US1850141A - Method of making molds - Google Patents

Method of making molds Download PDFInfo

- Publication number

- US1850141A US1850141A US301037A US30103728A US1850141A US 1850141 A US1850141 A US 1850141A US 301037 A US301037 A US 301037A US 30103728 A US30103728 A US 30103728A US 1850141 A US1850141 A US 1850141A

- Authority

- US

- United States

- Prior art keywords

- mold

- metal

- molds

- pattern

- making molds

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004519 manufacturing process Methods 0.000 title description 8

- 229910052751 metal Inorganic materials 0.000 description 15

- 239000002184 metal Substances 0.000 description 15

- 238000000034 method Methods 0.000 description 10

- 238000000151 deposition Methods 0.000 description 7

- 230000008021 deposition Effects 0.000 description 4

- 229910045601 alloy Inorganic materials 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- 238000005304 joining Methods 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 101100400378 Mus musculus Marveld2 gene Proteins 0.000 description 1

- 229910052787 antimony Inorganic materials 0.000 description 1

- -1 antimony metals Chemical class 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 239000008151 electrolyte solution Substances 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000003923 scrap metal Substances 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23P—METAL-WORKING NOT OTHERWISE PROVIDED FOR; COMBINED OPERATIONS; UNIVERSAL MACHINE TOOLS

- B23P15/00—Making specific metal objects by operations not covered by a single other subclass or a group in this subclass

- B23P15/24—Making specific metal objects by operations not covered by a single other subclass or a group in this subclass dies

Definitions

- Another object of the invention is to provide a method of making molds whereby a single pattern may be utilized to form a mold having a. plurality of matrices of the shape of the article to be made.

- Molds. for forming articles of galvanoplastic metal areV generally constructed by preparing awax pattern or imprint of the surface to be reproduced, coatingthe wax member with graphite or other metallic preparation and submerging the same in an elecc tric'solution in which is provided a .cathode of scrap metal which is deposited on the coated surface of the wax member whichis constituted an anode in a suitable electrical circuit adapted vfor effecting the deposition ⁇ of metal thereon.

- Molds of Vthis character are expensive to manufacture and have usually been rvmade of quent use as matrices 'for forming other articles of galvanoplastic metal.

- lead and antimony metals which were best adapted for subse-y alloys can be successfully utilized as molds timony alloys may be made into suitable mold sections by 'employing a metal spray. for effecting the depositionof the metalf either lin the form of small particles or as molten metal by'applying such powdered or molten metal to the object on which the mold section isto be formed under pressure.

- Y -f i Metal spraying has ⁇ been Y developed "for platingY objects and to provide a coatingon the exterior ofarticles-for various purposes.

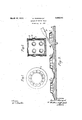

- Fig. 1 - is a plan view of a patternin the form cfa-wall bracket for lighting yfixtures from-whichthe mold is to be made.

- Fig. ⁇ 2 is a sectional elevational view of aimold made in accordance with the inventiomand Fig. 8 a sectional eleyational view 'of a.y portion of the"k mold illustrating the manner ⁇ in which it isfo'rmed.

- the pattern l After the pattern l has been completely covered with the deposited metal, it is removed and placed on the support 2 in suitable relation to the deposit formed thereon and a secondcoating isapplied which is extended over to they original deposition to form a continuous integral wall sectionand in this man nerf any desired number of matrices 7 may be formed integrally, three being shown in y ma Fig. ⁇ 3 to form a mold section which isVA 'my hand.

- molds can be cheaply made by the use of a single pattern and can accurately reproduce the configuration and dimensions of the pattern from which it is made. Molds as heretofore constructed were very expensive and greatly enhanced the cost of the articles-made therefrom.

- articles can be made of galvanoplastic metal, and other plastic materials, at a cost far belovsT the cost of manufacturing similar articles when made either by galvanoplastic process or by the die forming machine methods.

- Another advanl tage of the untilization of the present invention is in the speeding up of production, since the long delays of' Waiting on molds or dies is thereby eliminated.

- a plurality of matrices of -identicalfform which comprises, depositing Vparticles of metal under pressure on a pattern toV form a Wall section therearound, removing said pattern andforming a deposit of metal thereon adjacentsaid first named deposit and joining the. same to'said first deposit, said deposits forming an integral mold section having matrices ofthe formV and dimensions of l the. articles to be formed.V Y

- TheV method of making molds-Which comprises, depositing particles of metalY under pressure on afpattern to form a vWall section, removing said pattern and forming a vdeposit thereon integrally With said first named deposit, shaping said deposits to the form of'a slab to constitutesections of a ⁇ mold andV joining a plurality ofthe sections so i formed to constitute a unitary mold adaptedV to contain an electrical solution.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

Description

G. RosENQvlsT 1,856,141

METHOD OF MAKING MOLDS March 22, 1932.

Filed Aug; 21, 192e .SMQ

INVENToR. @NW I ATTORNEYS.

Patented Mar.v 22, 1932 l UNITED* STATES:

y GUNNAR nosENQvIs'r, or PITTSBURGH-PENNSYLVANIA s METHOD or MAKING norms Application filed August 21, 19x28; f' Serial No. 301,037. v

duce a mold of a lead base alloy for use in galvanoplastic processes which possesses the characteristic of receiving-a deposition of galvanoplastic metal without causing the latter to adhere thereto and without 'requiring any preliminary preparation of the matrix surface of the mold to prevent adherence of the deposition made thereon. v

Another object of the invention is to provide a method of making molds whereby a single pattern may be utilized to form a mold having a. plurality of matrices of the shape of the article to be made. f

Molds. for forming articles of galvanoplastic metal areV generally constructed by preparing awax pattern or imprint of the surface to be reproduced, coatingthe wax member with graphite or other metallic preparation and submerging the same in an elecc tric'solution in which is provided a .cathode of scrap metal which is deposited on the coated surface of the wax member whichis constituted an anode in a suitable electrical circuit adapted vfor effecting the deposition `of metal thereon.

Molds of Vthis character are expensive to manufacture and have usually been rvmade of quent use as matrices 'for forming other articles of galvanoplastic metal. I have discovered that lead and antimony metals which were best adapted for subse-y alloys can be successfully utilized as molds timony alloys may be made into suitable mold sections by 'employing a metal spray. for effecting the depositionof the metalf either lin the form of small particles or as molten metal by'applying such powdered or molten metal to the object on which the mold section isto be formed under pressure. Y -f i Metal spraying has `been Y developed "for platingY objects and to provide a coatingon the exterior ofarticles-for various purposes.

It is applied by depositing a very thin-,layer of lcoating on the article to'be treated. In accordance with the present invention, I propose to formmolds 4of relatively heavy wall sections byfa metalspray process and by employing suche. method,` al single pattern may .be utilized to form a mold havingv any `desired-`number of matrices for reproducing a V'particular article by galvanoplastic process.

In the accompanying drawings constituting a part hereof, Vand Vin which like reference charactersfdesignate like parts, Fig. 1 -is a plan view of a patternin the form cfa-wall bracket for lighting yfixtures from-whichthe mold is to be made. Fig.`2 is a sectional elevational view of aimold made in accordance with the inventiomand Fig. 8 a sectional eleyational view 'of a.y portion of the"k mold illustrating the manner `in which it isfo'rmed. f "Referringzto Fig;3,toform a mold suchv as is illustrated in: Fig.v 2,1' place the pattern .of Fig. lonjav suitablek support" `Q'having a kplain 'smooth uppersurface 3. I then `apply acoatin'g A of metal either in powdered form ormolten metal by mean'sof the spray'y gun: 5 which operates in Lalwell known mannerfand` `which doesl not form a part yof the present "invention... `.'Iliezdeposit ca nbe made iniany desirablethickness forming lafwall section 6 which constitutesthe mold section.

After the pattern l has been completely covered with the deposited metal, it is removed and placed on the support 2 in suitable relation to the deposit formed thereon and a secondcoating isapplied which is extended over to they original deposition to form a continuous integral wall sectionand in this man nerf any desired number of matrices 7 may be formed integrally, three being shown in y ma Fig.` 3 to form a mold section which isVA 'my hand.

trimmed along the edge and assembled with other mold sections to a supporting frame 8, Fig. 2, to which it is joined to constitute a unitary mold structure capable of holding an electrolytic solution, such a mold structure having been described in my Patent No. 1,735,909.

By the use of the method described, molds can be cheaply made by the use of a single pattern and can accurately reproduce the configuration and dimensions of the pattern from which it is made. Molds as heretofore constructed were very expensive and greatly enhanced the cost of the articles-made therefrom. .With the present method, articles can be made of galvanoplastic metal, and other plastic materials, at a cost far belovsT the cost of manufacturing similar articles when made either by galvanoplastic process or by the die forming machine methods. Another advanl tage of the untilization of the present invention is in the speeding up of production, since the long delays of' Waiting on molds or dies is thereby eliminated.

It is obvious that any of the methods of forming molds as herein described may be applied to other shapes than that illustrated and for other purposes Without departing from the spirit of myinvention.

I claim herein as my invention:

`1. The method of making molds having .Y

a plurality of matrices of -identicalfform which comprises, depositing Vparticles of metal under pressure on a pattern toV form a Wall section therearound, removing said pattern andforming a deposit of metal thereon adjacentsaid first named deposit and joining the. same to'said first deposit, said deposits forming an integral mold section having matrices ofthe formV and dimensions of l the. articles to be formed.V Y

2. TheV method of making molds-Which comprises, depositing particles of metalY under pressure on afpattern to form a vWall section, removing said pattern and forming a vdeposit thereon integrally With said first named deposit, shaping said deposits to the form of'a slab to constitutesections of a `mold andV joining a plurality ofthe sections so i formed to constitute a unitary mold adaptedV to contain an electrical solution. i

In testimony whereof I haveV hereunto set l i GUNNAR nosENQvIsT.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US301037A US1850141A (en) | 1928-08-21 | 1928-08-21 | Method of making molds |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US301037A US1850141A (en) | 1928-08-21 | 1928-08-21 | Method of making molds |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1850141A true US1850141A (en) | 1932-03-22 |

Family

ID=23161659

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US301037A Expired - Lifetime US1850141A (en) | 1928-08-21 | 1928-08-21 | Method of making molds |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1850141A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2447620A (en) * | 1945-08-24 | 1948-08-24 | Bendix Aviat Corp | Method of forming molds |

| WO2002068147A1 (en) * | 2001-01-19 | 2002-09-06 | Honeywell International Inc. | Method for fabricating a plastic optic element injection mold |

-

1928

- 1928-08-21 US US301037A patent/US1850141A/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2447620A (en) * | 1945-08-24 | 1948-08-24 | Bendix Aviat Corp | Method of forming molds |

| WO2002068147A1 (en) * | 2001-01-19 | 2002-09-06 | Honeywell International Inc. | Method for fabricating a plastic optic element injection mold |

| US6735844B2 (en) | 2001-01-19 | 2004-05-18 | Honeywell International Inc. | Method for fabricating a plastic optic element injection mold |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JPS59202829A (en) | Mold for injection molding synthetic resin product | |

| US2327762A (en) | Method of forming dies and the like | |

| US2734243A (en) | Method of securing a metal skin in a matrix block | |

| US1850141A (en) | Method of making molds | |

| US2182775A (en) | Method of making dies | |

| US5393405A (en) | Method of electroforming a gold jewelry article | |

| JP6343701B2 (en) | Method for manufacturing a timer with a concave or raised outer element | |

| US2293571A (en) | Production of spray metal negatives of models | |

| US3801413A (en) | Process for producing ornamental figures for jewelry and resulting article | |

| JP6310595B2 (en) | Method for manufacturing a timer with raised outer elements | |

| GB1319466A (en) | Method for producing a metal die or mould | |

| US2280864A (en) | Mold | |

| US2280866A (en) | Production of spray metal negatives of models | |

| US2540212A (en) | Method of forming molds for casting | |

| JPH0114848B2 (en) | ||

| JPH02502610A (en) | How to make molds for making denture parts | |

| JPS61129236A (en) | Production of dressing button | |

| US3402755A (en) | Method for making a precision casting | |

| US1134571A (en) | Stencil. | |

| US3956085A (en) | Method for the manufacture of a tool-set for the forming of sheet metal objects | |

| US1979132A (en) | Method of making patterns for die structures | |

| JP2000279082A (en) | Baking mold and production thereof | |

| GB400089A (en) | Method of manufacturing dental plates and like articles of metallic alloys | |

| US1689810A (en) | Method of making metal articles | |

| JPH06105A (en) | Patterned metal jewelery and method of manufacturing the same |