JP6133705B2 - Pipe connection method or connection structure - Google Patents

Pipe connection method or connection structure Download PDFInfo

- Publication number

- JP6133705B2 JP6133705B2 JP2013128956A JP2013128956A JP6133705B2 JP 6133705 B2 JP6133705 B2 JP 6133705B2 JP 2013128956 A JP2013128956 A JP 2013128956A JP 2013128956 A JP2013128956 A JP 2013128956A JP 6133705 B2 JP6133705 B2 JP 6133705B2

- Authority

- JP

- Japan

- Prior art keywords

- hole

- water

- tube

- flange portion

- plastic material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Electric Cable Installation (AREA)

- Laying Of Electric Cables Or Lines Outside (AREA)

Description

本発明は、管材の接続方法及び接続構造に関し、特にFEP(Flexible Electric Pipe 波付硬質ポリエチレン管。以下)などの管材を、配管用の貫通孔に接続固定する接続方法及び接続構造に関する。 The present invention relates to a pipe material connection method and connection structure, and more particularly to a connection method and connection structure for connecting and fixing a pipe material such as FEP (Flexible Electric Pipe corrugated hard polyethylene pipe, hereinafter) to a through hole for piping.

近年、給電用ケーブルや通信ケーブルのような電気ケーブルを地中に埋設することが行われており、この地中埋設には、樹脂製などの管材を使い、この管材の中にこの電気ケーブルを通しているが、電気ケーブルを通すため、このような管材には防水性が要求される。このような防水のために、下記のようなものが考えられてきている。本件出願は、下記特許文献1、2、3、4、5の発明者(考案者)または出願人若しくはこれらの相続人において、同一である。

In recent years, electrical cables such as power supply cables and communication cables have been buried in the ground, and pipes made of resin or the like are used for the underground burial. However, in order to pass an electric cable, such a pipe material is required to be waterproof. The following have been considered for such waterproofing. This application is the same in the inventors (developers), applicants or their heirs of the following

本件発明は、上述した課題を解決するためになされたものであり、本発明の目的は、管材の接続において防水性・止水性を向上させることにある。本件発明は、上記特開2012−115106号及び特許第3090447号公報記載発明の改良である。 This invention is made | formed in order to solve the subject mentioned above, and the objective of this invention is to improve waterproofness and water stop in connection of a pipe material. The present invention is an improvement of the invention described in Japanese Patent Laid-Open No. 2012-115106 and Japanese Patent No. 3090447.

上記目的を達成するために、本発明の管材の接続方法または接続構造は、 貫通穴の内径より小さい、信号が流れるまたは電力が送られる線体が内部に収納される長尺状の管体の外側に、筒状の硬質の挟持体を螺合して、当該挟持体の端からこの管体を露出させ、この管体の露出部分を支持体に開けられた貫通穴内に入れて、上記挟持体を貫通穴の周囲の支持体に当接させ、 上記管体の内径より小さい、筒状の硬質の内筒体を、上記管体及び挟持体と反対側から貫通穴に入れて貫通させるとともに当該管体の内側に螺合させ、 この内筒体の全周面から外方に隙間なく延出され、上記貫通穴の内径より大きい硬質のフランジ部で、当該貫通穴を上記挟持体と反対側から隙間なく塞ぎ、この螺合の進行によって、上記挟持体と上記フランジ部との離間距離が縮まって、この挟持体とこのフランジ部とで上記貫通穴の周囲の支持体が挟持されることであって、 上記貫通穴の周りに沿って、このフランジ部の上記貫通穴に面する面に、水を吸収せず、水を透過せず、水に接触しても膨張も収縮もせず、水に濡れて硬化も軟化もせず、空気中でも水中でも時間が経過しても硬化も軟化もしない、上記フランジ部と上記貫通穴の周囲の支持体との間または上記フランジ部と上記管体の先端との間を密封して、水の浸透を防止する可塑材が充填されるようにした。 In order to achieve the above object, the pipe connection method or connection structure according to the present invention is an elongated pipe body in which a wire body through which a signal flows or power is sent is smaller than the inner diameter of the through hole. A tubular rigid sandwiching body is screwed on the outside, the tube body is exposed from the end of the sandwiching body, and the exposed portion of the tube body is placed in a through-hole opened in the support body. The body is brought into contact with a support around the through hole, and a cylindrical hard inner cylinder smaller than the inner diameter of the tube is inserted into the through hole from the side opposite to the tube and the sandwiching body and penetrated. Screwed into the inside of the tube body, extended outward from the entire circumferential surface of the inner cylinder without gaps, and a rigid flange portion larger than the inner diameter of the through hole, the through hole is opposite to the sandwiching body. Closed from the side without any gap, and by the progress of this screwing, the clamping body and the flange portion And the support body around the through hole is sandwiched between the sandwiching body and the flange portion, and along the periphery of the through hole, the support body around the through hole is sandwiched in the through hole of the flange portion. Does not absorb water, does not permeate water, does not expand or contract when contacted with water, does not cure or soften when exposed to water, and cures over time in air or water It is filled with a plastic material that seals between the flange part and the support around the through-hole or between the flange part and the tip of the tube body and prevents water penetration. I did it.

これにより、優れた防水性・止水性を管材の接続方法及び接続構造を提供し、熟練を全く要せず、短時間で簡単かつ確実に配管用貫通孔にFEP管などの管材を接続できる。 This provides a pipe material connection method and connection structure with excellent waterproofness and water-stopping capability, and it is possible to connect a pipe material such as an FEP pipe to a pipe through-hole easily and reliably in a short time without requiring any skill.

(1)管材の接続構造及び接続方法

図1はFEP管8(管体)の接続構造及び接続方法を示す。上記細長い断面円状の管状のFEP管8(管材)の外側には、筒状の硬質の円筒状の挟持外筒11が螺合挿通されていく。この挟持外筒11はFEP管8の外側を螺合回転しながら、この挟持外筒11の端(図1において左端)から、FEP管8が露出されていく。

(1) Connection structure and connection method of pipe material FIG. 1 shows the connection structure and connection method of the FEP pipe 8 (tube body). A cylindrical hard cylindrical sandwich

FEP管8の螺旋凹凸9の外側は、上記挟持外筒11の内周面の係合凸堤15…に螺合されながら回転していくことによって、押し込まれ、容易に外れない。このFEP管8及び挟持外筒11は、FEP管8の露出部分を支持壁1(支持体)に開けられた貫通穴2に、図1の右方から入れられ、図7に示すように、上記挟持外筒11の先端の外フランジ部12は貫通穴2の周囲の支持壁1に当接される。

The outer side of the

このFEP管8の太さ・外径は、貫通穴2の内径より小さい。このFEP管8は断面が多数の周期の波状、サインカーブ状であり、この螺旋凹凸9の波がFEP管8の周囲にそって螺旋状に形成されている。このFEP管8の材質は軟質または硬質の樹脂、例えば軟質のポリエチレン、ポリカーボネート、ABS、ポリプロピレン等、撓む軟質の材料からなっている。

The thickness and outer diameter of the

このFEP管8内には、種々の資材が挿通される。例えば、光または電気の信号が流れる通信ケーブルまたは電力が送られる給電用ケーブル、その他のライフライン素材(線体、図示せず)が内部に収納され挿通される。

Various materials are inserted into the

なお、FEP管8は太くて、FEP管8の先端が貫通穴2の周囲の支持壁1の表面に当接してもよい。この場合、上記内フランジ部4の充填可塑材7の外径は貫通穴2の内径より大きく、充填可塑材7は支持壁1表面に当接密着密封される。

The

支持壁1は、コンクリートからなる平坦で厚さが一定で、例えば四角筒状であり、内部に給電用ケーブルや通信ケーブルの接続機器、分配機器、配電機、中継機などの電気機器が収納される。この支持壁1は、敷地内の地下、道路の地下、その他の地下、地表、地上などに設けられ、または家の基礎壁などとなる。この支持壁1の厚さは1mm乃至1mであり、例えば数十cmであり、この支持壁1の任意の位置には真っ直ぐで直線状の貫通穴2が複数開けられている。

The

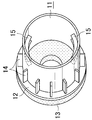

図2、図3及び図4は挟持外筒11を示す。挟持外筒11の端部・先端(図1左端)の全周面から外方に外フランジ部12が直角に隙間なく円板状かつ環状に延出されている。外フランジ部12の先端面つまり貫通穴2に面する面には、貫通穴2の周りに沿って、接着剤などによって、環状の密封パッキン13(密封体)が接着されている。この密封パッキン13は、クッション性及び可撓性があり、例えばウレタン製などで、水に触れても膨張せず、内部の気泡が独立気泡で、密封パッキン13自体は水の浸透を防止する。

2, 3, and 4 show the sandwiching

この密封パッキン13は上記貫通穴2の周囲の支持壁1の表面に当接密封密着して、挟持外筒11、外フランジ部12及び当該密封パッキン13と支持壁1との間の水の浸透を防止する。この密封パッキン13は挟持外筒11の中心方向に向かって内側に延出されており、この密封パッキン13の延出部分は、挟持外筒11が螺合回転されるとき、FEP管8の外面を擦れながら移動し、FEP管8外面に当接密着密封して、水の浸透を防止する。

The sealing packing 13 abuts and seals closely against the surface of the

挟持外筒11の周囲には長手方向に延びる補強板14が等間隔で形成されており、この補強板14の端は上記外フランジ部12に繋がっており、挟持外筒11及び外フランジ部12の強度が強化される。上記挟持外筒11、外フランジ部12及び補強板14の材質は硬質の樹脂、例えば硬質のポリエチレン、ポリカーボネート、ABS、ポリプロピレン等、ほとんど撓まない硬質の材料からなっている。

図5及び図6は内筒3を示す。内筒3(ベルマウス)は円筒状で、材質は硬質の樹脂、例えばポリエチレン、ポリカーボネート等、ほとんど撓まない硬質の材料からなっている。この内筒3の外径は、上記貫通穴2の内径及び上記FEP管8の内径より小さい。

5 and 6 show the

次いで、図8に示すように、貫通穴2の上記FEP管8及び挟持外筒11の挿入方向と反対側から入れられて、当該貫通穴2を貫通し、さらに上記FEP管8の内側に螺合していく。この内筒3の全外周面には、螺旋状の螺旋凸条5が突設されている。

Next, as shown in FIG. 8, the

この内筒3の端(図1の左)には、内フランジ部4が形成され、この内フランジ部4は内筒3の端部の全周面から外方に直角に隙間なく円板状かつ環状に延出されている。この内フランジ部4及び螺旋凸条5の材質は硬質または軟質の樹脂、例えば硬質のポリエチレン、ポリカーボネート、ABS、ポリプロピレン等、ほとんど撓まない硬質の材料からなっている。

An

この内フランジ部4の外径は上記貫通穴2の内径より大きく、内フランジ部4は貫通穴2を塞いでいる。この内フランジ部4の内筒3側(図1の右)の面、つまり貫通穴2に面する面には、貫通穴2の周りに沿って、環状のクッション性及び可撓性のある可撓パッキン6(可撓性体)が接着剤で接着されている。

The outer diameter of the

この可撓パッキン6(可撓性体)は、例えばウレタン製などで、水に触れても膨張せず、内部の気泡が独立気泡で、可撓パッキン6自体は水の浸透を防止する。この可撓パッキン6は上記貫通穴2の周囲の支持壁1の表面に当接密着密封して、内筒3、内フランジ部4及び当該可撓パッキン6と支持壁1との間の水の浸透を防止する。

The flexible packing 6 (flexible body) is made of urethane, for example, and does not expand even when it is touched with water, the internal bubbles are closed cells, and the

上記環状の可撓パッキン6の内側、つまり内筒3の外側、すなわち可撓パッキン6と内筒3との間には、内フランジ部4の表面に接着剤などによって可撓性のある充填可塑材7(防水止水材)で接着されている。この充填可塑材7は、上記貫通穴2の周りに沿って、上記内フランジ部4の上記貫通穴2に面する面に取り付けられている。

Inside the annular

そして、FEP管8内側に対して内筒3を螺合回転していくと、内筒3及び内フランジ部4と挟持外筒11及び外フランジ部12との離間距離が縮まり、挟持外筒11の外フランジ部12の先端面と、上記内筒3の内フランジ部4とで、貫通穴2の周囲の支持壁1が挟まれる。

When the

FEP管8の螺旋凹凸9の内側は、上記内筒3の外周面の螺旋凸条5に螺合して回転していくことによって、押し込まれ、容易に外れない。このFEP管8は強く押し込まれ、FEP管8の先端は、上記貫通穴2内面と内筒3外面との間に入り込み、さらには内フランジ部4の内側の充填可塑材7に当接密着密封される。

The inside of the

また、可撓パッキン6も貫通穴2の周囲の支持壁1により強く当接密着密封されて、止水性・防水性がより強固にされる。これらの結果、充填可塑材7とFEP管8先端とが互いにより強く当接密着密封されて、止水性・防水性がより強固にされる。

