RU2331808C2 - Способ изготовления многоступенчатого уплотнения (варианты) - Google Patents

Способ изготовления многоступенчатого уплотнения (варианты) Download PDFInfo

- Publication number

- RU2331808C2 RU2331808C2 RU2003125960/06A RU2003125960A RU2331808C2 RU 2331808 C2 RU2331808 C2 RU 2331808C2 RU 2003125960/06 A RU2003125960/06 A RU 2003125960/06A RU 2003125960 A RU2003125960 A RU 2003125960A RU 2331808 C2 RU2331808 C2 RU 2331808C2

- Authority

- RU

- Russia

- Prior art keywords

- seals

- pressure

- bristles

- seal

- load

- Prior art date

Links

- 238000000034 method Methods 0.000 title claims abstract description 28

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 7

- 238000009826 distribution Methods 0.000 claims abstract description 23

- 238000013461 design Methods 0.000 claims description 29

- 238000007789 sealing Methods 0.000 claims description 12

- 239000012530 fluid Substances 0.000 claims description 10

- 238000012986 modification Methods 0.000 claims description 7

- 230000004048 modification Effects 0.000 claims description 7

- 238000012360 testing method Methods 0.000 claims description 7

- 230000020169 heat generation Effects 0.000 claims description 4

- 238000012856 packing Methods 0.000 claims 1

- 230000000694 effects Effects 0.000 abstract description 7

- 238000010276 construction Methods 0.000 abstract description 2

- 230000008569 process Effects 0.000 abstract description 2

- 239000000126 substance Substances 0.000 abstract 1

- 230000008859 change Effects 0.000 description 6

- 238000010438 heat treatment Methods 0.000 description 6

- 231100000817 safety factor Toxicity 0.000 description 6

- 238000005452 bending Methods 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 238000005056 compaction Methods 0.000 description 3

- 238000004141 dimensional analysis Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 230000002411 adverse Effects 0.000 description 2

- 230000004888 barrier function Effects 0.000 description 2

- 230000003993 interaction Effects 0.000 description 2

- 230000007774 longterm Effects 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 229910000967 As alloy Inorganic materials 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000003245 working effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

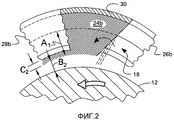

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/02—Preventing or minimising internal leakage of working-fluid, e.g. between stages by non-contact sealings, e.g. of labyrinth type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/002—Sealings comprising at least two sealings in succession

- F16J15/006—Sealings comprising at least two sealings in succession with division of the pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/16—Sealings between relatively-moving surfaces

- F16J15/32—Sealings between relatively-moving surfaces with elastic sealings, e.g. O-rings

- F16J15/3284—Sealings between relatively-moving surfaces with elastic sealings, e.g. O-rings characterised by their structure; Selection of materials

- F16J15/3288—Filamentary structures, e.g. brush seals

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2240/00—Components

- F05D2240/55—Seals

- F05D2240/56—Brush seals

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Sealing Devices (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/227,643 | 2002-08-26 | ||

| US10/227,643 US6854735B2 (en) | 2002-08-26 | 2002-08-26 | In situ load sharing brush seals |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2003125960A RU2003125960A (ru) | 2005-02-20 |

| RU2331808C2 true RU2331808C2 (ru) | 2008-08-20 |

Family

ID=31887506

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2003125960/06A RU2331808C2 (ru) | 2002-08-26 | 2003-08-25 | Способ изготовления многоступенчатого уплотнения (варианты) |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6854735B2 (enExample) |

| JP (1) | JP4618991B2 (enExample) |

| KR (1) | KR100912997B1 (enExample) |

| CN (1) | CN100538020C (enExample) |

| RU (1) | RU2331808C2 (enExample) |

Families Citing this family (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7040861B2 (en) * | 2004-03-04 | 2006-05-09 | General Electric Company | Method and apparatus for reducing self sealing flow in combined-cycle steam turbines |

| JP4776249B2 (ja) * | 2005-02-25 | 2011-09-21 | 株式会社東芝 | 液体の軸封装置とその軸封装置を用いた回転電機 |

| US8167313B2 (en) * | 2005-11-21 | 2012-05-01 | General Electric Company | Seal member, assembly and method |

| EP1813840A1 (de) * | 2006-01-26 | 2007-08-01 | Siemens Aktiengesellschaft | Mehrstufige Bürstendichtung |

| US7703774B2 (en) * | 2006-09-12 | 2010-04-27 | General Electric Company | Shaft seal using shingle members |

| US20080107525A1 (en) * | 2006-11-02 | 2008-05-08 | General Electric Company | Shaft seal formed of tapered compliant plate members |

| US20080217859A1 (en) * | 2007-03-05 | 2008-09-11 | United Technologies Corporation | Speed fit brush seal |

| DE102007018063B4 (de) | 2007-04-17 | 2012-02-09 | Siemens Ag | Gleichdruckturbine |

| US8080973B2 (en) | 2008-10-22 | 2011-12-20 | General Electric Company | Apparatus for energy transfer using converter and method of manufacturing same |

| US7932633B2 (en) | 2008-10-22 | 2011-04-26 | General Electric Company | Apparatus for transferring energy using power electronics and machine inductance and method of manufacturing same |

| DE102008055736A1 (de) * | 2008-11-04 | 2010-05-12 | Siemens Aktiengesellschaft | Bürstenringdichtung für eine Turbomaschine und Turbomaschine mit einer Bürstenringdichtungsanordnung |

| US20100164177A1 (en) * | 2008-12-30 | 2010-07-01 | Eaton Corporation | Hybrid multistage brush seal |

| US8061984B2 (en) * | 2009-04-06 | 2011-11-22 | Dresser-Rand Company | Dry gas blow down seal |

| US8206082B2 (en) * | 2009-04-29 | 2012-06-26 | General Electric Company | Packing seal rotor lands |

| US8505923B2 (en) * | 2009-08-31 | 2013-08-13 | Sealeze, A Unit of Jason, Inc. | Brush seal with stress and deflection accommodating membrane |

| US8936247B2 (en) | 2010-05-18 | 2015-01-20 | General Electric Company | Seal assembly including plateau and concave portion in mating surface for seal tooth in turbine |

| US9290097B2 (en) | 2010-11-05 | 2016-03-22 | Robert Louis Steigerwald | Apparatus for transferring energy using onboard power electronics with high-frequency transformer isolation and method of manufacturing same |

| DE102011080834A1 (de) * | 2011-08-11 | 2013-02-14 | Siemens Aktiengesellschaft | Bürstendichtung |

| US8932001B2 (en) * | 2011-09-06 | 2015-01-13 | General Electric Company | Systems, methods, and apparatus for a labyrinth seal |

| US20130181408A1 (en) * | 2012-01-13 | 2013-07-18 | General Electric Company | Brush seal arrangement combined with honeycomb seal |

| FR2998922B1 (fr) * | 2012-12-05 | 2018-06-15 | Safran Aircraft Engines | Etancheite d'enceintes de turbomachine realisee par joint a brosse et labyrinthe |

| WO2014091599A1 (ja) * | 2012-12-13 | 2014-06-19 | 株式会社日立製作所 | 回転流体機械 |

| KR101524627B1 (ko) * | 2015-03-05 | 2015-06-16 | 터보파워텍(주) | 터빈용 하이브리드 실링장치 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5704769A (en) * | 1995-03-20 | 1998-01-06 | Kabushiki Kaisha Toyoda Jidoshokki Seisakusho | Noise suppressing mechanism in piston-type compressor |

| US5749584A (en) * | 1992-11-19 | 1998-05-12 | General Electric Company | Combined brush seal and labyrinth seal segment for rotary machines |

| US6045134A (en) * | 1998-02-04 | 2000-04-04 | General Electric Co. | Combined labyrinth and brush seals for rotary machines |

| RU2158864C2 (ru) * | 1996-05-08 | 2000-11-10 | Мту Моторен-Унд Турбинен-Унион Мюнхен Гмбх | Щеточное уплотнение |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2198195B (en) * | 1986-12-06 | 1990-05-16 | Rolls Royce Plc | Brush seal |

| US5106104A (en) * | 1990-10-11 | 1992-04-21 | General Electric Company | Constant pressure drop multiple stage brush seal |

| GB9103459D0 (en) * | 1991-02-19 | 1991-04-03 | Cross Mfg Co | Brush seal assembly |

| US5758879A (en) * | 1991-08-01 | 1998-06-02 | Cross Manufacturing Company (1938) Limited | Brush seal assembly |

| US5181728A (en) * | 1991-09-23 | 1993-01-26 | General Electric Company | Trenched brush seal |

| US5335920A (en) * | 1992-08-20 | 1994-08-09 | General Electric Company | Brush seal |

| US5568931A (en) * | 1992-08-20 | 1996-10-29 | General Electric Company | Brush seal |

| US6131910A (en) * | 1992-11-19 | 2000-10-17 | General Electric Co. | Brush seals and combined labyrinth and brush seals for rotary machines |

| US5794942A (en) * | 1993-01-08 | 1998-08-18 | The Texas A&M University System | Modulated pressure damper seals |

| US5630590A (en) * | 1996-03-26 | 1997-05-20 | United Technologies Corporation | Method and apparatus for improving the airsealing effectiveness in a turbine engine |

| US5961279A (en) * | 1996-05-31 | 1999-10-05 | Atlantic Richfield Company | Turbine power plant having minimal-contact brush seal augmented labyrinth seal |

| CA2205877A1 (en) * | 1996-06-28 | 1997-12-28 | General Electric Company | Brush seals and combined labyrinth and brush seals for rotary machines |

| US6283716B1 (en) * | 1997-10-28 | 2001-09-04 | Coltec Industries Inc. | Multistage blowdown valve for a compressor system |

| WO1999030065A1 (en) * | 1997-12-11 | 1999-06-17 | Watson Cogeneration Company | Turbine power plant having minimal-contact brush seal augmented labyrinth seal |

| GB9821927D0 (en) * | 1998-10-08 | 1998-12-02 | Rolls Royce Plc | Improved brush seal |

| US6435011B1 (en) * | 1999-02-18 | 2002-08-20 | General Electric Company | Method and apparatus for determining if brush seals are defective |

| WO2001055624A1 (en) * | 2000-01-31 | 2001-08-02 | General Electric Company | Brush seals for steam turbine applications |

| WO2001076348A2 (en) * | 2000-04-06 | 2001-10-18 | Turbocare Inc. | Improved brush-seal designs for turbines and similar rotary apparatus |

| US6378371B1 (en) * | 2000-09-29 | 2002-04-30 | General Electric Company | Apparatus and methods for determining natural frequencies of brush seals |

-

2002

- 2002-08-26 US US10/227,643 patent/US6854735B2/en not_active Expired - Fee Related

-

2003

- 2003-08-25 RU RU2003125960/06A patent/RU2331808C2/ru not_active IP Right Cessation

- 2003-08-25 KR KR1020030058612A patent/KR100912997B1/ko not_active Expired - Fee Related

- 2003-08-26 CN CNB031549802A patent/CN100538020C/zh not_active Expired - Fee Related

- 2003-08-26 JP JP2003301000A patent/JP4618991B2/ja not_active Expired - Fee Related

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5749584A (en) * | 1992-11-19 | 1998-05-12 | General Electric Company | Combined brush seal and labyrinth seal segment for rotary machines |

| US6257586B1 (en) * | 1992-11-19 | 2001-07-10 | General Electric Co. | Combined brush seal and labyrinth seal segment for rotary machines |

| US5704769A (en) * | 1995-03-20 | 1998-01-06 | Kabushiki Kaisha Toyoda Jidoshokki Seisakusho | Noise suppressing mechanism in piston-type compressor |

| RU2158864C2 (ru) * | 1996-05-08 | 2000-11-10 | Мту Моторен-Унд Турбинен-Унион Мюнхен Гмбх | Щеточное уплотнение |

| US6045134A (en) * | 1998-02-04 | 2000-04-04 | General Electric Co. | Combined labyrinth and brush seals for rotary machines |

| US6105967A (en) * | 1998-02-04 | 2000-08-22 | General Electric Co. | Combined labyrinth and brush seals for rotary machines |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1495340A (zh) | 2004-05-12 |

| US6854735B2 (en) | 2005-02-15 |

| KR100912997B1 (ko) | 2009-08-20 |

| JP2004084951A (ja) | 2004-03-18 |

| US20040036227A1 (en) | 2004-02-26 |

| CN100538020C (zh) | 2009-09-09 |

| RU2003125960A (ru) | 2005-02-20 |

| JP4618991B2 (ja) | 2011-01-26 |

| KR20040018950A (ko) | 2004-03-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2331808C2 (ru) | Способ изготовления многоступенчатого уплотнения (варианты) | |

| CN1165698C (zh) | 密封装置,特别是用于一旋转机械的密封装置 | |

| US5961280A (en) | Anti-hysteresis brush seal | |

| RU2596889C2 (ru) | Осевое щеточное уплотнение | |

| EP2554879A2 (en) | Outward bristle brush seal design for gas turbine application | |

| US20100028135A1 (en) | Vibration damper | |

| US6644668B1 (en) | Brush seal support | |

| WO2011162330A1 (ja) | 軸シール機構、及びこれを備えた回転機械 | |

| US20100143102A1 (en) | Compliant plate seal with self-correcting behavior | |

| Schwarz et al. | Axial inclination of the bristle pack, a new design parameter of brush seals for improved operational behavior in steam turbines | |

| JP2011140943A (ja) | 逆圧力勾配シール機構 | |

| US20110286851A1 (en) | Guide blade arrangement for an axial turbo-machine | |

| Watanabe et al. | Development of new high efficiency steam turbine | |

| JP5818717B2 (ja) | ガスタービン | |

| US20070007730A1 (en) | Air riding seal | |

| EP2436883A1 (en) | Blade root, particularly of a turbine blade, a blade, and a turbomachine assembly | |

| Justak et al. | Self-acting clearance control for turbine blade outer air seals | |

| Stephen et al. | Development of brush seal technology for steam turbine retrofit applications | |

| Chupp et al. | Advanced seal development for large industrial gas turbines | |

| Dinc et al. | Fundamental design issues of brush seals for industrial applications | |

| Pedraza-Valle et al. | On the Development of a Pressure Actuated Leaf Seal for Turbomachinery Applications | |

| GB2432639A (en) | Axially adjustable sealing ring | |

| Chupp et al. | Advanced seals for industrial turbine applications | |

| Grondahl | Pressure actuated leaf seals for improved turbine shaft sealing | |

| Hasnedl et al. | Comparative study of a felt abradable seal |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| QB4A | Licence on use of patent |

Free format text: LICENCE Effective date: 20130315 |

|

| MM4A | The patent is invalid due to non-payment of fees |

Effective date: 20130826 |

|

| NF4A | Reinstatement of patent |

Effective date: 20140627 |

|

| QB4A | Licence on use of patent |

Free format text: LICENCE Effective date: 20140829 |

|

| MM4A | The patent is invalid due to non-payment of fees |

Effective date: 20150826 |