WO2014017429A1 - Method and device for treating ammonia nitrogen-containing water at low temperature - Google Patents

Method and device for treating ammonia nitrogen-containing water at low temperature Download PDFInfo

- Publication number

- WO2014017429A1 WO2014017429A1 PCT/JP2013/069776 JP2013069776W WO2014017429A1 WO 2014017429 A1 WO2014017429 A1 WO 2014017429A1 JP 2013069776 W JP2013069776 W JP 2013069776W WO 2014017429 A1 WO2014017429 A1 WO 2014017429A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- containing water

- ammonia

- concentration

- carrier

- nitrogen

- Prior art date

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

- C02F3/34—Biological treatment of water, waste water, or sewage characterised by the microorganisms used

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

- C02F3/30—Aerobic and anaerobic processes

- C02F3/302—Nitrification and denitrification treatment

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

- C02F3/02—Aerobic processes

- C02F3/10—Packings; Fillings; Grids

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

- C02F3/30—Aerobic and anaerobic processes

- C02F3/302—Nitrification and denitrification treatment

- C02F3/303—Nitrification and denitrification treatment characterised by the nitrification

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2101/00—Nature of the contaminant

- C02F2101/10—Inorganic compounds

- C02F2101/16—Nitrogen compounds, e.g. ammonia

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2209/00—Controlling or monitoring parameters in water treatment

- C02F2209/02—Temperature

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2301/00—General aspects of water treatment

- C02F2301/10—Temperature conditions for biological treatment

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

- C02F3/02—Aerobic processes

- C02F3/08—Aerobic processes using moving contact bodies

- C02F3/085—Fluidized beds

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W10/00—Technologies for wastewater treatment

- Y02W10/10—Biological treatment of water, waste water, or sewage

Definitions

- the present invention relates to a method and apparatus for treating ammonia nitrogen-containing water that biologically nitrifies ammoniacal nitrogen at low temperatures, and in particular, environmental purification such as sewage treatment, industrial waste liquid treatment, lake purification, Regarding removal of ammonia in water at water purification plants and aquariums.

- waste liquids containing low to high ammonia concentrations are discharged. Since these waste liquids cause eutrophication of water bodies and a decrease in dissolved oxygen, it is necessary to treat them before discharging them from factories.

- biological treatment is often performed in medium to high concentration ammonia treatment.

- a treatment method using an activated sludge method is usually performed.

- ammonia is nitrified by nitrifying bacteria to form nitric acid or nitrous acid, and then converted to nitrogen gas by denitrifying bacteria to remove nitrogen contained in the wastewater.

- nitrifying bacteria used in such an activated sludge method the present inventors have so far identified a nitrifying group (AH group, detected by culturing for 8 weeks in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more.

- AH bacteria group (Ammonia oxidizing bacteria detected by MPN method using High ammonium media)

- MPN method: most probable number method a group of nitrifying bacteria detected by culturing for 8 weeks in a low concentration ammonia sulfate solution with a concentration of 100 mg / L

- AL fungus group (Ammonia oxidizing bacteria detected by MPN method using Low ammonium media)

- the AH bacteria group is effective for the treatment of high-concentration ammoniacal nitrogen-containing water (about 400 mg / L to 500 mg / L)

- the AL fungus group is low-concentration ammoniacal nitrogen-containing water (about 100 mg).

- the concentration of ammoniacal nitrogen in general household wastewater is as low as 20 to 40 mg / L

- the AL fungus group suitable for the treatment of low-concentration ammoniacal nitrogen-containing water is mainly used for the treatment of such wastewater. It is used for.

- the present invention addresses such a problem, and usually treats wastewater at a low temperature using AH bacteria used for the treatment of high-concentration ammoniacal nitrogen-containing water. This is because the AH bacteria group obtained by the present inventors as a result of earnest research can be stably treated with ammoniacal nitrogen-containing water without significantly reducing the treatment activity even at low temperatures. Based on the findings of

- an object of the present invention is to provide a method capable of stably treating ammonia nitrogen-containing water even at a low temperature of 15 ° C. or lower.

- Another object of the present invention is to provide an apparatus capable of stably treating ammonia nitrogen-containing water even at a low temperature of 15 ° C. or lower.

- Still another object of the present invention is to provide a carrier holding AH bacteria group that can stably treat ammoniacal nitrogen-containing water even at a low temperature of 15 ° C. or lower.

- a method of treating ammonia nitrogen-containing water according to an aspect of the present invention includes: Ammonia nitrogen-containing water having an ammonia nitrogen concentration of 1 to 300 mg / L and a carrier on which a nitrifying bacteria group preferentially propagated by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks

- the method of treating ammonia nitrogen-containing water includes: Nitrifying bacteria detected by contacting ammonia-containing nitrogen water having an ammonia nitrogen concentration of 100 to 1000 mg / L with a microorganism-supporting carrier and culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks.

- a culture process for preferentially culturing the group The cultured nitrifying bacteria group is brought into contact with the ammoniacal nitrogen-containing water having an ammoniacal nitrogen concentration of 1 to 300 mg / L in an aerobic atmosphere at 0 ° C. or higher and 15 ° C. or lower to bring the ammoniacal nitrogen-containing water into contact.

- a nitrification step of nitrifying ammonia is provided.

- the treatment apparatus for ammoniacal nitrogen-containing water according to another aspect of the present invention, A nitrification tank, An introduction part for introducing ammonia nitrogen-containing water having an ammonia nitrogen concentration of 1 to 300 mg / L into the nitrification tank; A discharge section for discharging the ammoniacal nitrogen-containing water treated from the nitrification tank,

- the nitrification tank contains a carrier on which a nitrifying bacteria group preferentially propagated by culturing for 8 weeks in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more, In the nitrification tank, the ammoniacal nitrogen-containing water is treated at 0 ° C. or more and 15 ° C. or less.

- the treatment apparatus for ammoniacal nitrogen-containing water A culture tank for culturing a group of nitrifying bacteria detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks; A first introduction part for introducing ammoniacal nitrogen-containing water having an ammoniacal nitrogen concentration of 100 to 1000 mg / L into the culture tank; A discharge section for discharging the nitrifying bacteria group cultured from the culture tank; and a nitrification tank connected to the discharge section; A second introduction part for introducing ammonia nitrogen-containing water having an ammonia nitrogen concentration of 1 to 300 mg / L into the nitrification tank; A discharge section for discharging the ammoniacal nitrogen-containing water treated from the nitrification tank, Supplying the cultured nitrifying bacteria group from the culture tank to the nitrification tank via the discharge section; In the nitrification tank, the

- the bacteria holding carrier for the treatment of ammoniacal nitrogen-containing water according to another aspect of the present invention, A carrier; A group of nitrifying bacteria preferentially propagated on the carrier, which is detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks, A bacterial carrier for treating 1 to 300 mg / L of ammoniacal nitrogen-containing water at a temperature of 0 ° C. to 15 ° C.

- the present invention it is possible to provide a method and an apparatus for treating ammonia nitrogen-containing water, which can perform stable ammonia treatment at a low water temperature of 15 ° C. or lower and can always obtain stable treated water.

- FIG. 1 It is a schematic diagram of the nitrification tank by this invention. It is a figure which shows the apparatus for ammonia nitrogen containing water treatment by this invention provided with an AH fungal group culture tank. It is a figure which shows the apparatus for water treatment of ammonia nitrogen containing water by this invention to which two or more nitrification tanks were connected. It is a figure which shows the example of application of the multistage processing type by this invention. It is a figure which shows the example of application of the processing flow of the AH fungal group addition type by this invention. It is a figure which shows the influence of the water temperature which acts on the nitrification rate. It is a figure which shows the daily change of the process characteristic by this invention.

- AH fungal group refers to a nitrifying bacterial group detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks

- a fungal group This refers to a group of nitrifying bacteria detected by culturing in a low concentration ammonia sulfate solution having a concentration of 100 mg / L for 8 weeks. Therefore, any bacteria can be detected as long as it is detected under such conditions, and is not limited to a specific bacteria.

- the AH fungal group it is considered that it belongs to the genus Nitrosomonas, but it is not determined taxonomically.

- a single bacterium from the AH fungal group can be isolated and used, but it is preferable from the viewpoint of stability of activity that a plurality of types of bacteria coexist as the AH fungal group.

- “detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks” means at least 8 weeks in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more. This means that if cultured, nitrifying bacteria as AH bacteria are generated and can be detected, and it does not mean a culture period of just 8 weeks.

- the upper limit concentration of the ammonium sulfate solution was not defined, the upper limit is the concentration limit at which nitrifying bacteria can be cultured.

- nitrification refers to the production of nitric acid or nitrous acid from ammonia.

- microorganism holding carrier means a carrier on which activated sludge or the like is fixed.

- the “microorganism holding carrier” also includes a entrapping immobilization microorganism carrier.

- the carrier on which the nitrifying bacteria group preferentially propagated by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks means the number of bacteria retained on the carrier.

- the number of AH fungal groups is preferably 2 times or more of the number of AL fungal groups, more preferably 10 times or more, still more preferably 100 times or more, and most preferably 1000 times or more.

- a carrier dominant in AH bacteria group is also used synonymously.

- nitrification tank and “AH fungal culture tank” are used synonymously. This is because the nitrification tank for medium to high concentration treatment serves as a tank for treating water containing medium to high concentration ammoniacal nitrogen, and at the same time, the AH bacteria group is cultured in the tank.

- the AH fungal group used in the present invention can be acclimatized from general activated sludge, lake bottom mud and the like. Therefore, no special technique or raw material is required to obtain the AH bacteria group, and any method known in the art may be used.

- the AH bacteria group used in the present invention is a gellan gum medium (R. Takahashi, et al .: "Pure isolation of a new chemoautotrophic ammonia-oxidizing bacterium on gellan gum plate", J. Fermentation and Bioengineering, vol. 74, No. 1, pp. 52-54 (1992)) can be used. Further, enrichment culture is possible by immobilizing activated sludge from a sewage treatment plant and culturing it in inorganic wastewater containing an ammoniacal nitrogen concentration of 100 to 1000 mg / L.

- ⁇ Carrier> In order to retain the bacterium on the carrier, methods such as (i) adhesion immobilization and (ii) entrapping immobilization can be used.

- a material having many irregularities such as a spherical or cylindrical carrier, a string-like material, a gel-like carrier, or a nonwoven material is preferable for bacterial adhesion, and the use of such a carrier improves the removal rate of ammonia nitrogen.

- a bacterium and an immobilization material are mixed, polymerized, and the bacterium is comprehensively immobilized inside the gel.

- the monomer material acrylamide, methylenebisacrylamide, triacryl formal and the like are preferable.

- the prepolymer material is preferably polyethylene glycol diacrylate or polyethylene glycol methacrylate, and derivatives thereof can also be used.

- inclusion shapes such as spherical, square, and cylindrical inclusion carriers, string inclusion carriers, and nonwoven inclusion inclusions with many irregularities are preferable, and the ammonia nitrogen removal rate is improved.

- ammonia nitrogen-containing water includes, but is not limited to, wastewater such as domestic wastewater, human waste, and factory wastewater, and water in a domestic water tank and aquarium. Moreover, if ammonia nitrogen is contained, even the water can be treated by the method or apparatus according to the present invention.

- the ammoniacal nitrogen concentration of the ammoniacal nitrogen-containing water treated by the method and apparatus according to the present invention is preferably in the range of 1 to 1000 mg / L.

- the ammoniacal nitrogen concentration is preferably in the range of 1 to 300 mg / L, and 1 to 100 mg / L from the viewpoint of processing efficiency.

- the AH fungus group culture tank shown in FIG. 2 it is preferably in the range of 100 to 1000 mg / L, and more preferably in the range of 200 to 500 mg / L from the viewpoint of treatment efficiency.

- the multistage treatment shown in FIG. 3 it is preferably in the range of 50 to 500 mg / L, more preferably in the range of 100 to 300 mg / L from the viewpoint of treatment efficiency.

- the temperature of the ammoniacal nitrogen-containing water to be treated by the method and apparatus according to the present invention is preferably 0 ° C. or higher and 15 ° C. or lower, and more preferably 0 ° C. or higher and 10 ° C. or lower in view of particularly excellent treatment activity than the conventional method. Further, it is more preferable to use at 0 ° C. or higher and 5 ° C. or lower in consideration of the further excellent treatment activity. That is, nitrification of ammonia nitrogen-containing water by the conventional method hardly progresses at 10 ° C. or lower, but according to the method and apparatus of the present invention, it is stable even at 10 ° C. or lower, further 5 ° C. or lower. Nitrification treatment can be performed.

- the lower limit of the water temperature processed with a method and an apparatus is not set in particular, it understands that 0 degreeC vicinity which is a freezing point of water becomes a minimum, since this invention is related to water treatment.

- the nitrification tank 10 includes a carrier 12 in which AH bacteria are retained.

- the AH bacteria group retained on the carrier nitrifies ammonia to produce nitrous acid or nitric acid.

- the ammonia-containing nitrogen-containing water stays in the nitrification tank for a certain period of time and then flows out from the treated water outflow part 16 through the carrier separation network 18 as treated water.

- the treated water that has flowed out is then sent to a denitrification tank (not shown) where nitric acid and nitrous acid in the treated water are converted to nitrogen gas and removed.

- the nitrification tank may be anything as long as it can hold the carrier and waste water for a certain period of time, and the material and volume of the nitrification tank are not particularly limited.

- the filling rate of the carrier contained in the nitrification tank is preferably 1% to 60%, more preferably 5% to 20%, and most preferably 8% to 15% from the viewpoint of processing efficiency.

- the time during which the ammonia nitrogen-containing water stays in the nitrification tank depends on the ammonia nitrogen content of the water to be treated, but is preferably about 0.3 to 24 hours, preferably 0.5 to 12 hours. More preferably, it is 1 to 3 hours, and most preferable in terms of processing efficiency.

- the processing speed of the AH bacterial group is most preferable to increase.

- wastewater treatment in a cold region and ammonia removal in a low temperature water tank such as an aquarium can be stably performed.

- ammonia can be effectively removed even when ammonia is mixed in clean water having a temperature lower than that of waste water.

- a processing apparatus can be manufactured more compactly and at low cost.

- FIG. 2 shows a flow equipped with an apparatus for culturing AH bacteria using this detachment solution.

- the nitrification tank is used in the conventional activated sludge method, for example, floating A tank using a type activated sludge method may be used.

- the nitrification tank may contain a carrier holding the AH bacteria group.

- An embodiment including a carrier in which AH bacteria are held in a nitrification tank is preferable in that a larger amount of waste water can be treated at high speed and stably.

- the AH bacterium culture tank 20 contains a carrier 12 holding microorganisms, and the waste water containing medium to high concentration ammoniacal nitrogen (100 to 100%) from the medium to high concentration ammonia nitrogen containing water introduction section 24 is contained therein. 1000 mg / L) is introduced and brought into contact with the carrier, and the AH bacteria group is preferentially cultured on the carrier. As the culture of the AH fungal group proceeds, a part of the proliferated AH fungal group leaks from the carrier and is supplied to the nitrification tank 100 through the AH fungal group discharge unit 22.

- the bacteria supplied to the nitrification tank stay in the nitrification tank on average several days to one month.

- the supplied AH fungal group is contacted with the ammoniacal nitrogen-containing water introduced from the ammoniacal nitrogen-containing water introduction section 14 as in the case of FIG. This produces nitric acid.

- the treated water flowing out from the treated water outflow part 16 is sent to a denitrification tank (not shown), and nitric acid and nitrous acid in the treated water are converted into nitrogen gas and removed. .

- FIG. 1 An example in which an environment that easily retains the AH bacteria group is prepared by configuring the medium concentration wastewater in a multi-stage treatment, and the treatment capability at a low water temperature is enhanced. Since a plurality of nitrification tanks are connected, wastewater containing higher concentration ammoniacal nitrogen can be treated at a time.

- 28, 30, and 32 are the first nitrification tank, the second nitrification tank, and the third nitrification tank, respectively, and the concentration gradient in each tank can be made by multi-stage treatment, and the first nitrification tank has the highest NH 4 -N.

- the concentration is high, and the concentration of NH 4 -N decreases in the order of the second nitrification tank and the third nitrification tank.

- the growth of the AH fungal group depends on the NH 4 -N concentration in the atmosphere, and the higher the concentration, the better the growth of the AH fungal group. Therefore, the AH fungal group easily grows in the first nitrification tank. And the AH bacteria group which proliferated in the 1st nitrification tank will be supplied to a 2nd nitrification tank or a 3rd nitrification tank. Thereby, the processing performance in the entire three-stage process is maintained even at a low temperature, and the temperature resistance is improved.

- the treatment procedure of the ammonia nitrogen-containing water is substantially the same as that in FIG. 1, and the medium-concentration ammonia nitrogen-containing water introduced into the first nitrification tank 28 from the medium-concentration ammonia nitrogen-containing water introduction unit 26 is In contact with the AH bacteria group held on the carrier 12 in one nitrification tank 28, the AH bacteria group held on the carrier nitrifies a part of the ammonia in the water to produce nitrous acid or nitric acid.

- the ammoniacal nitrogen-containing water is introduced into the second nitrification tank 30 after having stayed in the first nitrification tank 28 for a certain period of time.

- the digestion of ammonia in water proceeds, and after staying for a certain time, the ammoniacal nitrogen-containing water flows out of the second nitrification tank 30 and moves to the third nitrification tank 32.

- the nitrification treatment is similarly performed here, and the treated water finally flowing out from the third nitrification tank is then sent to a denitrification tank (not shown) to convert nitric acid and nitrous acid in the treated water into nitrogen gas. Removed.

- Each nitrification tank may have a different capacity, shape and material, and the residence time and the filling amount of the carrier differ depending on the concentration of NH 4 —N and the treatment amount of ammonia nitrogen-containing water to be treated in each tank. May be. Moreover, the number of nitrification tanks can also be adjusted according to the property of the ammoniacal nitrogen-containing water to be treated.

- FIG. 4 is equipped with a denitrification device according to the present method

- FIG. 5 is equipped with a device for introducing the AH fungal group preferred carrier of the present method into the nitrification tank of the modified circulation method or introducing the AH fungal group. is there.

- ⁇ Production of entrapped immobilization microorganism carrier> Activated sludge from sewage treatment plant (obtained from T city end treatment plant, Gunma Prefecture), 15 parts of polyethylene glycol dimethacrylate ("Light Ester 14EG (product number)", manufactured by Kyoeisha Chemical Co., Ltd.), NNN'N 'tetramethylethylenediamine ("206-04006 (product number)", Wako Pure Chemical Industries, Ltd.) 0.5 part and water 69.25 parts are mixed to form a suspension, and potassium persulfate ("162-04235 (product number) ) ", Manufactured by Wako Pure Chemical Industries, Ltd.) When 0.25 part was added, the polymerization started and gelled. The obtained gel was cut into 3 mm square pellets and used in the following examples.

- Example 1 ⁇ Production of AH bacteria dominant carrier>

- the entrapping immobilization microorganism carrier cut into pellets was conditioned with inorganic synthetic wastewater (NH 4 -N: 400 mg / L) shown in Table 1 below.

- the acclimatization was carried out in a nitrification tank having a volume of 1.4 L shown in FIG. 1 for 2 months with a load of 0.5 kg-N / m 3 ⁇ d. What was acclimatized for 2 months on the said conditions was used as a carrier of AH bacteria group predominance.

- Comparative Example 1 ⁇ Preparation of carrier dominant in AL fungus group> A load of 0.5 kg-N / m was used in the same manner as in the case of the carrier dominant in the AH bacteria group, except that the inorganic synthetic wastewater was diluted 10-fold with tap water (NH 4 -N: 40 mg / L). It was prepared by acclimation at 3 ⁇ d and used as a carrier for the dominant AL fungus group.

- the carrier was crushed and the bacteria were dispersed.

- a fixed amount of carrier was collected in 9 ml of sterilized water, and crushed and dispersed.

- a homogenizer homogenizer PA type, manufactured by Ikemoto Rika Kogyo Co., Ltd.

- an ultrasonic treatment device US300 type, manufactured by Nippon Seiki Co., Ltd.

- Table 2 shows pretreatment conditions.

- the numbers of AH fungal group and AL fungal group were measured according to the most probable value method using a liquid in which bacteria were dispersed.

- the number of bacteria measuring medium AH bacteria group and AL bacteria group shown in Table 3 were prepared and after sterile filtration, sterile component into a plurality of test tubes put CaCO 3 to about 50mg and sterilized dry heat by 9mL Noted.

- a test tube different from that containing the measurement medium was prepared, 9 mL of sterilized water was added thereto, and further 1 mL of the pretreated liquid was added as a stock solution to dilute 10 times.

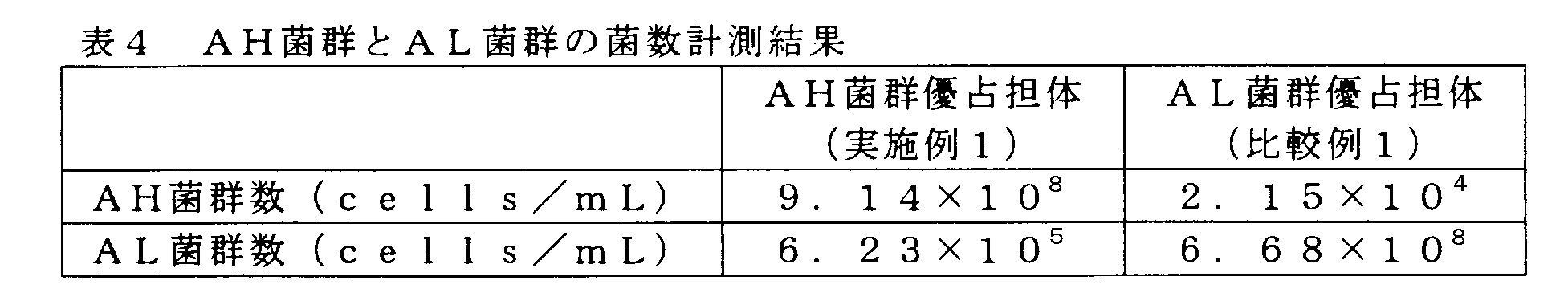

- the number of viable bacteria per 1 mL of the stock solution was calculated in the same manner for the carrier dominant in the AL group. The results are shown in Table 4.

- the carriers of Example 1 and Comparative Example 1 are carriers of the AH group dominant and AL groups dominant, respectively.

- Nitrification tank volume of 1.4L shown in FIG. 1 after 2 months acclimatization load 0.5kg-N / m 3 ⁇ d , it was measured nitrification rate of the carrier from the balance of the water quality in continuous operation These were 0.45 kg-N / m 3 ⁇ d and 0.46 kg-N / m 3 ⁇ d, respectively, which were almost equal.

- NH 4 —N, NO 3 —N, and NO 2 —N were measured as the quality of raw water and treated water.

- NH 4 -N conforms to the indophenol blue colorimetric method (JIS-K0102, where JIS is an abbreviation for Japanese Industrial Standards), and NO 3 -N and NO 2 -N represent ion chromatograph analyzers (" ICS-1600 (product number) ”(manufactured by Dionex). Further, since the suspended water in the treated water was slightly mixed, the treated water was filtered through a 0.45 ⁇ filter (“DISMIC-25cs (product number)”, manufactured by Advantech Co., Ltd.) in advance.

- Example 2 Using the carrier prepared in Example 1 (AH bacteria group dominant carrier), the nitrification rate according to temperature was measured. For the evaluation, batch treatment was performed using a nitrification tank having a volume of 1.4 L shown in FIG. 1 to obtain a nitrification rate. As raw water, NH 4 -N 40 mg / L obtained by diluting the inorganic synthetic waste water shown in Table 1 10 times was used. The carrier filling amount in the nitrification tank was 8%.

- Table 5 and FIG. 6 show the results of measurement under the above conditions with the temperature changed to 5, 10, 15 and 20 ° C.

- Comparative Example 2 The nitrification rate according to temperature was measured in the same manner as in Example 2 except that the carrier prepared in Comparative Example 1 (a carrier dominant in AL bacteria) was used. The results are shown in Table 5 and FIG. From this result, it can be seen that the carrier dominant in the AH group is more resistant to low temperature than the carrier dominant in the AL group. In particular, it can be seen that at a water temperature of 10 ° C. or less, the carrier predominantly AH group can obtain a significantly higher nitrification rate than the carrier predominantly AL group.

- Example 3 A long-term treatment operation was performed at 5 ° C. using the carrier prepared in Example 1 (AH group dominant carrier).

- synthetic inorganic wastewater (NH 4 -N concentration: 48 to 66 mg / L) was used in the nitrification tank having the configuration shown in FIG. The conditions of the processing operation are shown below.

- the results for Example 3 are shown in FIGS.

- Comparative Example 3 A long-term treatment operation was carried out at 5 ° C. in the same manner as in Example 3 except that the carrier prepared in Comparative Example 1 (a carrier predominantly AL bacteria) was used. The results for Comparative Example 3 are shown in FIGS. It is clear that the AH bacteria-dominant carrier according to the present invention is excellent in treatment performance at low water temperature in both aging ability and nitrification rate against volumetric load.

- Example 4 The apparatus of the flow of FIG. 2 was used.

- Medium-to-high concentration treatment of unfamiliar entrapped immobilization microorganism carrier activated sludge immobilization carrier

- activated sludge immobilization carrier produced using activated sludge using medium-to-high concentration ammoniacal nitrogen-containing water (desorbed liquid after sludge dehydration)

- the nitrification tank (culture tank) 20 is used, and a leaching solution containing medium to high concentration ammonia is introduced into the nitrification tank (culture tank) 20, and the AH bacteria group inside the carrier in the medium to high concentration treatment nitrification tank (culture tank) 20.

- a part of the AH bacteria group leaks from the carrier and is put into the nitrification tank 100.

- Activated sludge is suspended in the nitrification tank 100.

- Low concentration ammoniacal nitrogen-containing water was allowed to flow into the nitrification tank 100 from the ammoniacal nitrogen-containing water introduction section 14 to perform nitrification treatment.

- the unfamiliar entrapped immobilization microorganism carrier activated sludge immobilization carrier

- the immobilized activated sludge activated sludge from the T sewage treatment plant was used.

- the AH bacteria group grows on the carrier in the culture tank, the AH bacteria group leaks from the carrier, and is supplied to the nitrification tank, whereby nitrification is promoted at a low water temperature.

- the water temperature was 10 to 13 ° C.

- the ammoniacal nitrogen concentration in the treated water of the nitrification tank 100 was NH 4 —N: 1 mg / L or less.

- the treatment was performed using the previously unfamiliar entrapped immobilization microorganism carrier (activated sludge immobilization carrier).

- activated sludge immobilization carrier activated sludge from the T sewage treatment plant was used.

- the water temperature was 8 to 13 ° C.

- the ammoniacal nitrogen concentration in the treated water was NH 4 —N: 1 mg / L or less. Therefore, the effect of the method and apparatus according to the present invention is clear.

- Nitrification tank 12 Carrier 14 Ammonia nitrogen-containing water introduction part 16 Treated water outflow part 18 Carrier separation network 19 Nitrification liquid circulation line 20

- AH fungus group release part 24 Medium to high concentration ammonia nitrogen containing water introduction part 26

- First nitrification tank 30 Second nitrification tank 32

- Third nitrification tank 100 Conventional nitrification tank 120

- Conventional Carrier 130 conventional carrier 200 denitrification tank 310 denitrifying bacteria adhesion filler 500 organic substance supply tank

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Microbiology (AREA)

- Biodiversity & Conservation Biology (AREA)

- Hydrology & Water Resources (AREA)

- Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Water Supply & Treatment (AREA)

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Purification Treatments By Anaerobic Or Anaerobic And Aerobic Bacteria Or Animals (AREA)

- Biological Treatment Of Waste Water (AREA)

Abstract

Description

アンモニア性窒素濃度が1~300mg/Lのアンモニア性窒素含有水と、濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群が優先繁殖した担体とを、好気性雰囲気下、0℃以上15℃以下で接触させて前記アンモニア性窒素含有水中のアンモニアを硝化する硝化工程、

を含む。 A method of treating ammonia nitrogen-containing water according to an aspect of the present invention includes:

Ammonia nitrogen-containing water having an ammonia nitrogen concentration of 1 to 300 mg / L and a carrier on which a nitrifying bacteria group preferentially propagated by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks A nitrification step of nitrifying ammonia in the ammoniacal nitrogen-containing water by contacting at 0 ° C. or higher and 15 ° C. or lower in an aerobic atmosphere;

including.

アンモニア性窒素濃度が100~1000mg/Lのアンモニア性窒素含有水と微生物保持担体とを接触させて、濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群を優先培養する培養工程と、

前記培養された硝化菌群と、アンモニア性窒素濃度が1~300mg/Lのアンモニア性窒素含有水とを、好気性雰囲気下、0℃以上15℃以下で接触させて前記アンモニア性窒素含有水中のアンモニアを硝化する硝化工程と

を含む。 Moreover, the method of treating ammonia nitrogen-containing water according to another aspect of the present invention includes:

Nitrifying bacteria detected by contacting ammonia-containing nitrogen water having an ammonia nitrogen concentration of 100 to 1000 mg / L with a microorganism-supporting carrier and culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks. A culture process for preferentially culturing the group;

The cultured nitrifying bacteria group is brought into contact with the ammoniacal nitrogen-containing water having an ammoniacal nitrogen concentration of 1 to 300 mg / L in an aerobic atmosphere at 0 ° C. or higher and 15 ° C. or lower to bring the ammoniacal nitrogen-containing water into contact. A nitrification step of nitrifying ammonia.

硝化槽と、

前記硝化槽にアンモニア性窒素濃度が1~300mg/Lのアンモニア性窒素含有水を導入する導入部と、

前記硝化槽から処理した前記アンモニア性窒素含有水を排出する排出部と

を備え、

前記硝化槽の中に濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群が優先繁殖した担体が含まれており、

前記硝化槽では0℃以上15℃以下で、アンモニア性窒素含有水を処理する。 Moreover, the treatment apparatus for ammoniacal nitrogen-containing water according to another aspect of the present invention,

A nitrification tank,

An introduction part for introducing ammonia nitrogen-containing water having an ammonia nitrogen concentration of 1 to 300 mg / L into the nitrification tank;

A discharge section for discharging the ammoniacal nitrogen-containing water treated from the nitrification tank,

The nitrification tank contains a carrier on which a nitrifying bacteria group preferentially propagated by culturing for 8 weeks in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more,

In the nitrification tank, the ammoniacal nitrogen-containing water is treated at 0 ° C. or more and 15 ° C. or less.

濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群を培養する培養槽と、

前記培養槽にアンモニア性窒素濃度が100~1000mg/Lのアンモニア性窒素含有水を導入する第1の導入部と、

前記培養槽から培養された前記硝化菌群を放出する放出部と

前記放出部に接続された硝化槽と、

前記硝化槽にアンモニア性窒素濃度が1~300mg/Lのアンモニア性窒素含有水を導入する第2の導入部と、

前記硝化槽から処理した前記アンモニア性窒素含有水を排出する排出部と

を備え、

前記培養槽から前記硝化槽に、前記放出部を介して、培養した前記硝化菌群を供給し、

前記硝化槽では0℃以上15℃以下で、アンモニア性窒素含有水を処理する。 Moreover, the treatment apparatus for ammoniacal nitrogen-containing water according to another aspect of the present invention,

A culture tank for culturing a group of nitrifying bacteria detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks;

A first introduction part for introducing ammoniacal nitrogen-containing water having an ammoniacal nitrogen concentration of 100 to 1000 mg / L into the culture tank;

A discharge section for discharging the nitrifying bacteria group cultured from the culture tank; and a nitrification tank connected to the discharge section;

A second introduction part for introducing ammonia nitrogen-containing water having an ammonia nitrogen concentration of 1 to 300 mg / L into the nitrification tank;

A discharge section for discharging the ammoniacal nitrogen-containing water treated from the nitrification tank,

Supplying the cultured nitrifying bacteria group from the culture tank to the nitrification tank via the discharge section;

In the nitrification tank, the ammoniacal nitrogen-containing water is treated at 0 ° C. or more and 15 ° C. or less.

担体と、

前記担体に優先繁殖した硝化菌群であって、濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群と

を含み、

0℃以上15℃以下で1~300mg/Lのアンモニア性窒素含有水を処理する細菌保持担体である。 Furthermore, the bacteria holding carrier for the treatment of ammoniacal nitrogen-containing water according to another aspect of the present invention,

A carrier;

A group of nitrifying bacteria preferentially propagated on the carrier, which is detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks,

A bacterial carrier for treating 1 to 300 mg / L of ammoniacal nitrogen-containing water at a temperature of 0 ° C. to 15 ° C.

本明細書において、「AH菌群」とは、濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群のことをいい、「AL菌群」とは、濃度100mg/Lの低濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群のことを言う。したがって、このような条件で検出される菌であれば良く、特定の菌に限定されるものではない。AH菌群の具体的な例としては、ニトロソモナス(Nitrosomonas)属に属するものと考えられているが、分類学上定かではない。AH菌群からある単一の細菌を単離して用いることもできるが、AH菌群として複数種の細菌が共存している方が活性の安定性の面から好ましい。

なお、本発明において、「濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される」とは、濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で少なくとも8週間培養すればAH菌としての硝化菌が生じ、検出できるとの意味であり、8週間丁度の培養期間を意味するものではない。

また、硫酸アンモニア溶液の上限濃度は規定しなかったが、硝化菌が培養可能な濃度限界が上限となる。 <Definition>

In the present specification, “AH fungal group” refers to a nitrifying bacterial group detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks, and “AL fungal group” This refers to a group of nitrifying bacteria detected by culturing in a low concentration ammonia sulfate solution having a concentration of 100 mg / L for 8 weeks. Therefore, any bacteria can be detected as long as it is detected under such conditions, and is not limited to a specific bacteria. As a specific example of the AH fungal group, it is considered that it belongs to the genus Nitrosomonas, but it is not determined taxonomically. A single bacterium from the AH fungal group can be isolated and used, but it is preferable from the viewpoint of stability of activity that a plurality of types of bacteria coexist as the AH fungal group.

In the present invention, “detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks” means at least 8 weeks in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more. This means that if cultured, nitrifying bacteria as AH bacteria are generated and can be detected, and it does not mean a culture period of just 8 weeks.

Moreover, although the upper limit concentration of the ammonium sulfate solution was not defined, the upper limit is the concentration limit at which nitrifying bacteria can be cultured.

本発明に用いられるAH菌群は、一般的な活性汚泥や湖沼底泥などから馴養できる。したがって、AH菌群を得るためには何ら特別な手法または原料を必要とするものではなく、当業界において公知のいかなる方法を用いて調製しても良い。 <Activated sludge>

The AH fungal group used in the present invention can be acclimatized from general activated sludge, lake bottom mud and the like. Therefore, no special technique or raw material is required to obtain the AH bacteria group, and any method known in the art may be used.

菌を担体に保持させるには、(i)付着固定化、(ii)包括固定などの方法が用いることができる。(i)では球状や筒状などの担体、ひも状材料、ゲル状担体、不織布状材料など凹凸が多い材料が細菌の付着に好ましく、このような担体を用いるとアンモニア性窒素の除去率が向上する。(ii)では菌と固定化材料(モノマ、プレポリマ)を混合し、重合しゲルの内部に菌を包括固定化する。モノマー材料としてはアクリルアミド、メチレンビスアクリルアミド、トリアクリルフォルマールなどが好ましい。プレポリマ材料としてはポリエチレングリコールジアクリレートやポリエチレングリコールメタアクリレートが好ましく、その誘導体も用いることができる。形状は球状、方形状および筒状などの包括担体、ひも状包括担体、不織布状など凹凸が多い包括担体が接触効率の面で好ましく、アンモニア性窒素の除去率が向上する。 <Carrier>

In order to retain the bacterium on the carrier, methods such as (i) adhesion immobilization and (ii) entrapping immobilization can be used. In (i), a material having many irregularities such as a spherical or cylindrical carrier, a string-like material, a gel-like carrier, or a nonwoven material is preferable for bacterial adhesion, and the use of such a carrier improves the removal rate of ammonia nitrogen. To do. In (ii), a bacterium and an immobilization material (monomer, prepolymer) are mixed, polymerized, and the bacterium is comprehensively immobilized inside the gel. As the monomer material, acrylamide, methylenebisacrylamide, triacryl formal and the like are preferable. The prepolymer material is preferably polyethylene glycol diacrylate or polyethylene glycol methacrylate, and derivatives thereof can also be used. In terms of contact efficiency, inclusion shapes such as spherical, square, and cylindrical inclusion carriers, string inclusion carriers, and nonwoven inclusion inclusions with many irregularities are preferable, and the ammonia nitrogen removal rate is improved.

本発明によって処理するアンモニア性窒素含有水は、生活排水、し尿、および工場排水などの廃水、ならびに家庭用水槽および水族館における水槽の水が挙げられるが、これらに限定されるものではない。また、アンモニア性窒素が含まれていれば、上水であっても本発明による方法または装置によって処理することができる。 <Ammonia nitrogen-containing water>

The ammoniacal nitrogen-containing water to be treated according to the present invention includes, but is not limited to, wastewater such as domestic wastewater, human waste, and factory wastewater, and water in a domestic water tank and aquarium. Moreover, if ammonia nitrogen is contained, even the water can be treated by the method or apparatus according to the present invention.

本発明によるアンモニア性窒素含有水の硝化処理方法および装置を、図1を用いて説明する。硝化槽10内にAH菌群が保持された担体12が含まれており、アンモニア性窒素含有水導入部14からアンモニア性窒素含有水を導入することで、アンモニア性窒素含有水と該担体が接触し、担体に保持されたAH菌群がアンモニアを硝化して亜硝酸または硝酸を生じる。アンモニア性窒素含有水は硝化槽に一定時間滞留した後に、担体分離網18を通って処理水流出部16から処理水として流出する。流出した処理水は、次いで、脱窒槽(図示せず)に送られて処理水中の硝酸および亜硝酸が窒素ガスに変換されて除去される。 <Nitrification treatment>

A method and apparatus for nitrification of ammonia nitrogen-containing water according to the present invention will be described with reference to FIG. The

下水処理場では汚泥脱水後の脱離液が中~高濃度アンモニアを含有している。そこでこの脱離液を用いてAH菌群を培養する装置を具備したフローが図2である。このような構成にすると、下水処理場で少量発生する中~高濃度アンモニアを含有した脱離液を処理しつつ、そこで培養されたAH菌群を硝化槽に供給することができる。その結果、硝化槽内で低濃度アンモニアを含む廃水の処理効率が上がるため、好ましい。AH菌群の培養に用いる微生物保持担体として、未馴養の担体を用いることが費用面から好ましい。また、図2のような構成にすることで、中~高濃度処理用硝化槽(培養槽)から硝化槽にAH菌群が順次供給されるため、硝化槽は従来の活性汚泥法、例えば浮遊型活性汚泥法、を用いた槽であってもよい。なお、硝化槽内には、AH菌群を保持させた担体が含まれていてもよい。硝化槽内にAH菌群を保持させた担体を含む態様は、より大量の廃水を、高速、かつ、安定的に処理することができる点で好ましい。 <Operation for supplying AH bacteria group from AH bacteria culture tank>

In the sewage treatment plant, the effluent after sludge dehydration contains medium to high concentration ammonia. Therefore, FIG. 2 shows a flow equipped with an apparatus for culturing AH bacteria using this detachment solution. With such a configuration, the AH bacteria group cultured there can be supplied to the nitrification tank while treating the detachment liquid containing medium to high concentration ammonia generated in a small amount at the sewage treatment plant. As a result, the treatment efficiency of wastewater containing low-concentration ammonia in the nitrification tank is increased, which is preferable. From the viewpoint of cost, it is preferable to use an unfamiliar carrier as the microorganism-retaining carrier used for culturing the AH bacteria group. Further, with the configuration as shown in FIG. 2, since the AH bacteria group is sequentially supplied from the nitrification tank (culture tank) for medium to high concentration treatment to the nitrification tank, the nitrification tank is used in the conventional activated sludge method, for example, floating A tank using a type activated sludge method may be used. The nitrification tank may contain a carrier holding the AH bacteria group. An embodiment including a carrier in which AH bacteria are held in a nitrification tank is preferable in that a larger amount of waste water can be treated at high speed and stably.

本発明によるアンモニア性窒素含有水の多段処理を、図3を用いて説明する。この構成は、中濃度廃水において多段処理に構成することでAH菌群を保持しやすい環境を整え、低水温での処理能力を高めた例である。硝化槽が複数連なっているため、より高濃度のアンモニア性窒素を含む廃水を一度に処理することができる。図中28、30、32はそれぞれ第1硝化槽、第2硝化槽、第3硝化槽であり多段処理することにより各槽での濃度勾配ができ、第1硝化槽が最もNH4-Nの濃度が高く、第2硝化槽、第3硝化槽の順でNH4-Nの濃度が低くなる。AH菌群の増殖は雰囲気のNH4-N濃度に依存し、濃度が高いほどAH菌群の増殖に適しているため、AH菌群は第1硝化槽で増殖しやすくなる。そして、第1硝化槽で増殖したAH菌群が第2硝化槽や第3硝化槽に供給されることとなる。これにより3段処理全体での処理性能が低温でも維持され、温度耐性が向上する。 <Multistage processing>

The multistage treatment of ammoniacal nitrogen-containing water according to the present invention will be described with reference to FIG. This configuration is an example in which an environment that easily retains the AH bacteria group is prepared by configuring the medium concentration wastewater in a multi-stage treatment, and the treatment capability at a low water temperature is enhanced. Since a plurality of nitrification tanks are connected, wastewater containing higher concentration ammoniacal nitrogen can be treated at a time. In the figure, 28, 30, and 32 are the first nitrification tank, the second nitrification tank, and the third nitrification tank, respectively, and the concentration gradient in each tank can be made by multi-stage treatment, and the first nitrification tank has the highest NH 4 -N. The concentration is high, and the concentration of NH 4 -N decreases in the order of the second nitrification tank and the third nitrification tank. The growth of the AH fungal group depends on the NH 4 -N concentration in the atmosphere, and the higher the concentration, the better the growth of the AH fungal group. Therefore, the AH fungal group easily grows in the first nitrification tank. And the AH bacteria group which proliferated in the 1st nitrification tank will be supplied to a 2nd nitrification tank or a 3rd nitrification tank. Thereby, the processing performance in the entire three-stage process is maintained even at a low temperature, and the temperature resistance is improved.

本発明の応用例として、図4および図5のフローを示す。図4は本法での脱窒装置を具備したもの、図5は循環変法の硝化槽に本法のAH菌群優先担体を投入するか又はAH菌群を投入する装置を具備したものである。 <Application example of the present invention>

The flow of FIG. 4 and FIG. 5 is shown as an application example of this invention. FIG. 4 is equipped with a denitrification device according to the present method, and FIG. 5 is equipped with a device for introducing the AH fungal group preferred carrier of the present method into the nitrification tank of the modified circulation method or introducing the AH fungal group. is there.

下水処理場の活性汚泥(群馬県T市終末処理場より入手)15部、ポリエチレングリコールジメタクリレート(「ライトエステル14EG(品番)」、共栄社化学株式会社製)15部、NNN’N’テトラメチルエチレンジアミン(「206-04006(品番)」、和光純薬工業株式会社製)0.5部、および水69.25部を混合して懸濁液とし、そこに過硫酸カリウム(「162-04235(品番)」、和光純薬工業株式会社製)0.25部を加えると重合が始まり、ゲル化した。得られたゲルを3mm角のペレット状に切断して以下の例において使用した。 <Production of entrapped immobilization microorganism carrier>

Activated sludge from sewage treatment plant (obtained from T city end treatment plant, Gunma Prefecture), 15 parts of polyethylene glycol dimethacrylate ("Light Ester 14EG (product number)", manufactured by Kyoeisha Chemical Co., Ltd.), NNN'N 'tetramethylethylenediamine ("206-04006 (product number)", Wako Pure Chemical Industries, Ltd.) 0.5 part and water 69.25 parts are mixed to form a suspension, and potassium persulfate ("162-04235 (product number) ) ", Manufactured by Wako Pure Chemical Industries, Ltd.) When 0.25 part was added, the polymerization started and gelled. The obtained gel was cut into 3 mm square pellets and used in the following examples.

<AH菌群優占の担体の作製>

上記ペレット状に切断した包括固定化微生物担体を、下記表1に示す無機合成廃水(NH4-N:400mg/L)で馴養した。馴養は、図1に示す1.4Lの容積の硝化槽中で、負荷0.5kg-N/m3・dで2ヶ月行った。上記条件で2ヶ月馴養したものをAH菌群優占の担体として用いた。

<Production of AH bacteria dominant carrier>

The entrapping immobilization microorganism carrier cut into pellets was conditioned with inorganic synthetic wastewater (NH 4 -N: 400 mg / L) shown in Table 1 below. The acclimatization was carried out in a nitrification tank having a volume of 1.4 L shown in FIG. 1 for 2 months with a load of 0.5 kg-N / m 3 · d. What was acclimatized for 2 months on the said conditions was used as a carrier of AH bacteria group predominance.

<AL菌群優占の担体の作製>

上記無機合成廃水を水道水で10倍に希釈して用いた(NH4-N:40mg/L)以外は、AH菌群優占の担体の場合と同様にして負荷0.5kg-N/m3・dで馴養して作製し、AL菌群優占の担体として用いた。 Comparative Example 1

<Preparation of carrier dominant in AL fungus group>

A load of 0.5 kg-N / m was used in the same manner as in the case of the carrier dominant in the AH bacteria group, except that the inorganic synthetic wastewater was diluted 10-fold with tap water (NH 4 -N: 40 mg / L). It was prepared by acclimation at 3 · d and used as a carrier for the dominant AL fungus group.

(前処理)

得られたAH菌群優占の担体(実施例1)とAL菌群優占の担体(比較例1)において、AH菌群とAL菌群がそれぞれどれだけ含まれているのかを以下の方法で計測した。 <Measurement of the number of AH and AL bacteria>

(Preprocessing)

The following method was used to determine how much the AH fungal group and the AL fungal group were contained in the obtained carrier of the AH fungal group (Example 1) and the carrier of the AL fungal group (Comparative Example 1). Measured with.

前処理を終え、細菌が分散した液を用いてAH菌群およびAL菌群の数を最確値法に準じて計測した。まず、表3に示すAH菌群とAL菌群の菌数計測用培地を調製し、除菌濾過した後、約50mgのCaCO3を入れて乾熱滅菌した複数の試験管に9mLずつ無菌分注した。次いで、測定用培地を入れたものとは別の試験管を用意し、そこに殺菌した水を9mL入れ、さらに上記の前処理した液を原液として1mL加えることによって10倍に希釈した。この10倍に希釈した液を1mL抜き取り、別の9mLの殺菌した水に加えることにより、原液を基準として100倍に希釈した希釈液を得た。この操作を繰り返し、1010倍まで希釈した希釈液を調製した。ここで、各希釈倍率の希釈液を1mLずつ、5本の計測用培地に接種した。したがって、1つの試料について合計50本の試験管に接種した。接種した試験管を2~3本の無接種の試験管と共に30℃で8週間培養した。

After the pretreatment, the numbers of AH fungal group and AL fungal group were measured according to the most probable value method using a liquid in which bacteria were dispersed. First, the number of bacteria measuring medium AH bacteria group and AL bacteria group shown in Table 3 were prepared and after sterile filtration, sterile component into a plurality of test tubes put CaCO 3 to about 50mg and sterilized dry heat by 9mL Noted. Next, a test tube different from that containing the measurement medium was prepared, 9 mL of sterilized water was added thereto, and further 1 mL of the pretreated liquid was added as a stock solution to dilute 10 times. 1 mL of this 10-fold diluted solution was extracted and added to another 9 mL of sterilized water to obtain a diluted solution diluted 100 times based on the stock solution. This operation was repeated to prepare a diluted solution diluted 10 to 10 times. Here, 1 mL of the diluted solution at each dilution rate was inoculated into 5 measuring media. Therefore, a total of 50 tubes were inoculated for one sample. The inoculated tubes were cultured for 8 weeks at 30 ° C. with 2-3 uninoculated tubes.

実施例2

実施例1で作製した担体(AH菌群優占担体)を用いて、温度別硝化速度を測定した。評価は、図1に示す1.4Lの容積の硝化槽を用いて回分処理を行い硝化速度を求めた。原水は表1の無機合成廃水を10倍に希釈したNH4-N40mg/Lを用いた。なお、硝化槽内での担体の充填量は8%とした。 <Measurement of nitrification rate at each temperature>

Example 2

Using the carrier prepared in Example 1 (AH bacteria group dominant carrier), the nitrification rate according to temperature was measured. For the evaluation, batch treatment was performed using a nitrification tank having a volume of 1.4 L shown in FIG. 1 to obtain a nitrification rate. As raw water, NH 4 -N 40 mg / L obtained by diluting the inorganic synthetic waste water shown in Table 1 10 times was used. The carrier filling amount in the nitrification tank was 8%.

比較例1で作製した担体(AL菌優占の担体)を用いた以外は実施例2と同様にして、温度別硝化速度を測定した。結果を表5、および図6に示す。この結果から、AH菌群優占の担体はAL菌群優占の担体より低温耐性があることが分かる。特に、10℃以下の水温において、AH菌群優占の担体はAL菌群優占の担体に比べて顕著に高い硝化速度を得ることができることが分かる。

The nitrification rate according to temperature was measured in the same manner as in Example 2 except that the carrier prepared in Comparative Example 1 (a carrier dominant in AL bacteria) was used. The results are shown in Table 5 and FIG. From this result, it can be seen that the carrier dominant in the AH group is more resistant to low temperature than the carrier dominant in the AL group. In particular, it can be seen that at a water temperature of 10 ° C. or less, the carrier predominantly AH group can obtain a significantly higher nitrification rate than the carrier predominantly AL group.

実施例3

実施例1で作製した担体(AH菌群優占担体)を用いて、5℃で長期処理運転を行った。この処理には、図1の構成の硝化槽に合成無機廃水(NH4-N濃度:48~66mg/L)を用いた。

処理運転の条件を以下に示す。

硝化槽容積 1.4L

滞留時間 6~12時間

包括担体充填率 8%

NH4-N負荷 0.07~0.24kg-N/m3・d

運転期間 100日

実施例3についての結果を図7および8に示す。 <Long-term low water temperature measurement>

Example 3

A long-term treatment operation was performed at 5 ° C. using the carrier prepared in Example 1 (AH group dominant carrier). In this treatment, synthetic inorganic wastewater (NH 4 -N concentration: 48 to 66 mg / L) was used in the nitrification tank having the configuration shown in FIG.

The conditions of the processing operation are shown below.

Nitrification tank volume 1.4L

Residence time 6 to 12 hours Comprehensive

NH 4 -N load 0.07 to 0.24 kg-N / m 3 · d

比較例1で作製した担体(AL菌優占の担体)を用いた以外は実施例3と同様にして、5℃で長期処理運転を行った。比較例3についての結果を図9および10に示す。硝化能力の経日変化および容積負荷に対する硝化速度のいずれにおいても、本発明によるAH菌群優占担体が低水温で処理性能が優れていることが明らかである。 Comparative Example 3

A long-term treatment operation was carried out at 5 ° C. in the same manner as in Example 3 except that the carrier prepared in Comparative Example 1 (a carrier predominantly AL bacteria) was used. The results for Comparative Example 3 are shown in FIGS. It is clear that the AH bacteria-dominant carrier according to the present invention is excellent in treatment performance at low water temperature in both aging ability and nitrification rate against volumetric load.

実施例4

図2のフローの装置を用いた。活性汚泥を用いて作製した未馴養の包括固定化微生物担体(活性汚泥固定化担体)を、中~高濃度アンモニア性窒素含有水(汚泥脱水後の脱離液)を用いた中~高濃度処理用硝化槽(培養槽)20に投入し、そこに中~高濃度アンモニアを含有する脱離液を流入させ、中~高濃度処理用硝化槽(培養槽)20内の担体内部でAH菌群を馴養培養した。AH菌群の一部は担体からリークし、硝化槽100に投入される。硝化槽100には活性汚泥が懸濁している。硝化槽100にアンモニア性窒素含有水導入部14から低濃度アンモニア性窒素含有水を流入させ、硝化処理を行った。 <Operation for supplying AH bacteria group from AH bacteria culture tank>

Example 4

The apparatus of the flow of FIG. 2 was used. Medium-to-high concentration treatment of unfamiliar entrapped immobilization microorganism carrier (activated sludge immobilization carrier) produced using activated sludge using medium-to-high concentration ammoniacal nitrogen-containing water (desorbed liquid after sludge dehydration) The nitrification tank (culture tank) 20 is used, and a leaching solution containing medium to high concentration ammonia is introduced into the nitrification tank (culture tank) 20, and the AH bacteria group inside the carrier in the medium to high concentration treatment nitrification tank (culture tank) 20. Was cultivated. A part of the AH bacteria group leaks from the carrier and is put into the

各種アンモニア性窒素含有水のNH 4 -N濃度

汚泥脱水後の脱離液 350~410mg/L

アンモニア性窒素含有水導入部14に導入される廃水 32~40mg/L

硝化槽100の仕様

硝化槽容積 10L

滞留時間 4時間

MLSS濃度 4,000mg/L

NH4-N負荷 0.25~0.32kg-N/m3・d

中~高濃度処理用硝化槽(培養槽)20の仕様

中~高濃度処理用硝化槽(培養槽)容積 0.5L

滞留時間 12時間

包括担体充填率 20%

NH4-N負荷 0.7~0.8kg-N/m3・d Various water quality and equipment specifications are shown below.

NH 4 -N concentration of various ammoniacal nitrogen-containing waters Desorbed liquid after sludge dehydration 350-410 mg / L

Waste water to be introduced into the ammoniacal nitrogen-containing

Specifications of

Residence time 4 hours MLSS concentration 4,000 mg / L

NH 4 -N load 0.25 to 0.32 kg-N / m 3 · d

Specification of nitrification tank (culture tank) 20 for medium to high concentration treatment <br/> Volume of nitrification tank (culture tank) for medium to high concentration treatment 0.5L

NH 4 -N load 0.7 to 0.8 kg-N / m 3 · d

中~高濃度処理用硝化槽(培養槽)20を具備しない従来法(浮遊型活性汚泥法)を用いた以外は実施例4と同様にして、NH4-N32~40mg/Lを滞留時間4時間、MLSS濃度4000mg/Lで処理したところ、水温10~13℃で、処理水中にアンモニア性窒素が多く残留し、硝化槽から排出された処理水のアンモニア性窒素濃度はNH4-N:9~35mg/Lであった。したがって、本発明による方法および装置での効果は明らかである。 Comparative Example 4

NH 4 -N32 to 40 mg / L was maintained at a residence time of 4 in the same manner as in Example 4 except that a conventional method (floating activated sludge method) not equipped with a nitrification tank (culture tank) 20 for medium to high concentration treatment was used. When treated with an MLSS concentration of 4000 mg / L for a time, a large amount of ammonia nitrogen remained in the treated water at a water temperature of 10 to 13 ° C., and the ammonia nitrogen concentration in the treated water discharged from the nitrification tank was NH 4 -N: 9 -35 mg / L. Thus, the effects of the method and apparatus according to the present invention are obvious.

実施例5

図3に示す多段処理で処理を行った。

水質と装置の仕様を以下に示す。

廃水中NH4-N濃度 170~220mg/L

各硝化槽28、30、32の仕様

各槽の容積 2L

各槽の滞留時間 4時間

包括担体充填率 20% <Multistage processing>

Example 5

Processing was performed by the multistage processing shown in FIG.

The water quality and equipment specifications are shown below.

Waste water NH 4 -N concentration 170-220mg / L

Specification of each

Residence time of each tank 4 hours Comprehensive

12 担体

14 アンモニア性窒素含有水導入部

16 処理水流出部

18 担体分離網

19 硝化液循環ライン

20 中~高濃度処理用硝化槽(AH菌群培養槽)

22 AH菌群放出部

24 中~高濃度アンモニア性窒素含有水導入部

26 中濃度アンモニア性窒素含有水導入部

28 第1硝化槽

30 第2硝化槽

32 第3硝化槽

100 従来の硝化槽

120 従来の担体

130 従来の担体

200 脱窒槽

310 脱窒菌付着充填材

500 有機物供給槽 DESCRIPTION OF

22 AH fungus

Claims (11)

- アンモニア性窒素含有水を処理する方法であって、

アンモニア性窒素濃度が1~300mg/Lのアンモニア性窒素含有水と、濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群が優先繁殖した担体とを、好気性雰囲気下、0℃以上15℃以下で接触させて前記アンモニア性窒素含有水中のアンモニアを硝化する硝化工程、

を含む方法。 A method for treating ammonia nitrogen-containing water,

Ammonia nitrogen-containing water having an ammonia nitrogen concentration of 1 to 300 mg / L and a carrier on which a nitrifying bacteria group preferentially propagated by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks A nitrification step of nitrifying ammonia in the ammoniacal nitrogen-containing water by contacting at 0 ° C. or higher and 15 ° C. or lower in an aerobic atmosphere;

Including methods. - アンモニア性窒素含有水を処理する方法であって、

アンモニア性窒素濃度が100~1000mg/Lのアンモニア性窒素含有水と微生物保持担体とを接触させて、濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群を優先培養する培養工程と、

前記培養された硝化菌群と、アンモニア性窒素濃度が1~300mg/Lのアンモニア性窒素含有水とを、好気性雰囲気下、0℃以上15℃以下で接触させて前記アンモニア性窒素含有水中のアンモニアを硝化する硝化工程と

を含む方法。 A method for treating ammonia nitrogen-containing water,

Nitrifying bacteria detected by contacting ammonia-containing nitrogen water having an ammonia nitrogen concentration of 100 to 1000 mg / L with a microorganism-supporting carrier and culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks. A culture process for preferentially culturing the group;

The cultured nitrifying bacteria group is brought into contact with the ammoniacal nitrogen-containing water having an ammoniacal nitrogen concentration of 1 to 300 mg / L in an aerobic atmosphere at 0 ° C. or higher and 15 ° C. or lower to bring the ammoniacal nitrogen-containing water into contact. A nitrification step of nitrifying ammonia. - 前記微生物保持担体が、未馴養の微生物保持担体である、請求項2に記載の方法。 The method according to claim 2, wherein the microorganism holding carrier is an unfamiliar microorganism holding carrier.

- 前記硝化工程に用いられる前記アンモニア性窒素含有水中のアンモニア性窒素濃度が1~100mg/Lである、請求項1~3のいずれか一項に記載の方法。 The method according to any one of claims 1 to 3, wherein the ammoniacal nitrogen concentration in the ammoniacal nitrogen-containing water used in the nitrification step is 1 to 100 mg / L.

- 前記硝化工程において、前記アンモニア性窒素含有水と前記担体とを0℃以上10℃以下で接触させる、請求項1~4のいずれか一項に記載の方法。 The method according to any one of claims 1 to 4, wherein in the nitrification step, the ammoniacal nitrogen-containing water and the carrier are brought into contact at 0 ° C or higher and 10 ° C or lower.

- 1つ以上の追加の硝化工程をさらに含んでなる、請求項1~5のいずれか一項に記載の方法。 The method according to any one of claims 1 to 5, further comprising one or more additional nitrification steps.

- アンモニア性窒素含有水の処理装置であって、

硝化槽と、

前記硝化槽にアンモニア性窒素濃度が1~300mg/Lのアンモニア性窒素含有水を導入する導入部と、

前記硝化槽から処理した前記アンモニア性窒素含有水を排出する排出部と

を備え、

前記硝化槽の中に濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群が優先繁殖した担体が含まれてなる、

前記硝化槽では0℃以上15℃以下で、アンモニア性窒素含有水を処理する、処理装置。 A treatment apparatus for water containing ammonia nitrogen,

A nitrification tank,

An introduction part for introducing ammonia nitrogen-containing water having an ammonia nitrogen concentration of 1 to 300 mg / L into the nitrification tank;

A discharge section for discharging the ammoniacal nitrogen-containing water treated from the nitrification tank,

In the nitrification tank, a carrier in which a nitrifying bacteria group preferentially propagated by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks is included,

The processing apparatus which processes ammonia nitrogen containing water at 0 degreeC or more and 15 degrees C or less in the said nitrification tank. - アンモニア性窒素含有水の処理装置であって、

濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群を培養する培養槽と、

前記培養槽にアンモニア性窒素濃度が100~1000mg/Lのアンモニア性窒素含有水を導入する第1の導入部と、

前記培養槽から培養された前記硝化菌群を放出する放出部と

前記放出部に接続された硝化槽と、

前記硝化槽にアンモニア性窒素濃度が1~300mg/Lのアンモニア性窒素含有水を導入する第2の導入部と、

前記硝化槽から処理した前記アンモニア性窒素含有水を排出する排出部と

を備え、

前記培養槽から前記硝化槽に、前記放出部を介して、培養した前記硝化菌群を供給し、

前記硝化槽では0℃以上15℃以下で、アンモニア性窒素含有水を処理する、処理装置。 A treatment apparatus for water containing ammonia nitrogen,

A culture tank for culturing a group of nitrifying bacteria detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks;

A first introduction part for introducing ammoniacal nitrogen-containing water having an ammoniacal nitrogen concentration of 100 to 1000 mg / L into the culture tank;

A discharge section for discharging the nitrifying bacteria group cultured from the culture tank; and a nitrification tank connected to the discharge section;

A second introduction part for introducing ammonia nitrogen-containing water having an ammonia nitrogen concentration of 1 to 300 mg / L into the nitrification tank;

A discharge section for discharging the ammoniacal nitrogen-containing water treated from the nitrification tank,

Supplying the cultured nitrifying bacteria group from the culture tank to the nitrification tank via the discharge section;

The processing apparatus which processes ammonia nitrogen containing water at 0 degreeC or more and 15 degrees C or less in the said nitrification tank. - 前記培養槽に微生物保持担体が含まれている、請求項7に記載の装置。 The apparatus according to claim 7, wherein the culture vessel contains a microorganism holding carrier.

- 前記硝化槽に、さらに1つ以上の追加の硝化槽が連結されてなる、請求項7~9のいずれか一項に記載の装置。 The apparatus according to any one of claims 7 to 9, wherein one or more additional nitrification tanks are further connected to the nitrification tank.

- 担体と、

前記担体に優先繁殖した硝化菌群であって、濃度5000mg/L以上の高濃度な硫酸アンモニア溶液中で8週間培養して検出される硝化菌群と

を含み、

0℃以上15℃以下で1~300mg/Lのアンモニア性窒素含有水を処理する細菌保持担体。 A carrier;

A group of nitrifying bacteria preferentially propagated on the carrier, which is detected by culturing in a high concentration ammonia sulfate solution having a concentration of 5000 mg / L or more for 8 weeks,

A bacteria-retaining carrier for treating 1 to 300 mg / L of ammoniacal nitrogen-containing water at 0 to 15 ° C.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014526906A JP6161210B2 (en) | 2012-07-26 | 2013-07-22 | Method and apparatus for low temperature treatment of ammonia nitrogen containing water |

| KR20157002286A KR20150037909A (en) | 2012-07-26 | 2013-07-22 | Method and device for treating ammonia nitrogen-containing water at low temperature |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012-166093 | 2012-07-26 | ||

| JP2012166093 | 2012-07-26 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2014017429A1 true WO2014017429A1 (en) | 2014-01-30 |

Family

ID=49997240

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/069776 WO2014017429A1 (en) | 2012-07-26 | 2013-07-22 | Method and device for treating ammonia nitrogen-containing water at low temperature |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6161210B2 (en) |

| KR (1) | KR20150037909A (en) |

| WO (1) | WO2014017429A1 (en) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015226892A (en) * | 2014-06-02 | 2015-12-17 | 株式会社ウェルシィ | Ammonia nitrogen-containing water treatment method |

| JP2016107219A (en) * | 2014-12-08 | 2016-06-20 | 株式会社日立製作所 | Nitrogen treatment method and nitrogen treatment apparatus |

| JP2016140824A (en) * | 2015-02-02 | 2016-08-08 | 学校法人 東洋大学 | Processing method and processing apparatus of ammonia-containing waste water |

| JP2017104818A (en) * | 2015-12-11 | 2017-06-15 | 水ing株式会社 | Operation control method of water treatment installation |

| CN111847807A (en) * | 2020-08-26 | 2020-10-30 | 厚普环保科技(苏州)有限公司 | Cruise type micro/eutrophic river and lake bottom mud surface layer dredging and water quality repairing device |

| CN113213644A (en) * | 2021-04-20 | 2021-08-06 | 复旦大学 | Method for treating high-concentration ammonia nitrogen wastewater by culturing nitrification combined flora |

| CN114315022A (en) * | 2021-12-24 | 2022-04-12 | 江苏蓝必盛化工环保股份有限公司 | Full biological treatment method for high-concentration formaldehyde wastewater |

| WO2022138981A1 (en) | 2020-12-25 | 2022-06-30 | 株式会社クボタ | Method for treating organic wastewater |

| WO2024047922A1 (en) * | 2022-08-29 | 2024-03-07 | 株式会社クボタ | Method for culturing cold-resistant nitrifying bacteria, method for treating nitrogen-containing water, and device for treating nitrogen-containing water |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05169090A (en) * | 1991-12-24 | 1993-07-09 | Meidensha Corp | Device for supplying nitrification bacteria in biological activated carbon treatment tower |

| JPH0947787A (en) * | 1995-08-10 | 1997-02-18 | Hitachi Plant Eng & Constr Co Ltd | Waste water treating device |

| JPH0975984A (en) * | 1995-09-11 | 1997-03-25 | Hitachi Plant Eng & Constr Co Ltd | Biological nitrogen removing device |

| JP2000061494A (en) * | 1998-08-25 | 2000-02-29 | Hitachi Plant Eng & Constr Co Ltd | Biological treatment of ammonia nitrogen |

| JP3252887B2 (en) * | 1995-08-10 | 2002-02-04 | 日立プラント建設株式会社 | Method and apparatus for biological oxidation of ammoniacal nitrogen |

| JP2004305816A (en) * | 2003-04-02 | 2004-11-04 | Hitachi Plant Eng & Constr Co Ltd | Nitrification method and apparatus, and waste water treatment equipment |

-

2013

- 2013-07-22 JP JP2014526906A patent/JP6161210B2/en active Active

- 2013-07-22 WO PCT/JP2013/069776 patent/WO2014017429A1/en active Application Filing

- 2013-07-22 KR KR20157002286A patent/KR20150037909A/en not_active Application Discontinuation

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05169090A (en) * | 1991-12-24 | 1993-07-09 | Meidensha Corp | Device for supplying nitrification bacteria in biological activated carbon treatment tower |

| JPH0947787A (en) * | 1995-08-10 | 1997-02-18 | Hitachi Plant Eng & Constr Co Ltd | Waste water treating device |

| JP3252887B2 (en) * | 1995-08-10 | 2002-02-04 | 日立プラント建設株式会社 | Method and apparatus for biological oxidation of ammoniacal nitrogen |

| JPH0975984A (en) * | 1995-09-11 | 1997-03-25 | Hitachi Plant Eng & Constr Co Ltd | Biological nitrogen removing device |

| JP2000061494A (en) * | 1998-08-25 | 2000-02-29 | Hitachi Plant Eng & Constr Co Ltd | Biological treatment of ammonia nitrogen |

| JP2004305816A (en) * | 2003-04-02 | 2004-11-04 | Hitachi Plant Eng & Constr Co Ltd | Nitrification method and apparatus, and waste water treatment equipment |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015226892A (en) * | 2014-06-02 | 2015-12-17 | 株式会社ウェルシィ | Ammonia nitrogen-containing water treatment method |

| JP2016107219A (en) * | 2014-12-08 | 2016-06-20 | 株式会社日立製作所 | Nitrogen treatment method and nitrogen treatment apparatus |

| JP2016140824A (en) * | 2015-02-02 | 2016-08-08 | 学校法人 東洋大学 | Processing method and processing apparatus of ammonia-containing waste water |

| JP2017104818A (en) * | 2015-12-11 | 2017-06-15 | 水ing株式会社 | Operation control method of water treatment installation |

| CN111847807A (en) * | 2020-08-26 | 2020-10-30 | 厚普环保科技(苏州)有限公司 | Cruise type micro/eutrophic river and lake bottom mud surface layer dredging and water quality repairing device |

| WO2022138981A1 (en) | 2020-12-25 | 2022-06-30 | 株式会社クボタ | Method for treating organic wastewater |

| CN113213644A (en) * | 2021-04-20 | 2021-08-06 | 复旦大学 | Method for treating high-concentration ammonia nitrogen wastewater by culturing nitrification combined flora |

| CN114315022A (en) * | 2021-12-24 | 2022-04-12 | 江苏蓝必盛化工环保股份有限公司 | Full biological treatment method for high-concentration formaldehyde wastewater |

| CN114315022B (en) * | 2021-12-24 | 2023-12-22 | 江苏蓝必盛化工环保股份有限公司 | Full biological treatment method for high-concentration formaldehyde wastewater |

| WO2024047922A1 (en) * | 2022-08-29 | 2024-03-07 | 株式会社クボタ | Method for culturing cold-resistant nitrifying bacteria, method for treating nitrogen-containing water, and device for treating nitrogen-containing water |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20150037909A (en) | 2015-04-08 |

| JP6161210B2 (en) | 2017-07-12 |

| JPWO2014017429A1 (en) | 2016-07-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6161210B2 (en) | Method and apparatus for low temperature treatment of ammonia nitrogen containing water | |

| Singh et al. | Nutrient removal from membrane bioreactor permeate using microalgae and in a microalgae membrane photoreactor | |

| Li et al. | Aerobic sludge granulation in a full‐scale sequencing batch reactor | |

| Jamshidi et al. | Wastewater treatment using integrated anaerobic baffled reactor and Bio-rack wetland planted with Phragmites sp. and Typha sp. | |

| Pan et al. | Effects of the combination of aeration and biofilm technology on transformation of nitrogen in black-odor river | |

| Świątczak et al. | Treatment of the liquid phase of digestate from a biogas plant for water reuse | |

| WO2010150691A1 (en) | Method for treating wastewater containing ammonia nitrogen | |

| Gupta et al. | Simultaneous removal of organic matters and nutrients from high-strength wastewater in constructed wetlands followed by entrapped algal systems | |

| CN101691569B (en) | Bacillus cereus microbial preparation and method for treating nitrogenous waste water by using microbial preparation | |

| Zayed et al. | Removal of organic pollutants and of nitrate from wastewater from the dairy industry by denitrification | |

| CN111117914B (en) | Salt-tolerant heterotrophic aerobic nitrobacteria strain, culture method, bacterial liquid and application | |

| Kouba et al. | The impact of influent total ammonium nitrogen concentration on nitrite-oxidizing bacteria inhibition in moving bed biofilm reactor | |

| Van Den Brand et al. | Occurrence and activity of sulphate reducing bacteria in aerobic activated sludge systems | |

| US10227246B2 (en) | Method for the treatment of industrial waste | |

| Arango et al. | Effect of microalgae inoculation on the start-up of microalgae–bacteria systems treating municipal, piggery and digestate wastewaters | |

| Bellucci et al. | Disinfection and nutrient removal in laboratory‐scale photobioreactors for wastewater tertiary treatment | |

| Mery et al. | Evaluation of natural zeolite as microorganism support medium in nitrifying batch reactors: Influence of zeolite particle size | |

| CN105112337B (en) | One Enterobacter cloacae and its application | |

| Chaiwong et al. | Performance and kinetics of algal-bacterial photobioreactor (AB-PBR) treating septic tank effluent | |

| Teles et al. | Ecology of duckweed ponds used for nutrient recovery from wastewater | |

| Arango et al. | The potential of membrane-assisted microalgae-bacteria consortia for the treatment of real municipal sewage | |

| Jiang et al. | Immobilization of halophilic yeast for effective removal of phenol in hypersaline conditions | |

| Yang et al. | Bio-augmentation as a tool for improving the modified sequencing batch biofilm reactor | |

| Wang et al. | Vegetation effects on anammox spatial distribution and nitrogen removal in constructed wetlands treated with domestic sewage | |

| Xie et al. | Performance and bacterial community composition of volcanic scoria particles (VSP) in a biological aerated filter (BAF) for micro‐polluted source water treatment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13822889 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2014526906 Country of ref document: JP Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 20157002286 Country of ref document: KR Kind code of ref document: A |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 13822889 Country of ref document: EP Kind code of ref document: A1 |