Further, the

したがって、上記充填可塑材7には、FEP管8の先端の円形の線状の端部が当接し、上記可撓パッキン6には貫通穴2の周囲の面状の支持壁1の端部/端面が当接することになる。内筒3の可撓パッキン6と充填可塑材7との境界は、支持壁1の貫通穴2にほぼ一致している。これにより、貫通穴2に充填可塑材7を対向させ、防水性・止水性が低下しない。

Accordingly, a circular linear end portion of the tip of the

すなわち、上記充填可塑材7の外径は上記貫通穴2の内径にほぼ一致しており、充填可塑材7は、貫通穴2に入り込んで上記FEP管8(管体)の先端に当接密着密封して、上記内筒3及び内フランジ部4と当該FEP管8との間の水の浸透を防止する。

That is, the outer diameter of the filling

なお、充填可塑材7の幅を狭くし可撓パッキン6の幅を広くして、貫通穴2内に可撓パッキン6が対向又は入り込んでもよい。これにより、充填可塑材7がFEP管8だけに当接して防水性・止水性を一極に集中できる。また、充填可塑材7の幅を広くし可撓パッキン6の幅を狭くして、貫通穴2の外側の支持壁1の外面に充填可塑材7が対向または当接してもよい。これにより、防水性・止水性がより向上する。

In addition, the width of the filling

上記内筒3と内フランジ部4との境界部10は断面が直角に折れ曲がっており、この直角の境界部10は、内筒3の厚さまたは内フランジ部4の厚さの1.5倍乃至5.0倍、望ましくは2.0倍乃至4.0倍となっていて、強度が強化されている。

The

上記2.0倍未満の厚さでは上記充填可塑材7によって内筒3と内フランジ部4との境界部10が変形してしまい、防水性・止水性が低下してしまうし、上記1.5倍未満の厚さでは上記充填可塑材7によって内筒3と内フランジ部4との境界部10が大きく変形してしまう。

When the thickness is less than 2.0 times, the

上記4.0倍を越える厚さでは上記充填可塑材7によって内筒3と内フランジ部4との境界部10の周囲が変形してしまい、防水性・止水性が低下してしまうし、上記5.0倍を越える厚さでは上記充填可塑材7によって内筒3と内フランジ部4との境界部10の周囲がさらに大きく変形してしまう。

If the thickness exceeds 4.0 times, the periphery of the

このような境界部10の強度向上は、厚さだけでなく、素材を強固なものに代えても達成できる。例えば、内筒3及び内フランジ部4の素材を樹脂のリサイクル材を用い、上記境界部10にバージンの素材を用いたり、境界部10の外側裏面に不織布又は/及び樹脂を吹き付けたりするなどである。この場合には、上記境界部10の厚さは1.0倍乃至1.5倍でも大丈夫である。

Such an improvement in the strength of the

上記内筒3外面の螺旋凸条5の断面は板状で、FEP管8の螺旋凹凸9の断面が波状・サインカーブ状以外の、台形状、方形状、三角状、のこぎり刃状、いずれでも螺合可能となっている。このFEP管8の材質は、上述のように軟質の樹脂、例えば軟質のポリエチレン、ポリカーボネート、ABS、ポリプロピレン等、撓む硬質の材料からなっているが、硬質の材料から構成しても良く、この場合でも、細長いので、全体としてある程度撓む。

The cross-section of the

また、FEP管8は螺旋状の螺旋凹凸9の無い、例えば螺旋状ではない環状の凹凸で、断面が上記波状・サインカーブ状以外の、台形状、方形状、三角状、のこぎり刃状であってもよい。

Further, the

この場合には、内筒3の螺旋凸条5も同じく環状凸条となり、FEP管8は可撓性が持たされ、FEP管8は内筒3の外側に強く押し込まれ、FEP管8の環状凹凸が内筒3の環状凸条を順次越えて、FEP管8が内筒3外面から容易に離脱されないように固定される。これも螺合の一種である。

In this case, the

上述の支持壁1の外側のFEP管8側に土が盛られ、支持壁1の外側のFEP管8側が地中となる。場合によって、支持壁1の上側が地中となることもある。このような地中に雨水などの水が浸透してきて、FEP管8、挟持外筒11の外側から水が浸入しようとする。これが上記FEP管8と挟持外筒11との間の密封パッキン13によって止水・防水され、さらに支持壁1、内筒3、FEP管8との間の充填可塑材7及び可撓パッキン6によってさらに防水・止水される。

The soil is piled up on the

(2)充填可塑材7

上記充填可塑材7としては、例えば、オランダのストパック(STOPAQ)社の止水材のポリイソブデン(PIB)系の2100アクアストップが望ましい。この2100アクアストップの詳しい特性は、国際公開WO2005/005528に詳しく説明されている。この公報に開示されていることは、本発明の詳細な説明にも開催されているものとし、ここでの説明は省略する。

(2) Filled

As the filling

充填可塑材7は可塑材であり、可撓性があり軟らかく変形しやすい。この変形しやすさは、本管材の接続作業において、内筒3の可撓パッキン6の内側の環状の凹部に塗り込む充填するのに容易な変形しやすさである。内筒3の可撓パッキン6の内側にいったん充填された充填可塑材7は通常の重力では変形はしない。

The filled

この充填可塑材7は粘着性を有しており、凹凸があっても、この凹凸に沿って充填され、隙間ができない。したがって、防水性・止水性が低下しない。また、地震などで本管材が大きく振動して多少変形・変位されたりしても、充填可塑材7は可撓性があって、これらの変形・変位に対応してこの変形・変位を受け入れ、充填可塑材7自身が変形して、隙間ができず、自己修復性を達成できる。

The filled

特に、充填可塑材7自身には、若干の流動性があるので、充填可塑材7自身にカキ傷や微小小穴ができても、充填可塑材7自身の流動性によってこれらを自動的に修復でき、地震などがあっても、防水性・止水性が低下しない。この流動性があっても、重力で流動はしないので、不都合はない。

In particular, since the filled

上述のように上記充填可塑材7は、上記内フランジ部4と上記貫通穴2の周囲の支持壁1との間、または上記内フランジ部4と上記FEP管8(管体)の先端との間を密封して、水の浸透を防止する。これにより、管材の中の給電用ケーブルや通信ケーブルといった電気ケーブルのような機材を水から守り故障を防ぐことができる。

As described above, the filled

上記充填可塑材7は、水に対して親和性、親水性を有していない。したがって、充填可塑材7は、水を吸収せず、水を透過せず、水中でも、水に接触しても膨張せず、水に濡れて硬化も軟化もせず、粘性・流動性が変化しない。したがって、長期間にわったって、防水性・止水性が低下せず、管材の中の給電用ケーブルや通信ケーブルといった電気ケーブルのような機材を水から守り故障を防ぐことができる。

The filled

また、水中でも、水が流れている箇所でも、本管材の取付作業をしても、充填可塑材7が水で変異しないので、水がない箇所での作業と変わりなく、同様の作業をすることができ、作業効率が向上し、作業不良も生じない。

Also, even in water, even in locations where water is flowing, even if the main pipe is installed, the filled

さらに、充填可塑材7は、水中でも、水に触れても膨張しないので、充填可塑材7の膨張によって本管材が割れることがなく、防水性・止水性が低下しないし、充填可塑材7は、水に触れても収縮しないので、充填可塑材7と本管材との間に隙間ができず、防水性・止水性が低下しない。

Further, since the filled

充填可塑材7は、水中でも、水に触れても硬化しないので、充填可塑材7が硬化してクラックが発生せず、防水性・止水性が低下しないし、充填可塑材7は、水に触れても軟化しないので、充填可塑材7が流動性を帯びて充填可塑材7が流動変形を起こさず、防水性・止水性が低下しない。

Since the filled

また、充填可塑材7は、酸素を吸収も透過もしないため、空気中でも、長期間にわたって、時間が経過しても硬化も軟化もせず、粘性・流動性が変化しない。したがって、設置当初の管材のFEP管(管体)8と内筒3と支持壁(支持体)1などの間に、長期間にわたって、時間経過しても隙間ができず、防水性・止水性が低下せず、管材の中の給電用ケーブルや通信ケーブルといった電気ケーブルのような機材を水から守り故障を防ぐことができる。

In addition, since the filled

充填可塑材7は、上記のように酸素を吸収も透過もしないので、金属に対して錆を防ぐ効果もある。したがって、充填可塑材7楽音接触する管材の一部が金属でも、錆びを防ぐことができるし、この管材の一部が樹脂などでも酸素による酸化・劣化を防ぐことができる。

Since the filled

充填可塑材7は電気絶縁効果も高く、管材の中の給電用ケーブルや通信ケーブルといった電気ケーブルのような機材を漏電から守り故障を防ぐことができる。

The filled

充填可塑材7の充填量は、隣り合う可撓パッキン6の厚さとほぼ同じとされる。これにより、充填可塑材7と可撓パッキン6とに段差ができず、隙間ができなくなって、防水性・止水性が低下しない。

The filling amount of the filling

本管材を支持壁(支持体)1に取り付けたとき、締め付け具合によっては、内筒3の可撓パッキン6が圧縮されることがあるが、この場合でも充填可塑材7の方が支持壁(支持体)1の貫通穴2内に入り込むこととなり、密閉性は維持され、防水性・止水性が低下しない。このような、締め付け具合の変化によって、防水性・止水性が変化してしまうことがなくなる。

When the main pipe is attached to the support wall (support) 1, the

上記充填可塑材7は、有害物質を含まず無害であり、環境ホルモンも含まず、手足など、直接人体に触れても炎症などを起こすことがない。このような充填可塑材7は、均等の性質・性能を有していれば、上述の素材以外、例えばフタル酸エステル、アジピン酸エステル、トリメット酸エステル、ポリエステル、リン酸エステル、クエン酸エステル、エポキシ化植物油、セバシン酸エステル、安息香酸エステルなどを用いてもよい。充填可塑材7の厚さは、可撓パッキン6より厚くてもよいし、薄くてもよい。

The filled

(3)他の実施の形態

本発明は、上記実施例に限定されず、種々変更可能である。例えば、環板状の内フランジ部4及び外フランジ部12は、一部切欠されていたり、楕円、多角形状、花びら状、星状、網状などどのような形状でもよいし、厚さは板状のほか、ブロック状に厚くてもよいし、内筒3及び挟持外筒11の中央付近から外方に延出されていたりしてもよいし、内筒3及び挟持外筒11に対して直角方向ではなく、斜めに延出されてもよい。

(3) Other Embodiments The present invention is not limited to the above embodiments, and various modifications can be made. For example, the annular plate-shaped

上記貫通穴2の各断面は円形のほか、楕円、多角形状、花びら状、星状、テーパー状、ラッパの開口先端の湾曲テーパー状などどのような形状でもよいし、これに応じて内筒3、挟持外筒11、FEP管8などの断面形状も楕円、多角形状、花びら状、星状、テーパー状、ラッパの開口先端の湾曲テーパー状などどのような形状でもよいし、これらの筒の厚さも太くてもよいし、厚さも一定ではなく変化していてもよい。

Each cross-section of the through

貫通穴2は直線状のほか、湾曲していてもよいし、折れ曲がっていてもよい。この場合、FEP管8などは、湾曲または折曲げに応じて湾曲または折曲げされる。支持壁1の外側両面は平行ではなく、斜めになるなど、支持壁1の断面形状は台形などでもよいし、貫通穴2は支持壁1に対して斜めに開けられていてもよい。

The through

内フランジ部4及び外フランジ部12は、内筒3及び挟持外筒11に対して一体形成のほか、着脱自在でもよく、これらの一方が他方に螺合されてもよい。FEP管8の外面は、ホース状、円筒状に平坦でもよく、FEP管8の外面及び内面には螺旋状の凸条/凸堤が形成されていてもよい。

The

内筒3の外側の螺旋凸条5、挟持外筒11の外側の係合凸堤15は板状ではなく、山波形、山形、サインカーブの山形、三角形、台形、のこぎり波形、方形などでもよい。内筒3及び挟持外筒11は、FEP管8に螺合できれば、短くてもよい。内筒3及び挟持外筒11の側面は、FEP管8と同様に断面がサインカーブ等の波形でもよい。

The

上記密封パッキン(密封体)13の一部または全部は省略してもよい。FEP管8先端と内筒3及び内フランジ部4との間は、充填可塑材7によって防水・止水されているからである。密封パッキン13があれば、FEP管8先端と内筒3及び内フランジ部4との間の防止・止水は向上する。可撓パッキン(可撓体)6も省略可能である。

A part or all of the sealing packing (sealing body) 13 may be omitted. This is because the space between the tip of the

上記密封パッキン(密封体)13の一部または全部は、上記充填可塑材7で代用されてもよい。また、可撓パッキン6の一部または全部は、上記充填可塑材7で代用されてもよい。さらに、可撓パッキン6の一部または全部は省略可能である。これにより、密封パッキン13または可撓パッキン6を省略してコストダウンできる。

Part or all of the sealing packing (sealing body) 13 may be substituted by the filling

上記挟持外筒11はテーパー状となり、外フランジ部12は省略されまたはテーパー状の中に一体化され、挟持外筒11の側面で貫通穴2に当接しても良く、この場合には、貫通穴2もこれに合わせてテーパー状となる。また、内筒3もテーパー状となり、内フランジ部4は省略されまたはテーパー状の中に一体化され、内筒3の側面で貫通穴2に当接しても良く、この場合には、貫通穴2もこれに合わせてテーパー状となる。

The sandwiching

上記支持壁(支持体)1、貫通穴2、内筒(ベルマウス)3、内フランジ部4、螺旋凸条5、可撓パッキン(可撓体)6、充填可塑材(防水止水材)7、FEP管(管材)8、螺旋凹凸9、境界部10、挟持外筒(挟持体)11、外フランジ部12、密封パッキン(密封体)13、補強板14、係合凸堤15の一部または全体は省略されてもよいし、その数が増えても減ってもよいし、その形状は任意に変更可能であり、均等の他の物に置き換えられてもよいし、これらの2つまたは3つ以上が合体または一体化されて兼用されてもよいし、材質は硬質樹脂製のほか、軟質樹脂製、金属製、木製、集成材製、合成材製、合板製、表面に化粧紙が接着されたもの、竹製、樹脂製、ガラス製、綿製、布製、糸製、繊維製、ゴム製、紙製、セラミック製、カーボン製、硬質ウレタン製、これらの合成物製/混合物製/多層積層物製でもよい。

Support wall (support body) 1, through

(4)他の発明の効果

[請求項1]貫通穴の内径より小さい、信号が流れるまたは電力が送られる線体が内部に収納される長尺状の管体の外側に、筒状の硬質の挟持体を螺合して、当該挟持体の端からこの管体を露出させ、この管体の露出部分を支持体に開けられた貫通穴内に入れて、上記挟持体を貫通穴の周囲の支持体に当接させ、 上記管体の内径より小さい、筒状の硬質の内筒体を、上記管体及び挟持体と反対側から貫通穴に入れて貫通させるとともに当該管体の内側に螺合させ、 この内筒体の全周面から外方に隙間なく延出され、上記貫通穴の内径より大きい硬質のフランジ部で、当該貫通穴を上記挟持体と反対側から隙間なく塞ぎ、この螺合の進行によって、上記挟持体と上記フランジ部との離間距離が縮まって、この挟持体とこのフランジ部とで上記貫通穴の周囲の支持体が挟持されることであって、 水を吸収せず、水を透過せず、水に接触しても膨張も収縮もせず、水に濡れて硬化も軟化もせず、空気中でも水中でも時間が経過しても硬化も軟化もしない、上記フランジ部と上記貫通穴の周囲の支持体との間または上記フランジ部と上記管体の先端との間を密封して、水の浸透を防止する可塑材を、上記貫通穴の周りに沿って、このフランジ部の上記貫通穴に面する面に、充填することを特徴とする管材の接続方法。

(4) Effects of other inventions [Claim 1] A cylindrical rigid body outside the long tubular body in which a wire body through which a signal flows or power is sent is smaller than the inner diameter of the through hole. The tubular body is exposed from the end of the sandwiched body, the exposed portion of the tubular body is placed in a through hole opened in the support body, and the sandwiched body is placed around the through hole. A cylindrical rigid inner cylinder smaller than the inner diameter of the tube is inserted into the through-hole from the opposite side of the tube and the sandwiching body, and is threaded inside the tube. And extending from the entire circumferential surface of the inner cylindrical body without gaps, and with a hard flange portion larger than the inner diameter of the through hole, the through hole is closed without gaps from the opposite side of the sandwiching body. Due to the progress of the screwing, the separation distance between the holding body and the flange portion is shortened. The support around the through hole is sandwiched between the flange part, does not absorb water, does not permeate water, does not expand or contract when contacted with water, gets wet with water, and cures Between the flange and the support around the through hole, or between the flange and the tip of the tubular body. A pipe connecting method characterized by filling a surface of the flange portion facing the through hole along the periphery of the through hole with a plastic material that seals and prevents water penetration.

[請求項2]支持体に開けられた貫通穴の内径より小さい、信号が流れるまたは電力が送られる線体が内部に収納される長尺状の管体と、 この管体の外側に螺合され、端からこの管体を露出させ、この管体の露出部分を貫通穴内に入れて、貫通穴の周囲の支持体に当接される筒状の硬質の挟持体と、 上記管体及び挟持体と反対側から貫通穴に入れて貫通されるとともに当該管体の内側に螺合され、上記管体の内径より小さい筒状の硬質の内筒体と、 この内筒体の全周面から外方に隙間なく延出され、当該貫通穴を上記挟持体と反対側から隙間なく塞ぎ、上記内筒体の螺合の進行によって、上記挟持体と上記フランジ部との離間距離が縮まり、この挟持体とこのフランジ部とで上記貫通穴の周囲の支持体が挟持される、上記貫通穴の内径より大きい硬質のフランジ部と、 上記貫通穴の周りに沿って、このフランジ部の上記貫通穴に面する面に取り付けられた、水を吸収せず、水を透過せず、水に接触しても膨張も収縮もせず、水に濡れて硬化も軟化もせず、空気中でも水中でも時間が経過しても硬化も軟化もしない、上記フランジ部と上記貫通穴の周囲の支持体との間または上記フランジ部と上記管体の先端との間を密封して充填される、水の浸透を防止する可塑材とを備えたことを特徴とする管材の接続構造。 [Claim 2] A long tubular body in which a linear body through which a signal flows or power is transmitted is smaller than an inner diameter of a through hole formed in a support body, and is screwed to the outside of the tubular body. The tubular body is exposed from the end, the exposed portion of the tubular body is placed in the through hole, and a cylindrical rigid sandwiching body that comes into contact with the support around the through hole, and the tubular body and the sandwiched body From the opposite side of the body into the through-hole and screwed into the inside of the tube, and is a cylindrical hard inner cylinder smaller than the inner diameter of the tube, and from the entire circumferential surface of the inner tube Extending outwardly without gaps, the through hole is closed without gaps from the opposite side of the sandwiching body, and the distance between the sandwiching body and the flange portion is reduced by the progress of screwing of the inner cylindrical body. The inner diameter of the through-hole, where the support body around the through-hole is clamped by the sandwiching body and the flange portion A large rigid flange portion, and attached to the surface of the flange portion facing the through hole along the periphery of the through hole, does not absorb water, does not permeate water, and contacts water. Does not expand or contract, does not cure or soften when wet with water, and does not cure or soften over time in air, water, or between the flange and the support around the through hole or the flange A pipe connecting structure comprising: a plastic material for preventing permeation of water, which is sealed and filled between a portion and a tip of the pipe.

[請求項3]上記可塑材の外周囲には、水に触れても膨張しない、水の浸透を防止する可撓性を有する可撓性体が環状に取り付けられており、この環状の可撓性体と上記内筒体とで、上記フランジ部上に凹部が形成され、この凹部内において上記可塑材が充填されることを特徴とする請求項2記載の管材の接続構造。

[Claim 3] On the outer periphery of the plastic material, a flexible body having flexibility to prevent water permeation that does not expand even when touched by water is attached in an annular shape. 3. The pipe connection structure according to

これにより、上記凹部に、上記可塑材が順次入れられ添加される。したがって、可塑材を形成するための特別の型枠組を不要にすることができる。この結果、管材の接続の機材の破損または無理な力がかからないようにして、止水性及び防水性を高めることができる。 Thereby, the plastic material is sequentially put into the concave portion and added. Therefore, a special formwork for forming the plastic material can be eliminated. As a result, the waterproofness and waterproofness can be improved without damaging or excessively applying force to the pipe connection equipment.

[請求項4]上記可塑材には線状の端部が当接し、上記可撓性体には面状の端部が当接することを特徴とする請求項3記載の管材の接続構造。

[Claim 4] The pipe connection structure according to

これにより、可塑材が面ではなく、管体の端の線に当接しているので、本管材を接続する作業において、管体を可塑材に当接するとき、この端の線が可塑材によく食い込んで、止水性・防水性がより強固にされ、管体が破損してしなうこともなくなる。この結果、管材の接続の機材の破損または無理な力がかからないようにして、止水性及び防水性を高めることができる。 As a result, the plastic material is in contact with the end line of the tubular body, not the surface, so when connecting the main pipe material, the end line is good for the plastic material. By biting in, the water-stopping and waterproofing properties are strengthened, and the tube body is not damaged. As a result, the waterproofness and waterproofness can be improved without damaging or excessively applying force to the pipe connection equipment.

[請求項5]上記可塑材の外周囲には、水に触れても膨張しない、水の浸透を防止する可撓性を有する可撓性体が取り付けられており、上記可塑材の外径は上記貫通穴の内径にほぼ一致していて同貫通穴に入り込んで上記管材の先端に当接密着して、上記内筒体及びフランジ部と当該管材との間の水の浸透を防止し、当該可撓性体はこの貫通穴の周囲の上記支持体の表面に当接密着して、上記内筒体及びフランジ部と上記支持体との間の水の浸透を防止することを特徴とする請求項4記載の管材の接続構造。

[Claim 5] A flexible body is attached to the outer periphery of the plastic material, which does not expand even when touched by water, and has flexibility to prevent water penetration. The outer diameter of the plastic material is Substantially matches the inner diameter of the through-hole, enters the through-hole and comes into close contact with the tip of the pipe, and prevents water penetration between the inner cylinder and the flange and the pipe, The flexible body is in contact with and closely contacted with the surface of the support around the through-hole to prevent water penetration between the inner cylinder and the flange portion and the support.

これにより、この挟持体を強く締めても、可塑材の圧力は貫通穴に逃げることができ、フランジ部やフランジ部と内筒体との境界部に余分な力がかからず、フランジ部は破損しない。そして、この可塑材は、支持体にはあまり当たらないので、可塑材によってフランジ部に余分な力がかからず破損もない。この結果、管材の接続の機材の破損または無理な力がかからないようにして、止水性及び防水性を高めることができる。 As a result, even if this clamping body is tightened strongly, the pressure of the plastic material can escape to the through hole, and no extra force is applied to the flange portion or the boundary portion between the flange portion and the inner cylindrical body. Does not break. And since this plastic material does not hit a support body very much, an extra force is not applied to a flange part by a plastic material, and there is no breakage. As a result, the waterproofness and waterproofness can be improved without damaging or excessively applying force to the pipe connection equipment.

[請求項6]上記可撓性体の厚さと、上記可塑材の厚さはほぼ同じであり、この可撓性体は水に濡れても膨張せず、この可塑材も水に濡れても膨張しないことを特徴とする請求項5記載の管材の接続構造。

[Claim 6] The thickness of the flexible body and the thickness of the plastic material are substantially the same, and the flexible body does not expand even when wetted with water. The pipe connection structure according to

これにより、水が当たると、可塑材及び可撓性体の支持体への当接圧力は変化しないので、防水性・止水性を維持することができ、フランジ部に余分な圧力がかからないか、またはフランジ部への圧力増大が無いようにできる。この結果、管材の接続の機材の破損または無理な力がかからないようにして、止水性及び防水性を高めることができる。 Thereby, when the water hits, the contact pressure to the support body of the plastic material and the flexible body does not change, so that waterproofness and water stoppage can be maintained, and excess pressure is not applied to the flange part. Alternatively, there can be no increase in pressure on the flange portion. As a result, the waterproofness and waterproofness can be improved without damaging or excessively applying force to the pipe connection equipment.

[請求項7]上記貫通穴の周りに沿って、上記挟持体の上記貫通穴に面する面に、上記挟持体と上記貫通穴の周囲の支持体との間を密封して水の浸透を防止する、可撓性を有する密封体が取り付けられていることを特徴とする請求項6記載の管材の接続構造。これにより、管体と内筒体との止水性・防水性を向上できる。

[Claim 7] The permeation of water is performed by sealing a space between the holding body and the support body around the through hole on a surface of the holding body facing the through hole along the periphery of the through hole. The pipe connection structure according to

[請求項8]上記可塑材が取り付けられた内筒体及びフランジ部は、防水性の器または袋内に密封され、上記支持体または管材の接続場所まで運ばれて、当該器または袋から取り出されて、上記支持体に取り付けられることを特徴とする請求項7記載の管材の接続構造。これにより、内筒体及びフランジ部を取り付ける前に、柔らかい可塑材が不用意に変形または傷が付いてしまうことを防止できる。

[Claim 8] The inner cylinder body and the flange portion to which the plastic material is attached are sealed in a waterproof container or bag, and are transported to a connection place of the support body or pipe material and taken out from the container or bag. The pipe connection structure according to

管材の接続において止水・防水する。長尺状のFEP管8の外側に挟持外筒11を螺合して、挟持外筒11の端からFEP管8を露出させて、これを支持壁1の貫通穴2内に入れ、挟持外筒11が貫通穴2の周囲の支持壁1に当接する。貫通穴2の反対側から、内筒3が入れられて上記FEP管8の内側に挿通螺合され、内筒3の端の内フランジ部4で、貫通穴2が塞がれる。

Waterproof and waterproof when connecting pipes. The holding

この内フランジ部4の貫通穴2に面する面に、水を吸収せず、水を透過せず、水に接触しても膨張も収縮もせず、水に濡れて硬化も軟化もせず、空気中で時間が経過しても硬化も軟化もしない、充填可塑材7が充填されている。上記内筒3がFEP管8に螺合したまま回転移動して、挟持外筒11の先端と内フランジ部4とで貫通穴2の周囲の支持壁1が挟持される。これにより、FEP管8の先端が、内フランジ部4の充填可塑材7に強く押しつけられ、FEP管8の先端と内フランジ部4の充填可塑材7との間が密封され止水される。支持壁1の外側のFEP管8側が地中となる。

The surface facing the through-

1…支持壁(支持体)、2…貫通穴、

3…内筒(ベルマウス)、4…内フランジ部、

5…螺旋凸条、6…可撓パッキン(可撓性体)、

7…充填可塑材、8…FEP管(管体)、

9…螺旋凹凸、10…境界部、

11…挟持外筒(挟持体)、12…外フランジ部、

13…密封パッキン(密封体)、

14…補強板、15…係合凸堤。

1 ... support wall (support), 2 ... through hole,

3 ... Inner tube (bell mouth), 4 ... Inner flange,

5 ... spiral ridges, 6 ... flexible packing (flexible body),

7 ... filled plastic material, 8 ... FEP pipe (tube),

9 ... spiral irregularities, 10 ... boundary,

11 ... clamping outer cylinder (clamping body), 12 ... outer flange,

13 ... Sealing packing (sealing body),

14 ... reinforcing plate, 15 ... engaging convexity.

Claims (5)

上記管体の内径より小さい、筒状の硬質の内筒体を、上記管体及び挟持体と反対側から貫通穴に入れて貫通させるとともに当該管体の内側に螺合させ、この内筒体の全周面から外方に隙間なく延出され、上記貫通穴の内径より大きい硬質のフランジ部で、当該貫通穴を上記挟持体と反対側から隙間なく塞ぎ、この螺合の進行によって、上記挟持体と上記フランジ部との離間距離が縮まって、この挟持体とこのフランジ部とで上記貫通穴の周囲の支持体が挟持されることであって、水を吸収せず、水を透過せず、水に接触しても膨張も収縮もせず、粘着性を有し、重力で流動しない程度の流動性があり、酸素を吸収も透過もせず、水に濡れても硬化も軟化もせず、空気中でも水中でも時間が経過しても硬化も軟化もしない、上記フランジ部と上記管体の先端との間を密封して水の浸透を防止する可塑剤であるストパック社製2100アクアストップを、上記貫通穴の周りに沿って、このフランジ部の上記貫通穴に面する面に充填し、

上記2100アクアストップの外周囲には、水に濡れても膨張しない、水の浸透を防止する可撓性を有する可撓パッキンが環状に取り付けられており、この環状の可撓パッキンと上記内筒体とで、上記フランジ部上に凹部が形成され、この凹部内において上記2100アクアストップが充填され、

上記2100アクアストップには上記管体の先端の線状の端部が食い込んで当接密着密封され、上記可撓パッキンには上記貫通穴の周囲の面状の支持体の端面が当接することを特徴とする管材の接続方法。 A cylindrical rigid sandwiching body is screwed onto the outside of a long tubular body in which a wire body through which a signal flows or power is sent, which is smaller than the inner diameter of the through hole, This tube is exposed from the end, the exposed part of this tube is put in a through-hole opened in the support, and the sandwiching body is brought into contact with the support around the through-hole,

A cylindrical rigid inner cylinder smaller than the inner diameter of the tubular body is inserted through the through hole from the opposite side of the tubular body and the sandwiching body and is screwed into the inner side of the tubular body. The outer peripheral surface of the through hole is extended without gaps, and the through hole is closed from the opposite side of the clamping body with a hard flange portion larger than the inner diameter of the through hole. The separation distance between the sandwiching body and the flange portion is reduced, and the support body around the through hole is sandwiched between the sandwiching body and the flange portion, and does not absorb water and transmit water. In addition, it does not expand or contract even when in contact with water, has adhesiveness, has fluidity that does not flow due to gravity, does not absorb or permeate oxygen, does not cure or soften even when wet. Over the flange and above, which does not harden or soften over time in air or water A surface facing the through hole of the flange portion along the through hole around the 2100 aqua stop made by Strpack, which is a plasticizer that seals between the ends of the tube body and prevents water penetration. Filling

Around the outer periphery of the 2100 aqua stop, a flexible packing that does not expand even when wet with water and has flexibility to prevent water penetration is attached in an annular shape. The annular flexible packing and the inner cylinder With the body, a concave portion is formed on the flange portion, and the 2100 aqua stop is filled in the concave portion,

The linear end of the tube body bites into the 2100 aqua stop and abuts and is tightly sealed. The flexible packing is in contact with the end surface of the planar support around the through hole. A characteristic pipe connection method.

上記管体の外側に螺合され、端からこの管体を露出させ、この管体の露出部分を貫通穴内に入れて、貫通穴の周囲の支持体に当接される筒状の硬質の挟持体と、

上記管体及び挟持体と反対側から貫通穴に入れて貫通されるとともに当該管体の内側に螺合され、上記管体の内径より小さい筒状の硬質の内筒体と、

この内筒体の全周面から外方に隙間なく延出された、上記貫通穴の内径より大きい硬質の部材であって、上記当該貫通穴を上記挟持体と反対側から隙間なく塞ぐと共に、上記内筒体の螺合の進行によって上記挟持体との離間距離が縮まることで、この挟持体との間で上記貫通穴の周囲の支持体を挟持するフランジ部と、

上記貫通穴の周りに沿って、このフランジ部の上記貫通穴に面する面に取り付けられた、水を吸収せず、水を透過せず、水に接触しても膨張も収縮もせず、粘着性を有し、重力で流動しない程度の流動性があり、酸素を吸収も透過もせず、水に濡れても硬化も軟化もせず、空気中でも水中でも時間が経過しても硬化も軟化もしない、上記フランジ部と上記管体の先端との間を密封して充填される、水の浸透を防止する可塑剤であるストパック社製2100アクアストップとを備え、

上記2100アクアストップの外周囲には、水に濡れても膨張しない、水の浸透を防止する可撓性を有する可撓パッキンが環状に取り付けられており、この環状の可撓パッキンと上記内筒体とで、上記フランジ部上に凹部が形成され、この凹部内において上記2100アクアストップが充填され、

上記2100アクアストップには上記管体の先端の線状の端部が食い込んで当接密着密封され、上記可撓パッキンには上記貫通穴の周囲の面状の支持体の端面が当接することを特徴とする管材の接続構造。 This is a connection structure for connecting and fixing a long tubular body, which is smaller than the inner diameter of the through hole formed in the support body and accommodates a wire body through which a signal flows or power is sent, to the inside of the through hole. And

Screwed on the outside of the tube to expose the tube from the end, putting the exposed portion of the tube body in the through hole, sandwiching the cylindrical rigid that contacts the support around the through hole Body,

A cylindrical hard inner cylinder that is inserted into a through-hole from the opposite side of the tube body and the sandwiching body and screwed inside the tube body, and is smaller than the inner diameter of the tube body;

Is extended without gaps outward from the entire peripheral surface of the inner cylindrical member, a member of the larger hard than the inner diameter of the through hole, no gap busy Gutotomoni the said through hole from the side opposite to the holding member in Rukoto shrink the distance between the upper Kikyoji body by the progressive engagement of the inner cylindrical member, and a flange portion for holding the support around the through-hole between the holding member,

Attached to the surface of the flange portion facing the through-hole along the periphery of the through-hole, does not absorb water, does not transmit water, and does not expand or contract when contacted with water. It has fluidity that does not flow due to gravity, does not absorb or transmit oxygen, does not cure or soften even when wet, and does not cure or soften over time in air or water And 2100 aqua stop made by Strpack Co., which is a plasticizer that prevents water from penetrating and is sealed and filled between the flange portion and the tip of the tubular body,

Around the outer periphery of the 2100 aqua stop, a flexible packing that does not expand even when wet with water and has flexibility to prevent water penetration is attached in an annular shape. The annular flexible packing and the inner cylinder With the body, a concave portion is formed on the flange portion, and the 2100 aqua stop is filled in the concave portion,

The linear end of the tube body bites into the 2100 aqua stop and abuts and is tightly sealed. The flexible packing is in contact with the end surface of the planar support around the through hole. Characteristic tube connection structure.

A flexible material that prevents penetration of water by sealing a space between the holding body and the support body around the through hole on a surface of the holding body facing the through hole along the periphery of the through hole. 5. The pipe connection structure according to claim 4, wherein a sealing body having a property is attached.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013128956A JP6133705B2 (en) | 2013-06-19 | 2013-06-19 | Pipe connection method or connection structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013128956A JP6133705B2 (en) | 2013-06-19 | 2013-06-19 | Pipe connection method or connection structure |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015006042A JP2015006042A (en) | 2015-01-08 |

| JP2015006042A5 JP2015006042A5 (en) | 2016-09-08 |

| JP6133705B2 true JP6133705B2 (en) | 2017-05-24 |

Family

ID=52301529

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013128956A Active JP6133705B2 (en) | 2013-06-19 | 2013-06-19 | Pipe connection method or connection structure |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6133705B2 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6144394B1 (en) * | 2016-08-24 | 2017-06-07 | 共和ゴム株式会社 | Tube connection structure and bellmouth |

| JP6095841B1 (en) * | 2016-10-24 | 2017-03-15 | 昭和機器工業株式会社 | Air shelter for electrical equipment |

| JP6910616B2 (en) * | 2017-04-20 | 2021-07-28 | 株式会社立基 | Pipe material connector |

| JP7203638B2 (en) * | 2019-02-28 | 2023-01-13 | 未来工業株式会社 | Corrugated tube device, terminal member for corrugated tube, and corrugated tube end fixing device |

| CN110994467A (en) * | 2019-12-11 | 2020-04-10 | 王启栋 | Cable support frame for electric power construction |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL1000712C2 (en) * | 1995-06-30 | 1996-12-31 | Nooren Frans Bv | Use of a preparation for insulating sealing and coating purposes as well as a method for sealing manhole covers. |

| ZA200600482B (en) * | 2003-07-14 | 2007-04-25 | Frans Nooren Afdichtingssystem | Compososition for the protection of a shaped article against corrosion |

| JP2012115106A (en) * | 2010-11-26 | 2012-06-14 | Masashi Kishigami | Connecting method or connecting structure of pipe material |

-

2013

- 2013-06-19 JP JP2013128956A patent/JP6133705B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015006042A (en) | 2015-01-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6133705B2 (en) | Pipe connection method or connection structure | |

| ES2392791T3 (en) | An assembly and a method for providing a sealing system in an opening | |

| BRPI0717283A2 (en) | PIPE LINE FIELD JOINT COATING FOR WET INSULATION FIELD JOINTS. | |

| US20200087926A1 (en) | Swellable Sealing Lip | |

| JP6044981B2 (en) | Flowing water pipe repair method | |

| CN210461971U (en) | Waterproof sealing processing structure of wall pipe fitting | |

| JP2009041313A (en) | Wall surface waterproofing device, water cutoff member, connection fitting, and waterproofing method | |

| JP2009275840A (en) | Pipe joint, pipe connection structure, and pipe connection method | |

| CN211624441U (en) | Basement wall pipe waterproof construction | |

| CN207555004U (en) | PCCP pipeline prestressed reinforcement structures | |

| JP7186155B2 (en) | Waterproof sheet laying method | |

| CN209516524U (en) | Cable rope sleeve and cable laying bracket | |

| CN209839356U (en) | Novel plugging device | |

| CN209854946U (en) | Water-stopping repairing structure | |

| JP2014034825A (en) | Sheet fixing device and insulation waterproofing method | |

| RU158115U1 (en) | SEALED JOINT OF TECHNOLOGICAL WELLS OF PIPELINE | |

| CN207814664U (en) | Wall feed-through pipeline waterproof construction | |

| JP5102126B2 (en) | Piping material with protective layer | |

| JP5521527B2 (en) | Waterproof sheet laying method and waterproof structure | |

| CN218441286U (en) | Socket joint of prestressed steel cylinder concrete pipe | |

| JP4785086B2 (en) | Tube connection method in piping box | |

| CN210461992U (en) | Expansion joint waterproof structure for seawater high-water-pressure concrete pipeline | |

| CN105626139B (en) | Lightweight compound assemble type pipeline section and with the tunnel avoiding device of its assembly | |

| CN210034763U (en) | Sewer pipe non-excavation repair structure | |

| CN202868206U (en) | Anti-condensation structure at line branching position |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160616 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160616 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20160616 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170228 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170315 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170331 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170412 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170420 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6133705 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |