WO2012066922A1 - Gas manufacturing apparatus, gas manufacturing method, and gas manufacturing apparatus array - Google Patents

Gas manufacturing apparatus, gas manufacturing method, and gas manufacturing apparatus array Download PDFInfo

- Publication number

- WO2012066922A1 WO2012066922A1 PCT/JP2011/074971 JP2011074971W WO2012066922A1 WO 2012066922 A1 WO2012066922 A1 WO 2012066922A1 JP 2011074971 W JP2011074971 W JP 2011074971W WO 2012066922 A1 WO2012066922 A1 WO 2012066922A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- photoelectric conversion

- gas

- electrolysis electrode

- electrode

- electrolysis

- Prior art date

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B1/00—Electrolytic production of inorganic compounds or non-metals

- C25B1/50—Processes

- C25B1/55—Photoelectrolysis

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/36—Hydrogen production from non-carbon containing sources, e.g. by water electrolysis

Definitions

- the present invention relates to a gas production apparatus, a gas production method, and a gas production apparatus array.

- renewable energy In recent years, the use of renewable energy is desired from the viewpoint of depletion of fossil fuel resources and the suppression of global warming gas emissions.

- renewable energy sources such as sunlight, hydropower, wind power, geothermal power, tidal power, and biomass.

- sunlight has a large amount of available energy, and there are geographical restrictions on other renewable energy sources. Because of the relatively small amount, early development and popularization of technology that can efficiently use energy from sunlight is desired.

- Possible forms of energy generated from sunlight include electrical energy produced using solar cells and solar thermal turbines, thermal energy by collecting solar energy in a heat medium, and other types of sunlight.

- Examples include storable fuel energy such as liquid fuel and hydrogen by substance reduction.

- Many solar cell technologies and solar heat utilization technologies have already been put into practical use, but the energy utilization efficiency is still low, and the cost of producing electricity and heat is still high. Technology development is underway.

- these forms of electricity and heat can be used to supplement short-term energy fluctuations, it is extremely difficult to supplement long-term fluctuations such as seasonal fluctuations, It is a problem that there is a possibility that the operating rate of the power generation equipment may be reduced due to the increase in power generation.

- storing energy as a substance, such as liquid fuel and hydrogen is extremely effective as a technology that efficiently supplements long-term fluctuations and increases the operating rate of power generation facilities. It is an indispensable technology to raise and reduce carbon dioxide emissions thoroughly.

- liquid fuels such as hydrocarbons

- gaseous fuels such as biogas and hydrogen

- solid pellets such as biomass-derived wood pellets and metals reduced by sunlight. It can.

- liquid fuel, gaseous fuel including hydrogen in terms of total utilization efficiency improvement with fuel cells, etc. solid fuel in terms of storability and energy density

- a hydrogen production technique by decomposing water with sunlight has attracted particular attention from the viewpoint that water that can be easily obtained as a raw material can be used.

- platinum is supported on a photocatalyst such as titanium oxide, and this substance is put in water to perform light separation in a semiconductor, and an electrolytic solution.

- the water is decomposed directly at high temperature using the photolysis method by reducing protons and oxidizing water, or by using thermal energy such as a high-temperature gas furnace, or indirectly by coupling with redox of metals, etc.

- Pyrolysis method that uses the metabolism of microorganisms that use light such as algae

- water electrolysis method that combines electricity generated by solar cells and water electrolysis hydrogen production equipment

- photoelectric conversion used in solar cells Examples of the method include a photovoltaic method in which electrons and holes obtained by photoelectric conversion are used in a reaction by a hydrogen generation catalyst and an oxygen generation catalyst by supporting a hydrogen generation catalyst and an oxygen generation catalyst on the material.

- the photolysis method the one that has the possibility of producing a small hydrogen production device by integrating the photoelectric conversion unit and the hydrogen generation unit is considered to be a photolysis method, a biological method, a photovoltaic method

- the photovoltaic method is considered to be one of the technologies closest to practical use.

- Patent Document 1 a titanium oxide photocatalyst electrode on which a ruthenium complex is adsorbed and a platinum electrode, an apparatus using oxidation reduction of iodine or iron is disclosed.

- Patent Documents 2 and 3 an integrated structure is adopted by connecting two layers of photocatalysts in tandem, connecting a platinum counter electrode, and sandwiching an ion exchange membrane therebetween.

- Non-Patent Document 1 a concept of a hydrogen production apparatus in which a photoelectric conversion unit, a hydrogen generation unit, and an oxygen generation unit are integrated has been announced (Non-Patent Document 1). According to this, charge separation is performed by using a photoelectric conversion unit, and hydrogen generation and oxygen generation are performed using corresponding catalysts.

- the photoelectric conversion part is made of a material used for solar cells. For example, in Non-Patent Document 2, after charge separation is performed with three silicon pin layers, a platinum catalyst is responsible for hydrogen generation and ruthenium oxide is responsible for oxygen generation.

- Non-Patent Document 3 a multi-junction photoelectric conversion material that absorbs light of different wavelengths is used by using Pt as a hydrogen generation catalyst and RuO 2 as an oxygen generation catalyst to achieve high efficiency.

- Patent Document 4 and Non-Patent Document 3 a hydrogen generation catalyst (NiFeO) and three layers of silicon pin are stacked in parallel on a substrate, and an oxygen generation catalyst (Co-Mo) is further formed on the silicon layer. ) To produce an integrated hydrogen production apparatus.

- the gas generated from the electrode for electrolysis is recovered as bubbles in the electrolytic solution, so that two gases generated from the two electrodes for electrolysis are used.

- the recovery ports are close to each other, and the piping is complicated.

- This invention is made

- the present invention includes a photoelectric conversion unit having a light receiving surface and a back surface thereof, and first and second electrodes for electrolysis that are provided side by side on the back surface and each have a surface that can contact an electrolytic solution, When the first and second electrolysis electrodes come into contact with the electrolytic solution, the first and second electrolysis electrodes use the electromotive force generated by the photoelectric conversion unit to receive light to electrolyze the electrolytic solution, respectively. When the light receiving surface of the photoelectric conversion unit is leveled, the first electrolysis electrode and the second electrolysis electrode are horizontal with the surface that can come into contact with the electrolytic solution.

- a gas production apparatus characterized in that an inclination angle with respect to a reference plane is different.

- the first and second electrolysis electrodes are configured to electrolyze the electrolytic solution using the electromotive force generated by the light received by the photoelectric conversion unit to generate the first gas and the second gas, respectively. Since it is provided, the first gas can be generated on the surface of the first electrolysis electrode, and the second gas can be generated on the surface of the second electrolysis electrode. According to the present invention, since the first electrolysis electrode and the second electrolysis electrode are provided on the back surface of the photoelectric conversion portion, light can be incident on the light receiving surface of the photoelectric conversion portion without passing through the electrolyte solution. It is possible to prevent absorption of incident light and scattering of incident light.

- the amount of incident light to the photoelectric conversion unit can be increased, and the light use efficiency can be increased.

- the first electrolysis electrode and the second electrolysis electrode are provided on the back surface of the photoelectric conversion unit, the light incident on the light receiving surface is generated from the first and second electrolysis electrodes, respectively. It is not absorbed or scattered by the first gas and the second gas. As a result, the amount of incident light to the photoelectric conversion unit can be increased, and the light use efficiency can be increased.

- the first electrolysis electrode and the second electrolysis electrode have different inclination angles between the surface that can come into contact with the electrolytic solution and the horizontal reference surface, so that the first gas rises as bubbles.

- the gas production apparatus when the gas production apparatus is provided with a plurality of at least one of the first electrolysis electrode and the second electrolysis electrode, or when a plurality of gas production apparatuses are installed side by side, a plurality of first gas recovery ports are provided.

- the piping for connecting and the piping for connecting the plurality of second gas recovery ports can be provided without overlapping, and the piping can be simplified. Thereby, the installation cost when providing piping for recovering the first gas and the second gas can be reduced, and piping connection errors and the like can be prevented.

- the first electrolysis electrode and the second electrolysis electrode have different inclination angles between the surface that can contact the electrolytic solution and the horizontal reference surface, so that the light receiving surface of the photoelectric conversion unit is substantially horizontal. It is also possible to install so that the installation cost can be reduced. Moreover, it becomes possible to install a gas production apparatus on the surface of a pond or the sea.

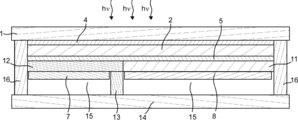

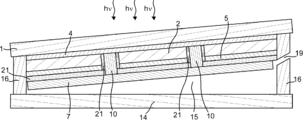

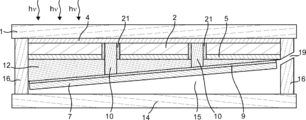

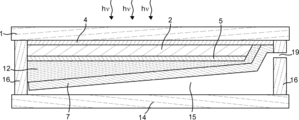

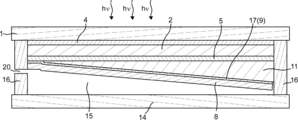

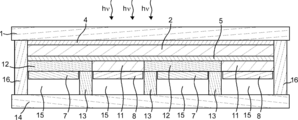

- FIG. 2 is a schematic cross-sectional view of the gas production apparatus taken along one-dot chain line AA in FIG.

- FIG. 2 is a schematic cross-sectional view of the gas production apparatus taken along a dotted line BB in FIG.

- FIG. 2 is a schematic cross-sectional view of a gas production apparatus taken along a dotted line CC in FIG.

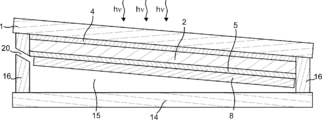

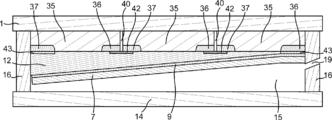

- It is a schematic back view which shows the structure of the gas manufacturing apparatus of one Embodiment of this invention.

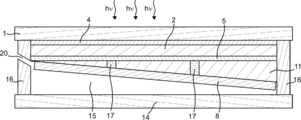

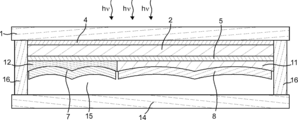

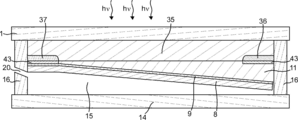

- It is a schematic sectional drawing which shows the structure of the gas manufacturing apparatus of one Embodiment of this invention.

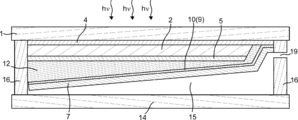

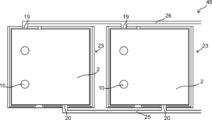

- FIG. 18 is a schematic cross-sectional view of the gas production apparatus taken along dotted line AA in FIG. It is a schematic plan view which shows the structure of the gas manufacturing apparatus array of one Embodiment of this invention.

- the gas production apparatus of the present invention includes a photoelectric conversion unit having a light receiving surface and a back surface thereof, first and second electrodes for electrolysis that are provided side by side on the back surface and each have a surface that can contact an electrolyte solution

- first and second electrolysis electrodes electrolyze the electrolytic solution using electromotive force generated by the photoelectric conversion unit receiving light.

- the first electrolysis electrode and the second electrolysis electrode can contact the electrolyte when the first gas and the second gas are generated, respectively, and the light receiving surface of the photoelectric conversion unit is horizontal. The inclination angle between the surface and the horizontal reference surface is different.

- the inclination angle is an inclination angle with respect to a horizontal reference plane, and is an angle in a range of 0 degrees to 180 degrees.

- the first electrode and the second electrode are electrodes for outputting photovoltaic power of the photoelectric conversion unit, and the first electrolysis electrode and the second electrolysis electrode are for electrolyzing the electrolytic solution. Electrode.

- a first gas discharge port provided close to the upper end of the surface of the first electrolysis electrode that can contact the electrolytic solution

- the second electrolysis electrode may have a surface that can contact the electrolyte solution that is inclined so that the second gas can be recovered from the second gas discharge port. preferable. According to such a configuration, the first gas can be recovered from the first gas outlet, and the second gas can be recovered from the second gas outlet.

- the photoelectric conversion unit has a rectangular light receiving surface, and the first and second gas discharge ports are provided close to opposite sides of the light receiving surface of the photoelectric conversion unit, respectively.

- the first gas outlet and the second gas outlet can be provided on both sides of the photoelectric conversion unit, and the pipe for recovering the first gas and the pipe for recovering the second gas Can be simplified.

- At least one of the first and second electrolysis electrodes has a plurality of surfaces that can contact the strip-shaped electrolyte solution, and the long sides of the surfaces are adjacent to each other. It is preferable that they are provided alternately. According to such a configuration, the distance between the portion where the reaction generating the first gas occurs and the portion where the reaction generating the second gas occurs can be shortened, and the ion concentration generated in the electrolyte can be reduced. Imbalance can be reduced. Moreover, the 1st gas and 2nd gas can be collect

- the first mold part and the second electrolysis electrode provided between the first electrolysis electrode and the back surface of the photoelectric conversion unit and the back surface of the photoelectric conversion unit are provided.

- the first mold part and the second mold part have a horizontal reference with a surface that can contact the electrolyte of the first electrolysis electrode when the light receiving surface of the photoelectric conversion unit is horizontal. It is preferable that the tilt angle between the reference surface and the tilt angle between the surface and the reference surface is different from the tilt angle between the second electrolysis electrode and the electrolyte.

- the inclination angle between the surface of the first electrolysis electrode that can contact the electrolytic solution and the horizontal reference surface, the surface of the second electrolysis electrode that can contact the electrolytic solution, and the reference can be easily made different.

- the first mold part and the second mold part are preferably made of a solid resin. According to such a configuration, the first mold part and the second mold part can be easily molded.

- a first conductive part is further provided between the first mold part and the first electrolysis electrode or between the second mold part and the second electrolysis electrode. According to such a configuration, when the electromotive force generated by the photoelectric conversion unit receiving light is output to the first and second electrolysis electrodes, the internal resistance can be further reduced.

- each of the first and second electrolysis electrodes preferably has a groove-like depression extending in an inclined direction on a surface that can contact the electrolytic solution.

- the first gas and the second gas can be raised as bubbles along the groove-shaped depression, and the first gas and the second gas can be separated and recovered.

- the partition provided between the electrode for 1st electrolysis and the electrode for 2nd electrolysis is also omissible.

- the first electrolysis electrode when the light receiving surface of the photoelectric conversion unit is horizontal, the first electrolysis electrode can contact an electrolytic solution having an inclination angle of 1 degree to 60 degrees with the horizontal reference plane It is preferable that the second electrolysis electrode has a surface that can contact an electrolytic solution having an inclination angle of 120 degrees or more and 179 degrees or less with respect to the reference surface.

- a recovery port for recovering the first gas and a recovery port for recovering the second gas can be provided on both sides of the gas production device, respectively, in order to recover the first gas.

- a pipe for recovering the second gas can be provided on both sides of the gas production apparatus.

- the photoelectric conversion unit receives light to generate an electromotive force between the light receiving surface and the back surface, and the first electrolysis electrode is electrically connected to the back surface of the photoelectric conversion unit. And it is preferable that the 2nd electrode for electrolysis is electrically connected with the light-receiving surface of the said photoelectric conversion part. According to such a structure, the thing of a laminated structure can be utilized for a photoelectric conversion part.

- the gas production apparatus further includes a first electrode that contacts the light receiving surface of the photoelectric conversion unit. According to such a configuration, the internal resistance can be reduced.

- the second conductive portion is provided in a contact hole that penetrates the photoelectric conversion portion. According to such a configuration, the wiring distance between the light receiving surface of the photoelectric conversion unit and the second electrolysis electrode can be shortened, and the internal resistance can be reduced.

- the gas manufacturing apparatus of the present invention includes a second mold part provided between the second electrolysis electrode and the back surface of the photoelectric conversion part, the second mold part having insulating properties, and the photoelectric conversion unit. It is preferable that the second conductive portion is provided on a portion of the second mold portion that covers the side surface of the photoelectric conversion portion. According to such a configuration, the second conductive portion can be provided with a small number of steps, and the manufacturing cost can be reduced.

- the gas manufacturing apparatus of the present invention includes a second mold part provided between the second electrolysis electrode and the back surface of the photoelectric conversion part, the second mold part having insulating properties, and the photoelectric conversion unit.

- the second electrolysis electrode is preferably provided on a portion of the second mold part that covers the side surface of the photoelectric conversion unit, and is in contact with the first electrode. According to such a configuration, the first electrode and the second electrolysis electrode can be electrically connected without providing the second conductive portion.

- the first mold part provided between the first electrolysis electrode and the back surface of the photoelectric conversion unit, and the second electrolysis electrode and the back surface of the photoelectric conversion unit are provided.

- a second electrode provided between the back surface of the photoelectric conversion unit and the first mold unit and between the back surface of the photoelectric conversion unit and the second mold unit.

- the internal resistance between the back surface of the photoelectric conversion unit and the first electrolysis electrode Can be made smaller.

- the third conductive portion is provided so as to cover the side portion of the first mold portion and is in contact with the second electrode.

- the back surface of a photoelectric conversion part and the 1st electrode for electrolysis can be electrically connected easily.

- the photoelectric conversion unit generates a potential difference between the first and second areas on the back surface by receiving light, the first area is electrically connected to the first electrolysis electrode, The second area is preferably electrically connected to the second electrolysis electrode. According to such a configuration, an electromotive force can be generated between the first area and the second area in the photoelectric conversion unit.

- the photoelectric conversion part is made of at least one semiconductor material having an n-type semiconductor part and a p-type semiconductor part, and one of the first and second areas is the n-type semiconductor part. It is preferable that the other part is a part of the p-type semiconductor part. According to such a configuration, an electromotive force can be generated between the first and second areas on the back surface of the photoelectric conversion unit when the photoelectric conversion unit receives light.

- a translucent substrate is further provided, and the photoelectric conversion unit is provided on the translucent substrate. According to such a structure, a photoelectric conversion part can be formed on a translucent board

- the gas manufacturing apparatus of the present invention further includes a translucent substrate, the photoelectric conversion unit is provided on the translucent substrate, and the translucent substrate has a light receiving surface of the photoelectric conversion unit horizontally. Then, the inclination angle between the surface of the first electrolysis electrode that can contact the electrolytic solution and the horizontal reference surface, and the surface between the surface of the second electrolysis electrode that can contact the electrolytic solution and the reference surface. It is preferable that it is formed so as to have a different inclination angle. According to such a configuration, the first and second electrolysis electrodes are provided so that the inclination angles of the surfaces of the first and second electrolysis electrodes that can contact the electrolytic solution differ depending on the shape of the translucent substrate. Can do.

- the second electrolysis electrode is provided on the back surface of the photoelectric conversion unit via an insulating unit. According to such a configuration, it is possible to prevent a leak current from occurring.

- the photoelectric conversion unit has a photoelectric conversion layer including a p-type semiconductor layer, an i-type semiconductor layer, and an n-type semiconductor layer. According to such a configuration, an electromotive force can be generated by causing light to enter the photoelectric conversion unit.

- the photoelectric conversion unit includes a plurality of photoelectric conversion layers connected in series, and the plurality of photoelectric conversion layers generate electromotive force generated by receiving light in the first electrolysis electrode and the second electrolysis. It is preferable to supply it to the electrode for use. According to such a configuration, a high voltage electromotive force can be easily output to the first and second electrolysis electrodes.

- each photoelectric conversion layer is preferably connected in series by a fourth conductive portion. According to such a configuration, the photoelectric conversion layers can be provided side by side.

- one of the first electrolysis electrode and the second electrolysis electrode is a hydrogen generation unit that generates H 2 from the electrolytic solution, and the other is oxygen generation that generates O 2 from the electrolytic solution.

- the hydrogen generation unit and the oxygen generation unit include a catalyst for a reaction in which H 2 is generated from the electrolytic solution and a catalyst for a reaction in which O 2 is generated from the electrolytic solution, respectively. According to such a configuration, hydrogen serving as a fuel for the fuel cell can be produced.

- At least one of the hydrogen generation unit and the oxygen generation unit has a catalyst surface area larger than an area of the light receiving surface. According to such a configuration, hydrogen and oxygen can be produced more efficiently.

- at least one of the hydrogen generation part and the oxygen generation part is a porous conductor carrying a catalyst. According to such a configuration, the catalyst area of the reaction in which hydrogen or oxygen is generated can be increased.

- the hydrogen generation unit includes at least one of Pt, Ir, Ru, Pd, Rh, Au, Fe, Ni, and Se as a hydrogen generation catalyst. According to such a configuration, hydrogen can be efficiently generated from the electrolytic solution.

- the oxygen generation unit includes at least one of Mn, Ca, Zn, Co, and Ir as an oxygen generation catalyst. According to such a configuration, oxygen can be efficiently generated from the electrolytic solution.

- the gas manufacturing apparatus of the present invention further includes a light-transmitting substrate and an electrolyte chamber, and the photoelectric conversion unit is provided on the light-transmitting substrate, and includes a first electrolysis electrode and a second electrolysis electrode. It is preferable that a top plate is further provided, and the electrolytic solution chamber is provided between the first electrolysis electrode and the second electrolysis electrode and the top plate.

- the surface of the first electrolysis electrode that can contact the electrolyte solution and the surface of the second electrolysis electrode that can contact the electrolyte solution can be provided facing the electrolyte chamber, The first and second electrodes for electrolysis can be brought into contact with the electrolytic solution.

- the gas production apparatus further includes a partition partitioning the electrolyte chamber between the first electrolysis electrode and the top plate and the electrolyte chamber between the second electrolysis electrode and the top plate.

- the first gas and the second gas can be separated by the partition wall.

- the partition preferably includes an ion exchanger. According to such a structure, the imbalance of the ion concentration which arises in electrolyte solution can be eliminated easily.

- this invention installs the gas manufacturing apparatus of this invention so that the light-receiving surface of the said photoelectric conversion part may become substantially horizontal

- the said gas manufacturing apparatus has the 1st gas exhaust port which discharges

- the second electrolysis chamber is provided with a second gas exhaust port for discharging the second gas, and an electrolytic solution chamber.

- the electrolytic solution is introduced into the electrolytic solution chamber, and sunlight is incident on the light receiving surface of the photoelectric conversion unit.

- a gas production method is also provided in which the first gas and the second gas are generated from the electrode for electrode and the electrode for second electrolysis, respectively, and the first gas and the second gas are discharged from the first gas outlet and the second gas outlet, respectively.

- the first gas and the second gas can be produced by allowing light to enter the photoelectric conversion unit, and the first gas and the second gas can be easily recovered.

- the present invention further includes a plurality of the gas production apparatuses of the present invention, a first gas discharge path, and a second gas discharge path, and each gas production apparatus includes a first gas discharge port and a first gas discharge port for discharging the first gas.

- a second gas discharge port for discharging two gases the first gas discharge path is electrically connected to the first gas discharge port of each gas production apparatus, and the second gas discharge path is a second gas of each gas production apparatus.

- a gas production device array in communication with the outlet is also provided. According to the gas production device array of the present invention, the generation amounts of the first gas and the second gas can be increased, and the first gas and the second gas are recovered from the first gas discharge path and the second gas discharge path, respectively. can do. Moreover, the 1st gas exhaust path and the 2nd gas exhaust path can be simplified and provided.

- Diagram 1 of a gas producing device is a schematic plan view showing the configuration of a gas producing device according to an embodiment of the present invention.

- 2 to 4 are schematic cross-sectional views of the gas production apparatus taken along one-dot chain line AA, dotted line BB, and dotted line CC in FIG. 1, respectively.

- FIG. 5 is a schematic back view showing the configuration of the gas production apparatus according to one embodiment of the present invention.

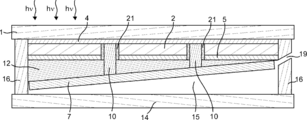

- 6 to 16 are schematic cross-sectional views showing the configuration of the gas production apparatus according to the embodiment of the present invention. 6, 13, and 15 correspond to the sectional view of the gas production apparatus taken along the dotted line BB in FIG. 1, and the sectional views of FIGS. 7, 8, 11, 12, 14, and 16 are 9 and 10 correspond to the cross-sectional view of the gas production apparatus taken along one-dot chain line AA in FIG.

- the gas production apparatus 23 includes a photoelectric conversion unit 2 having a light receiving surface and a back surface thereof, and a surface that is provided side by side on the back surface of the photoelectric conversion unit 2 and that can contact an electrolytic solution. 1 and second electrolysis electrodes 8 and 7, and when the first and second electrolysis electrodes 8 and 7 are in contact with the electrolytic solution, the first and second electrolysis electrodes 8 and 7 are connected to the photoelectric conversion unit 2.

- the electrolysis solution is electrolyzed using the electromotive force generated by receiving the light to generate the first gas and the second gas, respectively, and when the light receiving surface of the photoelectric conversion unit 2 is leveled, the first electrolysis

- the electrode for electrode 8 and the electrode for second electrolysis 7 are characterized in that the inclination angles between the surface that can contact the electrolyte and the horizontal reference surface are different.

- the gas manufacturing apparatus 23 of the present embodiment may include the translucent substrate 1. Hereinafter, the gas manufacturing apparatus of this embodiment is demonstrated.

- the translucent substrate 1 may be provided in the gas manufacturing apparatus 23 of the present embodiment. Moreover, the photoelectric conversion part 2 may be provided on the translucent board

- substrate 1 is a member used as the foundation for comprising this gas manufacturing apparatus.

- a substrate material having a high light transmittance for example, a transparent rigid material such as soda glass, quartz glass, Pyrex (registered trademark), or a synthetic quartz plate, or a transparent resin plate or film material is preferably used. In view of chemical and physical stability, it is preferable to use a glass substrate.

- a fine uneven structure can be formed so that incident light is effectively irregularly reflected on the surface of the photoelectric conversion unit 2.

- This fine concavo-convex structure can be formed by a known method such as reactive ion etching (RIE) treatment or blast treatment.

- the translucent substrate 1 has an inclination angle between the surface of the first electrolysis electrode 8 that can contact the electrolytic solution and a horizontal reference surface

- mold so that the inclination angle between the surface which can contact the electrolyte solution of the electrode 7 for 2 electrolysis and a horizontal reference plane differs.

- the gas manufacturing apparatus of the present embodiment can have a cross section as shown in FIGS. 6 is a cross-sectional view corresponding to the cross-sectional view taken along the dotted line BB in FIG. 1, and FIG. 7 is a cross-sectional view corresponding to the cross-sectional view taken along the dotted line CC in FIG.

- the first gas recovery port 20 and the second gas recovery port 19 can be provided on both sides of the gas production apparatus. Thereby, the piping for recovering the first gas and the piping for recovering the second gas can be simplified.

- Such a molded translucent substrate 1 may be formed by pouring glass or the like into a mold, may be formed by deforming a plate-like substrate, or may be formed by combining plate-like substrates. May be.

- the first electrode 4 can be provided on the translucent substrate 1 and can be provided in contact with the light receiving surface of the photoelectric conversion part 2. Moreover, the 1st electrode 4 may have translucency. Moreover, the 1st electrode 4 may be directly provided in the light-receiving surface of the photoelectric conversion part 2, when the translucent board

- the first electrode 4 can be electrically connected to the second electrolysis electrode 7. By providing the first electrode 4, the current flowing between the light receiving surface of the photoelectric conversion unit 2 and the second electrolysis electrode 7 can be increased. Further, when the photoelectric conversion unit 2 generates an electromotive force between the first area and the second area on the back surface of the photoelectric conversion unit 2 as shown in FIGS.

- the first electrode 4 is unnecessary.

- the first electrode 4 may be electrically connected to the second electrolysis electrode 7 through the second conductive portion 10 as shown in FIGS. 4, 7, 8, and 11, and as shown in FIG. It may be in contact with the electrode 7.

- the first electrode 4 may be made of a transparent conductive film such as ITO or SnO 2, or may be made of a metal finger electrode such as Ag or Au.

- the transparent conductive film is used to facilitate contact between the light receiving surface of the photoelectric conversion unit 2 and the second electrolysis electrode 7. What is generally used as a transparent electrode can be used. Specifically, In—Zn—O (IZO), In—Sn—O (ITO), ZnO—Al, Zn—Sn—O, SnO 2 and the like can be given.

- the transparent conductive film preferably has a sunlight transmittance of 85% or more, particularly 90% or more, and particularly 92% or more. This is because the photoelectric conversion unit 2 can absorb light efficiently.

- a known method can be used, and examples thereof include sputtering, vacuum deposition, sol-gel method, cluster beam deposition method, and PLD (Pulse Laser Deposition) method.

- the second conductive portion 10 can be provided so as to contact the first electrode 4 and the second electrolysis electrode 7 respectively. By providing the second conductive portion 10, the first electrode 4 and the second electrolysis electrode 7 that are in contact with the light receiving surface of the photoelectric conversion portion 2 can be easily electrically connected.

- the 2nd electroconductive part 10 may be provided in the contact hole which penetrates the photoelectric conversion part 2 or the 2nd type

- the contact hole provided with the second conductive portion 10 may be one or more, and may have a circular cross section.

- the 2nd electroconductive part 10 may be provided so that the side surface of the photoelectric conversion part 2 may be covered like FIG.

- the material of the second conductive portion 10 is not particularly limited as long as it has conductivity.

- a paste containing conductive particles for example, a carbon paste, an Ag paste or the like applied by screen printing, an inkjet method, etc., dried or baked, a method of forming a film by a CVD method using a raw material gas, a PVD method, Examples thereof include a vapor deposition method, a sputtering method, a sol-gel method, and a method using an electrochemical redox reaction.

- the photoelectric conversion unit 2 has a light receiving surface and a back surface, and a first electrolysis electrode 8 and a second electrolysis electrode 7 are provided on the back surface of the photoelectric conversion unit 2.

- the light receiving surface is a surface that receives light for photoelectric conversion

- the back surface is the back surface of the light receiving surface.

- the photoelectric conversion part 2 can be provided on the translucent substrate 1 provided with the first electrode 4 with the light receiving surface facing down.

- the photoelectric conversion unit 2 may generate an electromotive force between the light receiving surface and the back surface as shown in FIGS. 2 to 4 and 6 to 13, and the first area on the back surface as shown in FIGS. And an electromotive force may be generated between the first area and the second area.

- the photoelectric conversion unit 2 as shown in FIGS. 14 to 16 can be formed by a semiconductor substrate on which the n-type semiconductor region 37 and the p-type semiconductor region 36 are formed. Moreover, when the translucent board

- the shape of the photoelectric conversion part 2 is not specifically limited, For example, it can be set as a square shape.

- the photoelectric conversion unit 2 is not particularly limited as long as it can separate charges by incident light and generates an electromotive force. For example, the photoelectric conversion unit using a silicon-based semiconductor or the photoelectric conversion unit using a compound semiconductor A photoelectric conversion part using a dye sensitizer, a photoelectric conversion part using an organic thin film, and the like.

- the photoelectric conversion unit 2 When the first gas and the second gas are hydrogen and oxygen, the photoelectric conversion unit 2 is necessary for generating hydrogen and oxygen in the first electrolysis electrode 8 and the second electrolysis electrode 7 by receiving light. It is necessary to use a material that generates an electromotive force.

- the potential difference between the first electrolysis electrode 8 and the second electrolysis electrode 7 needs to be larger than the theoretical voltage (1.23 V) for water decomposition, and for this purpose, a sufficiently large potential difference needs to be generated in the photoelectric conversion unit 2.

- the photoelectric conversion unit 2 connects two or more junctions in series such as a pn junction to generate an electromotive force.

- it can have a structure in which photoelectric conversion layers provided in parallel are connected by the fourth conductive portion 42.

- Examples of materials that perform photoelectric conversion include silicon-based semiconductors, compound semiconductors, and materials based on organic materials, and any photoelectric conversion material can be used.

- these photoelectric conversion materials can be stacked. In the case of stacking, it is possible to form a multi-junction structure with the same material, but stacking multiple photoelectric conversion layers with different optical band gaps and complementing the low sensitivity wavelength region of each photoelectric conversion layer mutually By doing so, incident light can be efficiently absorbed over a wide wavelength region.

- the plurality of photoelectric conversion layers preferably have different band gaps. According to such a configuration, the electromotive force generated in the photoelectric conversion unit 2 can be increased, and the electrolytic solution can be electrolyzed more efficiently.

- the photoelectric conversion unit 2 may be a combination of these.

- the example of the following photoelectric conversion parts 2 can also be made into a photoelectric converting layer.

- Photoelectric conversion part using a silicon-based semiconductor examples include a single crystal type, a polycrystalline type, an amorphous type, a spherical silicon type, and combinations thereof. Any of them can have a pn junction in which a p-type semiconductor and an n-type semiconductor are joined. Further, a pin junction in which an i-type semiconductor is provided between a p-type semiconductor and an n-type semiconductor may be provided. Further, it may have a plurality of pn junctions, a plurality of pin junctions, or a pn junction and a pin junction.

- the silicon-based semiconductor is a semiconductor containing silicon, such as silicon, silicon carbide, or silicon germanium.

- the photoelectric conversion unit 2 using a silicon-based semiconductor may be a thin film or a thick photoelectric conversion layer formed on the translucent substrate 1, or a pn junction or a wafer such as a silicon wafer.

- a pin junction may be formed, or a thin film photoelectric conversion layer may be formed on a wafer having a pn junction or a pin junction.

- a first conductivity type semiconductor layer is formed on the first electrode 4 laminated on the translucent substrate 1 by a method such as a plasma CVD method.

- a method such as a plasma CVD method.

- As the first conductive type semiconductor layer a p + type or n + type amorphous Si thin film doped with a conductivity type determining impurity atom concentration of about 1 ⁇ 10 18 to 5 ⁇ 10 21 / cm 3 , a polycrystalline or A microcrystalline Si thin film is used.

- the material of the first conductivity type semiconductor layer is not limited to Si, and it is also possible to use a compound such as SiC, SiGe, or Si x O 1-x .

- a polycrystalline or microcrystalline crystalline Si thin film is formed as a crystalline Si photoactive layer by a method such as plasma CVD.

- the conductivity type is the first conductivity type having a lower doping concentration than the first conductivity type semiconductor, or the i conductivity type.

- the material for the crystalline Si-based photoactive layer is not limited to Si, and it is also possible to use a compound such as SiC, SiGe, or Si x O 1-x .

- a second conductivity type semiconductor layer having a conductivity type opposite to the first conductivity type semiconductor layer is formed by a method such as plasma CVD.

- a method such as plasma CVD.

- an n + type or p + type amorphous Si thin film doped with about 1 ⁇ 10 18 to 5 ⁇ 10 21 / cm 3 of a conductivity type determining impurity atom, or a polycrystalline or microscopic A crystalline Si thin film is used.

- the material of the second conductivity type semiconductor layer is not limited to Si, and it is also possible to use a compound such as SiC, SiGe, or Si x O 1-x .

- the second photoelectric conversion layer includes a first conductive semiconductor layer, a crystalline Si-based photoactive layer, and a second conductive semiconductor layer, and each layer corresponds to the first photoelectric conversion layer.

- the first conductive type semiconductor layer, the crystalline Si-based photoactive layer, and the second conductive type semiconductor layer are formed.

- the volume crystallization fraction of the crystalline Si photoactive layer of the second photoelectric conversion layer is preferably higher than that of the first crystalline Si photoactive layer.

- the volume crystallization fraction is preferably increased as compared with the lower layer.

- the silicon substrate a single crystal silicon substrate, a polycrystalline silicon substrate, or the like can be used, and may be p-type, n-type, or i-type.

- An n-type semiconductor region 37 is formed by doping an n-type impurity such as P into a part of the silicon substrate by thermal diffusion or ion implantation, and a p-type impurity such as B is heated on the other part of the silicon substrate.

- the p-type semiconductor region 36 can be formed by doping by diffusion or ion implantation.

- pn junction in the silicon substrate, pin junction can be formed and npp + junction or pnn + junction, it is possible to form a photoelectric conversion unit 2.

- Each of the n-type semiconductor region 37 and the p-type semiconductor region 36 can be formed on the silicon substrate as shown in FIGS. 14 to 16, and one of the n-type semiconductor region 37 and the p-type semiconductor region 36 is formed. A plurality of can be formed.

- the photoelectric conversion unit 2 can be formed by arranging the silicon substrates on which the n-type semiconductor region 37 and the p-type semiconductor region 36 are arranged side by side and connecting them in series by the fourth conductive unit 42. Note that, although described with reference to a silicon substrate, pn junction, pin junction, may use other semiconductor substrate or the like can be formed npp + junction or pnn + junction.

- the semiconductor layer is not limited to the semiconductor substrate and may be a semiconductor layer formed on the substrate.

- Photoelectric conversion part using a compound semiconductor is, for example, GaP, GaAs, InP, InAs, or IId-VI elements composed of group III-V elements, CdTe / CdS, Examples thereof include those in which a pn junction is formed using CIGS (Copper Indium Gallium DiSelenide) composed of the I-III-VI group.

- CIGS Copper Indium Gallium DiSelenide

- a method for manufacturing a photoelectric conversion unit using a compound semiconductor is shown below.

- MOCVD metal organic chemical vapor deposition

- a group III element material for example, an organic metal such as trimethylgallium, trimethylaluminum, or trimethylindium is supplied to the growth apparatus using hydrogen as a carrier gas.

- a gas such as arsine (AsH 3 ), phosphine (PH 3 ), and stibine (SbH 3 ) is used as the material of the group V element.

- a dopant of p-type impurities or n-type impurities for example, diethyl zinc for p-type conversion, monosilane (SiH 4 ), disilane (Si 2 H 6 ), hydrogen selenide (H 2 Se) for n-type conversion, for example. Etc. are used.

- These source gases can be thermally decomposed by supplying them onto a substrate heated to, for example, 700 ° C., and a desired compound semiconductor material film can be epitaxially grown.

- the composition of these growth layers can be controlled by the gas composition to be introduced, and the film thickness can be controlled by the gas introduction time.

- a known window layer on the light receiving surface side or a known electric field layer on the non-light receiving surface side may be provided to improve carrier collection efficiency.

- a buffer layer for preventing diffusion of impurities may be provided.

- the photoelectric conversion part using a dye sensitizer is mainly composed of, for example, a porous semiconductor, a dye sensitizer, an electrolyte, a solvent, and the like.

- a material constituting the porous semiconductor for example, one or more kinds of known semiconductors such as titanium oxide, tungsten oxide, zinc oxide, barium titanate, strontium titanate, cadmium sulfide can be selected.

- a paste containing semiconductor particles is applied by a screen printing method, an ink jet method and the like, dried or baked, a method of forming a film by a CVD method using a raw material gas, etc. , PVD method, vapor deposition method, sputtering method, sol-gel method, method using electrochemical oxidation-reduction reaction, and the like.

- the dye sensitizer adsorbed on the porous semiconductor various dyes having absorption in the visible light region and the infrared light region can be used.

- the carboxylic acid group, carboxylic anhydride group, alkoxy group, sulfonic acid group, hydroxyl group, hydroxylalkyl group, ester group, mercapto group, phosphonyl in the dye molecule It is preferable that a group or the like is present.

- These functional groups provide an electrical bond that facilitates electron transfer between the excited state dye and the conduction band of the porous semiconductor.

- dyes containing these functional groups include ruthenium bipyridine dyes, quinone dyes, quinone imine dyes, azo dyes, quinacridone dyes, squarylium dyes, cyanine dyes, merocyanine dyes, and triphenylmethane dyes.

- ruthenium bipyridine dyes quinone dyes, quinone imine dyes, azo dyes, quinacridone dyes, squarylium dyes, cyanine dyes, merocyanine dyes, and triphenylmethane dyes.

- Xanthene dyes porphyrin dyes, phthalocyanine dyes, berylene dyes, indigo dyes, naphthalocyanine dyes, and the like.

- Examples of the method of adsorbing the dye to the porous semiconductor include a method of immersing the porous semiconductor in a solution in which the dye is dissolved (dye adsorption solution).

- the solvent used in the dye adsorption solution is not particularly limited as long as it dissolves the dye, and specifically, alcohols such as ethanol and methanol, ketones such as acetone, ethers such as diethyl ether and tetrahydrofuran.

- Nitrogen compounds such as acetonitrile, aliphatic hydrocarbons such as hexane, aromatic hydrocarbons such as benzene, esters such as ethyl acetate, water, and the like.

- the electrolyte is composed of a redox pair and a solid medium such as a liquid or polymer gel holding the redox pair.

- a redox pair iron- and cobalt-based metals and halogen substances such as chlorine, bromine, and iodine are preferably used as the redox pair, and metal iodides such as lithium iodide, sodium iodide, and potassium iodide and iodine are used.

- the combination of is preferably used.

- imidazole salts such as dimethylpropylimidazole iodide can also be mixed.

- the solvent examples include carbonate compounds such as propylene carbonate, nitrile compounds such as acetonitrile, alcohols such as ethanol and methanol, water, aprotic polar substances, and the like. Of these, carbonate compounds and nitrile compounds are preferred. Used.

- Photoelectric conversion part using organic thin film Photoelectric conversion part 2 using an organic thin film is an electron hole transport layer composed of an organic semiconductor material having electron donating properties and electron accepting properties, or an electron transport layer having electron accepting properties. And a hole transport layer having an electron donating property may be laminated.

- the electron-donating organic semiconductor material is not particularly limited as long as it has a function as an electron donor, but it is preferable that a film can be formed by a coating method, and among them, an electron-donating conductive polymer is preferably used.

- the conductive polymer refers to a ⁇ -conjugated polymer, which is composed of a ⁇ -conjugated system in which double bonds or triple bonds containing carbon-carbon or hetero atoms are alternately connected to single bonds, and exhibits semiconducting properties. Point.

- Examples of the electron-donating conductive polymer material include polyphenylene, polyphenylene vinylene, polythiophene, polycarbazole, polyvinyl carbazole, polysilane, polyacetylene, polypyrrole, polyaniline, polyfluorene, polyvinyl pyrene, polyvinyl anthracene, and derivatives, Examples thereof include a polymer, a phthalocyanine-containing polymer, a carbazole-containing polymer, and an organometallic polymer.

- thiophene-fluorene copolymer polyalkylthiophene, phenylene ethynylene-phenylene vinylene copolymer, fluorene-phenylene vinylene copolymer, thiophene-phenylene vinylene copolymer and the like are preferably used.

- the electron-accepting organic semiconductor material is not particularly limited as long as it has a function as an electron acceptor. However, it is preferable that a film can be formed by a coating method, and among them, an electron-donating conductive polymer is preferably used.

- the electron-accepting conductive polymer include polyphenylene vinylene, polyfluorene, and derivatives and copolymers thereof, or carbon nanotubes, fullerene and derivatives thereof, CN group or CF 3 group-containing polymers, and —CF Examples thereof include 3- substituted polymers.

- an electron-accepting organic semiconductor material doped with an electron-donating compound an electron-donating organic semiconductor material doped with an electron-accepting compound, or the like can be used.

- the electron-accepting conductive polymer material doped with the electron-donating compound include the above-described electron-accepting conductive polymer material.

- a Lewis base such as an alkali metal such as Li, K, Ca, or Cs or an alkaline earth metal can be used. The Lewis base acts as an electron donor.

- the electron-donating conductive polymer material doped with the electron-accepting compound include the above-described electron-donating conductive polymer material.

- a Lewis acid such as FeCl 3 , AlCl 3 , AlBr 3 , AsF 6 or a halogen compound can be used.

- Lewis acid acts as an electron acceptor.

- photoelectric conversion unit 2 In the photoelectric conversion unit 2 shown above, it is assumed that sunlight is received and photoelectric conversion is primarily performed. However, it is emitted from a fluorescent lamp, an incandescent lamp, an LED, or a specific heat source depending on the application. It is also possible to perform photoelectric conversion by irradiating artificial light such as light.

- the second electrode 5 can be provided between the back surface of the photoelectric conversion unit 2 and the first mold unit 11 and between the back surface of the photoelectric conversion unit 2 and the second mold unit 12. .

- the second electrode 5 can be electrically connected to the first electrolysis electrode 8.

- the second electrode 5 may be electrically connected to the first electrolysis electrode 8 through the third conductive portion 17 as shown in FIGS. 3 and 13, or may be in contact with the first electrolysis electrode 8.

- the third conductive part 17 may be provided in a contact hole provided in the first mold part 11 as shown in FIG.

- the second electrode 5 is provided between the back surface of the photoelectric conversion unit 2 and the insulating unit 21 and between the back surface of the photoelectric conversion unit 2 and the first electrolysis electrode 8. Also good. Moreover, it is preferable that the 2nd electrode 5 has the corrosion resistance with respect to electrolyte solution, and the liquid shielding property with respect to electrolyte solution. Thereby, corrosion of the photoelectric conversion part 2 by electrolyte solution can be prevented. Although it will not specifically limit if the 2nd electrode 5 has electroconductivity, For example, it is a metal thin film, for example, is thin films, such as Al, Ag, Au.

- IZO In—Zn—O

- ITO In—Sn—O

- ZnO—Al Zn—Sn—O

- SnO 2 SnO 2

- the material of the third conductive portion 17 is not particularly limited as long as it has conductivity.

- a paste containing conductive particles for example, a carbon paste, an Ag paste or the like applied by screen printing, an inkjet method, etc., dried or baked, a method of forming a film by a CVD method using a raw material gas, a PVD method, Examples thereof include a vapor deposition method, a sputtering method, a sol-gel method, and a method using an electrochemical redox reaction.

- mold part 11 can be provided between the back surface of the photoelectric conversion part 2, and the electrode 8 for 1st electrolysis

- mold part 12 is It can be provided between the back surface of the photoelectric conversion unit 2 and the second electrolysis electrode 7. Further, the first mold part 11 and the second mold part 12 are arranged between a surface that can contact the electrolytic solution of the first electrolysis electrode 8 and a horizontal reference surface when the light receiving surface of the photoelectric conversion unit 2 is leveled. And the inclination angle between the surface of the second electrolysis electrode 7 that can contact the electrolytic solution and the horizontal reference surface may be different. By providing the first mold part 11 and the second mold part 12 formed in this way, the inclination angle between the surface of the first electrolysis electrode in contact with the electrolytic solution and the surface of the second electrolysis electrode in contact with the electrolytic solution. Can be adjusted.

- mold part 12 may have a groove-shaped hollow like FIG.

- the first mold part and the second mold part may have electrical insulation.

- the second mold part 12 can be provided so as to cover the side surface of the photoelectric conversion part 2 as shown in FIGS. 11 and 12, and the second mold part 12 covering the side surface of the photoelectric conversion part 2 can be provided.

- the second conductive portion 10 or the second electrolysis electrode 7 can be provided thereon.

- leakage current can be prevented and the second electrolysis electrode 7 and the first electrode 4 can be electrically connected.

- the first mold part 11 and the second mold part 12 can be formed from, for example, a solid resin. By using a solid resin, the first mold part 11 and the second mold part 12 having a desired shape can be formed.

- the first mold part 11 may be made of a conductive material. Thereby, the back surface of the photoelectric conversion unit 2 and the first electrolysis electrode 8 can be electrically connected via the first mold unit.

- the first conductive part 9 can be provided between the first mold part 11 and the first electrolysis electrode 8 or between the second mold part 12 and the second electrolysis electrode 7.

- the first conductive portion 9 can be provided between the second mold portion 12 and the second electrolysis electrode 7 as shown in FIGS. 8, 11, 14, and 16, for example.

- the 1st electroconductive part 11 has electroconductivity

- it is a metal thin film, for example, is thin films, such as Al, Ag, Au.

- IZO In—Zn—O

- ITO In—Sn—O

- ZnO—Al Zn—Sn—O

- SnO 2 SnO 2

- Insulating part 21 can be provided in order to prevent the occurrence of leakage current.

- the insulating portion 21 can be provided on the side wall of the contact hole.

- the insulating part 21 can also be provided between the 2nd type

- the insulating part 11 can be used regardless of an organic material or an inorganic material.

- organic polymers and inorganic materials include metal oxides such as Al 2 O 3 , SiO 2 such as porous silica films, fluorine-added silicon oxide films (FSG), SiOC, HSQ (Hydrogen Silsesquioxane) films, SiN x , It is possible to use a method of forming a film by dissolving silanol (Si (OH) 4 ) in a solvent such as alcohol and applying and heating.

- a film containing a paste containing an insulating material is applied by a screen printing method, an ink jet method, a spin coating method, etc., dried or baked, or a CVD method using a source gas is used. And a method using a PVD method, a vapor deposition method, a sputtering method, a sol-gel method, and the like.

- the first electrolysis electrode 8 and the second electrolysis electrode 7 are respectively provided on the back surface of the photoelectric conversion unit 2, and the back surface side surface of the photoelectric conversion unit 2 Each has a surface which is the back surface and can contact the electrolyte. Thus, the first electrolysis electrode 8 does not block light incident on the photoelectric conversion unit 2.

- the electrolysis solution is electrolyzed by using the electromotive force generated by the photoelectric conversion unit 2 receiving light, and the first gas is obtained. And a second gas is generated.

- the first electrolysis electrode 8 is connected to the back surface of the photoelectric conversion unit 2 as shown in FIGS.

- the second electrolysis electrode 7 can be electrically connected to the light receiving surface of the photoelectric conversion unit 2 as shown in FIGS. 4, 7, 8, 11, and 12.

- the first electrolysis electrode 8 is connected to the first area and the second area as shown in FIGS.

- the second electrolysis electrode 7 can be electrically connected to one of the two areas and the other of the first and second areas.

- first electrolysis electrode 8 and the second electrolysis electrode 7 include a surface that can contact the electrolytic solution of the first electrolysis electrode 8 and a horizontal reference surface when the light receiving surface of the photoelectric conversion unit 2 is horizontal. And the inclination angle between the surface of the second electrolysis electrode 7 that can come into contact with the electrolytic solution and the horizontal reference surface are different.

- first gas rises in the electrolyte as bubbles

- the surface of the second electrolysis electrode 7 that becomes the guide surface can be shifted from the surface that can contact the electrolyte.

- the difference between the inclination angles of the first electrolysis electrode 8 and the second electrolysis electrode 7 is, for example, that the first gas outlet 20 and the second gas outlet 19 for recovering the first gas and the second gas are photoelectrically converted.

- the difference may be shifted up and down when the light receiving surface of the portion 2 is leveled.

- the first electrolysis electrode 8 is formed such that the first gas discharge port 20 is formed on one of the both sides of the gas production apparatus 23 and the second gas discharge port 19 is formed on the other side.

- the difference of the inclination angle of the electrode 7 for 2nd electrolysis may be given.

- the surface of the first electrolysis electrode 8 that can come into contact with the electrolytic solution may have, for example, an inclination angle of 1 to 60 degrees, preferably 5 degrees. It may be 30 degrees or less. Further, at this time, the surface of the second electrolysis electrode 7 that can come into contact with the electrolytic solution may have an inclination angle of 120 degrees or more and 179 degrees or less, preferably 150 degrees or more and 175 degrees or less. .

- the first gas can be discharged from one of the two sides of the gas production device 23, the second gas can be discharged from the other, and a pipe for collecting the first gas and the second gas can be provided. It can be simplified.

- a method for making a difference between the inclination angle of the surface of the first electrolysis electrode 8 that can contact the electrolytic solution and the inclination angle of the surface of the second electrolysis electrode 7 that can contact the electrolytic solution is not particularly limited.

- the first mold part 11 and the second mold part 12 may be provided to provide a difference in inclination angle.

- the surface of the first electrolysis electrode 8 and the second electrolysis electrode 7 that can contact the electrolytic solution is a guide surface when the first gas or the second gas rises as bubbles in the electrolytic solution.

- it may be a flat surface or a curved surface.

- the inclination angle of this curved surface means the average inclination angle.

- the first electrolysis electrode 8 and the second electrolysis electrode 7 can each have a groove-like recess extending in an inclined direction on a surface that can contact the electrolytic solution.

- the first gas or the second gas can be raised as bubbles in the electrolytic solution along the groove-like depression, and the first gas and the second gas can be easily separated.

- the partition wall 13 formed between the first electrolysis electrode 8 and the second electrolysis electrode 7 can be omitted by forming such a groove-like depression.

- one groove-like depression may be formed on each surface of the first electrolysis electrode 8 and the second electrolysis electrode 7 that can come into contact with the electrolytic solution.

- a plurality of electrodes may be formed on the surfaces of the electrode for electrolysis 8 and the electrode for second electrolysis 7 that can contact the electrolytic solution.

- At least one of the first electrolysis electrode 8 and the second electrolysis electrode 7 has a plurality of surfaces, each of which has a surface that can contact the strip-shaped electrolyte solution, and the long sides of the surfaces are adjacent to each other It may be provided alternately.

- FIG. 17 is a schematic plan view of the gas production apparatus of the present embodiment

- FIG. 18 is a schematic cross-sectional view of the gas production apparatus taken along the dotted line AA in FIG.

- the cross-sectional view of the gas production device 23 in the direction perpendicular to the dotted line AA has a cross section as shown in FIGS.

- the distance between the portion where the reaction generating the first gas occurs and the portion where the reaction generating the second gas occurs is increased. It can be shortened, and the ion concentration imbalance generated in the electrolyte can be reduced.

- the 1st gas and 2nd gas can be collect

- the some 1st gas exhaust port 20 can be formed in one among the both sides of the gas manufacturing apparatus 23, and the some 2nd gas exhaust port 19 can be formed in the other.

- the first gas discharge path 25 for recovering the first gas and the second gas discharge path 26 for recovering the second gas can be provided on both sides of the gas production device 23, thereby simplifying the piping. be able to.

- the gas discharged from the first gas discharge port 20 or the second gas discharge port 19 is replaced with water through a gas collecting unit (not shown). It is possible to collect gas by a method such as a method.

- At least one of the first electrolysis electrode 8 and the second electrolysis electrode 7 has a catalyst surface area larger than the area of the light receiving surface. According to such a configuration, the first gas or the second gas can be generated more efficiently by the electromotive force generated in the photoelectric conversion unit 2.

- at least one of the first electrolysis electrode 8 and the second electrolysis electrode 7 is preferably a porous conductor carrying a catalyst. According to such a configuration, the surface area of at least one of the first electrolysis electrode 8 and the second electrolysis electrode 7 can be increased, and the first gas or the second gas can be generated more efficiently. Can do.

- One of the first electrolysis electrode 8 and the second electrolysis electrode 7 may be a hydrogen generation unit, and the other may be an oxygen generation unit.

- one of the first gas and the second gas is hydrogen, and the other is oxygen.

- the hydrogen generating part is a part for generating H 2 from the electrolytic solution, and is one of the first electrolysis electrode 8 and the second electrolysis electrode 7. Further, the hydrogen generation unit may include a catalyst for a reaction in which H 2 is generated from the electrolytic solution. Thereby, the reaction rate of the reaction in which H 2 is generated from the electrolytic solution can be increased.

- the hydrogen generation part may consist only of a catalyst for the reaction in which H 2 is generated from the electrolytic solution, or this catalyst may be supported on a support. Further, the hydrogen generation unit may have a catalyst surface area larger than the area of the light receiving surface of the photoelectric conversion unit 2. Thereby, the reaction in which H 2 is generated from the electrolytic solution can be set to a faster reaction rate.

- the hydrogen generation part may be a porous conductor carrying a catalyst. This can increase the catalyst surface area. In addition, a change in potential due to a current flowing between the light receiving surface or the back surface of the photoelectric conversion unit 2 and the catalyst included in the hydrogen generation unit can be suppressed. Furthermore, the hydrogen generation unit may include at least one of Pt, Ir, Ru, Pd, Rh, Au, Fe, Ni, and Se as a hydrogen generation catalyst. According to such a configuration, hydrogen can be generated at a higher reaction rate by the electromotive force generated in the photoelectric conversion unit 2.

- the catalyst for the reaction of generating H 2 from the electrolyte is a catalyst that promotes the conversion of two protons and two electrons into one molecule of hydrogen, is chemically stable, and generates hydrogen overvoltage.

- platinum group metals such as Pt, Ir, Ru, Pd, Rh, and Au, which have catalytic activity for hydrogen, and alloys or compounds thereof, Fe, Ni, and Se that constitute the active center of hydrogenase that is a hydrogen-producing enzyme.

- An alloy or a compound, a combination thereof, or the like can be preferably used.

- a nanostructure containing Pt and Pt has a small hydrogen generation overvoltage and can be suitably used.

- Materials such as CdS, CdSe, ZnS, and ZrO 2 whose hydrogen generation reaction is confirmed by light irradiation can also be used.

- the hydrogen generating catalyst can be supported on the conductor.

- the conductor carrying the catalyst include metal materials, carbonaceous materials, and conductive inorganic materials.

- the metal material a material having electronic conductivity and resistance to corrosion in an acidic atmosphere is preferable.

- noble metals such as Au, Pt, Pd, metals such as Ti, Ta, W, Nb, Ni, Al, Cr, Ag, Cu, Zn, Su, Si, and nitrides and carbides of these metals

- Examples of the alloy include stainless steel, Cu—Cr, Ni—Cr, and Ti—Pt.

- the metal material contains at least one element selected from the group consisting of Pt, Ti, Au, Ag, Cu, Ni, and W from the viewpoint that there are few other chemical side reactions.

- These metal materials have a relatively small electric resistance, and can suppress a decrease in voltage even when a current is extracted in the surface direction.

- a metal material having poor corrosion resistance in an acidic atmosphere such as Cu, Ag, Zn, etc.

- noble metals and metals having corrosion resistance such as Au, Pt, Pd, carbon, graphite, glassy carbon

- a metal surface having poor corrosion resistance may be coated with a conductive polymer, a conductive nitride, a conductive carbide, a conductive oxide, or the like.

- the carbonaceous material a chemically stable and conductive material is preferable.

- examples thereof include carbon powders and carbon fibers such as acetylene black, vulcan, ketjen black, furnace black, VGCF, carbon nanotube, carbon nanohorn, and fullerene.

- Examples of the inorganic material having conductivity include In—Zn—O (IZO), In—Sn—O (ITO), ZnO—Al, Zn—Sn—O, SnO 2 , and antimony oxide-doped tin oxide. .

- examples of the conductive polymer include polyacetylene, polythiophene, polyaniline, polypyrrole, polyparaphenylene, polyparaphenylene vinylene, and the like

- examples of the conductive nitride include carbon nitride, silicon nitride, gallium nitride, indium nitride, and nitride. Germanium, titanium nitride, zirconium nitride, thallium nitride, etc.

- conductive carbides include tantalum carbide, silicon carbide, zirconium carbide, titanium carbide, molybdenum carbide, niobium carbide, iron carbide, nickel carbide, hafnium carbide, tungsten carbide. , Vanadium carbide, chromium carbide, and the like.

- conductive oxide include tin oxide, indium tin oxide (ITO), and antimony oxide-doped tin oxide.

- the structure of the conductor supporting the hydrogen generation catalyst includes a plate shape, a foil shape, a rod shape, a mesh shape, a lath plate shape, a porous plate shape, a porous rod shape, a woven fabric shape, a nonwoven fabric shape, a fiber shape, and a felt shape. It can be used suitably. Further, a grooved conductor in which the surface of the felt-like electrode is pressure-bonded in a groove shape is preferable because the electric resistance and the flow resistance of the electrode liquid can be reduced.

- the oxygen generating portion is a portion that generates O 2 from the electrolytic solution, and is one of the first electrolysis electrode 8 and the second electrolysis electrode 7.

- the oxygen generation unit may include a catalyst for a reaction in which O 2 is generated from the electrolytic solution. Thereby, the reaction rate of the reaction in which O 2 is generated from the electrolytic solution can be increased.

- the oxygen generation part may consist only of a catalyst for the reaction that generates O 2 from the electrolytic solution, or the catalyst may be supported on a carrier.

- the oxygen generation unit may have a catalyst surface area larger than the area of the light receiving surface of the photoelectric conversion unit 2. Thereby, the reaction in which O 2 is generated from the electrolytic solution can be set to a faster reaction rate.

- the oxygen generation part may be a porous conductor carrying a catalyst. This can increase the catalyst surface area. In addition, a change in potential due to a current flowing between the light receiving surface or the back surface of the photoelectric conversion unit 2 and the catalyst included in the oxygen generation unit can be suppressed. Furthermore, the oxygen generation unit may include at least one of Mn, Ca, Zn, Co, and Ir as an oxygen generation catalyst. According to such a configuration, oxygen can be generated at a higher reaction rate by the electromotive force generated in the photoelectric conversion unit.

- the catalyst for the reaction of generating O 2 from the electrolyte is a catalyst that promotes the conversion of two water molecules into one molecule of oxygen, four protons, and four electrons, and is chemically stable.

- a material having a small oxygen generation overvoltage can be used.

- oxides or compounds containing Mn, Ca, Zn, Co, which are active centers of Photosystem II, which is an enzyme that catalyzes the reaction of generating oxygen from water using light and platinum such as Pt, RuO 2 , IrO 2

- compounds containing group metals, oxides or compounds containing transition metals such as Ti, Zr, Nb, Ta, W, Ce, Fe, Ni, and combinations of the above materials.

- iridium oxide, manganese oxide, cobalt oxide, and cobalt phosphate can be suitably used because they have low overvoltage and high oxygen generation efficiency.

- the oxygen generating catalyst can be supported on the conductor.

- the conductor carrying the catalyst include metal materials, carbonaceous materials, and conductive inorganic materials. These explanations apply as long as there is no contradiction in the explanation of the hydrogen generation catalyst described in “9.

- a promoter can be used. Examples thereof include oxides or compounds of Ni, Cr, Rh, Mo, Co, and Se.

- the method for supporting the hydrogen generating catalyst and the oxygen generating catalyst can be applied directly to a conductor or semiconductor, PVD methods such as vacuum deposition, sputtering, and ion plating, dry coating methods such as CVD,

- the method can be appropriately changed depending on the material such as an analysis method.

- a conductive material can be appropriately supported between the photoelectric conversion unit and the catalyst.

- the reaction surface area is increased by supporting it on porous materials such as metals and carbon, fibrous materials, nanoparticles, etc., and the hydrogen and oxygen generation rates are improved. It is possible to make it.

- the top plate 14 can be provided on the first electrolysis electrode 8 and the second electrolysis electrode 7 so as to face the translucent substrate 1.

- the top plate 14 can be provided such that a space is provided between the first electrolysis electrode 8 and the second electrolysis electrode 7 and the top plate 14. This space can be used as the electrolytic solution chamber 15, and the first electrolytic electrode 8 and the second electrolytic electrode 7 can be brought into contact with the electrolytic solution by introducing the electrolytic solution into the electrolytic solution chamber 15.

- the top plate 14 may be the bottom part of a box.

- the top plate 14 is a material that constitutes the electrolytic solution chamber 15 and confines the generated first gas and second gas, and a highly confidential substance is required. It is not particularly limited whether it is transparent or opaque, but it is preferably a transparent material in that it can be visually confirmed that the first gas and the second gas are generated. .