US1853486A - Depository device - Google Patents

Depository device Download PDFInfo

- Publication number

- US1853486A US1853486A US308515A US30851528A US1853486A US 1853486 A US1853486 A US 1853486A US 308515 A US308515 A US 308515A US 30851528 A US30851528 A US 30851528A US 1853486 A US1853486 A US 1853486A

- Authority

- US

- United States

- Prior art keywords

- receptacle

- bolt

- locking

- charging

- entrance

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000007599 discharging Methods 0.000 description 17

- 101100532451 Rattus norvegicus Slc22a17 gene Proteins 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05G—SAFES OR STRONG-ROOMS FOR VALUABLES; BANK PROTECTION DEVICES; SAFETY TRANSACTION PARTITIONS

- E05G7/00—Safety transaction partitions, e.g. movable pay-plates; Bank drive-up windows

- E05G7/001—Bank depositories

Definitions

- This invention relates to va device particularly adapted for use by banks or the like to enable depositors to safely deposit sums of money or valuables after closing hoursof the bank or upon holidays, when ordinary deposit cannot be made.

- This device consists of a rotary member of U-shape which in one position is arranged to receive the deposit and which then may be turned to a discharging position so that the deposit may drop therefrom into the chute. In this device, direct access to the chute by one on the outside of the building is prevented.

- the object of the present invention is the provision of a rotary depository device of this character which will prevent carelessness of the depositor in ascertaining whether the proper discharge of the contents has been made. Specifically, it is the object of the present device to provide mechanism which will necessitate, after turning of the rotary receptacle to discharging position, a reversal of movement to bring the receptacle back to charging position prior to locking or removal of the keyby the depositor, so that he may ascertain whether a complete and properdischarge has been made.

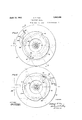

- Fig. 1 is a front elevation showing the appearance of the depository device from the outside of the bank.

- Fig. 2 is asection taken through the aXis of the rotary member on line 2-2 of Fig. 3.

- Fig. 3 is a sectional elevation of the mechanism which accomplishes the object of the present invention.

- Fig. 4 is a view similar to Fig. 3 showing Y the mechanism in a different operative position.

- Fig. 5 is a transverse section taken substantially on linepg5-5 of Fig. 2.

- Fig. 6 is a fragmentary sectional view 4(i5 taken on line 6 6 of Fig. 4. n

- the improved device is similar in many respects to the depository device disclosed in my application Ser. N o. 308,514, filed Sept.l 26, 1928, to which reference is hereby made for complete disclosure of and claims directed to l'various broad features of the present device.

- the present structure comprises a casing 2 secured to a face plate 4 provided withan entrance opening 6.

- This casing is provided with a sloping eXit opening 8 communicatingwith a suitable chute adapted to carry deposits into a vault in the '10 ⁇ interior ofthe building.

- the casing may be Y enclosed in a concrete or other suitable structure, as is customary'in devices of this character.

- trunnionsV 12 carried by kcylinder heads 14 and 16 secured to flanges on a rotary receptacle 18, provided with a receiving space 2O therein.

- the rotary receptacle is provided with an out- 80 wardly .extending knurled flange 22 which maybe grasped by a depositor to rotate the Y receptacle".

- Interiorly ofthe shell;like ⁇ struc ture comprising thereceptacle ⁇ is an insert of non-burnable, hardened metal lsuch as de- 85 yscribed inthe application referred to. Suitable burglar alarm wi'res 26 may be included within the receptacle.

- the left-hand cylinder head 14 is provided with anaperture 28 .into which a bolt 30, slid-M0 ably mounted in the casing, is adapted toenter to lock the cylinder in its discharging position.

- Bolt 30 is arranged tobe actuated by a lever 32 mounted on a spindle extending inwardly from a ,lock 34 adapted to be actu- 95 ated by a key.

- Lock V34 is of the well-known type preventing removal of the key unless bolt 30 is in position locking the receptacle.

- a 'plate 36 Rotatably journalled coaXially with the receptacle is a 'plate 36 provided ⁇ with twoI 100 ratchet teeth 38 and 40, shown in Figs. 3 and 4. Cooperating with these ratchet teeth is a pawl 42 pivoted at 44 to the left hand cylinder head and urged into engagement with plate 36 by a spring 46.

- Plate 36 is provided with an aperture 48 of a size permitting bolt 30 to pass therethrough. As illustrated in Fig. 6, plate 36 passes transversely of the path of movement of the end of bolt 30 so that, unless aperture 48 is aligned with the bolt, the bolt may not pass into opening 28 inthe cylinder head to lock the receptacle.V As indicated in Fig.

- the receptacle is provided with stop faces 52 and 54 arranged to cooperativelyengage with a iixed stop lug carried by the casing.

- the receptaclev is permitted to move from the position shown in Fig. 5 with the receiving space therein aligned with exit 8 in a counter-clockwise direction, as viewed in that ligure, to a position with opening 2O aligned with entrance opening 6.

- the stops prevent rotation from the charging position counter-clockwise to discharging position.

- a casing having entrance and exit openings, a rotary receptacle provided with a receiving space arranged to be brought into alignment with said entrance and exit openings when the receptacle is brought respectively into charging and for locking said receptacle, and rotatable means actuated by rotation of the receptacle for preventing operation of said locking means after the receptacle has been initially rotated from charging to I tion until the receptacle is rrotated to a position enabling a depositor to ascertain proper discharge of the contents and again rotated to locking position.

- a rotary receptacle provided with a receiving space arranged to be brought into alignment with said entrance and exit openings whenv the receptacle is brought respectively into 95 charging and discharging positions, means for locking Ysaid receptacle, and rotatable means actuated by rotation ofthe receptacle for preventing operation of said locking v means after the receptacle has been initially 10o rotated from charging to discharging position until the receptacle is rotated to charging position andagain rotated to locking position.

- a casing having entrance and exit openings, a rotary receptacle provided with a receiving space arranged to be brought into alignment with said. entrance and exit openings when the receptacle is brought-respectively into im means actuated upon rotation' of the recep- 115 tacle to prevent the engagement of the bolt with the receptacle after the receptacle has been initially moved from charging to discharging position until the receptacle is moved to a position enabling a depositor to ascertain proper discharge of the contents and again moved to locking position.

- a casing having entrance and exit openings, at..

- rotary receptacle provided with a receiving space arranged to be brought into alignment with saidv entrance Aand exit openings when the receptacle -is broughtA respectively into charging and discharging positions, means for locking said receptacle, said locking '130 discharging positions, means 80 discharging posia5 the character described, 90

- a casing having entrance and exit openings, a receptacle provided With a receiving space arranged to be brought into alignment With said entrance and exit openings

- means for locking said receptacle and means for preventing operation of said locking means after the receptacle has been initially moved from charging to discharging position until the receptacle is moved to a position enabling a depositor to ascertain proper discharge of the contents and again moved to locking position.

- receptacle provided with a receiving space arranged to be brought into alignment Withsaid entrance and exit openings when the receptacle is brought respectively into charging and discharging positions, means for locking said receptacle, and means for preventing operation of said locking means after the receptacle has been initially moved fromV charging to discharging position until the receptacle is moved to charging position'and again moved to locking position.

Landscapes

- Business, Economics & Management (AREA)

- Finance (AREA)

- Chutes (AREA)

Description

April 12, 1932. 1 F- YE@ 1,853,486

DEPOSITORY DEVICE Fi1ed sept. 26, 1928 8Y sheetssheet 1 MAW April 12, 1932. s. P. YEo l 1,853,486

DEPOSITORY DEVICE Filed Sept. 26, 1928 3 Sheets-Sheet 2 @faam Jam/ P 90 April 12, 1932. s. P. YEO

DEPosIToRY DEVICE Filed Sept. 26, 1928 3 Sheets-Sheet 3 wf/vrom Seb-:uff )Q0 Afro/Marys.

Patented Apr. 12, 1932 SAMUEL P. YEO, F IIEHIILADELIPHIA,` PENNSYLVANIA.

DEPOSITORY DEVICE Application led September 26, 1928. Serial No. 308,515.

This invention relates to va device particularly adapted for use by banks or the like to enable depositors to safely deposit sums of money or valuables after closing hoursof the bank or upon holidays, when ordinary deposit cannot be made. l

It has become customary to provide, for the purpose offpermitting depositsafter bank hours or on holidays, receptacles within the bank in which deposits may be made through chutes extending through the outer walls. In order to prevent tampering with such chutes in an attempt to reach the deposits, devices have been provided at the entrance to the chutes preventing access thereto except for legitimate purposes. One of such devices is disclosed in my prior Patent No.

1,57 6,125, dated March 9, 1926. This device consists of a rotary member of U-shape which in one position is arranged to receive the deposit and which then may be turned to a discharging position so that the deposit may drop therefrom into the chute. In this device, direct access to the chute by one on the outside of the building is prevented.

The object of the present invention is the provision of a rotary depository device of this character which will prevent carelessness of the depositor in ascertaining whether the proper discharge of the contents has been made. Specifically, it is the object of the present device to provide mechanism which will necessitate, after turning of the rotary receptacle to discharging position, a reversal of movement to bring the receptacle back to charging position prior to locking or removal of the keyby the depositor, so that he may ascertain whether a complete and properdischarge has been made.

In the accompanying drawings:

Fig. 1 is a front elevation showing the appearance of the depository device from the outside of the bank. v

Fig. 2 is asection taken through the aXis of the rotary member on line 2-2 of Fig. 3.

Fig. 3 is a sectional elevation of the mechanism which accomplishes the object of the present invention.

Fig. 4 is a view similar to Fig. 3 showing Y the mechanism in a different operative position.

Fig. 5 is a transverse section taken substantially on linepg5-5 of Fig. 2.

Fig. 6 is a fragmentary sectional view 4(i5 taken on line 6 6 of Fig. 4. n The improved device is similar in many respects to the depository device disclosed in my application Ser. N o. 308,514, filed Sept.l 26, 1928, to which reference is hereby made for complete disclosure of and claims directed to l'various broad features of the present device.

Similarly to the device disclosed in the application referred to, the present structure comprises a casing 2 secured to a face plate 4 provided withan entrance opening 6. This casing is provided with a sloping eXit opening 8 communicatingwith a suitable chute adapted to carry deposits into a vault in the '10` interior ofthe building. The casing may be Y enclosed in a concrete or other suitable structure, as is customary'in devices of this character.

. '.Suitably mounted in bearings 10, pref- 75 erably of an anti-friction type, are trunnionsV 12 carried by kcylinder heads 14 and 16 secured to flanges on a rotary receptacle 18, provided with a receiving space 2O therein. The rotary receptacle is provided with an out- 80 wardly .extending knurled flange 22 which maybe grasped by a depositor to rotate the Y receptacle". Interiorly ofthe shell;like`struc ture comprising thereceptacle `is an insert of non-burnable, hardened metal lsuch as de- 85 yscribed inthe application referred to. Suitable burglar alarm wi'res 26 may be included within the receptacle.

The left-hand cylinder head 14 is provided with anaperture 28 .into which a bolt 30, slid-M0 ably mounted in the casing, is adapted toenter to lock the cylinder in its discharging position. Bolt 30 is arranged tobe actuated by a lever 32 mounted on a spindle extending inwardly from a ,lock 34 adapted to be actu- 95 ated by a key. Lock V34 is of the well-known type preventing removal of the key unless bolt 30 is in position locking the receptacle.

Rotatably journalled coaXially with the receptacle is a 'plate 36 provided `with twoI 100 ratchet teeth 38 and 40, shown in Figs. 3 and 4. Cooperating with these ratchet teeth is a pawl 42 pivoted at 44 to the left hand cylinder head and urged into engagement with plate 36 by a spring 46. Plate 36 is provided with an aperture 48 of a size permitting bolt 30 to pass therethrough. As illustrated in Fig. 6, plate 36 passes transversely of the path of movement of the end of bolt 30 so that, unless aperture 48 is aligned with the bolt, the bolt may not pass into opening 28 inthe cylinder head to lock the receptacle.V As indicated in Fig. 3, the receptacle is provided with stop faces 52 and 54 arranged to cooperativelyengage with a iixed stop lug carried by the casing. By this means, the receptaclev is permitted to move from the position shown in Fig. 5 with the receiving space therein aligned with exit 8 in a counter-clockwise direction, as viewed in that ligure, to a position with opening 2O aligned with entrance opening 6. The stops prevent rotation from the charging position counter-clockwise to discharging position.

When the receptacle is locked the parts Voccupy the positions shown in Fig. 3, with bolt 30 passing through aperture 48 into opening 28 in the cylinder head. At this time, pawl 42 engages ratchet tooth 38. Upon unlocking of the device by withdrawal of bolt 30 from opening 28 and aperture 48 the depositor will turn the receptacle in a counter- Clockwise direction, as viewed in Figs. 3 and 4, juntil the receiving space is brought into alignment with opening 6. At this time Vthe parts will be in the positionsA shownl in Fig. 4. .A deposit is then placed in the receptacle and it is turned in a clockwise direction to discharging position. During this movement pawl 42 rides rearwardly away from tooth 38 and over tooth 40 and' occupies a position substantially such as shown in Fig. 3. During this operation, however, plate 36 will remain in the position shown in Fig. 4.

vThe contents of the vreceptacle should now be discharged through chute 8. If an attempt boit 3o.

' time he may view were now- Ymade to lock the receptacle, it would be unsuccessful, since aperture 48 is out of alignment with bolt 30 and a solid portion of plate 36 is in the path thereof. In order to permit locking, the depositor must againV move the receptacle in a counter-clockwise direction to charging position, at which the interior and ascertain whether or not a proper discharge of the contents has been effected. During this movement, pawl 42 will engagetooth 40, bringing vtooth 40 into that position occupied by tooth 38 in Fig. 4, or in other words, into the position occupied by tooth 40 in Fig. 3, at which time aperture 48 will be in alignment with Upon again imparting clockwise movementito the receptacle in order to bring it into discharging position, pawl 42 will ride y away from engagement with tooth 40 to a withdrawn, all the parts being now restored ,lo

to initial position.

What I claim and desire to protect by Letters Patent is:

i. In a device of the character described,

a casing having entrance and exit openings, a rotary receptacle provided with a receiving space arranged to be brought into alignment with said entrance and exit openings when the receptacle is brought respectively into charging and for locking said receptacle, and rotatable means actuated by rotation of the receptacle for preventing operation of said locking means after the receptacle has been initially rotated from charging to I tion until the receptacle is rrotated to a position enabling a depositor to ascertain proper discharge of the contents and again rotated to locking position.

2. In a device oi' a casing having entrance and exit openings, a rotary receptacle provided with a receiving space arranged to be brought into alignment with said entrance and exit openings whenv the receptacle is brought respectively into 95 charging and discharging positions, means for locking Ysaid receptacle, and rotatable means actuated by rotation ofthe receptacle for preventing operation of said locking v means after the receptacle has been initially 10o rotated from charging to discharging position until the receptacle is rotated to charging position andagain rotated to locking position.Y

3. In a device of the character described,m

a casing having entrance and exit openings, a rotary receptacle provided with a receiving space arranged to be brought into alignment with said. entrance and exit openings when the receptacle is brought-respectively into im means actuated upon rotation' of the recep- 115 tacle to prevent the engagement of the bolt with the receptacle after the receptacle has been initially moved from charging to discharging position until the receptacle is moved to a position enabling a depositor to ascertain proper discharge of the contents and again moved to locking position.

4. In a device of the character described, a casing having entrance and exit openings, at..

rotary receptacle provided with a receiving space arranged to be brought into alignment with saidv entrance Aand exit openings when the receptacle -is broughtA respectively into charging and discharging positions, means for locking said receptacle, said locking '130 discharging positions, means 80 discharging posia5 the character described, 90

means including a bolt slidable in the casing and adapted to engage the receptacle, a rotary plate positioned in the path of the bolt and provided With an aperture through which the bolt may pass to engage the receptacle, said plate being provided With ratchet teeth, and a paWl carried by the receptacle and cooperating With said teeth and arranged to move said plate during initial actuation of f the receptacle to bring the aperture out of the path of the bolt thus preventing engagement of the bolt With the receptacle after the receptacle has been initially moved from charging to discharging position, and to restore the plate to position With the aperture therein in alignment with the bolt duringy subsequent actuation of the receptacle so that the bolt may lock the same after the receptacle is moved to a position enabling a deposif Y tor to ascertain yproper discharge of the contents and again moved to locking position.

5. In a device of the character described, a casing having entrance and exit openings, a receptacle provided With a receiving space arranged to be brought into alignment With said entrance and exit openings When the receptacle is brought respectively into charging and discharging positions, means for locking said receptacle, and means for preventing operation of said locking means after the receptacle has been initially moved from charging to discharging position until the receptacle is moved to a position enabling a depositor to ascertain proper discharge of the contents and again moved to locking position.

6. In a device of the character described, a

casing having entrance and exit openings, a v

receptacle provided with a receiving space arranged to be brought into alignment Withsaid entrance and exit openings when the receptacle is brought respectively into charging and discharging positions, means for locking said receptacle, and means for preventing operation of said locking means after the receptacle has been initially moved fromV charging to discharging position until the receptacle is moved to charging position'and again moved to locking position.

In testimony of Whichrinvention, I have hereunto set my hand f at Philadelphia, Pennsylvania, on this 24th day of September,

SAMUEL P. YEO.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US308515A US1853486A (en) | 1928-09-26 | 1928-09-26 | Depository device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US308515A US1853486A (en) | 1928-09-26 | 1928-09-26 | Depository device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1853486A true US1853486A (en) | 1932-04-12 |

Family

ID=23194278

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US308515A Expired - Lifetime US1853486A (en) | 1928-09-26 | 1928-09-26 | Depository device |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1853486A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2617584A (en) * | 1949-07-22 | 1952-11-11 | Diebold Inc | Night depository construction |

| US4466357A (en) * | 1982-02-03 | 1984-08-21 | Kumahira Safe Co. Inc. | After hour depository |

| EP0257981A3 (en) * | 1986-08-21 | 1989-04-19 | F.C. Brown (Steel Equipment) Limited | Security closure mechanism |

-

1928

- 1928-09-26 US US308515A patent/US1853486A/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2617584A (en) * | 1949-07-22 | 1952-11-11 | Diebold Inc | Night depository construction |

| US4466357A (en) * | 1982-02-03 | 1984-08-21 | Kumahira Safe Co. Inc. | After hour depository |

| EP0257981A3 (en) * | 1986-08-21 | 1989-04-19 | F.C. Brown (Steel Equipment) Limited | Security closure mechanism |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2480685A (en) | Bank depository | |

| US3593881A (en) | Time and money controlled money vending-depository | |

| US1853486A (en) | Depository device | |

| US1060018A (en) | Safe-deposit box. | |

| GB1105517A (en) | Improvements in or relating to coin operated locks | |

| US3031133A (en) | Bank night depository entrance | |

| US1760462A (en) | Depository device | |

| US3690430A (en) | Cable operated article releaser | |

| US1853485A (en) | Depository device | |

| US2861667A (en) | Coin and key operated lock | |

| US871126A (en) | Indicator-lock. | |

| US2723018A (en) | Check-controlled lock mechanism | |

| US1373863A (en) | Coin-controlled locker-lock | |

| US1933263A (en) | Coin controlled lock | |

| USRE28308E (en) | Cash acceptance receptacle | |

| US1064860A (en) | Time-lock for cash-receptacles. | |

| US1722030A (en) | Coin-controlled safe | |

| US1753481A (en) | Coin-operated vending machine | |

| US1379335A (en) | Automatic coin controlled device for permutation safe locks or the like | |

| US1194950A (en) | Best available copt | |

| US1096671A (en) | Coin-controlled lock. | |

| US1851546A (en) | Revolving door depository | |

| US1444325A (en) | Coin lock | |

| US1766560A (en) | Cash protector | |

| US1218958A (en) | Dispensing-machine. |