12に示す構成である。

The vehicle drive device (prior application example 1) for which the applicant of this application has applied for a patent has the configuration shown in FIGS.

先願例1の車両駆動装置201における歯車装置300を構成する遊星歯車機構300L、300Rは、それぞれ内歯車RL、RRと、内歯車RL、RRと同軸上に設けられた遊星キャリヤCL、CRと、内歯車RL、RRと同軸上に設けられた太陽歯車SL、SRと、公転歯車としての遊星歯車PL、PRとを有する。歯車装置300は、一方の遊星キャリヤCLと他方の太陽歯車SRとを結合する第1結合部材231と、一方の太陽歯車SLと他方の遊星キャリヤCRとを結合する第2結合部材232を有し、第1結合部材231と第2結合部材232が同軸上に配置されると共に、第1結合部材231および第2結合部材232の内、第2結合部材232が中空軸、第1結合部材231が中空軸に挿通される軸を有し、2つの遊星歯車機構300L、300Rの間を通る軸が二重構造となる構成であって、遊星歯車機構300L、300Rの内歯車RL、RRと減速機構の入力歯車213とを、内歯車RL、RRに設けた外歯車217に係合して連結する構造である。

A planetary gear mechanism 300L constituting the gear device 300 in the vehicle driving apparatus 201 of Sakinegairei 1, 300R, respectively internal gear R L, and R R, the internal gear R L, planet carrier provided on R R coaxial a C L, and C R, the internal gear R L, the sun gear provided on R R coaxial S L, and S R, the planetary gear P L as a revolving wheel, and P R. Gear 300, one of the planet carrier C L and the other of the first coupling member 231 for coupling the sun gear S R, a second coupling member for coupling one of the sun gear S L and the other planet carrier C R 232, the first coupling member 231 and the second coupling member 232 are arranged coaxially, and among the first coupling member 231 and the second coupling member 232, the second coupling member 232 is a hollow shaft, The coupling member 231 has a shaft inserted through the hollow shaft, and the shaft passing between the two planetary gear mechanisms 300L and 300R has a double structure, and the internal gear R L of the planetary gear mechanisms 300L and 300R. , R R and the input gear 213 of the speed reduction mechanism are engaged with and connected to external gears 217 provided on the internal gears R L , R R.

また、特許文献3にも、トルク差増幅機構である差動装置を備えた車両駆動装置(従来技術3)が開示されている。

Also, Patent Document 3 discloses a vehicle drive device (prior art 3) provided with a differential device that is a torque difference amplification mechanism.

従来技術3の車両駆動装置は、図13のスケルトン図に示すように、第1及び第2の駆動源M1、M2と、左右の駆動輪WL、WRと、両駆動源M1、M2と左右の駆動輪WL、WRとの間に介設された差動装置302とを備え、差動装置302は、1本の軸に複数の遊星歯車が連設された連設ピニオン320と、連設ピニオン320の遊星歯車321、322と噛合する太陽歯車324、325、連設ピニオン320を枢支するキャリヤ323、連設ピニオン320の遊星歯車322と噛合する内歯歯車327とをそなえた回転機構である。この差動装置302に対して、駆動源M1、駆動源M2、左右の駆動輪WL、WRが接続され、駆動源M1は中空軸311を介して内歯車327に、駆動源M2は中空軸312を介して第2の太陽歯車325に、左駆動輪WLは軸313Lを介してキャリヤ323に、右駆動輪WRは軸313Rを介して第1の太陽歯車324にそれぞれ接続されている。

As shown in the skeleton diagram of FIG. 13, the vehicle drive device of Prior Art 3 includes first and second drive sources M 1 and M 2, left and right drive wheels WL and WR, both drive sources M 1 and M 2, A differential device 302 interposed between the drive wheels WL and WR. The differential device 302 includes a continuous pinion 320 having a plurality of planetary gears connected to one shaft, and a continuous pinion. The rotating mechanism includes sun gears 324 and 325 that mesh with the planetary gears 321 and 322 of 320, a carrier 323 that pivotally supports the continuous pinion 320, and an internal gear 327 that meshes with the planetary gear 322 of the continuous pinion 320. . A drive source M1, a drive source M2, and left and right drive wheels WL, WR are connected to the differential device 302. The drive source M1 is connected to the internal gear 327 via the hollow shaft 311, and the drive source M2 is connected to the hollow shaft 312. Are connected to the second sun gear 325, the left driving wheel WL is connected to the carrier 323 via the shaft 313L, and the right driving wheel WR is connected to the first sun gear 324 via the shaft 313R.

ところで、前記トルク差増幅機構である差動装置には、いずれも遊星歯車機構が同軸上に二つ組み合わされている。

By the way, in each of the differential gears that are the torque difference amplification mechanism, two planetary gear mechanisms are coaxially combined.

2つの遊星歯車機構の回転要素である内歯車RL、RRと遊星キャリヤCL、CRとの間には、回転を支持する軸受が必要である。

Between the internal gears R L , R R and the planet carriers C L , C R which are the rotating elements of the two planetary gear mechanisms, a bearing for supporting the rotation is required.

従来技術1~3では、回転を支持する軸受の具体例は示されていないが、先願例1では、図11及び図12に示すように、この軸受として、深溝玉軸受を使用している。

In the prior arts 1 to 3, no specific example of a bearing that supports rotation is shown, but in the prior application example 1, as shown in FIGS. 11 and 12, a deep groove ball bearing is used as this bearing. .

すなわち、内歯車RL、RRと遊星キャリヤCL、CRとの間に、深溝玉軸受220を配置している。

That is, the deep groove ball bearing 220 is disposed between the internal gears R L and R R and the planetary carriers C L and C R.

深溝玉軸受220は、内輪220a、転動体220b、外輪220cからなり、内輪220a、転動体220b、外輪220cという軸受要素を内歯車RL、RRと遊星キャリヤCL、CRとの間に配置する必要があるため、内輪220aや外輪220cの厚み分だけ、径方向の寸法が大型化する。

The deep groove ball bearing 220 includes an inner ring 220a, a rolling element 220b, and an outer ring 220c. The bearing elements such as the inner ring 220a, the rolling element 220b, and the outer ring 220c are arranged between the inner gears R L and R R and the planetary carriers C L and C R. Since it is necessary to arrange them, the radial dimension increases by the thickness of the inner ring 220a and the outer ring 220c.

車両駆動装置は、車体に搭載されるため、搭載空間を小さくして車室空間を広く確保することが優位であり、トルク差を増幅する歯車装置の小型化、軽量化は必須である。

Since the vehicle drive device is mounted on the vehicle body, it is advantageous to reduce the mounting space and secure a wide cabin space, and it is essential to reduce the size and weight of the gear device that amplifies the torque difference.

そこで、この発明は、車両駆動装置に組み込むトルク差増幅機構の径方向寸法の小型化を図ることを課題とするものである。

Therefore, an object of the present invention is to reduce the size in the radial direction of a torque difference amplification mechanism incorporated in a vehicle drive device.

前記の課題を解決するために、この発明は、車両に搭載され独立して制御可能な二つの駆動源と左右の駆動輪との間に、3要素2自由度の遊星歯車機構を同軸上に二つ組み合わせ、一方の遊星歯車機構の特定の要素と、他方の遊星歯車機構の特定の要素とを、第1結合部材と第2結合部材により相互に連結して二つの駆動源から左右の駆動輪にトルク差を増幅して出力する差動装置を設け、前記遊星歯車機構は、内歯車と、前記内歯車と同軸上に設けられた遊星キャリヤと、前記内歯車と同軸上に設けられた太陽歯車と、公転歯車としての遊星歯車とを有し、前記内歯車に減速機構としての外歯車が連結され、前記内歯車が前記遊星キャリヤに対して軸受を介して支持されている車両駆動装置において、前記内歯車と遊星キャリヤの対向面の少なくとも一方の面に、焼入れされた前記軸受の軌道面を形成したことを特徴とする。

In order to solve the above-described problems, the present invention provides a three-element and two-degree-of-freedom planetary gear mechanism coaxially between two drive sources mounted on a vehicle and independently controllable and left and right drive wheels. Two combinations, a specific element of one planetary gear mechanism and a specific element of the other planetary gear mechanism are connected to each other by a first coupling member and a second coupling member to drive left and right from two driving sources. A differential device for amplifying and outputting a torque difference is provided on the ring, and the planetary gear mechanism is provided with an internal gear, a planet carrier provided coaxially with the internal gear, and provided coaxially with the internal gear. A vehicle drive device having a sun gear and a planetary gear as a revolving gear, an external gear as a speed reduction mechanism connected to the internal gear, and the internal gear supported by the planet carrier via a bearing The opposing surface of the internal gear and the planet carrier On at least one side, characterized in that the formation of the raceway surface of the bearing that is hardened.

前記内歯車の内径面に、焼入れされた前記軸受の軌道面を形成してもよいし、前記遊星キャリヤの外径面に、焼入れされた前記軸受の軌道面を形成してもよい。

The bearing surface of the hardened bearing may be formed on the inner diameter surface of the internal gear, or the raceway surface of the hardened bearing may be formed on the outer diameter surface of the planet carrier.

前記内歯車または遊星キャリヤの材質を肌焼鋼とし、浸炭焼入れにより前記軸受の軌道面を形成することができる。

The material of the internal gear or planetary carrier is case-hardened steel, and the raceway surface of the bearing can be formed by carburizing and quenching.

また、前記内歯車または遊星キャリヤの材質を中炭素鋼とし、高周波焼入れにより前記軸受の軌道面を形成するようにしてもよい。

Further, the material of the internal gear or planet carrier may be medium carbon steel, and the raceway surface of the bearing may be formed by induction hardening.

前記内歯車の歯部も高周波焼入れするようにしてもよい。

The teeth of the internal gear may also be induction hardened.

前記軸受を深溝玉軸受とし、深溝玉軸受の保持器を樹脂製の冠型にすることができる。

The bearing can be a deep groove ball bearing, and the cage of the deep groove ball bearing can be a resin crown.

前記軸受として、保持器付きの円筒ころ軸受を使用し、前記軌道面の外側端部近傍に、スラストワッシャを配置してもよい。

A cylindrical roller bearing with a cage may be used as the bearing, and a thrust washer may be disposed near the outer end of the raceway surface.

前記軸受として、すべり軸受を使用し、軌道面にすべり軸受を配置する段差部を設けてもよい。

As the bearing, a slide bearing may be used, and a stepped portion for arranging the slide bearing on the raceway surface may be provided.

以上のように、この発明によれば、内歯車と遊星キャリヤの対向面の少なくとも一方の面に、焼入れされた前記軸受の軌道面を直接形成することにより、外輪又は内輪の少なくともいずれか一方を省略できるので、内輪又は外輪の厚み分だけ径方向寸法を小さくすることができる。

As described above, according to the present invention, at least one of the outer ring and the inner ring is formed by directly forming the hardened raceway surface of the bearing on at least one of the opposing surfaces of the inner gear and the planetary carrier. Since it can be omitted, the radial dimension can be reduced by the thickness of the inner ring or the outer ring.

以下、この発明の実施の形態を添付図面に基づいて説明する。

Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

図7に示す電気自動車AMは、後輪駆動方式であり、シャーシ60と、後輪としての駆動輪61L、61Rと、前輪62L、62Rと、この発明に係る2モータ式の車両駆動装置1、バッテリ63、インバータ64等を備える。図7では、車両駆動装置1の歯車構成をスケルトン図で示している。

The electric vehicle AM shown in FIG. 7 is a rear wheel drive system, and includes a chassis 60, drive wheels 61L and 61R as rear wheels, front wheels 62L and 62R, and a two-motor vehicle drive device 1 according to the present invention. A battery 63, an inverter 64, and the like are provided. In FIG. 7, the gear structure of the vehicle drive device 1 is shown with the skeleton figure.

図1に示す車両駆動装置1は、車両に搭載され独立して制御可能な二つの駆動源としての電動モータ2L、2Rと、左右の駆動輪61L、61Rと二つの電動モータ2L、2Rとの間に設けられる左右2基の減速装置3L、3Rとを備える。

A vehicle drive device 1 shown in FIG. 1 includes two electric motors 2L and 2R that are mounted on a vehicle and can be controlled independently, and left and right drive wheels 61L and 61R and two electric motors 2L and 2R. 2 left and right reduction gears 3L and 3R provided between them.

2モータ式の車両駆動装置1の駆動トルクは、等速ジョイント65a、65bと中間シャフト65cからなるドライブシャフトを介して左右の駆動輪61L、61Rに伝達される。

The driving torque of the two-motor type vehicle drive device 1 is transmitted to the left and right drive wheels 61L and 61R via a drive shaft composed of constant velocity joints 65a and 65b and an intermediate shaft 65c.

なお、2モータ式の車両駆動装置1の搭載形態としては、図7に示す後輪駆動方式の他、前輪駆動方式、四輪駆動方式でもよい。四輪駆動方式においては、図1に示す車両駆動装置は前輪又は後輪の双方に搭載してもよく、又はそのいずれか一方に搭載して、もう一方は例えばエンジン駆動の歯車装置など他の駆動装置であってもよい。

In addition, as a mounting form of the two-motor type vehicle drive device 1, a front wheel drive system or a four wheel drive system may be used in addition to the rear wheel drive system shown in FIG. In the four-wheel drive system, the vehicle drive device shown in FIG. 1 may be mounted on both the front wheels or the rear wheels, or may be mounted on one of them, and the other may be another device such as an engine-driven gear device. It may be a drive device.

2モータ式の車両駆動装置1における左右の電動モータ2L、2Rは、同一の最大出力を有する同一の出力特性の電動モータが用いられ、図1に示すように、モータハウジング4L、4R内に収容されている。

The left and right electric motors 2L and 2R in the two-motor type vehicle drive device 1 use electric motors having the same maximum output and the same output characteristics, and are housed in motor housings 4L and 4R as shown in FIG. Has been.

モータハウジング4L、4Rは、円筒形のモータハウジング本体4aL、4aRと、このモータハウジング本体4aL、4aRの外側面を閉塞する外側壁4bL、4bRと、モータハウジング本体4aL、4aRの内側面に減速装置3L、3Rと隔てる内側壁4cL、4cRとからなる。内側壁4cL、4cRには、モータ軸5aを引き出す開口部が設けられている。

The motor housings 4L and 4R include cylindrical motor housing bodies 4aL and 4aR, outer walls 4bL and 4bR that close the outer surfaces of the motor housing bodies 4aL and 4aR, and reduction gears on the inner surfaces of the motor housing bodies 4aL and 4aR. It consists of inner walls 4cL and 4cR separated from 3L and 3R. The inner walls 4cL and 4cR are provided with openings through which the motor shaft 5a is drawn.

電動モータ2L、2Rは、図1に示すように、モータハウジング本体4aL、4aRの内周面にステータ6を設け、このステータ6の内周にすきまをおいてロータ5を設けたラジアルギャップタイプのものを使用している。なお、電動モータ2L、2Rは、アキシャルギャップタイプのものを使用してもよい。

As shown in FIG. 1, the electric motors 2 </ b> L and 2 </ b> R are of a radial gap type in which a stator 6 is provided on the inner peripheral surface of the motor housing main body 4 aL and 4 aR, and a rotor 5 is provided with a gap in the inner periphery of the stator 6. I am using something. The electric motors 2L and 2R may be axial gap types.

ロータ5は、モータ軸5aを中心部に有し、そのモータ軸5aはモータハウジング本体4aL、4aRの内側壁4cL、4cRの開口部からそれぞれ減速装置3L、3R側に引き出されている。モータハウジング本体4aL、4aRの内側壁4cL、4cRの開口部周りとモータ軸5aとの間にはシール部材7が設けられている。

The rotor 5 has a motor shaft 5a in the center, and the motor shaft 5a is drawn from the openings of the inner walls 4cL and 4cR of the motor housing main bodies 4aL and 4aR to the reduction gears 3L and 3R, respectively. A seal member 7 is provided between the periphery of the inner side walls 4cL and 4cR of the motor housing bodies 4aL and 4aR and the motor shaft 5a.

モータ軸5aは、モータハウジング本体4aL、4aRの内側壁4cL、4cRと外側壁4bL、4bRとに転がり軸受8a、8bによって回転自在に支持されている(図1参照)。図1では、軸受8a、8bは同一のものとしているが、異なるサイズのものを組み合わせてもよい。

The motor shaft 5a is rotatably supported by the rolling bearings 8a and 8b on the inner walls 4cL and 4cR and the outer walls 4bL and 4bR of the motor housing bodies 4aL and 4aR (see FIG. 1). In FIG. 1, the bearings 8a and 8b are the same, but different sizes may be combined.

左右並列に設けられた2基の減速装置3L、3Rを収容する減速装置ハウジング9は、減速装置3L、3Rの歯車軸と直交する方向に3ピースに分割され、図1に示すように、中央ハウジング9aとこの中央ハウジング9aの両側面に固定される左右の側面ハウジング9bL、9bRの3ピース構造になっている。左右の側面ハウジング9bL、9bRは、中央ハウジング9aの両側の開口部に複数のボルト(図示省略)によって固定されている。

A reduction gear housing 9 that accommodates two reduction gears 3L and 3R provided in parallel on the left and right is divided into three pieces in a direction perpendicular to the gear shafts of the reduction gears 3L and 3R, as shown in FIG. The housing 9a has a three-piece structure including left and right side housings 9bL and 9bR fixed to both side surfaces of the central housing 9a. The left and right side housings 9bL and 9bR are fixed to the openings on both sides of the central housing 9a by a plurality of bolts (not shown).

減速装置ハウジング9の側面ハウジング9bL、9bRのアウトボード側(車体外側)の側面と電動モータ2L、2Rのモータハウジング本体4aL、4aRの内側壁4cL、4cRとを、複数のボルト10によって固定することにより、減速装置ハウジング9の左右に2基の電動モータ2L、2Rが固定配置される(図1参照)。

A plurality of bolts 10 are used to fix side faces 9bL and 9bR of the reduction gear housing 9 on the side of the outboard side (outside the vehicle body) and the inner side walls 4cL and 4cR of the motor housing bodies 4aL and 4aR of the electric motors 2L and 2R. Thus, the two electric motors 2L and 2R are fixedly arranged on the left and right sides of the reduction gear housing 9 (see FIG. 1).

中央ハウジング9aには、図1に示すように、中央に仕切り壁11が設けられている。減速装置ハウジング9は、この仕切り壁11によって左右に2分割され、2基の減速装置3L、3Rを収容する独立した左右の収容室が並列に設けられている。

As shown in FIG. 1, the central housing 9a is provided with a partition wall 11 in the center. The speed reducer housing 9 is divided into left and right parts by the partition wall 11, and independent left and right accommodation chambers for accommodating the two speed reducers 3L and 3R are provided in parallel.

減速装置3L、3Rは、図1に示すように、左右対称形に設けられ、モータ軸5aから動力が伝達される入力歯車12aを有する入力歯車軸12L、12Rと、この入力歯車12aに噛み合う大径の入力側外歯車13a及び出力歯車14aに噛み合う出力側小径歯車13bの双方を有する中間歯車軸13L、13Rと、出力歯車14aを有し、減速装置ハウジング9から引き出されて等速ジョイント65a、65b、中間シャフト65c(図7参照)を介して駆動輪61L、61R(図7参照)にトルクを伝達する出力歯車軸14L、14Rとを備える平行軸歯車減速機である。左右2基の減速装置3L、3Rの各入力歯車軸12L、12R、各中間歯車軸13L、13R、各出力歯車軸14L、14Rは、それぞれが同軸上に配置されている。

As shown in FIG. 1, the reduction gears 3L and 3R are provided symmetrically and have large input gear shafts 12L and 12R having an input gear 12a to which power is transmitted from the motor shaft 5a, and the input gear 12a. Intermediate gear shafts 13L and 13R having both an output side small gear 13b meshing with an input side external gear 13a and an output gear 14a, and an output gear 14a. The constant velocity joint 65a is pulled out from the speed reducer housing 9. 65 is a parallel shaft gear reducer including output gear shafts 14L and 14R that transmit torque to drive wheels 61L and 61R (see FIG. 7) via an intermediate shaft 65c (see FIG. 7). The input gear shafts 12L and 12R, the intermediate gear shafts 13L and 13R, and the output gear shafts 14L and 14R of the left and right reduction gears 3L and 3R are coaxially arranged.

減速装置3L、3Rの入力歯車軸12L、12Rの両端は、中央ハウジング9aの仕切り壁11の左右両面に形成した軸受嵌合穴16aと側面ハウジング9bL、9bRに形成した軸受嵌合穴16bにそれぞれ転がり軸受17a、17bを介して回転自在に支持されている。軸受嵌合穴16a、16bは、転がり軸受17a、17bの外輪が当接する壁部のある段付き形状になっている。図1では転がり軸受17a、17bは同一のものとしているが、異なるサイズのもので組みあわせてもよい。

Both ends of the input gear shafts 12L and 12R of the reduction gears 3L and 3R are respectively connected to bearing fitting holes 16a formed on both left and right sides of the partition wall 11 of the central housing 9a and bearing fitting holes 16b formed on the side housings 9bL and 9bR. It is rotatably supported via rolling bearings 17a and 17b. The bearing fitting holes 16a and 16b have a stepped shape having a wall portion with which the outer rings of the rolling bearings 17a and 17b abut. In FIG. 1, the rolling bearings 17a and 17b are the same, but they may be combined in different sizes.

入力歯車軸12L、12Rのアウトボード側の端部は、側面ハウジング9bL、9bRに設けた開口部から外側に引き出されており、開口部と入力歯車軸12L、12Rの外側端部との間にはオイルシール18を設け、減速装置ハウジング9に封入された潤滑油の漏洩を防止している。

The end portions on the outboard side of the input gear shafts 12L, 12R are drawn outward from the openings provided in the side housings 9bL, 9bR, and between the openings and the outer ends of the input gear shafts 12L, 12R. Is provided with an oil seal 18 to prevent leakage of the lubricating oil sealed in the speed reducer housing 9.

入力歯車軸12L、12Rは中空構造であり、この中空の入力歯車軸12L、12Rに、モータ軸5aの端部が挿入されている。入力歯車軸12L、12Rとモータ軸5aとは、スプライン(セレーションも含む、以下同じ)結合されている。