本発明の実施例1の電気掃除機は、電動送風機28を備えた掃除機本体1と、掃除機本体1に着脱自在な集塵装置2とを備え、集塵装置2は、吸い込んだ空気を旋回させて空気から塵埃を分離する分離部(例えば、塵埃分離部4)と、分離部に連通し塵埃を収容する収容部(例えば、塵埃収容部5)とを備え、分離部と収容部とは、軸方向に配列され、収容部は、分離部と連通する側に開口し分離部と連通する側とは反対側に凹んだ形状を有するフィルタ(例えば、集塵かご12)を備え、分離部の旋回流の外側の空気は、収容部内のフィルタ内に流入し、分離部の旋回流の内側の空気は、収容部内でかつフィルタの外側に流入することを特徴とする。

The vacuum cleaner according to the first embodiment of the present invention includes a vacuum cleaner body 1 having an electric blower 28 and a dust collector 2 that is detachably attached to the vacuum cleaner body 1. A separation unit (for example, a dust separation unit 4) that swirls and separates dust from the air, and a storage unit (for example, a dust storage unit 5) that communicates with the separation unit and stores the dust, the separation unit and the storage unit, Are arranged in the axial direction, and the accommodating portion is provided with a filter (for example, a dust collecting basket 12) having a shape opened on the side communicating with the separating portion and recessed on the opposite side to the side communicating with the separating portion. The air outside the swirling flow of the part flows into the filter in the housing part, and the air inside the swirling flow of the separating part flows into the housing part and outside the filter.

そして、本発明の実施例1によれば、分離部と収容部とを軸方向に配列して連通し、そして、分離部の旋回流の外側の空気を収容部内の凹んだ形状を有するフィルタ内に流入し、分離部の旋回流の内側の空気を収容部内でかつ凹んだ形状を有するフィルタの外側に流入することにより、使用者の手を煩わせることなく塵埃を圧縮し、堆積した塵埃を使用者が容易に排出でき、さらに、吸引力の低下を抑制することができる。

And according to Example 1 of this invention, the separation part and the accommodating part are arranged in the axial direction and communicated with each other, and the air outside the swirling flow of the separation part is in a filter having a recessed shape in the accommodating part. The air inside the swirling flow of the separation part flows into the housing part and outside the filter having a concave shape, thereby compressing the dust without bothering the user and removing the accumulated dust. The user can easily discharge, and can further suppress a decrease in suction force.

または、本発明の実施例1の電気掃除機は、本体吸気口21と吸引力を発生する電動送風機28とを備えた掃除機本体1と、掃除機本体の本体吸気口21と電動送風機28との間に着脱自在な集塵装置2とを備え、集塵装置2は、略円筒形状を有し本体吸気口21に連通可能な第1の集塵部(例えば、塵埃分離部4)と、第1の集塵部の軸方向端部に連通しかつ電動送風機28に連通する第2の集塵部(例えば、塵埃収容部5)とを備え、第1の集塵部は、円周面に複数の貫通孔33を有する内筒7を略円筒形状内に内包し、第2の集塵部は、第1の集塵部と連通する側に開口し第1の集塵部と連通する側とは反対側に凹んだ形状を有する通気部材(例えば、集塵かご12)を内包し、第1の集塵部の内筒7の外側は、第2の集塵部内の凹んだ形状を有する通気部材の開口に連通し、第1の集塵部の内筒7の内側は、第2の集塵部内でかつ凹んだ形状を有する通気部材の外側に連通することを特徴とする。

Or the vacuum cleaner of Example 1 of this invention is the cleaner main body 1 provided with the main body inlet 21 and the electric blower 28 which generate | occur | produces suction power, the main body inlet 21 of the cleaner main body, and the electric blower 28. A dust collecting device 2 that is detachable between the first dust collecting unit 2 and the first dust collecting unit (for example, the dust separating unit 4) that has a substantially cylindrical shape and can communicate with the main body inlet 21; A second dust collecting part (for example, a dust storage part 5) communicating with the axial end of the first dust collecting part and communicating with the electric blower 28, the first dust collecting part being a circumferential surface The inner cylinder 7 having a plurality of through-holes 33 is enclosed in a substantially cylindrical shape, and the second dust collecting portion opens on the side communicating with the first dust collecting portion and communicates with the first dust collecting portion. A ventilation member (for example, a dust collecting basket 12) having a shape recessed on the opposite side to the side is included, and the outer side of the inner cylinder 7 of the first dust collecting portion is recessed in the second dust collecting portion. It communicates with the opening of the ventilation member having the shape, and the inside of the inner cylinder 7 of the first dust collection portion communicates with the outside of the ventilation member having the recessed shape in the second dust collection portion. .

そして、本発明の実施例1によれば、第2の集塵部を第1の集塵部の軸方向端部に連通し、そして、第1の集塵部の内筒7の外側を第2の集塵部内の凹んだ形状を有する通気部材の開口に連通し、第1の集塵部の内筒7の内側を第2の集塵部内でかつ凹んだ形状を有する通気部材の外側に連通することにより、使用者の手を煩わせることなく塵埃を圧縮し、堆積した塵埃を使用者が容易に排出でき、さらに、吸引力の低下を抑制することができる。

According to the first embodiment of the present invention, the second dust collecting portion is communicated with the axial end portion of the first dust collecting portion, and the outer side of the inner cylinder 7 of the first dust collecting portion is connected to the first dust collecting portion. The inside of the inner cylinder 7 of the first dust collecting part is connected to the outside of the venting member having the recessed shape inside the second dust collecting part. By communicating, dust can be compressed without bothering the user, the accumulated dust can be easily discharged by the user, and a decrease in suction force can be suppressed.

図1に、本発明の実施例の掃除機本体1の側面から見た断面図を示す。電気掃除機の使用状態では、掃除機本体1が横置きとなり、電気掃除機の収納状態では、掃除機本体1が縦置きとなるのが好ましい。電気掃除機の使用状態において、本体吸気口21側を前方(上流側)、本体排気口30側を後方(下流側)とすると、電気掃除機の収納状態では、本体吸気口21が重力作用方向上側となり本体排気口30が重力作用方向下側となる。掃除機本体1が横置きされた場合は、掃除機本体1の下面が、掃除機本体1が置かれた面(例えば、床面)に対して平行になり、重力作用方向に対して垂直となる。

In FIG. 1, sectional drawing seen from the side surface of the cleaner body 1 of the Example of this invention is shown. It is preferable that the vacuum cleaner main body 1 is horizontally placed in the usage state of the vacuum cleaner, and the vacuum cleaner main body 1 is vertically placed in the housed state of the vacuum cleaner. When the vacuum cleaner is in use, if the main body inlet 21 side is the front (upstream side) and the main body exhaust port 30 side is the rear (downstream side), the main body inlet 21 is in the direction of gravity in the housed state of the vacuum cleaner. The main body exhaust port 30 is on the lower side in the direction of gravity action. When the cleaner body 1 is placed horizontally, the lower surface of the cleaner body 1 is parallel to the surface (for example, the floor surface) on which the cleaner body 1 is placed and is perpendicular to the direction of gravity action. Become.

まず、掃除機本体1の構造を説明する。吸い込んだ空気から塵埃を捕集する集塵装置2は、掃除機本体1の前側に着脱自在に配置される。集塵装置2の長手方向(軸方向)を重力作用方向(縦型配置)とすると、掃除機本体1の高さが高くなる。一方、集塵装置2内の旋回流の軸方向(集塵装置2の軸方向)が重力作用方向に近いほど遠心分離作用による分離効果が大きくなり、集塵装置2内の旋回流の軸方向が重力作用方向に対して45度を超えると遠心分離作用による分離効果が極端に低下する。そこで、掃除機本体1の高さを小さくすると共に遠心分離作用による分離効果の低下を抑制するために、本実施例では、集塵装置2の軸方向は、重力作用方向に対して40度〜45度程度とする。ただし、遠心分離作用による分離効果を高くするには、集塵装置2の軸方向は、重力作用方向に対して40度よりも小さくてもよい(例えば、0度)。塵埃分離部(旋回部)4を下側に配置し、塵埃収容部5を上側に配置する代わりに、塵埃分離部4を上側に配置し、塵埃収容部5を下側に配置してもよい。この場合は、入口管3は、塵埃分離部4の軸方向の前側端部の円周面に接続されるのが好ましい。

First, the structure of the cleaner body 1 will be described. The dust collector 2 that collects dust from the sucked air is detachably disposed on the front side of the cleaner body 1. When the longitudinal direction (axial direction) of the dust collector 2 is the gravity action direction (vertical arrangement), the height of the cleaner body 1 is increased. On the other hand, the closer the axial direction of the swirling flow in the dust collector 2 (the axial direction of the dust collecting device 2) is to the gravity acting direction, the greater the separation effect due to the centrifugal separation action, and the axial direction of the swirling flow in the dust collecting device 2 When the angle exceeds 45 degrees with respect to the direction of gravity action, the separation effect due to the centrifugal action is extremely reduced. Therefore, in order to reduce the height of the vacuum cleaner main body 1 and suppress a decrease in the separation effect due to the centrifugal separation action, in this embodiment, the axial direction of the dust collector 2 is 40 degrees to the gravity action direction. It is about 45 degrees. However, in order to increase the separation effect by the centrifugal separation action, the axial direction of the dust collector 2 may be smaller than 40 degrees (for example, 0 degree) with respect to the gravity action direction. Instead of disposing the dust separation unit (swivel unit) 4 on the lower side and the dust storage unit 5 on the upper side, the dust separation unit 4 may be disposed on the upper side and the dust storage unit 5 on the lower side. . In this case, the inlet pipe 3 is preferably connected to the circumferential surface of the front end portion in the axial direction of the dust separator 4.

集塵装置2は、吸い込んだ空気を旋回させ、遠心分離作用(サイクロン方式)によって塵埃を分離する塵埃分離部4と、塵埃分離部4に連通し、塵埃分離部4で分離された塵埃を収容する塵埃収容部5を備える。塵埃分離部4と塵埃収容部5とは、集塵装置2の軸方向に配列され、それぞれの軸方向端部で接続され、連通する。つまり、塵埃分離部4は、掃除機本体1の前側に配置され、塵埃収容部5は、塵埃分離部4に対して掃除機本体1の前側に配置される。使用者が塵埃分離部4と塵埃収容部5とを容易に分離可能なように、塵埃分離部4と塵埃収容部5とが連結されている。掃除機本体1の前端に、管状の本体吸気口21を備える。塵埃分離部4の軸方向の前側端面の一部は、開口しており、その開口部が入口管3に接続される。塵埃分離部4の軸方向の前側端面ではなく、塵埃分離部4の軸方向の前側端部の円周面が、入口管3に接続されてもよい。入口管3は、掃除機本体1の幅方向の中央に形成されるのが好ましい。内筒7および凹み部8も、掃除機本体1の幅方向の中央に形成されるのが好ましい。

The dust collector 2 swirls the sucked air and communicates with the dust separator 4 that separates the dust by a centrifugal separation action (cyclone method), and the dust separator 4 accommodates the dust separated by the dust separator 4. A dust container 5 is provided. The dust separator 4 and the dust container 5 are arranged in the axial direction of the dust collector 2 and are connected and communicated with each other in the axial direction. That is, the dust separator 4 is disposed on the front side of the cleaner body 1, and the dust container 5 is disposed on the front side of the cleaner body 1 with respect to the dust separator 4. The dust separator 4 and the dust container 5 are connected so that the user can easily separate the dust separator 4 and the dust container 5. A tubular main body inlet 21 is provided at the front end of the cleaner body 1. A part of the front end face in the axial direction of the dust separator 4 is open, and the opening is connected to the inlet pipe 3. Instead of the front end surface in the axial direction of the dust separator 4, the circumferential surface of the front end in the axial direction of the dust separator 4 may be connected to the inlet pipe 3. The inlet pipe 3 is preferably formed at the center in the width direction of the cleaner body 1. The inner cylinder 7 and the recessed portion 8 are also preferably formed at the center in the width direction of the cleaner body 1.

塵埃分離部4は、中空の略円筒状の外筒6と、外筒6と同心軸で外筒6に内包される中空の略円筒状の内筒7を備える。旋回流の軸心が重力によって重力作用方向にずれることによって遠心分離作用による分離効果が低下するのを抑制するために、塵埃分離部4の軸方向が重力作用方向に対して傾いている場合には、内筒7の軸心を外筒6の軸心に対して下方向にずらしてもよい。図3(A)に示すように、外筒6の軸方向一端面(前側端面)は、入口管3に接続される開口を除き閉塞されおり、外筒6の軸方向他端面(後側端面)は、開口している。外筒6は、使用者から塵埃の堆積が見えるようにまたは外筒6外に設けたセンサが塵埃の堆積を検出できるように、透明または半透明のプラスチックや樹脂で構成されるのが好ましい。内筒7の軸方向一端面(前側端面)は閉塞されており、内筒7の軸方向他端面(後側端面)は、開口している。図3(A)に示すように、内筒7の軸方向一端面の閉塞部分の中央に、内筒7の軸方向内側へ凹んだ凹み部8が形成される。入口管3は、内筒7の軸方向一端面の閉塞部分、つまり凹み部8に対向している。図3(A)に示すように、凹み部8の一部は、内筒7の外周端まで達している。空気の圧力損失を低減するために、凹み部8の開口方向は、下方向であるのが好ましい。ただし、凹み部8の開口方向は、上方向でも横方向でもよい。図3(A)に示すように、凹み部8の内筒7の外周端部では、凹み部8が内筒7の半径方向に真っ直ぐに向くのではなく、やや円周方向に傾いている。図1に示すように、凹み部8の軸方向の深さは、内筒7の円筒部分の軸方向の長さの略半分程度である。ただし、凹み部8の軸方向の深さは、内筒7の円筒部分の軸方向のほぼ全長にわたってもよい。この場合は、内筒7の円筒部分のほぼ全長にわたって内筒7の円周面の一部に凹み部8の開口が形成されることになる。さらに、凹み部8の外周端部に、案内管38が接続される。案内管38の断面は略1/2円形状であり、内筒7の外周面に沿って形成され、内筒7の外周面も流路の内壁面の一部を形成する。案内管38は内筒7の外周面に、円周方向に数cm程度形成される。よって、入口管3によって軸方向に流入した空気は、凹み部8によって半径方向に向きを変え、さらに、凹み部8の内筒7の外周端部でやや円周方向に変えられ、さらに案内管38で円周方向に変えられる。また、凹み部8は凹凸がなく、曲面で形成されるのが好ましい。これによって、圧力損失を抑制しつつ空気を十分に旋回させることができる。案内管38は、なくても構わない。内筒7の軸方向他端面(後側端面)の外周に、外筒6へ向かって延びる外延部34が形成される。つまり、図3(A)に示すように、内筒7の軸方向他端面(後側端面)は、内筒7の内側が開口した円環状となっている。

The dust separation unit 4 includes a hollow substantially cylindrical outer cylinder 6 and a hollow substantially cylindrical inner cylinder 7 enclosed in the outer cylinder 6 with a concentric axis with the outer cylinder 6. When the axial direction of the dust separation part 4 is inclined with respect to the gravity action direction in order to prevent the separation effect due to the centrifugal separation action from deteriorating due to the axial center of the swirling flow being shifted in the gravity action direction by gravity. The axis of the inner cylinder 7 may be shifted downward with respect to the axis of the outer cylinder 6. As shown in FIG. 3A, one end surface (front end surface) in the axial direction of the outer cylinder 6 is closed except for an opening connected to the inlet pipe 3, and the other end surface in the axial direction (rear end surface) of the outer cylinder 6. ) Is open. The outer cylinder 6 is preferably made of transparent or translucent plastic or resin so that dust accumulation can be seen by the user or a sensor provided outside the outer cylinder 6 can detect the accumulation of dust. One end face (front end face) in the axial direction of the inner cylinder 7 is closed, and the other end face (rear end face) in the axial direction of the inner cylinder 7 is open. As shown in FIG. 3A, a recessed portion 8 that is recessed inward in the axial direction of the inner cylinder 7 is formed at the center of the closed portion of one end surface in the axial direction of the inner cylinder 7. The inlet pipe 3 is opposed to the closed portion of one end surface in the axial direction of the inner cylinder 7, that is, the recessed portion 8. As shown in FIG. 3A, a part of the recessed portion 8 reaches the outer peripheral end of the inner cylinder 7. In order to reduce the pressure loss of air, it is preferable that the opening direction of the recessed part 8 is a downward direction. However, the opening direction of the recessed part 8 may be upward or lateral. As shown in FIG. 3A, at the outer peripheral end of the inner cylinder 7 of the recess 8, the recess 8 does not face straight in the radial direction of the inner cylinder 7 but is slightly inclined in the circumferential direction. As shown in FIG. 1, the depth of the recess 8 in the axial direction is about half of the axial length of the cylindrical portion of the inner cylinder 7. However, the axial depth of the recessed portion 8 may extend over substantially the entire axial length of the cylindrical portion of the inner cylinder 7. In this case, the opening of the recessed portion 8 is formed in a part of the circumferential surface of the inner cylinder 7 over almost the entire length of the cylindrical portion of the inner cylinder 7. Further, a guide tube 38 is connected to the outer peripheral end of the recess 8. The cross section of the guide tube 38 has a substantially ½ circular shape, is formed along the outer peripheral surface of the inner cylinder 7, and the outer peripheral surface of the inner cylinder 7 also forms part of the inner wall surface of the flow path. The guide tube 38 is formed on the outer peripheral surface of the inner cylinder 7 in the circumferential direction by about several centimeters. Therefore, the air that has flowed in the axial direction by the inlet pipe 3 is changed in the radial direction by the recessed portion 8 and further changed in the circumferential direction by the outer peripheral end portion of the inner cylinder 7 of the recessed portion 8. At 38, it can be changed in the circumferential direction. Moreover, it is preferable that the recessed part 8 does not have an unevenness | corrugation, and is formed in a curved surface. Thereby, air can be sufficiently swirled while suppressing pressure loss. The guide tube 38 may not be provided. An outer extension 34 extending toward the outer cylinder 6 is formed on the outer periphery of the other axial end surface (rear end face) of the inner cylinder 7. That is, as shown in FIG. 3A, the other axial end surface (rear side end surface) of the inner cylinder 7 has an annular shape with the inner side of the inner cylinder 7 opened.

図3(A)に示すように、外延部34の円周方向の一部は、開口している。この開口によって、内筒7外の空気が、塵埃収容部5に流入することができる。内筒7は、菌の繁殖を抑制できるように、抗菌作用のある金属(例えば、銀,銅)や抗菌物質(例えば、銀,銅)を含有するあるいは塗布された金属(例えば、ステンレス)で構成されるのが好ましい。ただし、内筒7は、円筒部分も含め樹脂で構成されてもよい。そして、図3(A)に示すように、外筒6の軸方向他端面から内筒7が軸方向へ挿入されることによって、外延部34の外周端が外筒6の内周に当接され、その結果、外筒6の軸方向他端面が閉塞される。使用者が外筒6と内筒7とを容易に分離可能なように、外筒6と内筒7とが連結される。内筒7の円周面に、複数の貫通孔33を備える。複数の貫通孔33によって、内筒7はフィルタ機能を有する。この貫通孔33によって、大きなごみが内筒7内へ流入することなく、内筒7外側から内筒7内側へ空気が流入することができる。吸込力にもよるが、1円玉以上の重さのごみは、外筒6内を吸い上げられることができず、外筒6内に残ることがある。使用者が外筒6と内筒7とを容易に分離可能なように、外筒6と内筒7とが連結することによって、使用者は、外筒6と内筒7とを容易に分離でき、外筒6内に堆積したごみを容易に排出でき、また、内筒7の貫通孔33にひっかかった髪の毛や糸くずを容易に除去することができる。

As shown in FIG. 3A, a part of the outer extending portion 34 in the circumferential direction is open. With this opening, air outside the inner cylinder 7 can flow into the dust container 5. The inner cylinder 7 is made of an antibacterial metal (for example, silver, copper) or an antibacterial substance (for example, silver, copper) or a coated metal (for example, stainless steel) so as to suppress the growth of bacteria. Preferably it is configured. However, the inner cylinder 7 may be comprised with resin also including a cylindrical part. Then, as shown in FIG. 3A, the outer cylinder 34 is inserted in the axial direction from the other axial end surface of the outer cylinder 6, so that the outer peripheral end of the outer extension 34 comes into contact with the inner periphery of the outer cylinder 6. As a result, the other axial end surface of the outer cylinder 6 is closed. The outer cylinder 6 and the inner cylinder 7 are connected so that the user can easily separate the outer cylinder 6 and the inner cylinder 7. A plurality of through holes 33 are provided on the circumferential surface of the inner cylinder 7. The inner cylinder 7 has a filter function by the plurality of through holes 33. The through-hole 33 allows air to flow from the outer side of the inner cylinder 7 to the inner side of the inner cylinder 7 without large dust flowing into the inner cylinder 7. Although it depends on the suction force, garbage having a weight of 1 yen or more cannot be sucked up in the outer cylinder 6 and may remain in the outer cylinder 6. By connecting the outer cylinder 6 and the inner cylinder 7 so that the user can easily separate the outer cylinder 6 and the inner cylinder 7, the user can easily separate the outer cylinder 6 and the inner cylinder 7 from each other. The dust accumulated in the outer cylinder 6 can be easily discharged, and the hair and lint caught in the through hole 33 of the inner cylinder 7 can be easily removed.

塵埃分離部4と塵埃収容部5との接続部の気密を保つために、内筒7の軸方向他端面に、パッキング9を備える。パッキング9は、外延部34に設けられるだけでなく、内筒7の軸方向にも突出している。よって、内筒7の内側は、完全な中空ではなく、パッキング9によって一部閉塞空間が存在する。さらに、パッキング9の内筒7の内側へ突出した部分に、内筒7の軸方向内側へ凹んだ凹み部39が形成される。凹み部39は把手の機能を有する。これにより、使用者が凹み部39に指を挿入して、塵埃分離部4あるいは内筒7を保持することができる。外延部34の上側の一部は、開口しており、前蓋11の外側流路35に連通する。つまり、外筒6の内側であって内筒7の円筒部分の外側が、前蓋11の外側流路35に連通する。図3(A)に示すように、外延部34の上側の一部の開口の円周方向の壁面は、円周方向に案内管38の開口に対向する側の壁面が高く、円周方向に案内管38の開口側の壁面が低いのが好ましい。例えば、塵埃分離部4を前方から見た場合に案内管38の開口方向が反時計回り方向だとすると、外延部34の上側の一部の開口の円周方向の壁面のうち左側の壁面が高く、右側の壁面が低い。つまり、外延部34の上側の一部が開口しているため、外延部34の円周方向は、内筒7の外周の一周分には満たないが、らせん状にずれている。よって、内筒7外の旋回流は、外延部34の上側の一部の開口の円周方向の高い壁面にぶつかって、スムーズに軸方向へ向きを変えることができ、旋回流に含まれる塵埃も塵埃収容部5へ流れやすくなる。一方、内筒7の内側は、前蓋11の内側流路36に連通する。

In order to keep the airtightness of the connecting portion between the dust separator 4 and the dust container 5, a packing 9 is provided on the other axial end surface of the inner cylinder 7. The packing 9 is not only provided on the outer extension 34, but also projects in the axial direction of the inner cylinder 7. Therefore, the inside of the inner cylinder 7 is not completely hollow, and a partially closed space exists due to the packing 9. Further, a recessed portion 39 that is recessed inward in the axial direction of the inner cylinder 7 is formed in a portion of the packing 9 that protrudes to the inner side of the inner cylinder 7. The recess 39 has a handle function. Thereby, the user can hold the dust separation part 4 or the inner cylinder 7 by inserting a finger into the recess 39. A part of the upper side of the extended portion 34 is open and communicates with the outer flow path 35 of the front lid 11. That is, the inside of the outer cylinder 6 and the outside of the cylindrical portion of the inner cylinder 7 communicates with the outer flow path 35 of the front lid 11. As shown in FIG. 3 (A), the circumferential wall surface of the opening on the upper side of the extended portion 34 has a high wall surface on the side facing the opening of the guide tube 38 in the circumferential direction. The wall surface on the opening side of the guide tube 38 is preferably low. For example, assuming that the opening direction of the guide tube 38 is the counterclockwise direction when the dust separation unit 4 is viewed from the front, the left wall surface is high among the circumferential wall surfaces of a part of the upper opening of the extension portion 34, The wall on the right side is low. That is, since a part of the upper side of the extended portion 34 is opened, the circumferential direction of the extended portion 34 is less than one round of the outer periphery of the inner cylinder 7 but is shifted in a spiral shape. Therefore, the swirling flow outside the inner cylinder 7 can collide with the wall surface in the circumferential direction of a part of the opening on the upper side of the extended portion 34 and can smoothly change the direction in the axial direction. Also easily flows to the dust container 5. On the other hand, the inner side of the inner cylinder 7 communicates with the inner flow path 36 of the front lid 11.

塵埃収容部5は、軸方向一端面(前側端面)と軸方向他端面(後側端面)とが開口し、横断面で略逆三角形状の中空のケース10を備える。ケース10の軸方向一端面は、開閉可能な前蓋11によって閉塞される。前蓋11の下端部に軸31を備え、軸31はケース10の下端部によって支持される。前蓋11は、軸31を支点としてケース10の軸方向に前後回動可能である。前蓋11の上端部のケース10側には、爪が突出している。一方、ケース10の前側上部に、使用者が押下することが可能なボタン17(レバーでもよい)を備え、ボタン17に、ケース10の前側に延びる伝達棒(ロッド)18が連結されている。伝達棒18の一端は、ボタン17に連結され、伝達棒18の他端は、爪状に形成されている。伝達棒18の他端の爪は、前蓋11の上端部の爪に係合可能である。ケース10に前蓋11が閉じられた状態では、伝達棒18の他端の爪と前蓋11の上端部の爪とが係合して、前蓋11が開くのを防止することができる。そして、使用者がボタン17を押下すると伝達棒18が前側へスライドして(上側に回動してもよい)、伝達棒18の他端の爪と前蓋11の上端部の爪との係合が解除され、重力によってケース10から前蓋11を開くことができる。把手16の形成方向が水平であるのに対して、ケース10の軸方向一端面(前蓋11部分に相当)の法線方向は、水平方向に対して45度〜50度傾斜している。つまり、使用者が把手16を握って塵埃収容部5を持ち上げた際には、ケース10の軸方向一端面(前蓋11部分に相当)は、下方向(重力作用方向)を向いている。よって、重力によってケース10から前蓋11が開くことができる。尚、後述するが、集塵かご(集塵容器)12が、バネ(弾性体)によってケース10の前側へ飛び出すように付勢されていれば、集塵かご12が前蓋11の後面を押すため、使用者がボタン17を押下すると、集塵かご12の押す力によってスムーズにケース10から前蓋11が開くこともできる。換言すると、集塵かご12の開口面が前蓋11の後面によって押さえ受けられることによって、集塵かご12がケース10内に収納され、その収納状態が維持される。

The dust container 5 is provided with a hollow case 10 having an axially one end face (front end face) and an axially other end face (rear end face) that are substantially inverted triangular in cross section. One end surface in the axial direction of the case 10 is closed by a front lid 11 that can be opened and closed. A shaft 31 is provided at the lower end of the front lid 11, and the shaft 31 is supported by the lower end of the case 10. The front lid 11 can be rotated back and forth in the axial direction of the case 10 with the shaft 31 as a fulcrum. A claw projects from the upper end portion of the front lid 11 on the case 10 side. On the other hand, a button 17 (which may be a lever) that can be pressed by the user is provided on the upper front side of the case 10, and a transmission rod (rod) 18 extending to the front side of the case 10 is connected to the button 17. One end of the transmission rod 18 is connected to the button 17, and the other end of the transmission rod 18 is formed in a claw shape. The claw at the other end of the transmission rod 18 can be engaged with the claw at the upper end of the front lid 11. When the front lid 11 is closed to the case 10, it is possible to prevent the front lid 11 from being opened by engaging the claw at the other end of the transmission rod 18 and the claw at the upper end of the front lid 11. When the user presses the button 17, the transmission rod 18 slides forward (may rotate upward), and the engagement between the other end of the transmission rod 18 and the upper end of the front lid 11 is engaged. The combination is released and the front lid 11 can be opened from the case 10 by gravity. While the handle 16 is formed in a horizontal direction, the normal direction of one end surface in the axial direction of the case 10 (corresponding to the front lid 11 portion) is inclined by 45 to 50 degrees with respect to the horizontal direction. That is, when the user holds the handle 16 and lifts the dust container 5, one end surface in the axial direction of the case 10 (corresponding to the front lid 11 portion) faces downward (the direction of gravity action). Therefore, the front lid 11 can be opened from the case 10 by gravity. As will be described later, if the dust collection basket (dust collection container) 12 is urged by a spring (elastic body) to jump out to the front side of the case 10, the dust collection basket 12 pushes the rear surface of the front lid 11. Therefore, when the user presses the button 17, the front lid 11 can be smoothly opened from the case 10 by the pressing force of the dust collecting basket 12. In other words, the dust collection basket 12 is stored in the case 10 by the opening surface of the dust collection basket 12 being held by the rear surface of the front lid 11, and the stored state is maintained.

ケース10の軸方向他端面は、開閉可能なフィルタ15によって閉塞される。フィルタ15の下端部に軸32を備え、軸32はケース10の下端部によって支持される。フィルタ15は、軸32を支点としてケース10の軸方向に前後回動可能である。フィルタ15は、断面形状が略四角形の枠体内にプリーツ状に折られたフィルタ部材79が形成される。図4(B)に示すように、フィルタ部材79の波方向は縦方向(重力作用方向)であるのが好ましい。フィルタ15は、例えば、高密度のHEPAフィルタ(High Efficiency Particulate Air Filter)である。HEPAフィルタとは、定格風量で粒径が0.3μmの粒子に対して99.97%以上の粒子捕集率をもち、かつ初期圧力損失が245Pa以下の性能を持つエアフィルタである。フィルタ15のケース10の反対側の面に、パッキング25を備えていてもよい。パッキング25によって、塵埃収容部5の軸方向他端面と掃除機本体1(特に吸気ダクト27入口)との気密を保持できる。尚、軸31と軸32は、共用されてもよい。また、軸32は、フィルタ15の下端部ではなく、フィルタ15の上端部に備えられてもよい。

The other axial end surface of the case 10 is closed by a filter 15 that can be opened and closed. A shaft 32 is provided at the lower end of the filter 15, and the shaft 32 is supported by the lower end of the case 10. The filter 15 can be rotated back and forth in the axial direction of the case 10 with the shaft 32 as a fulcrum. The filter 15 is formed with a filter member 79 folded in a pleat shape in a frame body having a substantially square cross-sectional shape. As shown in FIG. 4B, the wave direction of the filter member 79 is preferably the vertical direction (gravity acting direction). The filter 15 is, for example, a high-density HEPA filter (High Efficiency Particulate Air Filter). A HEPA filter is an air filter having a particle collection rate of 99.97% or more with respect to particles having a rated air volume of 0.3 μm and an initial pressure loss of 245 Pa or less. A packing 25 may be provided on the surface of the filter 15 opposite to the case 10. By the packing 25, the airtightness between the other axial end surface of the dust container 5 and the cleaner body 1 (particularly, the inlet of the intake duct 27) can be maintained. The shaft 31 and the shaft 32 may be shared. Further, the shaft 32 may be provided not at the lower end portion of the filter 15 but at the upper end portion of the filter 15.

ケース10に、集塵かご12を内包する。集塵かご12の形状は、一つの面が開口したかご形状,立体的形状,箱形状または容器形状であってもよいし、ちりとり形状であってもよい。つまり、集塵かご12は、開口と反対側に凹んだ形状を有する。集塵かご12の断面形状は、略四角形状であってもよいし、略円形状であってもよいし、略三角形状であってもよい。集塵かご12の断面形状は、開口面から底面へ向かって、小さくなるのが好ましい。これによって、塵埃が排出される側(開口側)に向かって断面積が拡がるため、使用者は、集塵かご12内に堆積した塵埃を容易に排出することができる。集塵かご12の形状は、枠体(支骨)によって形成される。集塵かご12の開口面以外の底面、上下左右面に、金属やナイロンなどで構成されたメッシュ部材が被覆または貼着されているのが好ましい。集塵かご12の底面だけでなく、上下左右面にも通気性を持たせることによって、集塵かご12の底面に塵埃が堆積しても流路を確保することができ、吸い込み空気の圧力損失を低減し、吸引力の低下を抑制することができる。このメッシュ部材は、通気性があり、塵埃を捕集するフィルタ機能を有する。通気性があり、塵埃を捕集するフィルタ機能を有するものであれば、メッシュ部材の代わりに使い捨てのティッシュペーパでもよいし、メッシュ部材とティッシュペーパとを組み合わせてもよい。例えば、メッシュ部材の上に使用者がティッシュペーパを装着してもよい。集塵かご12の開口面は、ケース10の軸方向一端面(前側端面)の開口面に一致する。つまり、集塵かご12の開口方向と、ケース10の軸方向一端面の開口方向とが同一である。そして、図6に示すように、集塵かご12の開口面の外周端の上側半分程度は、ケース10の軸方向一端面の内周面に当接し、集塵かご12の開口面の外周端の下側半分程度は、ケース10の軸方向一端面の内周面に当接していない。集塵かご12の下部に軸14を備える。軸14は、ケース10内に支持される。よって、集塵かご12は下部の軸14を支点として、ケース10の軸方向前後に回動可能である。これによって、塵埃収容部5から前蓋11が開かれた際に、重力によって塵埃収容部5から集塵かご12の一部が飛び出すことができる。ケース10に対する軸14の形成位置は、ケース10に対する軸31の形成位置と同じ側(下側)であるため、塵埃収容部5から前蓋11が開かれた際に、前蓋11によって阻害されることなく、塵埃収容部5から集塵かご12の一部が飛び出すことができる。さらに、軸14に、集塵かご12を前蓋11側に押し出す方向に弾性力が作用するつるまきバネを備えてもよい。これによって、塵埃収容部5から前蓋11が開かれた際に、バネの弾性力によって塵埃収容部5から集塵かご12の一部が勢いよく飛び出すことができ、使用者は、集塵かご12内に堆積した塵埃を容易に排出することができる。さらに、集塵かご12は、上下に2分割されており、つまり上半分の枠体(支骨)と下半分の枠体(支骨)という2つの構造物からなるのが好ましい。2分割された集塵かご12は、集塵かご12の底面の外側に形成された軸13によって連結される。よって、図4(A)に示すように、集塵かご12は、底面の中間を支点として、集塵かご12の開口面が上下に割れる。特に、集塵かご12の一部が塵埃収容部5から飛び出した際に、集塵かご12が上下に割れる。これによって、使用者は、集塵かご12内に堆積した塵埃をさらに容易に排出することができる。特に、集塵かご12の内面にへばりついた塵埃も容易にはがし落とすことができる。ただし、集塵かご12の上下2分割の構成は、必須ではない。また、上述したように、ケース10の前側は重力作用方向に対し40度〜45度傾いていることに加え、集塵かご12は塵埃収容部5から30度傾いて飛び出すため、集塵かご12内に堆積した塵埃を略重力方向に排出することができる。

A dust collecting basket 12 is enclosed in the case 10. The shape of the dust collecting basket 12 may be a cage shape with one surface opened, a three-dimensional shape, a box shape, a container shape, or a dustpan shape. That is, the dust collecting basket 12 has a shape recessed on the opposite side to the opening. The cross-sectional shape of the dust collecting basket 12 may be a substantially square shape, a substantially circular shape, or a substantially triangular shape. The cross-sectional shape of the dust collecting basket 12 is preferably smaller from the opening surface toward the bottom surface. As a result, the cross-sectional area increases toward the side (opening side) where the dust is discharged, so that the user can easily discharge the dust accumulated in the dust collecting basket 12. The shape of the dust collecting basket 12 is formed by a frame body (support frame). It is preferable that a mesh member made of metal, nylon, or the like is coated or adhered to the bottom surface of the dust collecting basket 12 other than the opening surface, the top, bottom, left and right surfaces. By providing air permeability not only on the bottom surface of the dust collecting basket 12 but also on the top, bottom, left and right surfaces, a flow path can be secured even if dust accumulates on the bottom surface of the dust collecting basket 12, and the pressure loss of the suction air Can be reduced, and a decrease in suction force can be suppressed. This mesh member is air permeable and has a filter function of collecting dust. A disposable tissue paper may be used instead of the mesh member, or a mesh member and a tissue paper may be combined as long as they are breathable and have a filter function for collecting dust. For example, the user may wear tissue paper on the mesh member. The opening surface of the dust collecting basket 12 coincides with the opening surface of one end surface (front end surface) in the axial direction of the case 10. That is, the opening direction of the dust collecting basket 12 and the opening direction of the one end surface in the axial direction of the case 10 are the same. As shown in FIG. 6, the upper half of the outer peripheral end of the opening surface of the dust collecting basket 12 abuts on the inner peripheral surface of one end surface in the axial direction of the case 10, and the outer peripheral end of the opening surface of the dust collecting basket 12 The lower half is not in contact with the inner peripheral surface of one end surface of the case 10 in the axial direction. A shaft 14 is provided at the bottom of the dust collecting basket 12. The shaft 14 is supported in the case 10. Therefore, the dust collecting basket 12 can be rotated back and forth in the axial direction of the case 10 with the lower shaft 14 as a fulcrum. Thereby, when the front lid 11 is opened from the dust container 5, a part of the dust collecting basket 12 can be ejected from the dust container 5 by gravity. Since the formation position of the shaft 14 with respect to the case 10 is on the same side (lower side) as the formation position of the shaft 31 with respect to the case 10, the front cover 11 is obstructed when the front cover 11 is opened from the dust container 5. A part of the dust collecting basket 12 can be ejected from the dust container 5 without any trouble. Further, the shaft 14 may be provided with a helical spring in which an elastic force acts in a direction in which the dust collecting basket 12 is pushed out to the front lid 11 side. As a result, when the front lid 11 is opened from the dust container 5, a part of the dust collection basket 12 can jump out of the dust container 5 vigorously by the elastic force of the spring. The dust accumulated in 12 can be easily discharged. Further, the dust collecting basket 12 is divided into two parts in the vertical direction, that is, it is preferably composed of two structures, that is, an upper half frame (support) and a lower half frame (support). The two divided dust collecting baskets 12 are connected by a shaft 13 formed outside the bottom surface of the dust collecting basket 12. Therefore, as shown in FIG. 4 (A), the dust collecting basket 12 has the opening surface of the dust collecting basket 12 split vertically, with the middle of the bottom as a fulcrum. In particular, when a part of the dust collection basket 12 jumps out of the dust container 5, the dust collection basket 12 breaks up and down. As a result, the user can more easily discharge the dust accumulated in the dust collecting basket 12. In particular, dust stuck to the inner surface of the dust collecting basket 12 can be easily removed. However, the upper and lower divided configuration of the dust collecting basket 12 is not essential. Further, as described above, in addition to the front side of the case 10 being inclined by 40 to 45 degrees with respect to the direction of gravity action, the dust collection basket 12 jumps out of the dust container 5 by 30 degrees, so that the dust collection basket 12 Dust accumulated inside can be discharged in the direction of gravity.

前蓋11内には、軸方向に貫通する外側流路35および内側流路36が形成される。そして、外側流路35は、前蓋11の上側に形成され、外側流路35の一端は塵埃分離部4の特に外筒6と内筒7の筒部の間にあたる外延部34の開口に連通し、外側流路35の他端はケース10の特に集塵かご12の開口に連通する。電気掃除機の停止時に、集塵かご12に堆積した塵埃が外側流路35および塵埃分離部4に逆流するのを防止するために、外側流路35の他端は集塵かご12の開口のうち半分よりも上側あるいは上端近傍に連通するのが好ましい。ただし、外側流路35の他端は、集塵かご12の開口の中央部に連通してもよい。さらに、電気掃除機の停止時に、集塵かご12に堆積した塵埃が外側流路35および塵埃分離部4に逆流するのを防止するために、外側流路35の内部または他端部に、外側流路35を覆う逆止弁(図示せず)を形成するのが好ましい。逆止弁は、上端を支点として、集塵かご12へ回動する。ただし、逆止弁は必須の構成ではない。外側流路35の断面積は、外側流路35の一端から他端へ向けて拡大している。外側流路35の形成方向は、外側流路35の一端から他端へ向けて前蓋11の外側から中心側へ向かう方向である。つまり、集塵かご12の外側から中心側へ向かう方向である。外側流路35から集塵かご12へ流入する空気の乱れを抑制するため、外側流路35の形成方向は、集塵かご12の外側流路35が連通する側の壁面(上側壁面)の方向であるのが好ましい。内側流路36は、前蓋11の中央から下側にかけて形成され、内側流路36の一端は塵埃分離部4の特に内筒7の軸方向他端開口(内筒7内)に連通し、内側流路36の他端はケース10の特に集塵かご12の外側に連通する。内側流路36の他端は、集塵かご12の外部下側に連通するのが好ましい。内側流路36は、外側流路35を避けて形成される。内側流路36の断面積は、外側流路35とは逆に、内側流路36の一端から他端へ向けて縮小している。

An outer channel 35 and an inner channel 36 penetrating in the axial direction are formed in the front lid 11. The outer flow path 35 is formed on the upper side of the front lid 11, and one end of the outer flow path 35 communicates with the opening of the extended part 34, particularly between the outer cylinder 6 and the inner cylinder 7 of the dust separation part 4. The other end of the outer flow path 35 communicates with the opening of the dust collecting basket 12 in the case 10. In order to prevent the dust accumulated in the dust collecting basket 12 from flowing back to the outer flow path 35 and the dust separation part 4 when the vacuum cleaner is stopped, the other end of the outer flow path 35 is the opening of the dust collecting basket 12. Of these, it is preferable to communicate with the upper half or near the upper end. However, the other end of the outer flow path 35 may communicate with the central portion of the opening of the dust collecting basket 12. Furthermore, in order to prevent the dust accumulated in the dust collecting basket 12 from flowing back to the outer flow path 35 and the dust separator 4 when the vacuum cleaner is stopped, A check valve (not shown) that covers the flow path 35 is preferably formed. The check valve rotates to the dust collecting basket 12 with the upper end as a fulcrum. However, the check valve is not an essential configuration. The cross-sectional area of the outer flow path 35 increases from one end of the outer flow path 35 toward the other end. The formation direction of the outer flow path 35 is a direction from the outer side of the front lid 11 toward the center side from one end of the outer flow path 35 to the other end. That is, the direction is from the outside of the dust collecting basket 12 toward the center side. In order to suppress the turbulence of the air flowing into the dust collecting basket 12 from the outer flow path 35, the outer flow path 35 is formed in the direction of the wall surface (upper wall surface) on the side where the outer flow path 35 of the dust collecting basket 12 communicates. Is preferred. The inner flow path 36 is formed from the center of the front lid 11 to the lower side, and one end of the inner flow path 36 communicates with the other end opening in the axial direction of the inner cylinder 7 (inside the inner cylinder 7) of the dust separator 4; The other end of the inner flow path 36 communicates with the case 10, particularly with the outside of the dust collecting basket 12. The other end of the inner flow path 36 is preferably in communication with the lower outside of the dust collecting basket 12. The inner flow path 36 is formed avoiding the outer flow path 35. Contrary to the outer flow path 35, the cross-sectional area of the inner flow path 36 is reduced from one end of the inner flow path 36 toward the other end.

塵埃収容部5の上部外側には、水平方向に延びる使用者が握ることが可能な把手16を備える。使用者は、この把手16を持って、塵埃収容部5を上方へ持ち上げ、塵埃分離部4を掃除機本体1に残したまま、塵埃収容部5のみを掃除機本体1から取り外すことができる。尚、塵埃分離部4と塵埃収容部5とを連結していれば、使用者は、この把手16を持って、塵埃収容部5を上方へ持ち上げれば、塵埃分離部4と塵埃収容部5とを一体として、つまり集塵装置2そのものを掃除機本体1から取り外すこともできる。図1に示すように、塵埃収容部5の軸方向他端面(フィルタ15部分に相当)の形成方向は、垂直面(重力作用方向)よりはケース10側に傾斜するのが好ましい。つまり、塵埃収容部5の軸方向他端面の上部よりも下部がケース10側に近いのが好ましい。また、図1に示すように、塵埃収容部5の軸方向一端面(前蓋11部分に相当)の形成方向は、垂直面(重力作用方向)よりはケース10側に40度〜45度程度傾斜している。つまり、塵埃収容部5の軸方向一端面の上部よりも下部がケース10側に近い。これによって、塵埃収容部5の軸方向一端面と軸方向他端面とは、垂直面(重力作用方向)を基準として、逆ハの字形状となる。これによって、使用者が塵埃収容部5を上方へ持ち上げる際に引っかかりが少なくなり、使用者は、塵埃収容部5を掃除機本体1から容易に取り外すことができる。そして、使用者は、塵埃収容部5の取り外し後に、凹み部39を持って、塵埃分離部4を上方または斜め上方へ持ち上げ、塵埃分離部4を掃除機本体1から容易に取り外すことができる。図1に示すように、塵埃分離部4の軸方向一端面(入口管3部分に相当)の形成方向は、垂直面(重力作用方向)よりは外筒6側に傾斜するのが好ましい。つまり、塵埃分離部4の軸方向他端面の上部よりも下部が外筒6側に近いのが好ましい。これによって、使用者が塵埃分離部4を上方または斜め上方へ持ち上げる際に引っかかりが少なくなり、使用者は、塵埃分離部4を掃除機本体1から容易に取り外すことができる。また、使用者が塵埃分離部4を取り外す場合だけでなく、塵埃分離部4と塵埃収容部5とを一体として、つまり集塵装置2そのものを掃除機本体1から取り外す際も、集塵装置2の軸方向一端面と軸方向他端面とは、垂直面(重力作用方向)を基準として、逆ハの字形状となるため、集塵装置2を上方へ持ち上げる際に引っかかりが少なくなり、使用者は、集塵装置2を掃除機本体1から容易に取り外すことができる。

A handle 16 that can be gripped by a user extending in the horizontal direction is provided on the outside of the upper portion of the dust container 5. The user can hold the handle 16, lift the dust container 5 upward, and remove only the dust container 5 from the cleaner body 1 while leaving the dust separator 4 in the cleaner body 1. In addition, if the dust separation part 4 and the dust storage part 5 are connected, if the user holds the handle 16 and lifts the dust storage part 5 upward, the dust separation part 4 and the dust storage part 5 will be described. And, that is, the dust collector 2 itself can be removed from the cleaner body 1. As shown in FIG. 1, the axial direction other end surface (corresponding to the filter 15 portion) of the dust container 5 is preferably inclined toward the case 10 than the vertical surface (gravity acting direction). That is, it is preferable that the lower part is closer to the case 10 side than the upper part of the other axial end surface of the dust container 5. Moreover, as shown in FIG. 1, the formation direction of the axial direction one end surface (equivalent to front cover 11 part) of the dust accommodating part 5 is about 40 to 45 degrees on the case 10 side from the vertical surface (gravity acting direction). Inclined. That is, the lower part is closer to the case 10 side than the upper part of the one axial end surface of the dust container 5. As a result, the one end surface in the axial direction and the other end surface in the axial direction of the dust container 5 have an inverted C shape with respect to the vertical surface (gravity acting direction). Thereby, when a user lifts the dust accommodating part 5 upward, it becomes less caught, and the user can easily remove the dust accommodating part 5 from the cleaner body 1. Then, the user can easily remove the dust separator 4 from the cleaner body 1 by holding the recess 39 and lifting the dust separator 4 upward or obliquely upward after removing the dust container 5. As shown in FIG. 1, it is preferable that the axial direction one end surface (corresponding to the inlet pipe 3 portion) of the dust separating portion 4 is inclined toward the outer cylinder 6 rather than the vertical surface (gravity acting direction). That is, it is preferable that the lower part is closer to the outer cylinder 6 side than the upper part of the other axial end surface of the dust separator 4. As a result, when the user lifts the dust separator 4 upward or obliquely upward, there is less catching, and the user can easily remove the dust separator 4 from the cleaner body 1. Further, not only when the user removes the dust separator 4, but also when the dust separator 4 and the dust container 5 are integrated, that is, when the dust collector 2 itself is removed from the cleaner body 1. Since the one end surface in the axial direction and the other end surface in the axial direction have an inverted C shape with respect to the vertical surface (the direction of gravity action), the user is less likely to be caught when lifting the dust collector 2 upward. Can easily remove the dust collector 2 from the cleaner body 1.

本体吸気口21には、ホース継手管20が挿入され、ホース継手管20を保持可能である。本体吸気口21の一端に、パッキング22を備える。これによって、ホース継手管20と入口管3との気密を保持できる。掃除機本体1の前方下端(集塵装置2の下側)に、キャスタを支持するためのキャスタ支持部23を備える。掃除機本体1内の後方上側に、掃除機本体1の前後方向に延びる吸気ダクト27を備える。吸気ダクト27の延設方向一端の開口は、フィルタ15に対向する。吸気ダクト27の一端の開口付近に、補助フィルタ26を備える。これによって、集塵装置2外に残った塵埃を電動送風機28が吸い込むのを抑制することができる。吸気ダクト27の延設方向他端は閉塞されており、吸気ダクト27の延設方向他端近傍の下部、つまり、電動送風機28側が開口している。掃除機本体1の吸気ダクト27の一端の開口の上部に、フィルタ15に接触する位置に、フィルタ15に付着した塵埃を除去する除塵装置24を備える。除塵装置24は回転体の外周にらせん状のバネ(弾性体)を備える。除塵装置24はモータによってまたはコードリールの引き出しによって回転し、らせん状のバネがフィルタ15のフィルタ部材79を弾くことによって、フィルタ15に付着した塵埃を振るい落とす。上述したように、フィルタ15の波方向は縦方向のため、振るい落とされた塵埃は重力作用方向に落ちやすくなっている。フィルタ15から振るい落とされた塵埃は、ケース10内に堆積することとなる。これによって、フィルタ15の目詰まりを抑制し、空気の圧力損失の低下を抑制し、吸引力の低下を抑制することができる。掃除機本体1内の後方下側に、吸引力を発生する電動送風機28を備える。電動送風機28は、電動送風機28の吸込口が上方を向く縦置きで設置される。電動送風機28の下流側かつ電動送風機28よりも前側に、電動送風機28の排気口に連通する排気ダクト40を備える。さらに、排気ダクト40の下流側かつ排気ダクト40よりも前側に、排気ダクト40に連通するフィルタ29を備える。フィルタ29は、断面形状が略四角形の枠体78内にプリーツ状に折られたフィルタ部材79が形成される。フィルタ部材79の波方向は縦方向(重力作用方向)であるのが好ましい。フィルタ15は、例えば、高密度のULPAフィルタ(Ultra Low Penetration Air Filter)である。ULPAフィルタは、定格風量で粒径が0.15μmの粒子に対して99.9995%以上の粒子捕集率をもち、かつ初期圧力損失が245Pa以下の性能を持つエアフィルタであり、HEPAフィルタの粒子捕集効率よりも高い粒子捕集効率を有する。そして、掃除機本体1の後端面に、本体排気口30を備える。

A hose joint pipe 20 is inserted into the main body inlet 21 and can hold the hose joint pipe 20. A packing 22 is provided at one end of the main body inlet 21. Thereby, the airtightness of the hose joint pipe 20 and the inlet pipe 3 can be maintained. A caster support portion 23 for supporting casters is provided at the front lower end of the vacuum cleaner body 1 (below the dust collector 2). An intake duct 27 extending in the front-rear direction of the cleaner body 1 is provided on the upper rear side in the cleaner body 1. An opening at one end in the extending direction of the intake duct 27 faces the filter 15. An auxiliary filter 26 is provided near the opening at one end of the intake duct 27. Thereby, it is possible to suppress the electric blower 28 from sucking the dust remaining outside the dust collector 2. The other end in the extending direction of the intake duct 27 is closed, and the lower portion near the other end in the extending direction of the intake duct 27, that is, the electric blower 28 side is opened. A dust removing device 24 that removes dust adhering to the filter 15 is provided at a position in contact with the filter 15 at an upper portion of one end of the intake duct 27 of the cleaner body 1. The dust removing device 24 includes a spiral spring (elastic body) on the outer periphery of the rotating body. The dust removing device 24 is rotated by a motor or by pulling out a cord reel, and a spiral spring bounces the filter member 79 of the filter 15 to shake off dust attached to the filter 15. As described above, since the wave direction of the filter 15 is the vertical direction, the dust that has been shaken off easily falls in the direction of gravity. The dust shaken off from the filter 15 accumulates in the case 10. Accordingly, clogging of the filter 15 can be suppressed, a decrease in air pressure loss can be suppressed, and a decrease in suction force can be suppressed. An electric blower 28 that generates a suction force is provided on the lower rear side in the cleaner body 1. The electric blower 28 is installed vertically so that the suction port of the electric blower 28 faces upward. An exhaust duct 40 communicating with the exhaust port of the electric blower 28 is provided on the downstream side of the electric blower 28 and on the front side of the electric blower 28. Further, a filter 29 communicating with the exhaust duct 40 is provided on the downstream side of the exhaust duct 40 and on the front side of the exhaust duct 40. The filter 29 is formed with a filter member 79 folded in a pleat shape in a frame body 78 having a substantially square cross section. The wave direction of the filter member 79 is preferably the vertical direction (gravity acting direction). The filter 15 is, for example, a high-density ULPA filter (Ultra Low Penetration Air Filter). The ULPA filter is an air filter having a particle collection rate of 99.9995% or more for particles having a rated air volume of 0.15 μm and an initial pressure loss of 245 Pa or less. The particle collection efficiency is higher than the particle collection efficiency. And the main body exhaust port 30 is provided in the rear-end surface of the cleaner body 1. FIG.

次に、電気掃除機の動作時(使用時)の空気の流れを説明する。図1中の矢印は、空気の流れを示す。使用者が電気掃除機の電源をONにすると、電動送風機28が作動し、吸引力を発生する。ホース継手管20から吸い込まれた空気は、入口管3を通って、外筒6内に流入し、凹み部8にぶつかって半径方向に向きを変え、さらに、凹み部8の内筒7の外周端部でやや円周方向に向きを変え、さらに案内管38で円周方向に向きを変える。この結果、空気は、外筒6の軸心を中心として外筒6を旋回する。つまり、旋回流となる。空気の旋回に伴う遠心分離作用によって、空気に含まれる重い塵埃は旋回流の外側に集まる。空気に含まれる軽い塵埃は旋回流の外側だけでなく、内側にも残る。ただし、一般家庭での掃除において、塵埃の大部分は旋回流の外側に集まり、旋回流の内側にはあまり塵埃が残らない。内筒7外の空気は重い塵埃と共に、外側流路35を通って、集塵かご12へ流入する。塵埃は集塵かご12によって捕集され、堆積し、さらに吸引力によって圧縮される。塵埃は吸引力によって自動的に圧縮されるため、使用者の手を煩わすことなく、多くの塵埃を保持できる。空気は集塵かご12の底面および上下左右面を通過して、フィルタ15に到達する。一方、旋回流の内側空気は、内筒7の貫通孔33から内筒7内に流入する。貫通孔33よりも大きな塵埃は、貫通孔33を通過することができず、内筒7外に残る。内筒7内の空気は軽い塵埃および小さい塵埃と共に、内側流路36を通って、ケース10内で集塵かご12の外部下側へ流入し、フィルタ15に到達する。集塵かご12内を通過した空気と集塵かご12内を通過しなかった空気は、フィルタ15の手前で合流して、フィルタ15を通過する。よって、集塵かご12は、ケース10内を、外側流路35に連通する空間と内側流路36に連通する空間とに区画している(仕切っている)。あるいは、集塵かご12は、ケース10内を、外側流路35に連通する空間とフィルタ15に面している空間とに区画している(仕切っている)。フィルタ15では、軽い塵埃および小さい塵埃その他空気に含まれる塵埃が捕集される。フィルタ15を通過して塵埃をほとんど含まない空気は、補助フィルタを通過して吸気ダクト27に流入し、吸気ダクト27の下部の開口を通り電動送風機28の上部の吸込口から吸い込まれる。電動送風機28の側部の排出口から排出された空気は、排気ダクト40を通って、フィルタ29に到達し、フィルタ29によって残った塵埃が捕集される。フィルタ29を通過した空気は、電動送風機28の周りやコードリール室(図示せず)、掃除機本体1の下部のすき間などを通って、本体排気口30から掃除機本体1外部へ排出される。特に、フィルタ29は、空気清浄機に搭載されるフィルタと同程度またはそれ以上の集塵効率を有するため、掃除機本体1から外部へ排出される空気は、空気清浄機と同程度またはそれ以上に清浄化されている。 図2(A)に、本発明の実施例の集塵装置2の斜視図を示し、図2(B)に、本発明の実施例の集塵装置2の側面から見た断面図を示す。使用者は、把手16を握って集塵装置2を上方へ持ち上げることによって、掃除機本体1から集塵装置2を取り外すことができる。ただし、塵埃分離部4を掃除機本体1に残して、塵埃収容部5のみを掃除機本体1から取り外すようにしてもよい。図2(A)に示すように、軸方向から見た塵埃分離部4の断面の外形状は、略円形状である。塵埃収容部5の断面の外形状は、前蓋11の部分では略円形状であるが、前蓋11の部分以降では略四角形状であり、フィルタ15の部分でも略四角形状である。図2(B)に示すように、ケース10の軸方向一端の開口方向とケース10の軸方向他端の開口方向とは一直線上になく、45度〜50度程度異なる。つまり、塵埃収容部5の軸方向は、中間よりも少し前側で、曲がっている。上述したが、集塵装置2の軸方向一端面(入口管3の部分)は、わずかに下方向(重力作用方向)を向き、集塵装置2の軸方向他端面(フィルタ15の部分)も、わずかに下方向(重力作用方向)を向いており、集塵装置2の軸方向一端面と軸方向他端面とは、垂直面(重力作用方向)を基準として、逆ハの字形状となるため、集塵装置2を上方へ持ち上げる際に引っかかりが少なくなり、使用者は、集塵装置2を掃除機本体1から容易に取り外すことができる。

Next, the flow of air during operation (when in use) of the vacuum cleaner will be described. The arrows in FIG. 1 indicate the flow of air. When the user turns on the power of the vacuum cleaner, the electric blower 28 operates and generates a suction force. The air sucked from the hose joint pipe 20 flows into the outer cylinder 6 through the inlet pipe 3, hits the dent portion 8, changes its direction in the radial direction, and further, the outer periphery of the inner cylinder 7 of the dent portion 8. The direction is slightly changed in the circumferential direction at the end, and the direction is further changed in the circumferential direction by the guide tube 38. As a result, air turns around the outer cylinder 6 about the axis of the outer cylinder 6. That is, it becomes a swirl flow. The heavy dust contained in the air collects outside the swirling flow by the centrifugal separation action accompanying the swirling of the air. Light dust contained in the air remains not only outside the swirl but also inside. However, in general household cleaning, most of the dust collects outside the swirling flow, and much dust does not remain inside the swirling flow. The air outside the inner cylinder 7 flows into the dust collecting basket 12 through the outer flow path 35 together with heavy dust. The dust is collected by the dust collecting basket 12, accumulated, and further compressed by the suction force. Since the dust is automatically compressed by the suction force, a lot of dust can be held without bothering the user. The air passes through the bottom surface and the top, bottom, left and right surfaces of the dust collecting basket 12 and reaches the filter 15. On the other hand, the swirling inner air flows into the inner cylinder 7 from the through hole 33 of the inner cylinder 7. Dust larger than the through hole 33 cannot pass through the through hole 33 and remains outside the inner cylinder 7. The air in the inner cylinder 7 together with light dust and small dust flows through the inner flow path 36 and flows into the lower outside of the dust collecting basket 12 in the case 10 and reaches the filter 15. The air that has passed through the dust collecting basket 12 and the air that has not passed through the dust collecting basket 12 merge before the filter 15 and pass through the filter 15. Therefore, the dust collecting basket 12 partitions (partitions) the inside of the case 10 into a space communicating with the outer flow path 35 and a space communicating with the inner flow path 36. Alternatively, the dust collection basket 12 partitions (partitions) the inside of the case 10 into a space communicating with the outer flow path 35 and a space facing the filter 15. The filter 15 collects light dust, small dust, and other dust contained in the air. Air that passes through the filter 15 and contains almost no dust flows through the auxiliary filter, flows into the intake duct 27, passes through the opening at the lower portion of the intake duct 27, and is sucked from the suction port at the upper portion of the electric blower 28. The air discharged from the discharge port on the side of the electric blower 28 reaches the filter 29 through the exhaust duct 40, and the dust remaining by the filter 29 is collected. The air that has passed through the filter 29 passes through the electric blower 28, the cord reel chamber (not shown), the gap at the bottom of the cleaner body 1, and the like, and is discharged from the body exhaust port 30 to the outside of the cleaner body 1. . In particular, since the filter 29 has a dust collection efficiency equivalent to or higher than that of a filter mounted on the air cleaner, the air discharged from the cleaner body 1 to the outside is equivalent to or higher than that of the air cleaner. Has been cleaned. FIG. 2A shows a perspective view of the dust collector 2 of the embodiment of the present invention, and FIG. 2B shows a cross-sectional view seen from the side of the dust collector 2 of the embodiment of the present invention. The user can remove the dust collector 2 from the cleaner body 1 by holding the handle 16 and lifting the dust collector 2 upward. However, the dust separator 4 may be left in the cleaner body 1 and only the dust container 5 may be removed from the cleaner body 1. As shown in FIG. 2A, the outer shape of the cross section of the dust separation portion 4 viewed from the axial direction is a substantially circular shape. The outer shape of the cross section of the dust container 5 is substantially circular at the front lid 11, but is substantially square after the front lid 11, and is also substantially square at the filter 15. As shown in FIG. 2B, the opening direction at one axial end of the case 10 and the opening direction at the other axial end of the case 10 are not in a straight line and differ by about 45 to 50 degrees. That is, the axial direction of the dust container 5 is bent slightly forward from the middle. As described above, one end surface in the axial direction of the dust collector 2 (portion of the inlet pipe 3) faces slightly downward (the direction of gravity action), and the other end surface in the axial direction of the dust collector 2 (portion of the filter 15) is also , Slightly facing downward (gravity acting direction), one end surface in the axial direction and the other end surface in the axial direction of the dust collector 2 have an inverted C shape with respect to the vertical surface (gravity acting direction). Therefore, when the dust collector 2 is lifted upward, the amount of catch is reduced, and the user can easily remove the dust collector 2 from the cleaner body 1.

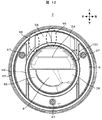

図3(A)に、本発明の実施例の内筒7および外筒6の斜視図を示し、図3(B)に、本発明の実施例の内筒7の裏側の斜視図を示す。外筒6の一端面は、入口管3の形成部分を除き、閉塞し、外筒6の他端面は、開口する。内筒7は、円筒部分の一端に、円環状の外延部34を有する。図3(A)に示すように、外筒6内に軸方向に内筒7の円筒部分から挿入されることによって、外筒6の他端面の外周端が外延部34の外周端に当接して、外筒6内に内筒7が形成される。図3(A)に示すように、入口管3の開口方向と凹み部8の開口とは対向している。凹み部8の内筒7の外周端部への開口方向は略下向きであり、案内管38の円周方向の開口方向は、反時計周りである。尚、案内管38の円周方向の開口方向は、時計周りであってもよい。そして、外延部34の上部に、軸方向に貫通する孔を備え、つまり外延部34の上部が開口している。開口の左壁面は、右壁面に比較して高くなっている。つまり、案内管38の円周方向の開口方向に対向する外延部34の上部の開口の壁面(左壁面)が他の壁面(右壁面)より高くなっている。そして、外延部34の表面はらせん状になっており、空気を外延部34の上部の開口に滑らかに導く流路の機能を有する。図3(B)に示すように、内筒7内の上側略半円部分に、内筒7の内側へ向かって凹み閉塞した凹み部39を備え、下側略半円部分は、内筒7内に開口している。集塵かご12に塵埃が堆積していない状態において内筒7内の空気の流量より内筒7外の空気の流量を多くする場合は、内筒7内の開口面積よりも外延部34上部の開口面積を大きくしてもよい。内筒7内への開口に比較して凹み部39の領域を多くしてもよいし、凹み部39に比較して内筒7内への開口の領域を多くしてもよい。そして、使用者は凹み部39に指を入れて、容易に塵埃分離部4あるいは内筒7を持つことができる。

3A shows a perspective view of the inner cylinder 7 and the outer cylinder 6 of the embodiment of the present invention, and FIG. 3B shows a perspective view of the back side of the inner cylinder 7 of the embodiment of the present invention. One end surface of the outer cylinder 6 is closed except for a portion where the inlet pipe 3 is formed, and the other end surface of the outer cylinder 6 is opened. The inner cylinder 7 has an annular extending portion 34 at one end of the cylindrical portion. As shown in FIG. 3A, the outer peripheral end of the other end surface of the outer cylinder 6 abuts on the outer peripheral end of the outer extension part 34 by being inserted into the outer cylinder 6 from the cylindrical portion of the inner cylinder 7 in the axial direction. Thus, the inner cylinder 7 is formed in the outer cylinder 6. As shown in FIG. 3A, the opening direction of the inlet pipe 3 and the opening of the recessed portion 8 are opposed to each other. The opening direction of the recess 8 toward the outer peripheral end of the inner cylinder 7 is substantially downward, and the opening direction of the guide tube 38 in the circumferential direction is counterclockwise. The circumferential opening direction of the guide tube 38 may be clockwise. And the hole penetrated to an axial direction is provided in the upper part of the outward extension part 34, ie, the upper part of the outward extension part 34 is opening. The left wall surface of the opening is higher than the right wall surface. That is, the wall surface (left wall surface) of the upper opening of the extension part 34 facing the opening direction in the circumferential direction of the guide tube 38 is higher than the other wall surface (right wall surface). The surface of the extended portion 34 is spiral, and has a function of a flow path that smoothly guides air to the opening above the extended portion 34. As shown in FIG. 3 (B), the upper substantially semicircular portion in the inner cylinder 7 is provided with a recessed portion 39 that is recessed toward the inner side of the inner cylinder 7, and the lower substantially semicircular portion is formed in the inner cylinder 7. Open in. When the flow rate of air outside the inner cylinder 7 is made larger than the flow rate of air inside the inner cylinder 7 in a state where dust is not accumulated in the dust collecting basket 12, the upper portion of the extended portion 34 is higher than the opening area inside the inner cylinder 7. The opening area may be increased. The area of the recessed portion 39 may be increased as compared with the opening into the inner cylinder 7, or the area of the opening into the inner cylinder 7 may be increased as compared with the recessed portion 39. Then, the user can easily hold the dust separation part 4 or the inner cylinder 7 by putting his / her finger into the recess 39.

内筒7の円筒部を抗菌効果のある金属材料で形成する場合は、先ず、金属の薄板に、直径0.1mm〜0.4mm程度の複数の貫通孔33をエッチング加工し、その後、両端を接合して円筒形状にする。貫通孔33はパンチング加工でもよい。抗菌効果のある金属材料として、例えば、ステンレス,銀,銅などがある。ステンレス,銀,銅に限らず、銀や銅を含むまたは銀や銅が表面析出した合金であればよい。金属の薄板の厚さは1mm以下であり、加工性を向上するには0.1mm〜0.5mm程度が好ましい。金属薄板の厚さが薄い場合には、強度や真円度を向上するために、円筒状の金属薄板の軸方向の両端を、成形性のよい樹脂で固定するのが好ましい。具体的には、凹み部8や案内管38を有する内筒7の略円形状の一端部の形状および円環状の外延部34を有する内筒7の他端部の形状が形成された形状に、円筒状の金属薄板をセットし、その後、型に樹脂を流し込むことによって、インサート成型する。インサート成型による場合、金属薄板は両端を接合して円筒形状にしなくてもよい。こうして、凹み部8や案内管38を有する内筒7の略円形状の一端部および円環状の外延部34を有する内筒7の他端部を樹脂で構成した、内筒7の円筒部分のみを金属材料で構成することができる。インサート成型によって、製造過程を簡素化できる。

When the cylindrical portion of the inner cylinder 7 is formed of a metal material having an antibacterial effect, first, a plurality of through-holes 33 having a diameter of about 0.1 mm to 0.4 mm are etched into a thin metal plate, and then both ends are formed. Join into a cylindrical shape. The through hole 33 may be punched. Examples of the metal material having an antibacterial effect include stainless steel, silver, and copper. The alloy is not limited to stainless steel, silver and copper, and may be any alloy containing silver or copper or having silver or copper surface-deposited. The thickness of the metal thin plate is 1 mm or less, and about 0.1 mm to 0.5 mm is preferable for improving workability. When the thickness of the metal thin plate is thin, it is preferable to fix both ends in the axial direction of the cylindrical metal thin plate with a resin having good moldability in order to improve the strength and roundness. Specifically, the shape of one end of the substantially circular shape of the inner cylinder 7 having the recess 8 and the guide tube 38 and the shape of the other end of the inner cylinder 7 having the annular outer extension 34 are formed. Then, a cylindrical metal thin plate is set, and then insert molding is performed by pouring resin into a mold. In the case of insert molding, the metal thin plate may not be formed into a cylindrical shape by joining both ends. Thus, only the cylindrical portion of the inner cylinder 7 in which the substantially circular one end portion of the inner cylinder 7 having the recessed portion 8 and the guide tube 38 and the other end portion of the inner cylinder 7 having the annular outer extending portion 34 are made of resin. Can be made of a metal material. Insert molding can simplify the manufacturing process.

図4(A)に、本発明の実施例の塵埃収容部5の前蓋11を開いた状態の斜視図を示し、図4(B)に、本発明の実施例の塵埃収容部5の後部フィルタを開いた状態の斜視図を示す。図4(A)に示すように、軸31を支点として前蓋11が下方向へ回動して開くと、軸14を支点として集塵かご12も下方向へ回動して飛び出す。この際に、集塵かご12は、軸13を支点として上下に2分割される。塵埃収容部5から飛び出した際の集塵かご12の開口は、塵埃収容部5内に収納されていた際の集塵かご12の開口に比較して拡がる。これによって、集塵かご12の内面にへばりついた塵埃を容易にはがし落とすことができる。尚、使用者が、集塵かご12の内面に沿ってティッシュペーパを装着した際には、ティッシュペーパの端を集塵かご12の開口部の枠体と前蓋11の外周端とで挟みこめば、ティッシュペーパがずれたり外れたりするのを抑制できる。図4(B)に示すように、軸32を支点としてフィルタ15も下方向へ回動して開く。これによって、使用者は、ケース10内で集塵かご12外部に堆積した塵埃を容易に排出することができ、さらに、フィルタ15のケース10側面に付着した塵埃も容易に除去することができる。

FIG. 4 (A) shows a perspective view of a state in which the front lid 11 of the dust container 5 of the embodiment of the present invention is opened, and FIG. 4 (B) shows the rear part of the dust container 5 of the embodiment of the present invention. The perspective view of the state which opened the filter is shown. As shown in FIG. 4A, when the front lid 11 is pivoted downward with the shaft 31 as a fulcrum, the dust collecting basket 12 is also pivoted downward with the shaft 14 as a fulcrum. At this time, the dust collecting basket 12 is divided into two parts up and down with the shaft 13 as a fulcrum. The opening of the dust collection basket 12 when it jumps out of the dust storage section 5 is wider than the opening of the dust collection basket 12 stored in the dust storage section 5. As a result, the dust stuck to the inner surface of the dust collecting basket 12 can be easily removed. When the user attaches the tissue paper along the inner surface of the dust collecting basket 12, the end of the tissue paper is sandwiched between the frame of the opening of the dust collecting basket 12 and the outer peripheral end of the front lid 11. In this case, the tissue paper can be prevented from shifting or coming off. As shown in FIG. 4B, the filter 15 is also rotated downward and opened with the shaft 32 as a fulcrum. As a result, the user can easily discharge the dust accumulated outside the dust collecting basket 12 in the case 10, and can easily remove the dust attached to the side surface of the case 10 of the filter 15.

図5(A)は、本発明の実施例の塵埃収容部5の前蓋11を塵埃収容部外側から見た正面図であり、図5(B)は、本発明の実施例の塵埃収容部5の前蓋11を塵埃収容部内側から見た正面図である。尚、図中の斜線部分は、断面ではなく、最も手前の表面を示している。前蓋11の下端に、ケース10に回動自在に支持される軸31を備える。前蓋11は、略円形状をしている。図5(A)に示す斜線部分の外側の略円部分は、塵埃分離部4の軸方向他端面の外周端に当接可能である。図5(A)に示す斜線部分の内側の略円部分は、塵埃分離部4の内筒7の軸方向他端面の外周端に当接可能である。前蓋11の上側つまり軸31と反対側で、斜線部分の外側の略円部分と内側の略円部分との間に、外側流路35の開口が形成される。外側流路35の表側(塵埃収容部5外側)の開口位置は、前蓋11の左右側や下側でもよいが、外側流路35の裏側(塵埃収容部5内側)の開口位置を前蓋11の上側とする場合は、外側流路35の長さを短くして空気の圧力損失を低減するために、外側流路35の表側の開口位置も、前蓋11の上側であるのが好ましい。一方、内筒7の内側に内側流路36の開口が形成される。図5(A)の正面図では、外側流路35の開口面積よりも内側流路36の開口面積のほうが大きいが、内筒7内の上側略半円部分は、凹み部39が形成されているので、内筒7内の空気の流量より内筒7外の空気の流量を多くする場合は、実質的な流路面積としては、外側流路35の開口面積よりも内側流路36の開口面積のほうが小さい。尚、斜線部分の外側の略円部分と内側の略円部分との間の外側流路35の開口が形成されていない部分は、閉塞されている。図5(B)に示す斜線部分の外側の略円部分は、ケース10の軸方向一端面の外周端および集塵かご12の開口の外周端の一部に当接する。図5(B)に示すように、前蓋11の上下方向中心線よりも上側に、外側流路35の開口が形成される。これによって、電気掃除機の停止時に、集塵かご12に堆積した塵埃が外側流路35および塵埃分離部4に逆流するのを防止することができる。ただし、前蓋11の上下方向中心線を含む中央部に、外側流路35の開口が形成されてもよい。さらに、外側流路35を覆う逆止弁(図示せず)を形成するのが好ましい。これによって、さらに、電気掃除機の停止時に、集塵かご12に堆積した塵埃が外側流路35および塵埃分離部4に逆流するのを防止することができる。一方、前蓋11の下端近傍に、内側流路36の開口が形成される。ただし、内側流路36の開口位置は、外側流路35の開口位置に対して、下側でもよいし、左右側または上側でもよい。尚、内側流路36の開口の上側の斜線部分は、集塵かご12の開口の外周端の下端に当接する。そして、図5(B)に示すように、前蓋11の裏側(塵埃収容部5の内側)では、内側流路36の開口面積よりも外側流路35の開口面積のほうが大きい。さらに、図5(A)と図5(B)に示すように、外側流路35の他端(裏側)の開口面積(図5(B))は、外側流路35の一端(表側)の開口面積(図5(A))よりも大きい。つまり、外側流路35は、一端から他端へ向かって拡がっている。一方、図5(A)と図5(B)に示すように、内側流路36の他端(裏側)の開口面積(図5(B))は、内側流路36の一端(表側)の開口面積(図5(A))よりも小さい。つまり、内側流路36は、一端から他端へ向かって狭まっている。

FIG. 5A is a front view of the front lid 11 of the dust container 5 according to the embodiment of the present invention as viewed from the outside of the dust container, and FIG. 5B is a dust container according to the embodiment of the present invention. It is the front view which looked at the front lid 11 of 5 from the dust accommodating part inner side. The hatched portion in the figure shows the frontmost surface, not the cross section. A shaft 31 that is rotatably supported by the case 10 is provided at the lower end of the front lid 11. The front lid 11 has a substantially circular shape. A substantially circular portion outside the shaded portion shown in FIG. 5A can contact the outer peripheral end of the other end surface in the axial direction of the dust separation portion 4. A substantially circular portion inside the hatched portion shown in FIG. 5A can contact the outer peripheral end of the other axial end surface of the inner cylinder 7 of the dust separating portion 4. On the upper side of the front lid 11, that is, on the side opposite to the shaft 31, an opening of the outer flow path 35 is formed between a substantially circular portion outside the shaded portion and a substantially circular portion inside. The opening position on the front side (outside of the dust container 5) of the outer channel 35 may be the left and right sides or the lower side of the front lid 11, but the opening position on the back side (inside the dust container 5) of the outer channel 35 is the front cover. 11, the opening position on the front side of the outer flow path 35 is also preferably above the front lid 11 in order to reduce the pressure loss of the air by reducing the length of the outer flow path 35. . On the other hand, an opening of the inner flow path 36 is formed inside the inner cylinder 7. In the front view of FIG. 5A, the opening area of the inner flow path 36 is larger than the opening area of the outer flow path 35, but the upper semicircular portion in the inner cylinder 7 has a recess 39. Therefore, when the flow rate of air outside the inner cylinder 7 is made larger than the flow rate of air inside the inner cylinder 7, the substantial flow path area is that the opening of the inner flow path 36 is larger than the opening area of the outer flow path 35. The area is smaller. A portion where the opening of the outer flow path 35 between the substantially circular portion outside the shaded portion and the inner substantially circular portion is not formed is closed. A substantially circular portion outside the shaded portion shown in FIG. 5B abuts on the outer peripheral end of the axial end surface of the case 10 and a part of the outer peripheral end of the opening of the dust collecting basket 12. As shown in FIG. 5B, the opening of the outer flow path 35 is formed above the vertical center line of the front lid 11. Thereby, when the vacuum cleaner is stopped, it is possible to prevent the dust accumulated in the dust collecting basket 12 from flowing back to the outer flow path 35 and the dust separator 4. However, the opening of the outer flow path 35 may be formed in the center portion including the vertical center line of the front lid 11. Furthermore, it is preferable to form a check valve (not shown) that covers the outer flow path 35. This further prevents the dust accumulated in the dust collecting basket 12 from flowing back to the outer flow path 35 and the dust separator 4 when the vacuum cleaner is stopped. On the other hand, an opening of the inner flow path 36 is formed near the lower end of the front lid 11. However, the opening position of the inner flow path 36 may be lower than the opening position of the outer flow path 35, or may be on the left or right side or the upper side. The hatched portion on the upper side of the opening of the inner flow path 36 contacts the lower end of the outer peripheral end of the opening of the dust collecting basket 12. Then, as shown in FIG. 5B, the opening area of the outer flow path 35 is larger than the opening area of the inner flow path 36 on the back side of the front lid 11 (inside the dust container 5). Furthermore, as shown in FIGS. 5A and 5B, the opening area (FIG. 5B) of the other end (back side) of the outer flow path 35 is equal to that of one end (front side) of the outer flow path 35. It is larger than the opening area (FIG. 5A). That is, the outer flow path 35 extends from one end to the other end. On the other hand, as shown in FIGS. 5 (A) and 5 (B), the opening area (FIG. 5 (B)) of the other end (back side) of the inner flow path 36 is equal to that of one end (front side) of the inner flow path 36. It is smaller than the opening area (FIG. 5A). That is, the inner flow path 36 is narrowed from one end to the other end.

図6に、本発明の実施例の塵埃収容部5の前蓋11を除いたときの塵埃分離部側から見た正面図を示す。尚、図5と同様に、図中の斜線部分は、断面ではなく、最も手前の表面を示している。略円形状の斜線部分は、前蓋11の外周端に当接する。図6に示すように、ケース10の軸方向一端面の開口の外周端は、集塵かご12の開口の外周端の一部に当接する。また、図6に示すように、ケース10の軸方向一端面の開口の80%以上は、集塵かご12の開口が占めている。そして、ケース10の開口の集塵かご12の開口以外の領域(残り20%程度以下)は、内側流路36の開口に対向し、内側流路36に連通する。

FIG. 6 shows a front view as seen from the dust separating portion side when the front lid 11 of the dust accommodating portion 5 of the embodiment of the present invention is removed. As in FIG. 5, the hatched portion in the figure indicates the frontmost surface, not the cross section. The substantially circular shaded portion is in contact with the outer peripheral end of the front lid 11. As shown in FIG. 6, the outer peripheral end of the opening on one end surface in the axial direction of the case 10 abuts a part of the outer peripheral end of the opening of the dust collecting basket 12. As shown in FIG. 6, 80% or more of the opening on one end surface in the axial direction of the case 10 is occupied by the opening of the dust collecting basket 12. A region other than the opening of the dust collection basket 12 in the opening of the case 10 (the remaining 20% or less) faces the opening of the inner flow path 36 and communicates with the inner flow path 36.

図7は、本発明の実施例の電気掃除機の概観図である。電気掃除機は、掃除機本体1以外に、吸口を有する吸込具50と、一端が吸込具50に連通し伸縮自在な継手管(延長管)51と、一端が継手管51の他端に連通し使用者が握る把手53や操作ボタン/スイッチを有する操作管52と、一端が操作管52の他端に連通し他端にホース継手管20が形成されるホース54とを備える。掃除機本体1の本体吸気口21にホース継手管20が挿入され、保持可能である。また、掃除機本体1の両側面に車輪55を備える。そして、使用者から操作ボタン/スイッチへの操作によって電気掃除機の電源がONされると、電動送風機28が作動して吸引力を発生する。吸込具50の吸口から吸い込まれた空気は、継手管51,操作管52,ホース54,ホース継手管20の順に通過して、掃除機本体1に流入する。

FIG. 7 is a schematic view of a vacuum cleaner according to an embodiment of the present invention. In addition to the vacuum cleaner main body 1, the vacuum cleaner includes a suction tool 50 having a suction port, one end communicating with the suction tool 50, a telescopic joint pipe (extension pipe) 51, and one end communicating with the other end of the joint pipe 51. An operation tube 52 having a handle 53 and an operation button / switch that are gripped by the user, and a hose 54 having one end communicating with the other end of the operation tube 52 and the other end forming the hose coupling tube 20 are provided. The hose joint pipe 20 is inserted into the main body inlet 21 of the cleaner body 1 and can be held. Further, wheels 55 are provided on both side surfaces of the cleaner body 1. And if the power supply of a vacuum cleaner is turned ON by operation to an operation button / switch from a user, the electric air blower 28 will act | operate and will generate | occur | produce suction | attraction force. The air sucked from the suction port of the suction tool 50 passes through the joint pipe 51, the operation pipe 52, the hose 54, and the hose joint pipe 20 in this order, and flows into the cleaner body 1.

図8は、本発明の実施例の掃除機本体1の斜視図である。掃除機本体1の上面の中央付近には、一端が掃除機本体1に回動可能に軸によって支持された集塵装置2用の上カバー56を備え、掃除機本体1の上面のカバー56よりも後側には、掃除機本体1に回動可能に軸によって支持され使用者が掃除機本体1を持ち上げるための把手37を備える。

FIG. 8 is a perspective view of the cleaner body 1 according to the embodiment of the present invention. In the vicinity of the center of the upper surface of the cleaner body 1, an upper cover 56 for the dust collector 2, one end of which is rotatably supported on the cleaner body 1 by a shaft, is provided. On the rear side, a handle 37 is provided that is rotatably supported by the vacuum cleaner main body 1 by a shaft so that the user can lift the vacuum cleaner main body 1.

本発明の実施例によれば、使用者の手を煩わせることなく塵埃を圧縮し、圧縮し堆積した塵埃を使用者が容易に排出し、さらに、吸引力の低下を抑制することができる。上カバー56は、閉じた状態で集塵装置2の把手16を覆う大きさおよび位置に形成されるのが好ましい。さらに、上カバー56は、掃除機本体1の作動中は開かないように、その回動がロックされる、または上カバー1が開いた場合掃除機本体1の作動が停止するのが好ましい。上カバー56により、掃除機本体1の作動中に使用者が集塵装置2を取り外すのを防止することができ、電気掃除機の安全性を向上することができる。

According to the embodiment of the present invention, dust can be compressed without bothering the user, the user can easily discharge the dust that has been compressed and accumulated, and a reduction in suction force can be suppressed. The upper cover 56 is preferably formed in a size and position that covers the handle 16 of the dust collector 2 in a closed state. Furthermore, it is preferable that the rotation of the upper cover 56 is locked so that the upper cover 56 does not open during the operation of the cleaner body 1 or the operation of the cleaner body 1 is stopped when the upper cover 1 is opened. The upper cover 56 can prevent the user from removing the dust collector 2 during the operation of the cleaner body 1 and can improve the safety of the vacuum cleaner.

実施例1の内筒7の詳細を、実施例2として説明する。

Details of the inner cylinder 7 of the first embodiment will be described as a second embodiment.

本発明の実施例2の電気掃除機は、集塵装置2が円周面に複数の貫通孔33を有する内筒7を内包し、内筒7の軸方向の一端が閉塞され、内筒7の軸方向の他端が開口して電動送風機28側へ連通し、内筒7の軸方向の一端が、集塵装置2の入口管3の出口側開口に対向した位置に形成される。そして、内筒7の軸方向の一端が、集塵装置2の入口管3から吸い込まれた空気を円周方向へ旋回させるよう構成されることを特徴とする。

In the vacuum cleaner according to the second embodiment of the present invention, the dust collector 2 includes the inner cylinder 7 having a plurality of through holes 33 on the circumferential surface, and one end in the axial direction of the inner cylinder 7 is closed. The other end in the axial direction is opened and communicated with the electric blower 28 side, and one end in the axial direction of the inner cylinder 7 is formed at a position facing the outlet side opening of the inlet pipe 3 of the dust collector 2. And the one end of the axial direction of the inner cylinder 7 is comprised so that the air suck | inhaled from the inlet tube 3 of the dust collector 2 may be rotated in the circumferential direction.

または、本発明の実施例2の電気掃除機は、内筒7の軸方向の一端の閉塞部が、集塵装置2の入口管3から吸い込まれた空気を円周方向へ旋回させる機能を持つ形状を有することを特徴とする。

Or the vacuum cleaner of Example 2 of this invention has the function in which the obstruction | occlusion part of the end of the axial direction of the inner cylinder 7 turns the air inhaled from the inlet pipe 3 of the dust collector 2 to the circumferential direction. It has a shape.

または、本発明の実施例2の電気掃除機は、内筒7の軸方向の一端の閉塞部が、内筒7の軸方向の内側へ凹んだ形状を有し(例えば、凹み部8)、凹んだ形状の一部は、内筒7の円周面に開口することを特徴とする。

Or the vacuum cleaner of Example 2 of this invention has the shape where the obstruction | occlusion part of the axial direction end of the inner cylinder 7 was dented inside the axial direction of the inner cylinder 7 (for example, the recessed part 8), A part of the recessed shape is characterized by opening in the circumferential surface of the inner cylinder 7.

そして、本発明の実施例2によれば、内筒7の一端に旋回機能を持たせることによって、幅を大きくすることなく集塵装置2の軸方向の長さを短くでき、電気掃除機をコンパクトにできる。

And according to Example 2 of this invention, by giving the turning function to the end of the inner cylinder 7, the axial length of the dust collector 2 can be shortened without increasing the width, and the vacuum cleaner can be Can be made compact.

図9は、本発明の実施例2の内筒7を円筒部分側から見た正面図である。内筒7の円筒部分は、中空の半円柱形状の円柱部分57と中空円錐台形状の円錐台部分58とから構成される。円柱部分57は、内筒7の円筒部分の先端側に位置し、円錐台部分58は、内筒7の円筒部分の根元側に位置する。円錐台部分58の根元は、外延部34の内周端に接合している。円錐台部分58によって、円柱部分57と外延部34との接合部がなだらかになり、空気の流れの剥離や乱流の発生を抑制し、吸い込んだ空気のエネルギー損失を低減し、また騒音も抑制できる。内筒7は、外延部34と案内管38(ガイド部材)と円柱部分57と円錐台部分58とが一体成形されるのが好ましい。円筒部分は、円柱部分57と円錐台部分58とから構成されるのではなく、円柱部分57のみまたは円錐台部分58のみで構成されてもよい。つまり、円柱部分57は円柱形状であってもよいし、円錐台形状であってもよい。

FIG. 9 is a front view of the inner cylinder 7 according to the second embodiment of the present invention as viewed from the cylindrical portion side. The cylindrical portion of the inner cylinder 7 includes a hollow semi-columnar column portion 57 and a hollow truncated cone portion 58. The column portion 57 is located on the distal end side of the cylindrical portion of the inner cylinder 7, and the truncated cone portion 58 is located on the root side of the cylindrical portion of the inner cylinder 7. The base of the truncated cone part 58 is joined to the inner peripheral end of the outer extension 34. The frustoconical portion 58 gently smoothes the joint between the cylindrical portion 57 and the extension 34, suppresses air flow separation and turbulence, reduces the energy loss of the sucked air, and suppresses noise. it can. In the inner cylinder 7, it is preferable that the outer extending portion 34, the guide tube 38 (guide member), the columnar portion 57, and the truncated cone portion 58 are integrally formed. The cylindrical portion is not composed of the column portion 57 and the truncated cone portion 58 but may be composed of only the column portion 57 or only the truncated cone portion 58. That is, the columnar portion 57 may have a columnar shape or a truncated cone shape.

R1は円柱部分57の外形半径、R2は円錐台部分58の外形半径、R3は外延部34の外形半径、R4は案内管38の外形半径である。外延部34の外形は略真円である。円柱部分57の半円も、略真円である。外延部34と円柱部分57と円錐台部分58とは、同心軸上に形成され、R1<R2<R3の関係である。例えば、R1は3cm程度で、R2は5cm程度で、R3は、6.5cm程度である。案内管38の軸心は、円柱部分57の軸心に対して図9では左側にずれて位置し、R1<R4<R2の関係である。例えば、R4は4cm程度である。円柱部分57の円周方向の一端(図9の下側)は終端し、他端(図9の上側)は案内管38に接合する。案内管38の側壁は、円柱部分57の他端から案内管終端部59の手前に至るまで、曲率半径R4で半円形状になだらかに湾曲し、案内管終端部59の側壁でも、円柱部分57の外側で円柱部分57の外周に沿って(円錐台部分58の外周に沿って)なだらかに湾曲する。つまり、案内管38は、一端が凹み部8の開口に連結され、他端が円柱部分57の外側で円柱部分57の外周に沿った方向(円錐台部分58の外周に沿った方向)に向き、その間180°転向するように、略半円形状になだらかに湾曲する。凹み部8自身は、凹み部8の側壁から底部中心に向かって段差なく、なだらかに球状に形成されるのが好ましく、凹み部8から案内管38の接合部も、段差なく、なだらかに形成されるのが好ましい。これによって、吸い込んだ空気のエネルギー損失を低減し、また騒音も抑制できる。

R1 is the outer radius of the cylindrical portion 57, R2 is the outer radius of the truncated cone portion 58, R3 is the outer radius of the extension 34, and R4 is the outer radius of the guide tube 38. The outer shape of the extended portion 34 is a substantially perfect circle. The semicircle of the cylindrical portion 57 is also a substantially perfect circle. The extension part 34, the columnar part 57, and the truncated cone part 58 are formed on concentric axes and have a relationship of R1 <R2 <R3. For example, R1 is about 3 cm, R2 is about 5 cm, and R3 is about 6.5 cm. The axial center of the guide tube 38 is shifted to the left in FIG. 9 with respect to the axial center of the cylindrical portion 57, and has a relationship of R1 <R4 <R2. For example, R4 is about 4 cm. One end of the cylindrical portion 57 in the circumferential direction (lower side in FIG. 9) is terminated, and the other end (upper side in FIG. 9) is joined to the guide tube 38. The side wall of the guide tube 38 is gently curved in a semicircular shape with a radius of curvature R 4 from the other end of the column portion 57 to the front of the guide tube end portion 59. Is gently curved along the outer periphery of the cylindrical portion 57 (along the outer periphery of the truncated cone portion 58). That is, one end of the guide tube 38 is connected to the opening of the recessed portion 8, and the other end faces the direction along the outer periphery of the cylindrical portion 57 outside the cylindrical portion 57 (the direction along the outer periphery of the truncated cone portion 58). In the meantime, it is gently curved into a substantially semicircular shape so as to turn 180 °. The recess 8 itself is preferably formed in a gentle spherical shape with no step from the side wall of the recess 8 toward the center of the bottom, and the joint between the recess 8 and the guide tube 38 is also formed smoothly without a step. It is preferable. Thereby, the energy loss of the inhaled air can be reduced and noise can be suppressed.