WO2011154331A1 - Polymers for delivery of nucleic acids - Google Patents

Polymers for delivery of nucleic acids Download PDFInfo

- Publication number

- WO2011154331A1 WO2011154331A1 PCT/EP2011/059239 EP2011059239W WO2011154331A1 WO 2011154331 A1 WO2011154331 A1 WO 2011154331A1 EP 2011059239 W EP2011059239 W EP 2011059239W WO 2011154331 A1 WO2011154331 A1 WO 2011154331A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- polymer

- acid

- fmoc

- resin

- group

- Prior art date

Links

- 0 CC(CN)C(*)N**C(O)=O Chemical compound CC(CN)C(*)N**C(O)=O 0.000 description 2

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G73/00—Macromolecular compounds obtained by reactions forming a linkage containing nitrogen with or without oxygen or carbon in the main chain of the macromolecule, not provided for in groups C08G12/00 - C08G71/00

- C08G73/02—Polyamines

- C08G73/028—Polyamidoamines

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K48/00—Medicinal preparations containing genetic material which is inserted into cells of the living body to treat genetic diseases; Gene therapy

- A61K48/0008—Medicinal preparations containing genetic material which is inserted into cells of the living body to treat genetic diseases; Gene therapy characterised by an aspect of the 'non-active' part of the composition delivered, e.g. wherein such 'non-active' part is not delivered simultaneously with the 'active' part of the composition

- A61K48/0025—Medicinal preparations containing genetic material which is inserted into cells of the living body to treat genetic diseases; Gene therapy characterised by an aspect of the 'non-active' part of the composition delivered, e.g. wherein such 'non-active' part is not delivered simultaneously with the 'active' part of the composition wherein the non-active part clearly interacts with the delivered nucleic acid

- A61K48/0041—Medicinal preparations containing genetic material which is inserted into cells of the living body to treat genetic diseases; Gene therapy characterised by an aspect of the 'non-active' part of the composition delivered, e.g. wherein such 'non-active' part is not delivered simultaneously with the 'active' part of the composition wherein the non-active part clearly interacts with the delivered nucleic acid the non-active part being polymeric

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G69/00—Macromolecular compounds obtained by reactions forming a carboxylic amide link in the main chain of the macromolecule

- C08G69/02—Polyamides derived from amino-carboxylic acids or from polyamines and polycarboxylic acids

- C08G69/08—Polyamides derived from amino-carboxylic acids or from polyamines and polycarboxylic acids derived from amino-carboxylic acids

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G69/00—Macromolecular compounds obtained by reactions forming a carboxylic amide link in the main chain of the macromolecule

- C08G69/02—Polyamides derived from amino-carboxylic acids or from polyamines and polycarboxylic acids

- C08G69/26—Polyamides derived from amino-carboxylic acids or from polyamines and polycarboxylic acids derived from polyamines and polycarboxylic acids

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12N—MICROORGANISMS OR ENZYMES; COMPOSITIONS THEREOF; PROPAGATING, PRESERVING, OR MAINTAINING MICROORGANISMS; MUTATION OR GENETIC ENGINEERING; CULTURE MEDIA

- C12N15/00—Mutation or genetic engineering; DNA or RNA concerning genetic engineering, vectors, e.g. plasmids, or their isolation, preparation or purification; Use of hosts therefor

- C12N15/09—Recombinant DNA-technology

- C12N15/11—DNA or RNA fragments; Modified forms thereof; Non-coding nucleic acids having a biological activity

- C12N15/111—General methods applicable to biologically active non-coding nucleic acids

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0012—Galenical forms characterised by the site of application

- A61K9/0019—Injectable compositions; Intramuscular, intravenous, arterial, subcutaneous administration; Compositions to be administered through the skin in an invasive manner

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12N—MICROORGANISMS OR ENZYMES; COMPOSITIONS THEREOF; PROPAGATING, PRESERVING, OR MAINTAINING MICROORGANISMS; MUTATION OR GENETIC ENGINEERING; CULTURE MEDIA

- C12N2310/00—Structure or type of the nucleic acid

- C12N2310/10—Type of nucleic acid

- C12N2310/14—Type of nucleic acid interfering N.A.

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12N—MICROORGANISMS OR ENZYMES; COMPOSITIONS THEREOF; PROPAGATING, PRESERVING, OR MAINTAINING MICROORGANISMS; MUTATION OR GENETIC ENGINEERING; CULTURE MEDIA

- C12N2310/00—Structure or type of the nucleic acid

- C12N2310/30—Chemical structure

- C12N2310/35—Nature of the modification

- C12N2310/351—Conjugate

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12N—MICROORGANISMS OR ENZYMES; COMPOSITIONS THEREOF; PROPAGATING, PRESERVING, OR MAINTAINING MICROORGANISMS; MUTATION OR GENETIC ENGINEERING; CULTURE MEDIA

- C12N2320/00—Applications; Uses

- C12N2320/30—Special therapeutic applications

- C12N2320/32—Special delivery means, e.g. tissue-specific

Landscapes

- Health & Medical Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Genetics & Genomics (AREA)

- Biomedical Technology (AREA)

- Medicinal Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Polymers & Plastics (AREA)

- Biotechnology (AREA)

- Molecular Biology (AREA)

- General Engineering & Computer Science (AREA)

- Wood Science & Technology (AREA)

- Zoology (AREA)

- General Health & Medical Sciences (AREA)

- Bioinformatics & Cheminformatics (AREA)

- Biochemistry (AREA)

- Pharmacology & Pharmacy (AREA)

- Physics & Mathematics (AREA)

- Biophysics (AREA)

- Veterinary Medicine (AREA)

- Plant Pathology (AREA)

- Public Health (AREA)

- Microbiology (AREA)

- Epidemiology (AREA)

- Animal Behavior & Ethology (AREA)

- Medicines That Contain Protein Lipid Enzymes And Other Medicines (AREA)

- Pharmaceuticals Containing Other Organic And Inorganic Compounds (AREA)

- Medicinal Preparation (AREA)

Abstract

Polyamide polymers containing defined oligo (alkylene amino) acids, methods for their production, their use as a delivery reagent for nucleic acids, pharmaceutical compositions containing said polyamide polymers, and uses thereof are provided.

Description

POLYMERS FOR DELIVERY OF NUCLEIC ACIDS

The present invention relates to polyamide polymers (PAA) containing defined oligo (alkylene amino) acids (OAA), methods for their production, their use as a delivery reagent for nucleic acids, pharmaceutical compositions containing said polyamide polymers, and uses thereof. In the recent years the application of nucleic acids has become a powerful approach in molecular medicine and diagnostics. Of particular interest is the specific targeting and delivery of double stranded RNA molecules (dsRNA) to and into target tissues and target cells. Double- stranded ribonucleic acid (dsRNA) molecules have been shown to block gene expression in a highly conserved regulatory mechanism known as RNA interference (RNAi). However the in vivo application requires the nucleic acids specifically and efficiently interacting with target cells. The efficient in vivo delivery of functional therapeutic or diagnostic agents to a target tissue or cell still remains one of the biggest obstacles in drug development. Specific targeting and delivery of nucleic acids to and into target tissues and target cells is a major bottleneck, which has not satisfactorily been solved by current technologies. Most so far described nucleic acid delivery entities consist not of one defined molecule but rather are a cocktail of molecules or particles. However, for therapeutic applications, homogenous defined entities are desired.

The nucleic acid payloads must be attached covalently or non-covalently with good stability to assure specific targeting and avoid systemic nonspecific release of the payload. The carrier protects the nucleic acids from degradation in the extracellular environment. However, to enable entry into the cell, the payload is ideally released at or within target cells. To combine good stability within the circulation with effective release at the target is a major bottleneck in conjugate development. In addition the carrier has to be thus designed that it does not cause immunogenicity and is not toxic when accumulating in the body. One approach is to attach the nucleic acids covalently or non-covalently to a polymeric carrier. For example polyamine structures have been widely used as artificial non-viral carrier systems. A major drawback of the polyamine carriers known so far is that they are random

polymerization derived macromolecules and thus poorly defined, heterogeneous molecules in terms of their molecular weight and isomer distribution. The exact composition of these macromolecular polymeric systems is unknown and hence selective modification is impossible and structure activity relationships are difficult to predict. Targeted nucleic acids frequently accumulate in endosomes from which they need to escape to be active. However, effective non-toxic, non-immunogenic endosome escape mechanisms for targeted dsRNAs still have to be found.

Hartmann et al. (e.g. Hartmann L, Hafele S, Peschka-Suss R, Antonietti M, Borner HG. Tailor-Made Poly(amidoamine)s for Controlled Complexation and Condensation of DNA. Chemistry 2008;14(7):2025-2033.) describe linear PEG-polyamidoamines for controlled complexation and condensation of DNA, which are composed of propyleneamine subunits and sometimes combined with spermine. These structures are assembled using commercially available PEG (2.7 kDa, -63 repating units), diamino-N-methyl-dipropylamine, spermine succinic acid anhydride, and lysine. Hartmann et al describe the successful synthesis optimization using a double condensation strategy and show successful complexation of DNA at high N/P ratios. However, these polymers are not suitable for successful siRNA/Oligo/pDNA delivery in vivo. None of the described structures contain lipophilic modifications or thiols for polyplex stabilization. Incorporation of a spacer peptide sequence is described but without any relevance to either polymer properties or delivery. Polymers were not optimized for pDNA binding or lytic activity. Polymer design is restricted by the boundaries of the synthesis and by the limited scope of commercial available amine building blocks. Furthermore the use of tri/tetramines results in a decreased charge density further weakening the nucleic acid complexation. Taken together all described sequences apparently possess no delivery potential. Substances were not tested for lytic activity but with regard to the published cytotoxicity results lytic activity is not very likely.

Wang et al (e.g. Wang XL, Ramusovic S, Nguyen T, Lu ZR, Novel polymerizable surfactants with pH-sensitive amphiphilicity and cell menrane disruption for efficient siRNA delivery, Bioconjugate Chemistry, 2007, 18, 2169-2177) specifically aimed at the development of amphiphilic cationic lipids with classical Y-shape. The substances are characterized by a maximum of 5 charges per molecule and a rather high HLB value. The synthetic route used does not allow the incorporation of additional amines. The structure is therefore not a polymer and could be described as a dipeptide and fatty acid modified oligoamine. Polymer design is

restricted by the narrow boundaries of the synthesis and by the limited scope of commercial available amine building blocks. None of the described structures contain more than one amine building block and the synthesis is limited to commercially available amines. The synthesized structures are exclusively branched structures and have more similarity to PAMAM dendrons than to classical linear polyamidoamines as the amine building block is connected via an alkyl bond to the peptide domain. The polymer design is restricted by the boundaries of the synthesis and by the limited scope of commercial available amine building blocks. Furthermore the use of a single amine building block results in a decreased charge density compared to classical PAAs. Complex, multimodal, programmable delivery polymers can't be synthesized by this strategy as its inherently restricted by its inability to incorporate more than one amino acid unit. Structures were tested for lytic activity and siRNA delivery but show only moderate efficiency. DNA delivery results were not reported. Targeting/shielding can only be incorporated via post- pegylation approaches making the system less flexible and difficult to control.

These drawbacks of prior art are overcome by the polymers of the present invention, providing defined polymeric systems which can be used as effective carriers for the delivery of nucleic acids, with the ability to deliver the nucleic acids into the cytosol across cellular membranes, for example by delivery into and release from endosomal compartments. The polymers of the invention are pH specifically protonated and thus act as pH responsive lytic polymers.

Solid-phase synthesis of linear PEG-polyamidoamines was first reported by Hartmann et al. using a alternating condensation approach resulting in defined, linear, propylenimine based polyamidoamines with high purity. To generate a oligoethyleneimine based library the corresponding boc-protected oligoethylenimine building blocks were synthesized. Application of the published synthesis protocols on synthesis of the novel polymers comprising oligo(alkyleneamine) of this invention was not succesful as the reaction tended to generate cross- linked fragments on the resin. Therefore a new solid phase synthesis strategy based on fmoc/tBu was developed. An object of the present invention is to provide a synthetically defined nucleic acid delivery carrier of low toxicity and high safety based on oligo(alkyleneamine) units. The carrier, when used to administer a nucleic acid such as a siRNA into an animal-derived cell or organism, is capable of delivering efficiently the nucleic acids into the cells while protecting it from being

degraded. In one preferred embodiment, the carrier is (totally or partly) prepared by iterative solid-phase synthesis. The nucleic acid delivery formulation is prepared by either mixing the nucleic acid delivery carrier with a nucleic acid or covalently conjugating the nucleic acid to the carrier, or a combination of both. A polymer comprising oligo(alkyleneamino) acid units is provided, wherein the units have the general structure 1 :

Z is chosen from

either an alkyl group with the general structure L , wherein the number c of methylene (CH2) groups is 0-8;

an amino group with the general structure , wherein the number n of methylene groups is 1-7;

R is either a methylene group (CH2) or a carbonylgroup (C=0); and the number a of alkyleneamino ((CH2)b NH) groups is 1-7, wherein the number b of methylene (CH2) groups is 2-7 .

The oligo (alkyleneamino) acid units of the polymer are covalently linked via the terminal carboxygroup of a first oligo (alkyleneamino) acid unit and a terminal amino group of a second oligo(alkyleneamino) acid unit. Thus, the polymer comprises oligo (alkyleneamino) acid units covalently linked to each other via an amide bond, and is terminated by a free carboxyl group (-

COOH) at the one end and terminated by a free amine group (-NH2) at the other end. Hence the polymer has a C (carboxy) terminus and an N (amino) terminus.

Said polymer comprises 2-60 oligo(alkyleneamino) acid units having the general structure 1, preferably 2-10 oligo(alkyleneamino) acid units having the general structure 1, most preferably 2-5 oligo(alkyleneamino) acid units having the general structure 1. The polymer can optionally have the same oligo(alkyleneamino)acid units recurring or may also have a combination of varying oligo(alkyleneamino)acid units recurring.

In other embodiments said polymer comprises identical oligo(alkyleneamino)acid units and at least one amino acid recurring, in yet other embodiments said polymer comprises a combination of varying oligo(alkyleneamino)acid units and at least one amino acid recurring.

Below preferred embodiments of the oligo(alkyleneamino)acid units of general structure 1 are described.

As stated above, substituent Z of the oligo(alkyleneamino) acid units are selected from an alkyl group, an amino group or an aromatic group. Below preferred but not limiting embodiments are described wherein Z is an alkyl group.

In a preferred embodiment, Z is an alkyl group wherein the number c of methylene (CH2) groups is 0-8; R is either a methylene group or a carbonyl group; and the number a of alkyleneamino ((CH2)b NH) groups is 1-7, wherein the number b of methylene (CH2) groups is -7. Accordingly said oligo(alkyleneamino) acid units have the general structure 2:

Said polymer comprises 2-60 oligo(alkyleneamino) acid units having the general structure 2, preferably 2-10 oligo(alkyleneamino) acid units having the general structure 2, most preferably 2-5 oligo(alkyleneamino) acid units having the general structure 2. The polymer can optionally have the same oligo(alkyleneamino)acid units recurring or may also have a combination of varying oligo(alkyleneamino)acid units recurring.

In a preferred embodiment, Z is an alkyl group wherein the number c of methylene (CH2) groups is 0-8, R is a carbonylgroup, and the number a of alkyleneamino ((CH2)b NH) groups is 1-7, wherein the number b of methylene (CH2) groups is 2-7 . Accordingly said oligo(alkyleneamino) acid units have the general structure 3:

As illustrated above in the general structure 3, said oligo(alkyleneamino) acid units preferably comprise of 2 - 7, most preferably 3 or 4, alkyleneamine monomers wherein one alkyleneamine monomer is covalently linked to an aliphatic dicarboxylic acid. Preferably said alkyleneamine monomer is selected from the group: Ethyleneamine, propyleneamine, butyleneamine, pentylenamine and hexyleneamine. Preferably said dicarboxylic acid is an aliphatic dicarboxylic acid selected from the group oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, pimelic acid, suberic acid, azelaic acid and sebacic acid. Said polymer comprises 2-60 oligo(alkyleneamino) acid units having the general structure 3, preferably 2-10 oligo(alkyleneamino) acid units having the general structure 3, most preferably 2-5 oligo(alkyleneamino) acid units having the general structure 3. The polymer can optionally have the same oligo(alkyleneamino)acid units recurring or may also have a combination of varying oligo(alkyleneamino)acid units recurring. In a preferred embodiment, Z is an alkyl group wherein the number c of methylene (CH2) groups is 0-8, R is a carbonylgroup, and the number a of alkyleneamino ((CH2)b NH) groups is 1-7, wherein the number b of methylene (CH2) groups is 2 . Accordingly in this embodiment said oligo(alkyleneamino) acid units are oligo (ethyleneamino) acid units, said units having the general structure 4:

, wherein a: 2-7, c: 0-8.

GENERAL STRUCTURE 4

Said polymer comprises 2-60 oligo(ethyleneamino) acid units having the general structure 4, preferably 2-10 oligo(ethylenamino) acid units having the general structure 4, most preferably 2- 5 oligo(ethylenamino) acid units having the general structure 4.

As illustrated above in the general structure 4, said oligo(ethyleneamino) acid units preferably comprise of 2 to 7 ethyleneamine monomers wherein one ethyleneamine monomer is covalently linked to a dicarboxylic acid. Preferably said dicarboxylic acid is an aliphatic dicarboxylic acid selected from the group oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, pimelic acid, suberic acid, azelaic acid and sebacic acid. In a preferred embodiment, Z is an alkyl group wherein the number c of methylene (CH2) groups is 1, R is a carbonylgroup, and the number a of alkyleneamino ((CH2)b NH) groups is 4, wherein the number b of methylene (CH2) groups is 2. Hence the oligo(ethylenamino) acid units of this embodiment are tetraethylenepentamine succinic acid (Stp) units. Preferably the polymer comprises 2-5 of these (Stp) units. In another embodiment, Z is an alkyl group wherein the number c of methylene (CH2) groups is 0-8; R is a methylene group; and the number a of alkyleneamino ((CH2)b NH) groups is 2-7, wherein the number b of methylene (CH2) groups is 2-6. Accordingly said oligo(alkyleneamino) acid units have the general structure 5:

ΗΟ¾^Ν{¾Ν¾Η

H GENERAL STRUCTURE 5 a: 2-7; b: 2-6, c: 0-8

Said polymer comprises 2-60 oligo(alkyleneamino) acid units having the general structure 5, preferably 2-10 oligo(alkyleneamino) acid units having the general structure 5, most preferably 2-5 oligo(alkyleneamino) acid units having the general structure 5. The polymer can optionally have the same oligo(alkyleneamino)acid units recurring or may also have a combination of varying oligo(alkyleneamino)acid units recurring.

As illustrated above in the general structure 5, said oligo(alkyleneamino) acid units preferably comprise of 2 - 7 alkyleneamine monomers wherein one alkyleneamine monomer is

covalently linked to a monocarboxylic acid. Preferably said alkyleneamine monomer is selected from the group: Ethyleneamine, propyleneamine, butyleneamine, pentylenamine and

hexyleneamine. Preferably said carboxylic acid is an aliphatic carboxylic acid selected from the group acetic acid, propionic acid, butanoic acid, pentanoic acid, hexanoic acid, heptanoic acid, octanoic acid and nonaoic acid.

In another embodiment, Z is an alkyl group wherein the number c of methylene (CH2) groups is 0-8; R is a methylene group; and the number a of alkyleneamino ((CH2)b NH) groups is 2-7, wherein the number b of methylene (CH2) groups is 2. Accordingly said

wherein a: 2-7, c: 0-8. GENERAL STRUCTURE 6

Said polymer comprises 2-60 oligo(ethyleneamino) acid units having the general structure 6, preferably 2-10 oligo(ethylenamino) acid units having the general structure 6, most preferably 2-5 oligo(ethylenamino) acid units having the general structure 6.

As illustrated above in the general structure 6, said oligo(ethyleneamino) acid units preferably comprise of 2 to 7 ethyleneamine monomers wherein one ethyleneamine monomer is covalently linked to a carboxylic acid. Preferably said carboxylic acid is an aliphatic carboxylic acid selected from the group acetic acid, propionic acid, butanoic acid, pentanoic acid, hexanoic acid, heptanoic acid, octanoic acid and nonaoic acid.

As stated above, substituent Z of the oligo(alkyleneamino) acid units are selected from an alkyl group, an amino group or an aromatic group. Below preferred but not limiting

embodiments are described wherein Z is an amino group of the general structure , wherein the number n of methylene groups is 1-7. Preferably, R is a carbonyl group. In one preferred option, R is a carbonyl group and n is 1 or 2.

In one embodiment said oligo(alkyleneamino) acid polymers has the formula

The oligo(alkyleneamino) acid polymers and derivatives described above are preferably synthesized by solid phase synthesis. The oligo(alkyleneamino) acid polymers provided herein are defined monodisperse molecules of low toxicity with the ability to noncovalently bind nucleic acids. Nucleic acids bear anionic groups and can form an ionic bond with the polymers of this invention. The protonation of the alkyleneamine subunits of the polymers is pH dependent, therefore the payload is released specifically from the endosome. Hence in a preferred embodiment the oligo(alkyleneamino) acid polymers comprise a nucleic acid complexed or covalently conjugated to the polymer. Therefore the oligo(alkyleneamino) acid polymers of the invention are potent carrier molecules useful for the delivery of nucleic acids. In addition, the oligo(alkyleneamino) acid polymers can be designed according to the different requirements for the delivery of various nucleic acid species and are thus useful for the delivery of such different nucleic acid species like DNA, RNA, siRNA, LNA, PNA and others.

To meet the certain needs required for the successful in vivo delivery of nucleic acids, the oligo(alkyleneamino) acid polymers of the invention can be further modified. Targeted nucleic acids frequently accumulate in endosomes from which they need to escape to be active. It is known that the delivery of the nucleic acid into the cytoplasm can be facilitated by the addition of hydrophobic structures to the carrier molecule, as these hydrophobic structures increase the ability of the carrier to lyse lipid membranes. Due to the acidic environment of the endosomal/lysosomal compartments it is crucial for a nucleic acid delivery carrier to display a low buffering capacity at physiological pH values and a high buffering capacity at endosomal/lysosomal pH, thus facilitating selective endosomal/lysosomal membrane disruption. In one preferred embodiment of the invention the oligo(alkyleneamino) acid polymers additionally comprise a hydrophobic domain, which provides a pH-responsive lytic activity.

The hydrophobic domain comprises either multiple hydrophobic amino acid residues, such as leucine, valine, isoleucine, tyrosine or phenylalanine, or at least one fatty acid, such as, for example, myristic acid, palmitic acid, arachidic acid or other fatty acids. Preferred fatty acids

include but are not limited to butyric acid, caprylic acid, myristic acid, oleic acid, linolic acid, arachidic acid, stearic acid, lauric acid and palmitic acid. Additionally, linker groups, between the hydrophobic domain and the oligo(alkyleneamino) acid polymer are also part of the invention. Preferably such linker groups are amino acids, most preferably lysine (for stable linkage) or cysteine (for bioreducible linkage). The use of naturally occurring amino acids or fatty acids is preferable to other hydrophobic moieties because they are relatively non- immunogenic and non-toxic. In addition, other hydrophobic domains such as hydrocarbon chains (saturated or unsaturated long chain aliphatic alcohols or thiols), stabilizing siRNA complexes and supporting endosome escape can be covalently linked to the polymers of the invention. The hydrophobic domain described above is preferably covalently linked to the oligo(alkyleneamino) acid polymers of the invention.

In one embodiment, said hydrophobic domain is linked to the amine group at the N- terminus of the oligo(alkyleneamino) acid polymer, resulting in an i-shape as illustrated in figure 1 b. In other embodiments, said hydrophobic domain is connected to the N- terminus of the oligo(alkyleneamino) acid polymer through a linker group. Said linker group is covalently linked to the amine group at the N-terminus of the polymer and comprises preferably at least one amino acid. Preferably said at least one amino acid is selected from the group of: one lysine, two lysines covalently linked to each other via an amide bond, a cysteine and a lysine covalently linked to each other via an amide bond, and two cysteines covalently linked to each other via an amide bond.

In one embodiment the hydrophobic domain consists of two fatty acids covalently linked to a lysine residue via an amide bond using both amino functions. The lysine residue is either covalently connected to the N-terminus of the oligo(alkyleneamino) acid polymer via its carboxyl group, or covalently linked to the N-terminus of another aminoacid which is then connected to the N-terminus of the oligo(alkyleneamino) acid polymer via its carboxyl group. This second amino acid of the linker is preferably a lysine or a cysteine, as stated above. Said cysteine can be part of a crosslinking domain as stated below (see also Figure 1 d).

Other linker groups envisaged are amino acids with thiol groups such as cysteine. In this embodiment the hydrophobic domain is covalently linked to cysteine residues at the N-terminus of the oligo(alkyleneamino) acid polymer via a disulfide linkage.

In other embodiments said hydrophobic domain is covalently linked to two oligo(alkyleneamino) acid polymer chains of the invention, resulting in a t-shape as illustrated in figure 1 e. Preferably, said hydrophobic domain is connected to the oligo(alkyleneamino) acid polymers through a linker group. Said linker group is covalently linked to the two oligo(alkyleneamino) acid polymers via the amine group at the N-terminus or the carboxygroup at the C-terminus and comprises preferably at least one amino acid. Preferably said at least one amino acid is selected from the group of: one lysine, two lysines covalently linked to each other via an amide bond, a cysteine and a lysine covalently linked to each other via an amide bond, and two cysteines covalently linked to each other via an amide bond.

In one embodiment, said linker group is lysine, which is covalently linked to the amine group at the N-terminus of a first oligo(alkyleneamino) acid polymer chain and covalently linked to the carboxygroup of the C-terminus of a second oligo(alkyleneamino) acid polymer chain, and which is covalently linked via its second amine group with one fatty acid. In other embodiments, the second amine group is covalently linked to the carboxygroup of a lysine group, which is covalently linked to two fatty acids via an amide bond using both amino functions.

Apart from the t-shaped polymers described above, other branched oligo(alkyleneamino) acid polymers are also part of this invention.

A key requirement for efficient transport using synthetic nucleic acid delivery systems is their ability to compact nucleic acids and the formation of stable polyplexes suitable for the efficient delivery to and into the cell. The nucleic acid compacting ability of polymers is strongly influenced by charge density, molecular weight and hydrophobic interactions of the polymers with the nucleic acid. Hence, structural modifications of the oligo(alkyleneamino) acid polymers that enhance compaction of the nucleic acid payload and formation of stable polyplexes are part of the invention. In one preferred embodiment, said polymer described above additionally comprises at least one head group which increases binding to the nucleic acid, formulation stability or interaction with lipid membranes.

The head group is preferably covalently linked to the N- or C-terminus of the oligo(alkyleneamino) acid polymers, preferably via a peptide bond. In one preferred embodiment the headgroup preferably comprises a polar positively charged head group, a coupling or crosslinking domain or a polar positively charged head group in the vicinity of a coupling or crosslinking domain.

Said coupling and crosslinking domain facilitates cross-linking of the oligo(alkyleneamino) acid polymers (dimerisation or polymerisation) and the coupling onto macromolecules such as nucleic acids. Thus the coupling or crosslinking domain increases self- stabilisation of oligo(alkyleneamino) acid polymers. The dimerisation/polymerisation of polymer molecules increases the positive charge and the number of aliphatic chains per molecule, which positively influence the transfection efficiency as well as the noncovalent binding of nucleic acids to the polymers. The resulting crosslinked polyplexes (i.e. crosslinked oligo(alkyleneamino) acid polymers) disintegrate after transport into the cell due to the bioreversible nature of the crosslinking. In addition, it is possible to covalently link the nucleic acid to the carrier polymer via the coupling and crosslinking domain.

Said coupling and crosslinking domain preferably comprises a functional group which facilitates bioreversible ligation, and comprises inter alia a cysteine (for disulfide bond formation), tyrosine trimers or oligomers (for noncovalent aromatic stabilization), ureido- pyrimidinones (for noncovalent hydrogen bonding), aldehydes (for imine, oxime or hydrazone formation) or azide (for click chemistry with alkyne groups). In one embodiment, the oligo(alkyleneamino) acid polymer has a coupling domain comprising at least one, preferably two or three cysteine groups (Figure 1 c to Figure 1 f). Preferably the oligo(alkyleneamino) acid polymer comprises two cysteine groups covalently linked via a peptide bond to each terminus of the polymer. In one embodiment, the oligo(alkyleneamino) acid polymer additionally comprises a hydrophobic domain which is covalently linked to one of the terminal cysteine groups, which results in the i-shape topology (Figure 1 d). As stated above, the hydrophobic group is either covalently linked via a peptide bond to the cysteine group directly or via a lysine group that is covalently linked to the cysteine and the hydrophobic group. In another embodiment, a polymer molecule with t-shape conformation is envisaged, comprising two oligo(alkyleneamino) acid polymer chains to each of which a cysteine group is covalently linked to one terminus, said oligo(alkyleneamino) acid polymers being connected via a central linker group, and a lipophilic domain which is covalently linked to the central linker group (Figure 1 e). Preferably said linker

group is at least one amino acid, most preferably one lysine or two lysines covalently linked to each other via a peptide bond. In another embodiment, the oligo(alkyleneamino) acid polymer has a coupling domain comprising at least one, tyrosine trimer, or a tyrosine oligomer comprising 3 to 50, preferably 3 to 10, most preferably 3-5 tyrosines, instead of cysteine groups. The tyrosine groups are linked to said polymers as outlined for cysteine above.

In another embodiment, the oligo(alkyleneamino) acid polymer has a coupling domain comprising at least one, preferably two or three ureido-pyrimidinones instead of cysteine groups. Preferably said ureido-pyrimidinones is 2-(6-Isocyanahexylaminocarbonylamino)-6-methyl- 4(1 H) pyrimidinone (ICH-CAMP). The ureido-pyrimidinones are linked to said polymers as outlined for cysteine above.

In another embodiment, the oligo(alkyleneamino) acid polymer has a coupling domain comprising aldehydes. Preferred aldehydes used herein are aliphatic aldehydes such as propionaldehyde linked at the omega carbon position to the polymer.

In another embodiment, the oligo(alkyleneamino) acid polymer has a coupling domain comprising azides which can be used for coupling with alkynes by click reaction.

In other embodiments, said head group comprises a polar head group. Said polar head group facilitates nucleic acid/formulation stability or lipid membrane interaction and preferably comprises a thiol group, such as cysteine and is preferably flanked by at least one polar positively charged amino acid, such as lysine, arginine or histidin. In one preferred embodiment, said oligo(alkyleneamino) acid polymer comprises a polar headgroup and a hydrophobic domain. In another preferred option, said oligo(alkyleneamino) acid polymer comprises a crosslinking domain and a hydrophobic domain. Said domains are covalently linked to the oligo(alkyleneamino) acid polymer, either directly via the amine group or via a linker group. Said domains can be thus linked to the oligo(alkyleneamino) acid polymer to form a chain, an i- shaped polymer or a t-shaped polymer. In addition, other configurations (branched polymers) are envisaged. One non-limiting example is shown in figure lh. In another embodiment a branched polymer with four or five arms is envisaged, as shown in figure 36.

Further, in one embodiment the oligo(alkyleneamino) acid polymers additionally comprise agents that facilitate other functions in the eukaryotic cell, e.g. receptor recognition (targeting), internalization, release, nucleus localization and systemic in vivo stabilization. Such

agent preferably comprises a targeting ligand, which recognizes tissue specific cell-surface structures, such as receptors. Most preferably said targeting ligand comprises a targeting peptide, a targeting antibody, a protein, a small molecule or a carbohydrate ligand. In one embodiment said targeting ligand is selected from the group of transferrin receptor binding molecules such as transferrin or phage-derived synthetic peptides such as B6, epidermal growth factor (EGF) receptor binding molecules such as EGF or phage derived synthetic peptide GE11, folic acid, cyclic RDG peptide (for binding integrin) and peptide CMP (for binding the hepatocyte growth factor c-Met). In a preferred embodiment said targeting ligand is CMP.

In another embodiment, said agents that facilitate other functions in the eukaryotic cell are selected from agents that facilitate endosomal escape. Preferred therein is the use of endosome-buffering imidazoles such as histidine for enabling endosomal escape. Therefore one or more imidazoles are incorporated in the oligo(alkyleneamino) acid polymer backbone, preferably in form of the amino acid histidine via amide bond formation like in standard peptide synthesis. In another preferred embodiment, non-amino acid forms of imidazoles are incorporated, such as derivatives of 3-aminopropyl-imidazole via amide bond formation. One non-limiting example of a 3-aminopropyl-imidazole derivative is 3-(imidazole)propane amino- Ν,Ν-diacetic acid.

Other agents that facilitate endosomal escape are endosomolytic peptides such as mellitin, Inf7 and cell penetrating peptides such as the TAT peptide or oligoarginine peptide. Thus, in another embodiment said polymer comprises an agent that facilitates endosomal escape chosen from the group of imidazoles and endosomolytic peptides.

In one embodiment said polymer comprises a targeting ligand chosen from the group of a peptide sequence, a vitamin, a proteins, an antibody, or a synthetic chemical receptor-binding ligand. Non-limiting examples of targeting proteins useful herein are EGF and Transferrin. A preferred vitamin is Folic Acid (FolA). Preferred synthetic chemical receptor-binding ligands are anisamide, clenbuterol and iloprost.

In one preferred embodiment, said polymer described above additionally comprises a shielding moiety. Said shielding moiety is useful for in vivo stabilization of the oligo(alkyleneamino) acid polymer/ nucleic acid polyplex while circulating in the blood and to reduce undesired interactions or agglomeration oligo(alkyleneamino) acid polymer/ nucleic acid polyplex and preferably comprises monodisperse or polydisperse polyethylene glycol (PEG).

In one preferred embodiment, said polymer comprises a targeting ligand attached to a monodisperse PEG which is attached to the polymer (Figure 1 g). In one preferred embodiment, a bifunctionally modified PEG chain is attached via a carboxy group to the amino group of a targeting ligand, and the oligo(alkyleneamino) acid polymer is attached to the amino-group of the PEG chain.

For shielding/stabilization purposes a PEG-chain (preferably monodisperse) of a Mw > 1 kDa can be attached at any position of the oligo(alkyleneamino) acid polymer using the epsilon- amino function of lysine or the amino function at the N-terminus, or the carboxy function at the C-terminus. In other embodiments, the oligo(alkyleneamino) acid polymers are combined with lipids, including also PEG-lipids. In another embodiment the oligo(alkyleneamino) acid polymers are combined with transfection reagents. Non-limiting examples of transfection reagents are lipoplexes, liposomes and cationic lipids.

In one preferred embodiment use of the oligo(alkyleneamino) acid polymers and its derivatives for the delivery of nucleic acids are envisaged. Particularly of interest herein is the delivery of siRNA into its target cell. The siRNA can be modified or conjugated to contain functional units such as endosomolytic peptides (such as Inf7) or targeting ligands (such as FolA). Other therapeutic nucleic acids of interest are antisense molecules, microRNAs, microRNA blocking antagomirs, apoptosis-inducing RNAs, immunostimulatory RNAs, messenger RNAs, or DNA molecules encoding gene expression units.

Another embodiment provides a pharmaceutical composition comprising the oligo(alkyleneamino) acid polymers and a nucleic acid, and may further comprise an agent that is complexed to the polymer. In particular, said pharmaceutical composition comprises a oligo(alkyleneamino) acid polymers and an siRNA molecule. These pharmaceutical compositions are particularly useful in the inhibition of the expression of a target gene in a cell, a tissue or an organism. The pharmaceutical composition comprising the oligo(alkyleneamino) acid polymers of the invention may also comprise (a) pharmaceutically acceptable carrier(s), diluent(s) and/or excipient(s). Yet a further embodiment provides a method of treating a mammal, comprising administering the oligo(alkyleneamino) acid polymers complexed with a nucleic acid to a mammal.

Definitions:

The term "nucleic acid" as used herein means an oligomer or polymer composed of nucleotides, e.g., deoxyribonucleotides or ribonucleotides, or compounds produced synthetically (e.g., PNA as described in U.S. Pat. No. 5,948,902 and the references cited therein) which can hybridize with naturally occurring nucleic acids in a sequence specific manner analogous to that of two naturally occurring nucleic acids, e.g., can participate in Watson-Crick base pairing interactions. Non-naturally occurring nucleic acids are oligomers or polymers which contain nucleobase sequences which do not occur in nature, or species which contain functional equivalents of naturally occurring nucleobases, sugars, or inter-sugar linkages, like peptide nucleic acids (PNA), threose nucleic acids (TNA), locked nucleic acids (LNA), or glycerol nucleic acids (GNA). This term includes oligomers that contain the naturally occurring nucleic acid nucleobases adenine (A), guanine (G), thymine (T), cytosine (C) and uracil (U), as well as oligomers that contain base analogs or modified nucleobases. Nucleic acids can derive from a variety of natural sources such as viral, bacterial and eukaryotic DNAs and RNAs. Other nucleic acids can be derived from synthetic sources, and include any of the multiple oligonucleotides that are being manufactured for use as research reagents, diagnostic agents or potential and definite therapeutic agents. The term includes oligomers comprising of a single strand nucleic acid or a double strand nucleic acid.

The term "siRNA" as used herein refers to double- stranded RNA molecules (dsRNA) capable of blocking gene expression in a highly conserved regulatory mechanism known as RNA interference (RNAi). The term "double-stranded RNA", "dsRNA molecule", or "dsRNA", as used herein, refers to a ribonucleic acid molecule, or complex of ribonucleic acid molecules, having a duplex structure comprising two anti-parallel and substantially complementary nucleic acid strands. The dsRNAs may comprise naturally occurring nucleotides or at least one modified nucleotide, such as a 2'-0-methyl modified nucleotide, a nucleotide comprising a 5'- phosphorothioate group, and a terminal nucleotide linked to a cholesteryl derivative or dodecanoic acid bisdecylamide group. 2' modified nucleotides may have the additional advantage that certain immunostimulatory factors or cytokines are suppressed when the inventive dsRNA molecules are employed in vivo, for example in a medical setting. Alternatively and non-limiting, the modified nucleotide may be chosen from the group of: a 2'- deoxy-2'-fluoro modified nucleotide, a 2'-deoxy-modified nucleotide, a locked nucleotide, an abasic nucleotide, 2'-amino-modified nucleotide, 2'-alkyl-modified nucleotide, morpholino

nucleotide, a phosphoramidate, and a non-natural base comprising nucleotide. The two strands forming the duplex structure may be different portions of one larger RNA molecule, or they may be separate RNA molecules. Where the two strands are part of one larger molecule, and therefore are connected by an uninterrupted chain of nucleotides between the 3 '-end of one strand and the 5' end of the respective other strand forming the duplex structure, the connecting RNA chain is referred to as a "hairpin loop". The RNA strands may have the same or a different number of nucleotides. In addition to the duplex structure, a dsRNA may comprise one or more nucleotide overhangs. The nucleotides in said "overhangs" may comprise between 0 and 5 nucleotides, whereby "0" means no additional nucleotide(s) that form(s) an "overhang" and whereas "5" means five additional nucleotides on the individual strands of the dsRNA duplex. These optional "overhangs" are located in the 3' end of the individual strands. As will be detailed below, also dsRNA molecules which comprise only an "overhang" in one the two strands may be useful and even advantageous in context of this invention. The "overhang" comprises preferably between 0 and 2 nucleotides. Most preferably 2 "dT" (deoxythymidine) nucleotides are found at the 3' end of both strands of the dsRNA. Also 2 "U"(uracil) nucleotides can be used as overhangs at the 3' end of both strands of the dsRNA. Accordingly, a "nucleotide overhang" refers to the unpaired nucleotide or nucleotides that protrude from the duplex structure of a dsRNA when a 3'-end of one strand of the dsRNA extends beyond the 5'-end of the other strand, or vice versa. For example the antisense strand comprises 23 nucleotides and the sense strand comprises 21 nucleotides, forming a 2 nucleotide overhang at the 3' end of the antisense strand. Preferably, the 2 nucleotide overhang is fully complementary to the mRNA of the target gene. "Blunt" or "blunt end" means that there are no unpaired nucleotides at that end of the dsRNA, i.e., no nucleotide overhang. A "blunt ended" dsRNA is a dsRNA that is double- stranded over its entire length, i.e., no nucleotide overhang at either end of the molecule. The term "antisense strand" refers to the strand of a dsRNA which includes a region that is substantially complementary to a target sequence. As used herein, the term "region of complementarity" refers to the region on the antisense strand that is substantially complementary to a sequence, for example a target sequence. Where the region of complementarity is not fully complementary to the target sequence, the mismatches are most tolerated outside nucleotides 2-7 of the 5' terminus of the antisense strand

The term "sense strand," as used herein, refers to the strand of a dsRNA that includes a region that is substantially complementary to a region of the antisense strand. "Substantially

complementary" means preferably at least 85% of the overlapping nucleotides in sense and antisense strand are complementary.

As used herein, the term "fatty acid" includes both saturated, i.e. an alkane chain as known in the art, having no double bonds between carbons of the chain and having the maximum number of hydrogen atoms, and unsaturated, i.e. an alkene or alkyne chain, having at least one double or alternatively triple bond between carbons of the chain, respectively, and further terminating the chain in a carboxylic acid as is commonly known in the art, wherein the hydrocarbon chain is not less then four carbon atoms.

The process of delivering a nucleic acid to a cell has been commonly termed transfection or the process of transfecting. The term transfecting as used herein refers to the introduction of a nucleic acid or other biologically active compound from outside a cell to inside cell such the nucleic acid has biologically activity. The nucleic acid may be used for research purposes or to produce a change in a cell that can be therapeutic. The delivery of a nucleic acid can lead to modification of the genetic material present in the target cell. A transfection reagent or delivery vehicle is a compound or compounds that bind(s) to or complex(es) with oligonucleotides and nucleic acids, and mediates their entry into cells.

In vitro transfection reagents, or delivery vehicles, are compounds or compositions of compounds that bind to or complex with nucleic acids and mediate their entry into cells. Examples of transfection reagents include, but are not limited to, protein and polymer complexes (polyplexes), lipids and liposomes (lipoplexes), combinations of polymers and lipids (lipopolyplexes), calcium phosphate precipitates, and dendrimers. Typically, the transfection reagent has a component with a net positive charge that binds to the oligonucleotide's or nucleic acid's negative charge. Cationic transfection agents may also condense large nucleic acids. Transfection agents may also be used to associate functional groups with a nucleic acid. Functional groups include cell targeting signals, nuclear localization signals, compounds that enhance release of contents from endosomes or other intracellular vesicles (such as membrane active compounds), and other compounds that alter the behavior or interactions of the compound or complex to which they are attached (interaction modifiers).

As used herein, a "pharmaceutical composition" comprises a pharmacologically effective amount of a nucleic acid complexed with the oligo(alkyleneamino) acid polymers of the

invention and a pharmaceutically acceptable carrier. However, such a "pharmaceutical composition" may also comprise individual strands of such a nucleic acid molecule. As used herein, "pharmacologically effective amount," "therapeutically effective amount" or simply "effective amount" refers to that amount of a nucleic acid effective to produce the intended pharmacological, therapeutic or preventive result.

The term "pharmaceutically acceptable carrier" refers to a carrier for administration of a therapeutic agent. Such carriers include, but are not limited to, saline, buffered saline, dextrose, water, glycerol, ethanol, and combinations thereof. The term specifically excludes cell culture medium. For drugs administered orally, pharmaceutically acceptable carriers include, but are not limited to pharmaceutically acceptable excipients such as inert diluents, disintegrating agents, binding agents, lubricating agents, sweetening agents, flavoring agents, coloring agents and preservatives as known to persons skilled in the art.

It is in particular envisaged that the pharmaceutically acceptable carrier allows for the systemic administration of the nucleic acids complexed with the oligo(alkyleneamino) acid polymers of this invention. Whereas also the enteric administration is envisaged the parenteral administration and also transdermal or transmucosal (e.g. insufflation, buccal, vaginal, anal) administration as well was inhalation of the drug are feasible ways of administering to a patient in need of medical intervention the compounds of this invention. When parenteral administration is employed, this can comprise the direct injection of the compounds of this invention into the diseased tissue or at least in close proximity. However, also intravenous, intraarterial, subcutaneous, intramuscular, intraperitoneal, intradermal, intrathecal and other administrations of the compounds of this invention are within the skill of the artisan, for example the attending physician.

For intramuscular, subcutaneous and intravenous use, the pharmaceutical compositions of the invention will generally be provided in sterile aqueous solutions or suspensions, buffered to an appropriate pH and isotonicity. In a preferred embodiment, the carrier consists exclusively of an aqueous buffer. In this context, "exclusively" means no auxiliary agents or encapsulating substances are present which might affect or mediate uptake of nucleic acids in the cells. Aqueous suspensions according to the invention may include suspending agents such as cellulose derivatives, sodium alginate, polyvinyl-pyrrolidone and gum tragacanth, and a wetting agent such as lecithin. Suitable preservatives for aqueous suspensions include ethyl and n-propyl p-hydroxybenzoate.

The term "oligo(alkyleneamino) acid polymer" as used herein includes all variations and derivatives of polymers formed by oligo (alkylenamino) acid units of the general structure

Z is chosen from either an alkyl group with the general structure L J , wherein c

NH2 is 0-8; or an amino group with the eneral structure , wherein n is 1-7; or an aromatic

group with the structure

, or either CH2 or C=0; and a is 1-7 and b is 2-7. The oligo (alkyleneamino) acid units of the polymer are covalently linked via the terminal carboxygroup of a first oligo (alkyleneamino) acid unit and a terminal aminegroup of a second oligo(alkyleneamino) acid unit. Thus, the polymer comprises oligo (alkyleneamino) acid units covalently linked to each other via an amide bond, and is terminated by a free carboxyl group (- COOH) at the one end and terminated by a free amine group (-NH2) at the other end. Hence the polymer has a C (carboxy) terminus and an N (amino) terminus.

Said polymer comprises 2-60 oligo(alkyleneamino) acid units having the general structure 1, preferably 2-10 oligo(alkyleneamino) acid units having the general structure 1, most preferably 2-5 oligo(alkyleneamino) acid units having the general structure 1. The polymer can optionally have the same oligo(alkyleneamino)acid units recurring or may also have a combination of varying oligo(alkyleneamino)acid units recurring.

In other embodiments said polymer comprises identical oligo(alkyleneamino)acid units and at least one amino acid recurring, in yet other embodiments said polymer comprises a combination of varying oligo(alkyleneamino)acid units and at least one amino acid recurring.

A oligo(alkyleneamino) acid polymer can comprise more than one chain. Where the two oligo(alkyleneamino) acid polymer chains are connected covalently by means other than an uninterrupted chain of oligo(alkyleneamino) acid units, the connecting structure is referred to as a "linker". Mostly the linker is at least one amino acid. Through introduction of a linker into the oligo(alkyleneamino) acid polymer, branching of the oligo(alkyleneamino) acid polymer is possible. One example of a branched oligo(alkyleneamino) acid polymer is a t-shape, wherein two oligo(alkyleneamino) acid polymer chains are connected through an amino acid, to which a hydrophobic domain is covalently linked via another linker amino acid group. In addition to the t-shape, other branched oligo(alkyleneamino) acid polymers are envisaged with the oligo(alkyleneamino) acid polymer comprising 1-8 amino acids as branching points, preferably lysines and cysteines. To these branching points within the oligo(alkyleneamino) acid polymer, more oligo(alkyleneamino) acid polymer chains are attached either on solid-phase or in solution, resulting in a multiple branched oligo(alkyleneamino) acid polymer.

If not stated otherwise all domains are connected by peptide bonds, linking the carboxy term of the domain covalently to the oligo(alkyleneamino) acid polymer. The peptide bond is the preferred option but can be substituted by bond types stable to the conditions of peptide synthesis either on solid-phase or in solution e.g. disulfide bond, Huisgen cycloaddition product: 1,2,3- triazole.

The term "head group" as used herein refers to any functional group covalently linked to the C or N-terminus of the oligo(alkyleneamino) acid polymer, preferably at the N-terminus, which increases binding to the nucleic acid, formulation stability or interaction with lipid membranes. The head group can either be a polar positively charged head group, a coupling or crosslinking domain or a polar positively charged head group in the vicinity of a coupling or crosslinking domain. Therefore the term "polar positively charged head group" refers to any polar positively charged functional group covalently linked to the C- or N-terminus of the oligo(alkyleneamino) acid polymer. Non-limiting examples of polar positively charged functional groups are thiol groups, such as cysteine, and polar positively charged amino acids like lysine, arginine or histidine. The term "coupling or crosslinking domain" refers to any functional group covalently linked to the C- or N-terminus of the oligo(alkyleneamino) acid

polymer which enables crosslinking of the oligo(alkyleneamino) acid polymer (dimerisation or polymerisation). Said crosslinking is preferably bioreversible, therefore preferred functional groups of a crosslinking domain are disulfide-forming cysteine, oxime- or imine-forming aldehydes, or hydrazone-forming hydrazines. Said crosslinking can also be noncovalent, for example hydrogen bonding by ureido-pyrimidinones, or aromatic stabilization by tyrosine trimers.

The term "shielding moiety" as used herein refers to any moities that can be attached to the oligo(alkyleneamino) acid polymer resulting in a macromolecular structure to reduce unspecific interactions, uptake and agglomeration tendencies. For example a PEG-chain (preferably monodisperse) of a Mw > 1 kDa can be attached at any position of the polymer sequence using the gamma-amino function of lysine or the N-terminus and provide effiecient shielding of the oligo(alkyleneamino) acid polymer.

The term "hydrophobic domain" as used herein refers to highly hydrophobic functional groups covalently attached of the oligo(alkyleneamino) acid polymer, preferably to the N- terminus. Highly hydrophobic groups include but are not limited to amino acids or fatty acids. Preferably two fatty acids or a stretch of hydrophobic amino acids are linked to the amino functions of a N-terminal lysine residue or the epsilon amino function of a branching lysine.

Short description of the figures:

Figure 1 - Topological structures of the polymer (a) chain b) - d) i- shape e) t- shape f) branched polymer g) shielded and targeted polymer h) four arm polymer.

Figure 2 - Representative DNA gel-shift assay. Comparison of the gel retardation of DNA of the different PAAs. All polymers were tested at a w/w of 10. Polymers showing no complete retardation at that concentration are shown in increasing concentrations. Picture 1 - 4 dimerizing i-shape family (67, 68, 69, 70); Picture 5 - 7 crosslinking i-shape family (45, 46, 51) 7 w/w 5,10,20; Picture 8 - 11 t-shape family (74, 49, 78, 82); 12 - 14 crosslinking chains family (72, 76, 80) w/w 5, 10.

Figure 3 - Representative RNA gel-shift assay. Comparison of the gel retardation of siRNA of the different PAA families. Picture 1 - 4 dimerizing i-shape family (69, 70, 72, 71) N/P 12, 20; Picture 5 - 8 crosslinking i-shape family (50, 45, 46, 51) N/P 12, 20; Picture 9 - 12 t-shape family (49, 76, 80, 84) N/P 6, 12.

Figure 4 - Dynamic light scattering. Particle formation study of in vivo applied polymeric carrier systems. N/P ratio: molar ratio of protonable polymer nitrogens to DNA phosphates.

Figure 5 - Erythrocyte leakage assay. Analysis of the lytic activity of the polymers at a concentration of 5 μΜ by erythrocyte leakage assay at different pHs. Figure 6 - Cell viability assay and Luciferase reporter gene expression. Numbers in brackets depict ID numbers of polymers tested, (a) Reporter gene expression and metabolic activity of cells 24 h after transfection with pCMVLuc (Plank C, Zatloukal K, Cotten M, Mechtler K, Wagner E. Bioconjug Chem. 1992, 3:533-9.) using i-shape PAA carrier systems, (b) Reporter gene expression and metabolic activity of cells 24h after transfection with pCMVLuc using t- shape PAA carrier systems (c) Reporter gene expression and metabolic activity of cells 24 h after transfection with pCMVLuc using non hydrophobical modified t-shape PAA carrier systems.

Figure 7 - Cell viability assay and Luciferase reporter gene silencing, (a) i- shapes. Comparison of different FA modifications (Polymer ID 45: C-Stp3-C-K-MyrA2, Polymer ID 46: C-Stp3-C-K- 01eA2, Polymer ID 51: C-Stp3-C-K) - "Luc siRNA": SEQ ID No 1/2 , "Mut siRNA": SEQ ID No. 3/4 (b) t-shapes. Comparison one FA vs. 2FA (Polymer ID 58: C-Stp2- K(01eA)-Stp2-C, Polymer ID 49: C-Stp2-K-(K-01eA2)- Stp2-C) "Luc siRNA": SEQ ID No 1/2 , "Mut siRNA": SEQ ID No. 3/4 (c) Dimer-forming PAAs. (Polymer ID 72: C-Stp2-K- 01eA2, Polymer ID 71: C-K-Stp2-K-01eA2), "Luc siRNA": SEQ ID No 1/2 , "Mut siRNA": SEQ ID No. 3/4 (d) TShape, Comparison on two different cell lines (Polymer ID 49: C-Stp2-K- (K-01eA2)-Stp2-C), "Luc siRNA": SEQ ID No 5/6 , "Mut siRNA": SEQ ID No. 7/8 (e) siRNA Knockdown comparison of two cross-linking i-shape homologues (Stp-backbone Polymer ID 46: C-Stp3-C-K-01eA2 vs. Gtp-backbone Polymer ID 213: C-Gtp3-C-K-01eA2). "Luc siRNA": SEQ ID No 5/6 , "Mut siRNA": SEQ ID No. 7/8. Figure 8 - Luciferase reporter gene expression of targeted polymers/cell viability (a) Reporter gene expression 24 h after transfection with targeted and shielded carrier systems. HUH7 cells were transfected using 200 ng pCMVLuc (2 μg/mL DNA) plasmid. Polyplexes were prepared at different w/w ratios and compared to standard LPEI polyplexes. Luciferase reporter gene expression is presented as mean value + SD of quintuplicates. (b) Metabolic activity of transfected cells 24 h after transfection with targeted and shielded carrier systems. HUH7 cells were transfected using 200 ng pCMVLuc (2 μg/mL DNA) plasmid.

Polyplexes were prepared at different w/w ratios and compared to standard LPEI polyplexes. Metabolic activity was measured by MTT assay and is presented as mean value + SD of quintuplicates.

Figure 9 - In vivo luciferase reporter gene expression in different organs (He, heart; Lu, lung; Li, liver; Sp, spleen; Ki, kidney; Tu, tumor; Mu, muscle; Va, isolated blood vessel ) after systemic application. Systemic gene transfer in tumor bearing mice was carried out using polyplexes containing 50 μg pEGFPLuc DNA (Clontech Laboratories, Mountain View, CA) per 20 g body weight at a concentration of 200 μg/mL DNA in HBG and a polymer/DNA w/w ratio of 10. Results for polymers 46 (Figure 9 a) , 49 (Figure 9 b), 82 (Figure c) are shown. Figure 10 - Cell viability assay and Luciferase reporter gene expression in Neuro2A GFPLuc cells with Ptp-containing i- shapes, (a) Polymer ID 364: C-K-Ptp2- K- 01eA2, Polymer ID 365: C-Ptp3-C-K-01eA2 (b) Polymer ID 367: C-Gtt2-Ptp-C-K- 01eA2, Polymer ID 368: C-Stp-Gtt-Ptp-C-K-01eA2, Polymer ID 370: C-Gtp-Ptp2-C-K- 01eA2.N/P ratios are as indicated. "GFP" siRNA: SEQ ID No 5/6 , "control" siRNA: SEQ ID No. 7/8. Figure 11 - Cell viability assay and Luciferase reporter gene expression in Neuro2AGFPLuc cells with optimised siRNA carriers, (a) Polymer ID 230 (b) Polymers ID 199, ID 386, ID 277 (c) Polymers ID280, ID278, ID 352 (d) Polymer ID279. N/P ratios are as indicated. "GFP" siRNA: SEQ ID No 5/6 , "control" siRNA: SEQ ID No. 7/8.

Figure 12 - Luciferase gene expression and cell viability after transfection of (a,b) Neuro2A or (c,d) HUH7 cells. Transfections (a,c) and viability assays (b,d) were performed as described for "Luciferase reporter gene expression" and "Cell viability assay (MTT Assay)". Cells were transfected with polymers ID23: K-Stp5-K; ID286: A- K-(K-(Stp)2)2; ID287: A-K- (K-(Stp2)2)2; ID288: A-K-(K-(Stp3)2)2; ID289: A-K-(K- (Stp4)2)2.

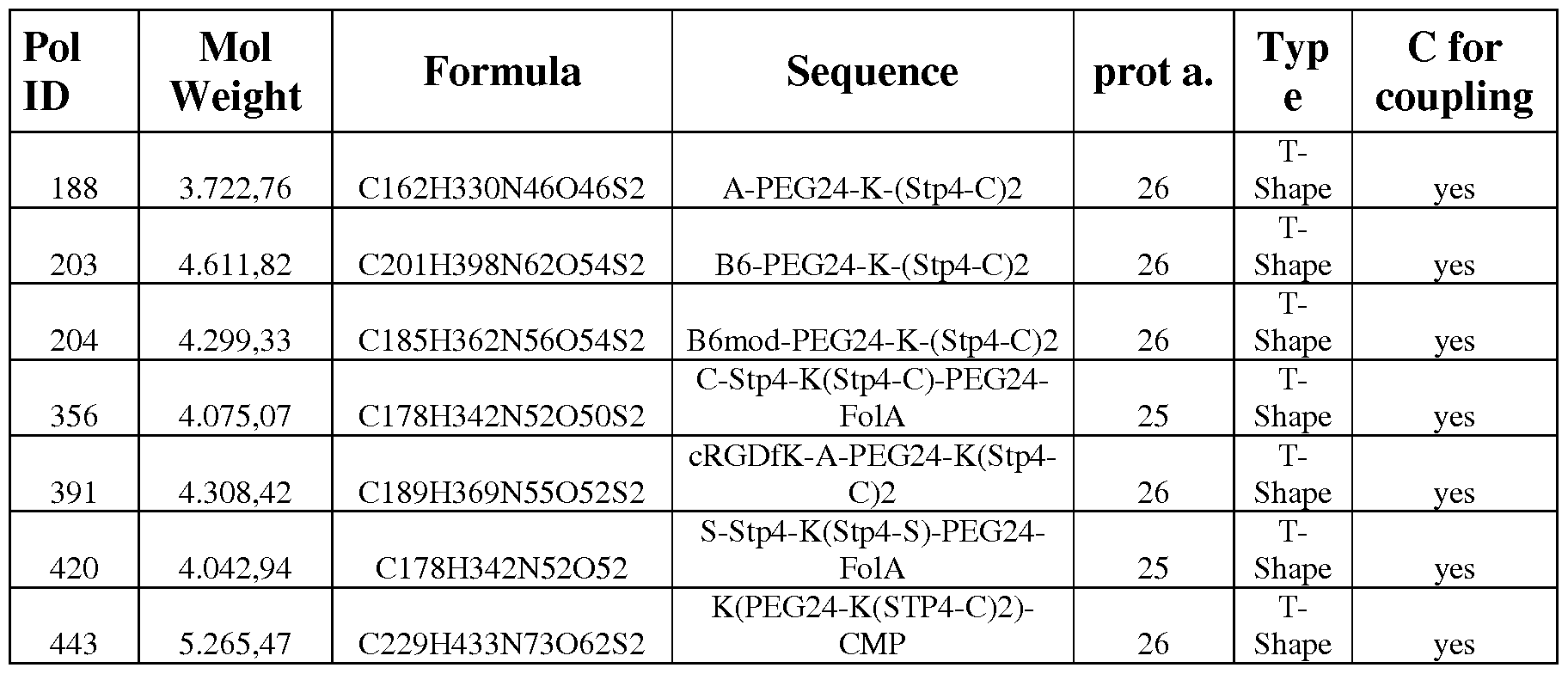

Figure 13 - Luciferase gene expression after transfection of cells using transferrin receptor targeting. Neuro2A-cells were transfected with B6-PEG24-K-(Stp4-C)2, #203 (targeting transferrin receptor) or B6mod-PEG24-K-(Stp4-C)2, #204 (modified non targeting sequence) in different N/P ratios as indicated and treated with chloroquine lh after transfection.

Figure 14 - Luciferase gene expression after transfection of cells using ανβ3 integrin receptor targeting. Dul45-cells were transfected with cRGDfK-A-PEG24-K-(Stp4-C)2, #391

(targeting for α νβ3 integrin receptor) or A-PEG24-K-(Stp4-C)2, #188 (non targeted sequence) in different N/P ratios as indicated and treated with chloroquine lh after transfection.

Figure 15 - Luciferase gene expression after transfection of cells using folic acid receptor targeting. IGROV-cells were transfected with FolA-PEG24-K-(Stp4-C)2, #356 (targeting for folic acid receptor) or A-PEG24-K-(Stp4-C)2, #188 (non targeted sequence) in different N/P ratios as indicated and either not treated or treated with chloroquine lh after transfection.

Figure 16 a - Cell viability assay and luciferase reporter gene silencing in KB-eGFPLuc cells with FolA-siRNA /siRNA at indicated % ratios using Polymer ID 233 as carrier system. As control FolA-siRNA was transfected without polymer. "GFP" siRNA: SEQ ID No 5/6 , "siControl" siRNA: SEQ ID No. 7/8.

Figure 16 b - Transfection via folate receptor targeting using ligand bound PAA and endosomolytic siRNA. Transfection of KB-EGFPLuc cells with functional polymer ID 356 in combination with Inf7 -GFP- siRNA (a), functional polymer ID 356 in combination with GFP- siRNA (b), control polymer ID 188 without ligand in combination with Inf7-GFP-siRNA (c), control polymer ID 420 with serines instead of cysteines in combination with Inf7-GFP-siRNA (d) or functional polymer ID 356 in combination with Inf7-Control-siRNA (e) at indicated N/P ratios. Transfections were performed using 250ng siRNA.

Figure 17 - Erythrocyte leakage assay. Analysis of the lytic activity of free Inf7 and Inf7 covalently attached to siRNA at a concentration of 5 μΜ at different pHs. Figure 18 - Cell viability assay and Luciferase reporter gene silencing, (a) Reporter gene expression 48 h after transfection of endosomolytic siRNA with i-shape or t-shape carrier system. Neuro2A-eGFPLuc cells were transfected using 500 ng siGFP/ siGFP-Inf7/ siGFP- DMMAnMel (5 μg/mL siRNA). Polyplexes were prepared at different N/P ratios as indicated using i-shape (#46) and t-shape (#49) structures. Luciferase reporter gene expression is presented as relative mean value + SD of triplicates. Expression level of HBG treated cells was set to 100%. (b) Metabolic activity of transfected cells 48 h after transfection of endosomolytic siRNA with i-shape or t-shape carrier system. Neuro2A-eGFPLuc cells were transfected using 500 ng siGFP/ siGFP-Inf7/ siGFP-DMMAnMel (5 μg/mL siRNA). Polyplexes were prepared at different N/P ratios as indicated using i-shape (#46) and t-shape (#49) structures. Metabolic

activity was measured by MTT assay and is presented as rel. mean value + SD of triplicates. Metabolic activity of HBG treated cells was set to 100%.

Figure 19 - Cell viability assay and Luciferase reporter gene silencing. Comparison of knockdown efficiency of siRNA and endosomolytic siRNA. Neuro2A eGFPLuc cells were treated with siGFP and siCtrl mixted with polymer #76 or siGFP-Inf7 and siCtrl-Inf7 mixed with polymer #76 in different N/P ratios as indicated.

Figure 20 - Transfection via transferrin receptor targeting using ligand bound PAA and endosmolytic siRNA. (a) Transfection of DU145-eGFPLuc cells with functional polymer #203 containing functional targeting ligand. Comparison of transfection efficiency with endosomolytic or nonmodified siRNA (b) Transfection of DU145-eGFPLuc cells with functional polymer #204 containing nonfunctional targeting ligand. Comparison of transfection efficiency with endosomolytic or nonmodified siRNA (c) Transfection of DU145- eGFPLuc cells with functional polymer #188 without targeting ligand. Comparison of transfection efficiency with endosomolytic or nonmodified siRNA. Figure 21 - Microscopic pictures of stained tumor slices. Slices are prepared as described out of subcutaneous KB tumors from NMRI mice (A) or subcutaneous N2A tumors from A/J mice (B-D). Animals were treated with one intravenous injection of either polymer # 356 in combination with EG5-siRNA (A), polymer #233 in combination with EG5-siRNA-Inf7 (B), polymer #49 in combination with EG5-siRNA-Inf7 (C) or polymer #49 in combination with EG5-siRNA. Arrows mark mitotic figures ("Asters") due to silencing of EG5.

Figure 22 - Luciferase reporter gene silencing after transfection with a T-shape polymers containing a Y3-motif instead of fatty acids. Neuro2A-eGFPLuc cells were either transfected with C-Stp3-K(K-(Y3)2)-Stp3-C ID 304 or K(Stp3-Y3-C)2), ID 331. "GFP siRNA": SEQ ID No 5/6 , "Control siRNA": SEQ ID No. 7/8. Figure 23 - Luciferase reporter gene silencing after transfection with a T-shape polymer containing Y3-motifes instead of cysteines. Neuro2A-eGFPLuc cells were transfected with Y3- Stp2-K(K-01eA2)-Stp2-Y3, ID 332. "GFP siRNA": SEQ ID No 5/6, "Control siRNA": SEQ ID No. 7/8.

Figure 24 - Luciferase reporter gene silencing after transfection with a T-shape polymer containing ICH-CAMP motifes instead of cysteines. Neuro2A-eGFPLuc cells were

transfected with (01eA2-K)K(K(Stp2-ICH-CAMP)2)), ID 354. "GFP siRNA": SEQ ID No 5/6 , "Control siRNA": SEQ ID No. 7/8.

Figure 25 - Luciferase reporter gene silencing after transfection with a T-shape polymer containing ICH-CAMP and Y3 motifes. Neuro2A-eGFPLuc cells were transfected with ((Y3)2-K)K(K(Stp2-ICH-CAMP)2)), ID 355. "GFP siRNA": SEQ ID No 5/6 , "Control siRNA": SEQ ID No. 7/8.

Figure 26 - Luciferase gene expression and cell viability after transfection of Neuro2A.

Transfections and viability assays were performed as described for "Luciferase reporter gene expression" and "Cell viability assay (MTT Assay)". Cells were transfected with polymers ID402: A-K-(K-(Stp4-C)2)2.

Figure 27 - Luciferase gene expression and cell viability after transfection of Neuro2A.

Transfections and viability assays were performed as described for "Luciferase reporter gene expression" and "Cell viability assay (MTT Assay)". Cells were transfected with polymers ID421: A-K-(K-(Stp5-C)2)2. Figure 28 - Luciferase gene expression and cell viability after transfection of Neuro2A.

Transfections and viability assays were performed as described for "Luciferase reporter gene expression" and "Cell viability assay (MTT Assay)". Cells were transfected with polymers ID424: A-Stp3-K-(K-(Stp3-C)2)2; ID425: A-Stp4-K-(K-(Stp4-C)2)2.

Figure 29 - Luciferase reporter gene silencing. Neuro2A-eGFPLuc cells were transfected with polymer ID392: A- K-(K-(Stp3-C)2)2 at indicated ratios. Black bars: transfection using GFP- siRNA SEQ ID No 5/6, grey bars: transfection using Control-siRNA SEQ ID No. 7/8.

Figure 30 - Luciferase reporter gene silencing. Neuro2A-eGFPLuc cells were transfected with polymer ID414: A-Stp2-K-(K-(Stp2-C)2)2 or ID415: A-C-Stp2-K-(K-(Stp2-C)2)2.at indicated ratios. Black bars: transfection using GFP-siRNA SEQ ID No 5/6, grey bars: transfection using Control-siRNA SEQ ID No. 7/8.

Figure 31 - Luciferase gene expression after transfection of cells using HGF receptor targeting. PC3-cells were transfected with CMP-PEG24-K-(Stp4-C)2, ID443 (targeting HGF receptor c-Met) in different N/P ratios as indicated or A-PEG24-K-(Stp4-C)2, ID 188 (non targeted sequence) in a N/P ratio of 6 and treated with chloroquine lh after transfection.

Figure 32 - Luciferase gene expression after transfection of cells using transferrin receptor targeting and histidine modified polymer. DU145-cells were transfected with "B6-PEG24-K- (Stp4-C)2-HIS", ID 441 (targeting transferrin receptor, containing histidines in polymeric backbone), or "B6-PEG24-K-(Stp4-C)2", ID 203 (targeting transferrin receptor, no histidines in polymeric backbone) in a N/P ratio of 6. A subset of cells was treated with chloroquine lh after transfection as indicated.

Figure 33 - Luciferase gene expression after transfection of cells using HGF receptor targeting and histidine modified polymer. PC3-cells were transfected with "CMP-PEG24-K- (Stp4-C)2-HIS", ID 442 (targeting HGF receptor c-Met, containing histidines in polymeric backbone) or "CMP-PEG24-K-(Stp4-C)2", ID 443 (targeting HGF receptor c-Met, no histidines in polymeric backbone) in different N/P ratios as indicated. A subset of cells was treated with chloroquine lh after transfection as indicated.

Figure 34 - Luciferase gene expression after transfection of cells using transferrin receptor targeting and histidine modified polymer. DU145-cells were transfected with "CMP-PEG24- K-(Stp4-C)2-HIS", ID 442 (targeting HGF receptor c-Met, containing histidines in polymeric backbone) in different N/P ratios as indicated. A subset of cells was treated with chloroquine lh after transfection as indicated.

Figure 35 - Reporter gene silencing via targeted siRNA. KB-EGFPLuc cells were treated with FolA-PEG24-triazol-s-s-siPvNA (using FolA for folate receptor targeting) mixed in different ratios with unmodified siRNA at indicated amounts (% of modified siRNA). For transfection, polyplexes were formed with polymer ID386 at N/P ratio 20.

Figure 36 - Topological structures of four and five arm polymers

Examples:

Abbreviations A/J mice Strain A of the Jackson Laboratory

Bisboc bis-tert-butoxycarbonyl

Bistfa bis-trifluoroacetyl

Boc tert-butoxycarbonyl

Boc-Cys(trt)-OH Na-Boc-S-trityl-L-cysteine, N-(tert-Butoxycarbonyl)-S-trityl-L- cysteine

C, Cys cysteine

CMP c-Met binding peptide

cRGDfK See RGD (real structure: cyclicRGD, f: (D)-Phenylalanine, K:

Lysine)

CuBr Copper(I) bromide

DAPI 4' ,6-Diamidin-2' -phenylindoldihydrochlorid

DBU l,8-diazabicyclo[5.4.0]undec-7-ene

DCM Dichloromethane

dde-Lys(fmoc)OH Na-(4-4-Dimethyl-2,6-dioxocyclohex-l-ylidene)ethyl-N-e-(9- fuorenylmethyloxycarbonyl)-L-lysine

DIPEA Di-isopropylethyleneamine

DMF Dimethylformamide

DMMAnMel 2,3-Dimethylmaleic anhydride modified mellitin

EG5 Kinesin 11 gene, kinesin spindle protein (KSP) gene

EtOAc Ethyl acetate

FA fatty acid

Fmoc (9-Fluorenylmethoxycarbonyloxy)

Fmoc-Gtp-OH l-(9-Fluorenylmethoxycarbonylamino)-3,6,9-tris(tert- butoxycarbonyl)- 13-oxo-3,6,9, 12-tetraazaheptadecan-17-oic acid

Fmoc-Gtt-OH l-(9-Fluorenylmethoxycarbonylamino)-3,6,-bis(tert- butoxycarbonyl)- 10-oxo-3,6,9-triazatetradecan- 14-oic acid

Fmoc-His(Trt)-OH Fmoc-Nim-trityl-L-histidine

Fmoc-Lys(ivDDE)-OH Fmoc-Ne-l-(4,4-dimethyl-2,6-dioxocyclohex-l-ylidene)-3- methylbutyl-L-lysine

Fmoc-Osu N-(9-Fluorenylmethoxycarbonyloxy) succinimide

Fmoc-Stp(boc3)-OH l-(9-Fluorenylmethoxycarbonylamino)-3,6,9-tris(tert- butoxycarbonyl)- 13-oxo-3,6,9, 12-tetraazahexadecan-16-oic acid FolA folic acid

Gtp Glutaryl tetraethylenepentamine

Gtt Glutaryl triethylenetetramine

HATU 2-(lH-7-Azabenzotriazol-l-yl)-l,l,3,3-tetramethyl uronium HFIP

Hexafluoro-2-propanol

HOAt (l-Hydroxy-7-azabenzotriazole)

HOBt Hydroxybenzotriazole hexafluorophosphate

ICH-CAMP 2-(6-Isocyanahexylaminocarbonylamino)-6-methyl-

4(lH)pyrimidinone

INF7 Influenza peptide

K, Lys lysine

KB cells Human cervix carcinoma cell line

LinA Linoleic acid

MTBE Methyl tert-butyl ether

NMRI mice Rj:NMRI-nu (nu/nu) (Naval Medical Research Institute)

OAA oligo (alkylene amino) acids

OleA Oleic acid

PAA polyamide polymers

PEG24 poly(ethylene glycol) containing 24 ethylenoxide monomers

Ptp ortho-Phthaloyl-tetraethylenpentamine

Pybop (Benzotriazol- 1 -yloxy)tripyrrolidinophosphonium

hexafluorophosphate

Pybop/HOBt PyBOP®/l-Hydroxybenzotriazole

RBF Round-bottom flask

RGD avB3 integrin targeting molecule (R: arginine, G: Glycine, D:

Aspartic acid)

SEC size-exclusion chromatography

Stp Succinyl tetraethylenepentamine (l-Amino-13-oxo-3,6,9,12- tetraazahexadecan-16-oic acid)

TBTA Tris [( 1 -benzyl- 1 H- 1 ,2,3-triazol-4-yl)methyl] amine

TEPA Tetraethylenepentamine

TETA Triethylenetetramine

TFA Trifluoroacetic acid

TFA/TIS Trifluoroacetic acid/ Triisopropylsilane

THF Tetrahydrofuran

Trisboc tris-tert-butoxycarbonyl

Y Tyrosine

Y3 Oligotyrosine consisting of 3 monomers

Synthesis of bistfa-trisboc-Tetraethylenepentamine (bistfa-trisboc-TEPA) using tetraethylenepentamine pentahydrochloride

10 g (26.9 mmol) tetraethylenepentamine pentahydrochloride were weighed in a 1 1 round bottom flask and dissolved in 250 ml dichloromethane (DCM) /methanol (2: 1). 18.75 ml (134.5 mmol) triethylamine was added and after stirring for 2 - 12 h the mixture was cooled down to 0 °C. 6.72 ml (56.5 mmol) trifluoroacetic ethyl ester were diluted in dichloromethane (40 ml) and added dropwise over 2 h at 0 °C. The round bottom flask was allowed to warm to room temperature after 2 h and was stirred for another hour. Di-t-butyl dicarbonate (23.4 g, 107.6 mmol) was dissolved in 40 ml dichloromethane (DCM) and added dropwise over one hour. Afterwards 15 ml of triethylamine (107.5 mmol) were added and the mixture was stirred over night. The organic phase was reduced to approximately 150 ml and washed three times with saturated sodium bicarbonate, then three times with 5 % sodium citrate solution and finally three times with water. The organic phase was dried over sodium sulfate and the solvent was evaporated to a yellowish viscous, waxy solid. The residue was recrystallized: Therefore it was dissolved in the minimal amount of dichloromethane (37 ml) which was heated to reflux. Then slowly n-hexane (65 ml) was added to the boiling dichloromethane till clouding could be observed at the drop-in point. The crystallization solution was stored over night at 4 °C. The microcrystalline residue was filtered, washed with cooled n-hexane and dried, yielding 12.48 g (68.0 %) of bistfa-trisboc-tetraethylenepentamine.