US1852968A - Method of burning low-volatile carbonaceous material - Google Patents

Method of burning low-volatile carbonaceous material Download PDFInfo

- Publication number

- US1852968A US1852968A US337359A US33735929A US1852968A US 1852968 A US1852968 A US 1852968A US 337359 A US337359 A US 337359A US 33735929 A US33735929 A US 33735929A US 1852968 A US1852968 A US 1852968A

- Authority

- US

- United States

- Prior art keywords

- flame

- burner

- combustion

- carbonaceous material

- fuel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title description 11

- 239000003575 carbonaceous material Substances 0.000 title description 10

- 238000002485 combustion reaction Methods 0.000 description 17

- 239000000463 material Substances 0.000 description 17

- 239000000446 fuel Substances 0.000 description 13

- 239000000571 coke Substances 0.000 description 4

- 239000003245 coal Substances 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C3/00—Combustion apparatus characterised by the shape of the combustion chamber

- F23C3/006—Combustion apparatus characterised by the shape of the combustion chamber the chamber being arranged for cyclonic combustion

- F23C3/008—Combustion apparatus characterised by the shape of the combustion chamber the chamber being arranged for cyclonic combustion for pulverulent fuel

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S48/00—Gas: heating and illuminating

- Y10S48/04—Powdered fuel injection

Definitions

- This invention relates to a new and useful method of burning pulverized coke or other carbonaceous material, low or lacking in volatile matter; and the principal object of devise a method whereby non-volatile carbonaceous material unsuitable for burning by means and methods used in ordinary pulverized coal practice, may be satisfactorily and completely burned.

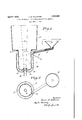

- Fig. 1 is a diagrammatic vertical sectional view of a boiler or other heat receiving element provided with means for carrying into effect the method which is the principal object of this invention.

- Fig. 2 is a sectional view taken substantially on line 22 of Fig. 1.

- crushed coke or other non-volatile carbonaceous material is fed at velocity atone end of a cylindrical chamber or elongated burner and at a tangent to the inner wall of said burner passing helically to the other end of said chamber or burner where it is forced into and mixed with a reversely moving axial current of air so that a flame is produced which passes through the core (i. e. along the axis) of the burner.

- This flame preheats the incoming feed which surrounds it, so that the incoming feed has its temperature raised to at least as high a temperature as the ignition temperature of the fuel, so that a shorter flame is produced and of higher temperature than in ordinary practice.

- Carbon dust in suspension in the medium which carries it in its helical path ofl'ers ideal conditions for being acted upon by the radiant heat of the flame, so the flame is not obliged to contact with the fuel feed in order to heat it.

- the helical feed may be either up or down or in any direction so long as the flame passes through the center of the feed so as to preheat the fuel. It will also be understood that in order to start the operation of the apparatus it may be heated up with a pulverized coal flame, gas or oil, or electric means or in any desired manner.

- FIG. 11 represents a cylindrical burner to which comminuted coke is fed from a hopper 12 by a conveyor 13.

- the conveyor 13 feeds coke to the burner 11 near one end of the latter and tangentially to the inner surface of the same and may feed through one or a multiplicity of inlets in the burner wall; and tan- C5 gential injectors or accelerators indicated at l inject the fuel at velocity into the burner, without producing combustion or chemical combination so that the fuel takes a helical path from the end near which it is injected toward the other end of the burner and following the inner wall of the latter.

- the end of the burner 11 opposite to that at whichthe fuel is fed is curved inwardly and upwardly as at 15 so as to direct the stream of fuel toward the axis of the burner and back towardrthe end of the burner from which the fuel has been fed.

- a jet of air is passed into the burnerthrough the pipe 16 and mixing with the fuel which has been fed along the surface 15 produces an axial flame indicated by the dot and dash lines 17.

- This flame passing along the axis of the on-coming fuel preheats it so that by the time this fuel reaches the point at which combustion is to occur, the fuel has attained a temperature which is at least the ignition temperature of the fuel so that a flame is immediately produced and this flame is a shorter flame than in present practice and an exceedingly hot Air which is fed to the pipe 16 is also preheated by drawing this air down between the burner 11 and a shell or jacket 18, said jacket 18 being so formed at 19 as to direct the heated air into the pipe 16.

- the method of burning carbonaceous material which consists in conducting the ma.- terialto be burned in a helical path along a burner wall and in the presence of an axial flame ositioned within said path and of then directing the material in another direction into the flame for combustion and in conduct ing air for combustion along the exterior of the burner wall and then directing the same to the burner for combustion.

- the method of burning carbonaceous material which consists in conducting the material to be burnedin one direction in a helical path along a burner wall and in the presence of a flame positioned axially of said path, thereby preheating said material without combustion thereof, and of then directing the material in another direction into said flame for combustion of said material and in conducting air for combustion along the exterior of the burner wall thereby to cool the burner wall, and then directing the air to the flame for combustion.

- a method of burning comminuted carbonaceous material low in volatile matter which consists in feeding said material to a furnace in a helical path, establishing a flame axially within said helical path in a position to preheat said material prior to combustion thereof, and then passing said preheated material into the flame to cause complete combustion of said material.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Solid-Fuel Combustion (AREA)

Description

April 5 1932. c. B. HILLHOUSE METHOD OF BURNING LOW VOLATILE CARBONACEOUS MATERIAL Filed Feb. 4, 1929 anvawcoz ;the invention is to Patented Apr. 5, 1932 UNITED STATES PATENT OFFICE CHARLES IB. HILLHOUSE, OF NEW YORK, N. Y.

Application flledlebruary 4, 1929. Serial No'. 337,359.

This invention relates to a new and useful method of burning pulverized coke or other carbonaceous material, low or lacking in volatile matter; and the principal object of devise a method whereby non-volatile carbonaceous material unsuitable for burning by means and methods used in ordinary pulverized coal practice, may be satisfactorily and completely burned.

Other objects will be apparent as the .description proceeds, and will be particularly pointed out in the appended claims. All of these objects are attained by means 51111 51 trated in the accompanying drawings, in which:

Fig. 1 is a diagrammatic vertical sectional view of a boiler or other heat receiving element provided with means for carrying into effect the method which is the principal object of this invention.

Fig. 2 is a sectional view taken substantially on line 22 of Fig. 1.

Like characters of reference refer to like parts in both views.

In carrying this invention into effect, crushed coke or other non-volatile carbonaceous material is fed at velocity atone end of a cylindrical chamber or elongated burner and at a tangent to the inner wall of said burner passing helically to the other end of said chamber or burner where it is forced into and mixed with a reversely moving axial current of air so that a flame is produced which passes through the core (i. e. along the axis) of the burner. This flame preheats the incoming feed which surrounds it, so that the incoming feed has its temperature raised to at least as high a temperature as the ignition temperature of the fuel, so that a shorter flame is produced and of higher temperature than in ordinary practice. Carbon dust in suspension in the mediumwhich carries it in its helical path ofl'ers ideal conditions for being acted upon by the radiant heat of the flame, so the flame is not obliged to contact with the fuel feed in order to heat it.

It will, of course, be understood that the helical feed may be either up or down or in any direction so long as the flame passes through the center of the feed so as to preheat the fuel. It will also be understood that in order to start the operation of the apparatus it may be heated up with a pulverized coal flame, gas or oil, or electric means or in any desired manner.

Referring to the drawings in detail, represents a boiler or other device to be heated, shown in the drawings in diagrammatic form. 11 represents a cylindrical burner to which comminuted coke is fed from a hopper 12 by a conveyor 13. The conveyor 13 feeds coke to the burner 11 near one end of the latter and tangentially to the inner surface of the same and may feed through one or a multiplicity of inlets in the burner wall; and tan- C5 gential injectors or accelerators indicated at l inject the fuel at velocity into the burner, without producing combustion or chemical combination so that the fuel takes a helical path from the end near which it is injected toward the other end of the burner and following the inner wall of the latter.

The end of the burner 11 opposite to that at whichthe fuel is fed is curved inwardly and upwardly as at 15 so as to direct the stream of fuel toward the axis of the burner and back towardrthe end of the burner from which the fuel has been fed. A jet of air is passed into the burnerthrough the pipe 16 and mixing with the fuel which has been fed along the surface 15 produces an axial flame indicated by the dot and dash lines 17. This flame passing along the axis of the on-coming fuel, preheats it so that by the time this fuel reaches the point at which combustion is to occur, the fuel has attained a temperature which is at least the ignition temperature of the fuel so that a flame is immediately produced and this flame is a shorter flame than in present practice and an exceedingly hot Air which is fed to the pipe 16 is also preheated by drawing this air down between the burner 11 and a shell or jacket 18, said jacket 18 being so formed at 19 as to direct the heated air into the pipe 16.

What I claim is:

1. The method of burning carbonaceous material which consists in conducting the ma.- terialto be burned in a helical path along a burner wall and in the presence of an axial flame ositioned within said path and of then directing the material in another direction into the flame for combustion and in conduct ing air for combustion along the exterior of the burner wall and then directing the same to the burner for combustion.

2. The method of burnin carbonaceous material which consists in con ucting the material to be burned in one direction in a helical path along a burner and in the resence of a flame positioned axially ofsald path, maintainin the material and flame in a relation to pre eat said material without .-combustion thereof, and of then directin the material in another direction into said ame for combustion.

3. The method of burning carbonaceous material which consists in conducting the material to be burnedin one direction in a helical path along a burner wall and in the presence of a flame positioned axially of said path, thereby preheating said material without combustion thereof, and of then directing the material in another direction into said flame for combustion of said material and in conducting air for combustion along the exterior of the burner wall thereby to cool the burner wall, and then directing the air to the flame for combustion.

4. The method of burnin carbonaceous material which consists in conducting the material to be burned in one direction along a helical path and without combustion of said material, establishing a combustion zone axially of said helical path to preheat said material, supplying air axially into said zone to maintain combustion therein and feeding the preheated material into said combustion zone.

5. A method of burning comminuted carbonaceous material low in volatile matter, which consists in feeding said material to a furnace in a helical path, establishing a flame axially within said helical path in a position to preheat said material prior to combustion thereof, and then passing said preheated material into the flame to cause complete combustion of said material.

In testimony whereof I afiix m signature.

CHARLES B. HILL OUSE.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US337359A US1852968A (en) | 1929-02-04 | 1929-02-04 | Method of burning low-volatile carbonaceous material |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US337359A US1852968A (en) | 1929-02-04 | 1929-02-04 | Method of burning low-volatile carbonaceous material |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1852968A true US1852968A (en) | 1932-04-05 |

Family

ID=23320246

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US337359A Expired - Lifetime US1852968A (en) | 1929-02-04 | 1929-02-04 | Method of burning low-volatile carbonaceous material |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1852968A (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2572829A (en) * | 1948-12-28 | 1951-10-30 | Phillips Petroleum Co | Coal gasification process and apparatus |

| US2614513A (en) * | 1950-03-28 | 1952-10-21 | Hofft Company Inc | Method of and vortex-type furnace for burning waste fuel |

| US2672108A (en) * | 1948-10-01 | 1954-03-16 | Gerald D Arnold | Furnace |

| US2717563A (en) * | 1950-01-16 | 1955-09-13 | Babcock & Wilcox Co | Horizontal cyclone furnace |

| US2745250A (en) * | 1952-09-26 | 1956-05-15 | Gen Electric | Reverse vortex combustion chamber |

| US2881719A (en) * | 1949-07-08 | 1959-04-14 | Babcock & Wilcox Co | Cyclone furnace |

| US3022753A (en) * | 1955-01-11 | 1962-02-27 | Jacksonville Blow Pipe Company | Incinerator |

| US3119379A (en) * | 1958-04-30 | 1964-01-28 | Sweeney Maxwell Patrick | Apparatus for combustion of fuels |

| WO1989012787A1 (en) * | 1988-06-14 | 1989-12-28 | Hultgren Karl S H | An arrangement for supplying pre-heated combustion air to a combustion chamber |

| WO2013070761A3 (en) * | 2011-11-11 | 2014-02-06 | Air Products And Chemicals, Inc. | Precombustor system and method for combustion for biomass |

-

1929

- 1929-02-04 US US337359A patent/US1852968A/en not_active Expired - Lifetime

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2672108A (en) * | 1948-10-01 | 1954-03-16 | Gerald D Arnold | Furnace |

| US2572829A (en) * | 1948-12-28 | 1951-10-30 | Phillips Petroleum Co | Coal gasification process and apparatus |

| US2881719A (en) * | 1949-07-08 | 1959-04-14 | Babcock & Wilcox Co | Cyclone furnace |

| US2717563A (en) * | 1950-01-16 | 1955-09-13 | Babcock & Wilcox Co | Horizontal cyclone furnace |

| US2614513A (en) * | 1950-03-28 | 1952-10-21 | Hofft Company Inc | Method of and vortex-type furnace for burning waste fuel |

| US2745250A (en) * | 1952-09-26 | 1956-05-15 | Gen Electric | Reverse vortex combustion chamber |

| US3022753A (en) * | 1955-01-11 | 1962-02-27 | Jacksonville Blow Pipe Company | Incinerator |

| US3119379A (en) * | 1958-04-30 | 1964-01-28 | Sweeney Maxwell Patrick | Apparatus for combustion of fuels |

| WO1989012787A1 (en) * | 1988-06-14 | 1989-12-28 | Hultgren Karl S H | An arrangement for supplying pre-heated combustion air to a combustion chamber |

| WO2013070761A3 (en) * | 2011-11-11 | 2014-02-06 | Air Products And Chemicals, Inc. | Precombustor system and method for combustion for biomass |

| JP2014535033A (en) * | 2011-11-11 | 2014-12-25 | エア プロダクツ アンド ケミカルズ インコーポレイテッドAir Products And Chemicals Incorporated | Pre-combustion system and method for combustion for biomass |

| US9683736B2 (en) | 2011-11-11 | 2017-06-20 | Air Products And Chemicals, Inc. | Precombustor system and method for combustion for biomass |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1852968A (en) | Method of burning low-volatile carbonaceous material | |

| US3250236A (en) | Combustion apparatus and method of operation | |

| US2800093A (en) | Apparatus for burning pulverized fuel | |

| GB980818A (en) | Method and apparatus for generating vapor | |

| US1726870A (en) | Method and apparatus for burning fuels | |

| US2249489A (en) | Combustion apparatus | |

| US2430601A (en) | Method for treating argillaceous material | |

| US1657698A (en) | Art of burning fuel | |

| US2806516A (en) | Combustion apparatus for use with boilers | |

| CA1223775A (en) | Burner for pulverized, gaseous and/or liquid fuels | |

| US836219A (en) | Process of burning fuel. | |

| US2096945A (en) | Burner | |

| US2038657A (en) | Method for making gas | |

| GB1014379A (en) | Manufacture of carbon black | |

| US1807321A (en) | Process and apparatus for the production from hydrocarbon oil of black pigment consisting of carbon | |

| US2833230A (en) | Pulverized coal firing system | |

| US1149734A (en) | Short-flame method of burning pulverized fuel. | |

| US867177A (en) | Method of burning finely-divided fuel. | |

| US3051556A (en) | Carbon black apparatus | |

| US1469178A (en) | Apparatus for supplying heat | |

| US1956506A (en) | Oil burner | |

| US691337A (en) | Apparatus for feeding fine fuel. | |

| US1561070A (en) | Process of and apparatus for producing cement | |

| DE881715C (en) | Ignition device for pulverized fuel systems | |

| US3441634A (en) | Process for producing cement and similar materials |