JP5673573B2 - Fixing structure for supporting material for installation on the roof - Google Patents

Fixing structure for supporting material for installation on the roof Download PDFInfo

- Publication number

- JP5673573B2 JP5673573B2 JP2012013054A JP2012013054A JP5673573B2 JP 5673573 B2 JP5673573 B2 JP 5673573B2 JP 2012013054 A JP2012013054 A JP 2012013054A JP 2012013054 A JP2012013054 A JP 2012013054A JP 5673573 B2 JP5673573 B2 JP 5673573B2

- Authority

- JP

- Japan

- Prior art keywords

- support material

- support

- roof

- folded

- opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000463 material Substances 0.000 title claims description 139

- 238000009434 installation Methods 0.000 title claims description 16

- 230000000694 effects Effects 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 238000010248 power generation Methods 0.000 description 2

- 238000005452 bending Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 239000011295 pitch Substances 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02B—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO BUILDINGS, e.g. HOUSING, HOUSE APPLIANCES OR RELATED END-USER APPLICATIONS

- Y02B10/00—Integration of renewable energy sources in buildings

- Y02B10/10—Photovoltaic [PV]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

Landscapes

- Roof Covering Using Slabs Or Stiff Sheets (AREA)

Description

本願は、太陽光発電パネル等の屋根上設置物を屋根材に取り付ける際に用いる、支持材の固定構造に関する。 The present application relates to a support material fixing structure used when an installation object on a roof such as a photovoltaic power generation panel is attached to a roof material.

従来技術について、まず図6により説明する。図6(ア)(イ)(ウ)は、特許第4505283号に記載された技術である。(ア)は、横葺屋根14上に、太陽電池モジュール16を設置した例を示している。(イ)は止め具22の実施例を示す図であり、(ウ)は支持部材18の実施例を示す図である。

支持部材18は、上面にスロット24を形成することで、異なる働き幅の屋根材に対応していて、スリット26を形成したものさえある。

図6の場合には、横葺屋根14に対して、軒棟方向に複数の止め具22を挟持させ、それらの止め具22の支持板32に、支持部材18を架け渡す。次に、支持部材18にコ字形帯状の部品をかぶせ、ボルト・ナット組立体34で結合している。

The prior art will be described first with reference to FIG. FIGS. 6A, 6A, and 6C are techniques described in Japanese Patent No. 4505283. (A) shows an example in which the

The

In the case of FIG. 6, a plurality of

図7と図8とは、支持材が、アルミ押し出し材の例である。

図7は、特開2011−149168に記載されたものである。(a)と(b)と記載されているのは、その図1であり、(h)と記載されているのは、図2に記載されていたものである。

図7の場合には、まず、外装材7に取り付けられた持出部材3に連結材4を取り付け、その連結材4に対して、支持部材2を取り付ける。

支持部材2は、側方が解放する側方調整溝21と、上方が解放する上方調整溝22とを、長手方向に備える構成である。

そして、各調整溝21・22に、棒状材2a・2bのそれぞれの頭部が嵌合保持されることで、長手方向に摺動可能となっている。

7 and 8 show examples in which the support material is an aluminum extruded material.

FIG. 7 is described in JP2011-149168A. (A) and (b) are described in FIG. 1, and (h) is described in FIG.

In the case of FIG. 7, first, the connecting

The

The heads of the rod-

図8は、特開2003−343058に記載された技術である。(a)(b)とあるのは、その図2であり、縦桟31の一例を示している。

その縦桟31には、「予め側面の両端部に貫通孔32が設けられ、また、両側面にそれぞれ2本の溝33が長手方向に平行に設けられている。」と、記載されている。

そのような縦桟31に対して、リボンナット35とボルト36を用いたり、貫通孔32から貫通ボルト29を打ち込んだりして、縦桟31を固定する。

FIG. 8 shows a technique described in Japanese Patent Application Laid-Open No. 2003-343058. (A) and (b) are the FIG. 2 and show an example of the

In the

The

図6に用いられている支持部材18は、下向きに開口する単純な倒コ字状である。そして、上面には、多様な取り付けピッチに対応するためのスロット24やスリット26が形成されている。

このため、支持部材18の断面係数が低下し、支持部材18自体の剛性がなくなっていた。このことにより、設置場所が限定されるという問題点があった。強度を上げようとすると、多くの止め具22を必要とし、コストアップにつながっていた。

The

For this reason, the section modulus of the

図7と図8の支持材はアルミ押し出し材でできており、断面係数の低下は防げる。しかし、次のような問題点があった。

まず、細かいボルトとナットを扱うため、屋根上で落とす可能性があった。そして、その取り付けに手間がかかり、特に、横方向からは、とても施工しづらかった。

また、支持材は、溝を複数形成したり貫通孔をあけたりして複雑な形状となるため、高価な部材となっていた。

The support material of FIGS. 7 and 8 is made of an extruded aluminum material, and the reduction of the section modulus can be prevented. However, there were the following problems.

First of all, there was a possibility of dropping on the roof to handle fine bolts and nuts. And it took a lot of work to install, especially from the side, it was very difficult to work.

Further, since the support material has a complicated shape by forming a plurality of grooves or through holes, it has been an expensive member.

図7の場合には、上記の記載に加え、次のような問題点もあった。

図7の支持部材2は、側面一側に形成された調整溝21に、棒状材2aを嵌合保持する。このため、外設部材1が載置されたときに、支持部材2に均等に力がかからず、強固な固定になりにくかった。

また、調整溝21に棒状材2aを嵌合保持させる位置が限定されるので、軒棟方向の高さ調整がしにくかった。

In the case of FIG. 7, in addition to the above description, there are the following problems.

The

Moreover, since the position which fits and hold | maintains the rod-

図8の場合には、下固定金具26に対する、縦桟31の貫通孔32の位置決めに時間がかかり、貫通ボルト29を挿入してナットで締め付けるのにも手間がかかっていた。

さらに、リボンナット35・ボルト36・貫通ボルト29といった細かい部品や、各屋根材に取り付ける下固定金具26と、部材点数も多かった。

In the case of FIG. 8, it takes time to position the through

In addition, there were many small parts such as

本願は、折り曲げ加工品であっても、比較的強度の高い支持材を用い、その支持材を支持材受け具に載置して、支持材固定具を用いて固定する。

これにより、低コストで強度が高い、屋根上設置物用支持材の固定構造を提供することを目的とする。また、作業性のよい固定構造を提供するものである。

The present application uses a support material having a relatively high strength even if it is a bent product, places the support material on a support material receiver, and fixes it using a support material fixing tool.

Thereby, it aims at providing the fixing structure of the support material for installation objects on a roof with low cost and high intensity | strength. Moreover, the fixing structure with good workability is provided.

本願の屋根上設置物用支持材の固定構造は、支持材受け具に屋根上設置物用支持材が載せられ、その支持材が、支持材固定具を用いて固定される構造である。

本願の屋根上設置物用支持材の固定構造には、次のような部材を用いる。

支持材は、支持材受け具に載置される基底部と、立面部と、支持材上面部を有している。そして、支持材上面部には、開口部が形成されている。

前記支持材を載置する支持材受け具は、支持材を載せるための受支面と、支持材受け具が載る載置面とを有している。

前記支持材を固定する支持材固定具は、当接部と、締め付け部を有している。

The structure for fixing the support material for rooftop installation according to the present application is a structure in which the support material for installation on the roof is placed on a support material receiver, and the support material is fixed using the support material fixing tool.

The following member is used for the fixing structure of the support material for roof installations of this application.

The support member has a base portion that is placed on the support member receiver, an elevation surface portion, and a support material upper surface portion. And the opening part is formed in the support material upper surface part.

The support material holder on which the support material is placed has a support surface on which the support material is placed and a placement surface on which the support material support is placed.

The support material fixture for fixing the support material has a contact portion and a tightening portion.

そして、各部材が次のように施工された固定構造である。支持材受け具が、軒棟方向に所定の間隔で取り付けられている。そこで、複数の支持材受け具の受支面に支持材を架け渡し、該支持材の前記開口部に、支持材固定具の当接部を挿入する。次に、支持材固定具を用いて支持材を固定する。このとき、支持材上面部の開口部の左右端縁に前記当接部が当接していることを特徴とする屋根上設置物用支持材の固定構造である。 And it is the fixed structure where each member was constructed as follows. Support material receptacles are attached at predetermined intervals in the eaves-ridge direction. Therefore, the support material is bridged over the support surfaces of the plurality of support material receivers, and the contact portion of the support material fixing tool is inserted into the opening of the support material. Next, a support material is fixed using a support material fixing tool. At this time, the support structure for an installation object on the roof is characterized in that the contact portions are in contact with the left and right edges of the opening on the upper surface of the support material.

本願の支持材は、基底部と、立面部と、支持材上面部を有している。このため、比較的簡易な形状で安価な折り曲げ加工品であっても、図6とは異なり、剛性の高い支持材となっている。これにより、風荷重が大きい場所にも使用することが可能である。

また、支持材が固定されたときに、締め付け部によって支持材の角部が締め付けられている。そして、支持材上面部の開口部から挿入された当接部が、開口部の左右端縁に当接している。支持材が締め付けられるとともに、当接部によって支持材の左右の動きが規制されるので、支持材が強固に固定される構造である。

さらに、図7や図8の構造とは異なり、横方向から、細かいボルトやナットを用いた施工をしなくて済む。このため、作業性のよい固定構造となっている。

The support material of the present application has a base portion, an elevation surface portion, and a support material upper surface portion. For this reason, even if it is a comparatively simple shape and an inexpensive bending processed product, unlike FIG. 6, it is a highly rigid support material. Thereby, it can be used also in a place with a large wind load.

Further, when the support material is fixed, the corner portion of the support material is tightened by the tightening portion. And the contact part inserted from the opening part of a support material upper surface part is contact | abutted to the right-and-left edge of an opening part. Since the support material is tightened and the left and right movements of the support material are restricted by the contact portion, the support material is firmly fixed.

Furthermore, unlike the structure of FIGS. 7 and 8, it is not necessary to perform construction using fine bolts and nuts from the lateral direction. For this reason, it is a fixed structure with good workability.

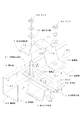

本願の屋根上設置物用支持材の固定構造について、まず、図1と図2により説明する。

図1(ア)(イ)は、本願の屋根上設置物用支持材の固定構造の実施例を示す説明図である。(ア)は正面から見た状態であり、(イ)は側面から見た状態を示している。

図2は、本願に用いる部材の実施例を示す説明図である。

First, the fixing structure of the support for a roof installation object according to the present application will be described with reference to FIGS.

FIGS. 1A and 1A are explanatory views showing an example of a fixing structure for a support for a roof-mounted object according to the present application. (A) is the state seen from the front, and (A) shows the state seen from the side.

FIG. 2 is an explanatory view showing an example of a member used in the present application.

図1と図2では、横葺き屋根材(図示せず)に取り付け金具4を固定し、その取り付け金具4に対して、支持材6を固定した場合を示している。

取り付け金具4は、固定ピース41と差し込みピース42で、横葺き屋根材に挟み込んで固定されている。

1 and 2 show a case where the mounting

The mounting

次に、取り付け金具4に組み合わせられる支持材受け具5について説明する。

支持材受け具5は、本実施例の場合には、上方に開口する略ハット形をしている。そして、取り付け金具4に支持材受け具5を載せるための載置面51と、その両側を立ち上げてから外側方向に折り曲げた受支面52・52とを有している。

本実施例の載置面51は、取り付け金具4に組み合わせるために、当該箇所を切り欠いてある。また、載置面51には、支持材固定具7と組み合わせるためのボルトS1が上向きに取り付けられている。

この支持材受け具5は、あらかじめ取り付け金具4に組み合わせておくとよい。

Next, the

In the case of the present embodiment, the support

The mounting

The

支持材受け具5の受支面52・52は、支持材6を載せる面である。

支持材受け具5は、支持材6を載せるための受支面52と、支持材受け具5が載る載置面51とを有していればよい。

The support surfaces 52 and 52 of the

The

支持材受け具5の受支面52・52に載置される支持材6は、次のような形状をしている。

本実施例の場合には、基底部63と、その両側を立ち上げた立面部62・62と、立面部62・62の上端縁をそれぞれ内側方向に折り曲げた支持材上面部61・61とを有している。

支持材上面部61・61の端縁の間には、間隔がある。そこで、本実施例の支持材6は、支持材上面部61の長さ方向中央部分全体を開口部Kとしている。

本実施例の支持材6は、図6の支持部材18と異なり、働き幅に対応した長穴に左右されることはない。図6と比べたときに、支持材6全体を軒棟方向に動かすことで容易に位置決めができる、という効果もある。

支持材上面部61の開口部Kは、図3(ア)から(ウ)のような実施例でもよい。図3は、口形状の支持材6の支持材上面部61を楕円形や四角形に切り欠いて形成している。図3は、支持材6の開口部Kの形状及び幅や長さが限定されない例として示している。

The

In the case of the present embodiment, the base portion 63, the raised

There is a gap between the edges of the upper surface portions 61 and 61 of the support material. Therefore, the

Unlike the

The opening K of the support member upper surface portion 61 may be an embodiment as shown in FIGS. In FIG. 3, the support material upper surface portion 61 of the mouth-shaped

次に、前述の支持材6を固定する支持材固定具7について説明する。図1と図2の通り、本実施例の支持材固定具7は、上面部71と、上面部71の対向する二辺を折り下げた折り下げ面74・74を有している。この折り下げ面74・74は、支持材6の開口部Kの左右端縁に当接する当接部を有している。

上面部71の対向する他の二辺は、折り下げられて締め付け部72・72を形成している。本実施例の場合には、上面部71から斜めに折り下げられた締め付け部72・72となっている。締め付け部72・72は、上面部71から斜めに折り下げてから垂下させて形成してもよい。

また、締め付け部72・72は、それぞれ外側方向に折り曲げられて底面部73・73となっている。底面部73・73には、支持材受け具5のボルトS1を通すための穴があけられている。

Next, the

The other two opposite sides of the

Further, the

さらに、本実施例の支持材固定具7の折り下げ面74・74について説明する。本実施例の場合には、折り下げ面74・74は、中央部分74bと、その両脇の両脇部分74a・74aとから成っている。

本実施例の場合には、中央部分74bが支持材6の開口部Kにはまり、両脇部分74a・74aの下側端縁が支持材上面部61・61に載るように形成されている。

Furthermore, the folding surfaces 74 and 74 of the

In the case of the present embodiment, the central portion 74b is fitted into the opening K of the

続いて、これまで述べた部材を用いた固定構造について説明する。

あらかじめ、支持材受け具5が、軒棟方向に、所定の間隔で複数取り付けられている。そこで、軒棟方向に隣り合う複数の支持材受け具5の受支面52・52に、支持材6を架け渡す。

Subsequently, a fixing structure using the members described so far will be described.

In advance, a plurality of

こうして支持材6を架け渡したのち、上から支持材固定具7をはめる。このとき、支持材上面部61・61間の開口部Kに支持材固定具7の折り下げ面74・74の中央部分74bをはめる。また、底面部73・73の穴に、支持材受け具5から突出しているボルトS1・S1を通す。そして、ナットS2・S2で締め付けて、支持材6を固定する。

このようにして固定された支持材6の上に、太陽光発電パネル等の屋根上設置物を取り付ける。

本実施例では、締め付け具Sとして、ボルトS1やナットS2等を用いている。しかし、支持材固定具7を用いて、支持材受け具5の受支面52に支持材6を固定することができればよく、その手段は限定されない。

After the

An on-roof installation such as a photovoltaic power generation panel is attached on the

In this embodiment, a bolt S1, a nut S2, or the like is used as the fastening tool S. However, it is only necessary that the

本願の固定構造の効果について、さらに説明する。

本実施例の支持材固定具7の締め付け部72・72は、上面部71から斜めに折り下げられている。または、斜めに折り下げられた面を有している。

そして、その面が、支持材6の支持材上面部61と立面部62の角部に当接する。締め付け具Sで締め付けられたときには、支持材6の角部を支持材固定具7が押圧する。このため、支持材6を強く締め付けることができる。

The effect of the fixing structure of the present application will be further described.

The

Then, the surface comes into contact with the corners of the support material upper surface portion 61 and the

さらに、本実施例の折り下げ面74の場合には、中央部分74bの小口が支持材6の開口部Kの左右端縁に当接する。また、支持材上面部61・61に、両脇部分74a・74aの下側端縁が当接する。

このため、締め付け具Sで支持材6が締め付けられたときには、支持材6と支持材固定具7とに、反発し合う力が働く。しかも、当接するのは小口である。

従って、図1(ア)に支持材6を破線で描いた通り、開口部Kの左右端縁に折り下げ面74・74が食い込むようになり、強固な固定構造となるのである。

たとえ、本実施例の支持材6の基底部63に長穴があいていたとしても、倒コ字状である図6の支持部材18とは構成が異なり、高い強度が得られる。

Further, in the case of the folded

For this reason, when the

Therefore, as shown in FIG. 1A, the

Even if the base portion 63 of the

図4(ア)から(オ)は、折り下げ面74の他の実施例を示している。

(ア)は、支持材固定具7の上面部71において、対向する二辺を折り下げて折り下げ面74・74を形成した例である。本実施例の折り下げ面74・74は、図1(ア)の折り下げ面74・74から、両脇部分74a・74aを無くしたものである。

この実施例の場合には、支持材上面部の開口部の左右端縁に対して、折り下げ面74・74の小口が当接部となる。

(イ)は、支持材固定具7の上面部71において、端縁から切り込みを入れ、さらに切り込みの先端を対向させて、L字状の切り込みとする。そして、切り離された箇所を折り下げることで、折り下げ面74・74を形成している。

この実施例の場合には、支持材上面部の開口部の左右端縁に対して、折り下げ面74・74の小口ではなく、折り下げられた面が当接部となる。

(ウ)は、支持材固定具7の上面部71において、上面部71の中央部分に切り込みを入れてから折り下げることで、折り下げ面74・74を形成している。

この実施例の場合にも、支持材上面部の開口部の左右端縁に対して、折り下げ面74・74の小口ではなく、折り下げられた面が当接部となる。

(エ)は、上面部71にコ字状の切り込みを入れ、その面を折り下げて折り下げ面74・74を形成している。上面部71からの折り下げ箇所は、一カ所でもよい。

この実施例の場合には、支持材上面部の開口部の左右端縁に対して、折り下げ面74・74の小口が当接部となる。

(オ)は、支持材上面部の開口部の左右端縁への当接部として、折り下げ面74・74にくびれ部を形成している。

(ア)から(オ)のいずれも、支持材上面部の開口部の左右端縁に、折り下げ面74のいずれかの箇所が当接する。締め付け具Sを用いて支持材6を締め付けたときに、小口または面が当接するので、強固な固定ができる。これにより、支持材6の動きが規制されるので、高い強度が得られる。

このように、折り下げ面74は、支持材の開口部に合わせ、開口部に挿入し、その左右端縁に当接する当接部を形成すればよい。

4A to 4E show other examples of the

(A) is an example in which, on the

In the case of this embodiment, the small edges of the folding surfaces 74 and 74 serve as contact portions with respect to the left and right edges of the opening on the upper surface of the support material.

(B) In the

In the case of this embodiment, the folded surface is not the small edge of the folded surfaces 74 and 74 but the abutting portion with respect to the left and right edges of the opening on the upper surface of the support material.

In (c), on the

Also in the case of this embodiment, the folded surface is a contact portion with respect to the left and right edges of the opening portion of the upper surface portion of the support material, not the small edge of the folded surfaces 74 and 74.

In (D), a U-shaped cut is made in the

In the case of this embodiment, the small edges of the folding surfaces 74 and 74 serve as contact portions with respect to the left and right edges of the opening on the upper surface of the support material.

(E) forms constricted portions on the folding surfaces 74 and 74 as contact portions to the left and right edges of the opening of the upper surface portion of the support material.

In any of (a) to (e), any part of the

As described above, the

図5(ア)から(ウ)は、本願に用いる各部材の他の実施例を示している。

(ア)の支持材6は、図3(ア)のように、支持材上面部61を切り欠いて開口部Kを形成した例を示している。また、支持材受け具5が、倒コ字状をしていて、載置面51を兼ねる受支面52となっている。

支持材受け具5は、このように、支持材受け具5を載置する金具に合わせて形成すればよい。また、その支持材受け金具5に、支持材6の基底部63を受支できればよい。

(イ)は、支持材6がハット形をしていて、支持材上面部61を切り欠いて開口部Kを形成した例である。

(ウ)は、図1(ア)と同じ断面形状の支持材6を、上下逆にしたものである。そして、支持材上面部61を切り欠いて開口部Kを形成している。

このように、支持材上面部61の形成方法は、いろいろ考えられる。

また、当接部も、これまで述べた以外にも、開口部Kに挿入することができ、その左右端縁に当接して、支持材6の動きを規制できるように形成すればよい。

FIGS. 5A to 5C show another embodiment of each member used in the present application.

As shown in FIG. 3A, the

The

(A) is an example in which the

(C) is a

As described above, various methods of forming the support material upper surface portion 61 are conceivable.

In addition to the above, the abutting portion can be inserted into the opening K, and the abutting portion may be formed so as to abut against the left and right edges thereof to restrict the movement of the

これまで、本願の屋根上設置物用支持材の固定構造について、横葺き屋根材に対して取り付けられた部材で説明してきた。しかし、次のような場合にも応用することができる。

たとえば、屋根材が馳折板であり、左右に隣り合う馳部に取り付けられた金具に対して、本願に係る各部材を用いる場合である。

その場合には、まず、取り付け金具に対して、支持材受け具を組み合わせて固定する。次に、左右に隣り合う支持材受け具に、横支持材を架け渡す。そして、横支持材に支持材固定具をかぶせて、支持材受け具に固定する。

このときの作用効果は、これまで述べた実施例と同じである。

So far, the fixing structure of the support material for roof installations according to the present application has been described with the members attached to the side roofing material. However, it can also be applied to the following cases.

For example, the roofing material is a folded plate, and each member according to the present application is used for the metal fittings attached to the right and left adjacent saddles.

In that case, first, a support material receiver is combined and fixed to the mounting bracket. Next, the lateral support material is bridged between the support material receivers adjacent to the left and right. And a support material fixing tool is covered on the horizontal support material, and it fixes to a support material receiver.

The effect at this time is the same as the embodiment described so far.

4 取り付け金具

41 固定ピース

42 差し込みピース

5 支持材受け具

51 載置面

52 受支面

6 支持材

61 支持材上面部

62 立面部

63 基底部

7 支持材固定具

71 上面部

72 締め付け部

73 底面部

74 折り下げ面

74a 中央部分

74b 両脇部分

S 締め付け具

S1 ボルト

S2 ナット

4 Mounting

Claims (1)

該支持材が支持材固定具を用いて固定される屋根上設置物用支持材の固定構造であって、

支持材は、基底部と立面部と支持材上面部を有しており、

該支持材上面部には開口部が形成されており、

支持材受け具は、受支面と載置面を有しており、

支持材固定具は、

上面部と、

該上面部から折り下げられた折り下げ面と、

該折り下げ面に形成された当接部と、

前記上面部の対向する二辺から斜めに折り下げられた締め付け部と、

該締め付け部がそれぞれ外側方向に折り曲げられた底面部を有しており、

支持材受け具が、軒棟方向に所定の間隔で取り付けられており、

複数の支持材受け具の受支面に支持材が架け渡され、

該支持材の前記開口部に支持材固定具の当接部が挿入され、

支持材固定具の底面部が締め付け具で締め付けられて支持材が固定されたときに、

前記開口部の左右端縁に前記当接部が当接し、

支持材上面部と立面部の角部に前記締め付け部が当接している

屋根上設置物用支持材の固定構造。 The support material for the installation object on the roof is placed on the support material receiver,

The support material is a structure for fixing a support material for an installation on a roof, which is fixed using a support material fixing tool,

The support material has a base portion, an elevation surface portion, and a support material upper surface portion,

An opening is formed in the upper surface of the support material,

The support material receiver has a receiving surface and a mounting surface,

The support fixture is

An upper surface,

A folded surface folded from the upper surface,

A contact portion formed on the folded surface;

A tightening portion that is obliquely folded from two opposite sides of the upper surface portion;

Each of the tightening portions has a bottom surface portion that is bent outward.

Support material receivers are attached at predetermined intervals in the direction of the eaves,

A support material is laid over the support surface of a plurality of support material receivers,

A contact portion of a support fixture is inserted into the opening of the support,

When the bottom of the support fixture is tightened with the clamp and the support is fixed,

The abutting part abuts on the left and right edges of the opening ,

A structure for fixing a support material for an installation on a roof , wherein the tightening portion is in contact with a corner portion between the upper surface portion and the elevation surface portion of the support material.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012013054A JP5673573B2 (en) | 2012-01-25 | 2012-01-25 | Fixing structure for supporting material for installation on the roof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012013054A JP5673573B2 (en) | 2012-01-25 | 2012-01-25 | Fixing structure for supporting material for installation on the roof |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013151819A JP2013151819A (en) | 2013-08-08 |

| JP2013151819A5 JP2013151819A5 (en) | 2013-11-14 |

| JP5673573B2 true JP5673573B2 (en) | 2015-02-18 |

Family

ID=49048350

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012013054A Active JP5673573B2 (en) | 2012-01-25 | 2012-01-25 | Fixing structure for supporting material for installation on the roof |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5673573B2 (en) |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2917847B2 (en) * | 1995-02-23 | 1999-07-12 | 株式会社ヤネハル | Solar power generation panel mounting device |

| JP4785958B2 (en) * | 2009-06-20 | 2011-10-05 | 三晃金属工業株式会社 | Solar power plant |

-

2012

- 2012-01-25 JP JP2012013054A patent/JP5673573B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013151819A (en) | 2013-08-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9800200B2 (en) | Solar cell apparatus | |

| US8935893B2 (en) | Direct rooftop mounting apparatus for solar panels | |

| US9145685B2 (en) | Panel mounting bracket for standing seam roof and related methods | |

| JP3907668B2 (en) | Mounting structure of solar cell module | |

| WO2011077538A1 (en) | Auxiliary members | |

| US11114577B2 (en) | Photovoltaic power generation device | |

| JP2008095278A (en) | Mounting structure of solar cell module | |

| KR101708472B1 (en) | Fixing structure for Solar panel | |

| EP3442115A1 (en) | Slide-in track for supporting photovoltaic module and mounting assembly for photovoltaic module | |

| JP5944695B2 (en) | Building fixture | |

| JP5673573B2 (en) | Fixing structure for supporting material for installation on the roof | |

| JP2014163136A (en) | Mounting device for solar cell module | |

| JP6140089B2 (en) | Snow stop structure | |

| US10742162B2 (en) | Fixing structure of solar cell module | |

| JP5686771B2 (en) | Solar cell module fixing structure and solar cell module fixing method | |

| JP2014234588A (en) | Installation structure and installation method of solar panel | |

| JP5584810B1 (en) | Photovoltaic panel mounting bracket, roof panel, and roof structure | |

| JP2014136935A (en) | Fitting structure of snow stop member | |

| JP6193049B2 (en) | Solar panel support structure and support member | |

| JP5798701B1 (en) | Solar cell module mounting structure and external member mounting tool for solar cell module | |

| JP5709079B2 (en) | Exterior structure and construction method | |

| JP2015078589A (en) | Metal fitting for photovoltaic power generation panel, roof panel, and roof structure | |

| JP4125336B2 (en) | Solar cell module mounting cover | |

| JP2014020023A (en) | Eaves for building | |

| JP5540045B2 (en) | Mounting structure of solar cell module |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130926 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130926 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140624 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140902 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20141101 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20141202 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20141215 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5673573 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |