US3097828A - Method and apparatus for mixing pulverulent or fine-grain material - Google Patents

Method and apparatus for mixing pulverulent or fine-grain material Download PDFInfo

- Publication number

- US3097828A US3097828A US809404A US80940459A US3097828A US 3097828 A US3097828 A US 3097828A US 809404 A US809404 A US 809404A US 80940459 A US80940459 A US 80940459A US 3097828 A US3097828 A US 3097828A

- Authority

- US

- United States

- Prior art keywords

- container

- pressure

- nozzles

- materials

- mixing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000463 material Substances 0.000 title claims description 32

- 238000002156 mixing Methods 0.000 title claims description 17

- 238000000034 method Methods 0.000 title description 9

- 230000005484 gravity Effects 0.000 claims description 7

- 238000007599 discharging Methods 0.000 claims description 2

- 239000007788 liquid Substances 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- 239000000203 mixture Substances 0.000 description 2

- 235000021028 berry Nutrition 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 238000000265 homogenisation Methods 0.000 description 1

- 230000002045 lasting effect Effects 0.000 description 1

- 210000003141 lower extremity Anatomy 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F33/00—Other mixers; Mixing plants; Combinations of mixers

- B01F33/40—Mixers using gas or liquid agitation, e.g. with air supply tubes

- B01F33/406—Mixers using gas or liquid agitation, e.g. with air supply tubes in receptacles with gas supply only at the bottom

- B01F33/4061—Mixers using gas or liquid agitation, e.g. with air supply tubes in receptacles with gas supply only at the bottom through orifices arranged around a central cone

Definitions

- the novel method of mixing two or more pulverulent or fine-grain materials, wherein the materials are whirled upwards within a closed cylindrical chamber by pressure gas introduced into the said chamber from the bottom and issuing through filter elements in the chamber roof, consists in that the gas under pressure is made to act on the materials for mixing in a plurality of pressure waves each lasting for only a short period of time and following one another at short intervals.

- the intensity of the pressure waves is so dimensioned that at each pressure wave the coarsest particles or the particles of highest specific gravity are put into a suspended state.

- the gas under pressure is expediently blown into the advantageously cylindiical chamber through a ring of nozzles in a plurality of obliquely upward directed part-streams so that the part-streams whirl the material in a rotating manner.

- the time between the successive pressure Waves is advantageously so calculated that the materials whirled upwards by each preceding pressure wave and in so doing mixed with one another have settled again to the bottom of the chamber before the next pressure wave begins or are just completing the settling movement, i.e. the excess pressure built up in the chamber by the preceding pressure wave has approximately reached equilibrium again with the ambient pressure through the filter elements, the intensity and the duration of the successive pressure waves and also the intervals between the individual pressure waves can be varied within a mixing operation.

- the novel method results in whirling the materials upwards several times but in each case for only short periods, the degree of mixing being improved with each further pressure wave, and after a few pressure waves a com.- pletely uniform mixture has already been achieved, and the relatively rapid homogenisation of the mixture is also substantially promoted by the fact that the materials whirled about in rotary movement during a pressure wave fall down again before the succeeding pressure waves, i.e. are always whirled upwards again with succeeding pressure waves.

- the novel method is carried out in an up- 3,097,828 Patented July 16, 1963 right cylindrical container whose bottom portion has a conical shape, the inlet nozzles being arranged in a circle near the lower extremity of the conical bottom portion about the emptying door which closes the said bottom portion, and being directed obliquely upwards in accordance with generatrices of the conical bottom portion.

- the conically tapering bottom portion of the container can also be closed by a comically shaped closure which in the closed position bears against the inner wall of the conical bottom portion and which is constructed as a hollow cone, is adapted to be connected to the source of gas under pressure and is provided near its closure edge with nozzle apertures directed towards the conical bottom portion.

- the novel method can also be used for mixing liquid substances with pulverulent or fine-grain materials, a circle of nozzles penetrating through the container w-all injecting a liquid medium in finely sprayed jets at each pressure wave.

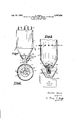

- FIGURE 1 is a side view of 1a first form of embodiment

- FiGURE 2 is a cross-sectional view taken on the line IIIl of FIGURE 1 and FIGURE 3 is an axial sectional view of a second form of embodiment.

- the mixing apparatus consists of a cylindrical container 1 which is situated in an upright position and is closed at the top by a roof 2 and whose lower edge is connected to a downwardly narrowing conical portion 3.

- the end of the conical portion 3 forms an outlet pipe 4 which can be closed by a door 5.

- the door 5 can be operated by an operating handle 6.

- the roof 2 has a filling hole closable by means of a door not shown in the drawings, and is provided with a circle of holes into which cylindrical hose pieces 9 made of filter cloth are inserted.

- the filter hoses 9 are closed at the ends by closure walls 10.

- the conical portion 3 is surrounded at its lower region by an annular pipe 12 which can communicate with a source of compressed air and which is connected by branch pipes 13 to nozzles 14.

- the nozzles 14 project through the conical portion 3 and are so arranged therein that their axes follow approximately the inclination of the wall of the conical portion 3, but are directed obliquely thereto.

- a central nozzle '15 which is situated in alignment with the axis of the cone 3 and which is also connected to the annular pipe 12.

- the outlet 17 of the conical portion 3 is closed by a hollow cone 18 whose base surface diameter is somewhat larger than the diameter of the outlet 17.

- the closure cone 18 when in the closed position bears on the inner wall of the conical portion 3 near the outlet 17.

- the hollow cone 18 is lifted by any desired means.

- the hollowcone 18 is carried by the piston rod 19 of a pressure medium cylinder 20.

- the hollow cone 18 is connected to air pulsing means, diagrammatically indicated in FIG. 3, by a flexible feed pipe 23 which follows the up and down movement of the cone.

- the annular feed pipe 12 of FIG. 1 may be similarly connected to air pulsing means by a connection 24.

- the wall of the hollow cone 18 is provided near its base surface with a circle of nozzles 14 or apertures for accommodating nozzle elements. These nozzles 14 are directed obliquely upwards and obliquely to the axis of the conical portion 3 so that the gas under pressure issuing J from these nozzles imparts a twisting movement to the material which is to be whirled upwards.

- An apparatus for mixing pulverulent materials of different specific gravity comprising, in combination,

- the material in the container is alternately whirled upwardly in the form of a vortex by each pressure wave to mix and distribute the material throughout the cylinder, and the intervals between successive waves cause the material to settle toward the bottom of the container as pressure in the chamber reaches equilibrium due to the pulsing pressure passing through said filter means before the next wave begins.

- a central discharge nozzle is disposed axially of the container and surrounded by said annular series of nozzles.

- an inverted hollow closure cone is disposed within the conical portion of the container

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Nozzles (AREA)

Description

July 16, 1963 G. GRUN METHOD AND APPARATUS FOR MIXING PULVERULENT OR FINE-GRAIN MATERIAL Filed April 28, 1959 Flexible Hose 4 if Pu/s my Means INVENTOR. BY 3 M ATTORNEY United States Patent 3,097,828 METHOD AND APPARATUS FOR lt HXING PUL- VERULENT 0R FINE-GRAIN MATERIAL Gustav Griin, 73 Ortenberger Strasse, Lissberg, Germany Filed Apr. 28, 1959, Ser. No. 809,404 Claims priority, application Germany Apr. 30, 1958 4 Claims. (Cl. 259-4) For mixing two or more pulverulent or fineagrain materials with one another it is known to introduce the materials into a closed container whose lid has outlet apertures closed by filter elements and in whose bottom portion there are mounted nozzles which can be connected to a source of compressed air, and to blow compressed air or a gas under pressure into this container from the bottom. The pulverulent contents of the container are churned upwards and mixed together by sheer turbulence from a stream of. gas under pressure. It may, however, happen that the continual stream of gas under pressure hurls more particularly the materials having a low specific gravity beyond the other materials which have a higher specific gravity, against the container roof .and said materials of lower specific gravity are so pressed against the filter elements by the pressure gas streams which escape through the said elements, that the aim of achieving the most uniform mixing is not attained.

It has now been found that an intimate uniform. mixing can be achieved in a very short period of time if the gas under pressure is made to act on the materials during several brief periods of time following one another at short intervals.

Thus, the novel method, of mixing two or more pulverulent or fine-grain materials, wherein the materials are whirled upwards within a closed cylindrical chamber by pressure gas introduced into the said chamber from the bottom and issuing through filter elements in the chamber roof, consists in that the gas under pressure is made to act on the materials for mixing in a plurality of pressure waves each lasting for only a short period of time and following one another at short intervals.

Advantageously, the intensity of the pressure waves is so dimensioned that at each pressure wave the coarsest particles or the particles of highest specific gravity are put into a suspended state. The gas under pressure is expediently blown into the advantageously cylindiical chamber through a ring of nozzles in a plurality of obliquely upward directed part-streams so that the part-streams whirl the material in a rotating manner.

The time between the successive pressure Waves is advantageously so calculated that the materials whirled upwards by each preceding pressure wave and in so doing mixed with one another have settled again to the bottom of the chamber before the next pressure wave begins or are just completing the settling movement, i.e. the excess pressure built up in the chamber by the preceding pressure wave has approximately reached equilibrium again with the ambient pressure through the filter elements, the intensity and the duration of the successive pressure waves and also the intervals between the individual pressure waves can be varied within a mixing operation.

The novel method results in whirling the materials upwards several times but in each case for only short periods, the degree of mixing being improved with each further pressure wave, and after a few pressure waves a com.- pletely uniform mixture has already been achieved, and the relatively rapid homogenisation of the mixture is also substantially promoted by the fact that the materials whirled about in rotary movement during a pressure wave fall down again before the succeeding pressure waves, i.e. are always whirled upwards again with succeeding pressure waves.

Expediently, the novel method is carried out in an up- 3,097,828 Patented July 16, 1963 right cylindrical container whose bottom portion has a conical shape, the inlet nozzles being arranged in a circle near the lower extremity of the conical bottom portion about the emptying door which closes the said bottom portion, and being directed obliquely upwards in accordance with generatrices of the conical bottom portion. The conically tapering bottom portion of the container can also be closed by a comically shaped closure which in the closed position bears against the inner wall of the conical bottom portion and which is constructed as a hollow cone, is adapted to be connected to the source of gas under pressure and is provided near its closure edge with nozzle apertures directed towards the conical bottom portion.

The novel method can also be used for mixing liquid substances with pulverulent or fine-grain materials, a circle of nozzles penetrating through the container w-all injecting a liquid medium in finely sprayed jets at each pressure wave.

The novel method will be explained in more detail hereinafter with reference to two apparatuses used for carrying it into efliect. In the drawings:

FIGURE 1 is a side view of 1a first form of embodiment,

FiGURE 2 is a cross-sectional view taken on the line IIIl of FIGURE 1 and FIGURE 3 is an axial sectional view of a second form of embodiment.

The mixing apparatus consists of a cylindrical container 1 which is situated in an upright position and is closed at the top by a roof 2 and whose lower edge is connected to a downwardly narrowing conical portion 3. The end of the conical portion 3 forms an outlet pipe 4 which can be closed by a door 5. The door 5 can be operated by an operating handle 6.

The roof 2 has a filling hole closable by means of a door not shown in the drawings, and is provided with a circle of holes into which cylindrical hose pieces 9 made of filter cloth are inserted. The filter hoses 9 are closed at the ends by closure walls 10.

The conical portion 3 is surrounded at its lower region by an annular pipe 12 which can communicate with a source of compressed air and which is connected by branch pipes 13 to nozzles 14. The nozzles 14 project through the conical portion 3 and are so arranged therein that their axes follow approximately the inclination of the wall of the conical portion 3, but are directed obliquely thereto.

Also provided in the plane of the nozzles 14 is a central nozzle '15 which is situated in alignment with the axis of the cone 3 and which is also connected to the annular pipe 12.

In the modified form shown in 'FIGURE 3, the outlet 17 of the conical portion 3 is closed by a hollow cone 18 whose base surface diameter is somewhat larger than the diameter of the outlet 17. The closure cone 18 when in the closed position bears on the inner wall of the conical portion 3 near the outlet 17. For emptying the mixing chamber 1, the hollow cone 18 is lifted by any desired means. In the example of the embodiment, the hollowcone 18 is carried by the piston rod 19 of a pressure medium cylinder 20. The hollow cone 18 is connected to air pulsing means, diagrammatically indicated in FIG. 3, by a flexible feed pipe 23 which follows the up and down movement of the cone. It will also be understood that the annular feed pipe 12 of FIG. 1 may be similarly connected to air pulsing means by a connection 24.

