US1746292A - Towel cabinet - Google Patents

Towel cabinet Download PDFInfo

- Publication number

- US1746292A US1746292A US225350A US22535027A US1746292A US 1746292 A US1746292 A US 1746292A US 225350 A US225350 A US 225350A US 22535027 A US22535027 A US 22535027A US 1746292 A US1746292 A US 1746292A

- Authority

- US

- United States

- Prior art keywords

- cabinet

- towel

- roll

- web

- pinch roll

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 244000208734 Pisonia aculeata Species 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47K—SANITARY EQUIPMENT NOT OTHERWISE PROVIDED FOR; TOILET ACCESSORIES

- A47K10/00—Body-drying implements; Toilet paper; Holders therefor

- A47K10/24—Towel dispensers, e.g. for piled-up or folded textile towels; Toilet paper dispensers; Dispensers for piled-up or folded textile towels provided or not with devices for taking-up soiled towels as far as not mechanically driven

- A47K10/28—Towel dispensers, e.g. for piled-up or folded textile towels; Toilet paper dispensers; Dispensers for piled-up or folded textile towels provided or not with devices for taking-up soiled towels as far as not mechanically driven dispensing a clean part and taking-up a soiled part, e.g. using rolls; with dispensers for soap or other detergents; with disinfecting or heating devices

Definitions

- Aof my present invention is to provide a towel cabinet wherein provision is made for placing theclean towel in only one way, so ⁇ there is no possibility of the attendant ⁇ making an error when loading the cabinot. Inother words, ⁇ the easiest way to ⁇ load the cabinet is the right-way.

- a furtherob- ⁇ :ject is to provide a cabinet which canbe loaded Mfrom the front, that is, without the necessity of passing the hands up through or into the baclr of the cabinet and a-still further obyject is to provide a cabinet ⁇ which after the floadingoperation is performed-,will be automatically set yby the closing-of the cabinet loer ⁇ and rendered loperative for immediate ⁇ use .when the loading operation is completed.

- lfortlie attendant to omit any step and cause the ,Cabinet t0 be inoperative.

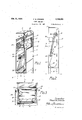

- Figure l is a perspective view with the side wall of the cabinet-removed showing the inner arrangement

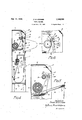

- Figure 2 is a side elevation of the cabinet

- Figure 3 is a front view of the upper portion of the cabinet with the door removed;

- Figure 4 1s a vertical sectional View showing ⁇ the web of towel drawn outwardly to a using position through the cabinet door, as indicated by dotted lines, the normal position of the towel being indicated by full lines;

- Figure 5 is a detailed view showing-the gate in its open or cabinet loading position; and e Figure (i is a detailed view showing the means for holding the pinch roll in its worling position when the cabinet is in use.

- FIG. 2 represents ⁇ the side walls of the cabinet, 3 the bottom on floor-*supported by suitable legs 4a 5 is the toplo'flthe cabinet and 6 ⁇ the rear wall thereof; 7 is a door closing the opening in the front of the cabinet andproif'ided with spring hinges 7 and an opening S of suitable height from the floor to allow the towel user to view the cleantowel and reach through the opening and grasp the clean web.

- "At ⁇ the bottomof the opening 8 l prefer to provide a roller 9 on which the web of towel falls when releasedV by the user, ⁇ to facilita-toits return into the cabinet.

- the ⁇ door 7 is preferably provided with a suitable loclr by means of which unauthorized access to the interior of the cabinet is pyrevented.

- the door 'I prefer to provide the usual mirror ⁇ l0 for convenience of the fromside to side and extending from' the rear wall forwardly to a point adjacent the door opening 8.

- This shelf is adapted to support the supply of clean towel 12 placed thereon.

- a gate or door 13 is provided with spring hinges 14 secured to the forward edge of the shelf and is adapted to swing downwardly and forwardly through the opening in the front of the cabinet when the door 7 is opened.

- This gate may be made of any suita le material, flexible or inflexible if preferred, but generally sheet metal or a wood anel will be employed and when the gate 1s in its raised position it will be substantially vertical as shown in Figure 1 and will conceal the supply of towel on the shelf 1'1.

- the upper edge of the gate has brackets 15- thereon provided with vertical slots 16 and a pinch roll 17 has a spindle 18 in the slots of said brackets at each end of the gate.

- a delivery feed roll 19 is mounted in bearings in the side walls of the cabinet adjacent the pinch roll 17 and the web of clean towel is stretched from the supply up between the feed roll 19 and the pinch roll and from thence depends opposite the door o ening where it can be conveniently graspec by the user.

- Plates 20 are mounted on the side walls of the cabinet and have inclined upper edges 21 terminating in prongs 22 which overhang the inner ends of the plates andhave bevelled lower edges 23.

- the first step after opening the cabinet door is to disengage the pinch roll from the prongs 22, swing the gate to the position indicated in Figure 5 and then insert the supply of clean towel upon the shelf 11.

- the end of the web is then stretched over the pinch roll as indicated and when the gate is alloyed to swing back to its normal vertical position the pinch roll will move to a point beyond the prongs 22 and then drop down either to its working position or be pulled down when the towel 1s used.

- This takeup feed roll for convenience in loading is operated in the opposite direction from the delivery feed roll 19 and I accomplish this by providing a chain 27 engaging a sprocket 28 on the roll 19, a similar idle sprocket 29 on the wall of the cabinet and an intermediate sprocket 30 on the takeup roll. lVith this arrangement the person loading the cabinet does not have to pass the web to the rear of the takeup feed roll, but may stretch it from the front of the cabinet direct to the takeup roll, the shorter and easier way. This sometimes was done by a careless attendant when the feed rolls were operated in the same direction, thereby preventing the takeup roll from performing its function.

- a lock device 31 adapted to be tripped by the finger of the user is provided in connection with the roll 19 for releasing and allowing it to make a single revolution, the locking device automatically setting itself to prevent a second revolution when the first one has been completed.

- This frame has the function of drawing the soiled web of towel into the cabinet where it will be partially concealed and inconspicuous when the cabinet is not in use. A user drawing out a length of towel will after use drop it and the web, unless means are provided to pull it back into the cabinet, would drop down and drape itself over the roller 9 and the front of the cabinet, but by providing the pull-back device 32 I am able to immediately withdraw the soiled section of the towel from view as soon as it is used and released.

- Atowel cabinet comprising a casing having a door and opening therein through which the web of clean towel is visible and may be drawn outwardly for use, a support for the clean towel supply within said cabinet, a feed roll mounted in said cabinet, a pinch roll adaptedl to press the web of clean towel againstsaid feed roll, a swinging support for the pinch roll having slotted bearings thereforwherein said pinch roll is movable transversely of the pinch roll axis, means for normally locking the pinch roll and its support in a raised position, ⁇ said transverse movement of said pinchroll in its slotted bearings operatively disengaging it and said support from said locking means ani allowing the roll and support to.

- a towel cabinet comprising a casing hav- ⁇ ing an opening therein and a door provided with a panel opening through which the web of clean towel is visible and accessible for use, a support for the clean towel supply within said cabinet, a feed roll mounted in said cabinet, a pinch roll and means supportingit adlocking said pinch rollin its working position, said pinch roll having means for freedom of lateral movement in said supportingmeans to adapt it for releasemanually from said locking means and said supporting means being pivoted to move outwardly through said .door opening with said pinch roll to a cabinetloading position, when the .web ofvclean towel may be'stretched over said pinch roll to depend within the cabinet and means for first directing said pinch roll automatically back to its normal working position adjacent said feed roll upon the return movement of said pinch roll into the cabinet and then wedging the pinch roll against the feed roll.

- A. towel cabinet comprising a casing having an opening through which accessv may Abe had to theclean towel, means within the casing for supporting a supply of clean towel, a" delivery feed roll mountedwithin ⁇ the cabinet,- apinch roll having a spindle supportedadjacent said feed roll, a support Iprovided with loose bearings for said spindle having a movement forwardly to allow the web of clean towel to be stretched over said pinch roll and between it and said delivery roll, plates mounted in said casing and having prongs thereon normally overhanging the supporting spindle of said pinch roll and preventing upward and outward movement thereof, said pinch roll having freedom of upward movement in its loose bearings on said support for manual disengagement from said plates and prongs and said plates have inclined upper surfaces to contact with the spindle of said pinch roll when moved toward said delivery roll and direct said pinch roll to a point where downward pull on the towel web will move said pinch roll to its working position adjacent said feed roll.

- a towel cabinet comprising a casing having an opening in its front wall, a shelf in the rear of said opening adapted to support a supply of clean towel, a delivery feed roll mounted above said shelf, a gate hinged to the forward portion of said shelf and having means for normally holding it in a raised position, a pinch roll having a spindle adapted to slide in slots provided on the .upper portion of said gate and normally pressing the web of clean towel stretched between said rolls into contact with said feed roll, means for locking said pinch roll and gate in their raised position but permitting manual re- .lease and downward movement of said gate and pinch roll through the opening in said casing to a loading position, the space above said shelf being exposed when said gate is moved downwardly to allow the insertion of the clean towel and such space being normally concealed when said gate is returned to its raised locking position.

- a towel cabinet comprising a casing having an opening through which access may be had to the web 4of clean towel, a support for the clean towel supply within said cabinet, a feed roll mounted in said cabinet, a pinch roll between which and said feed roll the web of clean towel may be stretched, an oscillating support for said pinch roll whereon it is movable outwardly through said opening to facilitate stretching the clean web thereover, means for normally locking said pinch roll against such outward movement, said pinch roll being loosely mounted in said support whereby it may be moved inwardlyv and upwardly thereon to release it from said locking means.

- a towel cabinet comprising a casing having an opening ⁇ through which access may be had to the web of clean towel therein, a support for the clean towel supply within said casing, a feed roll mounted in said cabinet, a pinch roll to press the web of clean towel against said feed roll, pivoted means for supporting said pinch roll andv adapted to separate the soiled web of towel from the clean web and prevent contact between them, means for normally wedging said pinch roll to its position against said feed roll, saidsupporting means having a slot therein tol permit movement of the pinch roll to separate it from said holding means, said pinch roll and its pivoted support having a movement downwardly and outwardly through the opening in said casing to a loading position wherethe web of clean towel may be conveniently stretched over said pinch roll and thereafter said pinch roll and support may be returned to their normal position adjacent said feed roll.

- a towel cabinet comprising a casing having an opening through which the web of clean towel may be drawn for use, a pair of rolls within the cabinet, pivoted means for supporting one of said rolls for movement outwardly and downwardly to a position convenient Vfor loading the cabinet, where the web of clean t-owel may be stretched over said movable roll during the loading ⁇ operation, means for locking said movable roll when in its raised position adjacent the other 2@ roll, said locking means including a cam for forcing said r-olls together upon the downward pull of the user on the web of clean towel.

- a towel cabinet having a door with a a5 panel therein, a shelf in the upper portion of the cabinet in rea-r of said panel, a feed roll mounted in said cabinet above the shelf, v a gate pivoted to the shelf and extending up between the shelf and said panel, a pinch roll carried by the gate and movable outside said door for towel loading purposes when the door is opened.

- a towel cabinet having a door with a panel therein, a shelf in the upper portion ofthe cabinet, a feed roll mounted in said cabinet above the shelf, a gate pivoted to the shelf and extending up between a towel supply on the shelf'and said panel, a pinch roll i carried by the gate and movable outside said 40 door when the same is opened, a takeup roll below the panel, a chamber in the lower part of the cabinet, and means in the chamber for drawing the towel web back into the chamber after the same is pulled through the panel said means being below the talreup roll.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Unwinding Webs (AREA)

Description

F. M. sTElNER TOWEL ('JABIHTl Feb. 11`, 1930.

Filed Oct. -10. 192'? 2 Sheets-Sheet 1 Patented Feb. 11, A193() Unirse .STATES mais;

PATENT orFItEN FRANK M. STEIN IER,` OF MINNEAPOLIS, MINNES-Tl, ASSIG-NOR TO STEINER COM- PANY, OF SALT LAKE CITY, UTAH, A CRIEOlEtATIOllT` OF UTAH TOWEL CABINET Application filed October 10, 1927. Serial No. 2.255350.

In the operation and maintenance of towel cabinets adapted for use in hotels, office buildings, factories, clubs and the like, it is necessary :at intervals to fill or reload the cabinet with a clean towel web Vremoving the soiled in has' neglected, throughlaclr -oftime or inattention, "to properly stretch or placegthe towel web in the cabinet so Vthat :the person using ,the towel will `have no ldiiiculty in `obtaining the desiredlength for wiping purposes. It has .been the practice to provide i a certain routine or manner `of placing the towel web in the cabinet and if Athis procedure is followed there 1is then no difficulty `in using the ltowel but if the web is improperly placed or stretched 1n the wrong manner in the `cabinet then it cannot be used untilthelerror `is corrected. It also often happens that `the `attendant in a hurry will forget to perform some essential `part ofthe operation and `the cabinet as a result `cannot perform its functions until the step that has been omitted 4has been performed. The object therefore Aof my present invention is to provide a towel cabinet wherein provision is made for placing theclean towel in only one way, so` there is no possibility of the attendant `making an error when loading the cabinot. Inother words,` the easiest way to `load the cabinet is the right-way. A furtherob- `:jectis to provide a cabinet which canbe loaded Mfrom the front, that is, without the necessity of passing the hands up through or into the baclr of the cabinet and a-still further obyject is to provide a cabinet `which after the floadingoperation is performed-,will be automatically set yby the closing-of the cabinet loer `and rendered loperative for immediate `use .when the loading operation is completed. Thusthereis no chance lfortlie attendant to omit any step and cause the ,Cabinet t0 be inoperative. Other objects of the invention will appear from the following detailed description.v

The invention consists generally in various constructions and combinations as heretofore described and particularly pointed out in the claims. A i

t `In the accompanying drawings forming part of this specification,

Figure l is a perspective view with the side wall of the cabinet-removed showing the inner arrangement;

Figure 2 is a side elevation of the cabinet;

Figure 3 is a front view of the upper portion of the cabinet with the door removed;

Figure 4 1s a vertical sectional View showing` the web of towel drawn outwardly to a using position through the cabinet door, as indicated by dotted lines, the normal position of the towel being indicated by full lines;

Figure 5 is a detailed view showing-the gate in its open or cabinet loading position; and e Figure (i is a detailed view showing the means for holding the pinch roll in its worling position when the cabinet is in use.

In the drawings 2 represents `the side walls of the cabinet, 3 the bottom on floor-*supported by suitable legs 4a 5 is the toplo'flthe cabinet and 6 `the rear wall thereof; 7 is a door closing the opening in the front of the cabinet andproif'ided with spring hinges 7 and an opening S of suitable height from the floor to allow the towel user to view the cleantowel and reach through the opening and grasp the clean web. "At `the bottomof the opening 8 l prefer to provide a roller 9 on which the web of towel falls when releasedV by the user, `to facilita-toits return into the cabinet. The `door 7 is preferably provided with a suitable loclr by means of which unauthorized access to the interior of the cabinet is pyrevented. Above" the door 'I prefer to provide the usual mirror `l0 for convenience of the fromside to side and extending from' the rear wall forwardly to a point adjacent the door opening 8. This shelf is adapted to support the supply of clean towel 12 placed thereon. A gate or door 13 is provided with spring hinges 14 secured to the forward edge of the shelf and is adapted to swing downwardly and forwardly through the opening in the front of the cabinet when the door 7 is opened. This gate may be made of any suita le material, flexible or inflexible if preferred, but generally sheet metal or a wood anel will be employed and when the gate 1s in its raised position it will be substantially vertical as shown in Figure 1 and will conceal the supply of towel on the shelf 1'1. The upper edge of the gate has brackets 15- thereon provided with vertical slots 16 and a pinch roll 17 has a spindle 18 in the slots of said brackets at each end of the gate. A delivery feed roll 19 is mounted in bearings in the side walls of the cabinet adjacent the pinch roll 17 and the web of clean towel is stretched from the supply up between the feed roll 19 and the pinch roll and from thence depends opposite the door o ening where it can be conveniently graspec by the user. Plates 20 are mounted on the side walls of the cabinet and have inclined upper edges 21 terminating in prongs 22 which overhang the inner ends of the plates andhave bevelled lower edges 23. These bevelled lower edges contact with the spindle of the pinch roll and normally hold it in its depressed position where it presses the web of towel against the sanded surface of the feed roll 9 with sufricient friction so that when the user pulls on the web of towel and revolves the pinch roll, the feed roll 19 will also be revolved. When access is desired to the towel supply or the delivery feed roll the attendant will press the gate and pinch roll inwardly until the spindle 18 clears the prongs 22 and then the gate and pinch roll may be swung downwardly and outwardly to the position indicated by full lines in Figure 5. Normally however the plates 20 will prevent such outward movement until the pinch roll is dislodged from the prongs 22 by the inward and upward movement of the roll. In loading the cabinet therefore the first step after opening the cabinet door is to disengage the pinch roll from the prongs 22, swing the gate to the position indicated in Figure 5 and then insert the supply of clean towel upon the shelf 11. The end of the web is then stretched over the pinch roll as indicated and when the gate is alloyed to swing back to its normal vertical position the pinch roll will move to a point beyond the prongs 22 and then drop down either to its working position or be pulled down when the towel 1s used.

I prefer to provide means for winding up the soiled portion of the towel and therefore provide guides 24 in the side walls of the cabinet to receive a takeup roll 25 that is adapted to slide in said guides and rest upon a takeup feed roll 26 having a sanded surface and mounted in bearings in the side walls of.

the cabinet. This takeup feed roll for convenience in loading is operated in the opposite direction from the delivery feed roll 19 and I accomplish this by providing a chain 27 engaging a sprocket 28 on the roll 19, a similar idle sprocket 29 on the wall of the cabinet and an intermediate sprocket 30 on the takeup roll. lVith this arrangement the person loading the cabinet does not have to pass the web to the rear of the takeup feed roll, but may stretch it from the front of the cabinet direct to the takeup roll, the shorter and easier way. This sometimes was done by a careless attendant when the feed rolls were operated in the same direction, thereby preventing the takeup roll from performing its function. My present arrangement prevents any mistake in stretching the web to the takeup roll as the easy way of stretching the web is the proper way. A lock device 31 adapted to be tripped by the finger of the user is provided in connection with the roll 19 for releasing and allowing it to make a single revolution, the locking device automatically setting itself to prevent a second revolution when the first one has been completed.

In the lower portion of the cabinet I prefer to provide a frame 32 pivoted at 33 and carrying a roller 34 under which the web of towel is carried to the takeup roll. This frame has the function of drawing the soiled web of towel into the cabinet where it will be partially concealed and inconspicuous when the cabinet is not in use. A user drawing out a length of towel will after use drop it and the web, unless means are provided to pull it back into the cabinet, would drop down and drape itself over the roller 9 and the front of the cabinet, but by providing the pull-back device 32 I am able to immediately withdraw the soiled section of the towel from view as soon as it is used and released.

When the supply of clean towel is exhausted the door of the cabinet will be opened and held in an open position and the roll of soiled towel removed, then the pinch roll will be pushed inwardly and upwardly to disengage it from the locking plates and allow the gate 13 to be swung outwardly to the position shown in Figure 5 and when this has been done the supply of clean towel is placed on the shelf and the web stretched outwardly over the pinch roll and then carried downwardly under the roller 34 to the takeup roll 25. There is only one easy way the clean towel can be inserted in the cabinet and it will be almost impossible for an attendant or any one else to place the towel improper'- ly in the cabinet, and all the work can be performed from the front of the cabinet as soon as the door is opened. When the gate is v jacent said feed roll, means for normally' pinch roll in its normal position to resist 4out- Ward pull thereon of the .towel web' when it is inf use. c

4. Atowel cabinet comprising a casing having a door and opening therein through which the web of clean towel is visible and may be drawn outwardly for use, a support for the clean towel supply within said cabinet, a feed roll mounted in said cabinet, a pinch roll adaptedl to press the web of clean towel againstsaid feed roll, a swinging support for the pinch roll having slotted bearings thereforwherein said pinch roll is movable transversely of the pinch roll axis, means for normally locking the pinch roll and its support in a raised position, `said transverse movement of said pinchroll in its slotted bearings operatively disengaging it and said support from said locking means ani allowing the roll and support to. be moved forwardly through said opening when the cabinet is to be loaded with the clean towel supply, means yfor engaging and automatically raising said pinch roll relative to itssupport when said swinging support is returned to its normal position within the cabinet, a web of Vclean towel being adapted to depend from said pinch roll to the lower portion of the cabinet.

5. A towel cabinet comprising a casing hav-` ing an opening therein and a door provided with a panel opening through which the web of clean towel is visible and accessible for use, a support for the clean towel supply within said cabinet, a feed roll mounted in said cabinet, a pinch roll and means supportingit adlocking said pinch rollin its working position, said pinch roll having means for freedom of lateral movement in said supportingmeans to adapt it for releasemanually from said locking means and said supporting means being pivoted to move outwardly through said .door opening with said pinch roll to a cabinetloading position, when the .web ofvclean towel may be'stretched over said pinch roll to depend within the cabinet and means for first directing said pinch roll automatically back to its normal working position adjacent said feed roll upon the return movement of said pinch roll into the cabinet and then wedging the pinch roll against the feed roll. i A

7. A towel cabinet comprising a casing having an opening in its front wall, a shelf in the rear of said opening adapted to support a supply of clean towel, a delivery feed roll mounted above said shelf, a gate hinged to the forward portion of said shelf and having means for normally holding it in a raised position, a pinch roll having a spindle adapted to slide in slots provided on the .upper portion of said gate and normally pressing the web of clean towel stretched between said rolls into contact with said feed roll, means for locking said pinch roll and gate in their raised position but permitting manual re- .lease and downward movement of said gate and pinch roll through the opening in said casing to a loading position, the space above said shelf being exposed when said gate is moved downwardly to allow the insertion of the clean towel and such space being normally concealed when said gate is returned to its raised locking position.

8.l A towel cabinet comprising a casing having an opening through which access may be had to the web 4of clean towel, a support for the clean towel supply within said cabinet, a feed roll mounted in said cabinet, a pinch roll between which and said feed roll the web of clean towel may be stretched, an oscillating support for said pinch roll whereon it is movable outwardly through said opening to facilitate stretching the clean web thereover, means for normally locking said pinch roll against such outward movement, said pinch roll being loosely mounted in said support whereby it may be moved inwardlyv and upwardly thereon to release it from said locking means.

9. A towel cabinet comprising a casing having an opening` through which access may be had to the web of clean towel therein, a support for the clean towel supply within said casing, a feed roll mounted in said cabinet, a pinch roll to press the web of clean towel against said feed roll, pivoted means for supporting said pinch roll andv adapted to separate the soiled web of towel from the clean web and prevent contact between them, means for normally wedging said pinch roll to its position against said feed roll, saidsupporting means having a slot therein tol permit movement of the pinch roll to separate it from said holding means, said pinch roll and its pivoted support having a movement downwardly and outwardly through the opening in said casing to a loading position wherethe web of clean towel may be conveniently stretched over said pinch roll and thereafter said pinch roll and support may be returned to their normal position adjacent said feed roll.

10. A towel cabinet comprising a casing having an opening through which the web of clean towel may be drawn for use, a pair of rolls within the cabinet, pivoted means for supporting one of said rolls for movement outwardly and downwardly to a position convenient Vfor loading the cabinet, where the web of clean t-owel may be stretched over said movable roll during the loading` operation, means for locking said movable roll when in its raised position adjacent the other 2@ roll, said locking means including a cam for forcing said r-olls together upon the downward pull of the user on the web of clean towel.

11. A towel cabinet having a door with a a5 panel therein, a shelf in the upper portion of the cabinet in rea-r of said panel, a feed roll mounted in said cabinet above the shelf, v a gate pivoted to the shelf and extending up between the shelf and said panel, a pinch roll carried by the gate and movable outside said door for towel loading purposes when the door is opened.

12. A towel cabinet having a door with a panel therein, a shelf in the upper portion ofthe cabinet, a feed roll mounted in said cabinet above the shelf, a gate pivoted to the shelf and extending up between a towel supply on the shelf'and said panel, a pinch roll i carried by the gate and movable outside said 40 door when the same is opened, a takeup roll below the panel, a chamber in the lower part of the cabinet, and means in the chamber for drawing the towel web back into the chamber after the same is pulled through the panel said means being below the talreup roll.

In witness whereof, I have hereunto set my hand this 5th day of October,'1927. i i FRANK M. STEINER.

les

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US225350A US1746292A (en) | 1927-10-10 | 1927-10-10 | Towel cabinet |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US225350A US1746292A (en) | 1927-10-10 | 1927-10-10 | Towel cabinet |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1746292A true US1746292A (en) | 1930-02-11 |

Family

ID=22844523

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US225350A Expired - Lifetime US1746292A (en) | 1927-10-10 | 1927-10-10 | Towel cabinet |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1746292A (en) |

-

1927

- 1927-10-10 US US225350A patent/US1746292A/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2380644A (en) | Means for mounting rolls in dispensing cabinets | |

| US1901243A (en) | Dispenser | |

| US3207566A (en) | Holder for collapsible tubes | |

| US3484052A (en) | Paper dispenser | |

| US2390399A (en) | Paper dispenser | |

| US1141274A (en) | Ticket-rack and storage system for same. | |

| US1054707A (en) | Clothes-pin holder. | |

| US2959368A (en) | Toilet tissue holder and dispenser | |

| US2560327A (en) | Dispensing machine | |

| US1686911A (en) | Paper-dispensing device | |

| US1746292A (en) | Towel cabinet | |

| US2434206A (en) | Folded napkin dispenser | |

| US2421342A (en) | Sanitary cabinet with means for dispensing papers | |

| US1746293A (en) | Towel cabinet | |

| US1408283A (en) | Roller-towel cabinet | |

| US1909093A (en) | Cabinet ironing board | |

| US3090572A (en) | Toilet tissue holding and dispensing device | |

| US1563867A (en) | Dispensing cabinet | |

| US1721927A (en) | Towel cabinet | |

| US1724228A (en) | Feed-control device for towel cabinets | |

| US1256274A (en) | Towel-holder. | |

| US1983646A (en) | Towel cabinet | |

| US1719338A (en) | Dispensing cabinet | |

| US1810599A (en) | Cabinet | |

| US2122060A (en) | Towel service cabinet |