RU2652926C1 - Heat-resistant alloy - Google Patents

Heat-resistant alloy Download PDFInfo

- Publication number

- RU2652926C1 RU2652926C1 RU2017132678A RU2017132678A RU2652926C1 RU 2652926 C1 RU2652926 C1 RU 2652926C1 RU 2017132678 A RU2017132678 A RU 2017132678A RU 2017132678 A RU2017132678 A RU 2017132678A RU 2652926 C1 RU2652926 C1 RU 2652926C1

- Authority

- RU

- Russia

- Prior art keywords

- heat

- nickel

- resistant alloy

- copper

- alloy

- Prior art date

Links

- 229910045601 alloy Inorganic materials 0.000 title claims abstract description 14

- 239000000956 alloy Substances 0.000 title claims abstract description 14

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims abstract description 18

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical group [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims abstract description 12

- 229910052759 nickel Inorganic materials 0.000 claims abstract description 9

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims abstract description 8

- 229910052802 copper Inorganic materials 0.000 claims abstract description 8

- 239000010949 copper Substances 0.000 claims abstract description 8

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 claims abstract description 7

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 claims abstract description 7

- 229910052779 Neodymium Inorganic materials 0.000 claims abstract description 7

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 claims abstract description 7

- 229910052782 aluminium Inorganic materials 0.000 claims abstract description 7

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims abstract description 7

- 229910052791 calcium Inorganic materials 0.000 claims abstract description 7

- 239000011575 calcium Substances 0.000 claims abstract description 7

- QEFYFXOXNSNQGX-UHFFFAOYSA-N neodymium atom Chemical compound [Nd] QEFYFXOXNSNQGX-UHFFFAOYSA-N 0.000 claims abstract description 7

- 229910052710 silicon Inorganic materials 0.000 claims abstract description 7

- 239000010703 silicon Substances 0.000 claims abstract description 7

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims abstract description 6

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims abstract description 6

- 229910052796 boron Inorganic materials 0.000 claims abstract description 6

- 229910052799 carbon Inorganic materials 0.000 claims abstract description 6

- 229910052742 iron Inorganic materials 0.000 claims abstract description 6

- 229910052804 chromium Inorganic materials 0.000 claims abstract description 4

- 239000011651 chromium Substances 0.000 claims abstract description 4

- 239000000203 mixture Substances 0.000 abstract description 4

- 238000001816 cooling Methods 0.000 abstract description 3

- 238000005272 metallurgy Methods 0.000 abstract description 3

- 210000001520 comb Anatomy 0.000 abstract description 2

- 238000004519 manufacturing process Methods 0.000 abstract description 2

- NIFIFKQPDTWWGU-UHFFFAOYSA-N pyrite Chemical compound [Fe+2].[S-][S-] NIFIFKQPDTWWGU-UHFFFAOYSA-N 0.000 abstract description 2

- 229910052683 pyrite Inorganic materials 0.000 abstract description 2

- 239000011028 pyrite Substances 0.000 abstract description 2

- 239000004411 aluminium Substances 0.000 abstract 1

- 239000000126 substance Substances 0.000 abstract 1

- 238000000137 annealing Methods 0.000 description 2

- 238000005266 casting Methods 0.000 description 2

- 229910001018 Cast iron Inorganic materials 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/54—Ferrous alloys, e.g. steel alloys containing chromium with nickel with boron

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C30/00—Alloys containing less than 50% by weight of each constituent

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Mold Materials And Core Materials (AREA)

Abstract

Description

Изобретение относится к области металлургии и касается составов сплавов, которые могут быть использованы для изготовления колосников, охлаждающих рам печей, дистанционных гребенок паровых котлов, зубьев и гребков колчеданных печей.The invention relates to the field of metallurgy and relates to alloy compositions that can be used for the manufacture of grates, cooling frames of furnaces, remote combs of steam boilers, teeth and strokes of pyrite furnaces.

Известен жаростойкий сплав, содержащий, маc. %: алюминий 10,0-32,0; углерод 0,001-0,01; хром 0,05-6,0; медь 0,1-3,0; кальций 0,001-0,01; никель 0,05-5,0; бор 0,0003-0,03; кремний ≤ 3,0; железо - остальное [1].A heat-resistant alloy containing, by weight, is known. %: aluminum 10.0-32.0; carbon 0.001-0.01; chromium 0.05-6.0; copper 0.1-3.0; calcium 0.001-0.01; nickel 0.05-5.0; boron 0.0003-0.03; silicon ≤ 3.0; iron - the rest [1].

Задача изобретения состоит в повышении жаростойкости сплава.The objective of the invention is to increase the heat resistance of the alloy.

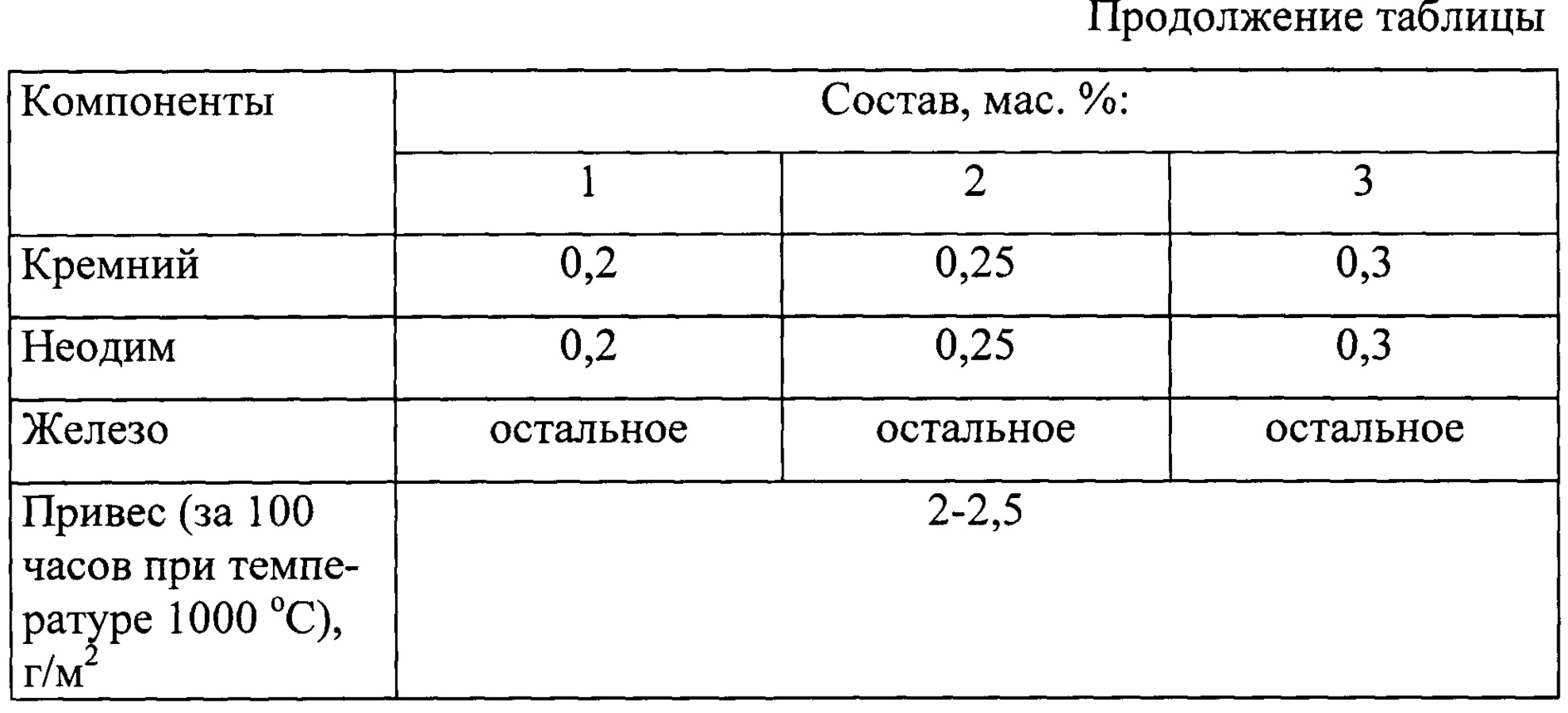

Технический результат достигается тем, что жаростойкий сплав, содержащий алюминий, углерод, хром, медь, кальций, никель, бор, кремний, железо, дополнительно включает неодим, причем компоненты находятся при следующем соотношении, маc. %: алюминий 28,0-30,0; углерод 0,03-0,05; хром 3,0-5,0; медь 0,03-0,05; кальций 0,0005-0,001; никель 7,0-10,0; бор 0,05-0,1; кремний 0,2-0,3; неодим 0,2-0,3; железо - остальное.The technical result is achieved in that the heat-resistant alloy containing aluminum, carbon, chromium, copper, calcium, nickel, boron, silicon, iron, additionally includes neodymium, and the components are in the following ratio, wt. %: aluminum 28.0-30.0; carbon 0.03-0.05; chrome 3.0-5.0; copper 0.03-0.05; calcium 0.0005-0.001; nickel 7.0-10.0; boron 0.05-0.1; silicon 0.2-0.3; neodymium 0.2-0.3; iron is the rest.

В таблице приведены составы чугуна.The table shows the composition of cast iron.

В составе сплава компоненты проявляют себя следующим образом. Хром, неодим, никель, кремний и алюминий препятствуют окислению сплава, обеспечивают повышение жаростойкости. Неодим и кальций раскисляют сплав. Никель улучшает металлическую основу сплава. Медь способствует измельчению зерна. Медь и никель препятствуют образованию и развитию трещин при перепадах температур.In the composition of the alloy, the components manifest themselves as follows. Chrome, neodymium, nickel, silicon and aluminum interfere with the oxidation of the alloy and provide an increase in heat resistance. Neodymium and calcium deoxidize the alloy. Nickel improves the metal base of the alloy. Copper contributes to the grinding of grain. Copper and nickel prevent the formation and development of cracks at temperature extremes.

Жаростойкий сплав выплавляют в электропечах. Отливки подвергают низкотемпературному отжигу при 620-680°С, причем длительность выдержки при отжиге составляет 1 час на 25 мм сечения отливки с последующим охлаждением с печью до 350-370 °С, далее - на воздухе.Heat-resistant alloy is smelted in electric furnaces. The castings are subjected to low-temperature annealing at 620-680 ° C, and the exposure time during annealing is 1 hour per 25 mm of the casting cross-section, followed by cooling with the furnace to 350-370 ° C, then in air.

Источники информацииInformation sources

1. JP 2005068549 А, 2005.1. JP 2005068549 A, 2005.

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2017132678A RU2652926C1 (en) | 2017-09-18 | 2017-09-18 | Heat-resistant alloy |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2017132678A RU2652926C1 (en) | 2017-09-18 | 2017-09-18 | Heat-resistant alloy |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| RU2652926C1 true RU2652926C1 (en) | 2018-05-03 |

Family

ID=62105303

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2017132678A RU2652926C1 (en) | 2017-09-18 | 2017-09-18 | Heat-resistant alloy |

Country Status (1)

| Country | Link |

|---|---|

| RU (1) | RU2652926C1 (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0642597A1 (en) * | 1992-05-15 | 1995-03-15 | Martin Marietta Energy Systems, Inc. | Corrosion resistant iron aluminides exhibiting improved mechanical properties and corrosion resistance |

| US6841011B2 (en) * | 2000-02-11 | 2005-01-11 | Hui Lin | Iron base high temperature alloy and method of making |

| RU2245760C2 (en) * | 1999-02-09 | 2005-02-10 | Крайзейлис Текнолоджиз Инкорпорейтед | Method for making articles of metallic alloy subjected to cold working (variants) |

| JP2005068549A (en) * | 2003-08-04 | 2005-03-17 | Nippon Steel Corp | High strength low specific gravity steel sheet excellent in ductility and its manufacturing method |

| CN102943202A (en) * | 2012-11-09 | 2013-02-27 | 无锡正一生源科技有限公司 | Fe-Al-B magnetostrictive thin piece material and preparation method thereof |

-

2017

- 2017-09-18 RU RU2017132678A patent/RU2652926C1/en active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0642597A1 (en) * | 1992-05-15 | 1995-03-15 | Martin Marietta Energy Systems, Inc. | Corrosion resistant iron aluminides exhibiting improved mechanical properties and corrosion resistance |

| RU2245760C2 (en) * | 1999-02-09 | 2005-02-10 | Крайзейлис Текнолоджиз Инкорпорейтед | Method for making articles of metallic alloy subjected to cold working (variants) |

| US6841011B2 (en) * | 2000-02-11 | 2005-01-11 | Hui Lin | Iron base high temperature alloy and method of making |

| JP2005068549A (en) * | 2003-08-04 | 2005-03-17 | Nippon Steel Corp | High strength low specific gravity steel sheet excellent in ductility and its manufacturing method |

| CN102943202A (en) * | 2012-11-09 | 2013-02-27 | 无锡正一生源科技有限公司 | Fe-Al-B magnetostrictive thin piece material and preparation method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2652926C1 (en) | Heat-resistant alloy | |

| RU2437952C1 (en) | Iron | |

| RU2609155C1 (en) | Steel | |

| RU2657394C1 (en) | Iron-based alloy | |

| RU2624547C1 (en) | Wear resistant alloy | |

| RU2624545C1 (en) | Cast iron | |

| RU2645526C1 (en) | Cast iron | |

| RU2650940C1 (en) | Steel | |

| RU2669256C1 (en) | Steel | |

| RU2605542C1 (en) | Cast iron | |

| RU2610101C1 (en) | Cast iron | |

| RU2652920C1 (en) | Alloy | |

| RU2629407C1 (en) | Cast iron | |

| RU2624548C1 (en) | Wear-resistanting alloy on base of iron | |

| RU2667263C1 (en) | Iron-based alloy | |

| RU2566098C1 (en) | Copper-based alloy | |

| RU2529324C1 (en) | Aluminium cast iron alloy | |

| RU2611227C1 (en) | Cast iron | |

| RU2554234C1 (en) | Cast iron | |

| RU2629409C1 (en) | Cast iron | |

| RU2650953C1 (en) | Steel | |

| RU2629410C1 (en) | Cast iron | |

| RU2629405C1 (en) | Cast iron | |

| RU2651065C1 (en) | Iron-based alloy | |

| RU2651071C1 (en) | Iron-based alloy |