The wall of the hollow cone 18 is provided near its base surface with a circle of nozzles 14 or apertures for accommodating nozzle elements. These nozzles 14 are directed obliquely upwards and obliquely to the axis of the conical portion 3 so that the gas under pressure issuing J from these nozzles imparts a twisting movement to the material which is to be whirled upwards.

Substantially at the height of the plane AA representing the uspension zone which is achieved by providing a specific gas pressure in accordance with the material being treated, it is possible to provide in the wall of the chamber 1 radially directed nozzles 21 which spray a liquid medium in a finely divided state into the suspension zone.

I claim:

1. An apparatus for mixing pulverulent materials of different specific gravity, comprising, in combination,

a cylindrical container providing a single mixing chamber,

a roof for said container and having air outlet filter means,

a downwardly narrowing conical portion at the lower end of the container and having an outlet,

an annular series of nozzles disposed in said conical portion, said nozzles discharging obliquely to the axis of the cylindrical container,

and air pulsing means connected to said nozzles to create successive waves of air pressure of short duration with relatively quiescent materials settling intervals therebetween,

whereby, the material in the container is alternately whirled upwardly in the form of a vortex by each pressure wave to mix and distribute the material throughout the cylinder, and the intervals between successive waves cause the material to settle toward the bottom of the container as pressure in the chamber reaches equilibrium due to the pulsing pressure passing through said filter means before the next wave begins.

2. An apparatus according to claim 1, wherein,

a central discharge nozzle is disposed axially of the container and surrounded by said annular series of nozzles.

3. An apparatus according to claim 1 wherein,

an inverted hollow closure cone is disposed within the conical portion of the container,

and pressure responsive lifting means is connected to the inner side of the cone to raise and lower it relative to the said outlet.

4. A process for mixing powdered or finely granulated material containing particles of light and heavy specific gravity, which consists in,

subjecting said material to intermittent blasts of air in the pattern of a vortex to move the material upwardly in a container about its axis,

and interrupting the blasts to provide periods of quiescence to cause the material to settle to the bottom of the container between successive agitating waves.

References Cited in the file of this patent UNITED STATES PATENTS 1,971,852 Goebels Aug. 28, 1934 2,528,514 Harvey et al Nov. 7, 1950 2,539,847 McGrath Jan. 30, 1951 2,653,801 Fontein et al Sept. 29, 1953 2,688,423 Davis Sept. 7, 1954 2,724,580 Revallier Nov. 22, 1955 2,750,681 Berry June 19, 1956 2,761,769 Elder Sept. 4, 1956 2,844,361 Dilcher et al July 22, 1958 2,884,230 Pyle Apr. 28, 1959 FOREIGN PATENTS 19,427 Great Britain Aug. 31, 1908 of 1907

Claims (1)

1. AN APPARATUS FOR MIXING PULVERULENT MATERIALS OF DIFFERENT SPECIFIC GRAVITY, COMPRISING, IN COMBINATION, A CYLINDRICAL CONTAINER PROVIDING A SINGLE MIXING CHAMBER, A ROOF FOR SAID CONTAINER AND HAVING AIR OUTLET FILTER MEANS, A DOWNWARDLY NARROWING CONICAL PORTION AT THE LOWER END OF THE CONTAINER AND HAVING AN OUTLET, AN ANNULAR SERIES OF NOZZLES DISPOSED IN SAID CONICAL PORTION, SAID NOZZLES DISCHARGING OBLIQUELY TO THE AXIS OF THE CYLINDRICAL CONTAINER, AND AIR PULSING MEANS CONNECTED TO SAID NOZZLES TO CREATE SUCCESSIVE WAVES OF AIR PRESSURE OF SHORT DURATION WITH RELATIVELY QUIESCENT MATERIALS SETTLING INTERVALS THEREBETWEEN, WHEREBY, THE MATERIAL IN THE CONTAINER IS ALTERNATELY WHIRLED UPWARDLY IN THE FORM OF A VORTEX BY EACH PRESSURE WAVE TO MIX AND DISTRIBUTE THE MATERIAL THROUGHOUT THE CYLINDER, AND THE INTERVALS BETWEEN SUCCESSIVE WAVES CAUSE THE MATERIAL TO SETTLE TOWARD THE BOTTOM OF THE CONTAINER AS PRESSURE IN THE CHAMBER REACHES EQUILIBRIUM DUE TO THE PULSING PRESSURE PASSING THROUGH SAID FILTER MEANS BEFORE THE NEXT WAVE BEGINS.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3097828X | 1958-04-30 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3097828A true US3097828A (en) | 1963-07-16 |

Family

ID=8086608

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US809404A Expired - Lifetime US3097828A (en) | 1958-04-30 | 1959-04-28 | Method and apparatus for mixing pulverulent or fine-grain material |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3097828A (en) |

Cited By (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3169664A (en) * | 1962-06-19 | 1965-02-16 | Truetzschler & Co | Supply apparatus for carding machine and method |

| US3179379A (en) * | 1963-01-09 | 1965-04-20 | Grun Gustav | Apparatus for treatment of powdered and granular material |

| US3249263A (en) * | 1963-07-25 | 1966-05-03 | Phillips Petroleum Co | Particulate material feeding |

| US3285157A (en) * | 1962-10-04 | 1966-11-15 | Hupp Corp | Roasting and heating apparatus |

| US3332780A (en) * | 1966-01-24 | 1967-07-25 | Hupp Corp | Method for cooling roasted coffee |

| US3411666A (en) * | 1965-06-09 | 1968-11-19 | Bergwerksverband Gmbh | Method and apparatus for successively metering identical quantities of particulate material |

| US3531093A (en) * | 1968-03-26 | 1970-09-29 | Susanna Mikhailovna Karpacheva | Device for pulsating mixing of liquid reagents and liquid-and-solid reagents |

| US3637135A (en) * | 1968-04-26 | 1972-01-25 | Atlas Copco Ab | Method of and apparatus for spray coating components |

| US3756475A (en) * | 1971-03-25 | 1973-09-04 | R Emery | Method of improving flow of particulate material |

| US3793742A (en) * | 1972-04-03 | 1974-02-26 | Universal Dynamics Corp | Hopper dryer for particulate material |

| US3840155A (en) * | 1972-04-18 | 1974-10-08 | Boardman Co | Nuclear fuel handling powder container |

| US3861753A (en) * | 1971-07-17 | 1975-01-21 | Zimmermann Maschbau Adolf | Method of and apparatus for discharging pulverulent material from silos or the like |

| US3913891A (en) * | 1973-12-26 | 1975-10-21 | Dynamic Air | Air blender for granular materials |

| US3976109A (en) * | 1974-12-18 | 1976-08-24 | Quaker State Oil Refining Corporation | Dispersing method and apparatus for metering the dispersing of dry particulate material into a liquid |

| US4326810A (en) * | 1974-12-09 | 1982-04-27 | National Research Development Corporation | Mixing devices |

| US4793714A (en) * | 1985-12-05 | 1988-12-27 | Achmed N. Sadik | Apparatus for mixing fluids |

| US4809886A (en) * | 1986-09-16 | 1989-03-07 | Shell Oil Company | Apparatus for controlling a flow of granular material |

| US4878758A (en) * | 1987-02-13 | 1989-11-07 | Harth & Seifert Gmbh | Process for mixing bulk materials |

| US4944598A (en) * | 1989-05-10 | 1990-07-31 | Dynamic Air Inc. | Continuous flow air blender for dry granular materials |

| US5106591A (en) * | 1989-01-05 | 1992-04-21 | Olin Corporation | Salt handling apparatus for a hypochlorous acid reactor |

| US6354465B2 (en) * | 2000-04-27 | 2002-03-12 | E. I. Du Pont De Nemours And Company | Protable device for accurately metering and delivering cohesive bulk solid powders |

| EP1380215A3 (en) * | 2002-07-13 | 2004-02-25 | Degussa AG | process for the preparation of bulk goods containing at least two active compounds |

| US20040178232A1 (en) * | 2003-03-12 | 2004-09-16 | Langlois Carl M. | Product storage and dispensing system |

| US20040233776A1 (en) * | 2003-05-21 | 2004-11-25 | Dynamic Air Inc. | Blender |

| US20080037364A1 (en) * | 2004-03-15 | 2008-02-14 | Frederic Dietrich | Method and Device for Pneumatic Treatment of Powder Materials |

| US20080044238A1 (en) * | 2002-05-31 | 2008-02-21 | James Edward Delves | Process for Homogenizing Polyolefin Drag Reducing Agents |

| US20100322721A1 (en) * | 2008-02-09 | 2010-12-23 | Uhde Gmbh | Method and apparatus for receiving fine-grained to coarse-grained solids from a vessel and transferring them to a higher-pressure system |

| US20110017786A1 (en) * | 2008-03-17 | 2011-01-27 | Uhde Gmbh | Method and device for metered removal of a fine-grained to coarse-grained solid material or solid material mixture from a storage container |

| US20110058905A1 (en) * | 2008-05-21 | 2011-03-10 | Uhde Gmbh | Device for discharging a solid material from a container |

| US20160354743A1 (en) * | 2014-05-06 | 2016-12-08 | Herbert VEIT | Device for receiving and discharging mixable materials |

| US10300441B2 (en) * | 2016-06-08 | 2019-05-28 | Asia Ic Mic-Process, Inc. | Injection mixer |

| US10654646B1 (en) * | 2019-04-01 | 2020-05-19 | Suncue Company Ltd. | Containing apparatus for eliminating bridging |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1971852A (en) * | 1931-06-03 | 1934-08-28 | Firm G Polysius Ag | Process for stirring up farinaceous materials in receptacles of any kind by compressed air, compressed gas, or the like |

| US2528514A (en) * | 1947-12-20 | 1950-11-07 | Tennessee Valley Authority | Method for the manufacture of superphosphate |

| US2539847A (en) * | 1947-06-25 | 1951-01-30 | Kellogg M W Co | Synthesis of organic compounds |

| US2653801A (en) * | 1950-10-13 | 1953-09-29 | Stamicarbon | Process and apparatus for dispersing a substance in a liquid |

| US2688423A (en) * | 1951-07-12 | 1954-09-07 | Nelson L Davis | Plug valve and gas agitating means for storage sumps |

| US2724580A (en) * | 1952-06-19 | 1955-11-22 | Stamicarbon | Method of mixing a pulverulent solid material and a liquid |

| US2750681A (en) * | 1953-04-21 | 1956-06-19 | Berry Francois Jacq Barthelemy | Fluidising devices |

| US2761769A (en) * | 1952-07-17 | 1956-09-04 | Gulf Research Development Co | Fluidized catalytic apparatus |

| US2844361A (en) * | 1955-06-28 | 1958-07-22 | Fuller Co | Method and apparatus for blending pulverulent material |

| US2884230A (en) * | 1955-11-18 | 1959-04-28 | Halliburton Oil Well Cementing | Pneumatic blender |

-

1959

- 1959-04-28 US US809404A patent/US3097828A/en not_active Expired - Lifetime

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1971852A (en) * | 1931-06-03 | 1934-08-28 | Firm G Polysius Ag | Process for stirring up farinaceous materials in receptacles of any kind by compressed air, compressed gas, or the like |

| US2539847A (en) * | 1947-06-25 | 1951-01-30 | Kellogg M W Co | Synthesis of organic compounds |

| US2528514A (en) * | 1947-12-20 | 1950-11-07 | Tennessee Valley Authority | Method for the manufacture of superphosphate |

| US2653801A (en) * | 1950-10-13 | 1953-09-29 | Stamicarbon | Process and apparatus for dispersing a substance in a liquid |

| US2688423A (en) * | 1951-07-12 | 1954-09-07 | Nelson L Davis | Plug valve and gas agitating means for storage sumps |

| US2724580A (en) * | 1952-06-19 | 1955-11-22 | Stamicarbon | Method of mixing a pulverulent solid material and a liquid |

| US2761769A (en) * | 1952-07-17 | 1956-09-04 | Gulf Research Development Co | Fluidized catalytic apparatus |

| US2750681A (en) * | 1953-04-21 | 1956-06-19 | Berry Francois Jacq Barthelemy | Fluidising devices |

| US2844361A (en) * | 1955-06-28 | 1958-07-22 | Fuller Co | Method and apparatus for blending pulverulent material |

| US2884230A (en) * | 1955-11-18 | 1959-04-28 | Halliburton Oil Well Cementing | Pneumatic blender |

Cited By (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3169664A (en) * | 1962-06-19 | 1965-02-16 | Truetzschler & Co | Supply apparatus for carding machine and method |

| US3285157A (en) * | 1962-10-04 | 1966-11-15 | Hupp Corp | Roasting and heating apparatus |

| US3179379A (en) * | 1963-01-09 | 1965-04-20 | Grun Gustav | Apparatus for treatment of powdered and granular material |

| US3249263A (en) * | 1963-07-25 | 1966-05-03 | Phillips Petroleum Co | Particulate material feeding |

| US3411666A (en) * | 1965-06-09 | 1968-11-19 | Bergwerksverband Gmbh | Method and apparatus for successively metering identical quantities of particulate material |

| US3332780A (en) * | 1966-01-24 | 1967-07-25 | Hupp Corp | Method for cooling roasted coffee |

| US3531093A (en) * | 1968-03-26 | 1970-09-29 | Susanna Mikhailovna Karpacheva | Device for pulsating mixing of liquid reagents and liquid-and-solid reagents |

| US3637135A (en) * | 1968-04-26 | 1972-01-25 | Atlas Copco Ab | Method of and apparatus for spray coating components |

| US3756475A (en) * | 1971-03-25 | 1973-09-04 | R Emery | Method of improving flow of particulate material |

| US3861753A (en) * | 1971-07-17 | 1975-01-21 | Zimmermann Maschbau Adolf | Method of and apparatus for discharging pulverulent material from silos or the like |

| US3793742A (en) * | 1972-04-03 | 1974-02-26 | Universal Dynamics Corp | Hopper dryer for particulate material |

| US3840155A (en) * | 1972-04-18 | 1974-10-08 | Boardman Co | Nuclear fuel handling powder container |

| US3913891A (en) * | 1973-12-26 | 1975-10-21 | Dynamic Air | Air blender for granular materials |

| US4326810A (en) * | 1974-12-09 | 1982-04-27 | National Research Development Corporation | Mixing devices |

| US3976109A (en) * | 1974-12-18 | 1976-08-24 | Quaker State Oil Refining Corporation | Dispersing method and apparatus for metering the dispersing of dry particulate material into a liquid |

| US4793714A (en) * | 1985-12-05 | 1988-12-27 | Achmed N. Sadik | Apparatus for mixing fluids |

| US4809886A (en) * | 1986-09-16 | 1989-03-07 | Shell Oil Company | Apparatus for controlling a flow of granular material |

| US4878758A (en) * | 1987-02-13 | 1989-11-07 | Harth & Seifert Gmbh | Process for mixing bulk materials |

| US5106591A (en) * | 1989-01-05 | 1992-04-21 | Olin Corporation | Salt handling apparatus for a hypochlorous acid reactor |

| US4944598A (en) * | 1989-05-10 | 1990-07-31 | Dynamic Air Inc. | Continuous flow air blender for dry granular materials |

| US6354465B2 (en) * | 2000-04-27 | 2002-03-12 | E. I. Du Pont De Nemours And Company | Protable device for accurately metering and delivering cohesive bulk solid powders |

| US8628276B2 (en) * | 2002-05-31 | 2014-01-14 | Cameron International Corporation | Fluidising apparatus with swirl-generating means |

| US20080044238A1 (en) * | 2002-05-31 | 2008-02-21 | James Edward Delves | Process for Homogenizing Polyolefin Drag Reducing Agents |

| EP1380215A3 (en) * | 2002-07-13 | 2004-02-25 | Degussa AG | process for the preparation of bulk goods containing at least two active compounds |

| US20040178232A1 (en) * | 2003-03-12 | 2004-09-16 | Langlois Carl M. | Product storage and dispensing system |

| US6883686B2 (en) | 2003-03-12 | 2005-04-26 | Community Coffee Company, L.L.C. | Product storage and dispensing system |

| US20040233776A1 (en) * | 2003-05-21 | 2004-11-25 | Dynamic Air Inc. | Blender |

| US7267475B2 (en) | 2003-05-21 | 2007-09-11 | Dynamic Air Inc. | Blender |

| US20080037364A1 (en) * | 2004-03-15 | 2008-02-14 | Frederic Dietrich | Method and Device for Pneumatic Treatment of Powder Materials |

| US8834011B2 (en) * | 2004-03-15 | 2014-09-16 | Dietrich Engineering Consultants S.A. | Device for pneumatic treatment of powder materials |

| US20100322721A1 (en) * | 2008-02-09 | 2010-12-23 | Uhde Gmbh | Method and apparatus for receiving fine-grained to coarse-grained solids from a vessel and transferring them to a higher-pressure system |

| US8646664B2 (en) * | 2008-03-17 | 2014-02-11 | Thyssenkrupp Uhde Gmbh | Method and device for the metered removal of a fine to coarse-grained solid matter or solid matter mixture from a storage container |

| US20110017786A1 (en) * | 2008-03-17 | 2011-01-27 | Uhde Gmbh | Method and device for metered removal of a fine-grained to coarse-grained solid material or solid material mixture from a storage container |

| US20110058905A1 (en) * | 2008-05-21 | 2011-03-10 | Uhde Gmbh | Device for discharging a solid material from a container |

| US20160354743A1 (en) * | 2014-05-06 | 2016-12-08 | Herbert VEIT | Device for receiving and discharging mixable materials |

| US10632434B2 (en) * | 2014-05-06 | 2020-04-28 | Herbert VEIT | Apparatus for accommodation and dispensing of miscible materials having discharge opening provided with a displacer apparatus |

| US10300441B2 (en) * | 2016-06-08 | 2019-05-28 | Asia Ic Mic-Process, Inc. | Injection mixer |

| US10654646B1 (en) * | 2019-04-01 | 2020-05-19 | Suncue Company Ltd. | Containing apparatus for eliminating bridging |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3097828A (en) | Method and apparatus for mixing pulverulent or fine-grain material | |

| US2125913A (en) | Method and apparatus for mixing finely divided material | |

| US3271304A (en) | Venturi aerator and aerating process for waste treatment | |

| US2831754A (en) | Solvent extraction process | |

| US4587744A (en) | Fluidized bed apparatus | |

| DE4006935A1 (en) | Fluidised bed appts. for mixing, drying and coating bulk solids - has support tube concentrically placed around down pipe to form ring shaped aperture in mixing chamber | |

| US3842888A (en) | Apparatus for introducing ingredients into a spray drying tower | |

| DE58900380D1 (en) | MEATBED APPARATUS FOR PRODUCING AND / OR TREATING GRANULAR GOODS. | |

| US4655603A (en) | Pneumatic mixing apparatus for bulk materials and filter apparatus therefor | |

| US3179379A (en) | Apparatus for treatment of powdered and granular material | |

| GB1029179A (en) | Device for sorting solid granular products | |

| US3288537A (en) | Means for handling material | |

| US3159383A (en) | Method of mixing materials and a pneumatic mixing device adapted to said method | |

| US3385724A (en) | Process and device for continuously treating powdered materials with stabilizing subsances | |

| US1884423A (en) | Mixer | |

| US2915790A (en) | Device and method for exfoliating and blending asbestos fiber | |

| US3003751A (en) | Blender | |

| US2838246A (en) | Machines for treating asbestos and similar fibers | |

| US1496807A (en) | Vertical mixing apparatus or machine | |

| US2930687A (en) | Roasting of ores | |

| US2782927A (en) | Vibrating screen | |

| GB943085A (en) | Method and apparatus for mixing granular materials | |

| US2964299A (en) | Mixing apparatus | |

| CN222057162U (en) | Powder mixing device | |

| GB1396606A (en) | Apparatus for treating parts and materials and for the thorough separation of the constituents |