WO2014087516A1 - Method for producing steel sheet - Google Patents

Method for producing steel sheet Download PDFInfo

- Publication number

- WO2014087516A1 WO2014087516A1 PCT/JP2012/081634 JP2012081634W WO2014087516A1 WO 2014087516 A1 WO2014087516 A1 WO 2014087516A1 JP 2012081634 W JP2012081634 W JP 2012081634W WO 2014087516 A1 WO2014087516 A1 WO 2014087516A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- steel sheet

- hot

- rolled steel

- cooling

- temperature

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B1/00—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations

- B21B1/22—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling plates, strips, bands or sheets of indefinite length

- B21B1/24—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling plates, strips, bands or sheets of indefinite length in a continuous or semi-continuous process

- B21B1/26—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling plates, strips, bands or sheets of indefinite length in a continuous or semi-continuous process by hot-rolling, e.g. Steckel hot mill

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/28—Control of flatness or profile during rolling of strip, sheets or plates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/16—Control of thickness, width, diameter or other transverse dimensions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B37/00—Control devices or methods specially adapted for metal-rolling mills or the work produced thereby

- B21B37/74—Temperature control, e.g. by cooling or heating the rolls or the product

- B21B37/76—Cooling control on the run-out table

Definitions

- the present invention relates to a steel plate manufacturing method.

- FIG. 19 is a diagram schematically showing a conventional method for producing a hot-rolled steel sheet.

- a slab S obtained by continuously casting a molten steel adjusted to a predetermined composition is rolled with a roughing mill 101, and then finished with a plurality of rolling stands 102a to 102d.

- Hot rolling is performed by the rolling mill 103 to form a hot-rolled steel sheet H having a predetermined thickness.

- this hot-rolled steel sheet H is cooled by the cooling water poured from the cooling device 111, it is wound up by the winding device 112 in a coil shape.

- the cooling device 111 is a facility for performing so-called laminar cooling on the hot-rolled steel sheet H that is generally conveyed from the finish rolling mill 103.

- the cooling device 111 injects cooling water as jet water from above in the vertical direction to the upper surface of the hot-rolled steel sheet H moving on the run-out table, and also to the lower surface of the hot-rolled steel sheet H. Then, the hot-rolled steel sheet H is cooled by injecting cooling water as jet water through the pipe laminator.

- Patent Document 1 discloses a technique for preventing a shape defect of a steel plate by reducing a difference in surface temperature between the upper and lower surfaces of the thick steel plate. According to the technique disclosed in Patent Document 1, based on the surface temperature difference obtained by simultaneously measuring the surface temperature of the upper and lower surfaces of the steel sheet with a thermometer during cooling by the cooling device, the upper and lower surfaces of the steel sheet Adjust the ratio of the amount of cooling water supplied to the.

- Patent Document 2 a steepness meter installed on the exit side of a rolling mill is used to measure the steepness of the steel sheet tip, and the cooling water flow rate is adjusted in the width direction according to the measured steepness.

- a technique for preventing perforation of a steel sheet is disclosed.

- the object is to eliminate the wavy plate thickness distribution in the plate width direction of the hot-rolled steel plate, and to uniformize the plate thickness in the plate width direction, in the plate width direction of the hot-rolled steel plate.

- a technique for controlling the difference between the maximum heat transfer coefficient and the minimum heat transfer coefficient to fall within a predetermined value range is disclosed.

- Japanese Unexamined Patent Publication No. 2005-74463 Japanese Patent Application Laid-Open No. 2005-271052 Japanese Unexamined Patent Publication No. 2003-48003

- the hot-rolled steel sheet H manufactured by the conventional manufacturing method described with reference to FIG. 19 is, for example, as shown in FIG. 20, a run-out table (hereinafter, referred to as “ROT”) in the cooling device 111.

- ROT run-out table

- the material that is, the hardness of the steel plate

- the temperature unevenness varies due to the temperature unevenness.

- Patent Document 1 does not consider the case where the hot-rolled steel sheet has a wave shape in the rolling direction. That is, in patent document 1, since surface height changes with the wave positions of a hot-rolled steel plate, it does not consider that the standard deviation of temperature differs in a rolling direction. Therefore, in the cooling method of patent document 1, it was not considered that the variation of a material generate

- Patent Document 3 since the cooling of Patent Document 3 is the cooling of a hot-rolled steel sheet immediately before a finish rolling mill roll bite, it cannot be applied to a hot-rolled steel sheet having a predetermined thickness after finish rolling. Furthermore, Patent Document 3 does not consider the case where the corrugation is formed in the rolling direction of the hot-rolled steel sheet, and as described above, due to the corrugation formed on the hot-rolled steel sheet, The occurrence of material variations was not taken into account.

- the present invention has been made in view of the above-described problems, and an object of the present invention is to provide a steel sheet manufacturing method capable of improving the yield of a steel sheet manufactured through at least a hot rolling process and a cooling process.

- a method of manufacturing a steel sheet according to an aspect of the present invention includes a hot-rolled steel sheet in which an ear-wave shape whose wave height varies periodically in the rolling direction is formed by hot-rolling a steel material with a finish rolling mill.

- a hot rolling step to obtain; and a cooling step for cooling the hot-rolled steel sheet in a cooling section provided on the sheet passing path, and the hot rolling step has been experimentally obtained in advance.

- the target steepness of the ear-wave shape Based on the first correlation data showing the correlation between the steepness of the ear-wave shape of the hot-rolled steel plate and the temperature standard deviation Y during or after cooling of the hot-rolled steel plate, the target steepness of the ear-wave shape And a shape control step for controlling the operating parameters of the finishing mill so that the steepness of the ear wave shape matches the target steepness.

- the target steepness in the target steepness setting step, may be set to more than 0% and within 1%.

- the cooling step is experimentally determined in advance under a condition in which the steepness and the sheet passing speed of the hot-rolled steel sheet are constant values.

- the second correlation showing the correlation between the upper and lower heat transfer coefficient ratio X, which is the ratio of the heat transfer coefficients of the upper and lower surfaces of the hot rolled steel sheet, and the temperature standard deviation Y during or after cooling the hot rolled steel sheet

- a cooling control step of controlling at least one of the upper surface cooling heat removal amount and the lower surface cooling heat removal amount of the hot-rolled steel sheet in the cooling section so as to coincide with the target ratio Xt.

- the temperature standard deviation Y is within a range from the minimum value Ymin to the minimum value Ymin + 10 ° C. based on the second correlation data.

- the upper and lower heat transfer coefficient ratio X that fits may be set as the target ratio Xt.

- the second correlation data is prepared for each of a plurality of conditions having different values of the steepness and the plate passing speed

- the target ratio setting In the step, the target ratio Xt may be set based on second correlation data corresponding to the measured values of the steepness and the plate passing speed among the plurality of second correlation data.

- the second correlation data may be data indicating a correlation between the upper and lower heat transfer coefficient ratio X and the temperature standard deviation Y by a regression equation. good.

- the regression equation may be derived by linear regression.

- the second correlation data may be data indicating a correlation between the upper and lower heat transfer coefficient ratio X and the temperature standard deviation Y in a table. .

- a cooling heat removal amount adjustment step of adjusting a total value with the heat removal amount.

- the cooling section is divided into a plurality of divided cooling sections along a plate-passing direction of the hot-rolled steel sheet, and the temperature measurement step and the fluctuation speed are divided.

- the measurement step the temperature and the fluctuation rate of the hot-rolled steel sheet are measured in time series at each boundary of the divided cooling section, and in the control direction determining step, the hot-rolled steel sheet at each boundary of the divided cooling section Based on the measurement results of the temperature and the fluctuation rate of the above, the direction of increase or decrease of the cooling heat removal amount of the upper and lower surfaces of the hot-rolled steel sheet is determined for each of the divided cooling sections, and in the cooling heat removal amount adjustment step, Based on the control direction determined for each, at least one of the upper surface cooling heat removal amount and the lower surface cooling heat removal amount of the hot-rolled steel sheet in each of the divided cooling sections. It may be performed feedback control or feed forward control to adjust the.

- the sheet passing speed of the hot-rolled steel sheet in the cooling section may be set in a range from 550 m / min or more to a mechanical limit speed or less.

- the hot-rolled steel sheet may have a tensile strength of 800 MPa or more.

- the finish rolling mill is configured by a plurality of rolling stands, and auxiliary cooling is performed to perform auxiliary cooling of the hot-rolled steel sheets between the plurality of rolling stands. You may have the process further.

- the cooling section includes an upper cooling device having a plurality of headers for injecting cooling water onto the upper surface of the hot-rolled steel plate, and a lower surface of the hot-rolled steel plate.

- a lower cooling device having a plurality of headers for injecting cooling water is provided, and the upper surface cooling heat removal amount and the lower surface cooling heat removal amount may be adjusted by on / off controlling the headers.

- the cooling section includes an upper cooling device having a plurality of headers for injecting cooling water onto the upper surface of the hot-rolled steel plate, and a lower surface of the hot-rolled steel plate.

- a lower cooling device having a plurality of headers for injecting cooling water, wherein the upper surface cooling heat removal amount and the lower surface cooling heat removal amount control at least one of the water amount density, pressure and water temperature of each header. It may be adjusted by doing.

- the cooling in the cooling section may be performed in a range where the temperature of the hot-rolled steel sheet is 600 ° C. or higher.

- the inventor of the present application conducted an extensive investigation on the relationship between the wave shape formed on the hot-rolled steel sheet obtained from the hot rolling process and the temperature standard deviation during or after cooling the hot-rolled steel sheet. It has been found that when the wave shape is controlled to an ear wave shape, the temperature standard deviation of the hot-rolled steel sheet can be controlled to an arbitrary value according to the steepness of the ear wave shape. That is, according to the present invention, in the hot rolling process, the experimentally obtained in advance the steepness of the ear wave shape of the hot-rolled steel sheet and the temperature standard deviation Y during or after cooling of the hot-rolled steel sheet.

- the target steepness of the ear wave shape is set, and finish rolling is performed so that the steepness of the ear wave shape formed on the hot-rolled steel sheet matches the target steepness.

- the temperature standard deviation of the hot-rolled steel sheet after cooling can be kept small (the hot-rolled steel sheet can be uniformly cooled).

- the yield can be improved by suppressing fluctuations in the thickness of the steel sheet finally obtained through the cold rolling process, which is a subsequent process. Can be realized.

- FIG. 1 shows the hot rolling equipment 1 for implement

- It is explanatory drawing which shows the outline of a structure of the cooling device 14 provided in the hot rolling equipment 1.

- FIG. It is explanatory drawing which shows a mode that the lowest point of the hot-rolled steel plate H contacts the conveyance roll 32.

- FIG. It is a graph which shows the temperature fluctuation in each location of the hot-rolled steel sheet H when the medium-wave shape with a steepness of 1% is formed on the hot-rolled steel sheet H and when the ear wave shape with a steepness of 1% is formed. .

- Cold rolling gauge fluctuation in the cold rolling process which is a subsequent process, when a medium wave shape with a steepness of 1% is formed on the hot-rolled steel sheet H and when an ear wave shape with a steepness of 1% is formed

- a graph showing the relationship between the temperature fluctuation and steepness of a hot-rolled steel sheet H in the ROT cooling of a typical strip in a normal operation shows the upper graph shows the temperature fluctuation with respect to the distance from the coil tip or the fixed point elapsed time.

- the lower graph shows the steepness with respect to the distance from the coil tip or the fixed point elapsed time. It is a graph which shows the relationship between the temperature fluctuation and the steepness of the hot-rolled steel sheet H in the ROT cooling of a typical strip in a normal operation.

- FIG. 6 is a graph showing the relationship between the temperature fluctuation and steepness of the hot-rolled steel sheet H when the upper surface cooling heat removal amount is decreased and the lower surface cooling heat removal amount is increased.

- the steepness of the wave shape of the hot-rolled steel sheet H is a value obtained by dividing the amplitude of the wave shape by the length in the rolling direction for one cycle.

- FIG. It is explanatory drawing which shows the detail of the periphery of the cooling device 14 in the hot rolling equipment 1.

- FIG. It is explanatory drawing which shows the modification of the cooling device. It is explanatory drawing which shows a mode that the temperature standard deviation was formed in the plate width direction of the hot-rolled steel plate H. It is explanatory drawing which shows the manufacturing method of the conventional hot-rolled steel plate H. It is explanatory drawing which shows the cooling method of the conventional hot-rolled steel plate H.

- FIG. 1 schematically shows an example of a hot rolling facility 1 for realizing the steel sheet manufacturing method in the present embodiment.

- This hot rolling facility 1 manufactures a steel plate (hot rolled steel plate H described later) having a minimum thickness of 1.2 mm by continuously rolling the heated slab S sandwiched between rolls, It is equipment intended to wind up steel plates.

- This hot rolling equipment 1 is rolled in the width direction, a heating furnace 11 for heating the slab S, a width-direction rolling mill 16 that rolls the slab S heated in the heating furnace 11 in the width direction, and the width direction.

- a roughing mill 12 that rolls the slab S from above and below to form a rough bar Br, and a steel plate having a predetermined thickness (hereinafter referred to as a hot-rolled steel plate) by continuously hot-rolling the rough bar Br. )

- Finish rolling mill 13 for forming H cooling device 14 for cooling hot-rolled steel sheet H conveyed from finishing mill 13 with cooling water, and hot-rolled steel sheet H cooled by cooling device 14 in a coil shape And a winding device 15 for winding.

- the heating furnace 11 is provided with a side burner, an axial flow burner, and a roof burner for heating the slab S by blowing out flames to the slab S carried in from the outside through the loading port.

- the slab S carried into the heating furnace 11 is sequentially heated in each heating zone formed in each zone, and further in the soaking zone formed in the final zone, the slab S is evenly heated using a roof burner, A coercive heat treatment is performed to enable conveyance at the optimum temperature.

- the slab S is transferred to the outside of the heating furnace 11 and moves to a rolling process by the roughing mill 12.

- the rough rolling mill 12 allows the slab S that has been conveyed to pass through a gap between cylindrical rotary rolls that are disposed across a plurality of stands.

- the roughing mill 12 hot-rolls the slab S only with the work rolls 12a disposed up and down in the first stand to form the rough bar Br.

- the rough bar Br that has passed through the first stand is further continuously rolled by a plurality of quadruple rolling mills 12b configured by work rolls and backup rolls.

- the rough bar Br is rolled to a thickness of about 30 to 60 mm and conveyed to the finishing mill 13.

- the finishing mill 13 hot finish-rolls the rough bar Br conveyed from the roughing mill 12 until its thickness reaches about several mm. These finishing mills 13 allow the rough bar Br to pass through the gap between the finish rolling rolls 13a arranged in a straight line over 6 to 7 stands, and gradually reduce this to obtain a predetermined plate thickness.

- the hot-rolled steel sheet H is formed.

- the hot-rolled steel sheet H formed by the finish rolling mill 13 is conveyed to the cooling device 14 by a conveyance roll 32 described later.

- the finish rolling mill 13 forms an ear wave shape in the rolling direction of the hot-rolled steel sheet H.

- the cooling device 14 is a facility for cooling the hot-rolled steel sheet H conveyed from the finish rolling mill 13 with a laminator or a spray. As shown in FIG. 2, the cooling device 14 has an upper cooling device 14 a that jets cooling water from the upper cooling port 31 to the upper surface of the hot-rolled steel sheet H that moves on the transport roll 32 of the run-out table, The lower side cooling device 14b which injects a cooling water from the lower side cooling port 31 with respect to the lower surface of the hot-rolled steel plate H is provided. A plurality of cooling ports 31 are provided for each of the upper cooling device 14a and the lower cooling device 14b. A cooling header (not shown) is connected to the cooling port 31.

- the cooling capacity of the upper cooling device 14a and the lower cooling device 14b is determined by the number of the cooling ports 31.

- the cooling device 14 may be composed of at least one of an upper / lower split laminar, a pipe laminar, spray cooling, and the like. Further, a section in which the hot-rolled steel sheet H is cooled by the cooling device 14 corresponds to a cooling section in the present invention.

- the winding device 15 winds the cooled hot-rolled steel sheet H conveyed from the cooling device 14 at a predetermined winding temperature.

