WO2014109407A1 - Hard coat film, curable resin composition for hard coat layers, and method for producing hard coat film - Google Patents

Hard coat film, curable resin composition for hard coat layers, and method for producing hard coat film Download PDFInfo

- Publication number

- WO2014109407A1 WO2014109407A1 PCT/JP2014/050379 JP2014050379W WO2014109407A1 WO 2014109407 A1 WO2014109407 A1 WO 2014109407A1 JP 2014050379 W JP2014050379 W JP 2014050379W WO 2014109407 A1 WO2014109407 A1 WO 2014109407A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- hard coat

- coat layer

- fine particles

- silica fine

- curable resin

- Prior art date

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D4/00—Coating compositions, e.g. paints, varnishes or lacquers, based on organic non-macromolecular compounds having at least one polymerisable carbon-to-carbon unsaturated bond ; Coating compositions, based on monomers of macromolecular compounds of groups C09D183/00 - C09D183/16

- C09D4/06—Organic non-macromolecular compounds having at least one polymerisable carbon-to-carbon unsaturated bond in combination with a macromolecular compound other than an unsaturated polymer of groups C09D159/00 - C09D187/00

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

-

- G02B1/105—

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/10—Optical coatings produced by application to, or surface treatment of, optical elements

- G02B1/14—Protective coatings, e.g. hard coatings

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/133502—Antiglare, refractive index matching layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/10—Coating on the layer surface on synthetic resin layer or on natural or synthetic rubber layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/26—Polymeric coating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/28—Multiple coating on one surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/10—Inorganic particles

- B32B2264/102—Oxide or hydroxide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/30—Properties of the layers or laminate having particular thermal properties

- B32B2307/306—Resistant to heat

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

- B32B2307/412—Transparent

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/536—Hardness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/584—Scratch resistance

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/20—Displays, e.g. liquid crystal displays, plasma displays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2571/00—Protective equipment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/12—Interconnection of layers using interposed adhesives or interposed materials with bonding properties

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/02—Diffusing elements; Afocal elements

- G02B5/0205—Diffusing elements; Afocal elements characterised by the diffusing properties

- G02B5/0236—Diffusing elements; Afocal elements characterised by the diffusing properties the diffusion taking place within the volume of the element

- G02B5/0242—Diffusing elements; Afocal elements characterised by the diffusing properties the diffusion taking place within the volume of the element by means of dispersed particles

Definitions

- the present invention relates to a hard coat film used for the purpose of protecting the surface of a display or the like.

- Image display surfaces in image display devices such as liquid crystal displays, CRT displays, projection displays, plasma displays, and electroluminescence displays are required to be provided with scratch resistance so that they are not damaged during handling.

- the performance required for hard coat films has been increasing in recent years, and there is a demand for further improved hardness and scratch resistance.

- Patent Document 1 As means for improving the hardness of the hard coat film, for example, in Patent Document 1, a substrate having a specific configuration is used, and the total thickness of the hard coat film, the thickness of the acrylic resin layer constituting the substrate, and the thickness of the hard coat layer are set. A method for making a specific range is disclosed. Patent Document 2 discloses a method of forming a hard coat layer using a curable composition to which inorganic oxide particles are added. Further, Patent Documents 3 to 7 disclose methods for forming a hard coat layer using a curable composition to which reactive irregularly shaped silica fine particles are added.

- Patent Document 5 discloses that good flexibility can be obtained by adding reactive irregular-shaped silica fine particles to a curable resin composition for a hard coat layer and further adding a polymer. However, there is a concern that the hardness is lowered and the scratch resistance is deteriorated simply by adding a polymer, and it is difficult to achieve both high hardness and workability.

- Patent Document 7 proposes that a reactive polymer having a specific structure and a weight average molecular weight is contained in a curable resin composition for a hard coat layer in order to improve hardness and reduce curl. However, the workability has not been studied.

- the present invention has been made in view of the above problems, and has as its main object to provide a hard coat film that is excellent in hardness, scratch resistance and workability.

- the present inventors form a hard coat layer using a curable resin composition containing reactive irregularly shaped silica fine particles, a monomer, and a specific polymer. As a result, it was found that a hard coat film having both high hardness and workability was obtained, and the present invention was completed.

- the present invention is a hard coat film in which a hard coat layer is formed on a substrate, and the hard coat layer has irregular-shaped silica fine particles and a weight average molecular weight in the range of 30,000 to 110,000.

- a hard coat film comprising an acrylic polymer having an acrylic equivalent in the range of 200 to 1,200 and a matrix resin is provided.

- the hard coat layer contains irregular shaped silica fine particles, whereby the hardness and scratch resistance can be improved. Further, by using an acrylic polymer having a weight average molecular weight and an acrylic equivalent within a predetermined range for the hard coat layer, it is possible to improve workability while maintaining high hardness.

- the hard coat layer may contain a polymerization initiator.

- the hard coat layer may contain a blue color material. This is because when the hard coat film of the present invention is used in an image display device, yellowness can be suppressed and visibility and color reproducibility can be improved.

- an antiglare layer may be formed on the hard coat layer. Even in the case where the antiglare layer is formed on the hard coat layer, the hard coat layer is excellent in hardness, so that high hardness can be achieved.

- the present invention is a hard coat film in which a hard coat layer is formed on a substrate, the hard coat layer is a curable resin composition containing reactive irregular silica fine particles, the acrylic polymer, and a monomer.

- a hard coat film comprising a cured product is provided.

- hardness and scratch resistance can be improved by using reactive irregularly shaped silica fine particles in the hard coat layer. Further, by using an acrylic polymer having a weight average molecular weight and an acrylic equivalent within a predetermined range for the hard coat layer, it is possible to improve workability while maintaining high hardness.

- the present invention also provides reactive irregularly shaped silica fine particles, an acrylic polymer having a weight average molecular weight in the range of 30,000 to 110,000 and an acrylic equivalent in the range of 200 to 1,200, and a monomer.

- a curable resin composition for a hard coat layer is provided.

- the curable resin composition for a hard coat layer contains reactive irregularly shaped silica fine particles, a hard coat layer having excellent hardness and scratch resistance can be obtained. Moreover, it is possible to achieve both high hardness and workability by adding an acrylic polymer having a weight average molecular weight and an acrylic equivalent within a predetermined range to the curable resin composition for a hard coat layer.

- the curable resin composition for a hard coat layer of the present invention may further contain a polymerization initiator.

- the curable resin composition for a hard coat layer of the present invention may further contain a blue color material. This is because when used in an image display device, a hard coat film capable of suppressing yellowness and improving visibility and color reproducibility can be obtained.

- the present invention also provides a reactive irregularly shaped silica fine particle on a substrate, an acrylic polymer having a weight average molecular weight in the range of 30,000 to 110,000 and an acrylic equivalent in the range of 200 to 1,200.

- a method for producing a hard coat film comprising a hard coat layer forming step of applying a curable resin composition for a hard coat layer containing a monomer and curing to form a hard coat layer.

- the present invention also relates to a hard coat film having a hard coat layer formed on a substrate, wherein the hard coat layer has reactive irregularly shaped silica fine particles and a weight average molecular weight in the range of 30,000 to 110,000.

- a hard coat film comprising a cured product of a curable resin composition containing an acrylic polymer having an acrylic equivalent in the range of 200 to 1,200, a monomer, and a polymerization initiator To do.

- the present invention also includes reactive irregularly shaped silica particles, an acrylic polymer having a weight average molecular weight in the range of 30,000 to 110,000 and an acrylic equivalent in the range of 200 to 1,200, a monomer, A curable resin composition for a hard coat layer comprising a polymerization initiator is provided.

- the hardness and scratch resistance can be improved by including the reactive deformed silica fine particles in the hard coat layer. Further, by using an acrylic polymer having a weight average molecular weight and an acrylic equivalent within a predetermined range for the hard coat layer, it is possible to improve workability while maintaining high hardness.

- the present invention has an effect that it is possible to improve any of hardness, scratch resistance and workability.

- the hard coat film of the present invention is a hard coat film in which a hard coat layer is formed on a substrate, and the hard coat layer has irregular-shaped silica fine particles and a weight average molecular weight of 30,000 to 110,000. And an acrylic polymer having an acrylic equivalent in the range of 200 to 1,200 and a matrix resin.

- the “hard coat film” is a concept including a member that can also be called a sheet or a plate.

- the hard coat layer contains irregular-shaped silica fine particles

- a hard coat layer having excellent hardness and scratch resistance can be obtained.

- an acrylic polymer having a weight average molecular weight and an acrylic equivalent within a predetermined range for the hard coat layer it is possible to achieve both high hardness and workability.

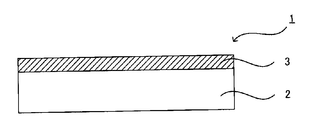

- FIG. 1 is a schematic sectional view showing an example of the hard coat film of the present invention.

- the hard coat film 1 includes a substrate 2 and a hard coat layer 3 formed on the substrate 2.

- the hard coat layer 3 contains irregular-shaped silica fine particles, an acrylic polymer having a weight average molecular weight and an acrylic equivalent within predetermined ranges, and a matrix resin. That is, the hard coat layer 3 is composed of a cured product of a curable resin composition containing reactive irregular shaped silica fine particles, an acrylic polymer having a weight average molecular weight and an acrylic equivalent within a predetermined range, and a monomer. Yes.

- each structure in the hard coat film of this invention is demonstrated.

- Hard coat layer The hard coat layer in this invention is formed on a board

- the hard coat layer of the first embodiment contains irregular-shaped silica fine particles, an acrylic polymer having a weight average molecular weight and an acrylic equivalent within predetermined ranges, and a matrix resin.

- the hard coat layer of the second aspect is a cured product of a curable resin composition containing reactive irregularly shaped silica fine particles, an acrylic polymer having a weight average molecular weight and an acrylic equivalent within a predetermined range, and a monomer. Is included.

- the configuration of the hard coat layer will be described.

- Curable resin composition used in the present invention contains reactive irregularly shaped silica fine particles, an acrylic polymer having a weight average molecular weight and an acrylic equivalent within a predetermined range, and a monomer. Is. Hereinafter, each component in the curable resin composition will be described.

- the reactive deformed silica fine particle is a component that contributes to improving the hardness of the hard coat layer.

- the reactive irregular shaped silica fine particles usually have a reactive functional group.

- a polymerizable unsaturated group is suitably used, preferably a photocurable unsaturated group, and particularly preferably an ionizing radiation curable unsaturated group.

- Specific examples include ethylenically unsaturated bonds such as (meth) acryloyl groups, vinyl groups, allyl groups, and epoxy groups.

- (meth) acryloyl means at least one of acryloyl and methacryloyl

- (meth) acrylate means at least one of acrylate and methacrylate

- (meth) acryl is at least one of acrylic and methacrylic. Means.

- Examples of reactive irregularly shaped silica fine particles include reactive irregularly shaped silica fine particles in which a plurality of fine silica particles are bonded by an inorganic chemical bond.

- the reactive irregularly shaped silica fine particles are reactive irregularly shaped silica fine particles having 3 to 20 silica fine particles having an average primary particle diameter of 1 nm to 100 nm bonded by an inorganic chemical bond and having a reactive functional group on the surface.

- the reactive irregularly shaped silica fine particles have a reactive functional group, so that they can undergo a curing reaction that crosslinks with the reactive irregularly shaped silica fine particles and the monomer, and can impart scratch resistance and hardness to the hard coat layer. .

- the average primary particle diameter of the silica fine particles constituting the reactive irregularly shaped silica fine particles is preferably in the range of 1 nm to 100 nm, and more preferably in the range of 5 nm to 80 nm. If the average primary particle size of the silica fine particles is small, only reactive irregularly shaped silica fine particles having a small average secondary particle size can be obtained, and sufficient hardness may not be imparted to the hard coat layer.

- the average primary particle size of the silica fine particles is large, the average secondary particle size of the reactive irregularly shaped silica fine particles tends to be large, and if the average secondary particle size is large, the transparency of the hard coat layer is lowered and the transmittance Deterioration and haze increase may occur.

- the average secondary particle size of the reactive irregularly shaped silica fine particles is preferably in the range of 5 nm to 300 nm, and more preferably in the range of 10 nm to 200 nm. When the average two particle diameters of the reactive irregularly shaped silica fine particles are within the above range, it is easy to impart hardness to the hard coat layer and maintain the transparency of the hard coat layer.

- the average primary particle size of the silica fine particles is determined by measuring the silica fine particles in the curable resin composition by a dynamic light scattering method, and the 50% particle size (d50 median) when the particle size distribution is expressed as a cumulative distribution. Diameter).

- the average primary particle size can be measured using a Microtrac particle size analyzer or a Nanotrac particle size analyzer manufactured by Nikkiso Co., Ltd.

- the average secondary particle size of the reactive irregularly shaped silica fine particles can be determined by the same method as the average primary particle size in the curable resin composition.

- the average secondary particle size of the reactive irregularly shaped silica fine particles is such that, in the hard coat layer, the cross section of the hard coat layer is observed using an SEM photograph or a TEM photograph, and the observed cured reactive irregularly shaped silica fine particles are 100. It can be obtained as an average value of individual selection.

- Silica fine particles do not exclude the use of particles having pores or porous structures inside the particles, such as hollow particles, but solid particles having no pores or porous structures inside the particles should be used. It is more preferable from the viewpoint of improving the hardness.

- the reactive irregularly shaped silica fine particles are formed by bonding the above-mentioned silica fine particles, preferably 3 to 20, more preferably 3 to 10, by inorganic chemical bonds.

- the number of silica fine particles bonded by inorganic chemical bonds is small, it is substantially the same as monodisperse particles, and it is difficult to obtain a hard coat layer excellent in adhesion to the substrate, scratch resistance, and pencil hardness.

- bonded by the inorganic chemical bond the transparency of a hard-coat layer will fall, and the deterioration of the transmittance

- inorganic chemical bonds include ionic bonds, metal bonds, coordination bonds, and covalent bonds.

- a bond in which the bonded silica fine particles are not dispersed even when the reactive deformed silica fine particles are added to the polar solvent specifically, a metal bond, a coordination bond, and a covalent bond is preferable, and a covalent bond is particularly preferable.

- the polar solvent include water and lower alcohols such as methanol, ethanol and isopropyl alcohol.

- silica fine particles As the particle state of the reactive irregularly shaped silica fine particles, 3 to 20 silica fine particles are bonded by an inorganic chemical bond and aggregated particles (aggregated particles), and 3 to 20 silica fine particles are inorganic. Examples thereof include chain particles bonded by chemical bonds and bonded in a chain. Among these, from the viewpoint of increasing the hardness of the hard coat layer, chain particles are preferable as the particle state of the reactive irregularly shaped silica fine particles. Further, it is preferable that the chain particles are contained in at least a part of the reactive irregular shaped silica fine particles.

- the average number of bonds of the silica fine particles is determined by observing the cross section of the hard coat layer using an SEM photograph or a TEM photograph and observing the cured reactive irregularly shaped silica fine particles. 100 are selected, the silica fine particles contained in each reactive deformed silica fine particle are counted, and the average value can be obtained.

- the method for producing reactive irregularly shaped silica fine particles is not particularly limited as long as the above-mentioned silica fine particles are bonded by an inorganic bond, and a conventionally known method can be appropriately selected and used.

- a conventionally known method can be appropriately selected and used.

- it can be obtained by adjusting the concentration or pH of the monodispersed silica fine particle dispersion and performing hydrothermal treatment at a high temperature of 100 ° C. or higher.

- a binder component can be added to promote the binding of the silica fine particles.

- ions may be removed by passing the silica fine particle dispersion used through an ion exchange resin. Such ion exchange treatment can promote the binding of silica fine particles. After the hydrothermal treatment, the ion exchange treatment may be performed again.

- the reactive irregular shaped silica fine particles have at least a part of the surface coated with an organic component, and have a reactive functional group introduced by the organic component on the surface.

- the organic component is a component containing carbon.

- a compound containing an organic component such as a silane coupling agent reacts with a hydroxyl group present on the surface of the silica fine particles to cause a part of the surface

- silica Examples include a mode in which an organic component is attached to a hydroxyl group present on the surface of the fine particle by an interaction such as hydrogen bonding, a mode in which silica fine particles are contained in the polymer particle, and the

- At least a part of the surface is coated with an organic component, and a method for preparing reactive deformed silica fine particles having a reactive functional group introduced by the organic component on the surface is a reactive functional group to be introduced into the reactive deformed silica fine particles.

- a conventionally known method can be appropriately selected and used.

- any one of the following reactive deformed silica fine particles (i) and (ii) may be appropriately selected and used. preferable.

- Reactive deformed silica fine particles having a reactive functional group on the surface obtained by (Ii) a compound containing a reactive functional group to be introduced into the deformed silica fine particle before coating, a group represented by the following chemical formula (1), and a silanol group or a group that generates a silanol group by hydrolysis, and metal oxide fine particles: Reactive deformed silica fine particles having a reactive functional group on the surface, obtained by bonding.

- Reactive deformed silica fine particles having a reactive functional group on the surface obtained by When the reactive irregularly shaped silica fine particles (i) are used, there is an advantage that the strength of the hard coat layer can be improved even if the organic component content is small.

- the surface-modifying compound used for the reactive deformed silica fine particles (i) is a carboxyl group, acid anhydride group, acid chloride group, acid amide group, ester group, imino group, nitrile group, isonitrile group, hydroxyl group, thiol.

- the chemical bond here preferably includes a covalent bond, an ionic bond or a coordination bond, but also includes a hydrogen bond.

- the coordination bond is considered to be complex formation.

- an acid-base reaction, complex formation or esterification according to Bronsted or Lewis occurs between the functional group of the surface modifying compound and the group on the surface of the deformed silica fine particle.

- the surface modification compound used for the reactive irregular shaped silica fine particles (i) can be used alone or in combination of two or more.

- the surface-modifying compound is usually added to at least one functional group capable of participating in chemical bonding with the surface group of the irregular-shaped silica fine particle, and after binding to the surface-modifying compound via this functional group, the irregular-shaped silica fine particle is newly added. It has molecular residues that give unique properties.

- at least one functional group that can participate in chemical bonding with a group on the surface of the irregular shaped silica fine particle is referred to as a first functional group.

- the molecular residue or a part thereof is hydrophobic or hydrophilic and, for example, stabilizes, integrates, or activates irregular shaped silica fine particles.

- the hydrophobic molecular residue includes an alkyl, aryl, alkaryl, aralkyl, or fluorine-containing alkyl group that causes inactivation or repulsion.

- the hydrophilic group include a hydroxy group, an alkoxy group, and a polyester group.

- the reactive functional group introduced to the surface so that the reactive irregular shaped silica fine particles can react with the monomer described later is appropriately selected according to the monomer.

- a polymerizable unsaturated group is suitably used, preferably a photocurable unsaturated group, and particularly preferably an ionizing radiation curable unsaturated group.

- Specific examples thereof include ethylenically unsaturated bonds such as (meth) acryloyl group, vinyl group and allyl group, and epoxy group.

- the first functional group contained in the surface modifying compound is reacted with the surface of the deformed silica fine particle.

- a surface modification compound further having a polymerizable unsaturated group is preferable.

- a second reactive functional group is contained, and the second reactive functional group is used as a foothold for the reactive deformed silica fine particles of (i).

- a reactive functional group capable of reacting with the monomer may be introduced on the surface.

- a hydrogen bond-forming group capable of hydrogen bonding such as a hydroxyl group and an oxy group is introduced as the second reactive functional group, and another surface modification compound is added to the hydrogen bond-forming group introduced on the surface of the fine particles. It is preferable to introduce a reactive functional group capable of reacting with the monomer by the reaction of the hydrogen bond forming group.

- a compound having a hydrogen bond forming group and a compound having a reactive functional group capable of reacting with a monomer such as a polymerizable unsaturated group and a compound having a hydrogen bond forming group in combination As mentioned.

- Specific examples of the hydrogen bond-forming group indicate a functional group such as a hydroxyl group, a carboxyl group, an epoxy group, a glycidyl group, an amide group, or an amide bond.

- the term “amide bond” means that the bond unit contains —NHC (O) or> NC (O) —.

- a carboxyl group, a hydroxyl group, and an amide group are particularly preferable.

- the surface-modifying compound used in the reactive irregularly shaped silica fine particles (i) above preferably has a molecular weight of 500 or less, particularly a molecular weight not exceeding 400, and particularly a molecular weight not exceeding 200. Since it has such a low molecular weight, it is presumed that the surface of the silica fine particles can be rapidly occupied and aggregation of the reactive irregular shaped silica fine particles can be prevented.

- the surface-modifying compound used in the reactive deformed silica fine particles (i) is preferably a liquid under the reaction conditions for surface modification, and is preferably soluble or at least emulsifiable in a dispersion medium.

- the polymer is dissolved in the dispersion medium and uniformly distributed as discrete molecules or molecular ions in the dispersion medium.

- Saturated or unsaturated carboxylic acids have 1 to 24 carbon atoms, such as formic acid, acetic acid, propionic acid, butyric acid, valeric acid, caproic acid, acrylic acid, methacrylic acid, crotonic acid, citric acid, Examples include adipic acid, succinic acid, glutaric acid, oxalic acid, maleic acid, fumaric acid, itaconic acid and stearic acid, and the corresponding acid anhydrides, chlorides, esters and amides such as caprolactam. Further, when an unsaturated carboxylic acid is used, a polymerizable unsaturated group can be introduced.

- n 0, 1 or 2.

- Residue Q is independently alkyl having 1 to 12, especially 1 to 6, particularly preferably 1 to 4, carbon atoms such as methyl, ethyl, n-propyl, i-propyl and butyl, and 6 to 24 Represents aryl, alkaryl or aralkyl having 5 carbon atoms such as phenyl, naphthyl, tolyl and benzyl.

- Examples of preferred amines include polyalkyleneamines, and specific examples are methylamine, dimethylamine, trimethylamine, ethylamine, aniline, N-methylaniline, diphenylamine, triphenylamine, toluidine, ethylenediamine, and diethylenetriamine. .

- Preferred ⁇ -dicarbonyl compounds are those having 4 to 12, particularly 5 to 8 carbon atoms, such as diketones such as acetylacetone, 2,3-hexanedione, 3,5-heptanedione, acetoacetate, acetoacetate Acetoacetic acid-C 1 -C 4 -alkyl esters such as ethyl esters, diacetyl and acetonyl acetone.

- Examples of amino acids include ⁇ -alanine, glycine, valine, aminocaproic acid, leucine and isoleucine.

- Preferred silanes are hydrolyzable organosilanes having at least one hydrolyzable group or hydroxy group and at least one non-hydrolyzable residue.

- examples of the hydrolyzable group include a halogen, an alkoxy group, and an acyloxy group.

- the non-hydrolyzable residue a non-hydrolyzable residue having a reactive functional group or not having a reactive functional group is used.

- Silanes having at least partially organic residues substituted with fluorine may also be used.

- the silane coupling agent is not particularly limited, and may include known ones such as KBM-502, KBM-503, KBE-502, KBE-503 manufactured by Shin-Etsu Chemical Co., Ltd. be able to.

- Examples of the metal compound having a functional group include a metal compound of metal M from at least one of the first group III to V and the second group II to IV of the periodic table. Specific examples include zirconium and titanium alkoxides represented by the following chemical formula. M (OR) 4 In the above formula, M is Ti or Zr. A part of the OR group is substituted with a complexing agent such as a ⁇ -dicarbonyl compound or a monocarboxylic acid. When a compound having a polymerizable unsaturated group such as methacrylic acid is used as a complexing agent, a polymerizable unsaturated group can be introduced.

- the dispersion medium at least one of water and an organic solvent is preferably used.

- a particularly preferred dispersion medium is distilled pure water.

- organic solvent polar, nonpolar and aprotic solvents are preferred. Examples thereof include alcohols such as C 1-6 aliphatic alcohols such as methanol, ethanol, n- and i-propanol and butanol, ketones such as methyl ethyl ketone, diethyl ketone, methyl isobutyl ketone, acetone and butanone, acetic acid Esters such as ethyl; ethers such as diethyl ether, tetrahydrofuran and tetrahydropyran; amides such as dimethylacetamide and dimethylformamide; sulfoxides and sulfones such as sulfolane and dimethyl sulfoxide; and optionally, such as pentane, hexane and cyclohexane Aliphatic hydro

- the dispersion medium preferably has a boiling point that can be easily removed by distillation, optionally under reduced pressure, and a solvent having a boiling point of 200 ° C. or lower, particularly 150 ° C. or lower is preferable.

- the concentration of the dispersion medium is usually within the range of 40% by mass to 90% by mass, preferably within the range of 50% by mass to 80% by mass, and particularly 55% by mass to 75%. It is in the range of mass%.

- the rest of the dispersion is composed of untreated silica fine particles and the surface modifying compound.

- the weight ratio of silica fine particles: surface modification compound is preferably 100: 1 to 4: 1, more preferably 50: 1 to 8: 1, and particularly preferably 25: 1 to 10: 1.

- Preparation of the reactive deformed silica fine particles (i) is preferably carried out in a temperature range from room temperature of about 20 ° C. to the boiling point of the dispersion medium.

- the dispersion temperature is 50 ° C. to 100 ° C.

- the dispersion time depends in particular on the type of material used, but is generally from a few minutes to a few hours, for example 1 to 24 hours.

- the compound may be referred to as a reactive functional group-modified hydrolyzable silane.

- the reactive functional group-modified hydrolyzable silane the reactive functional group to be introduced into the silica fine particles is not particularly limited as long as it is appropriately selected so as to be capable of reacting with a monomer described later. Suitable for introducing polymerizable unsaturated groups as described above.

- These groups can be used alone or in combination of two or more.

- At least one of a [—O—C ( ⁇ O) —] group, a [—O—C ( ⁇ S) —] group, and a [—S—C ( ⁇ O) —] group It is preferable to use one type in combination.

- Examples of the group that generates a silanol group by hydrolysis include groups having an alkoxy group, an aryloxy group, an acetoxy group, an amino group, a halogen atom, etc. on the silicon atom.

- An oxysilyl group is preferred.

- a silanol group or a group that generates a silanol group by hydrolysis can be bonded to the metal oxide fine particles by a condensation reaction or a condensation reaction that occurs following hydrolysis.

- the reactive functional group-modified hydrolyzable silane include, for example, compounds represented by the following chemical formulas (2) and (3), and the compound represented by the following chemical formula (3) is from the point of hardness. More preferably used.

- R a and R b may be the same or different, but are a hydrogen atom or a C 1 to C 8 alkyl group or aryl group, for example, methyl, ethyl, propyl , Butyl, octyl, phenyl, xylyl group and the like.

- m is 1, 2 or 3.

- Examples of the group represented by [(R a O) m R b 3-m Si—] include a trimethoxysilyl group, a triethoxysilyl group, a triphenoxysilyl group, a methyldimethoxysilyl group, a dimethylmethoxysilyl group, and the like. Can be mentioned. Of these groups, a trimethoxysilyl group or a triethoxysilyl group is preferable.

- R c is a divalent organic group having a C 1 to C 12 aliphatic or aromatic structure, and may contain a chain, branched or cyclic structure.

- examples of such an organic group include methylene, ethylene, propylene, butylene, hexamethylene, cyclohexylene, phenylene, xylylene, and dodecamethylene.

- preferred examples are methylene, propylene, cyclohexylene, phenylene and the like.

- R d is a divalent organic group and is usually selected from divalent organic groups having a molecular weight of 14 to 10,000, preferably a molecular weight of 76 to 500.

- chain polyalkylene groups such as hexamethylene, octamethylene, dodecamethylene; alicyclic or polycyclic divalent organic groups such as cyclohexylene and norbornylene; divalent groups such as phenylene, naphthylene, biphenylene and polyphenylene An aromatic group; and these alkyl group-substituted and aryl group-substituted products.

- these divalent organic groups may contain an atomic group containing an element other than carbon and hydrogen atoms, and include a polyether bond, a polyester bond, a polyamide bond, a polycarbonate bond, and a group represented by the above formula (1). Can also be included.

- R e is an (n + 1) valent organic group, preferably selected from a chain, branched or cyclic saturated hydrocarbon group and unsaturated hydrocarbon group.

- Y ′ represents a monovalent organic group having a reactive functional group.

- the reactive functional group itself as described above may be used.

- the reactive functional group is selected from a polymerizable unsaturated group, (meth) acryloyl (oxy) group, vinyl (oxy) group, propenyl (oxy) group, butadienyl (oxy) group, styryl (oxy) group, Examples include ethynyl (oxy) group, cinnamoyl (oxy) group, maleate group, (meth) acrylamide group and the like.

- N is preferably a positive integer of 1 to 20, more preferably 1 to 10, and particularly preferably 1 to 5.

- the method described in JP-A-9-100111 can be used. That is, for example, when it is desired to introduce a polymerizable unsaturated group, (A) an addition reaction between a mercaptoalkoxysilane, a polyisocyanate compound, and an active hydrogen group-containing polymerizable unsaturated compound capable of reacting with an isocyanate group is performed. it can. Moreover, it can carry out by (B) direct reaction with the compound which has an alkoxy silyl group and an isocyanate group in a molecule

- the reactive deformed silica fine particles of (ii) after separately hydrolyzing the reactive functional group-modified hydrolyzable silane, this is mixed with the deformed silica fine particles, followed by heating and stirring operation, Alternatively, a method of hydrolyzing a reactive functional group-modified hydrolyzable silane in the presence of deformed silica fine particles, and other components such as polyunsaturated organic compounds, monounsaturated organic compounds, radiation polymerization initiators, etc.

- the method of performing the surface treatment of the deformed silica fine particles in the presence of can be selected, a method of hydrolyzing the reactive functional group-modified hydrolyzable silane in the presence of the deformed silica fine particles is preferable.

- the temperature is usually 20 ° C. or higher and 150 ° C. or lower, and the treatment time is in the range of 5 minutes to 24 hours.

- an acid, salt or base may be added as a catalyst.

- the acid include organic acids and unsaturated organic acids

- examples of the base include tertiary amines or quaternary ammonium hydroxides.

- the addition amount of these acid or base catalysts is within the range of 0.001% by mass to 1.0% by mass, preferably 0.01% by mass to 0.1% by mass with respect to the reactive functional group-modified hydrolyzable silane. Within range.

- powdery fine particles not containing a dispersion medium may be used.

- the hard coat layer may include not only those in which the reactive functional group of the reactive irregular shaped silica fine particles has reacted but also those in which the reactive functional group of the reactive irregular shaped silica fine particles has not reacted.

- the content of the reactive irregularly shaped silica fine particles is preferably in the range of 40% by mass to 70% by mass, and in the range of 50% by mass to 60% by mass with respect to the total solid content of the curable resin composition. It is more preferable.

- the content is small, there is a possibility that sufficient hardness cannot be imparted to the hard coat layer.

- the content is large, the filling rate is excessively increased, the adhesion between the reactive irregularly shaped silica fine particles and the monomer is deteriorated, and the hardness of the hard coat layer may be lowered.

- solid content means things other than a solvent among the components contained in curable resin composition.

- the acrylic polymer used in the present invention has a weight average molecular weight and an acrylic equivalent within predetermined ranges, and is a component that contributes to improving the workability of the hard coat film.

- the weight average molecular weight of the acrylic polymer is in the range of 30,000 to 110,000, particularly in the range of 50,000 to 110,000, from the viewpoint of imparting flexibility to the hard coat layer and preventing cracks during processing. It is preferably within the range of 60,000 to 80,000.

- the weight average molecular weight refers to a weight average molecular weight which is a polystyrene conversion value measured by gel permeation chromatography.

- the acrylic polymer has an acrylic equivalent in the range of 200 to 1,200, and preferably in the range of 200 to 1,000.

- the acrylic equivalent indicates a value obtained by dividing the weight average molecular weight of the acrylic polymer by the number of (meth) acrylic groups in one molecule.

- the acrylic polymer is not particularly limited as long as it satisfies the above weight average molecular weight and acrylic equivalent, but it is a polymer of glycerol (meth) acrylate or a compound of a compound obtained by addition polymerization of (meth) acrylic acid to glycidyl methacrylate. It is preferably a coalescence. Specifically, a polymer of an acrylic monomer represented by the following chemical formula (4) or (5) is preferably used.

- R 1 to R 3 are each independently an acrylate group, a methacrylate group or a hydrogen atom, and one or more of R 1 to R 3 are an acrylate group or a methacrylate group. That is, the glycerol (meth) acrylate represented by the above formula (4) may be monofunctional, bifunctional, or trifunctional.

- R is an acrylic acid group or a methacrylic acid group.

- acrylic polymer is BL-2002 manufactured by Seiko PMC Co., Ltd.

- acrylic polymer you may use individually by 1 type, and may mix and use 2 or more types suitably.

- the content of the acrylic polymer is preferably in the range of 3% by mass to 20% by mass, more preferably in the range of 5% by mass to 10% by mass, based on the total solid content of the curable resin composition. More preferably, it is in the range of 6% by mass to 8% by mass. If the content of the acrylic polymer is within the above range, the workability of the hard coat film can be improved while maintaining the hardness of the hard coat layer.

- the content of the acrylic polymer can be set in the range of 5 to 80 parts by weight with respect to 100 parts by weight of the monomer described later, and is in the range of 20 to 40 parts by weight. Preferably, it is in the range of 10 to 30 parts by weight.

- a monomer is a component used as the matrix resin of a hard-coat layer.

- the monomer usually has a reactive functional group.

- Monomers crosslink between monomers when cured.

- the reactive functional group of the monomer has cross-linking reactivity with the reactive functional group of the reactive irregularly shaped silica fine particles, the monomer is crosslinked with the reactive irregularly shaped silica fine particles, forming a network structure, and the hardness of the hard coat layer And further improve the scratch resistance.

- a polymerizable unsaturated group is suitably used, preferably a photocurable unsaturated group, and particularly preferably an ionizing radiation curable unsaturated group.

- the reactive functional group of the monomer may be the same as or different from the reactive functional group of the reactive deformed silica fine particle.

- a curable organic resin is preferable, and a translucent material that transmits light when it is used as a coating film is preferable.

- An ionizing radiation curable resin that is a resin that is cured by ionizing radiation represented by ultraviolet rays or electron beams, Other known curable resins and the like may be appropriately employed according to required performance.

- the ionizing radiation curable resin include acrylate-based, oxetane-based, and silicone-based resins.

- the monomer one type or two or more types of monomers can be used.

- the monomer preferably has three or more reactive functional groups from the viewpoint of increasing the crosslinking density.

- the polyfunctional monomer having three or more reactive functional groups include pentaerythritol tri (meth) acrylate, pentaerythritol tetra (meth) acrylate, dipentaerythritol hexa (meth) acrylate, and dipentaerythritol penta (meth) acrylate. , Trimethylolpropane tri (meth) acrylate, trimethylolpropane hexa (meth) acrylate, and modified products thereof.

- pentaerythritol triacrylate, pentaerythritol tetra (meth) acrylate, dipentaerythritol hexaacrylate, pentaerythritol tetraacrylate, and dipentaerythritol pentaacrylate are preferably used, and dipentaerythritol hexaacrylate, penta Erythritol tetraacrylate and dipentaerythritol pentaacrylate are particularly preferably used.

- the hard coat layer may contain not only a monomer that is crosslinked but also a monomer that is not crosslinked.

- the monomer content is preferably in the range of 25% by mass to 44% by mass and more preferably in the range of 30% by mass to 40% by mass with respect to the total solid content of the curable resin composition. .

- the content is small, there is a possibility that sufficient hardness cannot be imparted to the hard coat layer.

- the content is large, the hardness of the hard coat layer is excessively increased, and the content of the acrylic polymer is relatively decreased, which may deteriorate the workability of the hard coat film.

- the curable resin composition may contain a polymerization initiator.

- a polymerization initiator is used when the curable resin composition is cured by ultraviolet irradiation or heating, but when it is cured by electron beam irradiation, a polymerization initiator is unnecessary.

- the polymerization initiator is decomposed by at least one of light and heat to generate radicals or cations to advance radical polymerization and cationic polymerization.

- radical polymerization initiators, cationic polymerization initiators, radicals and cationic polymerization initiators can be appropriately selected and used.

- the radical polymerization initiator only needs to be capable of releasing a substance that initiates radical polymerization by at least one of light and heat.

- photo radical polymerization initiators include imidazole derivatives, bisimidazole derivatives, N-aryl glycine derivatives, organic azide compounds, titanocenes, aluminate complexes, organic peroxides, N-alkoxypyridinium salts, thioxanthone derivatives, and the like. It is done. Specific examples include those described in JP 2010-102123 A and JP 2010-120182 A.

- the cationic polymerization initiator should just be able to discharge

- the cationic polymerization initiator include sulfonic acid ester, imide sulfonate, dialkyl-4-hydroxysulfonium salt, arylsulfonic acid-p-nitrobenzyl ester, silanol-aluminum complex, ( ⁇ 6 -benzene) ( ⁇ 5 -cyclopentadidiene).

- radical polymerization initiators and cationic polymerization initiators examples include aromatic iodonium salts, aromatic sulfonium salts, aromatic diazonium salts, aromatic phosphonium salts, triazine compounds, and iron arene complexes. Specific examples include those described in JP 2010-102123 A and JP 2010-120182 A.

- the polymerization initiator preferably has a relatively low absorption rate in the visible light region. This is because if the absorption rate in the visible light region is high, the light transmittance of the hard coat film may be lowered.

- the content of the polymerization initiator is preferably in the range of 2% by mass to 5% by mass with respect to the total solid content of the curable resin composition, and is preferably in the range of 2% by mass to 2.5% by mass. It is more preferable. If the content is small, the polymerization reaction of monomers or the like does not proceed sufficiently, and there is a possibility that sufficient hardness cannot be imparted to the hard coat layer. Moreover, when there is much content, polymerization reaction, such as a monomer, advances rapidly, and there exists a possibility that workability

- the curable resin composition used in the present invention may further contain a surfactant.

- the surfactant is a component that imparts coating stability, slipperiness, antifouling properties, and scratch resistance.

- examples of the surfactant include a fluorine-based surfactant, a silicon-based surfactant, and a fluorine-silicon-based surfactant. Of these, a fluorosilicone surfactant is preferably used because of its good slipperiness.

- surfactant a commercially available one can be used, and for example, leveling agents described in JP 2010-102123 A and JP 2010-120182 A can be used.

- fluorosilicone surfactant examples include a compound having a perfluoroalkyl group and a siloxane bond. Specifically, a compound having a perfluoroalkyl group and a copolymer of siloxane and polyether. Is mentioned.

- the perfluoroalkyl group has, for example, 4 to 10 carbon atoms.

- the perfluoroalkyl group may be linear or branched.

- the polyether group include a polyethylene oxide chain, a polypropylene oxide chain, and a copolymer thereof.

- fluorine silicon surfactants include compounds represented by the following chemical formula (6).

- R is a perfluoroalkyl group having 4 to 10 carbon atoms

- Q is a polyethylene oxide chain or a polypropylene oxide chain

- k and m are each 0 or 1

- n is 1, 2 or 3 It is.

- the fluorosilicone surfactant may have a reactive functional group.

- a reactive functional group for example, a polymerizable unsaturated group is used, specifically a photocurable unsaturated group, and more specifically an ionizing radiation curable unsaturated group.

- Specific examples of the reactive functional group include a (meth) acryloyl group.

- fluorosilicone surfactant examples include X-71-1203M, X-70-090, X-70-091, X-70-092, X-70-093, manufactured by Shin-Etsu Chemical Co., Ltd., DIC Corporation. Examples thereof include Megafac R-08, XRB-4, and the like.

- the hard coat layer has good surface wettability so that the antiglare layer can be formed on the hard coat layer. It is preferable to use a surfactant capable of obtaining Such a surfactant can be appropriately selected from the above and used.

- the content of the surfactant is preferably 0.2% by mass or less, and preferably in the range of 0.08% by mass to 0.1% by mass with respect to the total solid content of the curable resin composition. More preferred.

- the curable resin composition used in the present invention may further contain a blue color material. This is because when the hard coat film of the present invention is used in an image display device, yellowness can be suppressed and visibility and color reproducibility can be improved.

- a blue color material general pigments and dyes can be used. Specific examples include phthalocyanine pigments and indanthrene blue pigments.

- the content of the blue color material may be an amount such that the transmittance of the hard coat layer described later is 85% or more, and preferably 90% or more, and is appropriately adjusted. For example, the content of the blue color material is preferably 0.05% by mass or less with respect to the total solid content of the curable resin composition.

- the curable resin composition used in the present invention may further contain urethane acrylate. This is because by adding urethane acrylate, flexibility can be imparted to the hard coat layer and the occurrence of warpage can be suppressed.

- urethane acrylate flexibility can be imparted to the hard coat layer and the occurrence of warpage can be suppressed.

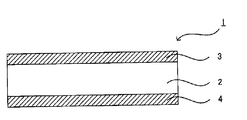

- a curable resin composition to which urethane acrylate is added is used. By forming the hard coat layer 3 and the second hard coat layer 4, it is possible to further suppress the occurrence of warping and improve the impact resistance.

- urethane acrylate for example, a general urethane acrylate used for a hard coat layer can be used. Specific examples include those described in JP 2011-31527 A, JP 2009-84328 A, and International Publication No. 2012/8444.

- the content of urethane acrylate may be an amount such that the pencil hardness of the hard coat layer, which will be described later, falls within a predetermined range, and is appropriately adjusted.

- the content of urethane acrylate can be set within the range of 4 to 100 parts by weight with respect to 100 parts by weight of the monomer.

- the curable resin composition used in the present invention usually contains a solvent.

- the solvent is not particularly limited, but a non-permeable solvent is preferable from the viewpoint of increasing the hardness of the hard coat film.

- permeation refers to dissolving or swelling the substrate.

- Specific examples of the non-permeable solvent include methyl isobutyl ketone, propylene glycol monomethyl ether, normal propanol, isopropanol, normal butanol, sec-butanol, isobutanol, and tert-butanol.

- the curable resin composition used for this invention may contain the antistatic agent, the glare-proof agent, various sensitizers, etc. as needed.

- Curable resin composition The curable resin composition is prepared by mixing a dispersion of reactive irregularly shaped silica fine particles, an acrylic polymer, a monomer, a polymerization initiator and the like in a solvent according to a general preparation method, and dispersing the mixture. Can do. For mixing and dispersing, a paint shaker or a bead mill can be used.

- the deformed silica fine particles contained in the hard coat layer in the present invention are obtained by crosslinking the reactive deformed silica fine particles contained in the curable resin composition, or the reactive deformed silica fine particles It is formed by crosslinking with monomers. That is, the hard coat layer contains cross-linked irregular-shaped silica fine particles or irregular-shaped silica fine particles crosslinked with the matrix resin.

- the hard coat layer includes not only the reactive functional group of the reactive irregular shaped silica fine particles reacted but also the reactive functional group of the reactive irregular shaped silica fine particles not reacting as the irregular shaped silica fine particles. It may be.

- the content of the irregular shaped silica fine particles in the hard coat layer can be the same as the content of the reactive irregular shaped silica fine particles in the total solid content of the curable resin composition.

- Acrylic polymer The acrylic polymer contained in the hard coat layer in the present invention has a weight average molecular weight and an acrylic equivalent within predetermined ranges.

- description here is abbreviate

- the content of the acrylic polymer in the hard coat layer can be the same as the content of the acrylic polymer in the total solid content of the curable resin composition.

- the matrix resin contained in the hard coat layer in the present invention is a resin forming a composite with irregular-shaped silica fine particles and an acrylic polymer. It is considered that the hardness and scratch resistance of the hard coat layer are increased by forming a three-dimensional network structure with the matrix resin, the deformed silica fine particles, and the acrylic polymer.

- Such a matrix resin examples include acrylic resin, silicone resin, and polyether.

- acrylic resin is preferable. This is because the properties of the hard coat layer are improved because of its high affinity with the acrylic polymer.

- the matrix resin is preferably formed by crosslinking of monomers contained in the curable resin composition, or by crosslinking of the monomer with reactive deformed silica fine particles. That is, the hard coat layer preferably contains a matrix resin having a cross-linked bond or a matrix resin cross-linked with irregular shaped silica fine particles.

- the matrix resin is preferably a polymer having a structural unit derived from a monomer.

- matrix resins are polymers having structural units derived from hydroxy group-containing monomers such as pentaerythritol, dipentaerythritol, and trimethylolpropane.

- the structural unit is preferably a structural unit derived from a monomer of pentaerythritol.

- structures such as pentaerythritol trimethyl ether and pentaerythritol tetramethyl ether, dipentaerythritol hexamethyl ether, and dipentaerythritol pentamethyl ether can be given as the similar skeleton.

- the content of the matrix resin in the hard coat layer can be the same as the content of the monomer in the total solid content of the curable resin composition.

- the hard coat layer in the present invention may contain a polymerization initiator.

- a polymerization initiator since it is the same as that of the polymerization initiator contained in the said curable resin composition, description here is abbreviate

- the content of the polymerization initiator in the hard coat layer can be the same as the content of the polymerization initiator in the total solid content of the curable resin composition.

- the hard coat layer in the present invention may contain a surfactant.

- surfactant since it is the same as that of surfactant contained in the said curable resin composition, description here is abbreviate

- the content of the surfactant in the hard coat layer can be the same as the content of the surfactant in the total solid content of the curable resin composition.

- Blue color material The hard coat layer in the present invention may contain a blue color material.

- a blue color material since it is the same as that of the blue color material contained in the said curable resin composition, description here is abbreviate

- the content of the blue color material in the hard coat layer can be the same as the content of the blue color material in the total solid content of the curable resin composition.

- the hard coat layer in the invention may contain urethane acrylate.

- urethane acrylate since it is the same as that of the urethane acrylate contained in the said curable resin composition about urethane acrylate, description here is abbreviate

- the urethane acrylate content in the hard coat layer can be the same as the urethane acrylate content in the curable resin composition.

- the hardness of the hard coat layer can be evaluated by a pencil hardness test (4.9 N load) specified by JIS K5600-5-4 (1999).

- the pencil hardness of the hard coat layer is preferably 6H or more, more preferably 7H or more, and particularly preferably 9H or more.

- the hard coat layer is light transmissive.

- the transmittance of the hard coat layer in the visible light region is preferably 80% or more, and more preferably 90% or more. This is because when the transmittance is in the above range, a hard coat layer having excellent light transmittance can be formed.

- the transmittance of the hard coat layer is the total light transmittance measured by the method defined in JIS K 7105.

- the haze value of the hard coat layer is appropriately determined according to the type of reactive irregularly shaped silica fine particles and is not particularly limited. For example, it is 1.0 or less, particularly 0.8 or less, particularly 0. .5 or less is preferable. It is because it can be set as the hard-coat layer with favorable light transmittance because haze value is the said range.

- the haze value can be measured by a method according to JIS-K-7136. For example, it can be measured with a direct reading haze meter manufactured by Toyo Seiki Seisakusho using a semi-integrating sphere.

- the haze value can also be measured by a method according to JIS K-7105, for example, a haze meter HM150 manufactured by Murakami Color Research Laboratory.

- the hard coat layer preferably has antifouling properties.

- the antifouling property can be evaluated by wettability.

- the wettability of the hard coat layer surface is appropriately determined according to the components used in the curable resin composition, and is not particularly limited.

- the contact angle of water droplets on the hard coat layer surface is preferably 90 ° or more, more preferably 100 ° or more, and even more preferably 110 ° or more. This is because if the wettability is as described above, the hard coat layer can exhibit good antifouling properties.

- the contact angle of the water droplet is usually 120 ° or less. The contact angle of the water droplet is obtained by measuring the contact angle with water 30 seconds after dropping the water droplet from the microsyringe using a contact angle measuring device CA-Z type manufactured by Kyowa Interface Science Co., Ltd. be able to.

- a hard coat layer has slipperiness.

- the slipperiness can be evaluated by a dynamic friction coefficient. The smaller the dynamic friction coefficient, the better the slipperiness.

- the coefficient of dynamic friction on the surface of the hard coat layer is, for example, 0.300 or less, preferably 0.200 or less, and more preferably 0.100 or less. This is because if the dynamic friction coefficient is too large, it may be difficult to perform a good touch operation on the surface of the hard coat layer.

- the dynamic friction coefficient can be measured by a method in accordance with JIS K7125. For example, a dynamic friction tester HEIDON Type HHS2000 manufactured by Shinto Kagaku Co., Ltd. is used, a stainless hard ball having a diameter of 10 mm, a load of 200 g, and a speed. The dynamic friction coefficient can be measured at 5 mm / sec.

- the thickness of the hard coat layer is not particularly limited as long as the desired hardness and workability can be exhibited.

- the thickness can be about 5 ⁇ m to 40 ⁇ m, and particularly within the range of 10 ⁇ m to 30 ⁇ m. In particular, it is preferably in the range of 18 ⁇ m to 22 ⁇ m. This is because if the hard coat layer is thin, sufficient hardness cannot be exhibited, and if it is thick, cracks and warpage may occur.

- the method for forming the hard coat layer is not particularly limited as long as the hard coat layer can be formed using the curable resin composition, and the curable resin composition is applied onto the substrate, A method of curing the coating film can be used.

- the coating method of the curable resin composition is not particularly limited as long as the curable resin composition can be uniformly coated on the substrate, and is not limited to spin coating, dipping, spraying, slide coating.

- Various methods such as a method, a bar coat method, a roll coater method, a meniscus coater method, a flexographic printing method, a screen printing method, and a speed coater method can be used.

- substrate so that the hard-coat layer of a desired film thickness may be obtained.

- the method for drying the coating film include reduced-pressure drying, heat drying, and combinations thereof. When drying at normal pressure, it is preferable to dry in a temperature range in which the substrate does not deteriorate, for example, in the range of 30 ° C. to 110 ° C.

- At least one of light irradiation and heating can be used.

- light irradiation ultraviolet rays, visible light, electron beams, ionizing radiation, etc. are mainly used, and among these, ultraviolet rays are preferably used.

- ultraviolet curing ultraviolet rays emitted from light such as an ultra high pressure mercury lamp, a high pressure mercury lamp, a low pressure mercury lamp, a carbon arc, a xenon arc, a metal halide lamp are used.

- the amount of irradiation with the energy radiation source of accumulative exposure at an ultraviolet wavelength of 365 nm is preferably in the range of, for example, 50mJ / cm 2 ⁇ 5000mJ / cm 2.

- it is preferable to heat in a temperature range in which the substrate does not deteriorate for example, in the range of 40 ° C. to 120 ° C.

- substrate used in the present invention is not particularly limited as long as it has optical transparency and satisfies physical properties that can be used as a substrate for a hard coat film.

- the substrate used for the hard coat film may be transparent, translucent, colorless or colored, but is required to have light transmittance.

- Examples of the material for the substrate include acrylate polymers, polycarbonates, polyesters, cellulose acylates, cycloolefin polymers, and the like.

- Specific examples of the acrylate polymer include methyl poly (meth) acrylate, poly (meth) ethyl acrylate, methyl (meth) acrylate-butyl (meth) acrylate, and the like.

- Specific examples of the polycarbonate include aromatic polycarbonates based on bisphenols such as bisphenol A, and aliphatic polycarbonates such as diethylene glycol bisallyl carbonate.

- Specific examples of the polyester include polyethylene terephthalate and polyethylene naphthalate.

- cellulose acylate examples include cellulose triacetate, cellulose diacetate, and cellulose acetate butyrate.

- cycloolefin polymer examples include norbornene polymers, monocyclic olefin polymers, cyclic conjugated diene polymers, vinyl alicyclic hydrocarbon polymer resins, and the like.

- the substrate may be a single layer or a laminate of a plurality of layers.

- the substrate material is preferably an acrylate polymer, more preferably polymethyl methacrylate. This is because the transparency is high.

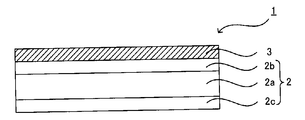

- the substrate in the case of a plurality of layers, has a plurality of resin layers.

- the number of resin layers may be two or more, preferably in the range of 3 to 5 layers, more preferably 3 layers.

- the outermost two layers are the outermost resin layers and the innermost resin layer is the innermost resin layer.

- the two outermost resin layers 2b and 2c are defined as the two outermost resin layers 2b and 2c

- the layer located inside 2c is referred to as an inner resin layer 2a.

- the inner resin layer 2a may be a single layer or a plurality of layers.

- the pencil hardness of the two outermost resin layers positioned on both sides of the substrate is higher than the pencil hardness of the inner resin layer.

- the difference in hardness between the outermost resin layer and the inner resin layer is preferably two or more steps, more preferably three or more steps, on the basis of pencil hardness.

- the pencil hardness of the outermost resin layer is preferably HB or higher, and more preferably H or higher and 5H or lower.

- the pencil hardness of the inner resin layer is preferably H or less, for example, and more preferably 3B or more and HB or less.

- the pencil hardness of the substrate is preferably 2H or more, and more preferably 3H or more. This is because the hardness of the hard coat film can be further improved.

- the pencil hardness of the substrate is preferably high, but is usually 4H or less.

- the pencil hardness of the substrate is preferably 2H or more.

- the inner resin layer 2a is polycarbonate

- the two outermost resin layers 2b and 2c are acrylate polymers. Is preferred. This is because the impact resistance is improved.

- the thickness of one outermost resin layer is preferably in the range of 60 ⁇ m to 110 ⁇ m.

- the substrate may contain a blue color material.

- a blue color material instead of adding a blue color material to the hard coat layer, a hard coat film capable of suppressing yellowishness and improving visibility and color reproducibility when used in an image display device is obtained by adding to a substrate. be able to.

- a blue color material it can be the same as that of what was described in the said hard-coat layer.

- the substrate transmits more light.

- the total light transmittance in the visible light region is preferably 80% or more, and more preferably 90% or more.

- the total light transmittance is a value measured by the method defined in JIS K 7105.

- the substrate may or may not have flexibility.

- the thickness of the substrate is not particularly limited, but in the case of a substrate that does not have flexibility, it is preferably 0.3 mm or more, more preferably in the range of 0.3 mm to 5 mm. . It is because sufficient impact resistance can be maintained within the above range.

- the thickness of the substrate varies depending on the material, configuration, etc., but can be set within a range of 10 ⁇ m to 500 ⁇ m, for example.

- the substrate may be subjected to surface treatment such as saponification treatment, glow discharge treatment, corona discharge treatment, ultraviolet treatment, flame treatment and the like.

- the second hard coat layer 4 may be formed on the surface of the substrate 2 opposite to the surface on which the hard coat layer 3 is formed. . By forming the second hard coat layer, the hardness of the hard coat film can be further improved.

- the curable resin composition used for the second hard coat layer is the same as the curable resin composition used for the hard coat layer. Especially, it is preferable that the curable resin composition used for a 2nd hard-coat layer contains urethane acrylate. In this case, it is preferable that the curable resin composition used for the hard coat layer also contains urethane acrylate. As described above, by adding urethane acrylate, flexibility can be imparted to the hard coat layer and the second hard coat layer, occurrence of warpage can be suppressed, and impact resistance can be improved. Because.

- the curable resin composition used for the second hard coat layer may be the same as or different from the curable resin composition used for the hard coat layer. Especially, it is preferable that the curable resin composition used for a 2nd hard-coat layer is the same as the curable resin composition used for the said hard-coat layer. This is because warpage can be further suppressed.

- the thickness of the second hard coat layer is the same as the thickness of the hard coat layer.

- the thickness of the second hard coat layer may be the same as or different from the thickness of the hard coat layer.

- it is preferable that the thickness of a 2nd hard-coat layer is the same as the thickness of the said hard-coat layer. It is because generation

- the characteristics and formation method of the second hard coat layer are the same as those of the hard coat layer.

- the antiglare layer 5 may be formed on the hard coat layer 3 as illustrated in FIG.

- the antiglare layer reflection of light on the surface of the hard coat film of the present invention can be suppressed, and when the hard coat film of the present invention is used for an image display device, it reflects external light. Can suppress glare and glare.

- the hard coat layer in the present invention is excellent in hardness, high hardness can be achieved even when an antiglare layer is formed on the hard coat layer.

- the antiglare layer is not particularly limited as long as it has an antiglare property, but among them, a layer containing a resin and fine particles is preferable. Antiglare property can be exhibited by forming irregularities on the surface of the antiglare layer by the fine particles.

- the fine particles are not particularly limited as long as they exhibit antiglare properties, but are preferably translucent fine particles.

- the fine particles both inorganic and organic can be used.

- the inorganic fine particles include amorphous silica particles and inorganic silica particles.

- the organic fine particles include plastic beads, and specific examples include polystyrene beads, melamine resin beads, acrylic beads, acrylic-styrene beads, benzoguanamine beads, benzoguanamine formaldehyde condensation beads, polycarbonate beads, polyethylene beads, and the like.

- the plastic beads preferably have a hydrophobic group on the surface, and examples thereof include styrene beads.

- the fine particles may be used alone or in combination of two or more.

- the fine particles may be primary particles or secondary particles.

- inorganic fine particles are preferably used from the viewpoint of improving the film strength of the antiglare layer, and silica fine particles are particularly preferably used.

- silica fine particles are particularly preferably used.