US1858099A - Rotary bin - Google Patents

Rotary bin Download PDFInfo

- Publication number

- US1858099A US1858099A US415814A US41581429A US1858099A US 1858099 A US1858099 A US 1858099A US 415814 A US415814 A US 415814A US 41581429 A US41581429 A US 41581429A US 1858099 A US1858099 A US 1858099A

- Authority

- US

- United States

- Prior art keywords

- bins

- bin

- arms

- standard

- lowered

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 235000013339 cereals Nutrition 0.000 description 6

- 238000010276 construction Methods 0.000 description 3

- 235000000346 sugar Nutrition 0.000 description 3

- 235000013312 flour Nutrition 0.000 description 2

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 235000005824 Zea mays ssp. parviglumis Nutrition 0.000 description 1

- 235000002017 Zea mays subsp mays Nutrition 0.000 description 1

- 235000005822 corn Nutrition 0.000 description 1

- 235000012054 meals Nutrition 0.000 description 1

- 235000009566 rice Nutrition 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47F—SPECIAL FURNITURE, FITTINGS, OR ACCESSORIES FOR SHOPS, STOREHOUSES, BARS, RESTAURANTS OR THE LIKE; PAYING COUNTERS

- A47F3/00—Show cases or show cabinets

- A47F3/14—Display trays or containers

- A47F3/145—Closable display containers

Definitions

- This invention relates to an apparatus for handling grain, either whole or ground, as well as sugar and likecommodities, an object being to provide an apparatus by means of which grain may be fed to a mill in a convenient manner.

- Another object of the invention is the provision of an apparatus of the above character which may also be used in stores for sugar, flour and other grains and meals, and maintained in an out-of-the-way position to conserve floor space, and readily moved into position for the removal of its contents.

- Another object of the invention is the pro- 15 vision of an apparatus which, in addition to the above and other advantageous features, is simple in construction, easy to operate and may be manufactured at a relatively small cost.

- Figure 2 is a side view with parts in sec 39 tion and showing one of the bins in lowered position.

- Figure 3 is a top plan view of a slightly different form of the invention.

- Figure 4 is a view similar to Figure 2 but showing the form of the invention illustrated in Figure 3.

- Figure 5 is a plan view of another form of the invention.

- Figure 6 is an elevation with one of the bins lowered and parts in section.

- the refence character 10 indicates a standard whose upper and lower ends are rotatably mounted in blocks 11 or other suitable bearing devices attached to the ceiling and floor of aroom, or

- the reference character 1e indicates bins or containers which are open at the top and provided with hinged covers 15 for conveniently filling the bins.

- the bins are preferably provided with legs 16 which space them from the floor as shown in Figure 2 of the drawings, and the bottoms of these bins are inclined as at 17 and are provided with discharge openings controlled by slides 18.

- a sack or other suitable container may thus be placed beneath the bin and a portion of all of the contents transferred to the sacks.

- T he binsare designed to be supported in elevated position for purposes hereinafter explained and are adapted to be lowered and raised.

- a cable 19 is passed through a sheave 20 secured to the top of the bin and through sheave 21 at the outer end of one of the arms 12.

- a bin is connected to each of the arms 12 in this manner so that it may be raised'or lowered and may be held in raised position by securing the free end of the cable 21 to aconvenient point upon the bin.

- Hingedly secured to the standard 22 are spaced arms 28 and the outer ends of these arms are provided with elongated slots24 to receive pins or pintles 25 which extend from opposite sides of each of the bins.

- These arms'23 provide guiding means for the bins during their raising and lowering movement and act to prevent independent rotary movement of thebins as the apparatus is rotated 85 through rotation of the standard 10.

- the invention may be used for feeding corn or other grain to a mill.

- One of the bins is lowered to the position shown in Figure 2 of the drawings and the customers grain is 90 placed within the bin and the toll checked.

- lf'he bin isthen raised by means of the cable 19 and secured in raised position, so that the apparatus may be rotated to bring another bin into position for another customers 95 grain.

- This operation is repeated until the first bin has reached a position above the mill, so that the contents of this bin may be fed to the mill. If the hopper of the mill does not accommodate the entire contents of 199 the bin, the latter may remain in position above the hopper and the mill properly fed until the contents of the bin have all been removed.

- the apparatus may be used in grocery stores as containers for sugar, rice, flour and like commodities. Normally, the bins are elevated so that considerable floor space is saved.

- a scale is positioned so that the bins may be raised and lowered and their contents conveniently transferred to the scale.

- the bin may be lowered directly above the scale and suflicient of the contents of the bin may be transferred into a sack or bag upon the scale until the desired amount has been obtained.

- the bin may then be raised to its normal position out of the way.

- the standard 1064 has extending radially therefrom horizontally disposed arms 12a.

- the standard is rotatably mounted and the arms 12a support bins 14a by means of cables 19a.

- Theese bins are carried by frames 26 which are provided with extensions or arms 27 having a sliding engagement with .guide rods 28 arranged parallel with the standard a.

- the frames are thus slidable along the guide rods and hold the bins against horizontal-swinging or rosary movement independent of the standar

- the free ends of the cables 19a are woundupon a roller or drum 29 which is provided with an operating wheel 30 and is carried by the frame 26. By means of the roller 29, the bins may be raised or lowered as previously described.

- the standard 10?) is rotatably mountedand carries upper radially extending arms 12?) and lower radially extending arms 31.

- the arms 12?) carry spaced sprockets 32 while the arms 31 carry sprockets 33.

- Chains 34 pass around these sprockets and have one of their ends connected with the bins 1%, while the opposite ends of the chains have weights 35 connected thereto to act as a counter-balance for the bins.

- the sprockets 33 are mounted upon the shafts 36 and these shafts have extending therefrom crank arms 37 which provide means for rotating the sprockets and operating the chains to raise and lower the bins.

- the bins have a sliding connection 38 with the chains so as to stabilize and prevent swinging movement of the bins.

- a platform-39 may be provided to support the lowered bin at a convenient elevation.

- Rotary bins comprising a vertically disposed and rotatably mounted standard, horizontally disposed arms secured to the upper JAMES R. MASSENGALE.

Landscapes

- Vending Machines For Individual Products (AREA)

Description

y 10, 1932- J. R. MASSENGALE 1,858,099

ROTARY B I N Filed Dec. 21, 1929 3 Sheets-Sheet 1 INVENTOR ATTORNEY y 10, 1932- J. R. MASSENGALE 1,858,099

ROTARY BIN Filed Dec. 21, 1929 5 Sheets-Sheet 2 James ffikfidrd/hssenya/e INVENTOR ATTORNEY y 10, 1932- .1 R. MASSENGALE 1,858,099

ROTARY BI N Filed Dec. 21, 1929 3 sheets sheet I5 Patented May 10, 1932 UNITEfi ITS JAMES RICHARD MASSENGALE, OF EDEN, MISSISSIPPI ROTARY BIN Application filed December 21,1929. Serial No. 415,814.

This invention relates to an apparatus for handling grain, either whole or ground, as well as sugar and likecommodities, an object being to provide an apparatus by means of which grain may be fed to a mill in a convenient manner.

Another object of the invention is the provision of an apparatus of the above character which may also be used in stores for sugar, flour and other grains and meals, and maintained in an out-of-the-way position to conserve floor space, and readily moved into position for the removal of its contents.

Another object of the invention is the pro- 15 vision of an apparatus which, in addition to the above and other advantageous features, is simple in construction, easy to operate and may be manufactured at a relatively small cost.

lVith the above and other objects in view, the invention further includes the following novel features and details of construction, to be hereinafter more fully described, illustrated in the accompanying drawings and pointed out in the appended claim.

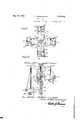

In the drawings 2-- Figure 1 is a top plan view of the invention.

, Figure 2 is a side view with parts in sec 39 tion and showing one of the bins in lowered position.

Figure 3 is a top plan view of a slightly different form of the invention.

, Figure 4 is a view similar to Figure 2 but showing the form of the invention illustrated in Figure 3.

Figure 5 is a plan view of another form of the invention.

Figure 6 is an elevation with one of the bins lowered and parts in section.

Referring to the drawings in detail and more especially to Figures 1 and 2, the refence character 10 indicates a standard whose upper and lower ends are rotatably mounted in blocks 11 or other suitable bearing devices attached to the ceiling and floor of aroom, or

to other convenient supporting structure. Extending radlally from and rlgld with the standard 10 are horizontally dlsposed arms 50 12 and these arms may be braced by means of braces l3 which connect them with the standard.

The reference character 1e indicates bins or containers which are open at the top and provided with hinged covers 15 for conveniently filling the bins. The bins are preferably provided with legs 16 which space them from the floor as shown in Figure 2 of the drawings, and the bottoms of these bins are inclined as at 17 and are provided with discharge openings controlled by slides 18. A sack or other suitable container may thus be placed beneath the bin and a portion of all of the contents transferred to the sacks. I

T he binsare designed to be supported in elevated position for purposes hereinafter explained and are adapted to be lowered and raised. To accomplish this, a cable 19 is passed through a sheave 20 secured to the top of the bin and through sheave 21 at the outer end of one of the arms 12. A bin is connected to each of the arms 12 in this manner so that it may be raised'or lowered and may be held in raised position by securing the free end of the cable 21 to aconvenient point upon the bin. Hingedly secured to the standard 22 are spaced arms 28 and the outer ends of these arms are provided with elongated slots24 to receive pins or pintles 25 which extend from opposite sides of each of the bins. These arms'23 provide guiding means for the bins during their raising and lowering movement and act to prevent independent rotary movement of thebins as the apparatus is rotated 85 through rotation of the standard 10.

The invention may be used for feeding corn or other grain to a mill. One of the bins is lowered to the position shown in Figure 2 of the drawings and the customers grain is 90 placed within the bin and the toll checked. lf'he bin isthen raised by means of the cable 19 and secured in raised position, so that the apparatus may be rotated to bring another bin into position for another customers 95 grain. This operation is repeated until the first bin has reached a position above the mill, so that the contents of this bin may be fed to the mill. If the hopper of the mill does not accommodate the entire contents of 199 the bin, the latter may remain in position above the hopper and the mill properly fed until the contents of the bin have all been removed.

In addition, the apparatus may be used in grocery stores as containers for sugar, rice, flour and like commodities. Normally, the bins are elevated so that considerable floor space is saved.

A scale is positioned so that the bins may be raised and lowered and their contents conveniently transferred to the scale. For example, the bin may be lowered directly above the scale and suflicient of the contents of the bin may be transferred into a sack or bag upon the scale until the desired amount has been obtained. The bin may then be raised to its normal position out of the way.

In Figures 3 and 4, the standard 1064 has extending radially therefrom horizontally disposed arms 12a. The standard is rotatably mounted and the arms 12a support bins 14a by means of cables 19a. Theese bins are carried by frames 26 which are provided with extensions or arms 27 having a sliding engagement with .guide rods 28 arranged parallel with the standard a. The frames are thus slidable along the guide rods and hold the bins against horizontal-swinging or rosary movement independent of the standar In this form of the invention, the free ends of the cables 19a are woundupon a roller or drum 29 which is provided with an operating wheel 30 and is carried by the frame 26. By means of the roller 29, the bins may be raised or lowered as previously described.

In Figuresfi and 6, the standard 10?) is rotatably mountedand carries upper radially extending arms 12?) and lower radially extending arms 31. The arms 12?) carry spaced sprockets 32 while the arms 31 carry sprockets 33.

The invention is susceptible of various changes in its form, proportions and minor details of construction and the right is herein reserved to make such changes as properly fall within the scope of the appended claim.

Having described the invention What is claimed 15:

Rotary bins comprising a vertically disposed and rotatably mounted standard, horizontally disposed arms secured to the upper JAMES R. MASSENGALE.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US415814A US1858099A (en) | 1929-12-21 | 1929-12-21 | Rotary bin |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US415814A US1858099A (en) | 1929-12-21 | 1929-12-21 | Rotary bin |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1858099A true US1858099A (en) | 1932-05-10 |

Family

ID=23647311

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US415814A Expired - Lifetime US1858099A (en) | 1929-12-21 | 1929-12-21 | Rotary bin |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1858099A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4093085A (en) * | 1976-03-16 | 1978-06-06 | Ingrid Hudelmaier | Apparatus for making ready-mixed concrete |

-

1929

- 1929-12-21 US US415814A patent/US1858099A/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4093085A (en) * | 1976-03-16 | 1978-06-06 | Ingrid Hudelmaier | Apparatus for making ready-mixed concrete |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1858099A (en) | Rotary bin | |

| US2407782A (en) | Tray stacker | |

| US2235942A (en) | Sacking machine | |

| US1563792A (en) | Cableless elevator | |

| US1430655A (en) | Hoisting mechanism | |

| US2523562A (en) | Conveyer and chute combined with swingably mounted measuring hopper | |

| US1297619A (en) | Rack for book-covers and the like. | |

| US1540165A (en) | Rag holding and measuring apparatus | |

| US2288159A (en) | Sacking device | |

| US1828167A (en) | Canning machine | |

| US2251875A (en) | Storage and dispensing apparatus | |

| US4161243A (en) | Fall brake | |

| US706197A (en) | Stone-handling apparatus. | |

| US1064194A (en) | Dough-proofing apparatus. | |

| US2564056A (en) | Apparatus for handling and packaging eggs | |

| US983669A (en) | Dough-conveying apparatus. | |

| US1380861A (en) | belair | |

| US894452A (en) | Apparatus for handling express matter, &c. | |

| US1898416A (en) | Bin | |

| US1127324A (en) | Discharge means for silos, &c. | |

| CH632209A5 (en) | Machine for emptying crates filled with loose material | |

| US2016789A (en) | Egg weigher | |

| US2223894A (en) | Grain conveyer and loader | |

| US1615716A (en) | Potato digger | |

| US1583201A (en) | Device for grading and packaging articles according to size |