- the hot-rolled steel sheet H wound in a coil shape by the winding device 15 is sent to a cold rolling facility (not shown) and cold-rolled to prepare a steel sheet that satisfies the specifications as a final product.

- the hot-rolled steel sheet H in which a corrugated shape whose surface height (wave height) fluctuates in the rolling direction is formed is performed, As described above, the hot-rolled steel sheet H can be made uniform by suitably adjusting the water volume density, pressure, water temperature, etc. of the cooling water injected from the upper cooling device 14a and the cooling water injected from the lower cooling device 14b. Cooling takes place. However, especially when the sheet passing speed is slow, the time for which the hot-rolled steel sheet H and the transport roll 32 are in local contact with each other becomes longer, and the contact portion of the hot-rolled steel sheet H with the transport roll 32 is cooled by contact heat removal. Since it becomes easy to be done, cooling will become non-uniform

- the hot-rolled steel sheet H may locally contact the transport roll 32 at the bottom of the corrugated shape.

- the part that is locally in contact with the transport roll 32 is more easily cooled than the other part by contact heat removal. For this reason, the hot-rolled steel sheet H is cooled unevenly.

- the hot rolling facility 1 when the hot-rolled steel sheet H is not uniformly cooled due to the wave shape being formed in the hot-rolled steel sheet H, the heat after cooling is reduced.

- the material (hardness etc.) of the rolled steel sheet H varies.

- a plate thickness variation occurs in the steel sheet (product steel sheet) finally obtained as a product. Since the plate thickness fluctuation of the product steel plate causes a decrease in yield, it is necessary to suppress it to a level at which it is not determined as a defective product in the inspection process. Therefore, the inventors of the present application conducted verification described below in order to examine the relationship between the wave shape formed in the hot-rolled steel sheet H and the thickness variation in the subsequent process (cold rolling process).

- FIG. 4 shows temperature fluctuations at various points of the hot-rolled steel sheet H when the hot-rolled steel sheet H has a medium-wave shape with a steepness of 1% and when an oto-wave shape with a steepness of 1% is formed. It is a graph to show.

- FIG. 5 shows a cold rolling process for each of a case where a medium wave shape having a steepness of 1% is formed on the hot-rolled steel sheet H and a case where an ear wave shape having a steepness of 1% is formed. It is a graph which shows cold-rolling gauge fluctuation

- WS work side

- DS drive side

- the plate width center (when the wave shape of the hot-rolled steel sheet H at the time of cooling in the hot rolling facility 1 is an oto-wave shape is greater than the case where the wave shape is an intermediate wave shape ( C) and width average temperature fluctuations are suppressed, and sheet thickness fluctuations in the cold rolling process are suppressed (as shown in FIG. 5, the ear wave shape is about 30% of the medium wave shape. It can be seen that the effect of suppressing fluctuations in sheet thickness can be obtained. This is because the middle wave shape is symmetrical at the center of the steel plate and is uniformly displaced in the width direction, so it is easy to cause uneven cooling deviation in the sheet passing direction (rolling direction).

- the influence of one edge wave becomes an antisymmetric shape that affects the other edge wave (for example, the wave shape of DS). That is, when the wave shape of the hot-rolled steel sheet H is an ear wave shape, the DS wave shape of the hot-rolled steel sheet H is 180 degrees out of phase with respect to the WS wave shape. Cooling deviations corresponding to the shapes are generated, and the temperature standard deviation in the sheet passing direction becomes small when the temperature average in the sheet width direction is taken. Therefore, when the wave shape of the hot-rolled steel sheet H is an ear-wave shape, the hot rolling facility 1 performs substantially uniform cooling that does not affect the thickness variation in the cold rolling process, and finally The yield of the product steel plate obtained can be improved.

- the wave shape of the hot-rolled steel sheet H is an ear-wave shape

- the hot rolling facility 1 performs substantially uniform cooling that does not affect the thickness variation in the cold rolling process, and finally The yield of the product steel plate obtained can be improved.

- FIG. 12 is data showing the correlation between the steepness and the temperature standard deviation Y, obtained under the condition that the plate passing speed and the below-described upper and lower heat transfer coefficient ratio X are constant values.

- a hot rolled steel sheet H in which an ear wave shape whose wave height fluctuates periodically in the rolling direction is formed by hot rolling a steel material (coarse bar Br) with a finish mill 13.

- a correlation between the steepness of the hot-rolled steel sheet H and the temperature standard deviation Y of the hot-rolled steel sheet H after cooling (or during cooling), which has been experimentally obtained in advance (FIG. 12).

- the target steepness setting step based on the first correlation data, the temperature standard deviation Y required during actual operation (temperature standard deviation Y that can suppress the plate thickness variation in the cold rolling step within an allowable level) Is obtained, and the steepness is set as the target steepness. For example, referring to FIG. 12, when the temperature standard deviation Y required during actual operation is 10 ° C., the target steepness is set to 0.5%.

- the operating parameters of the finishing mill 13 are controlled so that the steepness of the ear wave shape formed on the hot-rolled steel sheet H matches the target steepness (for example, 0.5%).

- the target steepness for example, 0.5%).

- operation parameters of the finishing mill 13 there are a sheet feeding speed, a heating temperature, a pressing force, and the like. Therefore, by adjusting the values of these operating parameters, the steepness of the ear wave shape formed in the hot-rolled steel sheet H can be matched with the target steepness. Specifically, if a distance meter that measures the distance from the surface (upper surface) of the hot-rolled steel sheet H is installed on the exit side of the finish rolling mill 13, based on the distance measurement result obtained from the distance meter.

- the steepness of the ear shape of the hot-rolled steel sheet H can be calculated in real time. Then, the operation parameters of the finishing mill 13 may be feedback controlled so that the calculation result of the steepness matches the target steepness.

- a controller equipped with a general microcomputer or the like can be used for the calculation of the steepness and the feedback control.

- the target steepness setting step it is preferable to set the target steepness within 0% and within 1%.

- the temperature standard deviation Y of the hot-rolled steel sheet H after cooling is suppressed to about 18 ° C. or less (see FIG. 12), and the thickness variation of the product steel sheet in the cold rolling process can be greatly suppressed.

- the temperature standard deviation Y of the hot-rolled steel sheet H can be suppressed to about 10 ° C. or less (see FIG. 12).

- the cooling process of the present embodiment described above includes two processes, a target ratio setting process and a cooling control process. It is preferable.

- the target ratio setting step heat transfer between the upper and lower surfaces of the hot-rolled steel sheet H, which has been experimentally determined in advance under the condition that the steepness of the hot-rolled steel sheet H and the sheet passing speed are constant values.

- the temperature standard deviation Y is the minimum value Ymin.

- the vertical heat transfer coefficient ratio X1 is set as the target ratio Xt. Further, in the cooling control step, the cooling section is set such that the vertical heat transfer coefficient ratio X of the hot rolled steel sheet H in the cooling section (the section in which the hot rolled steel sheet H is cooled by the cooling device 14) matches the target ratio Xt. At least one of the upper surface cooling heat removal amount and the lower surface cooling heat removal amount of the hot-rolled steel sheet H is controlled.

- the second correlation data used in the target ratio setting step is experimentally obtained in advance using the hot rolling facility 1 before actual operation (before actually manufacturing the hot-rolled steel sheet H).

- the cooling capacity (upper cooling capacity) of the upper cooling device 14a of the cooling apparatus 14 and the cooling capacity (lower cooling capacity) of the lower cooling device 14b are previously set. adjust.

- the upper cooling capacity and the lower cooling capacity are respectively the heat transfer coefficient of the upper surface of the hot rolled steel sheet H cooled by the upper cooling device 14a and the heat transfer of the lower surface of the hot rolled steel sheet H cooled by the lower cooling device 14b. Adjust using the coefficient.

- the temperature difference is a difference between the temperature of the hot-rolled steel sheet H measured by the thermometer on the inlet side of the cooling device 14 and the temperature of the cooling water used in the cooling device 14.

- the amount of heat removed from cooling is the amount of heat removed from the hot-rolled steel sheet H in the cooling device 14, and the difference in temperature between the hot-rolled steel plates H measured by the thermometer on the inlet side and the thermometer on the outlet side of the cooling device 14. And the specific heat of the hot-rolled steel sheet H and the mass of the hot-rolled steel sheet H cooled by the cooling device 14, respectively.

- the heat transfer coefficient of the hot-rolled steel sheet H calculated as described above is divided into the heat transfer coefficients of the upper surface and the lower surface of the hot-rolled steel sheet H.

- These heat transfer coefficients of the upper surface and the lower surface are calculated using, for example, a ratio obtained in advance as follows. That is, the heat transfer coefficient of the hot-rolled steel sheet H when the hot-rolled steel sheet H is cooled only by the upper cooling device 14a and the heat transfer of the hot-rolled steel plate H when the hot-rolled steel plate H is cooled only by the lower cooling device 14b. Measure the coefficient. At this time, the cooling water amount from the upper cooling device 14a and the cooling water amount from the lower cooling device 14b are the same.

- the reciprocal of the ratio between the measured heat transfer coefficient when using the upper cooling device 14a and the heat transfer coefficient when using the lower cooling device 14b is the upper and lower heat transfer coefficient ratio X described later as "1".

- the upper / lower ratio of the cooling water amount of the upper cooling device 14a and the cooling water amount of the lower cooling device 14b is obtained.

- the above-described hot-rolled steel sheet is obtained by multiplying the vertical ratio of the cooling water amount obtained in this way by the cooling water amount of the upper cooling device 14a or the cooling water amount of the lower cooling device 14b when the hot-rolled steel plate H is cooled.

- the ratio of the heat transfer coefficient between the upper surface and the lower surface of H (upper and lower heat transfer coefficient ratio X) is calculated.

- the heat transfer coefficient of the hot-rolled steel sheet H that is cooled only by the upper cooling device 14a and the lower cooling device 14b is used. However, it is cooled by both the upper cooling device 14a and the lower cooling device 14b.

- the heat transfer coefficient of the hot-rolled steel sheet H may be used. That is, the heat transfer coefficient of the hot-rolled steel sheet H when the amount of cooling water of the upper cooling device 14a and the lower cooling device 14b is changed is measured, and the ratio of the heat transfer coefficient is used to determine the upper and lower surfaces of the hot-rolled steel sheet H. The ratio of the heat transfer coefficient may be calculated.

- the heat transfer coefficient of the hot-rolled steel sheet H is calculated, and the upper surface of the hot-rolled steel sheet H is calculated based on the above ratio (upper and lower heat transfer coefficient ratio X) of the heat transfer coefficients between the upper and lower surfaces of the hot-rolled steel sheet H. And the heat transfer coefficient of the lower surface is calculated.

- the cooling capacity of the upper side cooling device 14a and the lower side cooling device 14b is each adjusted based on FIG. 6 using the up-and-down heat transfer coefficient ratio X of this hot-rolled steel sheet H.

- the horizontal axis in FIG. 6 represents the ratio of the average heat transfer coefficient of the upper surface of the hot rolled steel sheet H to the average heat transfer coefficient of the lower surface (that is, the same as the vertical heat transfer coefficient ratio X), and the vertical axis represents the hot rolled steel sheet H.

- the standard deviation of temperature between the maximum temperature and the minimum temperature in the rolling direction (temperature standard deviation Y) is shown.

- the vertical heat transfer coefficient ratio X and the temperature standard deviation Y obtained by actually measuring the temperature standard deviation Y of the hot-rolled steel sheet H after cooling while changing the vertical heat transfer coefficient ratio X of the hot-rolled steel sheet H.

- correlation data indicating the correlation with Referring to FIG. 6, the correlation between the temperature standard deviation Y and the upper and lower heat transfer coefficient ratio X is V-shaped, with the temperature standard deviation Y being the minimum value Ymin when the upper and lower heat transfer coefficient ratio X is “1”.

- the steepness of the wave shape of the hot-rolled steel sheet H is a value obtained by dividing the amplitude of the wave shape by the length in the rolling direction for one cycle.

- FIG. 6 shows the correlation between the vertical heat transfer coefficient ratio X and the temperature standard deviation Y obtained under the condition that the steepness of the hot-rolled steel sheet H is 2% and the sheet feeding speed is 600 m / min (10 m / sec). Showing the relationship.

- the temperature standard deviation Y may be measured during cooling of the hot-rolled steel sheet H, or may be measured after cooling.

- the target cooling temperature of the hot-rolled steel sheet H is 600 ° C. or higher, for example, 800 ° C.

- the upper and lower heat transfer coefficient ratio X1 at which the temperature standard deviation Y becomes the minimum value Ymin is set as the target ratio Xt based on the second correlation data obtained experimentally in advance as described above.

- the second correlation data may be prepared as data (table data) indicating the correlation between the vertical heat transfer coefficient ratio X and the temperature standard deviation Y in a table (table format), or the vertical heat transfer coefficient You may prepare the correlation of the ratio X and the temperature standard deviation Y as data which show with numerical formula (for example, regression equation).

- the second correlation data is prepared as data indicating the correlation between the vertical heat transfer coefficient ratio X and the temperature standard deviation Y as a regression equation

- the V-shaped line shown in FIG. Since it is drawn almost linearly, a regression equation may be derived by performing linear regression on this line. If it is a linear distribution, the number of times of confirmation with a test material and the number of times of calibration for predicting calculation can be reduced.

- the minimum value Ymin of the temperature standard deviation Y is searched by using various methods such as a dichotomy method, golden section method, and random search, which are generally known search algorithms.

- the upper and lower heat transfer coefficient ratio X1 at which the temperature standard deviation Y of the hot-rolled steel sheet H is the minimum value Ymin is derived.

- FIG. 7 shows a standard case in which different regression lines are obtained across the minimum value Ymin of the temperature standard deviation Y.

- first, temperature standard deviations Ya, Yb, Yc at points c, b, and points c in the middle of the points a and b are extracted.

- the middle of the points a and b indicates the point c having a value between the upper and lower heat transfer coefficient ratio Xa at the point a and the upper and lower heat transfer coefficient ratio Xb at the point b.

- the temperature standard deviation Yd at the point d between the points a and c is extracted.

- the temperature standard deviation Yd is closer to Ya or Yc. In the present embodiment, Yd is close to Yc.

- the temperature standard deviation Ye at the point e between the points c and d is extracted. Then, it is determined whether the temperature standard deviation Ye is closer to Yc or Yd. In the present embodiment, Ye is close to Yd.

- Such calculation is repeated to specify the minimum point f (minimum value Ymin) of the temperature standard deviation Y of the hot-rolled steel sheet H.

- the above-described calculation may be performed, for example, about 5 times.

- the range of the upper and lower heat transfer coefficient ratio X to be searched may be divided into 10, and the above-described calculation is performed in each range to specify the minimum point f.

- the upper and lower heat transfer coefficient ratio X may be calibrated by using a so-called Newton method.

- the deviation between the vertical heat transfer coefficient ratio X with respect to the actual temperature standard deviation Y value and the vertical heat transfer coefficient ratio X at which the temperature standard deviation Y becomes zero is obtained.

- the vertical heat transfer coefficient ratio X1 (Xf in FIG. 7) at which the temperature standard deviation Y of the hot-rolled steel sheet H becomes the minimum value Ymin is derived.

- the relationship between the V-shaped temperature standard deviation Y and the upper and lower heat transfer coefficient ratio X it is easy to obtain a regression function for each of them by the least square method or the like.

- the relationship between the temperature standard deviation Y and the upper and lower heat transfer coefficient ratio X is V-shaped, regardless of whether the wave shape formed on the hot-rolled steel sheet H is an ear wave shape or a medium wave shape. By utilizing this, it is possible to derive the vertical heat transfer coefficient ratio X1 at which the temperature standard deviation Y of the hot-rolled steel sheet H becomes the minimum value Ymin.

- the temperature standard deviation in the sheet width direction is caused by the fact that the temperature standard deviation Y in the rolling direction is alternately generated on the left and right, so if the temperature standard deviation Y in the rolling direction is reduced, The temperature standard deviation is also reduced.

- the vertical heat transfer coefficient ratio X1 at which the temperature standard deviation Y of the hot-rolled steel sheet H is the minimum value Ymin is “1”. Therefore, when the second correlation data as shown in FIG. 6 is obtained, in order to set the temperature standard deviation Y to the minimum value Ymin, that is, to uniformly cool the hot-rolled steel sheet H, the target ratio at the time of actual operation In the setting step, the target ratio Xt is set to “1”. In the cooling control step, the upper surface cooling of the hot-rolled steel sheet H in the cooling section is made so that the vertical heat transfer coefficient ratio X of the hot-rolled steel sheet H in the cooling section matches the target ratio Xt (that is, “1”).

- At least one of the amount of heat and the amount of heat extracted from the bottom surface cooling is controlled.

- the vertical heat transfer coefficient ratio X of the hot-rolled steel sheet H in the cooling section coincide with the target ratio Xt (that is, “1”), for example, the cooling capacity of the upper cooling device 14a and the lower cooling device

- the upper surface cooling heat removal amount and the lower surface cooling heat removal amount of the hot-rolled steel sheet H may be made equal by adjusting the cooling capacity of 14b equally.

- the difference between the two is within 10 ° C., that is, the condition where the operation is possible is “B”, and the condition which is performed by trial and error to obtain the above-described regression equation is “C”.

- the evaluation is “A”, that is, the vertical heat transfer coefficient ratio X1 at which the temperature standard deviation Y of the hot-rolled steel sheet H becomes the minimum value Ymin is “1”.

- the temperature standard deviation Y of the hot-rolled steel sheet H is at least within the range from the minimum value Ymin to the minimum value Ymin + 10 ° C., variations in yield stress, tensile strength, etc. can be suppressed within the production allowable range. Can be cooled uniformly. That is, in the above target ratio setting step, based on the second correlation data obtained experimentally in advance, the vertical heat transfer ratio X in which the temperature standard deviation Y falls within the range from the minimum value Y to the minimum value Ymin + 10 ° C. It may be set as the target ratio Xt.

- the allowable manufacturing range is a range in which the temperature standard deviation Y of the hot-rolled steel sheet H is within the minimum value Ymin + 10 ° C. from the minimum value Ymin.

- a straight line extends from the point on the vertical axis where the temperature standard deviation Y becomes the minimum value Ymin + 10 ° C. Then, two intersections between the straight line and the two regression lines on both sides of the V-shaped curve are obtained, and the target ratio Xt may be set from the vertical heat transfer coefficient ratio X between the two intersections.

- the temperature standard deviation Y can be kept within the range from the minimum value Ymin to the minimum value Ymin + 10 ° C. by setting the upper and lower heat transfer coefficient ratio X of “B” as the target ratio Xt. .

- the vertical heat transfer coefficient ratio X coincide with the target ratio Xt, it is easiest to operate the cooling water density of at least one of the upper cooling device 14a and the lower cooling device 14b. Therefore, for example, in FIG. 6 and FIG. 7, the value of the horizontal axis is read as the vertical water volume density ratio, and the hot rolled steel sheet H with respect to the vertical ratio of the water volume density on both sides sandwiching the same point above and below the average heat transfer coefficient.

- the regression equation of the temperature standard deviation Y may be obtained.

- the points that are equal above and below the average heat transfer coefficient are not necessarily equal points above and below the cooling water density, so it is better to perform a slightly wider test to obtain the regression equation.

- the second correlation data is prepared for each of a plurality of conditions having different values of the steepness and the sheet passing speed, and in the target ratio setting step, among the plurality of second correlation data, The target ratio Xt may be set on the basis of the second correlation data corresponding to the actual steepness during actual operation and the measured value of the sheet passing speed. Thereby, uniform cooling suitable for the manufacturing conditions during actual operation can be performed.

- the cooling capacity of the upper cooling device 14a and the lower cooling device 14b is adjusted (the upper surface cooling heat removal amount and the lower surface cooling heat removal amount of the hot rolled steel plate H are controlled.

- the inventors of the present application have made extensive studies on the characteristics of the temperature standard deviation Y generated by cooling in a state where the wave shape of the hot-rolled steel sheet H is generated, and as a result, have clarified the following.

- the temperature of the hot-rolled steel sheet H is controlled to a predetermined target temperature (temperature suitable for winding). Need to maintain the quality. Therefore, in the target ratio setting process and the cooling control process described above, based on the temperature measurement process for measuring the temperature of the hot-rolled steel sheet H on the downstream side of the cooling section (that is, the cooling device 14) in time series and the measurement result of the temperature.

- the temperature average value calculating step for calculating the time series average value of the temperature and the upper surface cooling heat removal amount and the lower surface cooling of the hot-rolled steel sheet H in the cooling section so that the time series average value of the temperature coincides with a predetermined target temperature.

- a cooling heat removal amount adjustment step for adjusting the total value of the heat removal amount may be newly added.

- a thermometer 40 that measures the temperature of the hot-rolled steel sheet H, which is arranged between the cooling device 14 and the winding device 15 as shown in FIG. Can do.

- the temperature measurement at the position determined in the rolling direction of the hot-rolled steel sheet H by the thermometer 40 is performed on the hot-rolled steel sheet H conveyed from the cooling device 14 to the winding device 15 at a certain time interval (sampling). Time interval data is obtained at intervals).

- the temperature measurement region by the thermometer 40 includes the entire width direction of the hot-rolled steel sheet H.

- the sampling time of each temperature measurement result is multiplied by the sheet feeding speed (conveying speed) of the hot-rolled steel sheet H

- the position in the rolling direction of the hot-rolled steel sheet H from which each temperature measurement result is obtained can be calculated. That is, when the time at which the temperature measurement result is sampled is multiplied by the sheet passing speed, the time series data of the temperature measurement result can be linked to the position in the rolling direction.

- the time series average value of the temperature measurement result is calculated using the time series data of the temperature measurement result. Specifically, every time a certain number of temperature measurement results are obtained, an average value of the temperature measurement results for the certain number may be calculated. Then, in the cooling heat removal amount adjustment step, the upper surface cooling heat removal amount and the lower surface cooling of the hot-rolled steel sheet H in the cooling section so that the time-series average value of the temperature measurement results calculated as described above coincides with the predetermined target temperature. Adjust the total value with heat removal.

- the shape meter 41 measures the shape of the same measurement position as the thermometer 40 defined on the hot-rolled steel sheet H (hereinafter, this measurement position may be referred to as a fixed point).

- the shape means the height or fluctuation component of the wave pitch by using the movement amount of the hot-rolled steel sheet H in the passing direction as the fluctuation amount in the height direction of the hot-rolled steel sheet H observed by the fixed point measurement. This is the steepness obtained by the line integral.

- the shape measurement region includes the entire region in the width direction of the hot-rolled steel sheet H, similarly to the temperature measurement region.

- FIG. 8 shows the relationship between the temperature fluctuation and the steepness of the hot-rolled steel sheet H that is cooled in the ROT of a typical strip in a normal operation.

- a region A in FIG. 8 is a region before the strip front end portion shown in FIG. 16 is bitten by the coiler of the winding device 15 (a region having a bad shape because there is no tension).

- a region B in FIG. 8 is a region after the strip front end portion is bitten by the coiler (a region where the wave shape is changed flat due to the influence of the unit tension). It is desired to improve a large temperature fluctuation (that is, temperature standard deviation Y) generated in the region A where the shape of the hot-rolled steel sheet H is not flat.

- the inventors of the present application have conducted intensive experiments with the goal of suppressing an increase in the temperature standard deviation Y in the ROT, and as a result, have obtained the following knowledge.

- FIG. 9 shows the temperature fluctuation component with respect to the same shape steepness of cooling in the ROT of a typical strip in a normal operation as in FIG.

- This temperature fluctuation component is a residual obtained by subtracting a time-series average of temperature (hereinafter sometimes referred to as “average temperature”) from the actual steel plate temperature.

- the average temperature may be averaged over a range of one or more wave shapes of the hot-rolled steel sheet H.

- the average temperature is in principle the average of the range in units of cycles.

- it has been confirmed by the operation data that the average temperature in the range of one cycle is not significantly different from the average temperature in the range of two cycles or more. Therefore, it is only necessary to calculate an average temperature in a range of at least one waveform.

- the upper limit of the corrugated range of the hot-rolled steel sheet H is not particularly limited, but preferably an average temperature with sufficient accuracy can be obtained if it is set to 5 cycles. Further, even if the range to be averaged is not a cycle unit range, an acceptable average temperature can be obtained if it is in the range of 2 to 5 cycles.

- the wave shape of the hot-rolled steel sheet H is a region where the fluctuation rate measured at a fixed point is positive.

- the temperature of the hot-rolled steel sheet H temperature measured at a fixed point

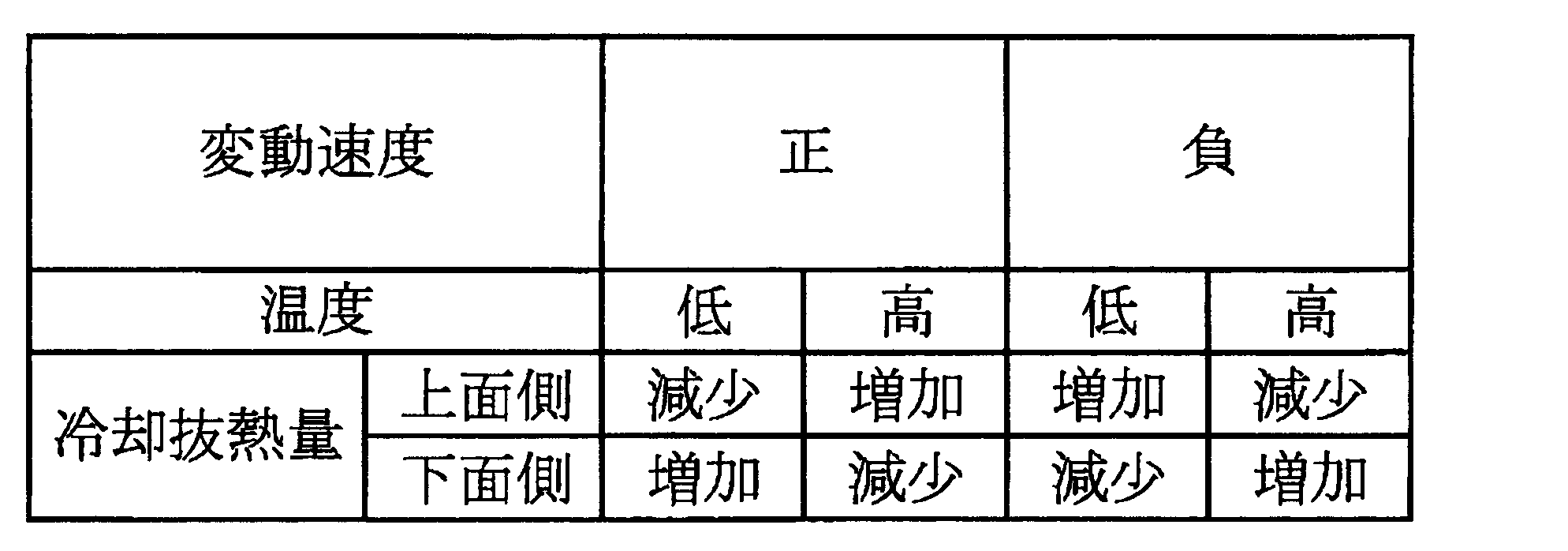

- the temperature of the hot-rolled steel sheet H is lower than the average temperature in the range of one cycle or more, at least one of the direction in which the upper surface cooling heat removal amount decreases and the direction in which the lower surface cooling heat removal amount increases.

- the control direction Is determined as the control direction, and when the temperature of the hot-rolled steel sheet H is higher than the average temperature, at least one of the direction in which the upper surface cooling heat removal amount increases and the direction in which the lower surface cooling heat removal amount decreases is determined as the control direction. To do. Further, when the temperature of the hot-rolled steel sheet H is lower than the above average temperature in the region where the fluctuation rate measured at a fixed point is negative, the direction in which the upper surface cooling heat removal amount increases and the direction in which the lower surface cooling heat removal amount decreases.

- the direction in which the upper surface cooling heat removal amount decreases and the direction in which the lower surface cooling heat removal amount increases is determined as a control direction, and when the temperature of the hot-rolled steel sheet H is higher than the above average temperature, at least one of the direction in which the upper surface cooling heat removal amount increases and the direction in which the lower surface cooling heat removal amount decreases is controlled. Determine as direction. Then, when at least one of the upper surface cooling heat removal amount and the lower surface cooling heat removal amount of the hot-rolled steel sheet H in the cooling section is adjusted based on the control direction determined as described above, as shown in FIG.

- the cooling stop temperature may be changed. That is, even when determining the increase / decrease direction (control direction) of the upper surface cooling heat removal amount and the lower surface cooling heat removal amount, the cooling heat removal amount is adjusted so that the cooling stop temperature of the hot-rolled steel sheet H becomes the predetermined target cooling temperature. Is done.

- the temperature measurement process for measuring the temperature (temperature at a fixed point) of the hot rolled steel sheet H on the downstream side of the cooling section in time series, and the hot rolled steel sheet H Fluctuation rate measurement process that measures the variation rate in the vertical direction of the hot-rolled steel sheet H at the same location (fixed point) as the temperature measurement location, and the amount of heat removed from the top surface and the bottom surface based on the temperature measurement result and the variation rate measurement result

- An adjustment step may be newly added.

- the fluctuation speed at the fixed point of the hot-rolled steel sheet H is a positive region, and the fixed temperature of the hot-rolled steel sheet H with respect to the average temperature at the fixed point of the hot-rolled steel sheet H.

- the temperature of the hot rolled steel sheet H is higher than the above average temperature Determines at least one of the direction in which the upper surface cooling heat removal amount increases and the direction in which the lower surface cooling heat removal amount decreases as the control direction.

- this control direction determination step when the temperature of the hot-rolled steel sheet H is lower than the average temperature in the region where the fluctuation speed is negative, the upper surface cooling heat removal amount and the lower surface cooling heat removal amount are increased.

- the direction of decreasing the upper surface cooling heat removal amount and the direction of increasing the lower surface cooling heat removal amount are determined. At least one is determined as a control direction. Even in this cooling method, it is necessary to adjust the upper surface cooling heat removal amount and the lower surface cooling heat removal amount while achieving the control target of making the upper and lower heat transfer coefficient ratio X of the hot rolled steel sheet H in the cooling section coincide with the target ratio Xt. There is.

- a cooling header connected to the cooling port 31 of the upper cooling device 14a and the cooling port 31 of the lower cooling device 14b.

- Each of the cooling headers connected to may be controlled on and off. Or you may control the cooling capacity of each cooling header in the upper side cooling device 14a and the lower side cooling device 14b. That is, you may adjust at least one of the water quantity density of the cooling water injected from each cooling port 31, a pressure, and water temperature.

- the cooling headers (cooling ports 31) of the upper cooling device 14a and the lower cooling device 14b may be thinned out to adjust the flow rate and pressure of the cooling water injected from the upper cooling device 14a and the lower cooling device 14b.

- the cooling capacity of the upper cooling device 14a before thinning out the cooling header is higher than the cooling capacity of the lower cooling device 14b, it is preferable to thin out the cooling header constituting the upper cooling device 14a.

- the cooling capacity thus adjusted is used to inject cooling water onto the upper surface of the hot-rolled steel sheet H from the upper cooling device 14a, and to inject cooling water onto the lower surface of the hot-rolled steel plate H from the lower cooling device 14b.

- the steel plate H is uniformly cooled.

- the hot-rolled steel sheet H can be made more uniform by setting the sheet passing speed to 550 m / min or more.

- the sheet passing speed of the hot-rolled steel sheet H is set to 550 m / min or more, even if the cooling water is injected onto the hot-rolled steel sheet H, the influence of the water on the hot-rolled steel sheet H is remarkably reduced. For this reason, the non-uniform cooling of the hot-rolled steel sheet H by the riding water can be avoided.

- board speed of the hot-rolled steel sheet H is so good that it is high, it is impossible to exceed a mechanical limit speed (for example, 1550 m / min). Therefore, the sheet feeding speed of the hot-rolled steel sheet H in the cooling section is substantially set in a range from 550 m / min or more to a mechanical limit speed or less.

- the operation upper limit speed (for example, 1200 m / min) is set from 550 m / min or more. min) is preferably set within a range up to or below.

- the steel sheet is a hot-rolled steel sheet H having a high tensile strength (particularly a steel sheet called so-called high tensile steel having a tensile strength (TS) of 800 MPa or more and a practical upper limit of 1400 MPa).

- TS tensile strength

- the inventors of the present application in the finishing mill 13 of the hot rolling facility 1, cooled (so-called) between a pair of finish rolling rolls 13 a (that is, rolling stands) provided over, for example, 6 to 7 stands. It was found that by performing (cooling between stands), the processing heat generation can be suppressed and the sheet passing speed of the hot-rolled steel sheet H in the cooling device 14 can be set to 550 m / min or more.

- TS tensile strength

- the cooling of the hot-rolled steel sheet H by the cooling device 14 is preferably performed in the range from the finish rolling mill outlet temperature to the temperature of the hot-rolled steel sheet H up to 600 ° C.

- the temperature region where the temperature of the hot-rolled steel sheet H is 600 ° C. or higher is a so-called film boiling region. That is, in this case, the so-called transition boiling region can be avoided and the hot-rolled steel sheet H can be water-cooled in the film boiling region.

- the transition boiling region when cooling water is sprayed onto the surface of the hot-rolled steel sheet H, a portion covered with a vapor film and a portion where the cooling water is directly sprayed onto the hot-rolled steel plate H are formed on the surface of the hot-rolled steel plate H. Mixed.

- the hot-rolled steel sheet H cannot be cooled uniformly.

- the hot-rolled steel sheet H in the film boiling region, since the hot-rolled steel sheet H is cooled in a state where the entire surface of the hot-rolled steel sheet H is covered with the vapor film, the hot-rolled steel sheet H can be uniformly cooled. Therefore, the hot-rolled steel sheet H can be cooled more uniformly in the range where the temperature of the hot-rolled steel sheet H is 600 ° C. or more as in this embodiment.

- the temperature standard deviation Y of the hot-rolled steel sheet H increases. That is, as shown in FIG. 13, as the vertical heat transfer coefficient ratio X increases from “1”, the temperature standard deviation Y increases in accordance with the steepness (steepness sensitivity).

- the relationship between the vertical heat transfer coefficient ratio X and the temperature standard deviation Y is represented by a V-shaped regression line for each steepness.

- the sheet passing speed of the hot-rolled steel sheet H is constant at 10 m / sec (600 m / min).

- the temperature standard deviation Y of the hot-rolled steel sheet H is increased. That is, as shown in FIG. 15, the temperature standard deviation Y increases as the vertical heat transfer coefficient ratio X deviates from “1” in accordance with the plate passing speed (the sensitivity of the plate passing speed).

- the relationship between the vertical heat transfer coefficient ratio X and the temperature standard deviation Y is represented by a V-shaped regression line for each plate passing speed.

- the steepness of the wave shape of the hot-rolled steel sheet H is constant at 2%.

- the vertical heat transfer coefficient ratio X of the hot-rolled steel sheet H is fixed in advance, and the steepness is changed stepwise from 3% to 0%, for example, as shown in FIG. Table data indicating a correlation with the temperature standard deviation Y after cooling of the steel plate H is obtained. Then, the temperature standard deviation Y with respect to the steepness z% of the actual hot-rolled steel sheet H is corrected to a temperature standard deviation Y ′ with respect to a predetermined steepness by an interpolation function. Specifically, when the predetermined steepness is set to 2% as the correction condition, the temperature standard deviation Yz ′ is calculated by the following equation (1) based on the temperature standard deviation Yz at the steepness z%.

- the steepness gradient ⁇ in FIG. 12 may be calculated by the least square method or the like, and the temperature standard deviation Yz ′ may be calculated using the gradient ⁇ .

- Yz ′ Yz ⁇ 2 / z (1)

- the steepness may be corrected to a predetermined steepness

- the temperature standard deviation Y may be derived from the regression equation.

- Table 3 shows the temperature standard deviation Y of the hot-rolled steel sheet H when the vertical heat transfer coefficient ratio X is varied as shown in FIG. 13 with respect to the steepness in FIG.

- the value obtained by subtracting 3.5 ° C. (difference of standard deviation from the minimum value) and the evaluation of each temperature standard deviation Y are shown.

- the display and evaluation criteria for the upper and lower heat transfer coefficient ratio X in Table 3 are the same as those in Table 1 and will not be described.

- the temperature standard deviation Y of the hot-rolled steel sheet H according to the steepness can be derived.

- the evaluation in Table 3 is “B”, that is, the ratio of the vertical heat transfer coefficient that the difference of the standard deviation from the minimum value of the hot-rolled steel sheet H is within 10 ° C.

- X can be set to 1.1.

- the sheet feeding speed is changed stepwise from 5 m / sec (300 m / min) to 20 m / sec (1200 m / min), and the sheet feeding speed and the hot rolled steel sheet H are changed.

- Table data indicating a correlation with the temperature standard deviation Y after cooling is obtained. Then, the temperature standard deviation Y with respect to the sheet passing speed v (m / sec) of the actual hot rolled steel sheet H is corrected to a temperature standard deviation Y ′ with respect to a predetermined sheet passing speed by an interpolation function.

- the temperature standard is expressed by the following formula (2) based on the temperature standard deviation Yv at the sheet passing speed v (m / sec).

- Deviation Yv ′ is calculated.

- the gradient ⁇ of the sheet feeding speed in FIG. 14 may be calculated by a least square method or the like, and the temperature standard deviation Yv ′ may be calculated using the gradient ⁇ .

- Yz ′ Yv ⁇ 10 / v (2)

- the plate passing speed may be corrected to a predetermined plate passing speed, and the temperature standard deviation Y may be derived from the regression formula.

- Table 4 shows the temperature standard deviation Y and the temperature standard deviation of the hot-rolled steel sheet H when the vertical heat transfer coefficient ratio X is varied as shown in FIG. 15 with respect to the sheet passing speed in FIG.

- the temperature standard deviation Y of the hot-rolled steel sheet H corresponding to the sheet passing speed can be derived.

- the evaluation in Table 4 is “B”, that is, the vertical heat transfer is such that the difference of the standard deviation from the minimum value of the hot rolled steel sheet H is within 10 ° C.

- the coefficient ratio X can be set to 1.1.

- the change in the temperature standard deviation Y with respect to the upper and lower heat transfer coefficient ratio X can be quantitatively and accurately determined even when the steepness and the sheet passing speed of the hot-rolled steel sheet H are not constant. Can be evaluated.

- the temperature and wave shape of the hot-rolled steel sheet H cooled by the cooling device 14 are measured, and the cooling capacity of the upper cooling device 14a and the cooling capacity of the lower cooling device 14b are determined based on the measurement result. You may adjust. That is, the cooling capacity of the upper cooling device 14a and the lower cooling device 14b may be feedback controlled.

- thermometer 40 that measures the temperature of the hot-rolled steel sheet H

- shape meter 41 that measures the wave shape of the hot-rolled steel sheet H

- the temperature and shape of the hot-rolled steel sheet H in the plate are measured at the same point by the thermometer 40 and the shape meter 41, and measured as time series data.

- the temperature measurement region includes the entire region in the width direction of the hot-rolled steel sheet H.

- the shape indicates the amount of fluctuation in the height direction of the hot-rolled steel sheet H observed by fixed point measurement.

- the shape measurement region includes the entire region in the width direction of the hot-rolled steel sheet H, similarly to the temperature measurement region.

- the fluctuation rate at the fixed point of the hot-rolled steel sheet H is a positive region, and the fixed point of the hot-rolled steel sheet H with respect to the average temperature at the fixed point.

- the temperature standard deviation Y can be reduced by reducing the upper cooling capacity (upper surface cooling heat removal amount).

- the temperature standard deviation Y can be reduced by increasing the lower cooling capacity (lower surface cooling heat removal amount). If this relationship is utilized, in order to reduce the temperature standard deviation Y, it becomes clear which cooling capacity of the upper cooling device 14a or the lower cooling device 14b of the cooling device 14 should be adjusted.

- the increase / decrease direction (control direction) of the upper cooling capacity (upper surface cooling heat removal amount) and the lower cooling capacity (lower surface cooling heat removal amount) to reduce the temperature standard deviation Y is determined, and the vertical heat transfer coefficient ratio X is adjusted. can do. Further, based on the magnitude of the temperature standard deviation Y, the vertical heat transfer coefficient ratio X can be determined so that the temperature standard deviation Y falls within an allowable range, for example, the range from the minimum value Ymin to the minimum value Ymin + 10 ° C. .

- the method for determining the upper and lower heat transfer coefficient ratio X is the same as that in the embodiment described with reference to FIGS.

- the temperature standard deviation Y within the range from the minimum value Ymin to the minimum value Ymin + 10 ° C, variations in yield stress, tensile strength, etc. can be kept within the manufacturing tolerances, and the hot-rolled steel sheet H can be cooled uniformly. it can.

- the cooling water amount density ratio is within ⁇ 5% of the cooling water amount density ratio at which the temperature standard deviation Y is the minimum value Ymin, the temperature standard deviation Y is minimized from the minimum value Ymin.

- the value can be kept within a range of Ymin + 10 ° C.

- the ratio of the cooling water amount density (cooling water amount density ratio) is set within ⁇ 5% with respect to the cooling water amount density ratio at which the temperature standard deviation Y is the minimum value Ymin.

- this allowable range does not necessarily include the same upper and lower water density.

- the cooling capacity of the upper cooling apparatus 14a and the lower cooling apparatus 14b can be feedback controlled to adjust the cooling capacity to an appropriate cooling capacity qualitatively and quantitatively. Can be improved.

- the cooling section in which the hot-rolled steel sheet H is cooled may be divided into a plurality of, for example, two divided cooling sections Z1 and Z2 in the rolling direction.

- a cooling device 14 is provided in each of the divided cooling zones Z1 and Z2.

- a thermometer 40 and a shape meter 41 are provided at the boundary between the divided cooling zones Z1 and Z2, that is, downstream of the divided cooling zones Z1 and Z2.

- the cooling section is divided into two divided cooling sections, but the number of divisions is not limited to this and can be arbitrarily set.

- the cooling section may be divided into 1 to 5 divided cooling sections.

- the temperature and the wave shape of the hot-rolled steel sheet H on the downstream side of the divided cooling zones Z1 and Z2 are measured by the thermometers 40 and the shape meters 41, respectively. And based on these measurement results, the cooling capacity of the upper side cooling device 14a and the lower side cooling device 14b in each division

- the cooling capacity of the upper cooling device 14a and the lower cooling device 14b is feedback-controlled based on the measurement results of the thermometer 40 and the shape meter 41 on the downstream side, and the upper surface cooling heat removal amount and At least one of the bottom surface cooling heat removal amount is adjusted.

- the cooling capacity of the upper cooling device 14a and the lower cooling device 14b may be feedforward controlled based on the measurement results of the thermometer 40 and the shape meter 41 on the downstream side, Alternatively, feedback control may be performed. In any case, at least one of the upper surface cooling heat removal amount and the lower surface cooling heat removal amount is adjusted in the divided cooling zone Z2.

- the method for controlling the cooling capacity of the upper cooling device 14a and the lower cooling device 14b based on the measurement results of the thermometer 40 and the shape meter 41 is the same as that in the above embodiment described with reference to FIGS. Therefore, detailed description is omitted.

- the hot-rolled steel sheet H can be cooled more uniformly.

- the measurement results of the thermometer 40 and the shape meter 41 are used.

- at least one of the steepness of the wave shape of the hot-rolled steel sheet H and the sheet passing speed may be used.

- the temperature standard deviation Y of the hot-rolled steel sheet H corresponding to at least the steepness or the sheet passing speed is corrected by the same method as the above-described embodiment described with reference to FIGS.

- the hot rolled steel sheet H it is possible to finish the hot rolled steel sheet H so as to have a uniform shape and material in the sheet width direction.

- the temperature standard deviation in the sheet width direction of the hot-rolled steel sheet H is caused by the fact that the temperature standard deviation Y in the rolling direction is alternately generated on the left and right, so if the temperature standard deviation Y in the rolling direction is reduced, The temperature standard deviation in the width direction is further reduced.

- FIG. 18 shows an example of a state in which wave shapes having different amplitudes are formed in the plate width direction of the hot-rolled steel plate H by medium elongation. As described above, even when wave shapes having different amplitudes occur in the plate width direction and a temperature standard deviation is formed in the plate width direction, according to the above-described embodiment, the temperature standard in the plate width direction is formed. The deviation can be reduced.

- Example 1 The inventor of the present application uses, as a material, high tension (so-called high-tensile steel plate) with a plate thickness of 2.3 mm and a plate width of 1200 mm as a material, and forms a medium wave shape and an ear wave shape in the material, respectively, and the steepness is determined.

- High tension so-called high-tensile steel plate

- Cold rolling gauge fluctuation sheet thickness fluctuation

- average in the sheet width direction in the subsequent process ie, cold rolling process

- Temperature fluctuation was measured and evaluated.

- Example 1 the steepness when the medium wave shape is formed is represented as -0.5% to -2%, and the case where the ear wave shape is formed. The steepness was expressed as 0.5% to 2%. Further, the measurement of the medium wave shape and the ear wave shape was measured using a commercially available shape measuring instrument, and the measurement location of the medium wave shape is the center portion of the plate within 30 mm on the left and right sides of the plate center. The measurement location was 25 mm from the edge of the plate.

- the measurement results and evaluation results are shown in Table 5 below.

- the evaluation criteria in the following examples are A (good as a product) in which the cold-rolling gauge fluctuation in the subsequent process is suppressed to 0 to 25 ⁇ m, and B (allowable range) in which 25 to 50 ⁇ m. In this case, the value exceeding 50 ⁇ m is evaluated as C (product defect).

- the comprehensive evaluation in Table 5 will be described later.

- Table 5 the temperature standard deviation of each wave shape in the steel sheet rolling direction is also shown for reference.

- the cold rolling gauge fluctuation in the cold rolling process is 30 ⁇ m to 120 ⁇ m.

- the shape of the ear wave was formed (when the steepness was 0.5% to 2% in the table)

- the cold rolling gauge fluctuation in the cold rolling process was 21 ⁇ m to 84 ⁇ m.

- the plate thickness fluctuation in the cold rolling process of the steel plate is small in order to suppress a decrease in yield such as product defects. Therefore, as shown in Table 5 above, when an ear wave shape is formed on a steel sheet, if the steepness of the ear wave shape is more than 0% and within 1%, the cold-rolling gauge fluctuation is small (for example, Table 5). It was found that the evaluations A and B) can be suppressed. Furthermore, it was found that when the steepness of the ear wave shape is more than 0% and within 0.5%, the cold-rolling gauge fluctuation can be suppressed to a smaller value (for example, evaluation A in Table 5).

- Example 2 Next, the inventor of the present application forms a medium wave shape and an ear wave shape in the same material as in Example 1 as Example 2, and the steepness is 0% (no wave formation) to 2%.

- the cold-rolling gauge fluctuation sheet thickness fluctuation

- the sheet width direction average temperature fluctuation in the subsequent process that is, cold rolling process

- the plate thickness variation in the cold rolling process is small in order to suppress a decrease in yield such as product defects. Therefore, as shown in Table 6 above, in the case where an ear wave shape is formed on a steel sheet, if the steepness of the ear wave shape is more than 0% and within 1.5%, the cold-rolling gauge variation is small (for example, It was found that evaluations A and B) in Table 6 were suppressed. Therefore, when the plate passing speed is increased, the control range of the ear wave shape can be extended to 1.5%. Furthermore, it was found that when the steepness of the ear wave shape is more than 0% and within 0.5%, the cold-rolling gauge fluctuation can be suppressed to a smaller value (for example, evaluation A in Table 6).

- Example 3 the inventor of the present application forms a medium wave shape and an ear wave shape in the same material as in Examples 1 and 2 as Example 3, and the steepness is 0% (no wave formation) to 2%.

- the cold-rolled gauge fluctuation sheet thickness fluctuation

- the sheet width direction average temperature fluctuation in the subsequent process that is, cold rolling process