JP6534501B2 - Plastic container lid - Google Patents

Plastic container lid Download PDFInfo

- Publication number

- JP6534501B2 JP6534501B2 JP2013234230A JP2013234230A JP6534501B2 JP 6534501 B2 JP6534501 B2 JP 6534501B2 JP 2013234230 A JP2013234230 A JP 2013234230A JP 2013234230 A JP2013234230 A JP 2013234230A JP 6534501 B2 JP6534501 B2 JP 6534501B2

- Authority

- JP

- Japan

- Prior art keywords

- circumferential

- locking

- projections

- radially inward

- container lid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Closures For Containers (AREA)

Description

本発明は、タンパーエビデント特性を備えた合成樹脂製容器蓋、更に詳しくは円形天面壁とこの天面壁の周縁から垂下する円筒形スカート壁とを具備し、スカート壁には周方向に延びる破断ラインが形成されていて、スカート壁は破断ラインよりも上方の主部と破断ラインよりも下方のタンパーエビデント裾部とに区画されており、スカート壁の主部の内周面には雌螺条が形成され、タンパーエビデント裾部の内周面には周方向に間隔をおいて周方向に延びる複数個の係止突起が配設されており、係止突起の各々は半径方向内方に延出する係止上面を有する合成樹脂製容器蓋に関する。 The present invention comprises a synthetic resin container lid having tamper-evident properties, more specifically, a circular top wall and a cylindrical skirt wall depending from the periphery of the top wall, and a circumferentially extending fracture in the skirt wall A line is formed, and the skirt wall is divided into a main part above the breaking line and a tamper-evidence foot below the breaking line, and a female screw is formed on the inner circumferential surface of the main part of the skirt wall A strip is formed, and on the inner circumferential surface of the tamper evident foot portion, a plurality of locking projections extending circumferentially at intervals in the circumferential direction are disposed, each of the locking projections being radially inward The present invention relates to a synthetic resin container lid having a locking upper surface extending therefrom.

周知の如く、外周面には雄螺条とこの雄螺条の下方に位置する係止あご部が配設されている円筒形状の口頸部を有する飲料用容器のための合成樹脂製容器蓋として、例えば下記特許文献1に開示されている如く、円形天面壁とこの天面壁の周縁から垂下する円筒形スカート壁とを具備し、スカート壁には周方向に延びる破断ラインが形成されていて、スカート壁は破断ラインよりも上方の主部と破断ラインよりも下方のタンパーエビデント裾部とに区画されている合成樹脂製容器蓋が広く実用に供されている。スカート壁の主部の内周面には雌螺条が形成されている。タンパーエビデント裾部の内周面には周方向に間隔をおいて周方向に延びる複数個の係止突起が配設されており、係止突起の各々は半径方向内方に延出する係止上面を有する。 As is well known, a synthetic resin container lid for a container for a beverage having a cylindrical neck and neck on which an external thread and a locking jaw located below the external thread are disposed. For example, as disclosed in Patent Document 1 below, a circular top wall and a cylindrical skirt wall depending from the periphery of the top wall are provided, and the skirt wall is formed with a circumferentially extending breaking line. The synthetic resin container lid, in which the skirt wall is divided into a main part above the breaking line and a tamper evidence part below the breaking line, is widely put to practical use. An internal thread is formed on the inner peripheral surface of the main portion of the skirt wall. A plurality of locking projections extending in the circumferential direction at intervals in the circumferential direction are disposed on the inner peripheral surface of the tamper evident foot, and the locking projections extend radially inward. It has a stop surface.

上記のとおりの合成樹脂製容器蓋は、容器の口頸部に被嵌して閉回転方向、即ち上方から見て時計方向、に回転せしめ、口頸部の雄螺条に容器蓋の雌螺条を螺合せしめることによって口頸部に装着される。タンパーエビデント裾部の内周面に形成されている係止突起は、口頸部の係止あご部を弾性的に乗り越えてその下方に位置せしめられる。容器の内容物を消費するために容器の口頸部を開封する際には、容器蓋を開回転方向、即ち上方から見て反時計方向、に回転せしめる。かくすると、雄螺条に対する雌螺条の螺合が漸次解除され、容器蓋の天面壁及びスカート壁の主部は開方向への回転と共に上昇せんとするが、タンパーエビデント裾部はその内周面に形成されている係止突起の係止上面が口頸部の係止あご部に係止することによって上昇が阻止され、かくして破断ラインに応力が生成されて破断ラインが破断され、タンパーエビデント裾部がスカート壁の主部から分離される。しかる後においては、タンパーエビデント裾部を口頸部に残留せしめて、天面壁及びスカート壁の主部は開回転方向の回転と共に自由に上昇せしめられて口頸部から離脱され、口頸部が開封される。タンパーエビデント裾部に軸線方向に延在する破断ラインが形成されている形態の合成樹脂製容器蓋においては、周方向に延びる破断ラインの破断は周方向全周ではなくて一部において破断されることなく維持され、タンパーエビデント裾部に形成されている軸方向に延在する破断ラインが破断されてタンパーエビデント裾部が無端環状形態から有端帯状形態にせしめられ、これによって口頸部の係止あご部に対する係止突起の係止が解除され、しかる後にタンパーエビデント裾部を含む容器蓋の全体が開回転方向の回転と共に自由に上昇せしめられて口頸部から離脱され、口頸部が開封される。 The synthetic resin container lid as described above is fitted on the mouth and neck of the container and rotated in the closing rotation direction, that is, clockwise as viewed from above, and the female thread of the container lid is screwed on the male screw of the mouth and neck. It is worn on the neck and neck by screwing the strip. The locking projection formed on the inner circumferential surface of the tamper-evident foot portion is elastically passed over the locking jaw portion of the neck and is positioned therebelow. When opening the neck of the container in order to consume the contents of the container, the container lid is rotated in the opening rotational direction, that is, counterclockwise as viewed from above. As a result, the screwing of the female screw to the male screw is gradually released, and the top wall of the container lid and the main part of the skirt wall do not rise with the rotation in the opening direction, but the tamper evident skirt By locking the locking upper surface of the locking projection formed on the circumferential surface to the locking jaw of the neck and neck, the rise is blocked, thus generating stress in the breaking line and breaking the breaking line, tampering The evident foot is separated from the main part of the skirt wall. After that, the tamper evident's skirt is left on the neck, and the top wall and the main part of the skirt wall are freely lifted with the rotation in the opening rotational direction and disengaged from the neck. Will be opened. In the synthetic resin container lid in which the fracture line extending in the axial direction is formed in the bottom portion of the tamper evident, the fracture line of the fracture line extending in the circumferential direction is broken not partially along the circumferential direction but partially Without breaking, the axially extending break line formed in the tamper evident skirt is broken so that the tamper evident skirt is converted from an endless annular form to an endless belt form, thereby causing the oral cervix The locking projections are released from the locking jaws of the head, and thereafter the entire container lid including the tamper evident foot is freely lifted with rotation in the opening rotational direction and is released from the neck The mouth and neck are opened.

本発明者の経験によれば、上述したとおりの形態の従来の合成樹脂容器蓋には、(1)タンパーエビデント裾部の端部に指或いは適宜の工具を係止せしめて半径方向外方に変位せしめながら容器蓋を開回転方向に回転せしめることによって、破断ラインを破断せしめることなく容器蓋の全体を口頸部から離脱せしめて口頸部が不正に開封されてしまう虞が皆無ではない、(2)容器の口頸部に容器蓋を装着する際、特にタンパーエビデント裾部の内周面に配設されている係止突起が口頸部の係止あご部を弾性的に乗り越える際に、破断ラインが偶発的に破断されてしまう虞がある、という解決すべき問題が存在する。 According to the inventor's experience, according to the conventional synthetic resin container lid as described above, (1) a finger or an appropriate tool is locked at the end of the tamper-evident skirt to radially outward By rotating the container lid in the opening and rotating direction while displacing it, there is no risk that the entire container lid can be detached from the mouth and neck without opening the fracture line and the mouth and neck being unfairly opened. (2) When attaching the container lid to the mouth and neck of the container, the locking projections disposed on the inner circumferential surface of the tamper evident's foot, in particular, resiliently ride over the locking jaw of the mouth and neck At the same time, there is a problem to be solved that the break line may be broken accidentally.

本発明は上記事実に鑑みてなされたものであり、その主たる技術的課題は、上記のとおりにして口頸部が不正に開封されることが確実に防止されると共に、口頸部に容器蓋を装着する際に破断ラインが偶発的に破断されることが可及的に防止される、新規且つ改良された合成樹脂製容器蓋を提供することである。 The present invention has been made in view of the above-mentioned facts, and the main technical problem thereof is to reliably prevent the opening of the mouth and neck from being illegally opened as described above, and to prevent the container lid from covering the mouth and neck It is an object of the present invention to provide a new and improved synthetic resin container lid in which the breakage line is prevented as much as possible from being broken accidentally when mounting the container.

本発明者は、鋭意検討の結果、係止突起の各々における係止上面の半径方向内方への延出長さを比較的長くすると、上記のとおりにして口頸部が不正に開封されることを確実に防止することができるが、口頸部に容器蓋を装着する際に破断ランイが偶発的に破断される傾向が増大する事実に鑑み、係止手段の各々の形態を周方向中間部の該係止上面の半径方向内方への延出長さは周方向両側部における該係止上面の半径方向内方への延出長さよりも大きいと共に、係止突起の各々における周方向中間部の該係止上面の半径方向内方への延出端縁は凸弧状であり、半径方向内方への延出長さは周方向中央から周方向両側に向かって漸次低減せしめられている独特な形態にすることによって上記主たる技術的課題を達成することができることを見出した。 As a result of intensive investigations, the inventors of the present invention found that if the radial inward extension length of the locking upper surface in each of the locking protrusions is relatively long, the mouth and neck is unfairly opened as described above. However, in view of the fact that the tendency of the broken line to be broken accidentally increases when attaching the container lid to the mouth and neck, each form of the locking means is circumferentially intermediate with not greater than the extension length of the radially inward engaging the upper surface in extending length of the section to the locking top radially inward of the circumferential sides, circumferential in each of the locking projections direction extending end of the intermediate portion to the locking top radially inward of a convex arc, extending length of the radially inward is caused to gradually decrease toward the circumferential center in the circumferential direction on both sides It is seen that it is possible to achieve the principal object by a unique form and It was.

即ち、本発明によれば、上記主たる技術的課題を達成する合成樹脂容器蓋として、

円形天面壁と該天面壁の周縁から垂下する円筒形スカート壁とを具備し、該スカート壁には周方向に延びる破断ラインが形成されていて、該スカート壁は該破断ラインよりも上方の主部と該破断ラインよりも下方のタンパーエビデント裾部とに区画されており、該スカート壁の該主部の内周面には雌螺条が形成され、該タンパーエビデント裾部の内周面には周方向に等間隔をおいて周方向に延びる3以上の奇数個の係止突起が配設されており、該係止突起の各々は半径方向内方に延出する係止上面を有し、該係止突起の各々の周方向長さは同一であり、該係止突起の各々の周方向中間部の直径方向反対部位には該係止突起が存在しない係止突起非存在部が位置し、該係止突起の各々の周方向両側部の直径方向反対部位には、夫々、該係止突起非存在部の周方向両側に位置する係止突起の周方向両側部の、該係止突起非存在部に隣接する片方が位置する合成樹脂製容器蓋において、

該係止突起の各々における周方向中間部の該係止上面の半径方向内方への延出長さは周方向両側部における該係止上面の半径方向内方への延出長さよりも大きく設定されており、

該係止突起の各々における周方向中間部の該係止上面の半径方向内方への延出端縁は凸弧状であり、該係止突起の各々における周方向中間部の該係止上面の半径方向内方への延出長さは周方向中央から周方向両側に向かって漸次低減せしめられており、

該係止突起の各々は、下方に向かって半径方向外方に傾斜して延在する案内下面を有し、該案内下面の下縁は周方向中間部から少なくとも周方向両側部の一部に渡って水平に延びる、

ことを特徴とする合成樹脂製容器が提供される。

That is, according to the present invention, as a synthetic resin container lid which achieves the above-mentioned main technical problems,

It has a circular top wall and a cylindrical skirt wall depending from the periphery of the top wall, and the skirt wall is formed with a circumferentially extending breaking line, the skirt wall being a main line above the breaking line Section and a tamper-evident skirt below the breaking line, and a female screw is formed on the inner circumferential surface of the main section of the skirt wall, the inner periphery of the tamper-evident skirt The surface is provided with three or more odd number of locking projections extending in the circumferential direction at equal intervals in the circumferential direction, and each of the locking projections has a locking upper surface extending radially inward. A locking projection non-presence portion in which the circumferential length of each of the locking projections is the same, and the locking projection does not exist at a diametrically opposite portion of a circumferential intermediate portion of each of the locking projections There located, in the diametrically opposite portion of the circumferential side portions of the respective engaging projections, respectively, engaging projections Circumferential both sides of the locking projection positioned on both sides in the peripheral direction of the missing portion, in plastic container closure which one is located adjacent to the engaging projection absence unit,

The radially inward extending length of the locking upper surface of the circumferential middle portion in each of the locking projections is greater than the radially inward extending length of the locking upper surface in both circumferential side portions Is set,

The radially inward extending end edge of the locking upper surface of the circumferential middle portion of each of the locking projections is a convex arc, and the locking upper surface of the circumferential middle portion of each of the locking protrusions is The radially inward extension length is gradually reduced from the circumferential center to both circumferential directions,

Each of the locking projections has a guiding lower surface which extends downwardly and radially outward and inclined, and the lower edge of the guiding lower surface extends from the circumferential middle to at least a part of the circumferential sides. Extend horizontally across,

A container made of synthetic resin is provided.

好ましくは、該係止突起は周方向に等間隔をおいて5個配設されている。 Preferably, five of the locking projections are arranged at equal intervals in the circumferential direction .

本発明の合成樹脂製容器蓋においては、係止突起の各々における周方向中間部の係止上面の半径方向内方への延出長さが周方向両側部における係止上面の半径方向内方への延出長さよりも大きく設定されている故に、タンパーエビデント裾部の端部に指或いは適宜の工具を係止せしめて半径方向外方に変位せしめて係止を毀損することが効果的に防止される。他方、係止突起の各々における周方向中間部のみにおいて係止上面の半径方向内方への延出長さが大きく設定されると共に、係止突起の各々における周方向中間部の係止上面の半径方向内方への延出端縁は凸弧状であり、係止突起の各々における周方向中間部の係止上面の半径方向内方への延出長さは周方向中央から周方向両側に向かって漸次低減せしめられ且つ係止突起の各々の周方向中間部の直径方向反対部位には該係止突起が存在しない係止突起非存在部が位置する故に、容器の口頸部に容器蓋を装着する際、特にタンパーエビデント裾部の内周面に配設されている係止突起が口頸部の係止あご部を弾性的に乗り越える際に、破断ラインが偶発的に破断されてしまうことが可及的に回避される。 In plastic container closure of the present invention, the radial lock top extending the length of the radially inward locking the upper surface of the circumferential direction intermediate portion of each of the locking projections in the circumferential direction both side portions inward Since it is set to be larger than the extension length, it is effective to lock a finger or an appropriate tool at the end of the tamper-evident skirt to displace it radially outward to break the lock. To prevent. On the other hand, the radially inward extension length of the locking upper surface is set large only at the circumferential middle portion of each of the locking protrusions, and the locking upper surface of the circumferential middle portion of each of the locking protrusions is The radially inward extending end edge is a convex arc, and the radially inward extending length of the locking upper surface of the circumferential middle portion in each of the locking projections is circumferentially from the circumferential center to both sides in the circumferential direction Since the locking projection non-presence portion in which the locking projection is not present is located at the diametrically opposite portion of the circumferential middle portion of each of the locking projections which is gradually reduced toward the container lid, the container lid is The breaking line is broken by accident when attaching, especially when the locking projections disposed on the inner circumferential surface of the tamper-evident foot part elastically ride over the locking jaw part of the neck and neck. It is avoided as much as possible.

以下、添付図面を参照して、本発明に従って構成された合成樹脂製容器蓋の好適実施形態について、更に詳述する。 The preferred embodiments of the synthetic resin container lid constructed in accordance with the present invention will be described in more detail with reference to the accompanying drawings.

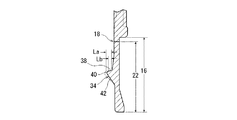

図1を参照して説明すると、ポリエチレン又はポリプロピレンの如き適宜の合成樹脂から射出成形又は圧縮成形することができる容器蓋2は、円形天面壁4とこの天面壁4の周縁から垂下する円筒形スカート壁6とを具備する。天面壁4の内面外周縁部には、下方に垂下する比較的長い円筒形状の内側シール片8と共に下方に垂下する比較的短い円筒形状の外側シール片10が形成されている。内側シール片8の外周面基端部には環状突出部12が形成されている。

Referring to FIG. 1, the

スカート壁6は比較的肉厚の厚肉上部14と比較的肉薄の薄肉下部16を有する。薄肉下部16の上端部には周方向に延びる破断ライン18が形成されており、スカート壁6は破断ライン18より上方の主部20と破断ライン18より下方のタンパーエビデント裾部22とに区画されている。図示の実施形態においては、破断ライン18は周方向に延びる複数個のスリット(切り溝)24とスリット24間に残留せしめられている複数個の橋絡部26とから構成されており、タンパーエビデント裾部22は複数個の橋絡部26を介して主部20に接続されている。

The

スカート壁6の主部20の外周面には、周方向に見て交互に存在する凹凸形状から構成された滑り止めローレット28が形成されている。スカート壁6の主部20の内周面には、雌螺条30と共に軸線方向に延びる複数個の切欠き32が形成されている。

On the outer peripheral surface of the

タンパーエビデント裾部22の内周面には周方向に等間隔をおいて5個の係止突起34が配設されており、係止突起34の各々の周方向長さは実質上同一であり、係止突起34の各々の周方向中間部34aの直径方向反対側には係止突起非存在部36が存在する。

Five

図1と共に図2及び図3を参照して説明を続けると、係止突起34の各々は、半径方向内方に延出する係止上面38、縦断面図において略半円弧形状である先端面40及び下方に向かって半径方向外方に傾斜して延在する案内下面42を有する。そして、本発明に従って構成された容器蓋2においては、係止突起34の各々において、係止上面38の半径方向内方への延出長さが周方向全体に渡って同一ではなく、周方向中間部34aにおける延出長さLaは、周方向両側部における延出長さLbよりも大きく設定されていると共に、係止上面38の周方向中間部34aにおける延出長さLaは、周方向中間から周方向両側に向かって漸次低減せしめられていることが重要である。周方向両側部34bにおける係止上面38の半径方向内方への延出長さLbは周方向において周方向中間部34aから離れるに従って漸次低減せしめられており、周方向外側端(周方向中間部34との非接続端)においては実質上零である。周方向中間部34aの周方向両端における係止上面の半径方向延出長さと周方向両側部34bの周方向内側端(周方向中間部34aとの接続端)における係止上面の半径方向延出長さは同一である。図示の実施形態においては、係止突起34の各々の案内下面42の下縁は上記周方向中間部34aから上記両側部34bの一部(即ち内側半部)に渡って実質上水平に延在している(図1を参照されたい)。上記周方向両側部34bの外側半部においては案内下面42の下縁は周方向外側端に向かって軸線方向上方に傾斜せしめられている。

Continuing with reference to FIGS. 2 and 3 in conjunction with FIG. 1, each of the

図1には容器蓋2と共に容器の口頸部44も図示されている。ポリエチレンテレフタレートの如き適宜の合成樹脂、ガラス或いは金属薄板から形成することができる容器の口頸部44は全体として円筒形状であり、口頸部44の外周面には雄螺条46と雄螺条46の下方に位置する係止あご部48が形成されている。係止あご部48は下方に向かって外径が漸次増大する弧状の上面及び実質上水平に延在する下面を有する。口頸部44の外周面には、更に、係止あご部48の下方に位置するサポートリング50(かかるサポートリング50は当業者には周知の如く容器の搬送に利用される)も配設されている。

The mouth and

容器内に内容物を充填した後に口頸部44に容器蓋2を装着して口頸部44を密封する際には、口頸部44に容器蓋2を被嵌して容器蓋2を閉回転方向、図1において上方から見て時計方向、に回転せしめ、容器蓋2の雌螺条30を口頸部44の雄螺条46に螺合せしめる。図1に示す状態まで雌螺条30を雄螺条46に螺合せしめると、容器蓋2の内側シール片8が口頸部44内に侵入して口頸部44の内周面に密接され、環状突出部12が口頸部44の頂面に密接せしめられ、外側シール片10が口頸部44の外周面に密接乃至近接せしめられ、かくして口頸部44が密封される。

When the

図1を参照して説明を続けると、口頸部44に容器蓋2を装着して口頸部44を密封する際には、タンパーエビデンド裾部22の内周面に配設されている係止突起34は口頸部44の係止あご部48を弾性的に乗り越え、係止あご部48の下方に位置せしめられる。この際には係止突起34の案内下面42の案内作用によって係止突起34は漸次半径方向外方に変位せしめられて円滑に係止あご部48を乗り越える。そして、係止突起34の各々の係止上面38の周方向全体ではなくて周方向中間部34aのみにおいて係止上面38の半径方向内方への延出長さLaが大きく設定されており、周方向中間部34aの半径方向内方への延出長さLaが周方向中央から周方向両側に向かって漸次低減せしめられている故に、係止突起34が係止あご部48を弾性的に乗り越える際に破断ライン18が偶発的に破断されてしまうことは可及的に回避される。

If description is continued with reference to FIG. 1, when attaching the

内容物を消費するために口頸部44を開封する際には、容器蓋2を開方向、即ち図1において上方から見て反時計方向、に回転せしめる。かくすると、雄螺条46と雌螺条30の螺合が漸次解除され、スカート壁6の主部20は回転と共に軸線方向上方に移動せしめられる。一方、タンパーエビデント裾部22は係止突起34が係止あご部48に係止せしめられる故に軸線方向上方への移動が阻止され、かくして破断ライン18の橋絡部26に応力が生成されて橋絡部26が破断され、タンパーエビデント裾部22がスカート壁6の主部20から切り離される。破断ライン18が破断された後においては、タンパーエビデント裾部22を口頸部44に残留せしめて、容器蓋2の天面壁4及びスカート壁6の主部20は回転と共に軸線方向上方に自由に移動せしめられて口頸部44から離脱され、かくして口頸部44が開封される。所望ならば、タンパーエビデント裾部22に軸線方向破断ラインを形成し、容器の口頸部44を開封する際には上記軸線方向破断ラインが破断され、一方周方向に延在する破断ライン18はその一端が破断されることなく維持され、タンパーエビデント裾部22が無端環状から有端環状に展開され、タンパーエビデント裾部22と共に容器蓋2の全体が口頸部44から離脱されるようになすこともできる。

When opening the

本発明に従って構成された容器蓋2においては、係止突起34の各々において、係止上面38の半径方向内方への延出長さが周方向全体に渡って同一ではなく、周方向中間部34a(従って、図示の実施形態においては係止突起非存在部36に対して直径方向反対側に位置する部位)において延出長さLaが周方向両側部における延出長さLbよりも大きく設定されており、周方向中間部34aの半径方向内方への延出長さLaが周方向中央から周方向両側に向かって漸次低減せしめられている。それ故に、タンパーエビデント裾部22の端部に指或いは適宜の工具を係止せしめて半径方向外方に変位せしめながら容器蓋2を開回転方向に回転せしめることによって、破断ライン18を破断せしめることなく容器蓋2の全体を口頸部44から離脱せしめて口頸部44が不正に開封されてしまうことが充分確実に防止される。

In the

2:容器蓋

4:天面壁

6:スカート壁

18:破断ライン

20:主部

22:タンパーエビデント裾部

26:橋絡部

30:雌螺条

34:係止突起

34a:係止突起の周方向中間部

34b:係止突起の周方向両側部

36:係止突起非存在部

38:係止突起の係止上面

40:係止突起の先端面

42:係止突起の案内下面

44:口頸部

46:雄螺条

48:係止あご部

2: Container lid 4: Top wall 6: Skirt wall 18: Broken line 20: Main part 22: Tamper evident foot 26: Bridge 30: Female thread 34: Locking

Claims (2)

該係止突起の各々における周方向中間部の該係止上面の半径方向内方への延出長さは周方向両側部における該係止上面の半径方向内方への延出長さよりも大きく設定されており、

該係止突起の各々における周方向中間部の該係止上面の半径方向内方への延出端縁は凸弧状であり、該係止突起の各々における周方向中間部の該係止上面の半径方向内方への延出長さは周方向中央から周方向両側に向かって漸次低減せしめられており、

該係止突起の各々は、下方に向かって半径方向外方に傾斜して延在する案内下面を有し、該案内下面の下縁は周方向中間部から少なくとも周方向両側部の一部に渡って水平に延びる、

ことを特徴とする合成樹脂製容器蓋。 It has a circular top wall and a cylindrical skirt wall depending from the periphery of the top wall, and the skirt wall is formed with a circumferentially extending breaking line, the skirt wall being a main line above the breaking line Section and a tamper-evident skirt below the breaking line, and a female screw is formed on the inner circumferential surface of the main section of the skirt wall, the inner periphery of the tamper-evident skirt The surface is provided with three or more odd number of locking projections extending in the circumferential direction at equal intervals in the circumferential direction, and each of the locking projections has a locking upper surface extending radially inward. A locking projection non-presence portion in which the circumferential length of each of the locking projections is the same, and the locking projection does not exist at a diametrically opposite portion of a circumferential intermediate portion of each of the locking projections There located, in the diametrically opposite portion of the circumferential side portions of the respective engaging projections, respectively, engaging projections Circumferential both sides of the locking projection positioned on both sides in the peripheral direction of the missing portion, in plastic container closure which one is located adjacent to the engaging projection absence unit,

The radially inward extending length of the locking upper surface of the circumferential middle portion in each of the locking projections is greater than the radially inward extending length of the locking upper surface in both circumferential side portions Is set,

The radially inward extending end edge of the locking upper surface of the circumferential middle portion of each of the locking projections is a convex arc, and the locking upper surface of the circumferential middle portion of each of the locking protrusions is The radially inward extension length is gradually reduced from the circumferential center to both circumferential directions,

Each of the locking projections has a guiding lower surface which extends downwardly and radially outward and inclined, and the lower edge of the guiding lower surface extends from the circumferential middle to at least a part of the circumferential sides. Extend horizontally across,

Container lid made of synthetic resin.

容器蓋。 The synthetic resin container lid according to claim 1, wherein five locking projections are arranged at equal intervals in the circumferential direction.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013234230A JP6534501B2 (en) | 2013-11-12 | 2013-11-12 | Plastic container lid |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013234230A JP6534501B2 (en) | 2013-11-12 | 2013-11-12 | Plastic container lid |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015093704A JP2015093704A (en) | 2015-05-18 |

| JP2015093704A5 JP2015093704A5 (en) | 2016-06-30 |

| JP6534501B2 true JP6534501B2 (en) | 2019-06-26 |

Family

ID=53196378

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013234230A Active JP6534501B2 (en) | 2013-11-12 | 2013-11-12 | Plastic container lid |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6534501B2 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6587341B2 (en) * | 2015-08-12 | 2019-10-09 | 株式会社Csiジャパン | Synthetic resin cap, closure device, and beverage closure device |

| JP6775996B2 (en) * | 2016-05-13 | 2020-10-28 | 日本クロージャー株式会社 | Synthetic resin container lid |

| JP6539011B1 (en) * | 2017-10-16 | 2019-07-03 | 日本山村硝子株式会社 | Synthetic resin cap and container |

| JP2020015558A (en) * | 2019-10-31 | 2020-01-30 | 日本クロージャー株式会社 | Synthetic resin container lid |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5487481A (en) * | 1994-10-31 | 1996-01-30 | Sander; Dieter | Tamper evident plastic closure |

| MX2013008035A (en) * | 2011-01-14 | 2013-12-02 | Creanova Universal Closures | Closure. |

| JP2012201402A (en) * | 2011-03-28 | 2012-10-22 | Japan Crown Cork Co Ltd | Combination of container with synthetic resin lid |

-

2013

- 2013-11-12 JP JP2013234230A patent/JP6534501B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015093704A (en) | 2015-05-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5215798B2 (en) | Plastic container lid | |

| JP5574582B2 (en) | Plastic container lid | |

| US20070034590A1 (en) | Bottle with retained ring finish feature | |

| CN103153804A (en) | Improved tamper-evident closure and package | |

| JP5697505B2 (en) | Plastic container lid | |

| JP6534501B2 (en) | Plastic container lid | |

| JP6518456B2 (en) | Synthetic resin container lid and combination thereof with container | |

| JP4413071B2 (en) | Plastic container lid | |

| JP2011143942A (en) | Synthetic resin container lid and combination of the lid and container | |

| JP6775996B2 (en) | Synthetic resin container lid | |

| JP6393497B2 (en) | Plastic container lid | |

| JP6017112B2 (en) | Combination of synthetic resin container lid and container | |

| JP2012126429A (en) | Container with cap | |

| JP5298350B2 (en) | A container composed of a synthetic resin lid and a container body | |

| JP6539011B1 (en) | Synthetic resin cap and container | |

| JP6254427B2 (en) | Plastic container lid | |

| JP5912247B2 (en) | Plastic container lid | |

| JP6276972B2 (en) | Plastic container lid | |

| JP4993591B2 (en) | Container lid | |

| JP6310743B2 (en) | Plastic container lid | |

| JP2012201402A (en) | Combination of container with synthetic resin lid | |

| JP5912260B2 (en) | Plastic container lid | |

| JP6189726B2 (en) | Plastic container lid | |

| JP2023118381A (en) | Synthetic resin-made container lid | |

| JP6128831B2 (en) | Plastic container lid |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160512 |

|

| A625 | Written request for application examination (by other person) |

Free format text: JAPANESE INTERMEDIATE CODE: A625 Effective date: 20161011 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170718 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170725 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170922 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20180109 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20181206 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190308 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20190529 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6534501 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |