JP5705666B2 - Substrate processing method, substrate processing system, and computer-readable storage medium storing substrate processing program - Google Patents

Substrate processing method, substrate processing system, and computer-readable storage medium storing substrate processing program Download PDFInfo

- Publication number

- JP5705666B2 JP5705666B2 JP2011151123A JP2011151123A JP5705666B2 JP 5705666 B2 JP5705666 B2 JP 5705666B2 JP 2011151123 A JP2011151123 A JP 2011151123A JP 2011151123 A JP2011151123 A JP 2011151123A JP 5705666 B2 JP5705666 B2 JP 5705666B2

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- processing

- back surface

- range

- processing step

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000758 substrate Substances 0.000 title claims description 434

- 238000003672 processing method Methods 0.000 title claims description 11

- 238000003860 storage Methods 0.000 title claims description 10

- 230000002093 peripheral effect Effects 0.000 claims description 133

- 230000007246 mechanism Effects 0.000 claims description 102

- 238000000034 method Methods 0.000 claims description 58

- 238000004140 cleaning Methods 0.000 description 44

- 239000007788 liquid Substances 0.000 description 26

- 238000004381 surface treatment Methods 0.000 description 19

- 239000000356 contaminant Substances 0.000 description 7

- 230000002411 adverse Effects 0.000 description 5

- 239000011261 inert gas Substances 0.000 description 4

- 239000004065 semiconductor Substances 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 230000007261 regionalization Effects 0.000 description 2

- 235000012431 wafers Nutrition 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 238000007517 polishing process Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02041—Cleaning

- H01L21/02082—Cleaning product to be cleaned

- H01L21/0209—Cleaning of wafer backside

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67017—Apparatus for fluid treatment

- H01L21/67028—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like

- H01L21/6704—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing

- H01L21/67046—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing using mainly scrubbing means, e.g. brushes

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Cleaning Or Drying Semiconductors (AREA)

- Weting (AREA)

Description

本発明は、基板の裏面の除去対象物を除去するための基板処理方法、基板処理システム及び基板処理プログラムを記憶したコンピュータ読み取り可能な記憶媒体に関するものである。 The present invention relates to a substrate processing method, a substrate processing system, and a computer readable storage medium storing a substrate processing program for removing an object to be removed from the back surface of a substrate.

従来より、半導体部品やフラットパネルディスプレイなどを製造する場合には、半導体ウエハや液晶基板などの基板を基板保持機構で保持した状態で、基板の表面に対してエッチング処理や成膜処理や洗浄処理などの各種の処理を繰り返し行っている。 Conventionally, when manufacturing semiconductor components, flat panel displays, etc., the substrate surface such as a semiconductor wafer or a liquid crystal substrate is held by a substrate holding mechanism, and etching, film formation or cleaning is performed on the surface of the substrate. Various processes such as are repeated.

そのため、基板に対して各種の処理を行う際に、基板の裏面が基板保持機構に接触することによって、基板の裏面にパーティクル等の汚染物質が付着したり、基板の裏面に凸部が形成されてしまうことがある。 Therefore, when various types of processing are performed on the substrate, the back surface of the substrate comes into contact with the substrate holding mechanism, so that contaminants such as particles adhere to the back surface of the substrate or convex portions are formed on the back surface of the substrate. May end up.

この基板の裏面に付着した汚染物質や基板の裏面に形成された凸部は、基板の各種処理に悪影響を及ぼすおそれがある。そのため、基板の裏面に回転するブラシで洗浄や研磨などの処理を施して基板の裏面から汚染物質や凸部などの除去対象物を除去している。その際には、基板の表面がパターン形成に使用されるために基板の表面を吸着して基板を保持することができず、基板の外周端縁を基板支持体で支持しながら基板の裏面の内周部から外周側の所定範囲をブラシで処理している(たとえば、特許文献1参照。)。 Contaminants adhering to the back surface of the substrate and convex portions formed on the back surface of the substrate may adversely affect various types of processing of the substrate. For this reason, the object to be removed such as contaminants and convex portions is removed from the back surface of the substrate by performing processing such as cleaning and polishing with a rotating brush on the back surface of the substrate. In that case, since the surface of the substrate is used for pattern formation, the substrate surface cannot be adsorbed and held, and the outer peripheral edge of the substrate is supported by the substrate support while A predetermined range from the inner periphery to the outer periphery is processed with a brush (see, for example, Patent Document 1).

ところが、基板の外周端縁を基板支持体で支持した場合には、基板の裏面の内周部から外周側の所定範囲をブラシで処理しても、基板の外周端縁付近ではブラシが基板支持体に接触してしまい、基板の外周端縁付近までブラシで処理することができなかった。 However, when the outer peripheral edge of the substrate is supported by the substrate support, the brush supports the substrate near the outer peripheral edge of the substrate even if a predetermined range from the inner peripheral part to the outer peripheral side of the back surface of the substrate is processed with a brush. It contacted the body and could not be processed with a brush up to the vicinity of the outer peripheral edge of the substrate.

そのため、従来においては、基板の外周端縁まで精度良く処理することが困難であり、基板の外周端縁付近の除去対象物を良好に除去することができず、基板の裏面に残存する汚染物質や基板の裏面の凸部の影響で基板の表面での処理精度が低下してしまい、除去対象物が残存することによって基板の表面の処理に悪影響を与えるおそれがあった。 Therefore, in the past, it is difficult to accurately process to the outer peripheral edge of the substrate, the removal target object near the outer peripheral edge of the substrate cannot be removed well, and contaminants remaining on the back surface of the substrate Further, the processing accuracy on the surface of the substrate is lowered due to the influence of the convex portion on the back surface of the substrate, and there is a possibility that the processing of the surface of the substrate is adversely affected by the removal target.

そこで、本発明では、基板の裏面の除去対象物を除去する基板処理方法において、基板支持体で基板の外周端縁を支持し、基板の裏面の内周部から基板支持体の近傍までの所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも外周側の除去対象物を除去しない裏面処理工程と、基板の裏面の外周端から内周側の所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも内周側の除去対象物を除去しない裏面周縁部処理工程とを有し、裏面処理工程での処理範囲と裏面周縁部処理工程での処理範囲とが重なる重畳処理範囲を設け、前記裏面処理工程の後に基板の反転を行ってから前記裏面周縁部処理工程を行う、又は、前記裏面周縁部処理工程の後に基板の反転を行ってから前記裏面処理工程を行うことにした。

Therefore, in the present invention, in a substrate processing method for removing an object to be removed on the back surface of a substrate, the substrate support supports the outer peripheral edge of the substrate, and the predetermined distance from the inner periphery of the back surface of the substrate to the vicinity of the substrate support is determined. The removal target object is removed in the processing range of the substrate and the removal target object on the outer peripheral side than the predetermined processing range is not removed, and the removal target object in the predetermined processing range on the inner peripheral side from the outer peripheral edge of the back surface of the substrate. And a back edge processing step that does not remove the object to be removed on the inner periphery side of the predetermined processing range, and the processing range in the back surface processing step overlaps the processing range in the back surface periphery processing step. An overlap processing range is provided , and the back surface peripheral portion processing step is performed after the substrate is reversed after the back surface processing step, or the substrate is reversed after the back surface peripheral portion processing step. Decided to do .

また、前記重畳処理範囲は、裏面処理工程と裏面周縁部処理工程のうちで先に行う工程で用いる基板保持機構の偏心量よりも広い範囲とすることにした。 In addition, the superimposing process range is set to a range wider than the amount of eccentricity of the substrate holding mechanism used in the first process among the back surface process and the back surface edge process.

また、前記裏面処理工程を行った後に、前記裏面周縁部処理工程を行い、その後、基板の表面の除去対象物を除去する表面処理工程を行うことにした。 Moreover, after performing the said back surface treatment process, it decided to perform the said back surface peripheral part process process, and the surface treatment process which removes the removal target object of the surface of a board | substrate after that.

また、前記裏面周縁部処理工程を行った後に、基板の表面の除去対象物を除去する表面処理工程を行い、その後、前記裏面処理工程を行うことにした。 Moreover, after performing the said back surface peripheral part process process, the surface process process which removes the removal target object of the surface of a board | substrate was performed, and it decided to perform the said back surface process process after that.

また、前記裏面周縁部処理工程では、基板の裏面の内周部を吸着して保持することにした。 Moreover, in the said back surface peripheral part process process, it decided to adsorb | suck and hold | maintain the inner peripheral part of the back surface of a board | substrate.

また、本発明では、基板の裏面の除去対象物を除去する基板処理システムにおいて、基板支持体で基板の外周端縁を支持し、基板の裏面の内周部から基板支持体の近傍までの所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも外周側の除去対象物を除去しない裏面処理装置と、基板の裏面の外周端から内周側の所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも内周側の除去対象物を除去しない裏面周縁部処理装置と、基板を反転させる基板反転装置とを有し、裏面処理装置での処理範囲と裏面周縁部処理装置での処理範囲とが重なる重畳処理範囲を設け、前記裏面処理装置による除去処理の後に前記基板反転装置による基板の反転を行ってから前記裏面周縁部処理装置による除去処理を行う、又は、前記裏面周縁部処理装置による除去処理の後に前記基板反転装置による基板の反転を行ってから前記裏面処理装置による除去処理を行うことにした。

Further, according to the present invention, in the substrate processing system for removing an object to be removed on the back surface of the substrate, the substrate support supports the outer peripheral edge of the substrate, and the predetermined distance from the inner periphery of the back surface of the substrate to the vicinity of the substrate support is determined. A back surface processing apparatus that removes an object to be removed within the processing range and does not remove an object to be removed on the outer peripheral side of the predetermined processing range; and the back edge processing apparatus without removing the inner peripheral side of the removal target than the predetermined processing range to remove, and a substrate inverting device for inverting the substrate, the processing range in the rear surface treatment apparatus and a back side rim portion A superposition processing range that overlaps with a processing range in the processing apparatus is provided , and after the removal process by the back surface processing apparatus, the substrate is reversed by the substrate reversing apparatus and then the removal processing by the back surface peripheral edge processing apparatus is performed, or The back edge And after performing the inversion of the substrate by the substrate reversing device after removal processing by the processing unit to perform the removal processing by the rear surface treatment apparatus.

また、前記重畳処理範囲は、裏面処理装置と裏面周縁部処理装置のうちで先に動作させる装置で用いる基板保持機構の偏心量よりも広い範囲とすることにした。 In addition, the superimposition processing range is set to a range wider than the amount of eccentricity of the substrate holding mechanism used in the apparatus that operates first among the back surface processing apparatus and the back surface peripheral edge processing apparatus.

また、前記裏面処理装置で基板の裏面を処理した後に、前記裏面周縁部処理装置で基板の裏面を処理し、その後、基板の表面の除去対象物を除去する表面処理装置で基板の表面を処理することにした。 In addition, after the back surface of the substrate is processed by the back surface processing apparatus, the back surface of the substrate is processed by the back surface peripheral portion processing apparatus, and then the surface of the substrate is processed by the surface processing apparatus that removes an object to be removed from the surface of the substrate. Decided to do.

また、前記裏面周縁部処理装置で基板の裏面を処理した後に、基板の表面の除去対象物を除去する表面処理装置で基板の表面を処理し、その後、前記裏面処理装置で基板の裏面を処理することにした。 In addition, after the back surface of the substrate is processed by the back surface peripheral edge processing apparatus, the surface of the substrate is processed by a surface processing apparatus that removes an object to be removed from the surface of the substrate, and then the back surface of the substrate is processed by the back surface processing apparatus. Decided to do.

また、前記裏面周縁部処理装置は、基板の裏面の内周部を吸着して保持することにした。 In addition, the back surface peripheral portion processing apparatus adsorbs and holds the inner peripheral portion of the back surface of the substrate.

また、本発明では、基板の裏面の除去対象物を除去する基板処理システムを用いて基板の裏面を処理させる基板処理プログラムを記憶したコンピュータ読み取り可能な記憶媒体において、基板支持体で基板の外周端を支持し、基板の裏面の内周部から基板支持体の近傍までの所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも外周側の除去対象物を除去しない裏面処理装置を用いて基板の裏面を処理させる裏面処理工程と、基板の裏面の外周端から内周側の所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも内周側の除去対象物を除去しない裏面周縁部処理装置を用いて基板の裏面を処理させる裏面周縁部処理工程とを有し、裏面処理工程での処理範囲と裏面周縁部処理工程での処理範囲とが重なる重畳処理範囲を設け、前記裏面処理工程の後に基板反転装置によって基板を反転させてから前記裏面周縁部処理工程を行う、又は、前記裏面周縁部処理工程の後に基板反転装置によって基板を反転させてから前記裏面処理工程を行うことにした。 Further, according to the present invention, in a computer-readable storage medium storing a substrate processing program for processing a back surface of a substrate using a substrate processing system for removing an object to be removed from the back surface of the substrate, an outer peripheral edge of the substrate is supported by the substrate support. A back surface processing apparatus that removes an object to be removed in a predetermined processing range from the inner periphery of the back surface of the substrate to the vicinity of the substrate support and does not remove an object to be removed on the outer peripheral side of the predetermined processing range. Using a back surface processing step for processing the back surface of the substrate, and removing an object to be removed in a predetermined processing range on the inner peripheral side from an outer peripheral edge of the back surface of the substrate, and removing an object on the inner peripheral side from the predetermined processing range. using backside edge processing apparatus is not removed and a back side rim portion processing step of processing the back surface of the substrate, the superimposition processing range and the processing ranges overlap in the processing range and the back edge processing steps in the back surface treatment process Only performs the back edge processing step from inverts the substrate by the substrate inverting device after the backside processing steps, or, the back processing from inverts the substrate by the substrate inverting device after the back edge processing step Decided to do the process .

本発明では、基板の裏面の端縁部から除去対象物を良好に除去することができ、除去対象物が残存することによる基板の表面の処理に与える悪影響を抑制することができる。 In the present invention, the removal target can be satisfactorily removed from the edge of the back surface of the substrate, and adverse effects on the processing of the surface of the substrate due to the removal target remaining can be suppressed.

以下に、本発明に係る基板処理システム及び基板処理方法並びに基板処理プログラムの具体的な構成について図面を参照しながら説明する。 A specific configuration of a substrate processing system, a substrate processing method, and a substrate processing program according to the present invention will be described below with reference to the drawings.

図1に示すように、基板処理システム1は、筺体2の前端部に基板搬入出台3を形成するとともに、基板搬入出台3の後部に基板処理室4を形成している。

As shown in FIG. 1, the

基板搬入出台3は、基板5(ここでは、半導体ウエハ。)を複数枚(たとえば、25枚。)まとめて収容した複数個(ここでは、3個。)のキャリア6を上部に左右に並べて載置している。

The substrate carry-in / out table 3 has a plurality of (here, three)

そして、基板搬入出台3は、キャリア6と後部の基板処理室4との間で基板5の搬入及び搬出を行うようにしている。

The substrate loading / unloading table 3 loads and unloads the

基板処理室4は、中央部に基板搬送装置7を配置し、基板搬送装置7の一側部に基板反転装置8と表面処理装置9とを前後に並べて配置するとともに、基板搬送装置7の他側部に裏面処理装置10と裏面周縁部処理装置11とを前後に並べて配置している。ここで、基板反転装置8は、基板5の表裏を反転させる装置である。表面処理装置9は、具体的な構成は後述するが、基板5の表面に付着した汚染物質や基板5の表面に形成された凸部などの除去対象物を基板5の表面から除去する装置である。裏面処理装置10は、具体的な構成は後述するが、基板支持体で外周端縁を支持した基板5の裏面の内周部から基板支持体の近傍までの範囲の除去対象物を除去する装置である。裏面周縁部処理装置11は、具体的な構成は後述するが、基板5の外周端から内周側の範囲の除去対象物を除去する装置である。

In the substrate processing chamber 4, the

そして、基板処理室4は、基板搬送装置7で基板搬入出台3の所定のキャリア6から1枚の基板5を受取り、基板搬送装置7で表面処理装置9、裏面処理装置10、裏面周縁部処理装置11、及び基板反転装置8との間で基板5を搬送するとともに各装置9〜11で基板5を処理し、その基板5を基板搬送装置7で基板搬入出台3の所定のキャリア6に受渡すようにしている。

The substrate processing chamber 4 receives one

この基板処理システム1は、制御装置12(コンピュータ)が接続されており、制御装置12で読み取り可能な記憶媒体13に記憶した基板処理プログラムにしたがって基板5を処理する。なお、記憶媒体13は、基板処理プログラム等の各種プログラムを記憶できる媒体であればよく、ROMやRAMなどの半導体メモリ型の記憶媒体であってもハードディスクやCD−ROMなどのディスク型の記憶媒体であってもよい。

The

なお、本発明に係る基板処理システムは、上記構成のように基板反転装置8と表面処理装置9と裏面処理装置10と裏面周縁部処理装置11とを一体的に構成したシステムに限定されるものではなく、各装置8〜11をそれぞれ別々に独立して構成したシステムであってもよい。また、基板処理システムは、基板5の裏面から除去対象物を除去するものであり、後述するように、洗浄液を用いた洗浄処理によって除去対象物を除去する場合に限られず、研磨材を用いた研磨処理によって除去対象物を除去するものでもよい。

The substrate processing system according to the present invention is limited to a system in which the

この基板処理システム1において、表面処理装置9は、図2に示すように、ケーシング14の内部に基板保持機構15と基板処理機構16とを収容している。

In the

基板保持機構15は、基板5の表面(主面:回路形成面)を上側に向けた状態で基板5の裏面の中央部(内周部)を吸着して基板5を水平に保持するとともに、保持した基板5を回転させる機構である。この基板保持機構15は、回転軸17の上端部に円板状の吸引テーブル18を取付けている。回転軸17には、基板回転駆動機構20が接続されており、吸引テーブル18には、吸引機構21が接続されている。基板回転駆動機構20及び吸引機構21は、制御装置12に接続されており、制御装置12でそれぞれ制御される。なお、吸引テーブル18の外周外方には、処理液等の飛散を防止するカップ22を設けている。基板保持機構15は、基板5の裏面を吸着して基板5を保持する構造に限られず、基板5の外周端縁を基板支持体で支持して基板5を保持する構造としてもよい。

The

基板処理機構16は、基板5の表面に洗浄液を供給し、基板5の表面を洗浄液で洗浄処理することによって基板5の表面から除去対象物を除去する機構である。この基板処理機構16は、支持軸23の上端部にアーム24の基端部を取付け、アーム24の先端部にノズル25を取付けている。また、基板処理機構16は、洗浄液を供給するための洗浄液供給源26をノズル25に流量調整器27を介して接続している。支持軸23には、アーム回転駆動機構28が接続されている。流量調整器27及びアーム回転駆動機構28は、制御装置12に接続されており、制御装置12でそれぞれ制御される。

The

そして、表面処理装置9は、図3に示すように、基板保持機構15で基板5を水平に保持しながら回転させ、基板処理機構16で基板5の表面に洗浄液を供給し、ノズル25を基板5の表面の中央部から外周端へ移動させる。これにより、表面処理装置9は、基板5の表面全体を洗浄処理して基板5の表面から除去対象物を除去する。

Then, as shown in FIG. 3, the

また、基板処理システム1において、裏面処理装置10は、図4に示すように、ケーシング29の内部に基板保持機構30と基板処理機構31とを収容している。

Further, in the

基板保持機構30は、基板5の裏面を上側に向けた状態で基板5の外周端縁を挟持して基板5を水平に保持するとともに、保持した基板5を回転させる機構である。この基板保持機構30は、回転軸32の上端部に円板状のテーブル33を取付け、テーブル33の外周部に3個の基板支持体34を円周方向に間隔をあけて取付けている。基板支持体34は、基板搬送装置7から基板5を受取る受取位置と基板5の外周端縁を挟持する保持位置との間を移動可能となっており、保持位置では基板5の外周端上方を覆っている(図6参照。)。回転軸32には、基板回転駆動機構35が接続されており、基板支持体34には、移動機構36が接続されている。基板回転駆動機構35及び移動機構36は、制御装置12に接続されており、制御装置12でそれぞれ制御される。なお、テーブル33の外周外方には、処理液等の飛散を防止するカップ37を設けている。

この基板保持機構30には、回転軸32及びテーブル33の中央部に吐出流路38が形成されており、その吐出流路38に、不活性ガス(たとえば、窒素ガス)を供給するための不活性ガス供給源39を流量調整器40を介して接続している。流量調整器40は、制御装置12に接続されており、制御装置12で制御される。

The

基板処理機構31は、基板5の裏面に洗浄液を供給しながら基板5の裏面をブラシで洗浄処理することによって基板5の裏面から除去対象物を除去する機構である。この基板処理機構31は、支持軸41の上端部にアーム42の基端部を取付け、アーム42の先端部にブラシヘッド43を取付け、ブラシヘッド43に洗浄ブラシ44を取付けている。また、基板処理機構31は、基板5(テーブル33)の中央部に向けてノズル45を配置し、ノズル45に洗浄液を供給するための洗浄液供給源46を流量調整器47を介して接続している。支持軸41には、アーム昇降・回転駆動機構48が接続されており、ブラシヘッド43には、ブラシ回転駆動機構49が接続されている。流量調整器47、アーム昇降・回転駆動機構48及びブラシ回転駆動機構49は、制御装置12に接続されており、制御装置12でそれぞれ制御される。

The

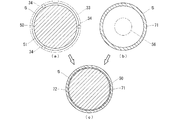

そして、裏面処理装置10は、図5に示すように、基板保持機構30で基板5を裏面を上側に向けた状態で水平に保持しながら回転させ、基板処理機構31で基板5の裏面に洗浄液を供給し、洗浄ブラシ44を回転させながら基板5の裏面の内周部(ここでは、中央部)から洗浄ブラシ44が基板支持体34に接触しない位置まで移動させる。これにより、裏面処理装置10は、図6(a)に示すように、基板5の裏面の内周部から基板支持体34の近傍までの所定の処理範囲50を洗浄処理して基板5の裏面から除去対象物を除去する。

Then, as shown in FIG. 5, the back

また、基板処理システム1において、裏面周縁部処理装置11は、図7に示すように、ケーシング52の内部に基板保持機構53と基板処理機構54とを収容している。

Further, in the

基板保持機構53は、基板5の表面を上側に向けた状態で基板5の裏面の中央部(内周部)を吸着して基板5を水平に保持するとともに、保持した基板5を回転させる機構である。この基板保持機構53は、回転軸55の上端部に円板状の吸引テーブル56を取付けている。回転軸55には、回転駆動機構57が接続されており、吸引テーブル56には、吸引機構58が接続されている。回転駆動機構57及び吸引機構58は、制御装置12に接続されており、制御装置12でそれぞれ制御される。なお、吸引テーブル56の外周外方には、処理液等の飛散を防止するカップ59を設けている。

The

基板処理機構54は、基板5の外周端縁及び基板5の裏面の外周端に洗浄液を供給しながら基板5の外周端縁及び基板5の裏面の外周端を同時にブラシで洗浄処理することによって基板5の裏面から除去対象物を除去する機構である。この基板処理機構54は、支持軸60の上端部にアーム61の基端部を取付け、アーム61の先端部にブラシヘッド62を取付け、ブラシヘッド62に洗浄ブラシ63を取付けている。また、基板処理機構54は、基板5の外周端に向けてノズル64を配置し、ノズル64に洗浄液を供給するための洗浄液供給源65を流量調整器66を介して接続している。支持軸60には、回転駆動機構67が接続されており、ブラシヘッド62には、回転駆動機構68が接続されている。流量調整器66及び回転駆動機構67,68は、制御装置12に接続されており、制御装置12でそれぞれ制御される。ここで、洗浄ブラシ63は、基板5の外周端縁に当接して洗浄処理する小径ブラシ部69と、小径ブラシ部69の下方に連設し、小径ブラシ部69よりも大径で基板5の裏面の外周端に当接して洗浄処理する大径ブラシ部70とで構成し、小径ブラシ部69を基板5の外周端縁に当接させるとともに大径ブラシ部70を基板5の裏面の外周端に当接させる。さらに、基板5の外周端縁と裏面の外周端とを同時に洗浄処理できる。なお、洗浄ブラシ63は、小径ブラシ部69を省略して大径ブラシ部70だけで構成し、大径ブラシ部70を基板5の外周端縁から内周方向に移動させて基板5の裏面の外周端を処理するようにしてもよい。

The

そして、裏面周縁部処理装置11は、図8に示すように、基板保持機構53で基板5を裏面を下側に向けた状態で水平に保持しながら回転させ、基板処理機構54で基板5の裏面の外周端に洗浄液を供給し、洗浄ブラシ63を回転させながら基板5の外周端縁へ移動させる。これにより、裏面周縁部処理装置11は、図6(b)に示すように、基板5の外周端縁及び裏面の外周端から内周側の所定の処理範囲71を洗浄処理して基板5の裏面から除去対象物を除去する。

Then, as shown in FIG. 8, the back surface peripheral

基板処理システム1では、図6(c)に示すように、裏面処理装置10で処理する基板5の裏面の処理範囲50と、裏面周縁部処理装置11で処理する基板5の裏面の処理範囲71との間に、裏面処理装置10及び裏面周縁部処理装置11の両方で処理する略リング状の重畳処理範囲72を設定している。基板処理システム1では、この重畳処理範囲72を裏面処理装置10と裏面周縁部処理装置11とで前後して重ねて処理することで、基板5の裏面から除去対象物を良好に除去して、除去対象物が残存することによる基板5の表面の処理に与える悪影響を抑制している。

In the

この重畳処理範囲72は、広く設定するほど除去対象物を良好に除去することができるが、その分だけ処理時間が長くなりスループットの低下を招くため、少なくとも裏面処理装置10の基板保持機構30と裏面周縁部処理装置11の基板保持機構53のうちで先に基板5の処理を行ういずれかの基板保持機構30,53の偏心量よりも広い範囲とすれば、基板保持機構30,53の構造上の偏心量を吸収して基板5の裏面を良好に処理することができる。特に、洗浄ブラシ63を小径ブラシ部69と大径ブラシ部70とで構成した場合には、小径ブラシ部69から張出した大径ブラシ部70の半径方向の張出量を基板保持機構30,53の偏心量よりも大きくすることで、重畳処理範囲72を基板保持機構30,53の偏心量よりも広い範囲とすることが容易にできる。

The wider the overlapping

基板処理システム1は、以上に説明したように構成しており、記憶媒体13に記憶した基板処理プログラムにしたがって以下に説明するように基板5の処理を行う。

The

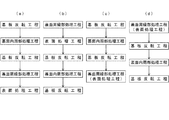

まず、基板処理プログラムでは、図9(a)に示すように、基板反転工程を実行する。この基板反転工程では、基板反転装置8を用いて基板5の表裏を反転させ、基板5の裏面を上方に向けた状態にする。

First, in the substrate processing program, as shown in FIG. In this substrate reversal process, the

次に、基板処理プログラムでは、図9(a)に示すように、裏面処理工程を実行する。この裏面処理工程では、裏面処理装置10を用いて基板5の裏面の内周部から基板支持体34の近傍までの所定の処理範囲50を洗浄処理して基板5の裏面から除去対象物を除去する。

Next, in the substrate processing program, as shown in FIG. In this back surface processing step, a

具体的には、基板処理システム1は、図5に示すように、制御装置12で基板保持機構30の移動機構36を制御して基板支持体34を開いた状態とし、基板搬送装置7から1枚の基板5を受取った後に移動機構36を制御して基板支持体34を閉じた状態とし、これにより、基板5の外周端縁を基板支持体34で保持する。

Specifically, as shown in FIG. 5, the

その後、基板処理システム1は、制御装置12で基板保持機構30の基板回転駆動機構35を制御して回転軸32を回転させ、基板5を回転させる。また、制御装置12で基板処理機構31の流量調整器47を制御して、洗浄液供給源46からノズル45を介して基板5の裏面中央部に向けて洗浄液を吐出する。さらに、制御装置12で基板処理機構31のアーム昇降・回転駆動機構48及びブラシ回転駆動機構49を制御して、洗浄ブラシ44を回転させながら基板5の裏面中央部と基板支持体34の近傍の間の処理範囲50を基板5の裏面に沿って移動させ、これにより、基板5の裏面の内周部(中央部)から基板支持体34の近傍までの所定の処理範囲50で除去対象物を除去する。その際に、制御装置12で流量調整器40を制御して、不活性ガス供給源39から吐出流路38を介して基板5の表面(下面:パターン形成面)に向けて不活性ガスを吐出するようにしている。これにより、基板5の裏面(上面)で除去された除去対象物が基板5の表面(下面)に回り込んで付着してしまうのを防止している。

Thereafter, the

その後、基板処理システム1は、制御装置12で流量調整器40,47を制御して洗浄液及び不活性ガスの吐出を停止し、必要に応じて基板5のリンス処理や乾燥処理を行った後に、制御装置12で基板保持機構30の基板回転駆動機構35を制御して基板5の回転を停止し、その後、制御装置12で基板保持機構30の移動機構36を制御して基板支持体34を開いた状態とし、基板搬送装置7へ基板5を受渡す。

Thereafter, the

次に、基板処理プログラムでは、図9(a)に示すように、基板反転工程を実行する。この基板反転工程では、基板反転装置8を用いて基板5の表裏を反転させ、基板5の表面を上方に向けた状態にする。

Next, in the substrate processing program, as shown in FIG. In this substrate reversal process, the

次に、基板処理プログラムでは、図9(a)に示すように、裏面周縁部処理工程を実行する。この裏面周縁部処理工程では、裏面周縁部処理装置11を用いて基板5の外周端縁及び基板5の外周端から内周側の所定の処理範囲71を洗浄処理して基板5の裏面から除去対象物を除去する。

Next, in the substrate processing program, as shown in FIG. In this back surface peripheral edge processing step, a

具体的には、基板処理システム1は、図8に示すように、基板搬送装置7から1枚の基板5を受取った後に、制御装置12で基板保持機構53の吸引機構58を制御して吸引テーブル56で基板5の裏面の中央部を吸引し、吸引テーブル56の上部に基板5を保持する。

Specifically, as shown in FIG. 8, the

その後、基板処理システム1は、制御装置12で基板保持機構53の回転駆動機構57を制御して回転軸55を回転させ、基板5を回転させる。また、制御装置12で基板処理機構54の流量調整器66を制御して、洗浄液供給源65からノズル64を介して基板5の裏面の外周端に向けて洗浄液を吐出する。さらに、制御装置12で基板処理機構54の回転駆動機構67,68を制御して、洗浄ブラシ63を回転させながら基板5の外周端縁に当接させ、洗浄ブラシ63の小径ブラシ部69で基板5の外周端縁を洗浄すると同時に洗浄ブラシ63の大径ブラシ部70で基板5の裏面の外周端から内周側の所定の処理範囲71を洗浄する。これにより、基板5の外周端縁及び基板5の外周端から内周側の所定の処理範囲71で除去対象物を除去する。

Thereafter, the

その後、基板処理システム1は、制御装置12で流量調整器66を制御して洗浄液の吐出を停止し、必要に応じて基板5のリンス処理や乾燥処理を行った後に、制御装置12で基板保持機構53の回転駆動機構57を制御して基板5の回転を停止し、その後、制御装置12で基板保持機構53の吸引機構58を制御して基板5の吸引を停止し、基板搬送装置7へ基板5を受渡す。

Thereafter, the

次に、基板処理プログラムでは、図9(a)に示すように、表面処理工程を実行する。この表面処理工程では、表面処理装置9を用いて基板5の表面を洗浄処理して基板5の表面から除去対象物を除去する。

Next, in the substrate processing program, as shown in FIG. In this surface treatment process, the surface of the

具体的には、基板処理システム1は、図3に示すように、基板搬送装置7から1枚の基板5を受取った後に、制御装置12で基板保持機構15の吸引機構21を制御して吸引テーブル19で基板5の裏面の中央部を吸引し、吸引テーブル19の上部に基板5を保持する。

Specifically, as shown in FIG. 3, the

その後、基板処理システム1は、制御装置12で基板保持機構15の基板回転駆動機構20を制御して回転軸17を回転させ、基板5を回転させる。また、制御装置12で基板処理機構16の流量調整器27を制御して、洗浄液供給源26からノズル25を介して基板5の表面中央部に向けて洗浄液を吐出する。さらに、制御装置12で基板処理機構16のアーム回転駆動機構28を制御して、ノズル25を基板5の表面中央部と外周端縁の間を移動させ、これにより、基板5の表面から除去対象物を除去する。

Thereafter, the

その後、基板処理システム1は、制御装置12で流量調整器27を制御して洗浄液の吐出を停止し、必要に応じて基板5のリンス処理や乾燥処理を行った後に、制御装置12で基板保持機構15の基板回転駆動機構20を制御して基板5の回転を停止し、その後、制御装置12で基板保持機構15の吸引機構21を制御して基板5の吸引を停止し、基板搬送装置7へ基板5を受渡す。

Thereafter, the

基板処理プログラムで実行する基板処理方法は、図9(a)に示すように基板反転工程・裏面処理工程・基板反転工程・裏面周縁部処理工程・表面処理工程の順で行う場合に限られず、裏面処理工程と裏面周縁部処理工程とを適宜組み合わせて処理することができ、図9(b)に示すように、裏面周縁部処理工程を行った後に、表面処理工程を行い、その後、基板反転工程を行い、裏面処理工程と基板反転工程を行うようにしてもよい。さらに、図9(c),(d)に示すように、裏面周縁部処理工程において、基板5の裏面を吸着して保持し基板5の裏面の周縁部の処理に加えて基板5の表面の処理(表面処理工程)を同じ処理装置で行うようにしてもよい。

The substrate processing method executed by the substrate processing program is not limited to the case of performing the substrate inversion process, the back surface processing process, the substrate inversion process, the back edge processing process, and the surface processing process as shown in FIG. The back surface processing step and the back surface peripheral portion processing step can be appropriately combined and processed, as shown in FIG. 9B, after the back surface peripheral portion processing step is performed, the surface processing step is performed, and then the substrate is inverted. You may make it perform a process and to perform a back surface process and a substrate inversion process. Further, as shown in FIGS. 9C and 9D, in the back surface peripheral edge processing step, the back surface of the

図9(a)に示すように、裏面処理工程を行った後に、裏面周縁部処理工程を行い、その後、表面処理工程を行った場合には、表面処理工程が最後に行われるために、基板5の表面を良好な状態にすることができ、また、基板5の裏面の処理が表面の処理よりも先に行われるために、基板5の表面を処理する際に基板保持機構15の吸引テーブル18を汚染することがない。

As shown in FIG. 9A, after performing the back surface processing step, performing the back surface edge processing step, and then performing the surface processing step, the surface processing step is performed last. The surface of the

また、図9(b)に示すように、裏面周縁部処理工程を行った後に、表面処理工程を行い、その後、裏面処理工程を行った場合には、裏面周縁部処理工程や表面処理工程で基板5の裏面に付着するおそれのある汚染物質等を最後の裏面処理工程で除去することができ、基板5の表面への転写を防止することができ、また、裏面周縁部処理工程で基板5の裏面に吸引跡が残ってしまっても最後の裏面処理工程で吸引跡を除去することができる。

Moreover, as shown in FIG.9 (b), after performing a back surface peripheral part treatment process, when performing a surface treatment process and then performing a back surface process process, in a back surface peripheral part process process and a surface treatment process, Contaminants and the like that may adhere to the back surface of the

また、図9(c),(d)に示すように、裏面周縁部処理工程で表面処理工程を同時に行う場合には、基板5の表裏の処理に要する時間を短縮することができスループットを向上させることができる。

Further, as shown in FIGS. 9C and 9D, when the surface treatment process is simultaneously performed in the back surface peripheral edge treatment process, the time required for processing the front and back of the

以上に説明したように、基板処理システム1では、裏面処理工程で基板5の裏面の内周部から基板支持体34の近傍までの所定の処理範囲50を処理して基板5の裏面から除去対象物を除去するとともに、裏面周縁部処理工程で基板5の外周端から内周側の所定の処理範囲71を処理して基板5の裏面から除去対象物を除去し、裏面処理工程及び裏面周縁部処理工程で重畳処理範囲72を重ねて処理している。これにより、基板処理システム1では、基板5の裏面から除去対象物を良好に除去することができ、汚染物質等の転写や基板5の裏面の凹凸によるデフォーカスなどといった除去対象物が残存することによる基板5の表面の処理に与える悪影響を抑制することができる。

As described above, in the

1 基板処理システム

5 基板

10 裏面処理装置

11 裏面周縁部処理装置

34 基板支持体

50 処理範囲

71 処理範囲

72 重畳処理範囲

1

10 Backside processing equipment

11 Back edge processing equipment

34 Substrate support

50 Processing range

71 Processing range

72 Overlay processing range

Claims (11)

基板支持体で基板の外周端を支持し、基板の裏面の内周部から基板支持体の近傍までの所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも外周側の除去対象物を除去しない裏面処理工程と、

基板の裏面の外周端から内周側の所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも内周側の除去対象物を除去しない裏面周縁部処理工程と、

を有し、

裏面処理工程での処理範囲と裏面周縁部処理工程での処理範囲とが重なる重畳処理範囲を設け、

前記裏面処理工程の後に基板の反転を行ってから前記裏面周縁部処理工程を行う、又は、前記裏面周縁部処理工程の後に基板の反転を行ってから前記裏面処理工程を行うことを特徴とする基板処理方法。 In the substrate processing method for removing the object to be removed on the back surface of the substrate,

The substrate support is used to support the outer peripheral edge of the substrate, and the removal target is removed in a predetermined processing range from the inner peripheral portion of the back surface of the substrate to the vicinity of the substrate support, and the removal target on the outer peripheral side from the predetermined processing range. A backside treatment process that does not remove objects ,

A back edge processing step that removes the removal target in a predetermined processing range on the inner peripheral side from the outer peripheral edge of the back surface of the substrate, and does not remove the removal target on the inner peripheral side from the predetermined processing range ;

Have

Provide a superimposition processing range where the processing range in the back surface processing step and the processing range in the back edge processing step overlap ,

The back surface peripheral portion processing step is performed after the substrate is inverted after the back surface processing step, or the back surface processing step is performed after the substrate is inverted after the back surface peripheral portion processing step. Substrate processing method.

基板支持体で基板の外周端を支持し、基板の裏面の内周部から基板支持体の近傍までの所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも外周側の除去対象物を除去しない裏面処理装置と、

基板の裏面の外周端から内周側の所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも内周側の除去対象物を除去しない裏面周縁部処理装置と、

基板を反転させる基板反転装置と、

を有し、

裏面処理装置での処理範囲と裏面周縁部処理装置での処理範囲とが重なる重畳処理範囲を設け、

前記裏面処理装置による除去処理の後に前記基板反転装置による基板の反転を行ってから前記裏面周縁部処理装置による除去処理を行う、又は、前記裏面周縁部処理装置による除去処理の後に前記基板反転装置による基板の反転を行ってから前記裏面処理装置による除去処理を行うことを特徴とする基板処理システム。 In a substrate processing system for removing an object to be removed on the back side of a substrate,

The substrate support is used to support the outer peripheral edge of the substrate, and the removal target is removed in a predetermined processing range from the inner peripheral portion of the back surface of the substrate to the vicinity of the substrate support, and the removal target on the outer peripheral side from the predetermined processing range. A backside treatment device that does not remove objects ,

A back surface peripheral portion processing apparatus that removes the removal target object in a predetermined processing range on the inner peripheral side from the outer peripheral end of the back surface of the substrate and does not remove the removal target object on the inner peripheral side than the predetermined processing range ;

A substrate reversing device for reversing the substrate;

Have

Provide a superimposition processing range where the processing range in the back surface processing device and the processing range in the back surface edge processing device overlap ,

After the removal process by the back surface processing apparatus, the substrate is reversed by the substrate reversing apparatus and then the removal process by the back surface peripheral edge processing apparatus is performed, or after the removal process by the back surface peripheral edge processing apparatus A substrate processing system characterized in that after the substrate is inverted by the step, the removal processing by the back surface processing apparatus is performed .

基板支持体で基板の外周端を支持し、基板の裏面の内周部から基板支持体の近傍までの所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも外周側の除去対象物を除去しない裏面処理装置を用いて基板の裏面を処理させる裏面処理工程と、

基板の裏面の外周端から内周側の所定の処理範囲で除去対象物を除去し前記所定の処理範囲よりも内周側の除去対象物を除去しない裏面周縁部処理装置を用いて基板の裏面を処理させる裏面周縁部処理工程と、

を有し、

裏面処理工程での処理範囲と裏面周縁部処理工程での処理範囲とが重なる重畳処理範囲を設け、

前記裏面処理工程の後に基板反転装置によって基板を反転させてから前記裏面周縁部処理工程を行う、又は、前記裏面周縁部処理工程の後に基板反転装置によって基板を反転させてから前記裏面処理工程を行うことを特徴とする基板処理プログラムを記憶したコンピュータ読み取り可能な記憶媒体。

In a computer-readable storage medium storing a substrate processing program for processing a back surface of a substrate using a substrate processing system for removing an object to be removed from the back surface of the substrate,

The substrate support is used to support the outer peripheral edge of the substrate, and the removal target is removed in a predetermined processing range from the inner peripheral portion of the back surface of the substrate to the vicinity of the substrate support, and the removal target on the outer peripheral side from the predetermined processing range. A back surface processing step of processing the back surface of the substrate using a back surface processing apparatus that does not remove the object ,

The back surface of the substrate using a back surface peripheral portion processing apparatus that removes the object to be removed in a predetermined processing range on the inner peripheral side from the outer peripheral edge of the back surface of the substrate and does not remove the target to be removed on the inner peripheral side from the predetermined processing range. Back surface peripheral edge processing step for processing,

Have

Provide a superimposition processing range where the processing range in the back surface processing step and the processing range in the back edge processing step overlap ,

After the back surface processing step, the substrate is reversed by a substrate reversing device and then the back surface peripheral portion processing step is performed, or after the back surface peripheral portion processing step, the substrate is reversed by the substrate reversing device and then the back surface processing step is performed. computer-readable storage medium storing a substrate processing program and performs.

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011151123A JP5705666B2 (en) | 2011-07-07 | 2011-07-07 | Substrate processing method, substrate processing system, and computer-readable storage medium storing substrate processing program |

| KR1020120070058A KR101600938B1 (en) | 2011-07-07 | 2012-06-28 | Method and system for processing substrate and computer-readable storage medium storing substrate processing program |

| TW105104685A TWI593040B (en) | 2011-07-07 | 2012-07-02 | Substrate processing method, substrate processing system, and computer-readable storage medium storing a substrate processing program |

| TW101123769A TWI529836B (en) | 2011-07-07 | 2012-07-02 | Substrate processing method, substrate processing system, and computer-readable storage medium storing a substrate processing program |

| KR1020160021071A KR101688492B1 (en) | 2011-07-07 | 2016-02-23 | Method and system for processing substrate and computer-readable storage medium storing substrate processing program |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011151123A JP5705666B2 (en) | 2011-07-07 | 2011-07-07 | Substrate processing method, substrate processing system, and computer-readable storage medium storing substrate processing program |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015034976A Division JP6027640B2 (en) | 2015-02-25 | 2015-02-25 | Substrate processing system |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013021026A JP2013021026A (en) | 2013-01-31 |

| JP2013021026A5 JP2013021026A5 (en) | 2013-08-29 |

| JP5705666B2 true JP5705666B2 (en) | 2015-04-22 |

Family

ID=47692204

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011151123A Active JP5705666B2 (en) | 2011-07-07 | 2011-07-07 | Substrate processing method, substrate processing system, and computer-readable storage medium storing substrate processing program |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP5705666B2 (en) |

| KR (2) | KR101600938B1 (en) |

| TW (2) | TWI593040B (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5904169B2 (en) | 2013-07-23 | 2016-04-13 | 東京エレクトロン株式会社 | Substrate cleaning apparatus, substrate cleaning method, and storage medium |

| KR102478317B1 (en) | 2015-04-08 | 2022-12-16 | 도쿄엘렉트론가부시키가이샤 | Substrate processing system |

| US10155252B2 (en) * | 2015-04-30 | 2018-12-18 | Taiwan Semiconductor Manufacturing Co., Ltd. | Semiconductor apparatus and washing method |

| JP6552404B2 (en) * | 2015-12-17 | 2019-07-31 | 東京エレクトロン株式会社 | Substrate processing method, substrate processing system, substrate processing apparatus, and computer readable storage medium storing substrate processing program |

| JP7175119B2 (en) * | 2018-07-25 | 2022-11-18 | 東京エレクトロン株式会社 | SUBSTRATE PROCESSING APPARATUS AND SUBSTRATE PROCESSING METHOD |

| US20240307925A1 (en) | 2021-03-03 | 2024-09-19 | Tokyo Electron Limited | Substrate processing method and substrate processing system |

| JP2022152751A (en) | 2021-03-29 | 2022-10-12 | 東京エレクトロン株式会社 | Droplet discharge device and method |

| JP2022188854A (en) | 2021-06-10 | 2022-12-22 | 東京エレクトロン株式会社 | Substrate processing apparatus and control method of substrate processing apparatus |

| TW202410144A (en) | 2022-05-18 | 2024-03-01 | 日商東京威力科創股份有限公司 | Substrate processing device, substrate processing method, and storage medium |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3892635B2 (en) * | 2000-02-04 | 2007-03-14 | 大日本スクリーン製造株式会社 | Cleaning device |

| JP2004247582A (en) * | 2003-02-14 | 2004-09-02 | Tokyo Electron Ltd | Cleaning brush and substrate cleaning device |

| US8356376B2 (en) * | 2008-06-18 | 2013-01-22 | Tokyo Electron Limited | Substrate cleaning apparatus, substrate cleaning method, and storage medium |

-

2011

- 2011-07-07 JP JP2011151123A patent/JP5705666B2/en active Active

-

2012

- 2012-06-28 KR KR1020120070058A patent/KR101600938B1/en active IP Right Grant

- 2012-07-02 TW TW105104685A patent/TWI593040B/en active

- 2012-07-02 TW TW101123769A patent/TWI529836B/en active

-

2016

- 2016-02-23 KR KR1020160021071A patent/KR101688492B1/en active IP Right Grant

Also Published As

| Publication number | Publication date |

|---|---|

| TW201624595A (en) | 2016-07-01 |

| KR20130006309A (en) | 2013-01-16 |

| TWI529836B (en) | 2016-04-11 |

| TW201308492A (en) | 2013-02-16 |

| KR20160026959A (en) | 2016-03-09 |

| KR101688492B1 (en) | 2016-12-21 |

| TWI593040B (en) | 2017-07-21 |

| KR101600938B1 (en) | 2016-03-08 |

| JP2013021026A (en) | 2013-01-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5705666B2 (en) | Substrate processing method, substrate processing system, and computer-readable storage medium storing substrate processing program | |

| JP6740066B2 (en) | Substrate cleaning apparatus, substrate processing apparatus and substrate cleaning method | |

| JP5478586B2 (en) | Cleaning device, peeling system, cleaning method, program, and computer storage medium | |

| KR20160143705A (en) | Substrate-processing device, substrate-processing method, and computer-readable recording medium on which substrate-processing program has been recorded | |

| JP5726686B2 (en) | Liquid processing apparatus and method for controlling liquid processing apparatus | |

| TW201624532A (en) | Substrate liquid processing method, substrate liquid processing device and storage medium | |

| JP6584532B2 (en) | Grinding apparatus and grinding method | |

| TWI681449B (en) | Polishing method and polishing apparatus | |

| JP2019021859A (en) | Substrate processing system | |

| JP6027523B2 (en) | Substrate processing apparatus, substrate processing method, and recording medium recording substrate processing program | |

| JP2015050213A (en) | Substrate processing system, substrate processing method, and storage medium capable of reading computer storing substrate processing program | |

| JP6027640B2 (en) | Substrate processing system | |

| JP6395673B2 (en) | Substrate processing equipment | |

| JP6254054B2 (en) | Coating apparatus, bonding system, coating method, bonding method, program, and information storage medium | |

| JP2018129476A (en) | Substrate processing device | |

| JP6513492B2 (en) | Substrate processing method, substrate processing apparatus and storage medium | |

| JP5634381B2 (en) | Substrate cleaning method, substrate cleaning apparatus, and computer-readable storage medium | |

| JP2017059784A (en) | Cup washing jig, substrate liquid processing device for washing cup using the same, and cup washing method | |

| JP2024044924A (en) | Substrate cleaning device and substrate cleaning method | |

| JP2024044905A (en) | Substrate cleaning device and substrate cleaning method | |

| JP6552404B2 (en) | Substrate processing method, substrate processing system, substrate processing apparatus, and computer readable storage medium storing substrate processing program | |

| JP5970102B2 (en) | Liquid processing equipment | |

| KR20230012426A (en) | Substrate cleaning device, substrate cleaning system, substrate processing system, substrate cleaning method and substrate processing method | |

| JP2012216624A (en) | Substrate processing apparatus and method for cleaning substrate processing apparatus | |

| JP2006041445A (en) | Substrate processing equipment and method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130712 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130712 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140522 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140527 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140711 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150127 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150225 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5705666 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |