WO2014080795A1 - Underpants-type absorbent article - Google Patents

Underpants-type absorbent article Download PDFInfo

- Publication number

- WO2014080795A1 WO2014080795A1 PCT/JP2013/080520 JP2013080520W WO2014080795A1 WO 2014080795 A1 WO2014080795 A1 WO 2014080795A1 JP 2013080520 W JP2013080520 W JP 2013080520W WO 2014080795 A1 WO2014080795 A1 WO 2014080795A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sheet

- main body

- region

- longitudinal direction

- absorbent article

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/496—Absorbent articles specially adapted to be worn around the waist, e.g. diapers in the form of pants or briefs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers

- A61F13/514—Backsheet, i.e. the impermeable cover or layer furthest from the skin

- A61F13/51474—Backsheet, i.e. the impermeable cover or layer furthest from the skin characterised by its structure

- A61F13/51484—Backsheet, i.e. the impermeable cover or layer furthest from the skin characterised by its structure being inhomogeneous in the plane of the sheet, i.e. having zones of different properties or structures

Definitions

- the present invention relates to a pants-type absorbent article.

- the exterior body is divided into an abdominal exterior body disposed on the wearer's ventral side and a backside exterior body disposed on the wearer's back side, and the absorbent main body is divided into the abdominal exterior body and the back side

- a pants-type disposable diaper is known that is fixed so as to be bridged over the exterior body, and in which the left and right side edges of the ventral side exterior body and the left and right side edges of the back side exterior body are joined (for example, see Patent Documents 1 and 2). According to this diaper, it is not necessary to remove the trim from the original fabric of the exterior body in the manufacturing process of the diaper, or the amount of trim to be removed can be reduced, which is economically advantageous. It is also desirable from the viewpoint of reducing environmental load.

- the outer body is intended from the absorbent main body because the diaper and the wearer's body rub against each other when the diaper is worn or during the wearing operation. It may peel off without.

- the external force applied due to the wearer's movement is likely to concentrate, so the exterior body may be more easily separated from the absorbent main body.

- the present invention includes an abdominal exterior body disposed on the wearer's ventral side, a back exterior body disposed on the wearer's back side, and a span between the abdominal exterior body and the back exterior body.

- An absorbent main body fixed to these exterior bodies so as to pass, and a crotch sheet disposed on the outer surface side of the absorbent body, and along the longitudinal direction of the ventral exterior body and the back exterior body

- a pant-type absorbent article having a side seal portion formed by joining the abdominal exterior body and the back exterior body to both side edges and having an annular exterior portion configured thereby. is there.

- the pants-type absorbent article has a longitudinal direction along the direction in which the absorbent main body extends and a width direction perpendicular thereto.

- An absorptive main body comprises the surface sheet located in the side near a wearer's skin, the back sheet located in the side far from a wearer's skin, and the absorption core located between both sheets.

- the absorbent core has one or a plurality of deformation induction regions along the longitudinal direction.

- the joint between the ventral-side exterior body and the absorbent main body is performed at a plurality of ventral-side joints extending in the width direction and intermittent in the longitudinal direction.

- the joining of the backside exterior body and the absorbent main body is performed at a plurality of backside joining portions extending in the width direction and intermittent in the longitudinal direction.

- the crotch sheet and the back sheet are joined at a plurality of crotch joints extending in the longitudinal direction and intermittent in the width direction.

- ventral side outer member and the junction region KS F of the absorbent body the longitudinal length of the area SG F where the junction region MS overlaps the crotch sheet and the absorbent body, the longitudinal length of the junction region KS F 50% or less.

- back-side outer member and the junction region KS B of the absorbent body the longitudinal length of the area SG B which overlap the junction region MS and crotch sheet and the absorbent body, the longitudinal length of the junction region KS B 50% or less.

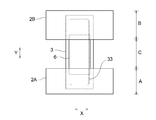

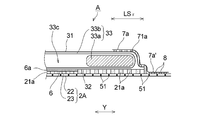

- FIG. 1 is a perspective view showing a pants-type disposable diaper as an embodiment of the pants-type absorbent article of the present invention.

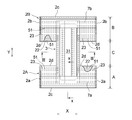

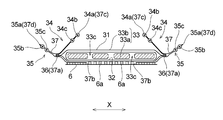

- FIG. 2 is a developed plan view of the state in which the diaper shown in FIG. 3 is a cross-sectional view taken along line III-III in FIG. 4A is a plan view of the absorbent core in the diaper shown in FIG. 2, and

- FIG. 4B is a cross-sectional view taken along the line bb in FIG. 4A.

- FIG. 5 is a plan view of the diaper shown in FIG. 2 as viewed from the back sheet side, and is a diagram showing an arrangement relationship among the abdomen and back exterior bodies, the absorbent main body, and the crotch sheet.

- FIG. 1 is a perspective view showing a pants-type disposable diaper as an embodiment of the pants-type absorbent article of the present invention.

- FIG. 2 is a developed plan view of the state in which the diaper shown in FIG. 3 is a cross-sectional view taken along line III-III in FIG. 4A

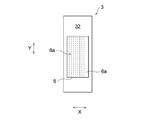

- FIG. 6 is a plan view showing a joined state between the absorbent main body and the crotch sheet in the diaper shown in FIG. 2.

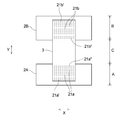

- FIG. 7 is a plan view showing a joined state of the abdominal and dorsal exterior bodies and the absorbent main body in the diaper shown in FIG.

- FIG. 8 is a plan view showing a joined state of the abdominal and dorsal exterior bodies, the absorbent main body, and the crotch sheet in the diaper shown in FIG.

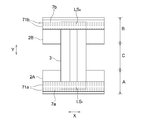

- FIG. 11 is a plan view showing a joined state of the abdominal and dorsal side end sheet, the abdominal and dorsal exterior body, and the absorbent main body in the diaper shown in FIG.

- the diaper 1 includes a rectangular sheet-like ventral exterior body 2A disposed on the wearer's belly side in a worn state, a rectangular sheet-like back exterior body 2B disposed on the wearer's back side, It comprises an absorbent main body 3 that is bridged and fixed to the side exterior body 2A and the back exterior body 2B. Both side edges 2a, 2a of the ventral side exterior body 2A and both side edges 2b, 2b of the back side exterior body 2B are joined, thereby forming a pair of side seal portions 4, 4. As a result, the annular exterior portion 10 composed of the abdominal exterior body 2A and the back exterior body 2B is formed.

- the diaper 1 is in a worn state, an abdominal side portion A disposed on the wearer's ventral side, a back side portion B disposed on the wearer's back side, and an abdominal side portion A. It has a crotch part C which is located between the back side part B and is arranged in a wearer's crotch part.

- the longitudinal direction of the diaper is a direction extending from the abdominal side A through the crotch C to the back side B or the opposite direction (Y direction in FIG. 2), and this direction is the same as the extending direction of the absorbent main body 3.

- a diaper width direction is a direction along a wearer's waistline direction, and is a direction (X direction in FIG.

- the diaper longitudinal direction is also simply referred to as the Y direction

- the diaper width direction is also simply referred to as the X direction.

- the “outer surface (outer surface side)” is a surface (surface side) directed to the side opposite to the wearer's skin side when the diaper is worn.

- the “inner surface (inner surface side)” is a surface (surface side) directed toward the wearer's skin when wearing a diaper.

- the absorbent main body 3 of the diaper 1 includes a liquid-permeable top sheet 31, a liquid-impermeable or water-repellent back sheet 32, and a cross-sectional view taken along line III-III in FIG.

- a liquid-retaining absorbent core 33 is disposed between both sheets 31 and 32.

- the absorbent main body 3 is formed in a rectangular shape that is long in the longitudinal direction Y.

- the surface sheet 31 is located on the side close to the wearer's skin.

- the back sheet 32 is located on the side far from the wearer's skin.

- the absorbent main body 3 has a first three-dimensional gather 34 that rises toward the center in the width direction X from the left and right side edges of the absorbent core 33 or in the vicinity thereof. Furthermore, the absorptive main body 3 has a second three-dimensional gather 35 that rises toward the outer side in the width direction X from the left and right side edges of the absorbent core 33 or the vicinity thereof. As for the 1st solid gather 34 and the 2nd solid gather 35, those base end parts 36 are located in the same position. As described above, the base end portion 36 is located on the left and right side edges of the absorbent core 33 or in the vicinity thereof. The base end portion 36 extends in the longitudinal direction Y. The first three-dimensional gather 34 and the second three-dimensional gather 35 are formed at least in the crotch part C of the absorbent main body 3 and extend to the ventral side part A and the back side part B beyond the crotch part C. It is preferable.

- the first three-dimensional gather 34 has a free end 34a and thread-like elastic members 34b and 34c located in the vicinity thereof. Both the thread-like elastic members 34b and 34c extend in the longitudinal direction Y. The thread-like elastic members 34b and 34c are fixed to the gather forming sheet 37 in an extended state. Similar to the first three-dimensional gather 34, the second three-dimensional gather has a free end 35a and thread-like elastic members 35b and 35c located in the vicinity thereof. Both the thread-like elastic members 35b and 35c extend in the longitudinal direction Y. The thread-like elastic members 35b and 35c are fixed to the gather forming sheet 37 in an extended state.

- the first three-dimensional gathers 34 and the second three-dimensional gathers 35 are formed from a single gather forming sheet 37.

- the gather forming sheet 37 is a rectangular sheet extending in the longitudinal direction, and has left and right first side edge portions 37a and second side edge portions 37b extending in the longitudinal direction.

- the first side edge portion 37 a of the rectangular sheet is positioned at the base end portion 36.

- the gather-forming sheet 37 is folded in two along a first folding line 37c extending in the longitudinal direction at a predetermined distance from the first side edge portion 37a toward the center in the width direction.

- the position of the first folding line 37 c becomes the free end 34 a of the first three-dimensional gather 34.

- the thread-like elastic members 34b and 34c are arranged in an extended state at the position of the first folding line 37c folded in the vicinity and the position near the first folding line 37c, and the thread-like elastic members 34b and 34c are disposed between the gather forming sheets 37 that overlap in two layers. Join and fix. Furthermore, the position corresponding to the base end portion 36 in the portion folded by folding in the gather forming sheet 37 is joined to the first side edge portion 37 a of the gather forming sheet 37. Thereby, the first three-dimensional gather 34 is formed. Furthermore, the part which is located in the 2nd side edge part 37 side rather than the site

- the gather forming sheet 37 is again inserted along the second folding line 37d extending in the longitudinal direction Y at a position spaced a predetermined distance from the base end portion 36 to the outer side in the width direction. Fold it.

- the position of the second folding line 37d becomes the free end 35a of the second solid gather 35.

- the elastic elastic members 35b and 35c are arranged in an extended state at the position of the second folded curve 37d folded in the vicinity and the position near the second folding curve 37d, and the elastic elastic members 35b and 35c are arranged between the gather forming sheets 37 that overlap in two layers. Join and fix.

- the position corresponding to the base end portion 36 of the gather forming sheet 37 that is folded back by the second folding curve 37d is the first side edge 37a of the gather forming sheet 37. Joined with. Thereby, the second three-dimensional gather 35 is formed. Furthermore, the part located in the 2nd side edge part 37b side rather than the part joined in the base end part 36 among the sheet

- a mixed fiber 33a of hydrophilic fibers such as fluff pulp and a superabsorbent polymer is covered with a hydrophilic core wrap sheet 33b such as tissue paper or hydrophilic nonwoven fabric.

- a hydrophilic core wrap sheet 33b such as tissue paper or hydrophilic nonwoven fabric.

- hydrophilic nonwoven fabric for example, a hydrophilic spunbond-meltblown-spunbond nonwoven fabric or the like can be used.

- various kinds of materials conventionally used for absorbent articles such as disposable diapers can be used without particular limitation.

- a single layer or multilayer nonwoven fabric, a perforated film, or the like can be used.

- a resin film, a laminate of a resin film and a nonwoven fabric, or the like can be used.

- a gather forming sheet 37 a water-repellent nonwoven fabric or the like can be used.

- the absorbent core 33 has a plurality of deformation induction regions 33c extending along the longitudinal direction Y. It is preferable that the deformation induction region 33c is formed at least in the crotch part C of the absorbent main body 3 and extends to the abdominal part A and the back part B beyond the crotch part C.

- the deformation induction region 33c is a portion serving as a flexible shaft that deforms the absorbent core 33 along the deformation induction region 33c.

- an opening that penetrates the absorbent core 33 in its thickness direction can be employed.

- region in the absorption core 33 is employable as the deformation

- region in the absorption core 33 is employable.

- the soft texture is more remarkable by making the joining pattern of the absorbent main body 3 and the crotch sheet 6 into a joining pattern of a plurality of strips extending in the longitudinal direction Y and intermittent in the width direction X. It will be a thing. 3 and 4 (a) and 4 (b) show a state in which a plurality of deformation induction regions 33c are formed, but depending on the degree of softness required for the diaper 1, Only one line of the deformation induction region 33c may be formed.

- the crotch sheet 6 is disposed on the outer surface of the back sheet 32 in the absorbent main body 3. As shown in FIG. 5, the crotch sheet 6 is disposed in at least the crotch part C in the absorbent main body 3 in the longitudinal direction Y, and extends to the abdominal part A and the back part B beyond the crotch part C. It is preferable.

- seat 6 is arrange

- the crotch sheet 6 is exposed on the outer surface of the diaper 1 only at the crotch part C.

- the crotch sheet 6 is used for the purpose of protecting the back sheet 32 by covering the back sheet 32 which may have low mechanical strength. Moreover, it is used for the purpose of improving the impression and feel of the appearance of the diaper 1.

- the width of the inseam sheet 6 is preferably the same as or narrower than the distance between the free ends 35a of the left and right second three-dimensional gathers 35 described above. By carrying out like this, since the impression and the touch of the external appearance of the diaper 1 can be improved, without inhibiting the elasticity of the 2nd three-dimensional gathers 35, it is preferable. Furthermore, the width of the crotch sheet 6 is preferably the same as the width of the absorbent core 33. This is most effective in improving the appearance and feel of the diaper 1. In the present embodiment, since the absorbent core 33 is substantially rectangular in plan view, the width of the absorbent core 33 is constant when viewed along the longitudinal direction Y. Depending on the shape of 33, the width may be different when viewed along the longitudinal direction Y. In such a case, the width of the crotch sheet 6 is preferably the same as the maximum width of the absorbent core 33.

- the absorbent main body 3 and the crotch sheet 6 are such that the back sheet 32 and the crotch sheet 6 of the absorbent main body 3 extend in the longitudinal direction Y and are intermittent in the width direction X. It is joined at a plurality of crotch joints 6a.

- Each crotch joint 6a is formed by application of an adhesive, for example.

- Each crotch joint 6a is formed in a stripe shape having a predetermined width.

- the formation pattern of each crotch joint part 6a is not limited to this, and may be formed in another pattern as long as it is formed in a streak shape along the longitudinal direction Y.

- a spiral bonding pattern or an ⁇ -shaped bonding pattern may be employed.

- Each crotch joint portion 6 a is formed continuously or discontinuously over the entire lengthwise direction of the crotch sheet 6. Between the crotch joint 6a adjacent in the width direction X, the back sheet 32 and the crotch sheet 6 are not joined.

- the rigidity of the absorbent main body 3 can be reduced, and the diaper 1 has a soft texture as a whole. Can be.

- the rigidity of the absorbent main body 3 can be further reduced due to the fact that the direction in which the crotch joint 6a extends coincides with the direction in which the deformation induction region 33c formed in the absorbent core 33 extends. It becomes possible.

- the crotch joint 6a that joins the back sheet 32 and the crotch sheet 6 it is preferable that the crotch joint 6a located on the outermost side in the width direction X is continuously formed over the entire length. As a result, even when the wearer's body rubs against the crotch sheet 6 when the diaper 1 is worn, the crotch sheet 6 is difficult to peel from the back sheet 32.

- the ventral-side exterior body 2 ⁇ / b> A has a horizontally long rectangular shape when the diaper 1 is deployed and extended (see FIG. 2), and a pair of left and right side edges 2 a and 2 a along the Y direction, It has a pair of upper and lower end edges 2c, 2d (upper end edge 2c, lower end edge 2d) along the X direction.

- the back side exterior body 2B has a horizontally long rectangular shape when the diaper 1 is unfolded and extended (see FIG. 2), and a pair of left and right side edges 2b and 2b along the Y direction, and along the X direction. It has a pair of upper and lower end edges 2c, 2d (upper end edge 2c, lower end edge 2d).

- the ventral-side exterior body 2 ⁇ / b> A and the back-side exterior body 2 ⁇ / b> B have a uniform length in the longitudinal direction Y in the width direction X.

- the length in the longitudinal direction Y of either the ventral-side exterior body 2A or the back-side exterior body 2B may be longer than the other exterior body in a part of the exterior body.

- the back side exterior body 2 ⁇ / b> B extends to the crotch C side in the longitudinal direction Y from the side seal portions 4, 4 and covers the buttocks.

- the ventral exterior body 2A and the back exterior body 2B are not continuous at the crotch, and both exterior bodies are joined by the side seal portions 4 and 4 to form the annular exterior portion 10. Good.

- dorsal exterior body 2B are joined in the shape of a palm, and as shown in FIG. , 4 are formed.

- known joining means such as a heat seal, a high frequency seal, an ultrasonic seal, and an adhesive are used.

- a waist opening 5a and a pair of leg openings 5b are formed.

- the absorbent main body 3 has an adhesive (not shown) in the center region in the width direction X of the ventral side exterior body 2 ⁇ / b> A at one end side in the longitudinal direction Y (a portion overlapping the ventral side exterior body 2 ⁇ / b> A). ) Is fixed through. Similarly, the other end side in the longitudinal direction Y (the portion overlapping the back side exterior body 2B) is fixed to the central region in the width direction Y of the back side exterior body 2B via an adhesive (not shown). Yes. Details of the bonding between the absorbent main body 3 and the ventral exterior body 2A and the details of the bonding between the absorbent main body 3 and the back exterior body 2B will be described later.

- the configuration of the abdominal exterior body 2A of the diaper 1 will be mainly described, but the back exterior body 2B has the same configuration unless otherwise specified. Accordingly, the description of the ventral exterior body 2A is applied to points that are not particularly described with respect to the back exterior body 2B.

- the ventral exterior body 2A in the diaper 1 includes an outer layer sheet 22 and an inner layer sheet 23 as shown in FIG.

- the outer layer sheet 22 forms the outermost surface of the ventral-side exterior body 2A.

- the inner layer sheet 23 is disposed adjacent to the outer layer sheet 22 inside the outer layer sheet 22.

- the outer layer sheet 22 and the inner layer sheet 23 have the same shape.

- the outer layer sheet 22 and the inner layer sheet 23 have the same shape.

- Each waistline elastic member 51 extends in the width direction X, and is fixed between the outer layer sheet 22 and the inner layer sheet 23 in an expanded state.

- the elastic member 51 is not disposed in the portion of the ventral-side exterior body 2A that overlaps the absorbent main body 3, or the elastic member 51 is disposed, the elasticity of the elastic member 51 is not exhibited. It is arranged in such a state.

- the waistline elastic member 51 due to the shrinkage of the waistline elastic member 51, a large number of wrinkles or irregularities are generated in the outer layer sheet 22 to form a gather (see FIG. 1).

- a gather is not formed in the site

- the absorbent main body 3 has a crotch part C of the diaper 1 in the central region in the longitudinal direction Y, and regions extending from the crotch part C to the front and rear in the longitudinal direction Y are the ventral-side exterior body 2A and The back side exterior body 2B is laminated and joined.

- the absorptive main body 3 is laminated and bonded to these exterior bodies 2A and 2B on the skin facing surface side of the abdominal exterior body 2A and the back exterior body 2B. As shown in FIG.

- the bonding between the ventral-side exterior body 2 ⁇ / b> A and the absorbent main body 3 is performed in a plurality of ventral-side bonding portions 21 a extending in the width direction X and intermittent in the longitudinal direction Y.

- the joining of the backside exterior body 2B and the absorbent main body 3 is also performed at a plurality of backside joining portions 21b extending in the width direction X and intermittent in the longitudinal direction Y.

- the ventral joint 21a and the back joint 21b are formed by application of an adhesive, for example.

- the ventral joint 21a and the back joint 21b are formed in a stripe shape having a predetermined width.

- the formation pattern of the ventral joint 21a and the back joint 21b is not limited to this, and may be formed in other patterns as long as it is formed in a streak shape along the width direction X.

- a spiral bonding pattern or an ⁇ -shaped bonding pattern may be employed.

- the ventral joint 21 a and the back joint 21 b are formed continuously or discontinuously over the width direction X of the absorbent main body 3.

- the absorptive main body 3 In the longitudinal direction Y, the absorptive main body 3, the abdominal exterior body 2 ⁇ / b> A, and the back exterior body 2 ⁇ / b> B are in a non-joined state between the adjacent abdominal joint 21 a and the back junction 21 b.

- the abdominal joint 21a ′ located on the outermost side in the longitudinal direction X has its full length. It is preferable that they are continuously formed.

- the ventral side joint portion 21a "located in the innermost side in the longitudinal direction X is also formed continuously over the entire length thereof, thereby joining the ventral side exterior body 2A and the absorbent main body 3 together. Even when the wearer's body rubs against the abdominal exterior body 2A or the absorbent main body 3 in the wearing state of the diaper 1, the abdominal exterior body 2A is difficult to peel from the absorbent main body 3.

- the part 21b ′ and the back side joining part 21b ′′ located in the innermost part in the longitudinal direction X are continuously formed over the entire length.

- a joint region between the ventral-side exterior body 2 ⁇ / b> A and the absorbent main body 3 is indicated by a symbol KS F.

- region of the back side exterior body 2B and the absorptive main body 3 is shown by the code

- both the junction region KS F and the junction region KS B are indicated by right-down hatching.

- region of the crotch sheet 6 and the absorptive main body 3 is shown by the code

- the junction region MS is indicated by the left-down hatching.

- the ventral region A there is a region where the junction region KS F and the junction region MS overlap, that is, a region where the right-down hatching and the left-down hatching intersect. ing. Indicated at SG F is referred to as the overlap region of the region.

- the back side portion B there is a region where the junction region KS B and the junction region MS overlap, that is, a region where the right-down hatching and the left-down hatching intersect. Indicated at SG B is referred to as the overlap region of the region.

- the length in the longitudinal direction Y of the overlapping region SG F is 50% or less of the length in the longitudinal direction Y of the bonding region KS F , and preferably 45% or less. More preferably, it is 35% or less.

- the lower limit of this value is preferably 5% or more, more preferably 10% or more, and even more preferably 15% or more.

- the length of the overlapping region SG F in the longitudinal direction Y is preferably 5% or more and 50% or less of the length of the joining region KS F in the longitudinal direction Y, and more preferably 10% or more and 45% or less. More preferably, it is 15% or more and 35% or less.

- the overlap length in the longitudinal direction Y of the region SG B is, has become less than 50% of the longitudinal direction Y length of the junction region KS B, preferably 45% or less, more preferably Is 35% or less.

- the lower limit of this value is preferably 5% or more, more preferably 10% or more, and even more preferably 15% or more.

- the length of the overlapping regions SG F , SG B in the longitudinal direction Y is set to the above-described range with respect to the length of the joining regions KS F , KS B in the longitudinal direction Y. Without impairing the softness and air permeability, it is possible to effectively prevent each of the exterior bodies 2A and 2B from being unintentionally peeled off from the absorbent main body 3 when the diaper 1 is worn.

- the length MS F to abdominal end 6 of the side 2A side of the crotch sheet 6 ', overlapping the longitudinal length of the area SG F is 50% or less, preferably 35% or less, more preferably 25 % Or less.

- the lower limit of this value is preferably 2% or more, more preferably 5% or more, and even more preferably 10% or more.

- the length in the longitudinal direction of the overlapping region SG B is 50% or less, preferably 35% or less with respect to the length MS B from the position M to the end 6 ′′ of the crotch seat 6 on the back side 2B side.

- the lower limit of this value is preferably 2% or more, more preferably 5% or more, still more preferably 10% or more, for example, length MS F the longitudinal length of the overlap region SG F for preferably not less than 50% 2%, further preferably 35% or less than 5%, or less more preferably from 25% 10% or more.

- the length in the longitudinal direction of the overlapping region SG B with respect to the length MS B is preferably 2% to 50%, more preferably 5% to 35%, and even more preferably 10% to 25%. is there.

- a modified guiding area 33c of the absorbent core 33 preferably does not overlap in the thickness direction of the diaper 1.

- junction region KS B junction regions KS F and the back side B of the stomach portion A described above also relates to the junction region KS B junction regions KS F and the back side B of the stomach portion A described above, these junction regions KS F, a longitudinal joint strength per unit area of the KS B, the junction region MS described above

- the width direction bonding strength per unit area of the bonding regions KS F and KS B is higher than the width direction bonding strength per unit area of the bonding region MS. It is preferable from the viewpoint of improving softness, touch and breathability while effectively preventing peeling of the joint regions KS F and KS B during use.

- the basis weight of the applied adhesive may be controlled, or the area of the applied adhesive may be controlled.

- the method for measuring the longitudinal bonding strength per unit area of the bonding regions KS F and KS B is as follows.

- the width direction of the sample piece is a diaper width direction (X direction) along the crotch side lower end of the ventral exterior body 2A from the joint region KS F ) In the central region of 50 mm in width.

- the longitudinal direction of the sample piece is a region having a length of 50 mm in the longitudinal direction (Y direction) of the diaper from the positions of both ends having a width of 50 mm toward the waist end side of the ventral-side exterior body.

- the 50 mm ⁇ 50 mm region is cut out in a state where the exterior body and the sheet member from which the surface sheet, the absorbent core, and the three-dimensional nonwoven fabric standing on the skin side are removed from the absorbent main body are joined in the joining region KS F.

- the width direction of the harvesting process sample piece of sample piece from the joint area KS B in dorsal B is along the crotch side lower end of the back-side outer body 2B from the junction region KS B, the diaper width direction (X direction ) In the central region of the width 50 mm.

- the longitudinal direction of the sample piece is a region having a length of 50 mm in the longitudinal direction (Y direction) of the diaper from the positions of both ends having a width of 50 mm toward the waist end side of the backside exterior body.

- the 50 mm ⁇ 50 mm region is cut out in a state where the exterior body and the sheet member from which the surface sheet, the absorbent core, and the three-dimensional nonwoven fabric standing on the skin side are removed from the absorbent main body are joined in the joining region KS B.

- the sample piece is pulled at a pulling speed of 300 mm / min so as to be peeled toward the waist end side of the diaper, and an integral load (N) when the joining regions KS F and KS B are all peeled off is obtained.

- the integrated load (N) is divided by the measured area within the sample piece (50 mm ⁇ 40 mm). The obtained value is defined as the longitudinal bonding strength per unit area of the bonding regions KS F and KS B.

- the width direction bonding strength per unit area of the bonding regions KS F and KS B is measured by rotating the tensile direction of the measurement sample by 90 degrees in the measurement of the longitudinal direction bonding strength.

- the measuring method of the width direction bonding strength per unit area of the bonding region MS is as follows.

- the width direction of the sample piece is a region of 50 mm in the central region in the diaper width direction (X direction) along the diaper width direction end of the crotch sheet 6.

- the longitudinal direction of the sample piece is a region having a length of 50 mm from the positions of both ends having a width of 50 mm toward the diaper longitudinal direction (Y direction).

- the 50 mm ⁇ 50 mm region is cut out in a state where the crotch sheet 6 and the sheet member from which the surface sheet, the absorbent core, and the three-dimensional nonwoven fabric standing on the skin side are removed from the absorbent main body are joined in the joining region MS.

- the obtained sample piece can be peeled from the end of the inseam sheet 6 in the width direction between chucks (distance between chucks: 15 mm) of a Tensilon tensile tester (product name “RTA-100” manufactured by Orientec Co., Ltd.). Hold it. At that time, a portion 10 mm in the longitudinal direction is used as a gripping portion for the chuck, and if there is a joint portion in the region, it is peeled off in advance. Next, the sample piece is pulled at a pulling speed of 300 mm / min so as to be peeled toward the center side in the width direction of the diaper, and an integrated load (N) when all of the joining regions MS have been peeled is obtained. Then, the integral load (N) is divided by the measured area of the sample piece (50 mm ⁇ 40 mm). The obtained value is defined as the bonding strength in the width direction per unit area of the bonding region MS.

- the longitudinal direction bonding strength per unit area of the bonding region MS is measured by rotating the tensile direction of the measurement sample by 90 degrees in the measurement of the width direction bonding strength.

- the end of the absorbent main body 3 on the ventral side 2A side in the longitudinal direction Y is covered with the ventral side end sheet 7a.

- the edge part by the side of the back side 2B of the longitudinal direction Y is coat

- the ventral side end sheet 7 a and the back side end sheet 7 b are disposed on the skin facing surface side of the absorbent main body 3.

- Both end sheets 7 a and 7 b are used to prevent leakage of fluff pulp and superabsorbent polymer, which are constituent materials of the absorbent core 33, from the end of the absorbent main body 3.

- various non-woven fabrics can be used as the end sheets 7a and 7b.

- ventral end sheet 7a and the dorsal end sheet 7b are joined to the ventral exterior body 2A and the back exterior body 2B at a portion extending from the periphery of the absorbent main body 3.

- the ventral side end sheet 7 a extends in the width direction X and has a plurality of ventral side end joint portions 71 a intermittent in the longitudinal direction Y.

- the main body 3 is joined.

- the back end sheet 7b extends in the width direction X and is joined to the back exterior body 2B and the absorbent main body 3 at a plurality of back side end joints 71b intermittent in the longitudinal direction Y. Yes.

- the end joints 71a and 71b are formed in a stripe shape having a predetermined width.

- the formation pattern of each end joint 71a, 71b is not limited to this, and may be formed in other patterns as long as it is formed in a streak shape along the width direction X.

- a spiral bonding pattern or an ⁇ -shaped bonding pattern may be employed.

- the end joints 71a and 71b are formed continuously or discontinuously over the entire region in the width direction X of the end sheets 7a and 7b. Between the end joints 71a and 71b adjacent in the longitudinal direction Y, the end sheets 7a and 7b, the exterior bodies 2A and 2B, and the absorbent main body 3 are not joined.

- the length in the longitudinal direction Y of the region LS F (see FIG. 9) where the ventral side end sheet 7a and the absorbent main body 3 overlap is the junction region KS F between the ventral exterior body 2A and the absorbent main body 3 described above. It is preferably 50% or less, more preferably 45% or less, and even more preferably 35% or less with respect to the length in the longitudinal direction (see FIG. 8).

- the lower limit of this value is preferably 5% or more, more preferably 10% or more, and even more preferably 15% or less.

- the length in the longitudinal direction of the region LS F is preferably 5% or more and 50% or less, more preferably 10% or more and 45% or less, with respect to the length in the longitudinal direction of the bonding region KS F. More preferably, it is 15% or more and 35% or less. By doing in this way, it becomes possible to improve the softness and breathability in ventral part A.

- the length in the longitudinal direction Y of the region LS B (see FIG. 9) where the back side end sheet 7b and the absorbent main body 3 overlap is the same as that of the back side exterior body 2B described above. It is preferably 50% or less, more preferably 45% or less, and further preferably 35% or less with respect to the length in the longitudinal direction of the bonding region KS B (see FIG. 8) with the adhesive main body 3. preferable.

- the lower limit of this value is preferably 5% or more, more preferably 10% or more, and even more preferably 15% or more.

- the length in the longitudinal direction of the region LS B is preferably 5% or more and 50% or less, more preferably 10% or more and 45% or less, with respect to the length in the longitudinal direction of the bonding region KS B. More preferably, it is 15% or more and 35% or less. By doing in this way, it becomes possible to improve the softness and breathability in back side B.

- ventral side end sheet 7a and the back side end sheet 7b There is no particular limitation on the material constituting the ventral side end sheet 7a and the back side end sheet 7b.

- the ventral side exterior body 2A and the back side exterior body 2B are composed of the outer layer sheet 22 and the inner layer sheet 23.

- the ventral end sheet 7 a and the back end sheet 7 b are made of the same material as the outer layer sheet 22. This is advantageous in that the touch on the outer side of the diaper is uniform, and an integrated touch like underwear is obtained despite the fact that the exterior body and the absorbent main body are divided.

- FIG. 10 is a sectional view taken along line XX in FIG.

- the ventral end sheet 7a extends outward from the end in the longitudinal direction Y of the absorbent main body 3, and the extending portion 7a 'is joined to the ventral exterior body 2A.

- the extension portion 7 a ′ and the ventral-side exterior body 2 ⁇ / b> A are joined at the extension region joint portion 8.

- the joining at the extension region joining portion 8 can be performed by, for example, an adhesive.

- the adhesive may be applied to the surface of the extending portion 7a ′ facing the ventral exterior body 2A, or may be applied to the surface of the ventral exterior body 2A facing the extending portion 7a ′. Good.

- FIG. 10 is a diagram showing a cross-sectional structure of the ventral side A, and the cross-sectional structure of the dorsal side B is the same as FIG.

- FIG. 10 extends in the width direction of the diaper 1 (in the direction orthogonal to the paper surface) and is intermittent in the longitudinal direction Y.

- an adhesive may be applied to the surface of the ventral exterior body 2A facing the extending portion 7a ′ without any gap.

- FIG. 11 can also be adopted. In FIG. 11, in the region LS F where the ventral end sheet 7 a and the absorbent main body 3 overlap, the adhesive is continuously applied to the region 72 a having a predetermined width extending outward from the peripheral edge of the absorbent main body 3. It is applied without a gap, and the ventral end sheet 7a and the absorbent main body 3 are joined by the adhesive.

- FIG. 11 in the region LS F where the ventral end sheet 7 a and the absorbent main body 3 overlap, the adhesive is continuously applied to the region 72 a having a predetermined width extending outward from the peripheral edge of the absorbent main body 3. It is applied without a gap, and the ventral end sheet 7a and the absorbent main body 3 are joined by the adhesive

- the region 72 a is indicated by left-downward hatching. Outside the region 72a, the ventral end sheet 7a and the ventral exterior body 2A are joined at a plurality of ventral end joints 71a extending in the width direction X and intermittent in the longitudinal direction Y. ing. Similarly, in the region LS B where the back-side end sheet 7b and the absorbent main body 3 overlap, the adhesive continuously extends to the region 72b having a predetermined width extending outward from the peripheral edge of the absorbent main body 3 without a gap. The ventral end sheet 7b and the absorbent main body 3 are joined by the adhesive. In FIG. 11, the region 72 b is indicated by left-down hatching.

- the back end sheet 7b and the back exterior body 2B are joined at a plurality of ventral end joining portions 71b extending in the width direction X and intermittent in the longitudinal direction Y. is doing.

- the adhesive can be applied to the regions of the ventral end sheet 7a and the back end sheet 7b corresponding to the regions 72a and 72b without any gaps.

- the adhesive can be applied intermittently in the longitudinal direction Y, extending in the width direction X to the regions outside the regions 72a and 72b.

- the dimensions at each part described so far are dimensions (design dimensions) in a state where each elastic member is extended and each member is stretched.

- the said embodiment is an example which applied this invention to the underpants type disposable diaper

- the underpants type absorbent article of this invention is applicable similarly to other absorbent articles, for example, a shorts type sanitary napkin etc. .

- the present invention further discloses the following pant-type absorbent articles with respect to the above-described embodiments.

- ⁇ 1> A ventral-side exterior body disposed on the wearer's ventral side, a back-side exterior body disposed on the wearer's back side, and a bridge between the abdominal-side exterior body and the back-side exterior body.

- the absorbent body fixed to these exterior bodies, and a crotch sheet disposed on the outer surface side of the absorbent body, both sides along the longitudinal direction of the ventral exterior body and the back exterior body

- a pants-type absorbent article having a side seal portion formed by joining the ventral exterior body and the back exterior body to the edge, and having an annular exterior portion configured thereby,

- the article has a longitudinal direction along the direction in which the absorbent main body extends, and a width direction orthogonal thereto.

- the absorbent main body comprises a top sheet located on the side close to the wearer's skin, a back sheet located on the side far from the wearer's skin, and an absorbent core located between both sheets,

- the absorbent core has one or more deformation induction regions along the longitudinal direction, Joining the ventral exterior body and the absorbent main body is performed in a plurality of ventral side joints extending in the width direction and intermittent in the longitudinal direction, The joining of the backside exterior body and the absorbent main body is performed in a plurality of backside joining portions extending in the width direction and intermittent in the longitudinal direction, Joining of the crotch sheet and the back sheet is performed in a plurality of crotch joints extending in the longitudinal direction and intermittent in the width direction,

- the ventral side outer member and the junction region KS F of the absorbent body the longitudinal length of the area SG F where the junction region MS overlaps the crotch sheet and the absorbent body, the longitudinal length of the junction region KS F Less than 50% of And back-side outer

- the longitudinal length of the overlap region SG F is, the longitudinal length of the junction region KS F, preferably 45% or less, more preferably 35% or less, preferably 5 % Or more, more preferably 10% or more, more preferably 15% or more,

- the length in the longitudinal direction of the overlapping region SG F is preferably 5% or more and 50% or less, more preferably 10% or more and 45% or less, and more preferably 15% of the length of the joining region KS F in the longitudinal direction.

- the longitudinal length of the overlap region SG B is a length in the longitudinal direction Y of the joining region KS B, preferably 45% or less, more preferably 35% or less, preferably Is 5% or more, more preferably 10% or more, more preferably 15% or more,

- the length of the overlapping region SG B in the longitudinal direction is preferably 5% or more and 50% or less, more preferably 10% or more and 45% or less, and more preferably 15% of the length of the joining region KS B in the longitudinal direction.

- the length in the longitudinal direction of the joining region KS B of the backside exterior body and the absorbent main body and the region SG B where the joint region MS of the crotch sheet and the absorbent main body overlaps is equal to the longitudinal direction of the article.

- the underpants-type absorbent article according to any one of the above items ⁇ 1> to ⁇ 3>, which is 50% or less with respect to a length MS B from a position to be divided to an end of the crotch sheet on the back side.

- ⁇ 5> The length in the longitudinal direction of the overlapping region SG F with respect to the length MS F from the position M at which the pant-type absorbent article is divided into two equal parts in the longitudinal direction to the end of the inseam sheet on the stomach side

- it is preferably 35% or less, more preferably 25% or less, preferably 2% or more, more preferably 5% or more, and still more preferably 10% or more.

- the length in the longitudinal direction of the overlapping region SG F with respect to the length MS F is preferably 2% to 50%, more preferably 5% to 35%, and even more preferably 10% to 25%.

- the length in the longitudinal direction of the overlapping region SG B with respect to the length MS B from the position M at which the pant-type absorbent article is equally divided in the longitudinal direction to the end of the crotch sheet on the back side is preferably 35% or less, more preferably 25% or less, preferably 2% or more, more preferably 5% or more, and still more preferably 10% or more.

- the length in the longitudinal direction of the overlapping region SG B with respect to the length MS B is preferably 2% to 50%, more preferably 5% to 35%, and even more preferably 10% to 25%.

- the abdomen end sheet and the dorsal end sheet covering the abdomen side end and the dorsal side end of the absorbent main body are disposed on the skin facing surface side of the absorptive main body. And Any one of the above ⁇ 1> to ⁇ 6>, wherein the ventral end sheet and the dorsal end sheet are joined to the ventral exterior body and the back exterior body at a portion extending from the periphery of the absorbent main body.

- the ventral end sheet extends in the width direction and is joined to the ventral exterior body and the absorbent main body in a plurality of ventral end joints intermittent in the longitudinal direction.

- ⁇ 10> The pants-type absorbent article according to any one of ⁇ 1> to ⁇ 9>, wherein the ventral end sheet and the dorsal end sheet do not overlap with the crotch sheet.

- the ventral exterior body has an outer layer sheet and an inner layer sheet disposed on the inner side of the outer layer sheet, and the outer layer sheet and the ventral end portion sheet are made of the same material, ⁇ 1> to ⁇ 10>, wherein the backside exterior body includes an outer layer sheet and an inner layer sheet disposed inside the outer layer sheet, and the outer layer sheet and the back end sheet are made of the same material.

- the underpants type absorbent article according to any one of the above.

- the absorbent main body according to any one of ⁇ 1> to ⁇ 12>, wherein the absorbent main body has a first three-dimensional gather that rises toward the center in the width direction from the left and right side edges of the absorbent core or the vicinity thereof.

- the underpants type absorbent article as described.

- the crotch sheet is disposed at least in the crotch part of the absorbent main body with respect to the longitudinal direction, and extends to the ventral part A and the back part B beyond the crotch part.

- the underpants type absorbent article according to any one of ⁇ 13>.

- the absorbent main body is a first three-dimensional gather that stands from the left and right side edges of the absorbent core or the vicinity thereof toward the center in the width direction, and the left and right side edges of the absorption core or the vicinity thereof toward the outer side in the width direction. And a second three-dimensional gather that stands up The underpants-type absorbent article according to any one of ⁇ 1> to ⁇ 14>, wherein the width of the crotch sheet is equal to or smaller than a distance between free ends of the left and right second three-dimensional gathers. .

- the absorbent main body is a first three-dimensional gather that stands from the left and right side edges of the absorbent core or the vicinity thereof toward the center in the width direction, and the left and right edges of the absorption core or the vicinity thereof toward the width direction outward.

- a second three-dimensional gather that stands up

- the first three-dimensional gather and the second three-dimensional gather are the pant-type absorbent articles according to any one of the above items ⁇ 1> to ⁇ 16>, wherein the base end portions are located at the same position.

- the absorbent main body is a first three-dimensional gather that stands from the left and right side edges of the absorbent core or the vicinity thereof toward the center in the width direction, and the left and right side edges of the absorption core or the vicinity thereof toward the width direction outward.

- a second three-dimensional gather that stands up The first three-dimensional gather and the second three-dimensional gather are formed at least in the crotch part of the absorbent main body, and extend from the crotch part to the abdominal side part and the dorsal side part ⁇ 1> to ⁇ 18 >

- the underpants type absorbent article as described in any one of>.

- the absorbent main body has a first three-dimensional gather that stands from the left and right side edges of the absorbent core or the vicinity thereof toward the center in the width direction,

- the first three-dimensional gather has a thread-like elastic member located at its free end and in the vicinity thereof,

- the thread-like elastic member extends in the longitudinal direction,

- the pants-type absorbent article according to any one of ⁇ 1> to ⁇ 19>, wherein the thread-like elastic member is in an extended state and is fixed to the gather forming sheet.

- the absorbent main body has a second three-dimensional gather that rises from the left and right side edges of the absorbent core or the vicinity thereof toward the outer side in the width direction,

- the second three-dimensional gather has a thread-like elastic member located at the free end and the vicinity thereof,

- the thread-like elastic member extends in the longitudinal direction

- the pants-type absorbent article according to any one of ⁇ 1> to ⁇ 20>, wherein the thread-like elastic member is in an extended state and is fixed to the gather forming sheet.

- the absorbent main body is a first three-dimensional gather that stands from the left and right side edges of the absorbent core or the vicinity thereof toward the center in the width direction, and the left and right edges of the absorption core or the vicinity thereof toward the width direction outward.

- a second three-dimensional gather that stands up The pant-type absorbent article according to any one of ⁇ 1> to ⁇ 21>, wherein the first three-dimensional gather and the second three-dimensional gather are formed from a single sheet for gather formation.

- ⁇ 26> The pants-type absorbent article according to ⁇ 25>, wherein the crotch joint is formed in a stripe shape having a predetermined width.

- ⁇ 27> The pants-type absorbent article according to ⁇ 25> or ⁇ 26>, wherein the crotch joint is formed continuously or discontinuously throughout the longitudinal direction of the crotch sheet.

- ⁇ 28> The pant-type absorbent article according to any one of ⁇ 25> to ⁇ 27>, wherein the back sheet and the crotch sheet are in a non-bonded state between the crotch joints adjacent in the width direction.

- the crotch joint located on the outermost side in the width direction is continuously formed over the entire length thereof.

- ⁇ 31> The pant-type absorbent article according to any one of ⁇ 1> to ⁇ 30>, wherein the ventral-side exterior body is a rectangular sheet shape and the back-side exterior body is a rectangular sheet shape.

- ⁇ 32> The pant-type absorbent article according to any one of ⁇ 1> to ⁇ 30>, wherein the absorbent main body is formed in a rectangular shape that is long in a longitudinal direction.

- the absorbent core is configured by covering a mixed fiber of a hydrophilic fiber and a superabsorbent polymer with a hydrophilic core wrap sheet. Pants-type absorbent article.

- ⁇ 34> The pant-type absorbent article according to any one of ⁇ 1> to ⁇ 33>, wherein the ventral-side exterior body and the back-side exterior body have a longitudinal length that is uniform in the width direction.

- ⁇ 35> Any one of the items ⁇ 1> to ⁇ 34>, wherein the longitudinal length of one of the ventral exterior body and the back exterior body is longer than the other exterior body in a part of the exterior body.

- ⁇ 36> The pant-type absorbent article according to any one of ⁇ 1> to ⁇ 35>, wherein the back side exterior body extends toward the crotch part in the longitudinal direction from the side seal portion.

- ⁇ 37> The pant-type absorbent article according to any one of ⁇ 1> to ⁇ 36>, wherein the ventral-side exterior body and the back-side exterior body are joined together at a side seal portion to form an annular exterior portion. . ⁇ 38> Said ⁇ 1> thru

- the underpants type absorbent article according to any one of the above. ⁇ 39> The pant-type absorbent article according to any one of ⁇ 1> to ⁇ 38>, wherein the ventral joint located on the outermost side in the longitudinal direction is continuously formed over the entire length thereof. ⁇ 40> The pant-type absorbent article according to any one of ⁇ 1> to ⁇ 39>, wherein the ventral joint located in the innermost part in the longitudinal direction is continuously formed over the entire length.

- ⁇ 41> The above-described ⁇ 1> to ⁇ 40, wherein the back side joint portion located on the outermost side in the longitudinal direction and the back side joint portion located on the innermost side in the longitudinal direction are continuously formed over the entire length.

- ⁇ 42> The pants type according to any one of ⁇ 1> to ⁇ 41>, wherein the bonding strength in the longitudinal direction per unit area of the bonding region KS F is higher than the bonding strength in the width direction per unit area of the bonding region MS. Absorbent article.

- ⁇ 43> The pants type according to any one of ⁇ 1> to ⁇ 42>, wherein the bonding strength in the longitudinal direction per unit area of the bonding region KS B is higher than the bonding strength in the width direction per unit area of the bonding region MS.

- ⁇ 44> The underpants type according to any one of ⁇ 1> to ⁇ 43>, wherein the bonding strength in the width direction per unit area of the bonding region KS F is higher than the bonding strength in the longitudinal direction per unit area of the bonding region MS.

- ⁇ 45> The underpants type according to any one of ⁇ 1> to ⁇ 44>, wherein a bonding strength in the width direction per unit area of the bonding region KS B is higher than a bonding strength in the longitudinal direction per unit area of the bonding region MS.

- ⁇ 46> The pant-type absorbent article according to any one of ⁇ 1> to ⁇ 45>, which is a pant-type disposable diaper.

- the present invention it is possible to effectively prevent the exterior body from being detached from the absorbent main body without impairing the softness and breathability of the absorbent article.

Abstract

Description

パンツ型吸収性物品は、吸収性本体の延びる方向に沿う長手方向と、それに直交する幅方向とを有する。

吸収性本体は、着用者の肌に近い側に位置する表面シートと、着用者の肌から遠い側に位置する裏面シートと、両シート間に位置する吸収コアとを具備する。

吸収コアは、長手方向に沿う一条又は複数条の変形誘導領域を有する。

腹側外装体と吸収性本体との接合が、幅方向に延び、長手方向に間欠している複数条の腹側接合部において行われる。

背側外装体と吸収性本体との接合が、幅方向に延び、長手方向に間欠している複数条の背側接合部において行われる。

股下シートと裏面シートとの接合が、長手方向に延び、かつ幅方向に間欠している複数条の股下接合部において行われる。

腹側外装体と吸収性本体との接合領域KSFと、股下シートと吸収性本体との接合領域MSとが重なる領域SGFの長手方向の長さが、接合領域KSFの長手方向の長さの50%以下である。

背側外装体と吸収性本体との接合領域KSBと、股下シートと吸収性本体との接合領域MSとが重なる領域SGBの長手方向の長さが、接合領域KSBの長手方向の長さの50%以下である。 The present invention includes an abdominal exterior body disposed on the wearer's ventral side, a back exterior body disposed on the wearer's back side, and a span between the abdominal exterior body and the back exterior body. An absorbent main body fixed to these exterior bodies so as to pass, and a crotch sheet disposed on the outer surface side of the absorbent body, and along the longitudinal direction of the ventral exterior body and the back exterior body A pant-type absorbent article having a side seal portion formed by joining the abdominal exterior body and the back exterior body to both side edges and having an annular exterior portion configured thereby. is there.

The pants-type absorbent article has a longitudinal direction along the direction in which the absorbent main body extends and a width direction perpendicular thereto.

An absorptive main body comprises the surface sheet located in the side near a wearer's skin, the back sheet located in the side far from a wearer's skin, and the absorption core located between both sheets.

The absorbent core has one or a plurality of deformation induction regions along the longitudinal direction.

The joint between the ventral-side exterior body and the absorbent main body is performed at a plurality of ventral-side joints extending in the width direction and intermittent in the longitudinal direction.

The joining of the backside exterior body and the absorbent main body is performed at a plurality of backside joining portions extending in the width direction and intermittent in the longitudinal direction.

The crotch sheet and the back sheet are joined at a plurality of crotch joints extending in the longitudinal direction and intermittent in the width direction.

The ventral side outer member and the junction region KS F of the absorbent body, the longitudinal length of the area SG F where the junction region MS overlaps the crotch sheet and the absorbent body, the longitudinal length of the junction region KS F 50% or less.

And back-side outer member and the junction region KS B of the absorbent body, the longitudinal length of the area SG B which overlap the junction region MS and crotch sheet and the absorbent body, the longitudinal length of the junction region KS B 50% or less.

また、以下の説明において「外面(外面側)」とは、おむつ着用時に、着用者の肌側とは反対側に向けられる面(面側)のことである。「内面(内面側)」とは、おむつ着用時に、着用者の肌側に向けられる面(面側)のことである。 As shown in FIGS. 1 and 2, the

Moreover, in the following description, the “outer surface (outer surface side)” is a surface (surface side) directed to the side opposite to the wearer's skin side when the diaper is worn. The “inner surface (inner surface side)” is a surface (surface side) directed toward the wearer's skin when wearing a diaper.

(1)腹側部Aにおける接合領域KSFからのサンプル片の採取方法

サンプル片の幅方向は、接合領域KSFから腹側外装体2Aの股下側下端部に沿う、おむつ幅方向(X方向)の中心域における幅50mmの領域とする。サンプル片の長手方向は、50mm幅の両端の位置から、腹側外装体のウエスト端部側に向かっておむつ長手方向(Y方向)に50mmの長さの領域とする。この50mm×50mmの領域を、外装体と、吸収性本体のうち表面シート、吸収コア及び肌側に起立する立体不織布を取り除いたシート部材とが接合領域KSFで接合された状態で切り出す。

(2)背側部Bにおける接合領域KSBからのサンプル片の採取方法

サンプル片の幅方向は、接合領域KSBから背側外装体2Bの股下側下端部に沿う、おむつ幅方向(X方向)の中央域における幅50mmの領域とする。サンプル片の長手方向は、50mm幅の両端の位置から、背側外装体のウエスト端部側に向かっておむつ長手方向(Y方向)に50mmの長さの領域とする。この50mm×50mmの領域を、外装体と、吸収性本体のうち表面シート、吸収コア及び肌側に起立する立体不織布を取り除いたシート部材とが接合領域KSBで接合された状態で切り出す。

(3)サンプル片の長手方向接合強度の測定

得られた各サンプル片を、テンシロン引っ張り試験機(オリエンテック社製、商品名「RTA-100」)のチャック間(チャック間距離15mm)に、おむつ股下側に相当する側から剥がせるように把持させる。その際、長手方向に10mmの部分をチャックへの把持部分とし、その領域に接合部分がある場合には、予め剥離させておく。次いで、おむつのウエスト端部側に向けて剥がれるように、サンプル片を引張速度300mm/minで引っ張り、接合領域KSF,KSBがすべて剥離し終えたときの積分荷重(N)を求める。そして、測定したサンプル片内の面積(50mm×40mm)で積分荷重(N)を除す。得られた値を、接合領域KSF,KSBの単位面積当たりの長手方向接合強度とする。 The method for measuring the longitudinal bonding strength per unit area of the bonding regions KS F and KS B is as follows.

(1) Sampling method of sample piece from joint region KS F in ventral side A The width direction of the sample piece is a diaper width direction (X direction) along the crotch side lower end of the ventral

(2) the width direction of the harvesting process sample piece of sample piece from the joint area KS B in dorsal B is along the crotch side lower end of the back-side

(3) Measurement of longitudinal joining strength of sample pieces Each sample piece obtained was placed between chucks (distance between chucks: 15 mm) of a Tensilon tensile tester (made by Orientec Co., Ltd., trade name “RTA-100”). Grip so that it can be peeled off from the side corresponding to the crotch side. At that time, a

サンプル片の幅方向は、股下シート6のおむつ幅方向端部に沿う、おむつ幅方向(X方向)の中央域における50mmの領域とする。サンプル片の長手方向は、50mm幅の両端の位置から、おむつ長手方向(Y方向)に向かって50mmの長さの領域とする。この50mm×50mmの領域を、股下シート6と、吸収性本体のうち表面シート、吸収コア及び肌側に起立する立体不織布を取り除いたシート部材とが接合領域MSで接合された状態で切り出す。

得られたサンプル片を、テンシロン引っ張り試験機(オリエンテック社製、商品名「RTA-100」)のチャック間(チャック間距離15mm)に、股下シート6の幅方向端部側から剥がせるように把持させる。その際、長手方向に10mmの部分をチャックへの把持部分とし、その領域に接合部分がある場合には、予め剥離させておく。次いで、おむつの幅方向中心側に向けて剥がれるように、サンプル片を引張速度300mm/minで引っ張り、接合領域MSがすべて剥離し終えたときの積分荷重(N)を求める。そして、測定したサンプル片の面積(50mm×40mm)で積分荷重(N)を除す。得られた値を、接合領域MSの単位面積当たりの幅方向接合強度とする。 The measuring method of the width direction bonding strength per unit area of the bonding region MS is as follows.

The width direction of the sample piece is a region of 50 mm in the central region in the diaper width direction (X direction) along the diaper width direction end of the

The obtained sample piece can be peeled from the end of the

<1> 着用者の腹側に配される腹側外装体と、着用者の背側に配される背側外装体と、該腹側外装体と該背側外装体との間を架け渡すようにこれらの外装体に固定された吸収性本体と、該吸収性本体の外面側に配置された股下シートとを具備し、該腹側外装体及び該背側外装体の縦方向に沿う両側縁部に該腹側外装体と該背側外装体とを接合して形成されたサイドシール部を有し、これにより構成された環状外装部を備えるパンツ型吸収性物品であって、

前記物品は、吸収性本体の延びる方向に沿う長手方向と、それに直交する幅方向とを有し、

吸収性本体は、着用者の肌に近い側に位置する表面シートと、着用者の肌から遠い側に位置する裏面シートと、両シート間に位置する吸収コアとを具備し、

吸収コアは、長手方向に沿う一条又は複数条の変形誘導領域を有し、

腹側外装体と吸収性本体との接合が、幅方向に延び、長手方向に間欠している複数条の腹側接合部において行われ、

背側外装体と吸収性本体との接合が、幅方向に延び、長手方向に間欠している複数条の背側接合部において行われ、

股下シートと裏面シートとの接合が、長手方向に延び、かつ幅方向に間欠している複数条の股下接合部において行われ、

腹側外装体と吸収性本体との接合領域KSFと、股下シートと吸収性本体との接合領域MSとが重なる領域SGFの長手方向の長さが、接合領域KSFの長手方向の長さの50%以下であり、

背側外装体と吸収性本体との接合領域KSBと、股下シートと吸収性本体との接合領域MSとが重なる領域SGBの長手方向の長さが、接合領域KSBの長手方向の長さの50%以下である、パンツ型吸収性物品。 The present invention further discloses the following pant-type absorbent articles with respect to the above-described embodiments.

<1> A ventral-side exterior body disposed on the wearer's ventral side, a back-side exterior body disposed on the wearer's back side, and a bridge between the abdominal-side exterior body and the back-side exterior body. The absorbent body fixed to these exterior bodies, and a crotch sheet disposed on the outer surface side of the absorbent body, both sides along the longitudinal direction of the ventral exterior body and the back exterior body A pants-type absorbent article having a side seal portion formed by joining the ventral exterior body and the back exterior body to the edge, and having an annular exterior portion configured thereby,

The article has a longitudinal direction along the direction in which the absorbent main body extends, and a width direction orthogonal thereto.

The absorbent main body comprises a top sheet located on the side close to the wearer's skin, a back sheet located on the side far from the wearer's skin, and an absorbent core located between both sheets,

The absorbent core has one or more deformation induction regions along the longitudinal direction,

Joining the ventral exterior body and the absorbent main body is performed in a plurality of ventral side joints extending in the width direction and intermittent in the longitudinal direction,

The joining of the backside exterior body and the absorbent main body is performed in a plurality of backside joining portions extending in the width direction and intermittent in the longitudinal direction,

Joining of the crotch sheet and the back sheet is performed in a plurality of crotch joints extending in the longitudinal direction and intermittent in the width direction,

The ventral side outer member and the junction region KS F of the absorbent body, the longitudinal length of the area SG F where the junction region MS overlaps the crotch sheet and the absorbent body, the longitudinal length of the junction region KS F Less than 50% of

And back-side outer member and the junction region KS B of the absorbent body, the longitudinal length of the area SG B which overlap the junction region MS and crotch sheet and the absorbent body, the longitudinal length of the junction region KS B A pants-type absorbent article that is 50% or less of the thickness.

重なり領域SGFの長手方向の長さは、接合領域KSFの長手方向の長さの5%以上50%以下であることが好ましく、10%以上45%以下であることが更に好ましく、15%以上35%以下であることが一層好ましい前記<1>に記載のパンツ型吸収性物品。

<3> 背側部においては、重なり領域SGBの長手方向の長さが、接合領域KSBの長手方向Yの長さの、好ましくは45%以下、更に好ましくは35%以下であり、好ましくは5%以上、更に好ましくは10%以上、一層好ましくは15%以上であり、

重なり領域SGBの長手方向の長さは、接合領域KSBの長手方向の長さの5%以上50%以下であることが好ましく、10%以上45%以下であることが更に好ましく、15%以上35%以下であることが一層好ましい前記<1>又は<2>に記載のパンツ型吸収性物品。

<4> 腹側外装体と吸収性本体との接合領域KSFと、股下シートと吸収性本体との接合領域MSとが重なる領域SGFの長手方向の長さが、前記物品を長手方向に前後二等分する位置から腹側部側の股下シートの端部までの長さMSFに対して50%以下であり、

背側外装体と吸収性本体との接合領域KSBと、股下シートと吸収性本体との接合領域MSとが重なる領域SGBの長手方向の長さが、前記物品を長手方向に前後二等分する位置から背側部側の股下シートの端部までの長さMSBに対して50%以下である前記<1>ないし<3>のいずれか1に記載のパンツ型吸収性物品。

<5> パンツ型吸収性物品を長手方向に前後二等分する位置Mから腹側部側の股下シートの端部までの長さMSFに対して、重なり領域SGFの長手方向の長さが、好ましくは35%以下、更に好ましくは25%以下であり、好ましくは2%以上、更に好ましくは5%以上、一層好ましくは10%以上であり、

長さMSFに対する重なり領域SGFの長手方向の長さは、好ましくは2%以上50%以下であり、更に好ましくは5%以上35%以下であり、一層好ましくは10%以上25%以下である前記<1>ないし<4>のいずれか1に記載のパンツ型吸収性物品。 <2> In the front section, the longitudinal length of the overlap region SG F is, the longitudinal length of the junction region KS F, preferably 45% or less, more preferably 35% or less, preferably 5 % Or more, more preferably 10% or more, more preferably 15% or more,

The length in the longitudinal direction of the overlapping region SG F is preferably 5% or more and 50% or less, more preferably 10% or more and 45% or less, and more preferably 15% of the length of the joining region KS F in the longitudinal direction. The pants-type absorbent article according to the above <1>, more preferably 35% or less.

<3> In the rear section, the longitudinal length of the overlap region SG B is a length in the longitudinal direction Y of the joining region KS B, preferably 45% or less, more preferably 35% or less, preferably Is 5% or more, more preferably 10% or more, more preferably 15% or more,

The length of the overlapping region SG B in the longitudinal direction is preferably 5% or more and 50% or less, more preferably 10% or more and 45% or less, and more preferably 15% of the length of the joining region KS B in the longitudinal direction. The pants-type absorbent article according to <1> or <2>, more preferably 35% or less.

<4> the ventral side outer member and the junction region KS F of the absorbent body, the longitudinal length of the area SG F where the junction region MS overlaps the crotch sheet and the absorbent body, said article longitudinally 50% or less with respect to the length MS F from the front and rear bisected position to the end of the crotch sheet on the ventral side,

The length in the longitudinal direction of the joining region KS B of the backside exterior body and the absorbent main body and the region SG B where the joint region MS of the crotch sheet and the absorbent main body overlaps is equal to the longitudinal direction of the article. The underpants-type absorbent article according to any one of the above items <1> to <3>, which is 50% or less with respect to a length MS B from a position to be divided to an end of the crotch sheet on the back side.

<5> The length in the longitudinal direction of the overlapping region SG F with respect to the length MS F from the position M at which the pant-type absorbent article is divided into two equal parts in the longitudinal direction to the end of the inseam sheet on the stomach side However, it is preferably 35% or less, more preferably 25% or less, preferably 2% or more, more preferably 5% or more, and still more preferably 10% or more.

The length in the longitudinal direction of the overlapping region SG F with respect to the length MS F is preferably 2% to 50%, more preferably 5% to 35%, and even more preferably 10% to 25%. The pants-type absorbent article according to any one of <1> to <4>.

長さMSBに対する重なり領域SGBの長手方向の長さは、好ましくは2%以上50%以下であり、更に好ましくは5%以上35%以下であり、一層好ましくは10%以上25%以下である前記<1>ないし<5>のいずれか1に記載のパンツ型吸収性物品。

<7> 吸収性本体の腹側部側の端部及び背側部側の端部を覆う腹側端部シート及び背側端部シートが、該吸収性本体の肌対向面側に配置されており、

腹側端部シート及び背側端部シートは、吸収性本体の周縁から延出する部位において腹側外装体及び背側外装体と接合されている前記<1>ないし<6>のいずれか1に記載のパンツ型吸収性物品。

<8> 腹側端部シートが、幅方向に延び、長手方向に間欠している複数条の腹側端部接合部において、腹側外装体及び吸収性本体と接合しており、

背側端部シートが、幅方向に延び、長手方向に間欠している複数条の背側端部接合部において、背側外装体及び吸収性本体と接合している前記<1>ないし<7>のいずれか1に記載のパンツ型吸収性物品。

<9> 腹側端部シートと吸収性本体とが重なる領域LSFの長手方向の長さが、腹側外装体と吸収性本体との接合領域KSFの長手方向の長さに対して50%以下であり、

背側端部シートと吸収性本体とが重なる領域LSBの長手方向の長さが、背側外装体と吸収性本体との接合領域KSBの長手方向の長さに対して50%以下である前記<1>ないし<8>のいずれか1に記載のパンツ型吸収性物品。

<10> 腹側端部シート及び背側端部シートが股下シートと重なっていない前記<1>ないし<9>のいずれか1に記載のパンツ型吸収性物品。 <6> The length in the longitudinal direction of the overlapping region SG B with respect to the length MS B from the position M at which the pant-type absorbent article is equally divided in the longitudinal direction to the end of the crotch sheet on the back side However, it is preferably 35% or less, more preferably 25% or less, preferably 2% or more, more preferably 5% or more, and still more preferably 10% or more.

The length in the longitudinal direction of the overlapping region SG B with respect to the length MS B is preferably 2% to 50%, more preferably 5% to 35%, and even more preferably 10% to 25%. The pants-type absorbent article according to any one of <1> to <5>.

<7> The abdomen end sheet and the dorsal end sheet covering the abdomen side end and the dorsal side end of the absorbent main body are disposed on the skin facing surface side of the absorptive main body. And

Any one of the above <1> to <6>, wherein the ventral end sheet and the dorsal end sheet are joined to the ventral exterior body and the back exterior body at a portion extending from the periphery of the absorbent main body. The pants-type absorbent article described in 1.

<8> The ventral end sheet extends in the width direction and is joined to the ventral exterior body and the absorbent main body in a plurality of ventral end joints intermittent in the longitudinal direction.

<1> to <7, wherein the back side end sheet is joined to the back side exterior body and the absorbent main body in a plurality of back side end joint portions extending in the width direction and intermittent in the longitudinal direction. > The underpants type absorbent article of any one of>.

<9> The length in the longitudinal direction of the region LS F where the ventral end sheet and the absorbent main body overlap is 50 with respect to the length in the longitudinal direction of the joint region KS F between the ventral exterior body and the absorbent main body. % Or less,

The length in the longitudinal direction of the region LS B where the back end sheet and the absorbent main body overlap is 50% or less with respect to the length in the longitudinal direction of the joining region KS B between the back exterior body and the absorbent main body. The pants-type absorbent article according to any one of <1> to <8>.

<10> The pants-type absorbent article according to any one of <1> to <9>, wherein the ventral end sheet and the dorsal end sheet do not overlap with the crotch sheet.

背側外装体が、外層シートと該外層シートの内側に配置された内層シートとを有し、該外層シートと背側端部シートとが同材質のものである前記<1>ないし<10>のいずれか1に記載のパンツ型吸収性物品。

<12> 腹側端部シートと吸収性本体とが重なる領域LSFにおいて吸収性本体の周縁から外方に延出する所定幅の領域に接着剤が連続して隙間なく塗布され、該接着剤によって腹側端部シートと吸収性本体とが接合されており、

背側端部シートと吸収性本体とが重なる領域LSBにおいて吸収性本体の周縁から外方に延出する所定幅の領域に接着剤が連続して隙間なく塗布され、該接着剤によって背側端部シートと吸収性本体とが接合されている前記<1>ないし<11>のいずれか一項に記載のパンツ型吸収性物品。

<13> 吸収性本体は、吸収コアの左右両側縁又はその近傍から幅方向の中心側に向けて起立する第1立体ギャザーを有している前記<1>ないし<12>のいずれか1に記載のパンツ型吸収性物品。

<14> 股下シートは、長手方向に関し、吸収性本体における少なくとも股下部に配置されており、股下部を越えて腹側部A及び背側部Bにまで延在している前記<1>ないし<13>のいずれか1に記載のパンツ型吸収性物品。

<15> 吸収性本体は、吸収コアの左右両側縁又はその近傍から幅方向中心側に向けて起立する第1立体ギャザーと、吸収コアの左右両側縁又はその近傍から幅方向外方側に向けて起立する第2立体ギャザーとを有し、

股下シートの幅が、左右の第2立体ギャザーの自由端間の距離と同じか又はそれよりも狭くなっている前記<1>ないし<14>のいずれか一項に記載のパンツ型吸収性物品。 <11> The ventral exterior body has an outer layer sheet and an inner layer sheet disposed on the inner side of the outer layer sheet, and the outer layer sheet and the ventral end portion sheet are made of the same material,

<1> to <10>, wherein the backside exterior body includes an outer layer sheet and an inner layer sheet disposed inside the outer layer sheet, and the outer layer sheet and the back end sheet are made of the same material. The underpants type absorbent article according to any one of the above.

<12> In a region LS F where the ventral side end sheet and the absorbent main body overlap, an adhesive is continuously applied to a region having a predetermined width extending outward from the periphery of the absorbent main body without any gap, and the adhesive The ventral end sheet and the absorbent main body are joined by

In a region LS B where the back side end sheet and the absorbent main body overlap, an adhesive is continuously applied to a region having a predetermined width extending outward from the periphery of the absorbent main body without any gap, and the back side is applied by the adhesive. The pants-type absorbent article according to any one of <1> to <11>, wherein the end sheet and the absorbent main body are joined.

<13> The absorbent main body according to any one of <1> to <12>, wherein the absorbent main body has a first three-dimensional gather that rises toward the center in the width direction from the left and right side edges of the absorbent core or the vicinity thereof. The underpants type absorbent article as described.

<14> The crotch sheet is disposed at least in the crotch part of the absorbent main body with respect to the longitudinal direction, and extends to the ventral part A and the back part B beyond the crotch part. The underpants type absorbent article according to any one of <13>.

<15> The absorbent main body is a first three-dimensional gather that stands from the left and right side edges of the absorbent core or the vicinity thereof toward the center in the width direction, and the left and right side edges of the absorption core or the vicinity thereof toward the outer side in the width direction. And a second three-dimensional gather that stands up

The underpants-type absorbent article according to any one of <1> to <14>, wherein the width of the crotch sheet is equal to or smaller than a distance between free ends of the left and right second three-dimensional gathers. .

<17> 吸収性本体は、吸収コアの左右両側縁又はその近傍から幅方向中心側に向けて起立する第1立体ギャザーと、吸収コアの左右両側縁又はその近傍から幅方向外方側に向けて起立する第2立体ギャザーとを有し、

第1立体ギャザー及び第2立体ギャザーは、それらの基端部が同じ位置に位置している前記<1>ないし<16>のいずれか一項に記載のパンツ型吸収性物品。

<18> 基端部が長手方向に延びている前記<17>に記載のパンツ型吸収性物品。

<19> 吸収性本体は、吸収コアの左右両側縁又はその近傍から幅方向中心側に向けて起立する第1立体ギャザーと、吸収コアの左右両側縁又はその近傍から幅方向外方側に向けて起立する第2立体ギャザーとを有し、

第1立体ギャザー及び第2立体ギャザーは、吸収性本体における少なくとも股下部に形成されており、股下部を越えて腹側部及び背側部にまで延在している前記<1>ないし<18>のいずれか一項に記載のパンツ型吸収性物品。

<20> 吸収性本体は、吸収コアの左右両側縁又はその近傍から幅方向中心側に向けて起立する第1立体ギャザーを有し、