WO2013061379A1 - Paper sheet processing device - Google Patents

Paper sheet processing device Download PDFInfo

- Publication number

- WO2013061379A1 WO2013061379A1 PCT/JP2011/006042 JP2011006042W WO2013061379A1 WO 2013061379 A1 WO2013061379 A1 WO 2013061379A1 JP 2011006042 W JP2011006042 W JP 2011006042W WO 2013061379 A1 WO2013061379 A1 WO 2013061379A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- unit

- bill

- storage

- guide

- processing unit

- Prior art date

Links

Images

Classifications

-

- G—PHYSICS

- G07—CHECKING-DEVICES

- G07D—HANDLING OF COINS OR VALUABLE PAPERS, e.g. TESTING, SORTING BY DENOMINATIONS, COUNTING, DISPENSING, CHANGING OR DEPOSITING

- G07D11/00—Devices accepting coins; Devices accepting, dispensing, sorting or counting valuable papers

- G07D11/10—Mechanical details

-

- G—PHYSICS

- G07—CHECKING-DEVICES

- G07D—HANDLING OF COINS OR VALUABLE PAPERS, e.g. TESTING, SORTING BY DENOMINATIONS, COUNTING, DISPENSING, CHANGING OR DEPOSITING

- G07D11/00—Devices accepting coins; Devices accepting, dispensing, sorting or counting valuable papers

- G07D11/40—Device architecture, e.g. modular construction

Definitions

- the present invention relates to a sheet processing apparatus for processing sheets such as banknotes.

- a bill processing apparatus mounted on an automatic teller machine is a bill for dispensing the deposited bills to the user or for dispensing the deposited bills inserted one by one.

- a deposit / withdrawal port, a bill discriminating section for discriminating deposited or dispensed bills, a temporary storage section for temporarily storing deposited bills, and a plurality of separated deposited and deposited bills for dispensing and storage as a deposited bill or the like It has a bill storage part and a bill conveyance way which connects the above-mentioned each part.

- the bill deposit / withdrawal port, the bill discriminating portion, and the temporary storage portion are integrally assembled to constitute an upper unit, and a plurality of bill storage portions are assembled to a tray to form a lower unit. I have stored it. Then, a guide mechanism by a rail is disposed between the housing and the upper unit and the lower unit, and the upper unit and the lower unit can be drawn out from the housing. This supports maintenance, reloading of banknotes, and increases in the number of types of money and capacity.

- the above-mentioned housings are likely to differ slightly in size from one unit to another.

- high dimensional accuracy is required in the horizontal gap between the casing and the upper unit and the lower unit, and there is a problem that the manufacturing is troublesome.

- the present invention has a simple configuration with a sheet processing apparatus having a unit guide mechanism capable of smoothly performing an operation of pulling out or storing a bill unit that processes sheets such as bills. To realize.

- the present invention has been made to solve at least a part of the above-described problems, and can be realized as the following modes or application examples.

- Application Example 1 determines a paper sheet to be inserted or fed, and separates and stores the determined paper sheet, a case having a storage space for storing the bill unit, and the case

- a sheet processing apparatus comprising: a unit guide mechanism which is interposed in a horizontal slide gap with the bill unit and guides the bill unit out from the storage space and guides the bill unit to be stored in the storage space.

- the unit guide mechanism includes: a guide portion disposed horizontally along the inner wall of the housing; a guided portion disposed on the outer wall side of the bill unit and movable along the guide portion; And a connection mechanism that performs at least one of connection between the body and the guide portion or connection between the bill unit and the guided portion.

- the connection mechanism has a distance adjustment unit that changes the distance between the guide and the housing or the distance between the guided portion and the bill unit when receiving a force in the horizontal direction by the movement of the bill unit. Processing device.

- a unit guide mechanism is disposed between the inner wall of the housing and the outer wall of the bill unit.

- the unit guide mechanism includes a guide portion fixed to the inner wall of the housing and a guided portion disposed on the side of the bill unit, and the guided portion moves relative to the guide portion, thereby the storage space of the housing Draw out the bill unit from the bill and store it in the storage space.

- connection mechanism of the unit guide mechanism performs at least one of connection of the bill unit and the guide portion or connection of the bill unit and the guided portion, and the movement of the bill unit by the distance adjustment unit.

- the distance between the guide portion and the housing or the distance between the guided portion and the bill unit is changed.

- the distance adjustment unit receives a horizontal force applied by the connection mechanism, the difference between the slide gaps can be reduced by changing the distance between the guide and the housing or the distance between the guided and the bill unit. Absorb.

- Such a distance adjusting portion absorbs the difference in the sliding gap, thereby reducing the increase in the frictional force generated when the guide portion and the guided portion slide, and hence, a small operating force for the bill unit relative to the housing Can slide smoothly.

- the bill unit is A sheet processing unit for determining a sheet to be fed or fed; A plurality of paper sheet storage units separately storing the determined paper sheets, and a storage body for storing the plurality of paper sheet storage units, and the paper disposed below the bill processing unit Leaf storage unit,

- the paper sheet is bidirectionally conveyed between the paper sheet processing unit and the paper sheet storage unit via a conveyance path connecting the paper sheet processing unit and the paper sheet storage unit.

- the transport mechanism Equipped with The unit guide mechanism includes a first slide mechanism disposed in the slide gap between the housing and the bill processing unit, and a second slide mechanism disposed in the slide gap between the housing and the bill storage unit.

- a sheet processing apparatus comprising a slide mechanism.

- connection mechanism includes a connection member that connects the outer wall of the guided portion and the bill unit.

- the distance adjusting unit has a fixing member fixed to one of the connecting member and the bill unit, and a long hole formed in the other of the connecting member and the bill unit and into which the fixing member is inserted.

- the distance adjusting unit includes a first connecting member fixed to the bill unit and a second connecting member fixed to the guided portion.

- the distance adjusting portion is formed on the other of the fixing member fixed to one of the first connecting member and the second connecting member, and the other of the first connecting member and the second connecting member, and the length to which the fixing member is inserted

- a sheet processing apparatus comprising: a hole; and the fixing member moving in the long hole to make the slide gap variable.

- the second slide mechanism is configured to slidably support the storage body

- the unit guide mechanism has a storage guide rail arranged in the moving direction in the bill processing unit, and a first roller provided in the bill storage unit and guided by the storage guide rail, and the bill storage A suspension mechanism configured to move the first roller in the storage guide rail in a state where the portion is lifted by the bill processing unit,

- the suspension mechanism arranges the storage guide rail and the first roller on both sides in the width direction of the bill processing unit, and one of the first rollers is positioned in the width direction to move on the storage guide rail A sheet processing apparatus, wherein the other first roller is configured to move on the storage guide rail with play in the width direction on the storage guide rail.

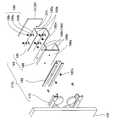

- FIG. 1 It is a perspective view which shows the external appearance of the automatic teller machine which mounts the banknote processing apparatus as a paper sheet processing apparatus. It is a sectional side view which shows schematic structure of a banknote processing apparatus. It is sectional drawing explaining a connection conveyance mechanism and a branch connection mechanism. It is explanatory drawing explaining operation

- FIG. 15 is an explanatory diagram for explaining an operation following FIG. 14; It is explanatory drawing explaining the operation

- FIG. 17 is an explanatory diagram for explaining an operation following FIG. 16;

- FIG. 18 is an explanatory diagram for explaining an operation following FIG. 17;

- FIG. 19 is an explanatory diagram for explaining an operation following FIG. 18;

- FIG. 20 is an explanatory diagram for explaining an operation following FIG. 19;

- FIG. 21 is an explanatory diagram for explaining an operation following FIG. 20;

- FIG. 22 is an explanatory diagram for explaining an operation following FIG. 21;

- FIG. 23 is an explanatory diagram for explaining an operation following FIG. 22; It is a side view showing a lock mechanism.

- FIG. 27 is an explanatory diagram for explaining an operation following FIG. 26.

- FIG. 28 is an explanatory diagram for explaining an operation following FIG. 27;

- FIG. 29 is an explanatory diagram for explaining an operation following FIG. 28;

- FIG. 30 is an explanatory diagram for explaining an operation following FIG. 29.

- FIG. 31 is an explanatory diagram for explaining an operation following FIG. 30.

- FIG. 32 is an explanatory diagram for explaining an operation following FIG. 31.

- FIG. 33 is an explanatory diagram for explaining an operation following FIG. 32.

- FIG. 34 is an explanatory diagram for explaining an operation following FIG. 33; It is explanatory drawing explaining the operation

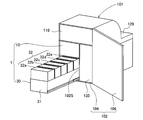

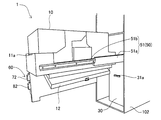

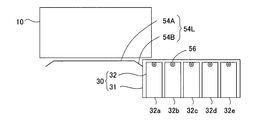

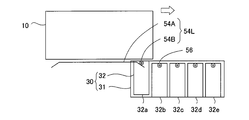

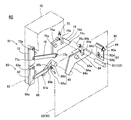

- FIG. 1 is a perspective view showing the appearance of an automated teller machine 101 equipped with a bill processing apparatus 1 as a paper sheet processing apparatus.

- the automated teller machine 101 is a device which is managed by a financial institution such as a bank and performs various transactions in accordance with the operation of the user (customer), for example, using a card, a bill, a statement slip as a medium and depositing the user. , Payment, transfer, etc.

- the automated teller machine 101 is stored in the storage space 102S of the housing 102.

- the case 102 is surrounded by a case body 104 and a door 106 for opening and closing the rear opening of the case body 104.

- the bill processing apparatus 1 is an apparatus disposed at the lower part of the automated teller machine 101 in the drawing for handling bills.

- the card and statement slip processing mechanism 110 is disposed at the top of the automated teller machine 101, is a device that processes a user's card, prints out a transaction slip, and outputs it.

- the customer operation unit 120 is a device for displaying and inputting the content of the transaction on the front of the device.

- the coin processing device 130 is disposed at the lower part of the automated teller machine 101 and is a device that handles coins.

- the automated teller machine 101 includes a power supply unit, a main control unit for controlling the entire automatic teller machine 101, and a main body to which each mechanism is connected by a line such as USB.

- a control unit (not shown) is also provided.

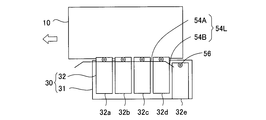

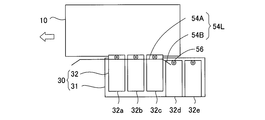

- the bill processing apparatus 1 includes a bill processing unit 10 (paper sheet processing unit) disposed in the upper part, a bill storage unit 30 (paper sheet storage unit) disposed in the lower part, and a control unit (control unit)

- the bill processing unit 10 and the bill storage unit 30 can be removed from the inside of the case 102 by opening the door 106 of the case 102.

- the mechanism for storing the bill processing unit 10 and the bill storage unit 30 will be described later.

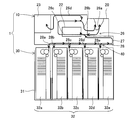

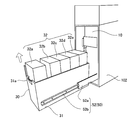

- FIG. 2 is a side sectional view showing a schematic configuration of the banknote handling apparatus 1.

- the bill processing unit 10 generally includes a mechanism necessary for exchanging bills with the user, and the bill depositing / dispensing port 20, the bill identifying unit 22, the temporary holding unit 23, and the bill among the respective units.

- An upper unit transport mechanism 26 for transporting, and a connection transport mechanism 27 for sending a bill from the upper unit transport mechanism 26 to the bill storage unit 30 are provided.

- the bill receiving / dispensing port 20 includes a deposit unit that allows the user to deposit and deposit bills, and a payment unit that dispenses bills.

- the bill validator 22 is a mechanism for discriminating whether or not a bill is a denomination, an authenticity, and a rejected bill, and outputting the discrimination result to the control unit. For example, an image obtained by scanning the bill It is a configuration using various information such as data, irregularities on the surface of a bill, magnetic characteristics, optical characteristics against ultraviolet light and the like.

- the rejected banknotes are banknotes that are incompatible due to the authenticity of the banknote, or banknotes that overlap or are broken and whose authenticity is unknown or the like.

- the temporary storage unit 23 is a mechanism for temporarily storing bills in the process of transporting the bills between the bill depositing / dispensing unit and the bill storage unit 30.

- the upper unit conveyance mechanism 26 is a mechanism that conveys a bill by rotational driving of a roller (not shown), and a deposit conveyance path 26a that conveys a bill inserted into the deposit unit of the bill deposit / withdrawal portion 20; It is equipped with a conveyance path 26b for paying out bills to a part, a conveyance path 26c for discrimination to make the bill identification part 22 pass the bill, and a conveyance path 26d for temporary stocking portion which carries the bill to the temporary stocking portion 23 ing.

- the discrimination conveyance path 26c, the temporary storage conveyance path, and the like are configured to be capable of being conveyed bidirectionally. Moreover, the gate etc.

- sensors for detecting passage of bills are disposed on the transport path, and detection signals of these sensors are sent to the control unit and used for judging passage of bills and presence / absence of bills. .

- the banknote storage unit 30 is provided with the storage body 31 and the banknote storage part 32 (paper sheet storage part).

- the storage body 31 is a box opened at the upper side, and the bill storage portion 32 is stored in the storage space.

- the bill storage unit 32 includes five bill storage units 32a to 32e, which have substantially the same configuration, and are disposed at the storage box forming a bill storage space for storing bills and at the top of the storage unit It has rollers and sensors.

- Each of the bill storage sections 32a to 32e stores the bills sent from the bill processing unit 10 in the bill storage space, and makes the stored bills bi-directionally with respect to the bill processing unit 10 by a transport mechanism such as a roller.

- banknote storage units 32a to 32e can be used so that the types of banknotes to be handled differ, and for example, the banknote storage for storing 10,000 yen, 5,000 yen, 1,000 yen, and 2,000 yen, or the above It can be used as a reject storage for storing reject bills.

- the connecting and conveying mechanism 27 is a secondary conveyance branched from the main conveyance path 28 and the main conveyance path 28 to the respective bill storage portions 32.

- the passages 28a to 28e are provided, and the banknotes are transported bidirectionally to the respective banknote storage portions 32a to 32e.

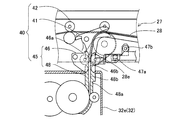

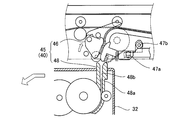

- FIG. 3 and 4 are cross-sectional views showing the vicinity of the branch point of the connecting and conveying mechanism 27.

- a branch connection mechanism 40 is disposed at each branch point of the connection and conveyance mechanism 27.

- the branch connection mechanism 40 includes a gate 41, a roller group 42 composed of a plurality of rollers for leading to the sub conveyance path 28e, and a connection mechanism 45.

- the gate 41 is an L-shaped member disposed at a branch point, and driven by a drive (not shown) (such as a solenoid) to copy the bill transported to the main transport path 28 into the roller group 42 and sub-steps

- the transport path 28e is switched to transport in both directions.

- the gate 41 (shown by a solid line) in FIG. 3 is a position for switching to the secondary conveyance path 28e, and the gate 41 indicated by a two-dot chain line is a position for transporting to the other secondary conveyance paths 28a to 28d.

- the connection mechanism 45 includes an upstream guide 46 and a downstream guide 48.

- the upstream guide portion 46 includes a guide main body 46 a.

- the guide main body 46a includes a guide groove 46b formed along the sub conveyance path 28a, and the bill is conveyed along the guide groove 46b.

- the downstream guide part 48 is provided with the guide main body 48a arrange

- the guide main body 48a has a guide groove 48b formed along the sub conveyance path 28e, and the bill is conveyed along the guide groove 48b.

- the upstream guide portion 46 and the downstream guide portion 48 are each formed in a comb-tooth shape, and their connection point, that is, the lower portion of the upstream guide portion 46 and the upper portion of the downstream guide portion 48 respectively enter each other between the combs,

- the guide grooves 46b and 48b formed by the unbroken wall surfaces constitute a part of the sub conveyance path 28e.

- the upstream guide portion 46 is rotatable by the rotation shaft 47a, and can rotate the rotation shaft 47a by receiving a driving force of a motor drive shaft 47b of a motor (not shown). Therefore, as shown in FIG. 4, the connection mechanism 45 moves with the upper portion of the downstream guide portion 48 when the power is not supplied to the motor or is reset, as shown in FIG.

- the connection mode (connection position) shown in FIG. 3 is established by the non-connection mode (non-connection position) where the overlapping portion disappears and power is supplied to the motor.

- the banknotes stored in the temporary storage unit 23 are separated and fed out one by one, and are further counted and identified by the banknote identification unit 22 via the discrimination conveyance path 26c, and the coupling conveyance mechanism 27 , And is transported from the coupling transport mechanism 27 to any of the bill storage sections 32 (32a to 32e) designated by the main body control section. This completes the deposit transaction.

- the banknotes are separated and fed one by one from the banknote storage unit 32 instructed by the main body control unit.

- the bill passes through the discrimination conveyance path 26c of the connection conveyance mechanism 27 and the upper unit conveyance mechanism 26, and after being discriminated and counted by the bill identification unit 22, the bill deposit / withdrawal port via the withdrawal conveyance path 26b.

- the delivery unit of the unit 20 is reached and provided to the customer. This completes the withdrawal transaction.

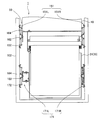

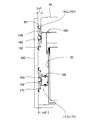

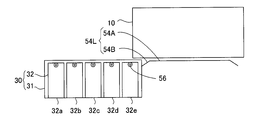

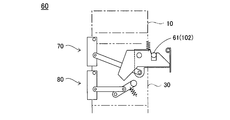

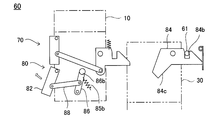

- FIG. 5 is a perspective view showing the bill processing unit 10 pulled out of the housing 102 through the unit guide mechanism 50.

- FIG. 6 shows the bill storage unit 30 pulled out of the housing 102 through the unit guide mechanism 50.

- FIG. 7A is a schematic configuration view for explaining the unit guide mechanism 50.

- the unit guide mechanism 50 includes a first slide mechanism 151 and a second slide mechanism 171.

- the first slide mechanism 151 is disposed between both sides of the bill processing unit 10 and the inner wall of the housing 102, and is a mechanism for pulling out the bill processing unit 10 from the housing 102.

- the second slide mechanism 171 is disposed between both sides of the bill storage unit 30 and the inner wall of the housing 102, and is a mechanism for pulling out the bill storage unit 30 from the housing 102.

- the first slide mechanism 151 includes a left slide mechanism 151L disposed on the left side of the bill processing unit 10 in the figure and a right slide mechanism 151R disposed on the right side of the bill processing unit 10 in the figure. It is slidably supported horizontally with respect to 102.

- the second slide mechanism 171 includes a left slide mechanism 171L disposed on the left side of the bill storage unit 30 in the drawing and a right slide mechanism 171R disposed on the right side of the bill storage unit 30 in the drawing. It is slidably supported horizontally with respect to 102.

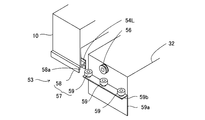

- FIG. 7B is an exploded perspective view of the left slide mechanism 151L of the first slide mechanism 151.

- the left slide mechanism 151L includes a first guide portion 152, a first guided portion 162, and a first connection mechanism 164.

- the first guide portion 152 includes a guide support upper frame 153, a guide support lower frame 154, and rails 155a and 155b in which a large number of rollers are disposed between the guide support upper frame 153 and the guide support lower frame 154. .

- a gap Sp for inserting the first guided portion 162 is formed between the rail 155a and the rail 155b.

- the upper guide support frame 153 and the lower guide support frame 154 are fixed to the inner wall of the housing 102 by fixing members 153 n and 154 n, respectively.

- the first guided portion 162 includes a guide base 162a formed in a rectangular shape in cross section and a guide piece 162b extended from an end of the guide base 162a.

- the guide base 162a is disposed in the gap Sp between the rail 155a and the rail 155b, and the guide piece 162b is pulled out by the rails 155a and 155b, whereby the guided member 162 is horizontal to the first guide portion 152. It is supported slidably in the direction.

- the first connection mechanism 164 is a mechanism for adjusting the horizontal position of the first guided portion 162 with respect to the outer wall of the bill processing unit 10, and includes a connection member 165 and a first distance adjustment portion 168. ing.

- the connecting member 165 includes a horizontal portion 166 and a vertical portion 167, and is formed in an L shape by being bent at a right angle. The end of the horizontal portion 166 is inserted into the slit 10d of the support plate 10c. The vertical portion 167 fixes the first guided portion 162 via the fixing member 162 n.

- FIG. 7C is a cross-sectional view for explaining the configuration around the first distance adjustment unit 168.

- the first distance adjusting portion 168 is a mechanism for movably connecting the bill processing unit 10 and the first guided portion 162 (FIG. 7B) in the horizontal direction relatively, and includes a long hole 10h formed in the support plate 10c. , A fastening hole 166h formed in the horizontal portion 166, a fixing member 169n which is a screw, and a spacer 169s.

- the fixing member 169n is screwed into the fastening hole 166h of the horizontal portion 166 through the hole of the spacer 169s, and the fixing member 169n and the spacer 169s are integrated with the connecting member 165.

- the elongated hole 10h is a hole having an inner diameter larger than the outer diameter of the spacer 169s in the arrow direction, and the spacer 169s and the connecting plate 165 do not contact each other even when the support plate 10c and the connecting member 165 move relatively horizontally. A gap Sp3 is secured between them. Therefore, the connecting member 165 is not restrained in the arrow direction (one side in the horizontal direction) with respect to the support plate 10c, and is connected after securing the movability.

- the right side slide mechanism 151R has the same configuration as the left side slide mechanism 151L without the first connection mechanism 164, and the bill processing unit 10 can slide against the inner wall of the housing 102 on the right side of the bill processing unit 10 in the figure.

- the bill processing unit 10 can slide against the inner wall of the housing 102 on the right side of the bill processing unit 10 in the figure.

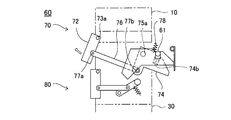

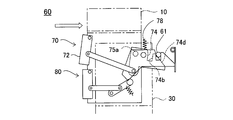

- FIG. 7D is an exploded perspective view of the second slide mechanism 171.

- FIG. The second slide mechanism 171 is different in the configuration of the second connection mechanism 184 from the configuration of the first connection mechanism 164 (FIG. 7B) of the first slide mechanism 151.

- the second connection mechanism 184 is a mechanism for connecting the second guided portion 182 to the outer wall of the bill storage unit 30 and adjusting the horizontal position, and includes a first connection member 185 and a second connection member 186. , And a second distance adjustment unit 188.

- the first connection member 185 includes a vertical plate 185a and a horizontal plate 185b disposed in parallel from the upper and lower ends of the vertical plate 185a, which are integrally formed, and the vertical plate 185a stores the banknotes via the fixing member 185n. It is fixed to the storage body 31 of the unit 30.

- the second connection member 186 includes a vertical plate 186a and horizontal plates 186b arranged in parallel from the upper and lower ends of the vertical plate 186a, which are integrally formed, and guided by the vertical plate 186a via the fixing member 182n.

- the member 182 is fixed.

- the second distance adjustment unit 188 is a mechanism that intervenes between and connects the storage body 31 of the bill storage unit 30 and the second guided portion 182, and is formed on the horizontal plate 185b of the first connection member 185.

- the first connecting member 185 and the second connecting member 186 are movably connected through the elongated hole 185 h and the screw hole 186 h by overlapping the horizontal plate 185 b and the horizontal plate 186 b.

- the first connection member 185 and the second connection member 186 are movably connected in one horizontal direction by the same configuration as the first distance adjustment unit 168 described in FIG. 7C. .

- the right side slide mechanism 171R has the same configuration as the left side slide mechanism 171L without the second connection mechanism 184 (FIG. 7C), and the illustrated right side of the bill storage unit 30 is the inner wall of the housing 102 in the inner wall of the housing 102.

- the storage body 31 is movably supported.

- the door 106 of the case 102 is opened, and as shown in FIG. 5, by holding the handle 11a of the bill processing unit 10 and applying a force to the bill processing unit 10 in the front direction, The bill processing unit 10 can be pulled out via the unit guide mechanism 50.

- the bill processing unit 10 can be pulled out via the unit guide mechanism 50.

- FIG. 6 by grasping the handle 31a of the storage body 31, pulling out the storage body 31, and taking out the bill storage portion 32, it is possible to carry out a bill collection operation and a loading operation.

- FIG. 7E is an explanatory view for explaining the withdrawal operation of the bill processing unit 10 or the like of the bill processing apparatus 1. Due to the variation in the dimension in the width direction of the housing 102, a difference may occur in the movement direction in the sliding gaps Ls1 and Ls2, which are the gaps between the inner wall of the housing 102 and the outer walls of the bill processing unit 10 and the bill storage unit 30. .

- the difference between the slide gaps Ls1 and Ls2 is caused by the first and second guide portions 152 and 172 and the first and second guided portions 162 and 182 when the bill processing unit 10 or the bill storage unit 30 is pulled out or stored.

- the first distance adjustment unit 168 may not be a gap or a first guided

- the second distance adjustment unit 188 absorbs the difference in the sliding gap Ls2 between the housing 102 and the bill storage unit 30.

- the first and second guide portions 152 and 172 and the first and second guided portions 162, 172 absorb the difference between the sliding gaps Ls1 and Ls2 by the first and second distance adjusting portions 168 and 188.

- the increase in the frictional force generated at the time of sliding with 182 can be reduced, and therefore, the bill processing unit 10 and the bill storage unit 30 can be smoothly slid with respect to the housing 102 with a small operation force.

- the first connecting mechanism 164 is connected between the bill processing unit 10 and the guide.

- the present invention is not limited to this configuration, and between the housing 102 and the first guide portion 152. Even if it arranges, the difference of the clearance for sliding can be absorbed.

- long hole 10h was formed in the support plate 10c of the banknote processing unit 10, not only this but a banknote processing unit and banknote storage unit

- a long hole may be formed on the connecting member side as long as it can be movably connected in the horizontal direction with the guide portion or the guided portion.

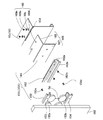

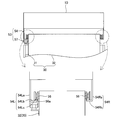

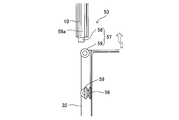

- FIG. 7F is an explanatory view for explaining the cooperation guide mechanism 53 for suspending and guiding the bill storage unit 32 of the bill storage unit 30 to the bill processing unit 10.

- FIG. 8 shows the bill storage unit 32 of the bill storage unit 30 from the bill processing unit 10. It is explanatory drawing explaining the cooperation guide mechanism 53 in the state which removed.

- the cooperation guide mechanism 53 suspends the plurality of bill storage portions 32 stored in the storage body 31 of the bill storage unit 30 with respect to the bill processing unit 10, and also the bill processing unit 10 and the bill storage unit 30. Is a mechanism that guides the movement of the bill storage unit 32 in the vertical direction and the horizontal direction when the bill holder moves relatively.

- the cooperation guide mechanism 53 includes a suspension mechanism 54 and a horizontal direction guide mechanism 57.

- the suspension mechanism 54 includes storage guide rails 54R and 54L fixed on both sides of the side wall of the bill processing unit 10, and a first roller 56 mounted on the upper side wall of the bill storage unit 32.

- the storage guide rails 54R, 54L are long members which are disposed over substantially the entire length of the bill processing unit 10 in the horizontal direction and suspend the bill storage portion 32.

- the storage guide rails 54R and the storage guide rails 54L are provided. And have different cross-sectional shapes.

- the storage guide rail 54L is bent upward from the end of the horizontal portion 54Lb, the rail base 54La provided downward from the side wall of the bill processing unit 10, the horizontal portion 54Lb bent from the lower end of the rail base 54La, and And the support standing portion 54Lc.

- the first roller 56 is rotatably supported on the upper side wall of both sides of the bill storage unit 32.

- the first roller 56 is in the form of a pulley having an inclined groove 56a inclined toward the center.

- the first roller 56 rolls on the storage guide rail 54L in a state where the support standing portion 54Lc of the storage guide rail 54L is inserted into the inclined groove 56a.

- the storage guide rail 54R includes a rail base 54Ra and a support horizontal portion 54Rb. The first roller 56 rolls on the storage guide rail 54R by being placed on the support horizontal portion 54Rb.

- FIG. 9 is an explanatory view for explaining the storage guide rail 54L side of the suspension mechanism 54 when the bill processing unit 10 and the bill storage unit 30 are viewed from the side. Since the storage guide rails 54R and 54L have substantially the same shape in the longitudinal direction, the storage guide rail 54L will be described as a representative.

- the storage guide rail 54L includes a general part 54A and guide inclined parts 54B formed on both sides of the general part 54A.

- the general part 54A is a linear shape having the cross-sectional shape shown in FIG. 7F as described above.

- the guide inclined portion 54B is inclined downward from the general portion 54A.

- FIG. 10 and 11 are explanatory views for explaining the positioning mechanism 55 of the general portion 54A of the storage guide rail 54L.

- a positioning mechanism 55 including a plurality of positioning portions 55a to 55e is formed on the upper portion of the general portion 54A.

- the positioning portions 55a to 55e are recesses for positioning each of the bill storage portions 32.

- each of the bill storage portions 32 can be connected to the connection mechanism 45 of the bill processing unit 10 (FIG. 3). Position with high accuracy.

- the horizontal distance L1 is longer than the distance L2 of the positioning portions 55b, 55c and 55d. Therefore, as shown in FIG.

- the positioning portion may be a protrusion or the like as long as the first roller 56 can be positioned in addition to the recess.

- FIG. 12 is a perspective view for explaining the horizontal guide mechanism 57

- FIG. 13 is an explanatory view of the vicinity of the horizontal guide mechanism 57 as viewed from above.

- the horizontal guide mechanism 57 is a mechanism for guiding the bill storage portion 32 in the left-right direction, and the second roller 59 mounted on one of the side walls of the bill storage portion 32 and the lower surface of the storage guide rail 54L.

- a fixed adjustment guide rail 58 The second roller 59 is provided with a fitting 59a attached to the side wall of the bill storage portion 32 in an L shape, and the flange 59b of the fitting 59a supports the second roller 59 so as to rotate on a horizontal surface.

- the adjustment guide rail 58 constitutes a guide groove 58a, and the second roller 59 is rotatably inserted into the guide groove 58a.

- FIGS. 14 to 23 are explanatory views for explaining the operation for pulling out or storing the bill processing unit 10 and the bill storage unit 30.

- A Withdrawal and Storage Operation of Banknote Processing Unit 10

- a -1 Drawout Operation of Banknote Processing Unit 10

- the banknote processing unit 10 and the banknote storage unit 30 are in the storage position.

- the five first rollers 56 mounted in the bill storage portion 32 are located in the general portion 54A of the storage guide rail 54R, as shown in FIG. It is positioned in the sections 55a to 55e.

- the bill storage portion 32 is at the lifting position away from the bottom of the storage body 31 by the distance Lv.

- connection mechanism 45 shown in FIG. 4 is set in the non-connection mode as shown in FIG. 4, and the lock mechanism 60 (see FIG. 24) is set in the non-locking position.

- the handle 11a (see FIG. 5) of the bill processing unit 10 is gripped and pulled by hand, the bill processing unit 10 moves in the arrow direction, as shown in FIG.

- the three first rollers 56 are positioned from the initial stage of operation to the positioning portions 55b to 55d.

- the second two first rollers 56 escape from the positioning portions 55a and 55e after having climbed up the inclined surface 55s of the above and finished climbing. Therefore, since the five first rollers 56 do not simultaneously escape from the positioning mechanism 55, the load (operation force) at the initial stage of operation can be reduced.

- bill processing unit 10 As shown in FIG. 15, as the bill processing unit 10 moves, the first roller 56 of the bill storage portion 32e is guided by the guide inclined portion 54B. As a result, the bill storage portion 32 e gradually descends and moves to the retracted position placed on the bottom surface of the storage body 31.

- the bill processing unit 10 is further moved through the states shown in FIGS. 16 and 17, the bill storage portions 32d, 32c, 32b, and 32b are sequentially guided by the guide inclined portion 54B and moved to the withdrawal position. Thereby, as shown in Drawing 18, bill processing unit 10 serves as a drawer position. By pulling out such a bill processing unit 10, it is possible to eliminate a jam or the like of the bill as described above.

- (A) -2 Storing Operation of Banknote Processing Unit 10

- the second roller 59 of the horizontal direction guide mechanism 57 strikes the end of the adjustment guide rail 58 and the adjustment guide rail 58 Is guided into the guide groove 58a of the Thereby, the bill storage unit 32 is aligned in the horizontal direction.

- the first roller 56 reaches the storage guide rail 54L (54R), as shown in FIG. 7F, one of the first rollers 56 rides on the supporting standing portion 54Lc of the storage guide rail 54L, (1) The roller 56 rides on the support horizontal portion 54Rb of the storage guide rail 54R. Then, as shown in FIG. 19, with the movement of the bill processing unit 10, the bill storage portion 32a is guided by the storage guide rail 54L (54R), and runs onto the general portion 54A from the guide inclined portion 54B.

- the bill storage unit 32b is lifted from the bill storage unit 32b by sequentially moving the first rollers 56 from the guide inclined portion 54B to the general portion 54A, and the connection mechanism 45 It is set so as to be directed to the transport path of FIG. 14 and passes through the states of FIG. 17, FIG. 16 and FIG. At this time, as shown in FIG. 10, the bill storage portion 32 is positioned when the first roller 56 reaches the positioning mechanism 55. Then, as shown in FIG. 3, by setting the connection mechanism 45 in the connection mode, the bill processing apparatus 1 can be driven.

- connection mechanism 45 is set to the non-connection mode and the lock mechanism 60 as in the case Set each to the non-locking position. Then, as shown in FIG. 20, when the grip 31a (see FIG. 5) of the bill storage unit 30 is grasped and pulled by hand, the bill storage unit 30 moves in the arrow direction. At this time, as shown in FIGS. 10 and 11, among the five first rollers 56 positioned in the positioning portions 55a to 55e, the three first rollers 56 are positioned from the initial stage of operation to the positioning portions 55b to 55d.

- the second two first rollers 56 escape from the positioning portions 55a and 55e after having climbed up the inclined surface 55s of the above and finished climbing. Therefore, since the five first rollers 56 do not simultaneously escape from the positioning mechanism 55, the load (operation force) at the initial stage of operation can be reduced.

- the bill storage portion 32a gradually descends following the inclination of the guide inclined portion 54B, It moves to the retracted position placed on the bottom of the storage body 31. Further, when the bill storage unit 30 moves through the states of FIG. 21, FIG. 22, and FIG. 23, the bill storage portions 32b, 32c, 32d, and 32e are sequentially guided by the guide inclined portion 54B and move to the withdrawal position. As a result, the bill storage unit 30 is in the withdrawal position. By pulling out the bill storage unit 30 in this manner, the bill storage unit 30 can be removed from the storage body 31 by being lifted above the respective bill storage portions 32.

- (B) -2 Storage Operation of Banknote Storage Unit 30

- a force is applied to the banknote storage unit 30 in the storage direction from the state of FIG.

- the horizontal guide mechanism 57 aligns in the horizontal direction.

- the first roller 56 rides on the storage guide rail 54L (54R), and along with the movement of the bill storage unit 30, the bill storage portion 32a is guided by the storage guide rail 54L (54R), and from the guide inclined portion 54B to the general part Get on to 54A.

- the bill storage portion 32a is sequentially lifted from the bill storage portion 32d by the movement of the first rollers 56 from the guide inclined portion 54B to the general portion 54A to the connection position. It moves to the storage position of FIG. At this time, as shown in FIG. 10, the bill storage portion 32 is positioned when the first roller 56 reaches the positioning mechanism 55. Then, as shown in FIG. 5, by setting the connection mechanism 45 in the connection mode, the bill processing apparatus 1 can be driven.

- the bill storage unit 30 can be linked by pulling it out through the first slide mechanism 151 of the unit guide mechanism 50 with respect to the housing 102.

- the guide mechanism 53 moves from the state in which the bill storage portion 32 is lifted with respect to the storage body 31 to the retracted position placed on the storage body 31.

- the cooperative guide mechanism 53 does not require a complicated configuration for retracting the bill storage portion 32 from the transport path of the connection mechanism 45 as described in the prior art, and the configuration is simplified.

- the horizontal direction guide mechanism 57 of the cooperative guide mechanism 53 performs the second operation when the banknote storage unit 32 is displaced in the left-right direction.

- the roller 59 strikes the end of the adjustment guide rail 58 and is guided into the guide groove 58 a of the adjustment guide rail 58.

- the bill storage portion 32 can be guided in the horizontal direction reliably.

- the positioning mechanism 55 of the cooperation guide mechanism 53 positions the bill storage portion 32 by dropping the first roller 56 to the positioning portions 55a to 55e of the recess respectively.

- connection reliability can be improved.

- the positioning portions 55a to 55e have different distances in the horizontal direction of the recess, and the first roller 56 does not separate from the positioning portion at the same time, so that the load (operating force) at the initial stage of operation can be reduced.

- the bill storage unit 32 is stored in the bill storage unit 32 by moving the first roller 56 at the top of the bill storage unit 32 on the storage guide rail 54L at the bottom of the bill processing unit 10 by the suspension mechanism 54.

- the bill storage unit 32 moves in the movement direction while being lifted from the above. Since one of the rollers of the suspension mechanism 54 is positioned in the width direction by the storage guide rail 54L, the suspension mechanism 54 is moved such that the slide gaps Ls1 and Ls2 are absorbed by the distance adjustment portion of the unit guide mechanism 50. Even if the bill storage unit 32 is positioned relative to the bill processing unit 10, the bill conveyance path between the bill processing unit 10 and the bill storage unit 32 is not misaligned, and there is no hindrance to the conveyance thereof. .

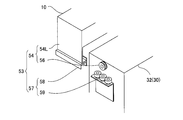

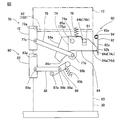

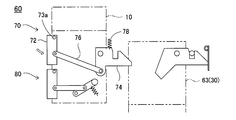

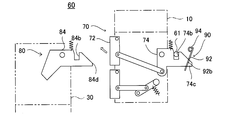

- FIG. 24 is a side view showing the locking mechanism 60

- FIG. 25 is an exploded perspective view of the locking mechanism 60.

- the lock mechanism 60 is a mechanism for locking the drawer of the bill processing unit 10 and the bill storage unit 30.

- the lock mechanism 60 includes a lock pin 61 protruding from the inner wall of the housing 102, a first lock mechanism 70 for locking the bill processing unit 10, and a second lock mechanism 80 for locking the bill storage unit 30. And a cooperative lock mechanism 90.

- the first lock mechanism 70 includes a first operation portion 72, a first lock member 74, a link member 76, and a spring 78.

- the first operation unit 72 is rotatably supported by a support substrate 62 extended from the lower portion of the bill processing unit 10 about the rotation shaft 73 a, and operated by the user, the first lock member 74. Is a member for operating the lock position from the locked position to the unlocked position.

- the first lock member 74 includes a lock plate main body 74 a, is rotatably supported by the support substrate 62 by the rotation shaft 75 a, and is biased by a spring 78.

- the lock plate main body 74a has an engagement portion 74b at its upper portion which takes an engagement position engaging with the lock pin 61 and a non-locking position non-engagement, a stopper portion 74c formed at an end thereof, and a stopper An inclined surface 74d continuous to the portion 74c.

- the link member 76 is connected to the first operation portion 72 via the connection shaft 77a, and is connected to the first lock member 74 via the connection shaft 77b. Therefore, when the first operation portion 72 is operated in the direction of the arrow to rotate about the rotation shaft 73a, the first lock member 74 is biased by the spring 78 about the rotation shaft 75a via the link member 76. By rotating in opposition, the lock pin 61 engaged with the engaging portion 74b can be disengaged.

- the second lock mechanism 80 includes a second operation portion 82, a second lock member 84, a kicker member 86, a link member 88, a spring 85b, and a spring 85c.

- the second operation unit 82 is rotatably supported by the support substrate 62 about the rotation shaft 83a, and operated by the user to operate the second lock member 84 from the locked position to the unlocked position. It is a member of The second lock member 84 includes a lock plate main body 84a, is rotatably supported by the support substrate 63 on the side of the bill storage unit 30 about the rotation shaft 85a, and is biased by a spring 85b.

- the lock plate main body 84a has an engagement portion 84b which takes an engagement position engaged by the lock pin 61 and a non-engagement position where it does not engage, a pressing portion 84c which projects obliquely downward at its end, and the other end And an inclined surface 84e continuous with the stopper portion 84d.

- the kicker member 86 is connected to the second operation unit 82 via a link member 88.

- the kicker member 86 includes a rod-like kicker main body 86a and a kicker portion 86b formed at an end of the kicker main body 86a, and is rotatably supported around a rotation shaft 87a.

- the link member 88 connects the second operation portion 82 and the kicker member 86 by being rotatably connected to the connection shaft 89b via the second operation portion 82 and the connection shaft 89a. Therefore, when the second operation portion 82 is operated in the direction of the arrow and rotated about the rotation shaft 83a, the kicker member 86 receives the biasing force of the spring 85b about the rotation shaft 87a via the link member 88. Rotate against. When the kicker portion 86b of the kicker member 86 presses the pressing portion 84c of the second lock member 84, the second lock member 84 is rotated, and the lock pin 61 engaged with the engagement portion 84b is disengaged. can do.

- the cooperative lock mechanism 90 includes a movable plate 92 rotatably supported by a pivot shaft 93 a and a spring 94, and is biased by the spring 94.

- the movable plate 92 includes an abutting portion 92a and a stopper portion 92b formed by a hole.

- the contact portion 92 a restricts the rotation of the second lock member 84 by the stopper portion 84 d of the second lock member 84 coming into contact with the contact portion 92 a.

- the stopper portion 92 b regulates the rotation of the first lock member 74 by the insertion of the stopper portion 74 c.

- the rotation operation of the first operation unit 72 causes the first lock member 74 to rotate about the rotation shaft 75a.

- the engaging portion 74b of the first lock member 74 is disengaged from the lock pin 61, and the first lock mechanism 70 shifts from the lock position to the non-lock position.

- the kicker portion 86b is the second lock member.

- the second lock member 84 does not rotate because it does not hit the pressing portion 84 c of 84. Therefore, the engaging portion 84b does not come off from the lock pin 61, and the bill storage unit 30 maintains the lock position.

- the first lock mechanism 70 integrated with the bill processing unit 10 also moves in the same direction. Then, when the inclined surface 74d of the first lock member 74 abuts on the lock pin 61, the first lock member 74 rotates about the rotation shaft 75a against the biasing force of the spring 78, and the engagement portion 74b is locked. Engage 61 Thereafter, the biasing force of the spring 78 causes the first lock member 74 to rotate in the reverse direction. Thereby, the first lock mechanism 70 shifts to the lock position, and the withdrawal of the banknote handling unit 10 is restricted.

- FIG. 26 Withdrawal Operation of Banknote Storage Unit 30

- the bill processing unit 10 and the bill storage unit 30 are in the storage position.

- the second operation portion 82 rotates the rotation shaft. Rotate in the same direction around 83a.

- one end of the link member 88 is connected to the connecting shaft 89a, and the other end of the link member 88 is connected to the connecting shaft 89b.

- the kicker member 86 is rotated about the rotation shaft 87 a via the member 88.

- the kicker portion 86b of the kicker member 86 pushes the pressing portion 84c of the second lock member 84, and the second lock member 84 rotates about the rotation shaft 87a.

- the engaging portion 84b of the second lock member 84 is disengaged from the lock pin 61, and the second lock mechanism 80 shifts from the locked position to the unlocked position.

- the second lock member 84 and the like of the second lock mechanism 80 mounted on the bill storage unit 30 are also moved integrally. At this time, parts such as the first lock member 74 integrated with the bill processing unit 10 remain in the storage position. Then, as shown in FIG. 34, the second lock member 84 of the second lock mechanism 80 is returned by the spring force of the spring 85c, and the second operation portion 82 is returned to the original position by the spring 85b.

- the movable plate 92 of the cooperative lock mechanism 90 comes in contact with the stopper portion 84d of the second lock member 84, so that the second lock member 84 moves from the state in which the rotation is restricted. Therefore, it rotates by the spring force of the spring 94. Thereby, the stopper portion 92 b of the movable plate 92 enters the stopper portion 84 d of the second lock member 84, and the rotation of the second lock member 84 is restricted. Accordingly, the engaging portion 84 b of the second lock member 84 is engaged with the lock pin 61.

- the lock mechanism 60 pulls out only one of the bill processing unit 10 and the bill storage unit 30 from the housing 102 when both the bill processing unit 10 and the bill storage unit 30 are in the storage position. It works to make it impossible. That is, as shown in FIG. 30, when the bill processing unit 10 is pulled out, the kicker portion 86b of the kicker member 86 is the second lock member even if the second operation portion 82 of the second lock mechanism 80 is rotated. The second lock mechanism 80 maintains the lock position because the second lock member 84 can not be rotated without hitting the pressing portion 84 c of 84. On the other hand, as shown in FIG.

- the stopper portion 92b of the movable plate 92 of the cooperative lock mechanism 90 is engaged with the stopper portion 84d of the second lock member 84, and the first lock Since the rotation of the member 74 is restricted, the first lock member 74 can not be rotated even if the first operation part 72 of the first lock mechanism 70 is rotated, and the first lock mechanism 70 is locked. Maintain position.

- the lock mechanism 60 can not move the bill processing unit 10 and the bill storage unit 30 to the withdrawal position at the same time, thereby achieving the following effects.

- the bill processing unit 10 and the bill storage unit 30 are configured to be moved by rails arranged in the horizontal direction, for example, when the bill processing unit 10 is at the withdrawal position, the bill processing unit 10 is inclined and the bill storage unit 30 is inclined. It is easy for the distance between Even in such a state, in order to allow the bill storage unit 30 to be drawn out smoothly, a large interval is required so that the bill processing unit 10 does not interfere with the bill storage unit 30. A large interval requires a large moving distance to move the bill storage unit 30 to the connection point of the connection mechanism 45, and the connection configuration is complicated.

- the lock mechanism 60 since only one of the bill processing unit 10 and the bill storage unit 30 can be pulled out, the lock mechanism 60 does not need to have a large interval therebetween, and the connection mechanism 45 can be connected. It is possible to simplify the configuration and to guarantee a smooth withdrawal operation.

- the first and second locked engagement members are common to the first and second lock mechanisms, and the configuration can be simplified.

- the present invention is not limited to the above embodiment, and can be carried out in various modes without departing from the scope of the invention. For example, the following modifications are possible.

- the present invention can be applied to an apparatus that handles various types of paper sheets such as banknotes, cards, and paper (printed paper).

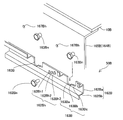

- FIG. 36 is an explanatory view for explaining the work of assembling the bill processing unit 10B to the first guided portion 162B.

- the present embodiment is characterized in the configuration of the first guided portion 162B.

- FIG. 36 is a partially broken perspective view showing a state before the bill processing unit 10B is assembled to the first guided portion 162B.

- the first guided portion 162B includes a guide base 162Ba and a guide piece 162Bb. In the guide base portion 162Ba, a fastening hole 162Bh and a positioning hole 163B are formed.

- the fastening holes 162Bh are composed of a first hole 162Bh1, a second hole 162Bh2 and a third hole 162Bh3 which are disposed at different positions in the vertical direction and obliquely.

- the fixing member 162Bn is inserted into one of the first to third holes 162Bh1 to 162Bh3 and is fastened to the fastening hole 167Bh.

- the positioning hole 163B is formed by one rectangular hole, and a first stepped portion 163Ba, a second stepped portion 163Bb and a third stepped portion 163Bc are respectively formed on the bottom of the hole.

- the first to third stepped portions 163Ba to 163Bc are formed in a step shape so that the positions in the vertical direction and the horizontal direction are different corresponding to the first to third holes 162Bh1 to 163Bh3.

- the first guided portion 162B is assembled to a first guide portion fixed to a housing (not shown), and the first guided portion 162B is pulled out of the first guide portion in advance. Further, the positioning member 163Bn is fixed in advance to the connecting member 165B of the first connecting mechanism 164B. Then, holding the bill processing unit 10B, the positioning member 163Bn is inserted into the positioning hole 163B. At this time, the positioning member 163Bn is placed on any of the first to third stepped portions 163Ba to 163Bc, and the bill processing unit 10B is temporarily placed on the first guided portion 162B.

- the fastening hole 162Bh is aligned with the fastening hole 167Bh, and the first to third steps are performed.

- the connecting member 165B is fixed to the first guided portion 162B by inserting the fixing member 162Bn into any of the holes 162Bh1 to 162Bh3 and screwing it into the fastening hole 167Bh.

- the bill processing unit 10B is temporarily placed on the first guided portion 162B temporarily via the positioning hole 163B and the positioning member 163Bn, and the fastening hole 162Bh is perpendicular to the fastening hole 167Bh. And because it can be adjusted in three levels in the horizontal direction, it is excellent in workability.

- the number of stages of the positioning holes 163B is not limited to three, and may be a large number of stages depending on alignment.

- Spring 80 second lock mechanism 82: second operation portion 83a: rotary shaft 84: second lock member 84a: lock plate main body 84b: engagement portion 84c: pressing portion 84d: stopper portion 84e: inclined surface 85a: rotation shaft 85b ... Spring 85c ... Spring 86 ... Kicker member 86a ... Kicker main body 86b ... Kicker portion 87a ... Rotation shaft 88 ... Link member 89a ... Coupling shaft 89b ... Coupling shaft 90 ... Cooperation lock mechanism 92 ... Movable plate 92a ... Contact portion 92b ... Stopper Section 93a ... rotation axis 94 ... spring 101 ... cash automatic transaction device 102 ... housing 102S ...

- First to third holes 162B first guided portion 162a: guide base portion 162b: guide piece 162n: fixed member 162Ba: guide base portion 162Bb: guide piece 162Bh: fastening hole 162Bn: fixed member 163B: positioning hole 163Ba: first 1 Part 163Ba, 163Bb, 163Bc ... 1st-3rd step part 163Bn ... Positioning member 164 ... 1st connection mechanism 164B ... 1st connection mechanism 165 ... Connection member 165B ... Connection member 166 ... Horizontal part 166h ... Fastening hole 167 ...

Abstract

A banknote processing unit (10) is provided with a housing (102), a banknote processing unit (10) and a banknote storage unit (30) which are housed within the housing (102), and a unit guide mechanism (50). The unit guide mechanism (50) is provided with a first guide unit (152) disposed horizontally along an inner wall of the housing (102), a first guided unit (162) disposed at an outer wall side of the banknote processing unit (10), and a first coupling mechanism (164). The first coupling mechanism (164) has a first distance adjusting unit (168) which modifies the distance between the first guided unit (162) and the banknote processing unit (10) when force in the horizontal direction is received as a result of movement of the banknote processing unit (10).

Description

この発明は、例えば紙幣などの紙葉類を処理する紙葉類処理装置に関する。

The present invention relates to a sheet processing apparatus for processing sheets such as banknotes.

この種の紙幣処理装置として、紙幣の入金取引や出金取引を行うATMやCDなどの現金自動取引装置が知られ、金融機関やコンビニエンスストア等の店舗に設置されている。例えば、現金自動取引装置に実装される紙幣処理装置は、特許文献1に記載されているように、利用者に出金紙幣を放出しもしくは投入された入金紙幣を一枚ずつ繰出すための紙幣入出金口と、入金もしくは出金紙幣を判別する紙幣判別部と、入金した紙幣を一旦収納する一時保留部と、入金紙幣を分別して収納・保管し出金紙幣等として繰出すための複数の紙幣収納部と、上記各部分を接続する紙幣搬送路とを備えている。

As this type of bill processing apparatus, cash automated teller machines, such as ATMs and CDs, which perform bill deposit and withdrawal transactions are known, and are installed in stores such as financial institutions and convenience stores. For example, as described in Patent Document 1, a bill processing apparatus mounted on an automatic teller machine is a bill for dispensing the deposited bills to the user or for dispensing the deposited bills inserted one by one. A deposit / withdrawal port, a bill discriminating section for discriminating deposited or dispensed bills, a temporary storage section for temporarily storing deposited bills, and a plurality of separated deposited and deposited bills for dispensing and storage as a deposited bill or the like It has a bill storage part and a bill conveyance way which connects the above-mentioned each part.

また、上記紙幣処理装置では、紙幣入出金口、紙幣判別部および一時保留部を一体に組み付けて上部ユニットを構成し、トレーに複数の紙幣収納部を組み付けて下部ユニットとし、これらを筐体に収納している。そして、筐体と上部ユニットおよび下部ユニットとの間にレールによるガイド機構を配置し、筐体から上部ユニットおよび下部ユニットとを引き出し可能に構成している。これにより、保守や紙幣の再装填、多金種化・大容量化に対応している。

Further, in the bill processing apparatus, the bill deposit / withdrawal port, the bill discriminating portion, and the temporary storage portion are integrally assembled to constitute an upper unit, and a plurality of bill storage portions are assembled to a tray to form a lower unit. I have stored it. Then, a guide mechanism by a rail is disposed between the housing and the upper unit and the lower unit, and the upper unit and the lower unit can be drawn out from the housing. This supports maintenance, reloading of banknotes, and increases in the number of types of money and capacity.

しかしながら上記筐体は、製造上のばらつきにより、1台毎に寸法が僅かに異なり易い。特に、上部ユニットや下部ユニットをスムーズに引き出すために、筐体と上部ユニットや下部ユニットとの水平方向の間隙に高い寸法精度が要求され、製造が面倒であるという課題があった。

However, due to manufacturing variations, the above-mentioned housings are likely to differ slightly in size from one unit to another. In particular, in order to pull out the upper unit and the lower unit smoothly, high dimensional accuracy is required in the horizontal gap between the casing and the upper unit and the lower unit, and there is a problem that the manufacturing is troublesome.

この発明は、上述した問題に鑑み、紙幣などの紙葉類を処理する紙幣ユニットを引き出しまたは収納する動作をスムーズに行なうことができるユニットガイド機構を備えた紙葉類処理装置を簡単な構成で実現する。

SUMMARY OF THE INVENTION In view of the problems described above, the present invention has a simple configuration with a sheet processing apparatus having a unit guide mechanism capable of smoothly performing an operation of pulling out or storing a bill unit that processes sheets such as bills. To realize.

本発明は、上述の課題の少なくとも一部を解決するためになされたものであり、以下の形態または適用例として実現することが可能である。

The present invention has been made to solve at least a part of the above-described problems, and can be realized as the following modes or application examples.

[適用例1]

適用例1は、投入または繰り出される紙葉類を判別し、該判別された紙葉類を分けて収納する紙幣ユニットと、該紙幣ユニットを収納する収納スペースを有する筐体と、上記筐体と上記紙幣ユニットとの水平方向のスライド用間隙に介在して上記紙幣ユニットを上記収納スペースから引き出しおよび上記収納スペースに収納するためにガイドするユニットガイド機構と、を備えた紙葉類処理装置であって、

上記ユニットガイド機構は、上記筐体の内壁に沿って水平方向に配置されたガイド部と、上記紙幣ユニットの外壁側に配置され上記ガイド部に沿って移動可能である被ガイド部と、上記筐体と上記ガイド部との連結または上記紙幣ユニットと上記被ガイド部との連結の少なくとも一方を行なう連結機構と、を備え、

上記連結機構は、上記紙幣ユニットの移動によって水平方向の力を受けたときに、上記ガイド部と筐体との距離または被ガイド部と紙幣ユニットとの距離を変える距離調節部を有する、紙葉類処理装置。 Application Example 1

Application Example 1 determines a paper sheet to be inserted or fed, and separates and stores the determined paper sheet, a case having a storage space for storing the bill unit, and the case A sheet processing apparatus comprising: a unit guide mechanism which is interposed in a horizontal slide gap with the bill unit and guides the bill unit out from the storage space and guides the bill unit to be stored in the storage space. ,

The unit guide mechanism includes: a guide portion disposed horizontally along the inner wall of the housing; a guided portion disposed on the outer wall side of the bill unit and movable along the guide portion; And a connection mechanism that performs at least one of connection between the body and the guide portion or connection between the bill unit and the guided portion.

The connection mechanism has a distance adjustment unit that changes the distance between the guide and the housing or the distance between the guided portion and the bill unit when receiving a force in the horizontal direction by the movement of the bill unit. Processing device.

適用例1は、投入または繰り出される紙葉類を判別し、該判別された紙葉類を分けて収納する紙幣ユニットと、該紙幣ユニットを収納する収納スペースを有する筐体と、上記筐体と上記紙幣ユニットとの水平方向のスライド用間隙に介在して上記紙幣ユニットを上記収納スペースから引き出しおよび上記収納スペースに収納するためにガイドするユニットガイド機構と、を備えた紙葉類処理装置であって、

上記ユニットガイド機構は、上記筐体の内壁に沿って水平方向に配置されたガイド部と、上記紙幣ユニットの外壁側に配置され上記ガイド部に沿って移動可能である被ガイド部と、上記筐体と上記ガイド部との連結または上記紙幣ユニットと上記被ガイド部との連結の少なくとも一方を行なう連結機構と、を備え、

上記連結機構は、上記紙幣ユニットの移動によって水平方向の力を受けたときに、上記ガイド部と筐体との距離または被ガイド部と紙幣ユニットとの距離を変える距離調節部を有する、紙葉類処理装置。 Application Example 1

Application Example 1 determines a paper sheet to be inserted or fed, and separates and stores the determined paper sheet, a case having a storage space for storing the bill unit, and the case A sheet processing apparatus comprising: a unit guide mechanism which is interposed in a horizontal slide gap with the bill unit and guides the bill unit out from the storage space and guides the bill unit to be stored in the storage space. ,

The unit guide mechanism includes: a guide portion disposed horizontally along the inner wall of the housing; a guided portion disposed on the outer wall side of the bill unit and movable along the guide portion; And a connection mechanism that performs at least one of connection between the body and the guide portion or connection between the bill unit and the guided portion.

The connection mechanism has a distance adjustment unit that changes the distance between the guide and the housing or the distance between the guided portion and the bill unit when receiving a force in the horizontal direction by the movement of the bill unit. Processing device.

適用例1にかかる紙葉類処理装置において、筐体の内壁と紙幣ユニットの外壁との間には、ユニットガイド機構が配置されている。ユニットガイド機構は、筐体の内壁に固定されたガイド部と、紙幣ユニット側に配置された被ガイド部とを備え、被ガイド部がガイド部に対して移動することにより、筐体の収納スペースから紙幣ユニットを引き出し、および収納スペースに収納する。

In the paper sheet processing apparatus according to the first application example, a unit guide mechanism is disposed between the inner wall of the housing and the outer wall of the bill unit. The unit guide mechanism includes a guide portion fixed to the inner wall of the housing and a guided portion disposed on the side of the bill unit, and the guided portion moves relative to the guide portion, thereby the storage space of the housing Draw out the bill unit from the bill and store it in the storage space.

また、ユニットガイド機構の連結機構は、上記紙幣ユニットと上記ガイド部との連結または上記紙幣ユニットと上記被ガイド部との連結の少なくとも一方を行ない、さらに、距離調節部により、上記紙幣ユニットの移動方向への移動によって水平方向の力を受けたときに、上記ガイド部と筐体との距離または被ガイド部と紙幣ユニットとの距離を変える。

In addition, the connection mechanism of the unit guide mechanism performs at least one of connection of the bill unit and the guide portion or connection of the bill unit and the guided portion, and the movement of the bill unit by the distance adjustment unit. When horizontal force is received by movement in the direction, the distance between the guide portion and the housing or the distance between the guided portion and the bill unit is changed.

こうした距離の調節により、以下のような作用効果を奏する。すなわち、筐体の水平方向の寸法のバラツキにより、筐体の内壁と紙幣ユニットの外壁との間に形成されるスライド用間隙に水平方向で差が生じることがある。こうしたスライド用間隙の差は、紙幣ユニットが移動するときにガイド部と被ガイド部との摩擦力の増大を招く。しかし、距離調節部は、連結機構が加わる水平方向の力を受けたときに、ガイド部と筐体との間隙または被ガイド部と紙幣ユニットとの距離を変えることにより、スライド用間隙の差を吸収する。このような距離調節部によるスライド用間隙の差を吸収する作用によって、ガイド部と被ガイド部とのスライド時に生じる摩擦力の増大を低減し、よって、紙幣ユニットを筐体に対して小さな操作力でスムーズにスライド動作させることができる。

By adjusting the distance, the following effects can be obtained. That is, due to the variation in the dimension in the horizontal direction of the housing, a difference may occur in the horizontal direction in the sliding gap formed between the inner wall of the housing and the outer wall of the bill unit. Such a difference in the slide gap causes an increase in the frictional force between the guide portion and the guided portion when the bill unit moves. However, when the distance adjustment unit receives a horizontal force applied by the connection mechanism, the difference between the slide gaps can be reduced by changing the distance between the guide and the housing or the distance between the guided and the bill unit. Absorb. Such a distance adjusting portion absorbs the difference in the sliding gap, thereby reducing the increase in the frictional force generated when the guide portion and the guided portion slide, and hence, a small operating force for the bill unit relative to the housing Can slide smoothly.

[適用例2]

適用例2において、上記紙幣ユニットは、

投入または繰り出される紙葉類を判別する紙葉類処理ユニットと、

上記判別された紙葉類を分けて収納する複数の紙葉類収納部と、該複数の紙葉類収納部を収納する収納体とを有し、上記紙幣処理ユニットの下方に配置された紙葉類収納ユニットと、

上記紙葉類処理ユニットと上記紙葉類収納ユニットとの間を接続する搬送路を介して上記紙葉類を上記紙葉類処理ユニットと上記紙葉類収納ユニットとの間で双方向に搬送する搬送機構と、

を備え、

上記ユニットガイド機構は、上記筐体と上記紙幣処理ユニットとの上記スライド用間隙に配置された第1スライド機構と、上記筐体と上記紙幣収納ユニットとの上記スライド用間隙に配置された第2スライド機構とを備えている、紙葉類処理装置。 Application Example 2

In Application Example 2, the bill unit is

A sheet processing unit for determining a sheet to be fed or fed;

A plurality of paper sheet storage units separately storing the determined paper sheets, and a storage body for storing the plurality of paper sheet storage units, and the paper disposed below the bill processing unit Leaf storage unit,

The paper sheet is bidirectionally conveyed between the paper sheet processing unit and the paper sheet storage unit via a conveyance path connecting the paper sheet processing unit and the paper sheet storage unit. The transport mechanism

Equipped with

The unit guide mechanism includes a first slide mechanism disposed in the slide gap between the housing and the bill processing unit, and a second slide mechanism disposed in the slide gap between the housing and the bill storage unit. A sheet processing apparatus comprising a slide mechanism.

適用例2において、上記紙幣ユニットは、

投入または繰り出される紙葉類を判別する紙葉類処理ユニットと、

上記判別された紙葉類を分けて収納する複数の紙葉類収納部と、該複数の紙葉類収納部を収納する収納体とを有し、上記紙幣処理ユニットの下方に配置された紙葉類収納ユニットと、

上記紙葉類処理ユニットと上記紙葉類収納ユニットとの間を接続する搬送路を介して上記紙葉類を上記紙葉類処理ユニットと上記紙葉類収納ユニットとの間で双方向に搬送する搬送機構と、

を備え、

上記ユニットガイド機構は、上記筐体と上記紙幣処理ユニットとの上記スライド用間隙に配置された第1スライド機構と、上記筐体と上記紙幣収納ユニットとの上記スライド用間隙に配置された第2スライド機構とを備えている、紙葉類処理装置。 Application Example 2

In Application Example 2, the bill unit is

A sheet processing unit for determining a sheet to be fed or fed;

A plurality of paper sheet storage units separately storing the determined paper sheets, and a storage body for storing the plurality of paper sheet storage units, and the paper disposed below the bill processing unit Leaf storage unit,

The paper sheet is bidirectionally conveyed between the paper sheet processing unit and the paper sheet storage unit via a conveyance path connecting the paper sheet processing unit and the paper sheet storage unit. The transport mechanism

Equipped with

The unit guide mechanism includes a first slide mechanism disposed in the slide gap between the housing and the bill processing unit, and a second slide mechanism disposed in the slide gap between the housing and the bill storage unit. A sheet processing apparatus comprising a slide mechanism.

[適用例3]

適用例3において、上記連結機構は、上記被ガイド部と上記紙幣ユニットとの外壁を連結する連結部材を備え、

上記距離調節部は、上記連結部材と上記紙幣ユニットの一方に固定される固定部材と、上記連結部材と上記紙幣ユニットの他方に形成され上記固定部材が挿入される長穴とを有し、上記固定部材が該長穴内を移動することで上記スライド用間隙を可変にするように構成した紙葉類処理装置。 Application Example 3

In Application Example 3, the connection mechanism includes a connection member that connects the outer wall of the guided portion and the bill unit.

The distance adjusting unit has a fixing member fixed to one of the connecting member and the bill unit, and a long hole formed in the other of the connecting member and the bill unit and into which the fixing member is inserted. A sheet processing apparatus, wherein the slide gap is made variable by moving a fixing member in the long hole.

適用例3において、上記連結機構は、上記被ガイド部と上記紙幣ユニットとの外壁を連結する連結部材を備え、

上記距離調節部は、上記連結部材と上記紙幣ユニットの一方に固定される固定部材と、上記連結部材と上記紙幣ユニットの他方に形成され上記固定部材が挿入される長穴とを有し、上記固定部材が該長穴内を移動することで上記スライド用間隙を可変にするように構成した紙葉類処理装置。 Application Example 3

In Application Example 3, the connection mechanism includes a connection member that connects the outer wall of the guided portion and the bill unit.

The distance adjusting unit has a fixing member fixed to one of the connecting member and the bill unit, and a long hole formed in the other of the connecting member and the bill unit and into which the fixing member is inserted. A sheet processing apparatus, wherein the slide gap is made variable by moving a fixing member in the long hole.

[適用例4]

適用例4において、上記距離調節部は、上記紙幣ユニットに固定された第1連結部材と、上記被ガイド部に固定された第2連結部材とを備え、

上記距離調節部は、上記第1連結部材と上記第2連結部材の一方に固定される固定部材と、上記第1連結部材と第2連結部材の他方に形成され上記固定部材が挿入される長穴とを有し、上記固定部材が該長穴内を移動することで上記スライド用間隙を可変にするように構成した紙葉類処理装置。 Application Example 4

In the application example 4, the distance adjusting unit includes a first connecting member fixed to the bill unit and a second connecting member fixed to the guided portion.

The distance adjusting portion is formed on the other of the fixing member fixed to one of the first connecting member and the second connecting member, and the other of the first connecting member and the second connecting member, and the length to which the fixing member is inserted A sheet processing apparatus, comprising: a hole; and the fixing member moving in the long hole to make the slide gap variable.

適用例4において、上記距離調節部は、上記紙幣ユニットに固定された第1連結部材と、上記被ガイド部に固定された第2連結部材とを備え、

上記距離調節部は、上記第1連結部材と上記第2連結部材の一方に固定される固定部材と、上記第1連結部材と第2連結部材の他方に形成され上記固定部材が挿入される長穴とを有し、上記固定部材が該長穴内を移動することで上記スライド用間隙を可変にするように構成した紙葉類処理装置。 Application Example 4

In the application example 4, the distance adjusting unit includes a first connecting member fixed to the bill unit and a second connecting member fixed to the guided portion.

The distance adjusting portion is formed on the other of the fixing member fixed to one of the first connecting member and the second connecting member, and the other of the first connecting member and the second connecting member, and the length to which the fixing member is inserted A sheet processing apparatus, comprising: a hole; and the fixing member moving in the long hole to make the slide gap variable.

[適用例5]

適用例5において、上記第2スライド機構は、上記収納体をスライド可能に支持するように構成し、

上記ユニットガイド機構は、上記紙幣処理ユニットに移動方向に配置された収納用ガイドレールと、上記紙幣収納部に設けられ上記収納用ガイドレールにガイドされる第1ローラとを有し、上記紙幣収納部を上記紙幣処理ユニットで吊り上げた状態にて上記第1ローラが収納用ガイドレールを移動するように構成された吊り下げ機構を備え、

上記吊り下げ機構は、上記収納用ガイドレールおよび上記第1ローラを紙幣処理ユニットの幅方向の両側にそれぞれ配置し、一方の第1ローラが幅方向に位置決めされて上記収納用ガイドレール上を移動し、他方の第1ローラが収納用ガイドレール上で幅方向に遊びを有して収納用ガイドレール上を移動するように構成された、紙葉類処理装置。 Application Example 5

In the application example 5, the second slide mechanism is configured to slidably support the storage body,

The unit guide mechanism has a storage guide rail arranged in the moving direction in the bill processing unit, and a first roller provided in the bill storage unit and guided by the storage guide rail, and the bill storage A suspension mechanism configured to move the first roller in the storage guide rail in a state where the portion is lifted by the bill processing unit,

The suspension mechanism arranges the storage guide rail and the first roller on both sides in the width direction of the bill processing unit, and one of the first rollers is positioned in the width direction to move on the storage guide rail A sheet processing apparatus, wherein the other first roller is configured to move on the storage guide rail with play in the width direction on the storage guide rail.

適用例5において、上記第2スライド機構は、上記収納体をスライド可能に支持するように構成し、

上記ユニットガイド機構は、上記紙幣処理ユニットに移動方向に配置された収納用ガイドレールと、上記紙幣収納部に設けられ上記収納用ガイドレールにガイドされる第1ローラとを有し、上記紙幣収納部を上記紙幣処理ユニットで吊り上げた状態にて上記第1ローラが収納用ガイドレールを移動するように構成された吊り下げ機構を備え、

上記吊り下げ機構は、上記収納用ガイドレールおよび上記第1ローラを紙幣処理ユニットの幅方向の両側にそれぞれ配置し、一方の第1ローラが幅方向に位置決めされて上記収納用ガイドレール上を移動し、他方の第1ローラが収納用ガイドレール上で幅方向に遊びを有して収納用ガイドレール上を移動するように構成された、紙葉類処理装置。 Application Example 5

In the application example 5, the second slide mechanism is configured to slidably support the storage body,

The unit guide mechanism has a storage guide rail arranged in the moving direction in the bill processing unit, and a first roller provided in the bill storage unit and guided by the storage guide rail, and the bill storage A suspension mechanism configured to move the first roller in the storage guide rail in a state where the portion is lifted by the bill processing unit,

The suspension mechanism arranges the storage guide rail and the first roller on both sides in the width direction of the bill processing unit, and one of the first rollers is positioned in the width direction to move on the storage guide rail A sheet processing apparatus, wherein the other first roller is configured to move on the storage guide rail with play in the width direction on the storage guide rail.

この適用例5の吊り下げ機構により、紙幣処理ユニットの下部の収納用ガイドレール上を紙幣収納部の上部の第1ローラが移動することで、紙幣収納部を収納体から吊り上げた状態にて、紙幣収納部が移動方向へ移動する。このような吊り下げ機構は、一方のローラが収納用ガイドレールで幅方向へ位置決めされているので、ユニットガイド機構の距離調節部によって距離が調節されても、紙幣収納部に紙幣処理ユニットに対して位置決めされ、紙幣処理ユニットと紙幣収納部との間の紙葉類の搬送路が位置ズレすることがなく、その搬送に支障がない。

In the state where the bill storage unit is lifted from the storage body by the first roller of the upper part of the bill storage unit moving on the storage guide rail of the lower part of the bill processing unit by the suspension mechanism of this application example 5; The bill storage unit moves in the moving direction. In such a suspension mechanism, one of the rollers is positioned in the width direction by the storage guide rail, so even if the distance is adjusted by the distance adjustment unit of the unit guide mechanism, the bill storage unit Therefore, the transport path of the paper sheet between the bill processing unit and the bill storage unit is not misaligned, and there is no hindrance to the transport.

(1) 現金自動取引装置101の概略構成