JP5432216B2 - Method and apparatus for supplying attached document in boxing machine - Google Patents

Method and apparatus for supplying attached document in boxing machine Download PDFInfo

- Publication number

- JP5432216B2 JP5432216B2 JP2011133606A JP2011133606A JP5432216B2 JP 5432216 B2 JP5432216 B2 JP 5432216B2 JP 2011133606 A JP2011133606 A JP 2011133606A JP 2011133606 A JP2011133606 A JP 2011133606A JP 5432216 B2 JP5432216 B2 JP 5432216B2

- Authority

- JP

- Japan

- Prior art keywords

- attached document

- attachment

- article

- molding frame

- frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Container Filling Or Packaging Operations (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

Description

この発明は、箱詰機において物品の説明書などの添付書類をカートンの開口より物品と共に詰め込む添付書類の供給方法およびその装置に関するものである。 The present invention relates to supply a method and apparatus for both stuffing attachments from attachments carton opening the object products such as articles of instructions in a box packer.

物品を箱詰めする際に、物品と共に使用方法などを記した説明書などの添付書類を同封することがある。添付書類を物品と共にカートンに詰め込む供給装置としては、カートンの開口の手前位置に添付書類を配置し、添付書類を物品で押送することで、添付書類を折り曲げつつ物品と共にカートンに収容する各種装置が提案されている。このような添付書類の供給装置は、厚手の紙素材などからなるシート材を折り重ねたコシの強い添付書類において、物品に負荷がかかって変形したり、カートン自体が変形したり、あるいはカートンに収容した添付書類の反発力によって物品がカートンの開口側へ押し返されてカートンへの収容がなされない等、の種々の問題が生じることがある。 When packaging an article, an attached document such as an instruction describing how to use it may be enclosed with the article. As the feeding device for packing the attached document into the carton together with the article, there are various devices that place the attached document in front of the opening of the carton and push the attached document with the article so that the attached document is folded and accommodated in the carton together with the article. Proposed. Such an attachment supply device is a strong attachment made by folding a sheet material made of thick paper material or the like, and the article is deformed by a load, the carton itself is deformed, or the carton itself is deformed. Various problems may occur, such as the article being pushed back to the opening side of the carton due to the repulsive force of the attached document and not being housed in the carton.

そこで、特許文献1または2に開示の装置のように、カートンへの供給前に添付書類に折り癖を付けた後に、添付書類を物品と共にカートンに詰め込むようにした装置が提案されている。特許文献1の装置は、スライド機構に開口したスライド口とスライド機構の固定板に開口した挿入口とを整合させた状態で添付書類を挿入し、スライド口と挿入口との位置をずらすことでスライド口後端部で添付書類に折り癖を付けて、添付書類をU字状に近い形状としている。そして、ガイドをカートンの開口から挿入する位置まで移動して、折り癖の付いた添付書類を物品と共に押し込んでいる。

Therefore, as in the device disclosed in

特許文献2の装置は、供給位置で物品の前方に設けた第1ガイドと第2ガイドとで添付書類を挟んで折り癖を付与するもので、プッシャで押されて移動する物品の前端部が両ガイドで挟んでいる添付書類に当接するタイミングに合わせて、第1ガイドから離れるように第2ガイドを前進しつつ物品の前端部で添付書類を押し進め、添付書類が所定位置まで移動した第2ガイドの内側を物品に押されてカートンに押し込まれる。 The device of Patent Document 2 is a device for providing a crease with an attached document sandwiched between a first guide and a second guide provided in front of an article at a supply position, and a front end portion of the article that is moved by being pushed by a pusher. In accordance with the timing of contact with the attached document sandwiched between the two guides, the attached document is pushed forward at the front end portion of the article while the second guide is advanced away from the first guide, and the attached document is moved to a predetermined position. The inside of the guide is pushed by the article and pushed into the carton.

特許文献1の装置は、折り重ね厚が厚手の添付書類の場合には、添付書類が押し込み機構により物品と共にカートンに押し込まれて挿入口とスライド口との間の隙間部を通過する際に、折り畳まれた添付書類は厚みが脹らみ、その隙間部において添付書類に過大な負荷が生じて案内される。このため、添付書類が隙間部で引っ掛かってしまい、添付書類の表面に、こすり傷や破れなどが生じたり、添付書類が目的の折曲位置とならなかったり、あるいは折曲先端部が先細り状となってカートン内に押し込まれた物品が押し戻されてしまうといった問題が指摘される。また、特許文献2の装置は、特許文献1と同様に、添付書類が物品と共に前進する際には、添付書類の内外両方の面が各ガイドにこすって案内される。このため、厚手の添付書類では、カートン内に押し込まれるまでに折り返し反発力によって各ガイドとの接触面にこすり傷や破れなどが生じたり、折り癖を付けた位置がカートン内に押し込まれるまでに位置ずれして規定の詰め込み状態になり得ないといった問題が指摘される。しかも、特許文献1および特許文献2の構成では、折り癖の付与状態が甘く物品を押し付ける面が円弧状になり易いといった問題も指摘される。

In the case of an attached document with a thick folding thickness, the device of

すなわち本発明は、従来の技術に係る箱詰機における添付書類の供給方法およびその装置に内在する前記問題に鑑み、これらを好適に解決するべく提案されたものであって、厚手の添付書類であっても、物品並びに添付書類に傷を付けることなく、物品と共に確実にカートンに詰め込むことができる箱詰機における添付書類の供給方法およびその装置を提供することを目的とする。 That is, the present invention has been proposed in order to suitably solve the problems inherent in the method and apparatus for supplying an attached document in a boxing machine according to the prior art, and is a thick attached document. Even if it exists, it aims at providing the supply method and apparatus of an attachment in a boxing machine which can be packed in a carton reliably with an article, without damaging an article and an attachment.

前記課題を克服し、所期の目的を達成するため、本願の請求項1に係る発明の箱詰機における添付書類の供給方法は、

添付書類を成形枠の入口部に配置し、

該成形枠の入口部に配置した添付書類の所定範囲を、その厚み方向から挟持手段で挟持して、前記入口部から成形枠内への通口を通過させることで、挟持手段より左右に延出する添付書類の延出基部に折り癖を付与して、添付書類を曲げ状態で成形枠内に保持し、

該成形枠内に保持した添付書類の折り癖より内側を物品で押して成形枠外への通口を通過させることで、物品の側部に沿って両側部が折れ曲がった添付書類をカートンに詰め込むことを特徴とする。

請求項1に係る発明によれば、物品と共に確実にカートンに添付書類を詰め込むことができる。特に、折り癖を付ける際に添付書類を厚み方向から挟むようにしたので、添付書類が折り癖付与時に位置ずれすることなく、正確かつ確実な折り癖を付けることができる。

In order to overcome the above-mentioned problems and achieve the intended object, a method for supplying an attached document in the boxing machine according to

Place the attached document at the entrance of the molding frame,

A predetermined range of the attached document arranged at the entrance of the molding frame is clamped by the clamping means from the thickness direction and passed through the entrance from the inlet to the molding frame, so that it extends to the left and right from the clamping means. Give the extension base of the attached document to be creased, hold the attached document in a bent state in the molding frame,

The inside of the attached document held in the forming frame is pushed by the article with the article and passed through the outside of the forming frame, so that the attached document bent on both sides along the side of the article is packed in the carton. Features.

According to the invention which concerns on

請求項2に係る発明では、前記成形枠における複数の間欠停止位置において、前記成形枠への添付書類の配置、前記入口部から成形枠内への通口の通過および前記カートンへの添付書類の詰め込みの夫々の処理を分散して行うようにしたことを特徴とする。

請求項2に係る発明によれば、夫々の処理を異なる間欠停止位置で同時期に実施することができるので、サイクルタイムを短縮することができる。

In the invention which concerns on Claim 2, in the some intermittent stop position in the said molding frame, arrangement | positioning of the attached document to the said molding frame, passage of the opening from the said entrance part into a molding frame, and the attached document to the said carton The stuffing process is performed in a distributed manner.

According to the invention which concerns on Claim 2, since each process can be implemented at the same period in a different intermittent stop position, cycle time can be shortened.

前記課題を克服し、所期の目的を達成するため、本願の請求項3に係る発明の箱詰機における添付書類の供給装置は、

入口部において添付書類を支持する成形枠と、

該成形枠の入口部で支持された添付書類を、その厚み方向から挟持する一対の挟持部材を有し、両挟持部材で挟持した添付書類を、成形枠内への通口を通過させて両挟持部材より左右に延出する延出基部に折り癖を付与すると共に成形枠内の保持部に受け渡すように、両挟持部材を進退移動する挟持手段と、

前記成形枠に設けられた前記通口を通過するよう移動可能に構成され、前記保持部に曲げ状態で保持された添付書類における折り癖の内側に物品を押し付けて成形枠外への通口を通過させることにより、物品の側部に沿って両側部を折り曲げた添付書類をカートンに詰め込む装填手段とを備えたことを特徴とする。

請求項3に係る発明によれば、物品と共に確実にカートンに添付書類を詰め込むことができる。特に、折り癖を付ける際に添付書類を厚み方向から挟むようにしたので、添付書類が折り癖付与時に位置ずれすることなく、正確かつ確実な折り癖を付けることができる。

In order to overcome the above-mentioned problems and achieve the intended purpose, an attachment supply device for a packaging machine according to claim 3 of the present application is

A molding frame to support the attached document at the entrance,

It has a pair of clamping members that clamp the attached document supported at the entrance of the forming frame from the thickness direction, and both the attached documents held by both holding members are passed through the opening into the forming frame. Clamping means for moving the both clamping members forward and backward so as to give a crease to the extending base extending from the clamping member to the left and right and to deliver to the holding part in the molding frame;

It is configured to be movable so as to pass through the opening provided in the molding frame, and the article is pressed against the inside of the fold in the attached document held in a bent state on the holding portion, and passes through the opening outside the molding frame. And a loading means for stuffing an attached document in which both side portions are bent along the side portion of the article into the carton.

According to the invention which concerns on Claim 3, an attached document can be reliably packed into a carton with an article | item. In particular, since the attached document is sandwiched from the thickness direction when attaching the crease, the attached document can be accurately and reliably attached without being displaced when the crease is applied.

請求項4に係る発明では、前記成形枠には、前記保持部で前記添付書類を逆台形となる曲げ状態で保持し得るように添付書類の両折曲端部を係止する係止部を設けたことを特徴とする。

請求項4に係る発明によれば、成形枠に係止部を設けるだけの簡単な構成により、添付書類の曲げ状態を適切に維持できる。

In the invention according to claim 4, the molding frame includes a locking portion that locks both folded end portions of the attached document so that the attached portion can be held in a bent state having an inverted trapezoidal shape by the holding portion. It is provided.

According to the invention which concerns on Claim 4, the bending state of an attached document can be maintained appropriately with the simple structure which only provides the latching | locking part in a shaping | molding frame.

請求項5に係る発明では、前記成形枠には、該成形枠外への通口を通過する際に前記添付書類の両側部を物品の側部に沿うよう折り曲げ案内する斜壁を設けたことを特徴とする。

請求項5に係る発明によれば、添付書類を成形枠外へ移送する際に両側部が物品の側部に沿って無理なく折り曲げられる。

In the invention according to claim 5, the molding frame is provided with a slanted wall that bends and guides both side portions of the attached document along the side portion of the article when passing through the opening to the outside of the molding frame. Features.

According to the invention which concerns on Claim 5, when transferring an attachment outside a forming frame, both sides are bent easily along the side of an article.

請求項6に係る発明では、折り重ねた添付書類を横並びの集積状態で載置する集積部と、この集積部から添付書類を個々に取り出して前記成形枠に配置する供給手段とを備えたことを特徴とする。

請求項6に係る発明によれば、折り畳まれた添付書類を集積部から1個ずつ切り離して成形枠まで配置することができる。

The invention according to claim 6 comprises a stacking unit for placing the folded attached documents in a side-by-side stacked state, and a supply means for individually taking out the attached documents from the stacking unit and placing them on the molding frame. It is characterized by.

According to the invention which concerns on Claim 6, the folded attachment can be cut | disconnected from the accumulation | stacking part one by one, and it can arrange | position to a forming frame.

本願発明によれば、厚手の添付書類であっても、物品並びに添付書類に傷を付けることなく、物品と共に確実にカートンに詰め込むことができる。 According to the present invention, even a thick attached document can be reliably packed in a carton together with the article without damaging the article and the attached document.

次に、本発明に係る箱詰機における添付書類の供給方法およびその装置につき、好適な実施例を挙げて、添付図面を参照して以下に説明する。 Next, a method for supplying an attached document and an apparatus therefor in a boxing machine according to the present invention will be described below with reference to the accompanying drawings.

実施例の箱詰機における添付書類の供給装置は、複数の添付書類10が集積された集積部20から添付書類10を供給する供給手段30と、この供給手段30で供給された添付書類10に折り癖を付ける成形手段40と、図示しない製函部において箱形に成形されて天面が開放されたカートン12が装填位置P3まで搬送して配置されるカートン搬送コンベヤ70と、物品14を搬送する物品搬入コンベヤ90から物品14を受け取って添付書類10と共にカートン12に詰め込む装填手段80とを備えている。なお、実施例では、箱形に成形されて天面が開口したカートン12に、円柱状の物品14と共に添付書類10を詰め込む場合を例示して説明するものであって、添付書類10は、カートン12の内底面と物品14の底面との間に、その左右の長手方向中央部が挟まれて、該長手方向両側部が物品14の側部に沿って上方へ折り曲げられてカートン12に押し込まれるようになっている。

The apparatus for supplying an attachment in the boxing machine of the embodiment includes a supply means 30 for supplying the

図1または図3に示すように、前記集積部20は、ベルトコンベヤに比較的厚手の紙製シートを折り畳んで所定厚となった添付書類10を折り重ね方向が搬送方向前後に指向し、長手方向を左右に向けた姿勢で整列した集積状態で載置される。添付書類10は、供給手段30による取り出しに伴い集積部20の取出口22側に順次搬送される。供給手段30は、集積部20の取出口22から添付書類10を吸着して取り出す吸着部材32と、この吸着部材32で取り出した添付書類10を後述する成形枠44に移送する移送部材34とから構成される。吸着部材32は、集積部20の取出口22に対して接離可能に設けられ、添付書類10の長手方向一端部を吸着して取出口22から離間することで、その長手方向他端部が取出口22に配設した規制片24から吸着部位まで後側に重なっている添付書類10から引き離されるようになっている。移送部材34は、回動アーム35が垂直に立った受取姿勢と水平に寝た受渡姿勢との90°の角度範囲で回動可能に支持されている。回動アーム35の先端に該回動アーム35に対して接近・離間可能にクランパ36,36が配設され、該クランパ36,36で添付書類10を保持して移送するようになっている。クランパ36,36は、回動アーム35の受取姿勢において吸着部材32で引き離された添付書類10の一端部側を挟持可能な位置まで移動して添付書類10を保持し、回動アーム35の前記受渡姿勢において成形枠44に添付書類10を載置したクランパ36,36を成形枠44の外方に退避して添付書類10を受け渡すようになっている。ここで、移送部材34は、集積部20から立てた姿勢で1枚ずつ取り出した添付書類10を、受取姿勢から受渡姿勢に回動することで、寝た姿勢で成形枠44に受け渡すようになっている。

As shown in FIG. 1 or FIG. 3, the stacking

図1に示すように、前記成形手段40は、モータ等の駆動手段によって水平回転可能に支持された支持台42に、90°間隔で配置した4基の成形枠44を備えている。成形手段40は、支持台42が90°毎で間欠的に回転されることで4基の成形枠44が90°毎に水平回転されて、添付書類10を受け取る供給位置P1、添付書類10が成形される成形位置P2、添付書類10と共に物品14をカートン12に詰め込む装填位置P3、次の成形サイクルに備える待機位置P4に、成形枠44が順次間欠停止されるようになっている。ここで、成形枠44は、供給位置P1で集積部20に最も近づき、供給位置P1から反時計回りに90°回転した成形位置P2で挟持手段60に臨み、成形位置P2から反時計回りに90°回転した装填位置P3でカートン搬送コンベヤ70の上方に位置し、装填位置P3から反時計回りに90°回転した待機位置P4を経て、待機位置P4から反時計回りに90°回転することで供給位置P1に戻る。なお、添付書類10および物品14の供給側が成形枠44の上方に設定されて、成形枠44に供給された添付書類10および物品14の送出側が下方に設定されている。

As shown in FIG. 1, the forming

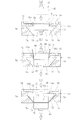

図4に示すように、成形枠44は、供給手段30によって供給された添付書類10を載置して支持する入口部46と、この入口部46の下側に設けられて、挟持手段60で移送された添付書類10を逆台形状となる凹形に折り曲げた状態で保持する保持部52と、該成形枠44の長手方向中央部を上下に貫通する上部通口58および下部通口59とからなる通口を備えている。上部通口58は、入口部46を上下に貫通するよう形成され、下部通口59は、保持部52を上下に貫通するよう形成されている。

As shown in FIG. 4, the forming

前記入口部46は、その外周縁に上方に突出形成された周壁50を備えている。添付書類10は、上部通口58を跨いで入口部46に載置されて該入口部46において支持されるようになっている。入口部46は、上部通口58の開口縁に向かうにつれて下方傾斜するテーパ状に形成された案内面46aを備えている。また、図1に示すように、前記入口部46における長手方向一側部には、成形枠44の外側方に開放した凹設部48が設けられている。該凹設部48は、クランパ36,36で保持した添付書類10を入口部46に載置する際のクランパ36,36の開放空間とされる。

The

図2に示すように、前記挟持手段60は、成形位置P2に到来した成形枠44の上下位置に臨む一対の挟持部材62,64を備え、各挟持部材62,64は、空気圧シリンダ63,65によって成形位置P2の成形枠44に対して夫々進退移動するようになっている。挟持手段60は、入口部46から成形枠44内への上部通口58を通過して成形枠44の上方から保持部52に挿入される第1挟持部材62と、成形枠44外への下部通口59を通過して成形枠44の下方から保持部52に挿入される第2挟持部材64とによって、入口部46に配置された添付書類10を厚み方向から挟持して上部通口58を介して保持部52に移送するよう構成されている。両挟持部材62,64は、厚み方向から挟持した添付書類10の厚み方向一方である下方に移動して、添付書類10を入口部46から上部通口58を通過させる。各挟持部材62,64は、添付書類10への当接部が物品14の底面の左右長より長い左右長に設定されて、添付書類10の長手方向中央部を挟持するよう構成されている。両挟持部材62,64より左右に延出する添付書類10の長手方向両側部は、添付書類10を挟持した挟持手段60が成形枠44内へ進入するときに第1挟持部材62の側部と上部通口58とによる隙間を案内されて、挟持手段60より延出する添付書類10の側部における延出基部に第1挟持部材62の側縁を基点として添付書類10の短手方向に沿う折り癖付けがなされる。

As shown in FIG. 2, the clamping means 60 includes a pair of clamping

前記第1挟持部材62は、添付書類10への当接部の左右長が上部通口58の左右寸法より小さく設定され、物品14の底面の左右長より長く設定されている。また、上部通口58および下部通口59は、その左右寸法が物品14の底面の左右長より大きく設定されている。ここで、第1挟持部材62と上部通口58との添付書類10が案内される隙間と比べて、物品14の側部と下部通口59との隙間が大きくなるよう設定されている。なお、第2挟持部材64における添付書類10への当接部は、第1挟持部材62と同じ大きさに設定されている。

The

図5(a)に示すように、前記保持部52は、下部通口59の上側に接続した斜壁54,54によって上方へ広がるように開放した凹形状に形成され、添付書類10を逆台形状となる折り曲げ状態で保持するようになっている。保持部52には、斜壁54の上部に形成した上壁からなる入口部46の下面に係止部56が設けられ、該係止部56に曲げ保持された添付書類10の折曲端部が当接して、添付書類10の上方への移動を規制して成形枠44に保持するよう構成されている。

As shown in FIG. 5 (a), the holding

前記カートン搬送コンベヤ70は、図示しない製函部においてブランクシートから上方に開口する箱状に組み立てられたカートン12を所定間隔毎に装填位置P3まで搬送し、該装填位置P3にある成形枠44の下方でカートン12の開口12aを下部通口59に臨ませた位置で停止して位置決め保持される。添付書類10と共に物品14が装填されたカートン12は、図示しない封函部に向けて搬送されて開口12aの各フラップが折曲成形されると共に天面パネルが閉じられて封止される。

The

前記装填手段80は、物品搬入コンベヤ90の物品受渡位置P5と装填位置P3にある成形枠44の上側との間を往復移動すると共に昇降可能に構成したピッキングハンド82が設けられている。ピッキングハンド82は、物品搬入コンベヤ90の物品受渡位置P5で昇降動作して物品14を保持して、該物品14を装填位置P3にある成形枠44の通口58,59を通過するように下降して該成形枠44の下方に配置されたカートン12に添付書類10と共に詰め込むようになっている。装填手段80で下降される物品14は、保持部52で曲げ状態で保持された添付書類10の左右の折り癖より内側を押すようになっている。物品14より左右に延出する添付書類10の長手方向両側部は、物品14に押されて成形枠44外へ移送されるときに物品14の側部と下部通口59とによる隙間を案内されて、物品14の側部に沿って折り曲げられる。物品搬入コンベヤ90は、カートン搬送コンベヤ70と並行して設けられ、一列に連ねて搬送される物品14を、搬送終端部の物品受渡位置P5において個々の物品14を後続の物品14から切り離して保持するようになっている。

The loading means 80 is provided with a picking

次に、前述した供給装置を用いた添付書類の供給方法について説明する。添付書類10は、図1に示すように、集積部20の取出口22に臨む長手方向一端部が吸着部材32で引き出され、添付書類10の長手方向他端部が集積部20に保持された状態で長手方向一端部が後続の添付書類10から分離される。移送部材34のクランパ36,36で添付書類10の長手方向一端部を挟んで他端部を取出口22から引き抜き、回動アーム35を受取姿勢から受渡姿勢に回動することで添付書類10を立った姿勢から寝た姿勢に変位し、寝た姿勢で供給位置P1にある成形枠44の入口部46に載置することで添付書類10は成形枠44内への入口に配置される(図3参照)。そして、支持台42が回転駆動されることで、供給位置P1で添付書類10が配置された成形枠44が反時計周りに90°回転されて成形位置P2に到る。

Next, an attachment document supply method using the above-described supply apparatus will be described. As shown in FIG. 1, one end of the

次に図4(a)に示すように、成形位置P2に到来した成形枠44の上下に配置された第1挟持部材62と第2挟持部材64とが相互に接近するように移動して、第2挟持部材64は上部通口58に跨って載置された添付書類10の長手方向中央部の下面に臨む。また、第1挟持部材62が下方へ移動することで、添付書類10を第2挟持部材64とで挟持する。そして、図4(b)に示すように、添付書類10を第1挟持部材62および第2挟持部材64とで挟持した状態で両挟持部材62,64を下方へ移動することで、添付書類10は上部通口58を通過して成形枠44内に移送される。図4(b)に示すように、添付書類10を挟持した第1挟持部材62が上部通口58を通過する際に、第1挟持部材62の側縁より延出する添付書類10の側部の夫々が、第1挟持部材62の側縁を基点として入口部46に押されて上方へ折り曲げられると共に、添付書類10の延出基部に該第1挟持部材62の側縁に沿って折り癖が付けられる。ここで、入口部46は、上部通口58の周辺がテーパ形状になった案内面46aを備えているので、添付書類10の側部を案内して添付書類10への摺接負荷を軽減できる。

Next, as shown in FIG. 4A, the first clamping

次に図4(c)に示すように、挟持手段60によって成形枠44内の保持部52に押し込まれた添付書類10は、その左右の側部が前記折り癖付けによって上方に向けて広がる逆台形となる。第1挟持部材62と第2挟持部材64とが相互に離間して添付書類10を解放し、保持部52に添付書類10を受け渡す。そして、添付書類10は、図5(a)に示すように、左右の側部が保持部52の斜壁54に引っ掛かって下方への移動が規制され、斜壁54の上方に位置して曲げ状態が保たれる。この際、保持部52の上部に設けられた係止部56,56によって添付書類10の側部の折曲端部を係止することで、添付書類10は、曲げ状態から平坦に戻ろうとする反発力による上方への迫り上りなどの移動を規制することができる。従って、保持部52において添付書類10を適切な曲げ状態で位置ずれすることなく保持させることができる。

Next, as shown in FIG. 4 (c), the

次に成形枠44が装填位置P3に到ると、図5(a)に示すように、ピッキングハンド82に保持された物品14を下降して、保持部52において前記曲げ状態で保持された添付書類10の曲げ凹部側から物品14の底部を左右の折り癖よりも内側に押し付けるよう前進移動する。図5(b)に示すように、物品14に押された添付書類10は、成形枠44外への通口としての下部通口59を通過する際に、該物品14の底部より左右に延出する側部の夫々が、癖付けされた折り目で折れ曲がって物品14の側部に沿うように折り曲げ案内される。そして、図5(b)に示すように、添付書類10は物品14と共に、装填位置P3の成形枠44の下側の近接位置で上部を開口状態で支持されているカートン12に挿入され、物品14の底部に挟まれた状態で添付書類10をカートン12に確実に詰め込むことができる。ピッキングハンド82は、物品14をカートン12に装填した後に通口58,59を介して上昇して成形枠44の上方に退避し、装填位置P3から物品受渡位置P5に移動して次の物品供給に備える。

Next, when the forming

前記添付書類10は、成形枠44内への上部通口58を通過する際に折り癖が付けられ、カートン12へ装填する際に折り曲げ状態が適切に保たれているので、物品14と共に確実にカートン12に詰め込むことができる。特に、折り癖を付けるに際して添付書類10を厚み方向から挟むようにしたので、添付書類10の折り目が円弧状になってしまうことはなく、カートン12に詰め込んだ後に、添付書類10の反発によって物品14がカートン12の開口12aに押し戻されることも回避できる。また癖付け時に添付書類10がずれて癖付け位置がずれたり、添付書類10が位置ずれしつつ挟持手段60を移動して添付書類10に傷がついてしまうといった問題を未然に防止できる。更に、成形枠44との摺接を最小限に抑え、添付書類10のこすり傷や破れ等の外観不良の発生を防止することができる。物品14の側部に沿わせてカートン12内に装填する際は事前に癖付けした添付書類10を成形枠44に曲げ状態で保持し、左右の折り癖の内側に物品14を押し当てて前進移動するので、位置ずれすることなく添付書類10をカートン12内に詰め込むことができる。更にまた、下部通口59と物品14の側部との隙間に、物品14の側部から延出する添付書類10の側部を折り曲げ案内可能な余裕をもたせてあるので、成形枠44外への下部通口59の通過時に添付書類10の擦れによる傷付きや物品14との位置ずれを防止できる。供給装置は、4基の成形枠44が間欠停止される供給位置P1、成形位置P2および装填位置P3において夫々の処理が分散して行われる。このように、異なる位置で処理を実施することができるので、物品14および添付書類10の詰め込みにかかるサイクルタイムを短縮することができる。

The

(変更例)

本発明は実施例の構成に限定されるものではなく、例えば、以下のようにも変更実施可能である。なお、以下の変更例に限らず、実施例に記載した構成については、本発明の主旨の範囲内において種々の実施形態を採用し得る。

(1)成形枠44は90°ごとに水平回動する構造としたが、供給位置P1、成形位置P2、装填位置P3の3箇所に等分した回動角にしたり、あるいは成形枠44への添付書類10の配置および添付書類10の入口部46から成形枠44内への通口58の通過、更にはカートン12への添付書類10の詰め込みを含め全ての処理を同位置で行うように構成してもよい。更には、成形枠44は所定間隔毎に水平方向に直線的に移動させるなどの形態も採用可能である。

(2)物品14の供給は、ロボットに代わる他の装填手段を採用し、物品搬入コンベヤ90から取り上げた物品14を水平移動と昇降動可能な別々の駆動手段を用いるようにしてもよい。

(3)集積部20からの個々の添付書類10の取り出し形態は実施例の形態に限るものではなく、例えば実施例のクランパ36,36を吸着部材としてもよい。

(4)実施例は、添付書類10および物品14を成形枠44の上方から供給して下方から送出する箱詰機を対象としているが、通口58,59が横方向に開口するものであってもよい。この際には成形枠44の入口部46に添付書類10を配置する際に、成形枠44に吸引手段で添付書類10を立った状態で支持することなど、添付書類10が成形枠44から離間することなく配置状態が維持可能な適宜形態を採用すればよい。

(5)成形枠44に添付書類10を曲げ状態が維持されるように保持するには、保持部52に収容されて折り曲げられている添付書類10の折曲端部を係止する係止部56に代えて、保持部52における添付書類10の側部に面する部位に吸引孔を設けるなどすることによって、曲げ状態の添付書類10を吸着保持するようにしてもよい。

(Example of change)

The present invention is not limited to the configuration of the embodiment, and can be modified as follows, for example. It should be noted that the present invention is not limited to the following modification examples, and various embodiments can be adopted within the scope of the present invention for the configurations described in the examples.

(1) Although the forming

(2) The

(3) The form of taking out the individual attached

(4) The embodiment is intended for a boxing machine that feeds the attached

(5) In order to hold the attached

10 添付書類,14 物品,20 集積部,30 供給手段,44 成形枠,

46 入口部,52 保持部,56 係止部,54 斜壁,58 上部通口(通口),

59 下部通口(通口),60 挟持手段,62 第1挟持部材(挟持部材),

64 第2挟持部材(挟持部材),80 装填手段,P1 供給位置(間欠停止位置),

P2 成形位置(間欠停止位置),P3 装填位置(間欠停止位置)

10 attachments, 14 articles, 20 stacking units, 30 supply means, 44 molding frames,

46 entrance part, 52 holding part, 56 locking part, 54 slant wall, 58 upper entrance (entrance),

59 lower opening (opening), 60 clamping means, 62 first clamping member (clamping member),

64 second clamping member (clamping member), 80 loading means, P1 supply position (intermittent stop position),

P2 molding position (intermittent stop position), P3 loading position (intermittent stop position)

Claims (6)

該成形枠(44)の入口部(46)に配置した添付書類(10)の所定範囲を、その厚み方向から挟持手段(60)で挟持して、前記入口部(46)から成形枠(44)内への通口(58)を通過させることで、挟持手段(60)より左右に延出する添付書類(10)の延出基部に折り癖を付与して、添付書類(10)を曲げ状態で成形枠(44)内に保持し、

該成形枠(44)内に保持した添付書類(10)の折り癖より内側を物品(14)で押して成形枠(44)外への通口(59)を通過させることで、物品(14)の側部に沿って両側部が折れ曲がった添付書類(10)をカートン(12)に詰め込む

ことを特徴とする箱詰機における添付書類の供給方法。 Place the attachment (10) at the entrance (46) of the forming frame (44),

A predetermined range of the attached document (10) arranged at the inlet portion (46) of the molding frame (44) is clamped by the clamping means (60) from the thickness direction, and the molding frame (44) is inserted from the inlet portion (46). ) Passing through the entrance (58) into the inside, the folding base is attached to the extension base of the attachment (10) extending from the clamping means (60) to the left and right, and the attachment (10) is bent. Hold in the molding frame (44) in the state,

By pressing the inner side of the folds of the attached document (10) held in the molding frame (44) with the article (14) and passing the opening (59) outside the molding frame (44), the article (14) A method for supplying an attached document in a boxing machine, wherein the attached document (10) having both sides bent along the side of the box is packed in a carton (12).

該成形枠(44)の入口部(46)で支持された添付書類(10)を、その厚み方向から挟持する一対の挟持部材(62,64)を有し、両挟持部材(62,64)で挟持した添付書類(10)を、成形枠(44)内への通口(58)を通過させて両挟持部材(62,64)より左右に延出する延出基部に折り癖を付与すると共に成形枠(44)内の保持部(52)に受け渡すように、両挟持部材(62,64)を進退移動する挟持手段(60)と、

前記成形枠(44)に設けられた前記通口(58,59)を通過するよう移動可能に構成され、前記保持部(52)に曲げ状態で保持された添付書類(10)における折り癖の内側に物品(14)を押し付けて成形枠(44)外への通口(59)を通過させることにより、物品(14)の側部に沿って両側部を折り曲げた添付書類(10)をカートン(12)に詰め込む装填手段(80)とを備えた

ことを特徴とする箱詰機における添付書類の供給装置。 A molding frame (44) supporting the attachment (10) at the entrance (46);

The forming frame (44) has a pair of clamping members (62, 64) for clamping the attachment (10) supported by the inlet portion (46) from the thickness direction thereof, and both clamping members (62, 64) The attached document (10) clamped in (1) is passed through the opening (58) into the molding frame (44) and the folds are given to the extending base extending from the both clamping members (62, 64) to the left and right. And clamping means (60) for moving both clamping members (62, 64) forward and backward so as to be delivered to the holding part (52) in the molding frame (44),

It is configured to be movable so as to pass through the openings (58, 59) provided in the forming frame (44), and the crease in the attached document (10) held in a bent state by the holding portion (52). By attaching the article (14) to the inside and passing the opening (59) to the outside of the forming frame (44), the attachment (10) folded on both sides along the side of the article (14) is cartoned. An apparatus for supplying an attached document in a boxing machine, comprising loading means (80) for packing in (12).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011133606A JP5432216B2 (en) | 2011-06-15 | 2011-06-15 | Method and apparatus for supplying attached document in boxing machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011133606A JP5432216B2 (en) | 2011-06-15 | 2011-06-15 | Method and apparatus for supplying attached document in boxing machine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013001414A JP2013001414A (en) | 2013-01-07 |

| JP2013001414A5 JP2013001414A5 (en) | 2013-04-11 |

| JP5432216B2 true JP5432216B2 (en) | 2014-03-05 |

Family

ID=47670379

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011133606A Active JP5432216B2 (en) | 2011-06-15 | 2011-06-15 | Method and apparatus for supplying attached document in boxing machine |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5432216B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2022064221A (en) * | 2020-10-13 | 2022-04-25 | 株式会社フジキカイ | Supply device for attachment |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04135406U (en) * | 1991-05-30 | 1992-12-16 | 鐘紡株式会社 | packaging equipment |

| JP2003267327A (en) * | 2002-03-15 | 2003-09-25 | Mutual Corp | Small box packing machine |

| JP2007197077A (en) * | 2006-01-30 | 2007-08-09 | Fuji Seal International Inc | Article inserting mechanism |

| JP4929221B2 (en) * | 2008-04-08 | 2012-05-09 | 株式会社フジキカイ | Attached document supply device in boxing machine |

| JP4990223B2 (en) * | 2008-06-05 | 2012-08-01 | 株式会社フジキカイ | Attached document supply device |

-

2011

- 2011-06-15 JP JP2011133606A patent/JP5432216B2/en active Active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2022064221A (en) * | 2020-10-13 | 2022-04-25 | 株式会社フジキカイ | Supply device for attachment |

| JP7318940B2 (en) | 2020-10-13 | 2023-08-01 | 株式会社フジキカイ | Attachment feeder |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013001414A (en) | 2013-01-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5878517B2 (en) | Carton supply apparatus and method for supplying carton to carton truck | |

| JP5878518B2 (en) | Carton supply system and method for simultaneously supplying a plurality of cartons to a conveyor track by utilizing a plurality of pickup heads | |

| US9573777B2 (en) | Transport device for conveying products | |

| EP1958875A1 (en) | Machine for packaging articles into boxes | |

| JP5432216B2 (en) | Method and apparatus for supplying attached document in boxing machine | |

| JP6801881B2 (en) | Boxing device | |

| JP4607654B2 (en) | Spout wearing method | |

| US20230264906A1 (en) | Device for feeding carton stacks | |

| KR20160086878A (en) | Apparatus for inserting documents into envelopes and associated method | |

| JP5841022B2 (en) | Packaging method and apparatus | |

| JP2005059918A (en) | Loading method and loading device for article and piece of paper | |

| JP3840591B2 (en) | Method and apparatus for supplying partition in boxing machine | |

| JP4216708B2 (en) | Box transfer device and boxing device | |

| JP5604211B2 (en) | Goods transfer device | |

| JP4990223B2 (en) | Attached document supply device | |

| JP6886335B2 (en) | Packing device, packing method | |

| JP5658870B2 (en) | Buffer device and bucket width adjustment method | |

| JP4866019B2 (en) | Article conveying device and pouch container conveying device | |

| JP7538540B2 (en) | Packing machine | |

| JP2599218B2 (en) | Opening device for packaging case | |

| ITTO20090300A1 (en) | DEVICE FOR FEEDING SHEETS. | |

| JP7318940B2 (en) | Attachment feeder | |

| JP3778415B2 (en) | Sheet product stacking device | |

| JP4058686B2 (en) | Method and apparatus for supplying partition in boxing machine | |

| JP6300151B2 (en) | Boxing method and boxing device for flat article |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130226 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130226 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20131115 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20131126 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20131205 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 5432216 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |