JP6032968B2 - Packaging bag feeder - Google Patents

Packaging bag feeder Download PDFInfo

- Publication number

- JP6032968B2 JP6032968B2 JP2012145109A JP2012145109A JP6032968B2 JP 6032968 B2 JP6032968 B2 JP 6032968B2 JP 2012145109 A JP2012145109 A JP 2012145109A JP 2012145109 A JP2012145109 A JP 2012145109A JP 6032968 B2 JP6032968 B2 JP 6032968B2

- Authority

- JP

- Japan

- Prior art keywords

- packaging bag

- stopper

- feeding

- uppermost

- belt conveyor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Description

本発明は、ベルトコンベア上の多数の包装袋を、送り方向後方へ傾倒するように縦列に並べて載置し、前記ベルトコンベアの送り方向前方に設置されたストッパに最上位の包装袋を正確に送り込む包装袋供給装置に関する。 In the present invention, a large number of packaging bags on the belt conveyor are placed side by side so as to tilt backward in the feeding direction, and the uppermost packaging bag is accurately placed on the stopper installed in the feeding direction of the belt conveyor. The present invention relates to a packaging bag supply device to be fed.

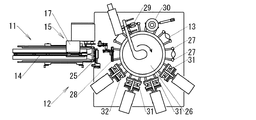

図3に示すように、ロータリー式自動包装機12は、回転する充填テーブル26の外周縁部にクランプ27を備える。包装袋供給装置11から吸着手段25で吸着した包装袋13を、受渡し装置28で前記クランプ27に受け渡す。続いて前記充填テーブル26の回転により移送されながら前記包装袋13は、袋口が開口装置29により開口され、被包装物が充填装置30により充填され、シール装置31により袋口をシールされ、冷却装置32により袋口を冷却され、機外に搬出される。

As shown in FIG. 3, the rotary

前記包装袋供給装置11の一形式として、図1に示すように、送り方向後方へ傾倒するように縦列に並べた包装袋13を載置するベルトコンベア14と、前記ベルトコンベア14を駆動するローラー33と、前記ベルトコンベア14の上方に設置した繰り出し装置15と、前記ベルトコンベア14の送り方向前方に設置されたストッパ16とからなる装置が存在する。

As a form of the packaging

図5に示すように、前記吸着手段25は、アーム40に備えられた支持棒41に支持され、前記アーム40は回動軸42に軸支されている。前記回動軸42は図示しない駆動源に連結されている。

As shown in FIG. 5, the suction means 25 is supported by a

前記吸着手段25は、前記包装袋供給装置11に載置された最上位の前記包装袋13を吸着する下降位置と、吸着した前記最上位の包装袋13を前記受渡し装置28に受け渡す上昇位置とを、前記回動軸42の回動によって上下動する。

The adsorbing

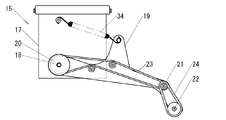

また、図2に示すように、前記繰り出し装置15は、ハウジング17に設けた支持軸18にレバー19を上下方向に揺動可能に組み付けられている。また、前記ハウジング17に内蔵した図示しないモータに連結しかつ前記支持軸18に同心の駆動プーリ20を備える。前記レバー19の右下端部には先端プーリ22を備える。前記駆動プーリ20と前記先端プーリ22との間の前記レバー19には2段プーリ溝構造の中間プーリ21を備える。前記駆動プーリ20と前記中間プーリ21の一方のプーリ溝とに駆動ベルト23を掛け渡し、前記中間プーリ21の他方のプーリ溝と前記先端プーリ22とに繰り出しベルト24を掛け渡している。

As shown in FIG. 2, the

次に作用を説明すると、この包装袋供給装置11では、図1に示すように、前記ベルトコンベア14に載置された包装袋13が前記繰り出しベルト24に押圧され、上下から前記両ベルト14,24に挟まれた状態になり、前記両ベルト14,24の回転によって前記包装袋13は前記ストッパ16に当接するまで搬送される。

Next, the operation will be described. In the packaging

前記ストッパ16に当接した最上位の包装袋13を、前記ストッパ16に備えた図示しないセンサーが検知すると、前記両ベルト14,24の回転は停止する。前記ストッパ16に当接した最上位の前記包装袋13を前記吸着手段25が下降位置に移動して吸着する。最上位の前記包装袋13は前記ストッパ16に当接した定められた所定位置に停止しているので、前記吸着手段25は前記包装袋13の袋口から吸着位置までの距離が一定になっている。前記吸着手段25が上昇位置に移動して吸着した前記包装袋13を前記受渡し装置28に受け渡し、前記受渡し装置28が前記ロータリー式自動包装機12の前記クランプ27に前記包装袋13を受け渡す。

When a sensor (not shown) provided on the

また、最上位の包装袋13が前記ストッパ16に当接すると、当該包装袋13の袋底部の後端は前記繰り出しベルト24で押圧されるエリアを丁度通過しているので、たとえ前記センサーの検知後に前記繰り出しベルト24が惰性で回転し続けても前記最上位の包装袋13は前進せず、最上位の前記包装袋13は前記ストッパ16に当接した定められた所定位置に停止している。

When the

この場合、前記繰り出しベルト24は、最上位の包装袋13より下位の包装袋13を押圧しているので、前記繰り出しベルト24が惰性で回転した場合には、前記下位の包装袋13が前記最上位の包装袋13の下に潜り込むように前進する。

In this case, since the

また、前記吸着手段25が下降位置のときは、当該吸着手段25が前記最上位の包装袋13を押さえつけており、この状態で下位の包装袋13を前記繰り出しベルト24で前進させると、当該下位の包装袋13に無理な力が加わり、皺や折れ曲がりが発生するので、前記両ベルト14,24を停止して前記下位の包装袋13を前進させないようにし、前記吸着手段25が上昇位置のときに、前記両ベルト14,24を回転させるようにしてある。

When the suction means 25 is in the lowered position, the suction means 25 presses the

なお、前記ハウジング17と前記レバー19の上端とに掛け渡した引っ張りバネ34は、前記レバー19や前記先端プーリ22などの重量を相殺し、前記繰り出しベルト24の包装袋13への押圧力を調整するものである。

A

図6に示すように、前記吸着手段25が上昇している間に、前記両ベルト14,24で最上位の前記包装袋13を前記ストッパ16に向けて前進させると、前記包装袋13がたまたま上向きに湾曲していた場合、前記包装袋13が前記ストッパ16を乗り越えることがある。前記ストッパ16を乗り越えた前記包装袋13が上昇位置から下降位置に移動中の前記吸着手段25に押さえつけられ、下降位置に移動した前記吸着手段25が前記包装袋13を吸着すると、前記包装袋13は前記ストッパ16に当接していなかったので、前記吸着手段25は前記包装袋13の袋口から吸着位置までの距離が所定よりずれてしまっている。かかる状態で前記吸着手段25が下降位置から上昇位置に移動して前記受渡し装置28に前記包装袋13を受け渡し、前記受渡し装置28が前記ロータリー式自動包装機12の前記クランプ27に受け渡すと、前記クランプ27は正常に当該包装袋13を掴めないおそれがある。

As shown in FIG. 6, when the

また、図7に示すように、最上位の前記包装袋13がたまたま下向きに湾曲していた場合、下位の包装袋13が前記ストッパ16に当接してセンサーが検知するまで前記両ベルト14,24の回転は停止しない。この場合も前記図6で説明したのと同様に、前記包装袋13は前記ストッパ16に達せず当接していないので、前記吸着手段25は前記包装袋13の袋口から吸着位置までの距離が所定よりずれてしまっているので、前記クランプ27は正常に当該包装袋13を掴めないおそれがある。

Further, as shown in FIG. 7, when the

本発明はかかる問題点に鑑み、最上位の包装袋13がストッパ16に当接した定められた所定位置へ正確に搬送することが可能な包装袋供給装置11を提供することを目的とする。

The present invention has been made in view of such a problem, and an object thereof is to provide a packaging

本発明の包装袋供給装置は、送り方向後方へ傾倒するように縦列に並べた包装袋を載置するベルトコンベアと、前記ベルトコンベアに載置された包装袋を繰り出しベルトで押圧しながら搬送する繰り出し装置と、前記ベルトコンベアの送り方向前方で包装袋を当接させるストッパと、前記ストッパに当接した包装袋を吸着する下降位置と吸着した前記包装袋を持ち上げた上昇位置とを上下動する吸着手段と、を備えた包装袋供給装置であって、前記吸着手段は、下降位置で最上位の包装袋を吸着して上昇し、前記最上位の包装袋の下位の包装袋が前進できる程度の隙間が空くように前記下降位置と前記上昇位置との中間位置で停止し、前記下位の包装袋がストッパ側に前進するように前記ベルトコンベアと繰り出しベルトが回転することを特徴とする。 The packaging bag supply device of the present invention conveys a belt conveyor on which packaging bags arranged in a column so as to tilt backward in the feeding direction, and the packaging bag placed on the belt conveyor while being pressed by a feeding belt. Moves up and down between a feeding device, a stopper for contacting the packaging bag in front of the belt conveyor in the feed direction, a lowered position for sucking the packaging bag in contact with the stopper, and a raised position for lifting the sucked packaging bag A packaging bag supply device comprising: a suction means , wherein the suction means sucks and lifts the uppermost packaging bag at a lowered position so that a lower packaging bag of the uppermost packaging bag can advance. Patent that the gap is stopped at an intermediate position between the lowered position and the raised position as vacant, the belt conveyor and feeding belt as packaging bag of the lower advances the stopper side to rotate To.

本発明は、前記構成により、最上位の包装袋をストッパに正確に送り込むことができる。 According to the present invention, the uppermost packaging bag can be accurately fed into the stopper by the above configuration.

基本構成は前記背景技術で述べたものと同じであるので、図面の符号を同じくして相違点を中心に説明する。図5に示すように、前記吸着手段25は、前記アーム40に固定された前記支持棒41に支持され、前記アーム40は前記回動軸42に軸支されている。図示しない駆動源に連結した前記回動軸42の回動によって、前記吸着手段25は上昇位置と下降位置とを上下動することができるのは、前記背景技術で説明したとおりである。

Since the basic configuration is the same as that described in the background art, the same reference numerals will be used in the drawings, and differences will be mainly described. As shown in FIG. 5, the suction means 25 is supported by the

本発明は、前記図示しない駆動源による前記回動軸42の回動を、前記吸着手段25の上昇位置と下降位置とに加えて中間位置で停止できるようにしてある。なお、前記駆動源については、カム、サーボモーター、シリンダーなどのいずれの手段でもよく、前記の上昇位置と下降位置と中間位置とで停止できるものであればよい。

In the present invention, the rotation of the

前記中間位置を詳細に説明すると、前記吸着手段25が下降位置で最上位の包装袋13を吸着し、吸着した最上位の前記包装袋13を、前記両ベルト14,24の回転で下位の包装袋が前進できる程度の隙間が空くように前記吸着手段25を下降位置から持ち上げた位置である。

The intermediate position will be described in detail. The suction means 25 sucks the

最上位の包装袋13を吸着した吸着手段25が前記中間位置にある状態で、図6に示す上向きに湾曲癖のある下位の包装袋13が前進した場合であっても、前記ストッパ16の上端より下に前記吸着手段25が吸着した包装袋13があるので、前記下位の包装袋13が前記ストッパ16を乗り越えることはない。しかも、前記に説明したように最上位の前記包装袋13がわずかな隙間が空く程度しか持ち上げられていないため、湾曲癖のある下位の前記包装袋13はまっすぐに伸びた状態で前記両ベルト14,24の作用で前進し、まっすぐに伸びた状態の下位の前記包装袋13は前記ストッパ16によって定められた所定位置に停止する。

Even when the

また、前記中間位置の状態で、下向きに湾曲癖のある下位の包装袋13が前進した場合であっても、当該下位の包装袋13の上位に前記吸着手段25が吸着した包装袋13があるので、前記下位の包装袋13は上下を規制されたまっすぐに伸びた状態になっているので、前記ストッパ16によって定められた所定位置に停止することができる。

In addition, even when the

次に図4の(A)〜(D)を用いて動作説明をする。

(A)

前記回動軸42の回動によって前記アーム40が回動し、前記アーム40に固定された支持棒41に支持された前記吸着手段25が上昇位置から下降位置に移動を開始する。

(B)

下降位置に移動した前記吸着手段25が最上位の包装袋13を吸着し、中間位置に移動を開始する。

(C)

中間位置に移動した前記吸着手段25が停止する。前記吸着手段25が最上位の包装袋13を持ち上げた後、前記最上位の包装袋13の下位の包装袋13の前進を前記両ベルト14,24の回転によって開始する。なお、図4(C)では、説明を分かりやすくする為に、吸着手段25で極端に包装袋13を持ち上げた中間位置の状態を示している。この場合でも問題ないが、中間位置は先に説明したように、下位の包装袋が湾曲することなく前進できる程度が好ましい。

(D)

前記下位の包装袋13が前進して前記ストッパ16に当接して停止する。前記吸着手段25が上昇位置に移動を開始する。

Next, the operation will be described with reference to FIGS.

(A)

The

(B)

The suction means 25 moved to the lowered position sucks the

(C)

The suction means 25 moved to the intermediate position stops. After the suction means 25 lifts the

(D)

The

また、包装袋供給装置11の送り方向前方が包装袋13の袋口部で、包装袋供給装置11の送り方向後方が包装袋13の袋底部として包装袋13の載置方向を説明したが、ロータリー式自動包装機の種類によっては載置方向が前後逆になったり横になったりすることもあり、その場合も本発明に含まれる。また、包装機にロータリー式自動包装機12を用いて説明したが、包装機はロータリー式自動包装機12である必要はなく、包装袋を直線状に搬送しながら包装する包装機であってもよい。

Moreover, although the feeding direction front of the packaging

本発明は、ベルトコンベア上の多数の包装袋を例えばロータリー式自動包装機に供給する包装袋供給装置において有用である。 The present invention is useful in a packaging bag supply apparatus that supplies a large number of packaging bags on a belt conveyor to, for example, a rotary automatic packaging machine.

11・・包装袋供給装置

12・・ロータリー式自動包装機

13・・包装袋

14・・ベルトコンベア

15・・繰り出し装置

16・・ストッパ

21・・中間プーリ

22・・先端プーリ

24・・繰り出しベルト

25・・吸着手段

11. Packaging

Claims (2)

前記吸着手段は、下降位置で最上位の包装袋を吸着して上昇し、前記最上位の包装袋の下位の包装袋が前進できる程度の隙間が空くように前記下降位置と前記上昇位置との中間位置で停止し、前記下位の包装袋がストッパ側に前進するように前記ベルトコンベアと繰り出しベルトが回転することを特徴とする包装袋供給装置。 A belt conveyor for placing packaging bags arranged in a row so as to tilt backward in the feeding direction, a feeding device for feeding the packaging bags placed on the belt conveyor while pressing them with a feeding belt, and feeding the belt conveyor A packaging bag comprising: a stopper that abuts the packaging bag forward in the direction; and a suction unit that moves up and down between a lowered position that sucks the packaging bag that is in contact with the stopper and a raised position that lifts the sucked packaging bag A feeding device,

The adsorbing means adsorbs the uppermost packaging bag at the lowered position and rises, and the lowering position and the raised position are spaced so that a gap is formed so that the lower packaging bag of the uppermost packaging bag can be advanced. The packaging bag supply device , wherein the belt conveyor and the feeding belt rotate so that the belt conveyor stops and the lower packaging bag advances toward the stopper side .

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012145109A JP6032968B2 (en) | 2012-06-28 | 2012-06-28 | Packaging bag feeder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012145109A JP6032968B2 (en) | 2012-06-28 | 2012-06-28 | Packaging bag feeder |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014008972A JP2014008972A (en) | 2014-01-20 |

| JP2014008972A5 JP2014008972A5 (en) | 2015-08-13 |

| JP6032968B2 true JP6032968B2 (en) | 2016-11-30 |

Family

ID=50106013

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012145109A Active JP6032968B2 (en) | 2012-06-28 | 2012-06-28 | Packaging bag feeder |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6032968B2 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016116366A1 (en) * | 2015-01-19 | 2016-07-28 | Krones Aktiengesellschaft | Device and method for separating individual intermediate layers from an intermediate layer stack |

| JP7117730B2 (en) * | 2018-05-23 | 2022-08-15 | 株式会社古川製作所 | Packaging bag supply system and control method for the packaging bag supply system |

| JP7085935B2 (en) * | 2018-07-31 | 2022-06-17 | 日本クロージャー株式会社 | Carry-out device |

| CN109835532A (en) * | 2018-08-07 | 2019-06-04 | 安徽御流包装机械有限公司 | A kind of bag arrangement |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5828166B2 (en) * | 1980-10-22 | 1983-06-14 | ゼネラルパツカ−株式会社 | Packaging bag feeding device |

| JP2004026290A (en) * | 2002-05-01 | 2004-01-29 | Furukawa Mfg Co Ltd | Packaging bag supplying apparatus |

-

2012

- 2012-06-28 JP JP2012145109A patent/JP6032968B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2014008972A (en) | 2014-01-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5107171B2 (en) | Empty bag supply method and empty bag supply device | |

| JP5897999B2 (en) | Conveyor magazine type empty bag feeder | |

| KR101445795B1 (en) | Box supply apparatus | |

| JP6032968B2 (en) | Packaging bag feeder | |

| JP2015168456A (en) | Method and apparatus for supplying bag | |

| JP3898158B2 (en) | Packaging bag feeder | |

| JP5898008B2 (en) | Conveyor magazine type empty bag feeder | |

| JP6315463B2 (en) | Conveyor magazine type empty bag feeder | |

| KR101191439B1 (en) | Apparatus for paper supply | |

| JP4762116B2 (en) | Sheet feeding device | |

| JP6404608B2 (en) | Bag conveyor | |

| JP4641256B2 (en) | Sheet take-out device and packing device | |

| JP5681604B2 (en) | Article conveying device | |

| KR101158322B1 (en) | feeding device of packing sheet and packing box | |

| JP4475129B2 (en) | Device for taking out sheet-like article | |

| KR100959200B1 (en) | Apparatus for paper supply | |

| JP2005104505A (en) | Bag feeding apparatus for bagging packaging machine | |

| CN107380552A (en) | A kind of automatic bag extractor and its method of work of facial mask folding machine | |

| JP2013237460A (en) | Packaging bag feeder | |

| JP2003137219A (en) | Conveyer-magazine-type bag feeder | |

| CN219970152U (en) | Bag feeding device of packaging machine | |

| CN215945050U (en) | Automatic product packaging line | |

| KR102474193B1 (en) | Pp bag feeding machine | |

| CN210064639U (en) | Conveying mechanism for package film printing | |

| JPH10287309A (en) | Apparatus for supplying packaging bag |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150625 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150625 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160324 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160330 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160516 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20161019 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20161025 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6032968 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |