US1664079A - Center-plait folder - Google Patents

Center-plait folder Download PDFInfo

- Publication number

- US1664079A US1664079A US17961A US1796125A US1664079A US 1664079 A US1664079 A US 1664079A US 17961 A US17961 A US 17961A US 1796125 A US1796125 A US 1796125A US 1664079 A US1664079 A US 1664079A

- Authority

- US

- United States

- Prior art keywords

- plait

- folder

- strip

- fabric

- center

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004744 fabric Substances 0.000 description 28

- 230000003014 reinforcing effect Effects 0.000 description 23

- 238000010276 construction Methods 0.000 description 5

- 239000002184 metal Substances 0.000 description 5

- 238000009958 sewing Methods 0.000 description 4

- 238000005452 bending Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 244000221110 common millet Species 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B35/00—Work-feeding or -handling elements not otherwise provided for

- D05B35/06—Work-feeding or -handling elements not otherwise provided for for attaching bands, ribbons, strips, or tapes or for binding

- D05B35/062—Work-feeding or -handling elements not otherwise provided for for attaching bands, ribbons, strips, or tapes or for binding with hem-turning

Definitions

- Fig. Sis a bottomvplan view of the same;

- Fig. vtais asectionalviewon the line 4 ⁇ 4

- Figi-dis a view', partlyin sectionand partly inperspective,showing a center plait formed on ⁇ the; machine:

- the invention is directed particularly to a center plait. folderrwrhichis provided with means for-:directing a str-ip, of; fabric,-l from which the centerv plait is.formed,-in.sucha waythatf the ⁇ side edges of the strip are turned underneath.- So vfan asA they construction of. the folder fon folding acenter plait isconeerned,it is of the .usualY construction.

- This plait is formedfroina fabric strip 1the side edges of which, indicated at 2 and 3, are folded underneath the body portion of the fabric strip. These side edges are also folded about a reinforcing or stiffeningstripvl.

- lIt i is noted thatthisreinforcing strip extends to a point adjacent'the. fold 5 in thefolded under-portion 3 atA one yside of the plait and tov-a ⁇ point Vadjacent the fold. 6 inthe folded under portion 2L at lthe other sideof the plait.

- I havefsho-wn a body Yfabric 7 to which the. center', plait: isattached. The parts are unitedby. lines of stitches Sand 9,

- the sewing machine ⁇ is provided Vwith two needlesil() and 11, which are thread carrying needles ofthe usual type, and means ⁇ are provided beneaththe throat plate 13 lof the machine Iwhich cooperate with these needles to make independent lines of stitches.

- the material 4 is held on vthe throatV plate by means of a presser footv13v carried bya presser bar 14 which likewise is of the usual construction.

- the center plait folder consists .of a metal body portion ⁇ 16. 1

- This metal body portion 16 includes anlouter wall 16 and an inner wall 16"'which arev parallel with each other, as'clearly'shown in Figs. 4. andf 5.

- These two walls at o ne side of the folder arebent downwardly and inwardly,.as indicated at 17.,.Said walls are also bent downwardly and'inwardly, as indicated at A18,v at the otherside ofthe folder.

- the two spaced walls form a guiding passage 19 fora fabric portion which is to make the plait proper.

- the side edges of this body portion extend down into the portions 17 and 18, and it is by the aid of these parts that the side portions of the plait are folded underneath. I have vshown in Fig. 5 the fabric passing through-the guide 19 in broken lines.

- the folded under portion 2 extends down into the portion of the folder indicated at 18, while the folder under portion 3 extends down into the portion of the folder indicated at 17.

- the Y metal parts above described are mounted on a bracket 20 which is secured to the cloth plate'of the machine by vmeans of screws 21. These screws pass through elongated slots 22 in the bracket and permit of a limited lateral adjustment of the folder.

- the portion 16- is provided with an elongated opening 23 which is for the purpose of aidingin passing the material into and through the folder.

- Said folder has .a receiving extension 24 which is mounted on a supporting wire 25 attached to the 4body part ofthe folder.

- Mounted Aon the under side of this folder is a metal portion 26 ywhich extends from a point adjacent the front or receiving end of the .plait folder VVto a point midway of the length thereof, as clearly shown in Fig. 3 of the drawings.

- the inner wall 16 of the plait folder is connected to a metal plate portion 28 so as to form a guiding channel 29 for the reinforcing or stiffening strip.

- This guiding passage is in line with kthe guiding passage in the part 26 and extends to the delivery end of the folder.

- the side members 17 and 18 are folded underneath this plate 28, as clearly shown iii Fig. 6 and, therefore, the side portions of the plait are carried underneath the reinforcing strip.

- the lower wall of the guiding member 28 is formed with a rib 30 which provides a groove on the inner face thereof.

- the upper member of the guiding passage 19, which is the under member of the plait folder, is formed with a rib 31 which extends into this groove.V As clearly shown in Fig.

- this rib and groove extends substantially from the .receiving end of the guiding portion 26 to the delivery end of the folder.

- the upper guiding'wall of the passage 29 projects beyond the delivery end ofthe folder, as indicated at 32 in Fig. 3 of the drawings.

- the groove terminates at the end of the folder.

- the rib,.however, eX- tends to the end of the projection 32 and is attened, as indicated at 33V in Fig. 3.

- the rib and groove referred toi above operate to fold the reinforcing strip inter-v mediate its ends, and this will cause the side ,edges ofthe reinforcing strip to be drawn back from the foldps'in the fabric portion V'forming the plait, and thus permit a very free running of said fabric portion .through the folder.

- the reinforcing strip ⁇ leaves the end of the folder, it will be flattened out through the combined action of the flattened rib and the projecting portion 32, and also the co-operating action of the presser foot.

- this reinforc-V ing strip by being bent between the' side edges, is drawn back from the. folds in the plait until the plait is completely shaped and ready for stitching, after which the reinforcing strip is forced outwardly untilV its side edges lie close'to the respective folded portions of the fabric forminggthe plait.

- a vcenter lplait folder forsewing ma ⁇ chincs comprising means for guiding-,and infolding' the fabric to form a center. plait, means for placing ⁇ a reinforcing strip with-l in said plait as it is formed, and means for bending said reinforcing strip alone intermediate the side edges thereof' for holding said edges out of Contact Ywith the fabric forming v the plait as said fabric passes through the yguiding andinfolding means.

- a center plait folder for sewingma- Y chines comprising means for guiding and infolding fabric to form a centerplait, mea-ns edges for withdrawing said edges from contact with the fabric as it passes through the guiding and infolding means therefor.

- a center plait folder for sewing machines comprising means for guiding and infolding fabric to form a center plait, means for guiding a reinforcing strip into said plait as it is formed, Saidl guiding means for said reinforcing strip having a projecting rib on one member thereof and a cooperating groove on the other member thereof, said rib and groove operating to bend the reinforcing strip intermediate its side edges for withdrawing said edges from Contact with the fabric as it passes through the guiding and infolding means thereof, and means for flattening said reinforcing strip and forcing the edfres thereof into substan-v tial Contact with the in folded portions of the fabric prior to the stltching of the parts together.

- a 'center plait ⁇ folder for sewing machines comprising means for guiding and infolding the fabric to form a center plait, meansr fo-r placing the reinforcing strip within said folder as -it is formed, means for bending said reinforcing strip intermediate the side edges thereof away from the center plait for withdrawing the side edges of the strip vfrom contact with the plait' passing through the guiding and infolding means, and means for fiattening said reinforcin strip after said plait leaves the folder an prior to the stitching of the fabric so that the edge portions of thereinforcing strip are forced outward] to lie close to the respective. folded portions of the fabric forming the plait.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Folding Of Thin Sheet-Like Materials, Special Discharging Devices, And Others (AREA)

Description

March 27, 192,8.

J. MANN' CENTER PLAIT FOLDER Fled March 24, 1925 2 Smets-Sheet' 1 a www l I ttonwqS March'zz 192s. 1,664Lo79 f J. MANN CENTER P'LAIT FoLbER Filed March 24, 1925 2 Sheets-Sheet 2 Patented MarmZ', 1928.

' Uni-TED STATES.

y Y 1,664,079 PATENT oFFrcll-za JOSEPH MANN,OF PHILADELPHIA, PENNSYLVANIAI.v ASSIGNOR TO UNIONSPECIAL MACHINE COIYIPANY,` OF" CHICAGO, ILLINOIS, A CORPORATION OFILLINOIS."

CENTERFPLAIT. FOLDER.

Application-med March 24,1925.. -Seria1No.;17,961;

ing strip after the-plait leaves the-folder andprior tothe stitching ofl theparts.

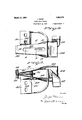

In Athe drawings, which show by way of illustration, one.- .embodiment ofi` the invenv tion :e f Y Figure 1 is an end view offa,sewing-ma-v chine having the improved folderl attached thereto; Y

llfigwis. atop, plan view ofv lthetplajt folder;A

Fig. Sis a bottomvplan view of the same; Fig. vtais asectionalviewon the line 4`4 Figi-dis a view', partlyin sectionand partly inperspective,showing a center plait formed on` the; machine:

The invention is directed particularly to a center plait. folderrwrhichis provided with means for-:directing a str-ip, of; fabric,-l from which the centerv plait is.formed,-in.sucha waythatf the` side edges of the strip are turned underneath.- So vfan asA they construction of. the folder fon folding acenter plait isconeerned,it is of the .usualY construction.

-There is associatedl with this folderV a guidingmeans for. guiding. and directing a reinforcingl oir-stiffening, strip, and this rcinforcing striplis soproportionedias to eX- tend from .one side edge to the other. ofthe center plait. `The side'edges ofrthe center plait are: folded around, the side ledges `of the stiifening or reinforeingstrip. In order to facilitate thev passage .ofz the fabric strip through the folder which forms the center' plait, Iy have constructed my improved folder with means whichfbends Vthe reinforcing` strip intermediate itsV edges,` and this draws the side edges of said reinforcing strip out of contact with the folder under portions of the fabric strip making the plait. Byk thisiconstruction, the fabric strip running;l through the' folder will*y .pass freely through the folder and not be retarded'in any` way. by the reinforcing strip. This bendingrof the reinforcing strip is accomplished byarib construction formed in the folder itself. After the reinforcing strip leavesthe-folder, then there is means which operatesto flatten the strip,.andtliis is accomplished before .the -parts are stitched.

-Referring more in detail to the drawin s,

in Fig. 6 `there is shown a plait with r'a stiffelling or reinforcing striptherein of the characterabove referred to. This plait is formedfroina fabric strip 1the side edges of which, indicated at 2 and 3, are folded underneath the body portion of the fabric strip. These side edges are also folded about a reinforcing or stiffeningstripvl. lIt i is noted thatthisreinforcing strip extends to a point adjacent'the. fold 5 in thefolded under-portion 3 atA one yside of the plait and tov-a` point Vadjacent the fold. 6 inthe folded under portion 2L at lthe other sideof the plait. I havefsho-wn a body Yfabric 7 to which the. center', plait: isattached. The parts are unitedby. lines of stitches Sand 9,

which are independent of. each other and' are parallel rand locatedI back a short distance from`- the respective side "edgesof the plait.v i y y v The sewing machine `is provided Vwith two needlesil() and 11, which are thread carrying needles ofthe usual type, and means `are provided beneaththe throat plate 13 lof the machine Iwhich cooperate with these needles to make independent lines of stitches. The material 4is held on vthe throatV plate by means of a presser footv13v carried bya presser bar 14 which likewise is of the usual construction.' The throat` plate l12;is mounted on the clothplate 15v ofthemachine.

The center plait folder consists .of a metal body portion` 16. 1 This metal body portion 16 includes anlouter wall 16 and an inner wall 16"'which arev parallel with each other, as'clearly'shown in Figs. 4. andf 5. These two walls at o ne side of the folder arebent downwardly and inwardly,.as indicated at 17.,.Said walls are also bent downwardly and'inwardly, as indicated at A18,v at the otherside ofthe folder. The two spaced walls form a guiding passage 19 fora fabric portion which is to make the plait proper. The side edges of this body portion extend down into the portions 17 and 18, and it is by the aid of these parts that the side portions of the plait are folded underneath. I have vshown in Fig. 5 the fabric passing through-the guide 19 in broken lines. The folded under portion 2 extends down into the portion of the folder indicated at 18, while the folder under portion 3 extends down into the portion of the folder indicated at 17.

`The Y metal parts above described are mounted on a bracket 20 which is secured to the cloth plate'of the machine by vmeans of screws 21. These screws pass through elongated slots 22 in the bracket and permit of a limited lateral adjustment of the folder. The portion 16-is provided with an elongated opening 23 which is for the purpose of aidingin passing the material into and through the folder. Said folder has .a receiving extension 24 which is mounted on a supporting wire 25 attached to the 4body part ofthe folder. Mounted Aon the under side of this folder is a metal portion 26 ywhich extends from a point adjacent the front or receiving end of the .plait folder VVto a point midway of the length thereof, as clearly shown in Fig. 3 of the drawings. This is a guide for directing a reinforcing ci' stiifening strip shown in Fig. 6 at 4. There is an extension 27 attached to the receiving end of this guide, which is bent at right angles so that the stiffening strip may be led from a point at one side ofthe folder into this guiding member 26.

The inner wall 16 of the plait folder is connected to a metal plate portion 28 so as to form a guiding channel 29 for the reinforcing or stiffening strip. This guiding passage is in line with kthe guiding passage in the part 26 and extends to the delivery end of the folder. The side members 17 and 18 are folded underneath this plate 28, as clearly shown iii Fig. 6 and, therefore, the side portions of the plait are carried underneath the reinforcing strip. The lower wall of the guiding member 28 is formed with a rib 30 which provides a groove on the inner face thereof. The upper member of the guiding passage 19, which is the under member of the plait folder, is formed with a rib 31 which extends into this groove.V As clearly shown in Fig. 3, this rib and groove extends substantially from the .receiving end of the guiding portion 26 to the delivery end of the folder. The upper guiding'wall of the passage 29 projects beyond the delivery end ofthe folder, as indicated at 32 in Fig. 3 of the drawings. The groove terminates at the end of the folder. The rib,.however, eX- tends to the end of the projection 32 and is attened, as indicated at 33V in Fig. 3.

As above noted, the fabric portion for appended claims.

26 and also the guiding passage 29 inthe n folder. The rib and groove referred toi above operate to fold the reinforcing strip inter-v mediate its ends, and this will cause the side ,edges ofthe reinforcing strip to be drawn back from the foldps'in the fabric portion V'forming the plait, and thus permit a very free running of said fabric portion .through the folder. As soon as the reinforcing strip` leaves the end of the folder, it will be flattened out through the combined action of the flattened rib and the projecting portion 32, and also the co-operating action of the presser foot. In other'words, this reinforc-V ing strip, by being bent between the' side edges, is drawn back from the. folds in the plait until the plait is completely shaped and ready for stitching, after which the reinforcing strip is forced outwardly untilV its side edges lie close'to the respective folded portions of the fabric forminggthe plait.

It is obvious that other waysmay'ibeprovided for maintaining theledges of the reim forcing strip out of contact with the plait as it is being formed, andthatzthedetails of construction of the folder described may bc changed without departing from; the spirit of thev inventionr as set forthlin the What I claim as new is 1. A center plait folder for sewing machines vcomprising meansfor. guiding and iiifolding the fabric tov form a center plait, means for placing a reinforcing strip within said plait as it is formed, means forA withdrawing the side edges of said strip from contact with the fabric while said fabric is passing throughV the guiding andV infolding means, and means for flattening Ysaid reinforcing strip after said fabricy leaves the folder and prior to the 'stitching ofthe fabric to finish the plait. j

2. A vcenter lplait folder forsewing ma` chincs comprising means for guiding-,and infolding' the fabric to form a center. plait, means for placing `a reinforcing strip with-l in said plait as it is formed, and means for bending said reinforcing strip alone intermediate the side edges thereof' for holding said edges out of Contact Ywith the fabric forming v the plait as said fabric passes through the yguiding andinfolding means. 1,20

3. A center plait folder for sewingma- Y chines comprising means for guiding and infolding fabric to form a centerplait, mea-ns edges for withdrawing said edges from contact with the fabric as it passes through the guiding and infolding means therefor.

4. A center plait folder for sewing machines comprising means for guiding and infolding fabric to form a center plait, means for guiding a reinforcing strip into said plait as it is formed, Saidl guiding means for said reinforcing strip having a projecting rib on one member thereof and a cooperating groove on the other member thereof, said rib and groove operating to bend the reinforcing strip intermediate its side edges for withdrawing said edges from Contact with the fabric as it passes through the guiding and infolding means thereof, and means for flattening said reinforcing strip and forcing the edfres thereof into substan-v tial Contact with the in folded portions of the fabric prior to the stltching of the parts together. l

5. A 'center plait` folder for sewing machines comprising means for guiding and infolding the fabric to form a center plait, meansr fo-r placing the reinforcing strip within said folder as -it is formed, means for bending said reinforcing strip intermediate the side edges thereof away from the center plait for withdrawing the side edges of the strip vfrom contact with the plait' passing through the guiding and infolding means, and means for fiattening said reinforcin strip after said plait leaves the folder an prior to the stitching of the fabric so that the edge portions of thereinforcing strip are forced outward] to lie close to the respective. folded portions of the fabric forming the plait.

In testimony whereof, I aiix my signa.- ture.

JOSEPH MANN.'

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US17961A US1664079A (en) | 1925-03-24 | 1925-03-24 | Center-plait folder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US17961A US1664079A (en) | 1925-03-24 | 1925-03-24 | Center-plait folder |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1664079A true US1664079A (en) | 1928-03-27 |

Family

ID=21785506

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US17961A Expired - Lifetime US1664079A (en) | 1925-03-24 | 1925-03-24 | Center-plait folder |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1664079A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4458610A (en) * | 1982-11-01 | 1984-07-10 | Consolidated Foods Corporation | Folding apparatus |

-

1925

- 1925-03-24 US US17961A patent/US1664079A/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4458610A (en) * | 1982-11-01 | 1984-07-10 | Consolidated Foods Corporation | Folding apparatus |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1664079A (en) | Center-plait folder | |

| US1764846A (en) | Apparatus for producing stitched trimming strips | |

| US2133225A (en) | Folder | |

| US1799132A (en) | Seam-opening device | |

| US2149755A (en) | Strip folder | |

| US1844411A (en) | Sewing machine attachment | |

| US1875578A (en) | Pants band sewing machine | |

| US1575453A (en) | Sewing-machine attachment | |

| US1451220A (en) | Plait folder for sewing machines | |

| US2025531A (en) | Method and apparatus for making blind stitched facing | |

| US1712305A (en) | Machine for making and applying waistbands to trousers | |

| US2028773A (en) | Universal folder for sewing machines | |

| US2096691A (en) | Sewing machine work-guides | |

| US1756036A (en) | Sewing machine | |

| US1453506A (en) | Sewing machine for stitching waistbands | |

| US1435661A (en) | Guiding device for sewing machines | |

| US1412001A (en) | Folder for sewing machines | |

| US1826677A (en) | Hemmer | |

| US1988140A (en) | Folding guide for sewing machines | |

| US1770002A (en) | Waistband | |

| US1932575A (en) | Sewing machine for attaching waist bands to body fabrics | |

| US2467680A (en) | Work guide for sewing machines | |

| US2674213A (en) | Work-guiding attachment for sewing machines | |

| US1842838A (en) | Machine for making ribbed innersoles | |

| US1742830A (en) | Piping and method of forming the same |