US1859945A - Towel rack - Google Patents

Towel rack Download PDFInfo

- Publication number

- US1859945A US1859945A US337439A US33743929A US1859945A US 1859945 A US1859945 A US 1859945A US 337439 A US337439 A US 337439A US 33743929 A US33743929 A US 33743929A US 1859945 A US1859945 A US 1859945A

- Authority

- US

- United States

- Prior art keywords

- section

- rack

- sections

- towel rack

- towel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000008093 supporting effect Effects 0.000 description 9

- 239000002184 metal Substances 0.000 description 7

- 229910052751 metal Inorganic materials 0.000 description 7

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- QWXYZCJEXYQNEI-OSZHWHEXSA-N intermediate I Chemical compound COC(=O)[C@@]1(C=O)[C@H]2CC=[N+](C\C2=C\C)CCc2c1[nH]c1ccccc21 QWXYZCJEXYQNEI-OSZHWHEXSA-N 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47K—SANITARY EQUIPMENT NOT OTHERWISE PROVIDED FOR; TOILET ACCESSORIES

- A47K10/00—Body-drying implements; Toilet paper; Holders therefor

- A47K10/04—Towel racks; Towel rails; Towel rods; Towel rolls, e.g. rotatable

Definitions

- My invention relates to improvements in towel rack.

- one of its objects is to provide 7 an improved towel rack adapted to be constructed bystamping from sheet metal.

- Another object is to provide a towel rack of maximum strength by stamping from sheet metal;

- Another object is to provide a towel rackby stamping from sheet metalwhichis ,economl cal of metal and utilizes practicallyall of the metal leaving practicallyno waste or scrap.

- Another obj ect is to provide an improved 1 towel rack which tends to retain the towels in which my improved towel rack is formed. 7

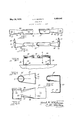

- Fig. 2 is a perspective. View, showing, a second step in the formation of the towel rack.

- Fig. 3 is a perspective view of a completed towel rack.

- Fig; 4 is as'ectional detail taken on line 44: of Fig. 3.

- Fig. 5 is a sectlonal detail taken on line 1 5-5 of Fig. 4.

- Fig. 6 is a sectional detail of a modification.

- the accompanying drawings illustrate one embodiment of my invention in which a long and relatively narrow fiat blank is formed

- the next step is to partially form the middle section 15'into a'tube or cylinder, which is done by stamping to cause the blank Fig. 1 to assume the shape shown in Fig. 2, by curving the middle of the section 15 transversely thereof andturn ing the opposite edges of the section 15 upwardly and substantially parallel one to the other.

- the edgesof'the section '15 are next closed together so as to form the section 15 into a tube'or hollow-cylinder.

- the longitudinal seam where'thei edges 'of the *s'ection15 meet maybe either tacked together at int'ervals .01 entirelyclosed by an .electrowelding operation; -Also l if desired, the

- sections 18 and-19 may be tacked in position" to the ends of the tubularsection.

- Ato wel' rack constructed'by stamping fromai single piece of sheet material coinprising'an intermediate tubular section, sup- -porting sections extending from opposite 'ends of said i'il'l'bilifar seCtiO Il' at substantially .iight""angies"thereto, and inwardly directed Q 7 shoe members adapted to attach said towels rack to a Wall extending from the free ends of said supporting. members s at substantially I right angles to said siipp orting meinbers.

- towei' rack constructed from sheet metal lay-stamping comprising: a central tu- 'bula-rsection, supportingsections extending from opposite ends of said tubuiarsection-at stilestjaaitia -l1y right angles thereto; and inw-al'd ly'd irected' shoe'members adapted: to attach; saidtowel racktoa wall extendin :trom s 1 thefree endsofs'aidsupportinggrmem ersat 'siibstantiaLly right angles to said supperting I members-and parallel-With said tubular secs towelrack constructed froni sheetmetal ystamp'ing comprising a central tubular mien, supporting sections extendfing from opposite endsrof said tubular; section, at substa ntiially right angles to said'tubuiar'section p aind sozas to close the" ends of said tnbiila'r members zit-substantially right anglesr

- a towel rack constrncted: .fIIQI II; sheet 7 metal by (stamping comprising a' centraltnhula-r secti on, supporting, sections extending trom-roppositeends of said tubular-section; at substantially right angles "thereto timnd' broader Va t theirireeJends than where attmdiedtotthe ends of said tubular rsecti olnzdnd 7 shoemembe rs adapted to attach said towel V crack to a Wailextending from tree-ends right, angles'ito saidsitpporting members; 3 1.5..

- a sheet metalb'lank for ⁇ 311301'W811 rack comprisingan intermediate section'iof suit v item 7 Width and of the length desired in the towel :mck, supporting sections at opposite ends of said intermediate section of substantially Ethersame width] as said intermediate I sectimPat'their outer endsian'd of less width at their: junction With said" intermediatesectionyand shoe sectionsextending outwardly 7 from the free ends of said supporting sec tionsi and'of stibstantial l'ythesameWidth? as s said intermediate section T :In testimony whereof hav i V signature.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Holders For Apparel And Elements Relating To Apparel (AREA)

Description

May 24, 1932. wHlTNEY 1,859,945 I TOWEL RACK Qriginal Filed Feb. 4. 1929 17 /5. A M H. meg f. jf

A TTOANL V Patented May. 24, 1932 V KARL H. WHITNEY, or KmK svILnE, iaissoniarnssrcnon qro .wnrriiraiiis FAGTURING COMPANY, INC., or KIRKYIIiLE, Issocni,,jA {ooit'rona'rron or;

mrssocm:

Application filedFebruary '4, 1929, Serial in; saiaaa new October 11 193 111 My invention relates to improvements in towel rack. one of its objects is to provide 7 an improved towel rack adapted to be constructed bystamping from sheet metal. Another object is to provide a towel rack of maximum strength by stamping from sheet metal;

Another object is to provide a towel rackby stamping from sheet metalwhichis ,economl cal of metal and utilizes practicallyall of the metal leaving practicallyno waste or scrap.

Another obj ect is to provide an improved 1 towel rack which tends to retain the towels in which my improved towel rack is formed. 7

Fig. 2 is a perspective. View, showing, a second step in the formation of the towel rack.

Fig. 3 is a perspective view of a completed towel rack. Y

Fig; 4 is as'ectional detail taken on line 44: of Fig. 3.

Fig. 5 is a sectlonal detail taken on line 1 5-5 of Fig. 4.

Fig. 6 is a sectional detail of a modification. The accompanying drawings illustrate one embodiment of my invention in which a long and relatively narrow fiat blank is formed,

by stamping from sheet metal, sheet iron or steel for instance. The next step is to partially form the middle section 15'into a'tube or cylinder, which is done by stamping to cause the blank Fig. 1 to assume the shape shown in Fig. 2, by curving the middle of the section 15 transversely thereof andturn ing the opposite edges of the section 15 upwardly and substantially parallel one to the other. The edgesof'the section '15 are next closed together so as to form the section 15 into a tube'or hollow-cylinder.

The end or shoe sections 16 and 17 ,which are perforated at .20, are then bent upwardly at right angles to the bracket or supporting sections 18 and 19 along the transverse lines 21. The sections; 18 and 19 are then bent at W L'ERM Y Fig. lmay have a strip 241 thereofroughened verse l nes 22, so that ' thesections 18 and 19 cover and close-thejopenings atthe ends of the tubular section 15, :which; brings: the sections lfiand 17 into 'one'plane'atone side of the section 15," and: so"; that the completed towel rack may ibe attached to the wall means of screws .or bolts .53 'passed'th-rough the perforations 20 and into thesidewall' of 7 building. :111 order i=toprevent: towels thrown or suspended over the tubular section 15 from slipping or sliding from; the t'owel rack, a strip 24 offthesection11'5 is made' sufiiciently rough exteriorly: :ofi the section" .15to havefa tend'ency to: retain the towels in any position in which. they may b'e'plac'ed' upon thetowel rack, and to prevent the towels from sliding over the face of} the sectionil5flso as to fallcfrom: the towel rack-n In' order :to 7

provide this roughened surface the blank by the original stamping operation asshown ti'on of forming the towel rackq If desired the longitudinal seam where'thei edges 'of the *s'ection15 meet maybe either tacked together at int'ervals .01 entirelyclosed by an .electrowelding operation; -Also l if desired, the

What I claim is: v

1. Ato wel' rack constructed'by stamping fromai single piece of sheet material coinprising'an intermediate tubular section, sup- -porting sections extending from opposite 'ends of said i'il'l'bilifar seCtiO Il' at substantially .iight""angies"thereto, and inwardly directed Q 7 shoe members adapted to attach said towels rack to a Wall extending from the free ends of said supporting. members s at substantially I right angles to said siipp orting meinbers.

towei' rack constructed from sheet metal lay-stamping comprising: a central tu- 'bula-rsection, supportingsections extending from opposite ends of said tubuiarsection-at stilestjaaitia -l1y right angles thereto; and inw-al'd ly'd irected' shoe'members adapted: to attach; saidtowel racktoa wall extendin :trom s 1 thefree endsofs'aidsupportinggrmem ersat 'siibstantiaLly right angles to said supperting I members-and parallel-With said tubular secs towelrack constructed froni sheetmetal ystamp'ing comprising a central tubular mien, supporting sections extendfing from opposite endsrof said tubular; section, at substa ntiially right angles to said'tubuiar'section p aind sozas to close the" ends of said tnbiila'r members zit-substantially right anglesrto said V supporting members.

section, and perforated shoe. members adapted to attach sazi d'towei rack to a wallxe xte'nd i ingcfirom the free ends oi' said supporting 4. A towel rack; constrncted: .fIIQI II; sheet 7 metal by (stamping comprising a' centraltnhula-r secti on, supporting, sections extending trom-roppositeends of said tubular-section; at substantially right angles "thereto timnd' broader Va t theirireeJends than where attmdiedtotthe ends of said tubular rsecti olnzdnd 7 shoemembe rs adapted to attach said towel V crack to a Wailextending from tree-ends right, angles'ito saidsitpporting members; 3 1.5.. A sheet metalb'lank for {311301'W811 rack comprisingan intermediate section'iof unii v item 7 Width and of the length desired in the towel :mck, supporting sections at opposite ends of said intermediate section of substantially Ethersame width] as said intermediate I sectimPat'their outer endsian'd of less width at their: junction With said" intermediatesectionyand shoe sectionsextending outwardly 7 from the free ends of said supporting sec tionsi and'of stibstantial l'ythesameWidth? as s said intermediate section T :In testimony whereof hav i V signature.

KARL WiiITNEY.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US337439A US1859945A (en) | 1929-02-04 | 1929-02-04 | Towel rack |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US337439A US1859945A (en) | 1929-02-04 | 1929-02-04 | Towel rack |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1859945A true US1859945A (en) | 1932-05-24 |

Family

ID=23320543

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US337439A Expired - Lifetime US1859945A (en) | 1929-02-04 | 1929-02-04 | Towel rack |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1859945A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2510452A (en) * | 1947-11-20 | 1950-06-06 | William S Witt | Necktie hanger |

| US5746329A (en) * | 1995-08-28 | 1998-05-05 | Northrop Grumman Corporation | Hanger system |

| US20050198732A1 (en) * | 2004-03-09 | 2005-09-15 | Knirk Gary L. | Wall mounted bathroom support bars with integral mounting flange |

-

1929

- 1929-02-04 US US337439A patent/US1859945A/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2510452A (en) * | 1947-11-20 | 1950-06-06 | William S Witt | Necktie hanger |

| US5746329A (en) * | 1995-08-28 | 1998-05-05 | Northrop Grumman Corporation | Hanger system |

| US20050198732A1 (en) * | 2004-03-09 | 2005-09-15 | Knirk Gary L. | Wall mounted bathroom support bars with integral mounting flange |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US958857A (en) | Dish-drainer. | |

| US9743811B1 (en) | Shower curtain assembly | |

| US1859945A (en) | Towel rack | |

| US1856323A (en) | Window screen | |

| FR1394392A (en) | Installation for transporting linen in laundries, dry cleaning establishments and the like | |

| US2163947A (en) | Sewer rod guide | |

| US747960A (en) | Collapsible protecting device for closet-seats. | |

| US1742613A (en) | Attachment for hot-air pipes or the like | |

| FR1432384A (en) | Hand case or similar case the edges of which are reinforced by profiled metal frames | |

| US1021867A (en) | Hanger-support. | |

| US1520686A (en) | Door construction | |

| US982626A (en) | Sitz-bath attachment. | |

| US332825A (en) | Aethue w | |

| CN209585470U (en) | A kind of handrail of waterproof scratching | |

| US1590738A (en) | Tub | |

| US2543701A (en) | Fastening member for building molding forms | |

| US1480516A (en) | Toilet seat | |

| NL165404C (en) | METHOD FOR PROVIDING A THICKNED WALL PART ON THE END OF A PIPE, THE THICKNESS OF WHICH IS LOCATED ON THE OUTSIDE OF THE PIPE WALL | |

| NL143807B (en) | ASSEMBLY OF A NUMBER OF PIPE SECTIONS, WITH MATCHING, ADJACENT ENDS, FOR BUILDING A HANDLE FOR A SWEEPER OR THE LIKE. | |

| USD76786S (en) | Design for a pump casing | |

| USD123484S (en) | Design foe, a screen and storm sash bracket | |

| FR633234A (en) | Brake improvements for cycles and the like | |

| FR736322A (en) | One-way plunger for shaving soap cases or the like | |

| AT307481B (en) | Roller brooms for street sweepers or the like. | |

| US1677039A (en) | Tiling |