US1853796A - Car roof - Google Patents

Car roof Download PDFInfo

- Publication number

- US1853796A US1853796A US509640A US50964031A US1853796A US 1853796 A US1853796 A US 1853796A US 509640 A US509640 A US 509640A US 50964031 A US50964031 A US 50964031A US 1853796 A US1853796 A US 1853796A

- Authority

- US

- United States

- Prior art keywords

- roof

- flanges

- sheets

- carline

- carlines

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000008093 supporting effect Effects 0.000 description 10

- 238000010276 construction Methods 0.000 description 4

- 239000000543 intermediate Substances 0.000 description 4

- 239000002184 metal Substances 0.000 description 2

- 230000000284 resting effect Effects 0.000 description 2

- 238000005728 strengthening Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 241001474033 Acar Species 0.000 description 1

- 235000019994 cava Nutrition 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61D—BODY DETAILS OR KINDS OF RAILWAY VEHICLES

- B61D17/00—Construction details of vehicle bodies

- B61D17/04—Construction details of vehicle bodies with bodies of metal; with composite, e.g. metal and wood body structures

- B61D17/12—Roofs

Definitions

- This invention relates principally to car roofs of the flexible single-course type Wherein the'roof sheets are secured to each other and to the car by seam caps that permit movementofsaid roof sheets to a limited extentso as-tobe able to accommodate themselves to the distortions of the car body. Its principal objects are to prevent leakage between the roofsheets and 'the seam caps, to provide for supporting the marginal portions of adjacent sheets on the carlines and to dispense Withthe use of purlins for supporting thereof sheets between carlines.

- the invention consists in the car roof andin the con: struction, combinations and arrangements of parts hereinafter describedand claimed.

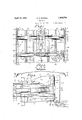

- Fig. 1 is a plan View-of acar roof embody? ing my invention

- 7 -Fig. 2 is .a.,-vertical transverse sectlon through; said'roof on the line 22 in Fig. l, 'Fig.-- 31is an enlarged fragmentary plan View of the eaves portion of the car in the region done of the roof seams, r

- a-Fig.'. 4f is. a vertical transverse section throughtheeaves portion of the roof on the lineal-4t in Fig. 1

- I @Fig. 5 is a fragmentary side elevation of the roof, showing the. eaves. end of one of the seam caps, V i I Fig. 6 isa vertical section on the line 6-6 in Fig.4,

- Fig. 7- is a similar section on the line 77 in Fig.4; and V I Fig. 8 is a similar section on the line-8'8 inFigdw: v 1

- the present construction comprises side plates A .of substantially Z-shapedicrosssection with the inner flange 1 upstanding and having riveted flatwise against the outer side of said flangev an angle-shaped member B whose upper leg 2 extends inwardly over the top of said side plate 'at an angle-conforming to the pitch of the roof and at the proper clevationfor'the'end portions of metal roof sheets C- to rest upon.

- v :At-suitable intervals, the-eaves angle support-B' has depressions 3 inits top flanges 2 of the proper shape to receive and form seats for the ends of metal carlines; D, which are riveted thereto.

- the carlines D are made of two members each.

- the upper or mainrmember 4 vofeach carline D is in the form of an inverted channel with outstanding base flanges. 5 atthe lower, edges of its side walls, the channel extendingfrom end to end of said upper carline member, but being of reduced depth at the end portions thereof.

- the upper portion of the channel-shaped'body of the upper carline member 4 is made narrower than the ATENT' OFFICE lower portion thereof to form exterior sheet ber 7 is in the form of a plate that extends.

- the bottom carline member 7 is made wider, than the upper carline member 4 and has its side marginal portionsstruck up beyond the base flanges 5 ofsaid upper carline member into the form of raised flanges 8 that are of proper height for body portions of the'roof sheets C to rest upon

- the roof sheets O extend from caves to eaves of the car between carlines D and are supported at their eaves ends on the inwardly extending flanges 2 of the combined carline and roof sheet supports B and along their side margins on the ledges 6 of the upper carline members 4 and on the sheet supporting flanges -8 of the lower carline members ,7.

- the side marginal portions of the roof sheets beyond the sheet supporting flanges 8 of the lower carline members 7 are pressed up into raised panels 9 that incline upwardly and outwardly .and terminate in vertical flanges 10 at the side edges of said sheets.

- the side marginal panels 9 of the roof sheets rest upon members 4, which ledges slope downwardly and outwardly at anangle conforming to the slope of said side marginal panels of the roof sheets.

- the adjacent side flanges 10 of the longitudinal ledges 6 of the upper carline adjacent roof sheets lie on oppositesides of the narrow upper portion of the inverted channel-shaped upper carline member a at a suflicient distance therefrom to afford adequate clearance to provide for distortions of the substructure.

- the transverse seam caps 11 are rigidly secured flatwise to the tops of the carlines by rivets 13, which also serve to secure running board saddles let to the topsof the seam caps, said running board saddles, in turn, constituting supports for a running board 15 which extends longitudina'lly of the car from end to end thereof.

- the eaves end portions of the seam caps 11 are removably secured to the reduced end portionsof the upper carline members 4 preferably by means of bolts 16 that extend through registering holes provided therefor in the upper and lower carline members and are provided below the lower carline members with nuts 17.

- the upperor headed ends o'rf the bolts 16 are supported in channelshaped brackets 18, which are located within the seam caps crosswise thereof and have outstanding flanges 19 at the upper ends of their'side walls that are riveted or otherwise permanently secured to the undersides of the top webs o-f said seamcaps.

- the webs of the channel-shaped bolt supporting brackets 18 are provided with notches 20 whereby the bolts maybe readily-attached to said brackets.

- the bolt hole 21 in the lower carline memher 7 has its edge 21a flanged or winged up to prevent any water that may reach the top of said lower member from passing through said hole. Any water that gets under the roof sheets onto the lower carline members 7 will drain lengthwise thereof and be delivered over the ends of the carline to the outside of the car.

- the unsupported middle portions of said sheets are provided with upstanding corrugations or stifliening ribs 22 that span thespaces between the sheet -supporting flanges 8 of adjacent carlines and overlap said flanges.

- the roof sheets are provided at their eaves ends with depending flanges 23 that overhang and are spaced from the combined carline and roof sheet supports B and the upstanding side plate flanges 1 to which said supports are secured; and likewise, the eaves ends of the .transverseseam caps 11 are provided with depending flanges 2.4 th'atloverhang and are spacedfroni adjacent end portions of depending eaves flanges'23 of adjacent roof sheets.

- the eaves flanges 23 of the roofsheets terminate at their lower ends in inwardly extending horizontal flanges 23a that are spaced irom the supports Br and likewise, the depending end flanges 24 of the seam caps terminate in inwardly extending horizontal flanges 24a that bear flatwise against the undersurfaces of the adj acentend portions of the intnrned lower ends 23a :of the depending eaves flanges 23 of adjacent roof sheetsand are also spaced fromzthe sup ports B.

- the eaves ends of the seamcaps are hooked beneath the eaves ends of the roof sheets and serve to hold the base flanges .12 :of said caps and-the raised side marginal panels 9 of said roof sheets in contact with :each other from the securing bolts out 10 the eaves.

- the caps are pressed inwardly to form strengthening corrugations 25 and :26, respectively.

- the raised side marginal panels 9 of the roof sheets are supported throughout their length on "the ledges 6 of the carlines andare thus prevented from falling away from the base flanges 12 of the transverse seam caps, which flanges,

- tions or ribs 22 formed in said roof sheets span the spaces between the sheet support-v ing flanges 8 of adjacent carlines and thus serve to increase the vertical strength of the port the Vertical roof load.

- the bolts 16 for securing the eaves portions of the seam caps to the carlines are supportedin the brackets 18 that are permanently attached to the seam caps and are slotted to permit said bolts to be readily attached to and detached from said brackets when the caps are detached from the car; and the pressure of said caps on the roof sheets may be regulated by tightening or loosening the nuts 17 on the lower end of said securing bolts.

- a car roof comprising side plates, carlines supported by said side plates and roof sheets movably supported on said side plates and carlines, said carlines having their side margins raised to provide supportsforsaid roof sheets, said roof sheets being provided with stiffening ribs that extend from the roof sheet support of one carline to the roof sheet support of the adjacent carline.

- a car roof comprising side plates, carlines. supported by said side plates and roof sheets movably supported on said side plates and said carlines, a carline comprising an upper member of inverted channel-shape with the upper portions of its side walls ofiset inwardly to form longitudinal support ing ledges for the side marginal portions of adjacent roof sheets. and a lower plate-like member secured to the bottom of said upper carline member, saidlower member being Wider than said upper member andhaving its side margins raised beyond said upper member to form supports for said roof sheets outwardly beyond and somewhat lower than said ledges.

- a car roof construction comprising side plates, carlines supported by said side plates, 'roof sheets movably supported on said side plates and said carlines, a carline comprising "an upper member of inverted channel-shape with the upper portions of its sidewalls offan adjacent carline.

- a carroof comprismg s1de-plates, -carliI-lfiS ELlPPGIti-Bd by said s de plates and roof sheets movably supported on said. side plates and carlines, said roof'sheets: havingtheir 'sideinargins' formed into panels that 'are raised above the bodies of the roof-sheets, said carlines having their'side margins raised to provide supports for the bodiesof said 3 root sheets and be'ing provided inter-mediate said raised-side inarginswith longitudinal ledgesslightly higher than said supports for supportingtheside'marginal panels of said roof sheets. 7 a 4' 5.

- a 1021:! roof comprising side plates, car- -lines vsupported by said side plates, roof sheets movahly supported .on said side plates and said carlines, and seam caps straddling said ca-rlines and the side marginal portions of :adjacentasheets and secured tocsaid carlines .interinediatesaid side plates, said roof sheets being provided with depending eaves flanges that overhang and are spaced from said side :pl ates,.said seam caps having depending end flanges that over-hang and are spaced from the depending eaves flanges of adjacent sheets and are :bent inwardly beneath and in contact with the lower ends of the depending eaves flanges of adjacent roof sheets.

- a car roof comprising side plates, carzlinessnpported by said side plates, roof-sheets 'movahly supported on said side plates and said .carllines, sea-1n caps secured to said carlines intermediate said side plates and straddlingsaid canlinesand the side marginal poritions-ef :adijacent sheets, said seam caps having ,rba-se flanges resting npon adjacent roof v as ⁇ 190 depending eaves flanges that overhang and nrespaced fromsaid side plates and are bent inwardly at their lower :ends, said seam caps having depending end flanges that overhang and are spaced from the depending eaves :flanges of adjacent sheets are provided at their lower ends with inwardly extending flanges .thatihearagainst the .undersides rof fthe rbent :lower .ends of the depending aeaves :flanges of adjacent roo'fzsheets.

Description

April 12, 1932. c. D. BONSALL 8 17 CAR ROOF Filed Jan. 19, 1951 2 Sheet s -Sheet 1 April -c. D. BONSALL 1,853,796

/ CAR ROOF Filed Jan. 19, 1931 2 Sheets-Sheet 2 1105 147-70 eMe Ks UNITED STATESJP eHAR Lns" nAvInjBoivsALL, or r rrrsnonen, 1=aimsxmumui, 'As'srenon no r. COMPANY, on new xnnsme'ron, ri nnsynvnmnjn CORPORATION OF Patented Apr. 12, 1932 f :en nsYLvA'n IA CAR noon Application filed January 19, 1931. Serial No. 509,640.

= This invention relates principally to car roofs of the flexible single-course type Wherein the'roof sheets are secured to each other and to the car by seam caps that permit movementofsaid roof sheets to a limited extentso as-tobe able to accommodate themselves to the distortions of the car body. Its principal objects are to prevent leakage between the roofsheets and 'the seam caps, to provide for supporting the marginal portions of adjacent sheets on the carlines and to dispense Withthe use of purlins for supporting thereof sheets between carlines. The invention consists in the car roof andin the con: struction, combinations and arrangements of parts hereinafter describedand claimed.

Y In theaccompanying drawings, which form partof this specification and-wherein like symbols refer to likeipartswherever they occur,

Fig. 1 is a plan View-of acar roof embody? ing my invention, 7 -Fig. 2 is .a.,-vertical transverse sectlon through; said'roof on the line 22 in Fig. l, 'Fig.-- 31is an enlarged fragmentary plan View of the eaves portion of the car in the region done of the roof seams, r

a-Fig.'. 4f is. a vertical transverse section throughtheeaves portion of the roof on the lineal-4t in Fig. 1, I @Fig. 5 is a fragmentary side elevation of the roof, showing the. eaves. end of one of the seam caps, V i I Fig. 6 isa vertical section on the line 6-6 in Fig.4,

Fig. 7-is a similar section on the line 77 in Fig.4; and V I Fig. 8 is a similar section on the line-8'8 inFigdw: v 1 The present construction comprises side plates A .of substantially Z-shapedicrosssection with the inner flange 1 upstanding and having riveted flatwise against the outer side of said flangev an angle-shaped member B whose upper leg 2 extends inwardly over the top of said side plate 'at an angle-conforming to the pitch of the roof and at the proper clevationfor'the'end portions of metal roof sheets C- to rest upon.v :At-suitable intervals, the-eaves angle support-B'has depressions 3 inits top flanges 2 of the proper shape to receive and form seats for the ends of metal carlines; D, which are riveted thereto.

The carlines D are made of two members each. The upper or mainrmember 4 vofeach carline D is in the form of an inverted channel with outstanding base flanges. 5 atthe lower, edges of its side walls, the channel extendingfrom end to end of said upper carline member, but being of reduced depth at the end portions thereof. The upper portion of the channel-shaped'body of the upper carline member 4 is made narrower than the ATENT' OFFICE lower portion thereof to form exterior sheet ber 7 is in the form of a plate that extends.

the full length of the carline and is riveted .to the outstanding base flanges 5 of the in Vertedchannel-shaped upper carline member 4. .The bottom carline member 7 is made wider, than the upper carline member 4 and has its side marginal portionsstruck up beyond the base flanges 5 ofsaid upper carline member into the form of raised flanges 8 that are of proper height for body portions of the'roof sheets C to rest upon The roof sheets O extend from caves to eaves of the car between carlines D and are supported at their eaves ends on the inwardly extending flanges 2 of the combined carline and roof sheet supports B and along their side margins on the ledges 6 of the upper carline members 4 and on the sheet supporting flanges -8 of the lower carline members ,7.

The side marginal portions of the roof sheets beyond the sheet supporting flanges 8 of the lower carline members 7 are pressed up into raised panels 9 that incline upwardly and outwardly .and terminate in vertical flanges 10 at the side edges of said sheets. The side marginal panels 9 of the roof sheets rest upon members 4, which ledges slope downwardly and outwardly at anangle conforming to the slope of said side marginal panels of the roof sheets. The adjacent side flanges 10 of the longitudinal ledges 6 of the upper carline adjacent roof sheets lie on oppositesides of the narrow upper portion of the inverted channel-shaped upper carline member a at a suflicient distance therefrom to afford adequate clearance to provide for distortions of the substructure.

Above the upper member l of each carline;

sheet supporting ledges 6 of said upper can The nclined side marginalline member. panels 9 of the roof sheets and'the inclined base flanges 12 ef the seam cap 11 are in contact, and the vertical portions of said seam cap arespaced away from the upstanding side marginal seam flanges 10 of the-roof sheets far enough to provide for proper clearance.

At the ridge of the car the transverse seam caps 11 are rigidly secured flatwise to the tops of the carlines by rivets 13, which also serve to secure running board saddles let to the topsof the seam caps, said running board saddles, in turn, constituting supports for a running board 15 which extends longitudina'lly of the car from end to end thereof.

The eaves end portions of the seam caps 11 are removably secured to the reduced end portionsof the upper carline members 4 preferably by means of bolts 16 that extend through registering holes provided therefor in the upper and lower carline members and are provided below the lower carline members with nuts 17. The upperor headed ends o'rf the bolts 16 are supported in channelshaped brackets 18, which are located within the seam caps crosswise thereof and have outstanding flanges 19 at the upper ends of their'side walls that are riveted or otherwise permanently secured to the undersides of the top webs o-f said seamcaps. The webs of the channel-shaped bolt supporting brackets 18 are provided with notches 20 whereby the bolts maybe readily-attached to said brackets. The bolt hole 21 in the lower carline memher 7 has its edge 21a flanged or winged up to prevent any water that may reach the top of said lower member from passing through said hole. Any water that gets under the roof sheets onto the lower carline members 7 will drain lengthwise thereof and be delivered over the ends of the carline to the outside of the car.

In order to render the roof sheets strong enough to transmit the vertical roof load from the roof sheets to carlines, the unsupported middle portions of said sheets are provided with upstanding corrugations or stifliening ribs 22 that span thespaces between the sheet -supporting flanges 8 of adjacent carlines and overlap said flanges. By thus strengthening the-roof sheets the use of purlins is dispensed with, thereby saving the cost of the purlins weaves and relieving the carline of the weight thereof.

The roof sheets are provided at their eaves ends with depending flanges 23 that overhang and are spaced from the combined carline and roof sheet supports B and the upstanding side plate flanges 1 to which said supports are secured; and likewise, the eaves ends of the .transverseseam caps 11 are provided with depending flanges 2.4 th'atloverhang and are spacedfroni adjacent end portions of depending eaves flanges'23 of adjacent roof sheets. The eaves flanges 23 of the roofsheets terminate at their lower ends in inwardly extending horizontal flanges 23a that are spaced irom the supports Br and likewise, the depending end flanges 24 of the seam caps terminate in inwardly extending horizontal flanges 24a that bear flatwise against the undersurfaces of the adj acentend portions of the intnrned lower ends 23a :of the depending eaves flanges 23 of adjacent roof sheetsand are also spaced fromzthe sup ports B. By this arrangement, the eaves ends of the seamcaps are hooked beneath the eaves ends of the roof sheets and serve to hold the base flanges .12 :of said caps and-the raised side marginal panels 9 of said roof sheets in contact with :each other from the securing bolts out 10 the eaves. In order to stiffen the seam .ca-ps where they are tinned down to form theidepending end flanges .24 where said flanges are turnedin-wardiy to form the flanges 24a, the caps are pressed inwardly to form strengthening corrugations 25 and :26, respectively.

By the arrangement just described, when the car goes out-of square under service conditions, the 'roofssheets slue or oscillate about their centers; and as an incident to this movement, two diagonally opposite corners of a sheet move away from the adjacentsideiplates respectively while the other two diagonally opposite corners of said sheet move toward said side plates respectively, producing at the eaves what is commonly :known as a sawtooth effect. This movement of :the two 1diagonally opposite corners of the sheet away from the side plate causes the rehent lower end portions 23a of the depending eaves flanges 23 of :said sheet to lower and thus press downwardly upon the rebent lower ends 240; of the depending end flanges of the seam caps and force the latter down upon the roof sheets; and this downward pull on thezseam caps throws a twist in the sheet and causes the other two diagonally opposite corners :of the sheet to spring upwardly into engagement with the underside of theseam cap.

By the arrangement described, the raised side marginal panels 9 of the roof sheets are supported throughout their length on "the ledges 6 of the carlines andare thus prevented from falling away from the base flanges 12 of the transverse seam caps, which flanges,

unsupported middle portions of said roof sheets and render them strong'enough to sup without departing from .the

tions or ribs 22 formed in said roof sheets span the spaces between the sheet support-v ing flanges 8 of adjacent carlines and thus serve to increase the vertical strength of the port the Vertical roof load. a The bolts 16 for securing the eaves portions of the seam caps to the carlines are supportedin the brackets 18 that are permanently attached to the seam caps and are slotted to permit said bolts to be readily attached to and detached from said brackets when the caps are detached from the car; and the pressure of said caps on the roof sheets may be regulated by tightening or loosening the nuts 17 on the lower end of said securing bolts.

Obviously, the hereinbefore described construction admits of considerable modification invention. Therefore, I do not wish'to be limited to the a precise arrangements shown and described.

What I claim is: 1. A car roof comprising side plates, carlines supported by said side plates and roof sheets movably supported on said side plates and carlines, said carlines having their side margins raised to provide supportsforsaid roof sheets, said roof sheets being provided with stiffening ribs that extend from the roof sheet support of one carline to the roof sheet support of the adjacent carline.

2. A car roof comprising side plates, carlines. supported by said side plates and roof sheets movably supported on said side plates and said carlines, a carline comprising an upper member of inverted channel-shape with the upper portions of its side walls ofiset inwardly to form longitudinal support ing ledges for the side marginal portions of adjacent roof sheets. and a lower plate-like member secured to the bottom of said upper carline member, saidlower member being Wider than said upper member andhaving its side margins raised beyond said upper member to form supports for said roof sheets outwardly beyond and somewhat lower than said ledges.

3. A car roof construction comprising side plates, carlines supported by said side plates, 'roof sheets movably supported on said side plates and said carlines, a carline comprising "an upper member of inverted channel-shape with the upper portions of its sidewalls offan adjacent carline. v i .6. A car roof construction comprising side; plates, carlines supported=bysaidside plates, 7 and roof' 'sheet's movably :suppOrted-onsaid marginal panels.

set inwardly toj'form' supporting ledges for the marginal portions of said sheets, and a lower plate-like member s'ecuredto thebot tom of said upper carline member, said'lower member being widen-than said upper member and having-its-side margins raised:be} yond said upper member to form. supports for said rool sheets at a somewhat lowerlevl f than said ledges said roof sheets bein rovided-with corrugations that span the spaces between the roof sheet supporting flanges of the lowermembers ofadjacent carlines. 1-; A carroof comprismg s1de-plates, -carliI-lfiS ELlPPGIti-Bd by said s de plates and roof sheets movably supported on said. side plates and carlines, said roof'sheets: havingtheir 'sideinargins' formed into panels that 'are raised above the bodies of the roof-sheets, said carlines having their'side margins raised to provide supports for the bodiesof said 3 root sheets and be'ing provided inter-mediate said raised-side inarginswith longitudinal ledgesslightly higher than said supports for supportingtheside'marginal panels of said roof sheets. 7 a 4' 5. A car reotcomprising. side plates,.car.- lines supported by said side plates and roof sheets niovably supported on said side plates and carl'ines, saidroof sheets; having their side margins formed into panels that are raised above the bodies of'the roof: sheets, said CELIllIlGS having their side margins raised to provide'supports for the bodies of said roof sheetsand being provided intermediate said raised side margins withlongitudinal ledges for supporting theside marginalpanels of-said roof sheets, the body portions-of said roofsheets being-provided with stillen- 'ing ribs that extend from the raised side mar.- I rginal roof sheet support of one carlme' t0 the raised side; marginal roof sheet support of side plates and said carlines and: having-their incline upwardly and outwardly, acarline side margins pressed'into raised panels that comprising an'iupper'member of inverted A channel shape with the upper portions of its sidewalls ofiset inwardly to form supports for the inclined side marginal panels of said sheets that are'inclined conformablylto the inclination thereof, and a lower plate like ,1 member securedyto the bottom of said "upper carline member, said lower member being wider than said upper member and having its side margins raised beyond said upper "member to form supports for the'portions ofsaid roof sheets that are -located' inside theirside 7. A car roof'having asubstructure including side plates, roof sheetsmovably supported on said side plates, and seam caps straddling the side marginal portions of adj acent roof a plates,said seam caps having depending end flangesthat overhang and are spaced from the depending eaves flanges of adjacent roof sheets and are provided at their lower ends with inwardly extending flanges that bear against the lower ends of said depending ceraugatien, at the angle termed-by the, p of thelcapsand their depending end flanges and :at the angle formed by the depending end flanges, 04 said caps and= t-h e inwardly BXtending flanges aty the lower ends of del sheets, said roof sheets being provided with Q waves .{ianges :o'f adj acent sheets are provided eaves .flanges. v

8. A 1021:! roof comprising side plates, car- -lines vsupported by said side plates, roof sheets movahly supported .on said side plates and said carlines, and seam caps straddling said ca-rlines and the side marginal portions of :adjacentasheets and secured tocsaid carlines .interinediatesaid side plates, said roof sheets being provided with depending eaves flanges that overhang and are spaced from said side :pl ates,.said seam caps having depending end flanges that over-hang and are spaced from the depending eaves flanges of adjacent sheets and are :bent inwardly beneath and in contact with the lower ends of the depending eaves flanges of adjacent roof sheets.

19. A car roof comprising side plates, carzlinessnpported by said side plates, roof-sheets 'movahly supported on said side plates and said .carllines, sea-1n caps secured to said carlines intermediate said side plates and straddlingsaid canlinesand the side marginal poritions-ef :adijacent sheets, said seam caps having ,rba-se flanges resting npon adjacent roof v as {190 depending eaves flanges that overhang and nrespaced fromsaid side plates and are bent inwardly at their lower :ends, said seam caps having depending end flanges that overhang and are spaced from the depending eaves :flanges of adjacent sheets are provided at their lower ends with inwardly extending flanges .thatihearagainst the .undersides rof fthe rbent :lower .ends of the depending aeaves :flanges of adjacent roo'fzsheets. 10. A car roof comprising side plates, carilinessnpportedPby said side plates, roof sheets amonably supported on said side plates and ;-saidwcarli-nes, seam caps secured to said car- ;lines intermediate said side plates and strade :dling isaid ecarlines and the side marginal portions of adjacent sheets, said seam caps shaving base flanges {resting :upo-n adjacent :roofsheets, said .rroof sheets being provided with depending :ea'ves flanges that overhang and :are spaced from saidside plates and are zbentinvaardly at'theii' lower ends,sa id sea-n1 caps haying depending end flanges thatoverhang and are spaced from the depending at their lower ends with inwardly extending flanges that bear against the u-ndersides of the inwandl-ylbent lower-ends of it-he depend- '-ilkg eanes:.=flanges Q-f adjacent roofsheets, said I caps being provided with-a sti fi'ening V l y r343

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US509640A US1853796A (en) | 1931-01-19 | 1931-01-19 | Car roof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US509640A US1853796A (en) | 1931-01-19 | 1931-01-19 | Car roof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1853796A true US1853796A (en) | 1932-04-12 |

Family

ID=24027497

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US509640A Expired - Lifetime US1853796A (en) | 1931-01-19 | 1931-01-19 | Car roof |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1853796A (en) |

-

1931

- 1931-01-19 US US509640A patent/US1853796A/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1853796A (en) | Car roof | |

| US1615105A (en) | And fbancis a | |

| US1921803A (en) | Car roof | |

| US1915773A (en) | Car roof | |

| US1526768A (en) | Car roof | |

| US1450243A (en) | Car roof | |

| US1627372A (en) | Car roof | |

| US1456732A (en) | Car roof | |

| US1330975A (en) | Charles david bonsai | |

| US1724746A (en) | Car roof | |

| US1526826A (en) | Car roof | |

| US1300258A (en) | Car-roof. | |

| US1718028A (en) | Car roof | |

| US1481823A (en) | Car roof | |

| US1829164A (en) | Railway car | |

| US1853655A (en) | Metal car roof | |

| US1724745A (en) | Car roof | |

| US1635305A (en) | Car roof | |

| US1481824A (en) | Car roof | |

| US2085540A (en) | Car roof | |

| US1964247A (en) | Car roof | |

| US1674089A (en) | Car roof | |

| US1855935A (en) | Car roof | |

| US1853797A (en) | Carline | |

| US1868190A (en) | Car roof |