WO2016143608A1 - Motor control apparatus, heat pump system, and air conditioner - Google Patents

Motor control apparatus, heat pump system, and air conditioner Download PDFInfo

- Publication number

- WO2016143608A1 WO2016143608A1 PCT/JP2016/056249 JP2016056249W WO2016143608A1 WO 2016143608 A1 WO2016143608 A1 WO 2016143608A1 JP 2016056249 W JP2016056249 W JP 2016056249W WO 2016143608 A1 WO2016143608 A1 WO 2016143608A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- phase

- current

- duty

- current detection

- timing

- Prior art date

Links

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02P—CONTROL OR REGULATION OF ELECTRIC MOTORS, ELECTRIC GENERATORS OR DYNAMO-ELECTRIC CONVERTERS; CONTROLLING TRANSFORMERS, REACTORS OR CHOKE COILS

- H02P27/00—Arrangements or methods for the control of AC motors characterised by the kind of supply voltage

- H02P27/04—Arrangements or methods for the control of AC motors characterised by the kind of supply voltage using variable-frequency supply voltage, e.g. inverter or converter supply voltage

- H02P27/06—Arrangements or methods for the control of AC motors characterised by the kind of supply voltage using variable-frequency supply voltage, e.g. inverter or converter supply voltage using dc to ac converters or inverters

- H02P27/08—Arrangements or methods for the control of AC motors characterised by the kind of supply voltage using variable-frequency supply voltage, e.g. inverter or converter supply voltage using dc to ac converters or inverters with pulse width modulation

- H02P27/085—Arrangements or methods for the control of AC motors characterised by the kind of supply voltage using variable-frequency supply voltage, e.g. inverter or converter supply voltage using dc to ac converters or inverters with pulse width modulation wherein the PWM mode is adapted on the running conditions of the motor, e.g. the switching frequency

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B49/00—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B49/00—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00

- F04B49/06—Control using electricity

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B49/00—Arrangement or mounting of control or safety devices

- F25B49/02—Arrangement or mounting of control or safety devices for compression type machines, plants or systems

- F25B49/025—Motor control arrangements

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02P—CONTROL OR REGULATION OF ELECTRIC MOTORS, ELECTRIC GENERATORS OR DYNAMO-ELECTRIC CONVERTERS; CONTROLLING TRANSFORMERS, REACTORS OR CHOKE COILS

- H02P27/00—Arrangements or methods for the control of AC motors characterised by the kind of supply voltage

- H02P27/04—Arrangements or methods for the control of AC motors characterised by the kind of supply voltage using variable-frequency supply voltage, e.g. inverter or converter supply voltage

- H02P27/06—Arrangements or methods for the control of AC motors characterised by the kind of supply voltage using variable-frequency supply voltage, e.g. inverter or converter supply voltage using dc to ac converters or inverters

- H02P27/08—Arrangements or methods for the control of AC motors characterised by the kind of supply voltage using variable-frequency supply voltage, e.g. inverter or converter supply voltage using dc to ac converters or inverters with pulse width modulation

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02P—CONTROL OR REGULATION OF ELECTRIC MOTORS, ELECTRIC GENERATORS OR DYNAMO-ELECTRIC CONVERTERS; CONTROLLING TRANSFORMERS, REACTORS OR CHOKE COILS

- H02P6/00—Arrangements for controlling synchronous motors or other dynamo-electric motors using electronic commutation dependent on the rotor position; Electronic commutators therefor

- H02P6/14—Electronic commutators

- H02P6/16—Circuit arrangements for detecting position

- H02P6/18—Circuit arrangements for detecting position without separate position detecting elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2600/00—Control issues

- F25B2600/02—Compressor control

- F25B2600/021—Inverters therefor

Definitions

- Embodiments of the present invention provide a control device that controls a motor via an inverter circuit by PWM-controlling a plurality of switching elements connected in a three-phase bridge, a heat pump system including the control device, and an air conditioner About.

- the present invention provides a motor control device that can employ a current detection method using one current detection element while avoiding an increase in switching loss, and a heat pump system and an air conditioner including the control device.

- the current detection unit calculates the phase current of the motor based on the signal generated by the current detection element connected to the DC side of the inverter circuit corresponding to the current value and the PWM signal pattern. Then, the rotor position determination unit determines the rotor position based on the phase current, and the PWM signal generation unit generates a two-phase or three-phase PWM signal pattern so as to follow the rotor position.

- the current detection rate calculation unit obtains a current detection rate according to the two-phase or three-phase PWM signal pattern, and the timing adjustment unit fixes the two-phase current within the carrier wave period of the PWM signal. Or at a variable timing according to the magnitude of the output voltage to the inverter circuit.

- the PWM signal generation unit increases / decreases the duty in both directions of the delay side and the advance side with respect to the arbitrary phase of the carrier wave period for the first phase of the three-phase PWM signal patterns, and for the second phase. Increases or decreases the duty in one direction of the delay side and the advance side with respect to an arbitrary phase of the carrier wave cycle, and for the third phase, increases or decreases the duty in the opposite direction to the above direction with reference to the arbitrary phase of the carrier wave cycle A three-phase PWM signal pattern is generated so that

- the current detection control unit outputs a two-phase PWM signal pattern in a state where the current detection rate is high when the motor is in a low-speed rotation region, and the current detection unit outputs one phase at a fixed timing.

- One phase is a first detection method in which current is detected at variable timing.

- a three-phase PWM signal pattern is output and the current detection unit detects two-phase current at a fixed timing.

- the second detection method is used.

- the two-phase PWM signal pattern is output, and the two-phase in which the duty pulse is output within the carrier wave period is the second phase in the state where the one-phase current detection is set as the variable timing.

- the first phase duty pulse is generated by a predetermined value, and the second phase and the third phase are generated.

- the PWM signal generation unit and the timing adjustment unit are controlled to increase the third-phase duty pulse by the predetermined value and use the third detection method in which the other one-phase current detection is also variable.

- step S13 The figure which shows the waveform example of the two-phase PWM pulse corresponding to the pattern (1-11) classified by the process of FIG.

- Flow chart showing processing contents of step S14 (A) is a diagram showing a three-phase PWM signal when the maximum duty is 95%, and (b) when the maximum duty is 105%, and sectors and patterns corresponding to them.

- step S15 The figure which shows the definition of U0, V0, W0 and V0_bai, W0_bai Flowchart showing the processing content of step S16 (part 1) Flowchart showing the processing content of step S16 (part 2) Flowchart showing processing contents of step S17 The figure which shows the example of a change of the two-phase PWM signal corresponding to the process of FIG.

- FIG. 23A is a diagram corresponding to FIG. 23A and is a diagram illustrating patterns (4 to 11).

- FIG. 2 is a diagram illustrating a third detection method (part 1) and illustrating a characteristic PWM signal pattern; 25 equivalent diagram 26 equivalent diagram 16 equivalent view (part 1) 17 equivalent diagram FIG.

- 16 equivalent diagram (2) 22 equivalent diagram The figure which illustrates a 3rd detection system (the 2), and shows the area where an electric current cannot be detected with the motor current waveform detected by the 3rd detection system (the 1)

- the figure which illustrates a characteristic PWM signal pattern The flowchart which shows the process performed following the process shown in FIG.

- the flowchart which shows the process performed following the process shown in FIG. 20 is a flowchart showing processing executed following the processing shown in FIG.

- the flowchart which shows the processing content of a part of step S11 The figure which illustrates a characteristic PWM signal pattern (the 1)

- FIG. 2 is a diagram illustrating a characteristic PWM signal pattern (part 2) The flowchart which shows the processing content of a part of step S9 The figure which illustrates a characteristic PWM signal pattern Diagram showing detected motor current waveform Flow chart illustrating the first and second detection methods, and showing interrupt processing executed for each carrier cycle when performing two-phase modulation.

- A is a figure which shows the phase in which a PWM duty pulse is output in the case of two-phase modulation, and the timing at which A / D conversion is performed on the terminal voltage of the resistance element, and (b) is based on orthogonal voltages V ⁇ and V ⁇ .

- FIG. 51 is a figure which shows a sector on an alpha beta coordinate Flowchart showing interrupt processing executed every half of the carrier cycle when performing three-phase modulation Fig. 51

- Vector diagram showing areas where current detection is not possible

- Flow chart showing selection process of current detection method in low speed region

- Flow chart showing the current detection method selection process in the medium speed region

- the figure which shows the PWM signal waveform of the rectangular wave drive system by 120 degrees energization The figure which shows the output voltage waveform of each phase corresponding to FIG.

- FIG. 3 is a flowchart showing an interrupt process that is executed every half of the carrier period when phase modulation is performed.

- the compressor (load) 2 constituting the heat pump system 1 is configured by accommodating the compression unit 3 and the motor 4 in the same iron hermetic container 5, and the rotor shaft of the motor 4 is connected to the compression unit 3.

- the compressor 2, the four-way valve 6, the indoor heat exchanger 7, the pressure reducing device 8, and the outdoor heat exchanger 9 are connected by a pipe serving as a heat transfer medium flow path so as to form a closed loop.

- the compressor 2 is, for example, a rotary compressor

- the motor 4 is, for example, a three-phase IPM (Interior Permanent Magnet) motor (brushless DC motor).

- the air conditioner E includes the heat pump system 1 described above.

- the four-way valve 6 is in a state indicated by a solid line during heating, and the high-temperature refrigerant compressed by the compression unit 3 of the compressor 2 is supplied from the four-way valve 6 to the indoor heat exchanger 7 and condensed. Thereafter, the refrigerant is depressurized by the decompression device 8, becomes a low temperature and flows into the outdoor heat exchanger 9, where it evaporates and returns to the compressor 2. On the other hand, at the time of cooling, the four-way valve 6 is switched to a state indicated by a broken line. For this reason, the high-temperature refrigerant

- the refrigerant is depressurized by the decompression device 8, becomes a low temperature and flows into the indoor heat exchanger 7, where it evaporates and returns to the compressor 2.

- the indoor and outdoor heat exchangers 7 and 9 are blown by the fans 10 and 11, respectively, so that the heat exchange between the heat exchangers 7 and 9 and the indoor air and the outdoor air is efficient. It is structured to be performed well.

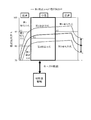

- FIG. 1 is a functional block diagram showing the configuration of the motor control device.

- the DC power supply unit 21 is indicated by a DC power supply symbol, but includes a rectifier circuit, a smoothing capacitor, and the like when a DC power supply is generated from a commercial AC power supply.

- An inverter circuit (DC AC converter) 23 is connected to the DC power supply unit 21 via a positive bus 22a and a negative bus 22b.

- a shunt resistor 24, which is a current detection element, is inserted on the negative bus 22b side.

- the inverter circuit 23 is configured by connecting, for example, N-channel power MOSFETs 25 (U +, V +, W +, U ⁇ , V ⁇ , W ⁇ ) as a switching element in a three-phase bridge connection. Each phase output terminal of the inverter circuit 23 is connected to each phase winding of the motor 4.

- the terminal voltage (signal corresponding to the current value) of the shunt resistor (current detection element) 24 is detected by a current detection unit (current detection unit, timing adjustment unit) 27.

- a current detection unit current detection unit, timing adjustment unit

- the current detection unit 27 performs A / D conversion and reads the terminal voltage

- the current Iu, Iv of each phase of U, V, W is output based on the two-phase or three-phase PWM signal pattern output to the inverter circuit 3.

- Iw is detected.

- Each phase current detected by the current detection unit 27 is input to a vector calculation unit (rotor position determination unit, PWM signal generation unit) 30.

- the torque current command Iqref is calculated based on the difference from the estimated actual rotational speed of the motor 4. Generated.

- the rotor position ⁇ of the motor 4 is determined from the phase currents Iu, Iv, and Iw of the motor 4, and the torque current Iq and the excitation current Id are calculated by vector control calculation using the rotor position ⁇ .

- a PI control calculation is performed to generate a voltage command Vq.

- the excitation current Id side is similarly processed to generate a voltage command Vd.

- the voltage commands Vq, Vd are converted into three-phase voltages Vu, Vv, Vw using the rotor position ⁇ .

- the three-phase voltages Vu, Vv, and Vw are input to a DUTY generation unit (PWM signal generation unit) 31, and duties U_DUTY, V_DUTY, and W_DUTY for generating PWM signals for each phase are determined.

- Each phase duty U, V, W_DUTY is given to the PWM signal generation unit (PWM signal generation unit) 32, and the level with the carrier is compared to generate a two-phase or three-phase PWM signal.

- a signal on the lower arm side is also generated by inverting the two-phase or three-phase PWM signal, and after a dead time is added as necessary, they are output to the drive circuit 33.

- the drive circuit 33 outputs a gate signal to each gate of the six power MOSFETs 25 (U +, V +, W +, U ⁇ , V ⁇ , W ⁇ ) constituting the inverter circuit 23 according to the given PWM signal.

- the gate signal on the upper arm side is output at a potential boosted by a necessary level.

- the vector calculation unit 30 outputs the torque current Iq and the excitation current Id to the power consumption calculation unit 34, calculates the estimated speed ⁇ e based on the torque current Iq, the excitation current Id, and the excitation voltage Vd, and the power consumption calculation unit. 34 and the detection method selection unit 35.

- the power consumption calculation unit 34 outputs the power consumption W to the detection method selection unit (current detection control unit) 35 when the power consumption W is calculated by the following equation based on each input current.

- T a motor output torque

- P the number of poles of the motor 4

- ⁇ an electric winding interlinkage magnetic flux

- Ld a d-axis inductance

- Lq a q-axis inductance.

- the current detection rate calculation unit (current detection rate calculation unit) 36 calculates a current detection rate for each carrier cycle in the current detection unit 27 based on the three-phase voltages Vu, Vv, and Vw input from the vector calculation unit 30. .

- the calculation result is output to the detection method selection unit 35.

- the speed fluctuation detection unit 37 detects the rotational speed of the motor 4 and the degree of speed fluctuation based on the phase current change period output by the current detection unit 27, and outputs the detection result to the detection method selection unit 35.

- the detection method selection unit 35 selects the detection method of the two-phase current in the current detection unit 27 based on the input information. Therefore, the detection method selection unit 35 also outputs a signal for switching between 2-phase modulation and 3-phase modulation to the PWM signal generation unit 32. Further, the PWM signal generation unit 32 outputs a current detection timing signal to the current detection unit 27.

- a rectangular wave drive calculation unit 38 is provided separately from the DUTY generation unit 31 .

- the PWM signal generation unit 32 outputs a 120 ° or 150 ° rectangular wave drive signal input from the rectangular wave drive calculation unit 38 to the drive circuit 33.

- the functions of the configurations 27 to 38 are functions realized by hardware and software of a microcomputer including a CPU.

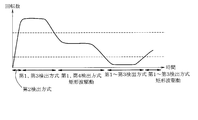

- FIG. 3 shows first to fourth detection methods to be described later for changes in the number of revolutions of the motor 4 built in the compressor 2 and two-phase current detection within the PWM carrier cycle when the cooling operation by the air conditioner is started. The switching state of which one is performed is shown.

- FIG. 4 is a flowchart schematically showing switching of the drive control method corresponding to FIG.

- PWM control is performed with three-phase modulation when the compressor 2 is started to operate the air conditioner (S301). Since the sensorless driving method cannot be executed in the region where the rotational speed of the motor 4 is low, the motor 4 is driven by forced commutation (S302). When the rotational speed increases to some extent, the position sensorless drive method is switched (S303). Thereafter, the detection method of the two-phase current in the current detection unit 27 is selected according to the rotation region (low speed, medium speed, high speed) of the motor 4 and the current detection rate as described later (S304 to S307).

- the rotation speed of the motor 4 is rapidly increased to reach the high speed region in order to rapidly decrease the temperature in the room where the air conditioner is installed.

- the second detection method is executed immediately after startup and while the rotation speed is increased until sensorless driving is possible (S301 to S303), and then the first or third detection method is executed (S307).

- the first or fourth detection method or the rectangular wave driving method is executed (S306).

- one of the first to third detection methods is executed (S305).

- the current detection method is determined according to the level of the rotation speed region of the motor 4 and the level of the current detection rate in each region.

- the threshold value X1 is set at a current detection rate of 90%, and the first detection method is switched to a threshold value X1 or higher, and the third detection method is switched below the threshold value X1.

- the threshold value X2 is set at a current detection rate of 85%, and the threshold is switched to the first detection method when the threshold value is X2 or more and to the fourth detection method when the threshold value is less than the threshold value X2.

- threshold values X3 and X4 are set to current detection rates of 90% and 80%, respectively, the first detection method is greater than or equal to threshold value X3, and the threshold value X4 is less than the third detection method and threshold value X4. If it is less, the second detection method is switched.

- First detection method> This is a general current detection method in two-phase modulation. One-phase current is detected at a fixed timing in the center phase of the carrier cycle, and the other one-phase current is detected at a variable timing according to the change in duty. (Conventional two-phase modulation, see Japanese Patent Application Laid-Open No. 2014-171321).

- ⁇ Third detection method> This is a mixture of two-phase modulation and three-phase modulation.

- one phase of current detection is a fixed timing and the other one phase of current detection is a variable timing.

- Duty pulses are output within the carrier cycle.

- the two phases are based on the center phase of the carrier cycle. Are the second phase and the third phase in which the duty is increased or decreased in the respective directions of the delay side and the advance side.

- a first-phase duty pulse for increasing or decreasing the duty in two directions with respect to the center phase is generated as well as a second value.

- the phase and third phase duty pulses are increased by the predetermined value to switch to three-phase modulation.

- other one-phase current detection that is detected at a fixed timing is also set to a variable timing. Details of this method will be described later.

- FIG. 5 shows the current detection rate of the first detection method that has been conventionally performed for two-phase modulation increases and decreases as the motor speed changes. Therefore, an optimum detection method is selected and switched in consideration of power consumption, drive noise, and current detection rate for each rotation speed region.

- FIG. 6 shows the current detection rate by each detection method according to the level of the modulation rate. From the viewpoint of power consumption, it is desirable to employ two-phase modulation as much as possible.

- the current detection rate at the modulation rate corresponding to the medium speed region is higher in the second detection method than in the first detection method.

- the second detection method has a demerit that driving noise becomes larger. Therefore, in the medium speed region, the first detection method is preferentially selected, and the second detection method is selected when the current detection rate decreases.

- the current detection rates of the first and fourth detection methods are both low, and the current detection rates of the second and third detection methods are both 100%. If switching from 2-phase modulation to 3-phase modulation in this region, current detection may become impossible at the switching timing. Therefore, the detection method is selected in the order of first ⁇ third ⁇ second as the current detection rate decreases.

- the current detection rate is higher in the order of 3> 1> 4th. Further, in the high speed region shown in FIG. 5 where the modulation rate exceeds 100%, the current detection rate of the first detection method is lowered. Therefore, the first detection method is preferentially selected from the viewpoint of power consumption, and the third detection method is selected when the current detection rate decreases.

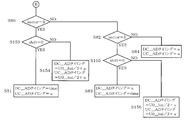

- FIG. 7 is a flowchart showing interrupt processing executed every half cycle of the carrier. That is, a PWM interrupt occurs at the peak and bottom of the triangular wave amplitude that is the carrier.

- S3 the A phase current is detected (S3).

- S3 a “Start F” process described later is executed.

- the A / D conversion processing of the terminal voltage of the shunt resistor 24 in the current detection unit 27 is executed twice within one carrier cycle separately from the processing shown in FIG. 3 (execution timing will be described later).

- the A / D converted data is stored in, for example, a register. Therefore, the process of step S2 reads the data stored in the register.

- the rotor position ( ⁇ ) of the motor 4 is estimated from the three-phase current by vector control calculation (S4), and frequency control (speed control, S5) and current control (PI control, etc.) are executed (S6). Then, the flag M_INT_flg is set to “1” (S7). The subsequent steps S8 to S10 are performed in the DUTY generation unit 31. With reference to the value of the carrier counter supplied from the PWM signal generation unit 32, it is determined whether the up-counting or down-counting is in progress (S8). If up-counting is in progress, D_Pwm_set_2 () is set (S9), and if down-counting is in progress, D_Pwm_set1_ () is set (S10). These will be described with reference to FIGS.

- step S1 If the flag M_INT_flg is “1 (set)” in step S1, a two-phase PWM signal is output (S11), and the flag M_INT_flg is set to “0” (S12). Then, when the processing of “Start A to E” is executed (S13 to S17), the process proceeds to step S8. That is, in the PWM interrupt process, steps S2 to S8 and S10 are executed in the first half of the cycle, and steps S11 to S17, S8, and S9 are executed in the second half of the cycle.

- FIG. 8 shows an execution time image of interrupt processing at the time of two-phase modulation together with a PWM carrier waveform.

- a motor for driving the fan 11 of the heat exchanger 9 corresponding to the outdoor unit is controlled in parallel with the compressor 2 by a single control circuit (microcomputer).

- the motor that drives the fan 10 of the heat exchanger 7 corresponding to the indoor unit is controlled by another control circuit, a driver IC, or the like.

- FIG. 8 shows processing times (1) to (4) related to motor control of the compressor 2 shown in FIG. 3, and (b) shows processing time related to motor (fan motor) control of the fan 11 ( 5). That is, when a PWM interrupt occurs at the bottom of the triangular wave amplitude, after executing the processing shown in FIG. 3, the motor current is also detected for the fan motor to perform vector control.

- the processes (1) to (4) indicated by circled numbers in the figure the processes (1) and (3) correspond to steps S2 to S8, and the processes (2) and (4) correspond to steps S9 and S10, respectively. It corresponds.

- the fan motor control (5) is performed after the processing (4) is executed.

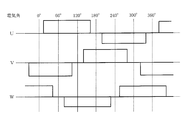

- FIG. 9 shows the output phase of each phase PWM duty pulse.

- the method disclosed in Patent Document 1 is used. That is, in the first phase among the three phases, the duty is increased / decreased in both directions of the delay side and the advance side with reference to the bottom of the triangular wave amplitude.

- the duty is increased or decreased on the leading phase side with respect to the bottom

- the duty is increased or decreased on the delayed phase side with respect to the bottom.

- the first, second, and third phases are the U, V, and W phases, respectively, but these correspondences are of course arbitrary.

- the carrier counter When an interrupt occurs at the peak of the triangular wave amplitude, the carrier counter is counting down, so the duty pulse of the first half of the current carrier cycle is output by D_Pwm_set_2 (). Note that the duty values of the U, V, and W phases are twice the duty values (U0, V0, and W0 described later) calculated in step S11.

- a pulse with half the duty is output from the timing after the interrupt at the peak to the bottom.

- the pulse is output in the period from the timing after the interruption at the peak to the bottom as in the U phase.

- the duty exceeds 50%, the excess pulses are output during the period from when the interrupt at the peak occurs until the bottom is reached. Therefore, it is these pulses that are output by D_Pwm_set_2 ().

- the carrier counter is counting up, so the D_Pwm_set_1 () outputs a duty pulse for the latter half of the current carrier cycle.

- a pulse having a duty of 1/2 is output in the period from the timing to the peak after the interruption at the bottom occurs.

- the duty exceeds 50%

- the excess pulses are output during the period from the timing when the interruption at the bottom occurs until the peak is reached.

- the W phase if the duty is less than 50%, the pulse is output in the period from the timing to the peak after the bottom interruption occurs, as in the U phase. Therefore, it is these pulses that are output by D_Pwm_set_1 ().

- FIG. 9 shows three-phase duty pulses, since the actual drive format is two-phase modulation, only two-phase duty pulses are output.

- the process (Start A) in step S13 will be described.

- the patterns are classified into patterns (0) to (11) according to the magnitude relationship of the respective phase duty pulses in the two-phase modulation PWM signal. These patterns are indicated by a variable ptn in the processing described later.

- the pattern division here is based on the following conditions.

- the current detection unit 27 sets a minimum duty that can be detected as a minimum width, and a maximum width (100%) obtained by subtracting the minimum width as a maximum width. For example, if the minimum time during which current can be detected is 10 ⁇ s and the carrier frequency is 4 kHz, the minimum width is 4% and the maximum width is 96%. If the duty that is less than the maximum width and exceeds the minimum width is an intermediate width, the output pattern of the two-phase PWM signal is divided into patterns according to the following combinations of U, V, and W phase duties.

- FIG. 11 shows two-phase PWM signal patterns corresponding to patterns (1) to (11).

- patterns (4) to (11) correspond to an overmodulation state in which the output voltage is extremely large.

- the pattern (7) is shown when the W-phase duty is less than the minimum width.

- step S14 the process (Start B) in step S14 will be described.

- the sectors (0) to (5) are classified according to the relative magnitude relationship of the duty pulses of each phase in the PWM signal of two-phase modulation. These sectors are indicated by a variable sector in the processing described later.

- the sector division here is based on the following conditions. (0) U phase is maximum and V phase> W phase (1) U phase is maximum and V phase ⁇ W phase (2) V phase is maximum and U phase> W phase (3) V phase is maximum And U phase ⁇ W phase (4) W phase is maximum and U phase> V phase (5) W phase is maximum and U phase ⁇ V phase

- FIG. 13 shows sectors and patterns that change according to the actual output of a PWM signal.

- A is the case where the maximum duty is 95%, which is near the maximum width, the sector changes from (0) to (5), and the pattern changes from (0) to (3), (8) to (10). is doing.

- B is the case where the maximum duty exceeds 105% (overmodulation state), the sector changes from (0) to (5), but the pattern changes from (0) to (9). ing. That is, as the output voltage increases, the time span occupied by the patterns (0) to (3) is expanded, and the section where the patterns (4) to (11) are generated at the boundary where the patterns (0) to (3) are switched. It can be seen that is increasing.

- step S15 the current detection unit 27 determines the timing for A / D conversion of the terminal voltage of the shunt resistor 24 within the carrier period in accordance with the combination of the pattern and the sector.

- ⁇ in the figure is set in consideration of the above-described current detectable time, current detection accuracy, and the like (for example, duty 5 to 10%).

- PWM_MAX is the maximum value of duty: 100%.

- U0, V0, and W0 in the figure correspond to 1/2 of the U, V, and W-phase duties that are initially determined with the intermediate point (bottom) of the carrier cycle as the base point, as shown in FIG. 15 (a). It is time to do.

- V0_bai and W0_bai are intermediate points of the carrier cycle when the V and W phase duty pulses are shifted in order to output the three-phase PWM signal in the pattern shown in FIG. This corresponds to the length of the pulse extending from the base point.

- Time is a variable indicating the A / D conversion timing of each phase of U, V, and W.

- Step S53 is the case of pattern (1) and sector (2), and the A / D conversion timing is set to (PWM_MAX- ⁇ ).

- Step S54 is the case of pattern (1) and sector (4), and the A / D conversion timing is set to (PWM_MAX- ⁇ ).

- Step S58 is the case of pattern (3) and sector (3) and overmodulation exceeding V0_bai (PWM_MAX ⁇ 2) (S57: YES), and the A / D conversion timing is set to ⁇ . Yes.

- Step S59 is a case of “NO” in Step S57, and the A / D conversion timing is set to (PWM_MAX ⁇ 2 ⁇ V0_bai + ⁇ ).

- Step S62 is a case of pattern (2) and sector (5), and a case of overmodulation in which W0_bai exceeds (PWM_MAX ⁇ 2) (S61: YES), and the A / D conversion timing is set to ⁇ . Yes.

- Step S63 is the case of “NO” in Step S61, and the A / D conversion timing is set to (PWM_MAX ⁇ 2 ⁇ W0_bai + ⁇ ).

- step S16 the process (Start D) in step S16 will be described.

- the timing at which the current detection unit 27 performs A / D conversion within the carrier period is reduced from the beginning (peak) to the half period (bottom) of the carrier period according to the combination of the pattern and the sector.

- the count period and the up-count period from the 1/2 period to the end of the carrier cycle, it is determined at which timing.

- the former is the first detection timing

- the latter is the second detection timing.

- the variable time for setting each timing is the one corresponding to the same combination in StartC.

- the down timing / up count AD timing is set to ⁇ (S72). That is, A / D conversion is performed at the timing when the remaining count value reaches ⁇ from the beginning of the carrier cycle and at the timing when time ⁇ passes from 1 ⁇ 2 of the carrier cycle.

- the U-phase A / D conversion timing is set to time in the up-count period, that is, (PWM_MAX- ⁇ ) determined in step S53. Further, the down-count period is set to ⁇ (S75).

- the up-count period ⁇ is set, and the down-count period is set to time, that is, (PWM_MAX ⁇ ) determined in step S54 ( S77). If the pattern is other than the sector (2-4) (S76: NO), the up-count period and the down-count period are set to ⁇ (S78).

- the up-count period is set to time, that is, ⁇ determined in step S58, or (PWM_MAX ⁇ 2-V0_bai + ⁇ ) determined in step S59. To do.

- the down-count period is set to ⁇ (S81).

- the timing of the up-count period is set to ⁇ . Further, the timing of the downcount period is set to time, that is, (PWM_MAX- ⁇ ) determined in step S60 (S83). If the pattern is (3) and other than sectors (3, 5) (S82: NO), the up-count period and the down-count period are set to ⁇ (S84).

- the timing of the up-count period is set to ⁇ , and the timing of the down-count period is determined to time, that is, determined in step S62.

- ⁇ or (PWM_MAX ⁇ 2-W0_bai + ⁇ ) determined in step S63 is set (S87).

- the timing of the up-count period is set to ⁇ , and the timing of the down-count period is set to ⁇ ⁇ 2 (S85b). If it is the pattern (11) (S85c: YES), the timing of the up count period is set to ⁇ ⁇ 2, and the timing of the down count period is set to ⁇ (S85d). If it is not the pattern (2) and the sector (5) (S86: NO), or if it is not the pattern (11) (S85c: NO), the timing of the up-count period and the down-count period is set to ⁇ , respectively. (S88).

- Step S17 the variable shift used to change the increasing / decreasing direction of the duty pulse is set to any one of “0 to 2” for either the second phase (V) or the third phase (W). .

- V-phase duty is greater than or equal to the maximum width and less than 100% (S91: YES)

- W0_bai is obtained by adding the minimum width to the difference obtained by subtracting V0_bai from PWM_MAX (MAX in the figure) ⁇ 2.

- FIGS. 19A and 19B illustrate the case of pattern (3).

- Pattern (3) is a case where the V-phase duty is greater than or equal to the maximum width and the W-phase duty is greater than or equal to the minimum width.

- a V-phase current is detected at a fixed first detection timing, and a negative U-phase current is detected at a variable second detection timing.

- a negative U phase current is detected. Therefore, the same V-phase current or W-phase current as the first detection timing is detected.

- the direction in which the W-phase duty is increased is changed to the same direction as the V-phase duty.

- the negative U-phase current is detected at the fixed first detection timing

- the V-phase current is detected at the variable second detection timing. Therefore, if the V-phase duty is reduced, the second detection timing may be shifted in the right direction in the drawing to cope with it. Further, even if the W-phase duty is reduced, if the width is equal to or greater than the minimum width, detection can be performed at the fixed first detection timing.

- FIG. 19C shows a case where the variable shift is set to “1” in the case of the pattern (3).

- the arrow with the circled number “1” in the figure indicates the value obtained by adding the minimum width to “the difference obtained by subtracting V0_bai from MAX ⁇ 2 (PWM_MAX ⁇ 2)” in the condition determination in step S92.

- the arrow with “2” indicates W0_bai.

- the variable shift is set to “1” in the case where the left end (variable end) side of the V-phase duty and the right end (variable end) side of the W-phase duty overlap in the up-count section.

- FIG. 19D shows a case where the variable shift is set to “2” in the case of the pattern (2).

- the arrow with the circled number “3” in the figure indicates the value obtained by adding the minimum width to “the difference obtained by subtracting W0_bai from MAX ⁇ 2” in the condition determination in step S96, and the circled number “4” is added.

- the indicated arrow indicates V0_bai.

- the variable shift is set to “2” because, like FIG. 19C, the left end (variable end) side of the V-phase duty and the right end (variable end) side of the W-phase duty in the down-count section are set. This is an overlapping case.

- Step S3 Start F

- the two-phase current is detected within the carrier period based on the combination of the pattern and sector determined in the above processes and the first and second detection timings of the phase current determined by the combination (A / D conversion). Then, a three-phase current is obtained from the detected two-phase current.

- patterns (4) to (11) shown in FIG. 20 are cases of an overmodulation state in which the output voltage of one or more phases is extremely large, and two-phase output is performed within the carrier period. Since it is difficult to detect the current, only the current of one phase is detected.

- the patterns (4), (7), (8), and (10) are down-count timing, and the patterns (5), (6), (9), and (11) are up-count timing, respectively.

- Phase (S102), U phase (S104), V phase (S106), U phase (S108), V phase (S110), W phase (S112), V phase (S114), and W phase (S116) currents are acquired. .

- the current detection timing is ⁇ ⁇ 2.

- step S122 it is determined whether or not it is pattern (1) (step S122). If it is pattern (1) (YES), W and V phase currents are detected at the first and second detection timings ( S123). On the other hand, if it is not the pattern (1) (NO), the W and U phase currents are detected at the first and second detection timings, and the V phase current is obtained by calculation (S124).

- step S125 if it is not the sector (3) in step S125 (NO), as shown in FIG. 22, it is further determined whether it is the sector (4) (S131) or the pattern (1) (S132). In the case of sector (4) and pattern (1) (S132: YES), W and V phase currents are detected at the first and second detection timings (S133). If the pattern is not the pattern (1) (S132: NO), the U and V phase currents are detected at the first and second detection timings (S134).

- step S135 it is determined whether variable shift is “2” (S135).

- the W and U phase currents are detected at the first and second detection timings (S136).

- “NO” it is determined whether or not the pattern is the pattern (2) (S137). If the pattern is the pattern (2) (YES), the U and W phase currents are determined at the first and second detection timings. Is detected (S138). If it is not the pattern (2) (S137: NO), the V and W phase currents are detected at the first and second detection timings (S141).

- FIG. 23 shows the case of pattern (0), and the sector can take all of (0 to 5).

- (B) shows a combination of an actual two-phase modulation PWM signal waveform and a corresponding pattern and sector. Although the phases to be detected are different depending on the sector, the first and second current detection timings are both fixed timings (both down count and up count are ⁇ ).

- FIG. 24 shows the case of pattern (1), and the sector is (2, 4).

- the first and second current detection timings are both fixed timings. However, one is ⁇ and the other is (PMW_MAX ⁇ ).

- FIG. 25 shows the case of pattern (2), and the sector is only (5).

- W0_bai exceeds PWM_MAX ⁇ 2 or shift (2).

- the first and second current detection timings are both fixed.

- W0_bai does not exceed PWM_MAX ⁇ 2

- the first current detection timing is variable, and in the case of shift (2), the V phase duty increase / decrease direction is made the same as the W phase. As a result, the phase to be detected is changed from (U, W) to (W, U).

- FIG. 26 shows the case of pattern (3), and the sector is only (3), but it is further divided into three cases depending on whether V0_bai exceeds PWM_MAX ⁇ 2 or shift (1).

- V0_bai exceeds PWM_MAX ⁇ 2 the first and second current detection timings are both fixed.

- V0_bai does not exceed PWM_MAX ⁇ 2 the second current detection timing is variable, and in the case of shift (1), the W phase duty increase / decrease direction is made the same as the V phase. As a result, the phase to be detected is changed from (V, U) to (U, V).

- FIG. 27 shows patterns (4) to (11) and corresponds to FIG.

- FIG. 28 shows an example of a characteristic change in detection timing in the case of pattern (2) or (3).

- the V and W phase duty pulses are output without a period in which they overlap each other, and the V and W phase currents are detected at the first and second detection timings, respectively.

- the W-phase duty exceeds 96%, a period in which the V and W-phase duty pulses overlap each other occurs in the first half of the carrier cycle. In this case, the phase of the current detected at the first detection timing is changed to the U phase ( ⁇ ).

- the V or W phase duty is reduced from this state, there is a possibility that the U phase current cannot be detected because the V and W phase duty pulses deviate from each other when the first detection timing remains fixed. Therefore, the first detection timing is made variable, and the U-phase current is detected continuously within the overlapping period of the V and W-phase duty pulses.

- FIG. 28 (b) shows a case where a period in which the V and W phase duty pulses overlap each other in the latter half of the carrier cycle due to the V phase duty exceeding 96%.

- the phase of the current detected at the second detection timing is changed to the U phase ( ⁇ ). If the V or W phase duty is reduced from this state, there is a possibility that the U phase current cannot be detected because the V and W phase duty pulses deviate from each other when the second detection timing remains fixed. Therefore, the second detection timing is made variable, and the U-phase current is detected continuously within the overlapping period of the V and W-phase duty pulses.

- FIG. 29 shows an example of a characteristic change in detection timing in the case of pattern (1).

- the period in which the U and V phase duty pulses overlap each other occurs only in the first half of the carrier cycle, and the W ( ⁇ ) and U phase currents are detected at the first and second detection timings, respectively.

- the current detected at the second detection timing is also the W phase ( ⁇ ). Therefore, the second detection timing is changed, and the V-phase current is detected in a period in which only the V-phase duty pulse is generated.

- the second detection timing is fixed at the changed timing (however, it may be variable depending on the change in the V-phase duty).

- FIG. 29 (b) is a case where a period in which the U and W phase duty pulses overlap each other in the first half of the carrier cycle occurs because the W phase duty exceeds 96%.

- the first detection timing is changed, and the W-phase current is detected during a period in which only the W-phase duty pulse is generated.

- the first detection timing is fixed at the changed timing (however, it may be made variable depending on the change in the W-phase duty).

- FIG. 30 shows (a) a motor current waveform detected by the method of the present embodiment and (b) a motor current waveform detected by the method of Patent Document 1 when the modulation factor is approximately 1.0. Is shown. As is apparent from this figure, as a result of the current detection rate being improved in this embodiment, the current waveform is less distorted and closer to a sine wave.

- the current detection unit 27 is configured to operate the motor based on the signal generated by the shunt resistor 24 connected to the DC side of the inverter circuit 23 corresponding to the current value and the PWM signal pattern.

- 4 phase currents Iu, Iv, and Iw are detected, and the vector control unit 30 determines the rotor position ⁇ based on the phase current, and together with the PWM signal generation unit 32, any one of the three phases follows the rotor position ⁇ .

- a two-phase PWM signal pattern is generated.

- the PWM signal generation unit 32 increases or decreases the duty in both directions of the delay side and the advance side with respect to the bottom of the carrier cycle for the U phase of the three-phase PWM signal pattern, and the V phase is based on the bottom.

- the W phase increases or decreases the duty in the direction opposite to the above direction.

- the current detection timing adjustment unit 34 detects the current at a fixed timing for one phase in the two-phase modulation within the carrier cycle, and detects the current at a fixed timing for the other phase.

- the detection timing is adjusted so that the current can be detected at a variable timing corresponding to the magnitude of the output voltage to the inverter circuit 23. Therefore, the current detection rate can be improved even in a region where the output voltage is high and the overmodulation state occurs, and the control accuracy can be improved while suppressing the switching loss.

- the current detection timing adjustment unit 34 determines whether the current detection for the other phase is a predetermined fixed timing or a timing changed from the fixed timing according to the two-phase PWM signal pattern. decide. Specifically, the current detection unit 27 sets the minimum duty that can be detected as the minimum width, determines the maximum width and the intermediate width based on the minimum width, and sets the output pattern of the two-phase PWM signal to any one of the widths. The pattern is divided into patterns (0 to 11) according to the combination of the three-phase duty, and the sector (0 to 5) is classified according to the magnitude relationship of the three-phase duty. Then, depending on the combination of the pattern (0 to 11) and the sector (0 to 5), it is determined whether the current detection for the other phase is set to a predetermined fixed timing or a changed timing. To do.

- the current detection timing adjustment unit 34 sets current detection for the other phase to a predetermined fixed timing, and the two phases in which the duty pulse is output within the carrier cycle are the V and W phases, and both fixed timings.

- the current detection timing adjustment unit 34 may change the period in which the V or W phase duty pulses overlap each other after changing one of the detection target phases to the U phase within a range in which the U phase can be detected. Change the current detection timing. Thereby, it is possible to prevent the repeated change as much as possible while maintaining the changed detection target phase.

- the current detection timing adjustment unit 34 has two phases for which a duty pulse is output within the carrier cycle, the U phase and the V or W phase, and the two-phase current detected at both fixed timings.

- the current detection for the other phase is set as a variable timing, and one of the phases to be detected is set to V or W from the U phase. Change to phase. Therefore, also in this case, the two-phase current can be reliably detected.

- the current detection timing adjustment unit 34 changes the current detection timing for the other phase once, and then fixes the changed timing to detect the V or W phase current. Also in this case, it is possible to prevent the repeated change while maintaining the detection target phase after the change as much as possible.

- the current detection timing adjustment unit 34 is configured such that the two phases for which the duty pulse is output within the carrier cycle are the V and W phases, and when one of these duties decreases, the two-phase current cannot be detected.

- the duty increase / decrease direction of the phase with the smaller duty is changed to the same direction as the other phases. As a result, a period in which the two-phase duty pulses overlap each other is generated, and the two-phase current can be detected.

- the motor 4 which comprises the compressor 2 is controlled about the air conditioner E provided with the heat pump system 1 provided with the compressor 2, the outdoor side heat exchanger 9, the decompression device 8, and the indoor side heat exchanger 7. Since it makes it object, the operating efficiency of the heat pump system 1 and the air conditioner E can be improved.

- ⁇ Third detection method (part 1)> In the fourth detection method, for example, as shown in FIG. 26, when the variable shift is “1” in the combination of the pattern (3) and the sector (3), the W phase duty increase / decrease direction is set to the same direction as the V phase. changed. In the third detection method (part 1), different actions are taken for the same case.

- a U-phase duty pulse is also output.

- the V-phase and W-phase duty pulses are increased by the amount of the duty pulse to temporarily enter a three-phase modulation state.

- the first current detection timing is also variable. As a result, the current detection rate is improved without changing the phase to be detected at the second detection timing.

- FIG. 31B corresponds to the case where the variable shift is “2” by the combination of the pattern (2) and the sector (5) shown in FIG. 25 in the description of the fourth detection method.

- a U-phase duty pulse is also output, and the V and W-phase duty pulses are increased by the amount corresponding to the duty pulse to temporarily enter a three-phase modulation state.

- FIGS. 32 and 33 A list including these processing patterns is shown in FIGS. 32 and 33 (corresponding to FIGS. 25 and 26).

- FIG. 34 to 36 are flowcharts of StartD corresponding to FIGS. 16 and 17. However, FIG. 34 shows only steps S71 to S79 in FIG. 16. If “YES” is determined in the step S79, the process proceeds to the process shown in FIG. 35, in the case of the pattern (2) and the sector (5) (S86: YES), it is determined whether or not the variable shift is “0” (S151). If the variable shift is “0” (YES). Step S87 is executed. On the other hand, if the variable shift is not “0” (NO), the first and second detection timings are set to a value obtained by adding ⁇ to the U-phase duty pulse (S152).

- FIG. 36 in the case of pattern (3) and sector (3) (S80: YES), it is determined whether or not the variable shift is “0” (S153), and if the variable shift is “0” (YES). Step S81 is executed. On the other hand, if the variable shift is not “0” (NO), the process is the same as S152 (S154). Also in the case of pattern (3) and sector (5) (S82: YES), it is determined whether or not the variable shift is “0” (S157). If the variable shift is “0” (YES), step S83. Execute. On the other hand, if the variable shift is not “0” (NO), the process is the same as S152 (S156).

- FIG. 37 is a diagram corresponding to FIG. 22 and is a part of the StartF process.

- the current detection timing adjustment unit 34 uses the current detection for the other phase as a variable timing, and the two phases for which the duty pulse is output within the carrier cycle are V

- the U-phase duty pulse is generated by a predetermined value, and the V- and W-phase duty pulses are generated. Is increased by the predetermined value.

- the current detection for one phase is also made variable timing. Thereby, a current detection rate can be improved.

- FIG. 40 shows a process (StartA +) executed after the flowchart of StartA shown in FIG. 10 is executed.

- the patterns are classified into patterns (0) to (5) indicated by the variable Ptn_3phs_ch according to the magnitude relationship of the duty pulses of the phases in the PWM signal of the two-phase modulation.

- the pattern division here is based on the following conditions.

- the minimum duty at which the current detection unit 27 can detect current is set as the minimum width, and the minimum width obtained by subtracting the minimum width from the maximum duty (100%) is set as the maximum width. For example, if the minimum time during which current can be detected is 10 ⁇ s and the carrier frequency is 4 kHz, the minimum width is 4% and the maximum width is 96%.

- the output pattern of the two-phase PWM signal is divided into patterns according to the following combinations of U, V, and W phase duties.

- U0bai_2, V0bai_2, and W0bai_2 are twice the duty values of the U, V, and W phases during the two-phase modulation calculated in step S11.

- W0bai_2 is less than maximum width or V0bai_2 is less than maximum width and U0bai_2 / 2 or V0bai_2 or W0bai_2 is less than minimum width and 0 or more

- W0bai_2 is more than maximum width or V0bai_2 is more than maximum width and U0bai_2 1/2 is less than the minimum width and V0bai_2 is less than the minimum width and 0 or more.

- W0bai_2 is more than the maximum width or V0bai_2 is more than the maximum width and 1/2 of U0bai_2 is more than the minimum width and W0bai_2 Is less than the minimum width and greater than or equal to 0.

- W0bai_2 is greater than or equal to the maximum width or V0bai_2 is greater than or equal to the maximum width and U0bai_2 is less than the minimum width and greater than or equal to 0 and V0bai_2 is greater than W0bai_2. Is greater than the maximum width or V0bai_2 is greater than the maximum width, 1/2 of U0bai_2 is less than the minimum width and greater than 0, and V0bai_2 is less than W0bai_2 (0) Other than the above Pattern (0) to (5); Variable Ptn We have separated the 3phs_ch.

- FIG. 41 is a process (StartD +) that is shifted to after the execution of step S88 in the flowchart of StartD shown in FIGS. 16 and 17, and the AD timing at the time of up-counting and down-counting is determined according to the variable Ptn_3phs_ch. .

- Ptn_3phs_ch is (2) to (5)

- the current detection timing is set to ⁇ ⁇ 3 during up-counting and down-counting (S172, S174) at the timing when the PWM pulse for one phase is ON. This is for detecting the current, and the magnification may be another value, for example, twice.

- the fixed timing ⁇ is set twice (S175).

- FIG. 42 is a process (StartF +) that is shifted to after the execution of step S141 in the flowchart of StartF shown in FIGS. 20 to 22, and two phases for detecting a current are determined according to Ptn_3phs_ch.

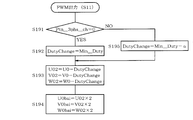

- FIG. 43 is a flowchart of PWM output corresponding to step S11.

- the duties U02, V02, and W02 for two-phase modulation are determined.

- Ptn_3phs_ch 0, the minimum of U, V, and W phases is calculated from the respective duty values U0, V0, and W0 calculated by three-phase modulation.

- the duty value Min_Duty is subtracted (S192).

- the U phase which has no pulse output in the two-phase modulation, is output with the pulse width ⁇ ⁇ 2, and the three-phase modulation is performed by adding the pulse width ⁇ ⁇ 2 to the V and W phase pulses. .

- FIG. 45 is a flowchart of a part for determining the U-phase duty value of D_Pwm_set_1 () corresponding to step S10.

- the duty of the V-phase pulse is a large value approaching 100%.

- V-phase current is detected twice during two-phase modulation, but (b) W-phase pulse is added.

- the U-phase pulse is further shifted leftward in the figure (output so as to extend the pulse in the advance direction from the center of the carrier period), and the current detection time is increased. This makes it possible to detect the W-phase current (negative).

- FIG. 47 is a flowchart of a portion for determining the U-phase duty value of D_Pwm_set_2 () corresponding to step S9.

- Ptn_3phs_ch 0 or 1

- the duty value is set to U0bai / 2 (S215).

- FIG. 48 shows a list including these processing patterns.

- FIG. 49 shows the waveform of the motor current detected by the third detection method (part 2). As is apparent from this figure, as a result of the current detection rate being improved by the three-phase modulation, the current waveform is less distorted and close to a sine wave.

- the third detection method (part 2), when one of the two-phase pulses in the two-phase modulation cannot be detected due to a decrease in one duty, the remaining one-phase is detected.

- a duty pulse is additionally generated by a predetermined value for three-phase modulation, and the two-phase duty pulse is increased by the predetermined value.

- the three-phase modulation is similarly performed to increase the maximum phase duty, and the PWM pulse The generation base point of the U-phase PWM pulse is shifted according to the magnitude. Thereby, a current detection rate can be improved.

- FIG. 50 is a flowchart showing interrupt processing executed for each carrier cycle when performing two-phase modulation.

- a / D converted data is extracted in the current detector 27 (S311)

- a three-phase current is detected based on the data (S312).

- the A / D conversion processing of the terminal voltage of the shunt resistor 24 in the current detection unit 27 is executed twice within one carrier cycle separately from the processing shown in FIG. 50 (execution timing will be described later).

- the A / D converted data is stored in, for example, a register. Therefore, the processing in step S211 reads the data stored in the register.

- the rotor position ( ⁇ ) of the motor 4 is estimated from the three-phase current by vector control calculation (S313), and frequency control (speed control, S314) and current control (PI control, etc.) are executed (S315).

- S313 vector control calculation

- S314 frequency control

- PI control current control

- S315 current control

- S316 a register, memory or the like

- the two-phase PWM duty obtained here is set in the output register in step S317 of the interrupt processing in the next carrier cycle.

- the two-phase PWM duty determined in the previous carrier cycle is used for output. It is set in the register (S317).

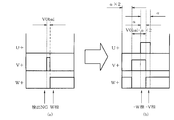

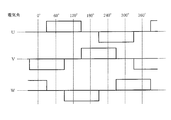

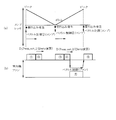

- FIG. 51A shows the phase at which a PWM duty pulse is output in the case of two-phase modulation, and the timing at which the current detector 27 A / D converts the terminal voltage of the shunt resistor 24.

- U and V phase duty pulses are output so that the bottom of the triangular wave is the center phase.

- the first A / D conversion is executed at the bottom timing.

- the current detected at this time is a W-phase negative current.

- the second A / D conversion is executed when a minute time ⁇ that further considers the switching delay has passed after the passage of the time D2 from the bottom.

- the current detected at this time is a U-phase positive current.

- the V-phase current is obtained by calculation based on the above two A / D conversion results.

- FIG. 51B is a table for calculating the two-phase PWM duty based on the orthogonal voltages V ⁇ and V ⁇ obtained in the vector control process.

- sectors 0 to 5 are determined according to the magnitude relationship between the voltages V ⁇ and V ⁇ , and pulse width values D1 and D2 are determined for each sector. Is determined based on the voltages V ⁇ and V ⁇ and the correction value H.

- the correction value H is a term for correcting the duty pulse width in accordance with the DC voltage that is the voltage of the DC power supply unit 21 and is expressed by the following equation.

- H ⁇ 3 ⁇ (PWM register maximum value) ⁇ 32768 / (DC voltage) (2)

- the “PWM register maximum value” is 65535 if the register is 16 bits, for example.

- the PWMa, PWMb and PWMc shown on the right side of FIG. 51 (b) correspond to the three-phase voltages Vu, Vv and Vw output from the vector calculation unit 30 in FIG. It becomes the sum of D1 and D2, or only the pulse width value D2, or “0”.

- FIG. 52 is a flowchart showing interrupt processing executed every half cycle of the carrier cycle when three-phase modulation is performed. Steps S321 to S325 are executed in the same manner as steps S311 to S315 shown in FIG. 50, but in the subsequent step S326, a three-phase PWM duty is output. The subsequent steps S327 to S329 are performed in the DUTY generation unit 31. With reference to the value of the carrier counter provided from the PWM signal generation unit 32, it is determined whether the up-counting or down-counting is in progress (S327). If up-counting is in progress, D_Pwm_set2 () is set (S328), and if down-counting is in progress, D_Pwm_set1 () is set (S329). These will be described with reference to FIGS.

- the two A / D conversion timings in the three-phase modulation are immediately before and after the triangular wave reaches the bottom.

- a W-phase current is obtained at the former timing

- a V-phase current is obtained at the latter timing.

- the former even if A / D conversion is performed at the timing that coincides with the bottom, it is possible to obtain the W-phase current due to the timing of each control, signal delay, and the like.

- FIG. 53 is a diagram corresponding to FIG. 51 (b), but conditions 1 to 3, sectors, D1 and D2 are exactly the same as in the case of two-phase modulation, and only the determined portions of PWMa, PWMb and PWMc are different. . These determinations include not only the pulse width values D1 and D2 but also the maximum value PD of the PWM register described in the explanation of the correction value H.

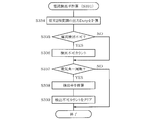

- FIG. 54 is a flowchart showing mainly the control contents executed by the detection method selection unit 36.

- the current detection rate is calculated (S331), and the calculation process is shown in FIG.

- the output duty is calculated for the PWM signal pattern of the first detection method (conventional two-phase modulation) (S334), it is determined whether or not two-phase current can be detected with the obtained duty (S335).

- FIG. 56 is a vector diagram in which current detection impossible periods are indicated by hatching. If the above PWM output duty vector is within the shaded range (for example, when the duty of one phase is around 100% and the duty of the other one phase is around 0%), it is determined that the current cannot be detected. (S335: YES), it counts as a carrier cycle in which current detection is impossible (current detection impossible cycle) (S336). Next, it is determined whether or not one electrical angle cycle has elapsed using the current estimated angle ⁇ Est (S337). When one cycle has elapsed (YES), the current detection rate in that cycle is calculated ( S338).

- S335 YES

- the current detection rate is obtained by the following equation.

- the current rotational speed of the motor 4 and the rotational speed threshold value, or the motor output voltage and the output voltage threshold value are compared, and the currently driven motor 4 rotational speed region (high speed / medium speed / low speed) is determined. judge.

- the output voltage Vm of the motor 4 is calculated as follows using the ⁇ -axis output voltage V ⁇ and the ⁇ -axis output voltage V ⁇ calculated by the vector calculation unit 30.

- Vm ⁇ (V ⁇ 2 + V ⁇ 2) (4)

- the low speed region is, for example, a rotational speed region near the minimum rotational speed

- the high speed region is, for example, a rotational speed region where overmodulation control is effective.

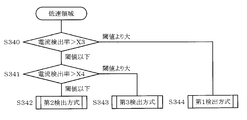

- the medium speed area is a speed area between the high speed area and the low speed area.

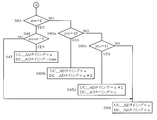

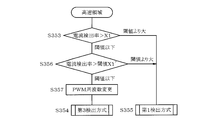

- FIG. 57 is a flowchart of processing for selecting a detection method in the low speed region.

- the current detection rate of the first detection method is compared with the threshold value X3 (S340). If the current detection rate is high (greater than the threshold value), the first detection method is selected (S344), and if the current detection rate is low ( The current detection rate of the first detection method is compared with the threshold value X4 (S341). If the current detection rate is high (greater than the threshold), the third detection method (2-phase + 3-phase modulation) is selected (S343), and if the current detection rate is low (below the threshold), the second detection method (new 3-phase modulation) is selected. Select (S342).

- the current detection rate of the first detection method tends to decrease, but it is preferable to adopt the first detection method in order to reduce power consumption. Therefore, when the current detection rate of the first detection method becomes equal to or less than the threshold value X3, the third detection method is selected to improve the current detection rate. Further, when the current detection rate of the third detection method becomes equal to or less than the threshold value X4, the second detection method is selected to improve the current detection rate again.

- FIG. 58 is a flowchart of processing for selecting a detection method in the medium speed region.

- the speed fluctuation detecting unit 37 detects the maximum value and the minimum value of the current estimated speed ⁇ Est during one mechanical angle rotation of the motor 4, and obtains the difference between them as a speed fluctuation width (S345).

- step S347 the above-described speed fluctuation width is compared with the fluctuation width threshold value. If the speed fluctuation width is small (below the threshold value), switching to rectangular wave driving (S348), and if the speed fluctuation width is large (greater than the threshold value), the process proceeds to step S349.

- step S349 the current detection rate of the first detection method is compared with the threshold value X2, and if the current detection rate is high (greater than the threshold value), the first detection method is selected (S351). On the other hand, if the current detection rate is low (below the threshold), the fourth detection method (new two-phase modulation) is selected (S350).

- the modulation rate is higher and the current detection rate is higher than in the low speed region. Therefore, the first detection method is adopted with an emphasis on reducing power consumption. However, the current detection rate is reduced when the motor load is reduced. Is equal to or lower than the threshold value X2, the fourth detection method is selected to improve the current detection rate. If the speed command is constant and the speed fluctuation range is equal to or less than the threshold value, switching to rectangular wave driving is performed to further reduce power consumption.

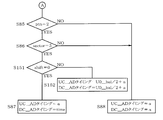

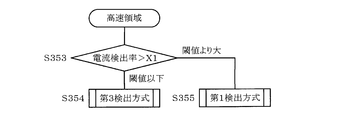

- FIG. 59 is a flowchart of a process for selecting a high-speed area detection method.

- step S353 the current detection rate of the first detection method is compared with the threshold value X1, and if the current detection rate is high (greater than the threshold value), the first detection method is selected (S355), and if the current detection rate is low (below the threshold value). )

- the third detection method is selected (S354).

- the current detection rate of the first detection method is reduced and controllability is deteriorated. Therefore, when the current detection rate of the first detection method becomes equal to or less than the threshold value X1, the third detection method is selected to improve the current detection rate.

- FIGS. 60 to 63 show the PWM signal waveform and the output voltage waveform in the rectangular wave driving method selected in step S348.

- FIGS. 60 and 61 show the case of the 120 ° energization method in FIG.

- FIG. 63 shows the case of the 150 ° energization method.

- the waveform on the upper side of each phase indicates the ON section of the upper arm

- the waveform on the lower side indicates the ON section of the lower arm. Since the induced voltage of the motor 4 appears in the non-energized section of each phase, the rotor position can be detected by detecting the zero cross point of the induced voltage there. By selecting the rectangular wave driving method in this way, the switching loss is further reduced.

- FIG. 64 is a flowchart schematically showing a modulation method switching process during operation of the air conditioner.

- step S361 if the detection method currently being executed is the first detection method, the process proceeds to step S362, and the cycle for generating the PWM interrupt is set to the same cycle as the carrier cycle. Then, current data is acquired by the first detection method, vector control processing is performed, and a two-phase PWM signal pattern is generated and output (S363).

- step S361 If the currently executed detection method is the second to fourth detection methods, the process proceeds from step S361 to S364, and the cycle for generating the PWM interrupt is set every half cycle of the carrier cycle. Then, current data is acquired by the second to fourth detection methods, vector control processing is performed, and a three-phase PWM signal pattern is generated and output (S365).

- step S361 If the detection method currently being executed is rectangular wave drive control, the process proceeds from step S361 to S366, and the cycle for generating the PWM interrupt is set to the same cycle as the carrier cycle. Then, rectangular wave drive control processing is performed by a position detection method according to rectangular wave drive, and a two-phase PWM signal pattern is generated and output (S367). In the case of rectangular wave driving, it is not necessary to detect a two-phase current for position detection, but only a one-phase current is detected for overcurrent protection.

- the current detection unit 27 is configured so that the motor 4 is based on the signal generated by the shunt resistor 24 connected to the DC side of the inverter circuit 23 corresponding to the current value and the PWM signal pattern.

- the phase calculation unit 30 determines the rotor position ⁇ based on the phase current, and together with the PWM signal generation unit 32, the two-phase or three-phase currents Iu, Iv, Iw are detected. A PWM signal pattern is generated.

- the PWM signal generation unit 32 increases or decreases the duty in either of the delay side and the advance side with respect to the bottom of the carrier cycle with respect to the three-phase PWM signal pattern, Is to increase or decrease the duty in one direction on the delay side and the advance side with respect to the bottom, and in the remaining one phase in the direction opposite to the direction.

- the PWM signal generation unit 32 generates a three-phase PWM signal pattern so that the current detection unit 27 can detect a two-phase current at two fixed or variable timings within the PWM signal carrier cycle. Alternatively, all three phases are output symmetrically from the center of the carrier wave, and a two-phase PWM signal pattern for detecting current at a variable timing is generated. Then, when the motor 4 is in the high speed region, the detection method selection unit 35 selects the first and third detection methods according to the current detection rate in the DUTY generation unit 31 and the PWM signal generation unit 32. Is in the low speed region, one of the first to third detection methods is selected. When the motor 4 is in the medium speed region, the first and fourth detection methods are selected. Thereby, it is possible to improve the control accuracy while suppressing the switching loss while maintaining the necessary current detection rate according to the rotation speed region of the motor 4.

- the detection method selection unit 35 selects a current detection method based on the result of referring to the duty ratio of the PWM signal and the length of the current detectable period within the carrier cycle. Therefore, switching of the PWM signal pattern can be performed appropriately based on the interrupt processing time and the length of the current detectable period.

- the motor 4 which comprises the compressor 2 is controlled object. Therefore, the operation efficiency of the heat pump system 1 and the air conditioner can be improved.

- FIG. 65 is a view corresponding to FIG. 59 showing the second embodiment.

- steps S356 and S357 are inserted between steps S353 and S354. If it is determined in step S353 that it is “below the threshold value”, the current detection rate is compared with a threshold value X1 ′ ( ⁇ X1) (S356).

- the PWM frequency in the PWM signal generation unit 32 is changed to be higher (for example, from 4.5 kHz to 5 kHz) (S357), and the third detection method is executed. (S354).

- the carrier period is adjusted to be shorter. Can be improved.

- FIG. 66 and 67 show the third embodiment, and FIG. 66 corresponds to FIG.

- steps S320, S325a, and S326a are added to the flowchart shown in FIG. 52, and the place where step S326 is executed is changed. That is, when step S325 is executed, the flag M_Int_flg is set to “1” (S325a). The above flag indicates that the processing of steps S321 to S325 has already been executed in the half cycle of the carrier.

- the interrupt processing times (1) and (3) shown in FIG. 66 are slightly shorter than those in the case of processing according to FIG. 52 (corresponding to the case shown in FIG. 8). Since the fan motor control process (5) of the outdoor unit is also executed in the second half of the carrier cycle, the processing time in the second half of the cycle can be provided by dividing the interrupt processing as described above.

- the process of dividing the first half and the second half is not limited to the above example, and may be set as appropriate.

- step S371 of FIG. 68 it is determined whether the modulation method being executed is two-phase modulation or three-phase modulation. In either case, an interrupt is generated every half of the carrier cycle (S372, S374). .

- the two-phase modulation current data is acquired by the corresponding first or fourth detection method, vector control processing is performed, and a two-phase PWM signal pattern is generated and output (S373).

- the three-phase modulation current data is acquired by the corresponding second or third detection method, vector control processing is performed, and a three-phase PWM signal pattern is generated and output (S375).