JP5080463B2 - パッシブ制御バルブ - Google Patents

パッシブ制御バルブ Download PDFInfo

- Publication number

- JP5080463B2 JP5080463B2 JP2008519117A JP2008519117A JP5080463B2 JP 5080463 B2 JP5080463 B2 JP 5080463B2 JP 2008519117 A JP2008519117 A JP 2008519117A JP 2008519117 A JP2008519117 A JP 2008519117A JP 5080463 B2 JP5080463 B2 JP 5080463B2

- Authority

- JP

- Japan

- Prior art keywords

- control valve

- passive control

- gas

- container

- opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000000463 material Substances 0.000 claims description 10

- 230000007423 decrease Effects 0.000 claims description 8

- 238000004140 cleaning Methods 0.000 claims description 3

- 230000000149 penetrating effect Effects 0.000 claims 2

- 239000012530 fluid Substances 0.000 claims 1

- 239000000551 dentifrice Substances 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 229910001369 Brass Inorganic materials 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 239000010951 brass Substances 0.000 description 1

- 230000001680 brushing effect Effects 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 239000013013 elastic material Substances 0.000 description 1

- 210000002615 epidermis Anatomy 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 210000000434 stratum corneum Anatomy 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K15/00—Check valves

- F16K15/14—Check valves with flexible valve members

- F16K15/144—Check valves with flexible valve members the closure elements being fixed along all or a part of their periphery

- F16K15/147—Check valves with flexible valve members the closure elements being fixed along all or a part of their periphery the closure elements having specially formed slits or being of an elongated easily collapsible form

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/7722—Line condition change responsive valves

- Y10T137/7736—Consistency responsive

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Details Of Valves (AREA)

- Filling Or Discharging Of Gas Storage Vessels (AREA)

- Lift Valve (AREA)

- Check Valves (AREA)

- Safety Valves (AREA)

Description

Claims (8)

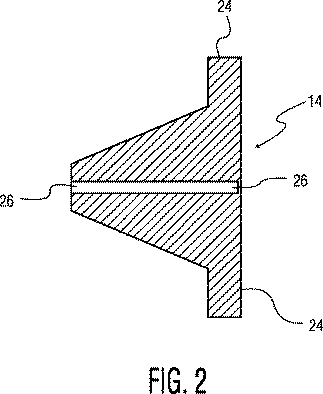

- 加圧気体容器に利用されるパッシブ制御バルブであって、

当該パッシブ制御バルブは、加圧容器からの気体の解放を制御する制御バルブを有し、

前記の解放された気体は、液滴を加速させるのに用いられ、

当該パッシブ制御バルブは、貫通する開口部を有するゴム製材料を有し、

前記開口部は、前記加圧容器からの流入口及び流出口を有し、

前記流入口と流出口との間には圧力差が存在し、

当該パッシブ制御バルブは、前記流入口での端部が狭く、かつ前記流出口での端部が広い切頭錐体形状を有し、

前記開口部は、前記加圧容器からの質量流が存在しないときには、当該パッシブ制御バルブの長さに沿って同一の断面積を有し、

当該パッシブ制御バルブは、制御された方法で、前記加圧容器から気体を逃がすことを可能にし、

前記ゴム製材料が有するショア硬度及び当該パッシブ制御バルブが有する配置は、当該パッシブ制御バルブを貫通する開口部のサイズ及び前記加圧容器中の気体圧力に対して、前記容器からの気体の質量流が、自然にほぼ一定となるように、前記圧力差が最初に直接内側に前記開口部を変形させることで、前記気体が前記容器から放出される際にサイズが増大する前記開口部の断面積を減少させる、

パッシブ制御バルブ。 - 前記気体が空気である、請求項1に記載のパッシブ制御バルブ。

- 前記ゴム製材料がゴムである、請求項1に記載のパッシブ制御バルブ。

- 当該バルブを貫通する前記開口部の断面積が、前記容器内の前記気体の圧力変化に十分に反比例することで、前記容器からの気体流がほぼ一定となるように、自然に変化する、請求項1に記載のパッシブ制御バルブ。

- 前記の面積変化に係る反比例パラメータが、0.9から1.1である、請求項4に記載のパッシブ制御バルブ。

- 前記反比例パラメータが、0.98から1.02である、請求項5に記載のパッシブ制御バルブ。

- 全体としての形状が切頭円錐であるパッシブ制御バルブであって、

前記開口部は当該パッシブ制御バルブのほぼ中心を貫通するように延び、かつ

前記ゴム製材料は、50のショア硬度を有する、

請求項1に記載のパッシブ制御バルブ。 - 前記加圧容器と共に、歯を洗浄する流体液滴システムの一部をなす、請求項1に記載のパッシブ制御バルブ。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US69565805P | 2005-06-30 | 2005-06-30 | |

| US60/695,658 | 2005-06-30 | ||

| PCT/IB2006/052213 WO2007004179A2 (en) | 2005-06-30 | 2006-06-30 | Passive control valve |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009500569A JP2009500569A (ja) | 2009-01-08 |

| JP5080463B2 true JP5080463B2 (ja) | 2012-11-21 |

Family

ID=37604867

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008519117A Expired - Fee Related JP5080463B2 (ja) | 2005-06-30 | 2006-06-30 | パッシブ制御バルブ |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20100116362A1 (ja) |

| EP (1) | EP1904774B1 (ja) |

| JP (1) | JP5080463B2 (ja) |

| CN (1) | CN101213393B (ja) |

| AT (1) | ATE521835T1 (ja) |

| WO (1) | WO2007004179A2 (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2954344B1 (fr) | 2009-12-17 | 2012-07-20 | Arjowiggins Security | Poudre pigmentaire a base de lanthanides. |

Family Cites Families (39)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2926686A (en) * | 1960-03-01 | gheen | ||

| US2721580A (en) * | 1950-11-06 | 1955-10-25 | Greer Hydraulics Inc | Bladder type pressure accumulator |

| US2764183A (en) * | 1951-08-13 | 1956-09-25 | Carroll T Gollehon | Flow control device |

| US2661764A (en) * | 1951-09-17 | 1953-12-08 | Johnson Axel | Automatic emergency valve control for air hoses and the like |

| US2775984A (en) * | 1953-10-30 | 1957-01-01 | Dole Valve Co | Flow control structure |

| US2781061A (en) * | 1954-01-08 | 1957-02-12 | Gen Motors Corp | Flow controller |

| US2981283A (en) * | 1954-11-02 | 1961-04-25 | Willetts | Automatic dump drain valve |

| US2816572A (en) * | 1955-01-17 | 1957-12-17 | Guardian Electric Mfg Co | Flow control device |

| US2910093A (en) * | 1955-05-19 | 1959-10-27 | Dole Valve Co | Side wall flow control |

| US2941544A (en) * | 1955-09-27 | 1960-06-21 | Renault | Fluid control devices and elastic pressure-responsive valves |

| US2839225A (en) * | 1956-06-18 | 1958-06-17 | Dev Res Inc | Dispenser valve providing controlled flow and quick gassing |

| US2878836A (en) * | 1957-05-13 | 1959-03-24 | Scovill Manufacturing Co | Two-piece flow control valve |

| US2939487A (en) * | 1957-08-21 | 1960-06-07 | Speakman Co | Flow control device |

| US2948300A (en) * | 1958-04-23 | 1960-08-09 | Speakman Co | Flow control unit |

| US3367363A (en) * | 1965-10-24 | 1968-02-06 | Allan C. Hoffman | Fluid flow control device |

| US3714964A (en) * | 1968-10-24 | 1973-02-06 | Factory Mutual Res Corp | Double rate flow controller |

| US3586040A (en) * | 1969-11-06 | 1971-06-22 | Machinery Co Const | Valve means |

| US3684013A (en) * | 1971-01-19 | 1972-08-15 | Brown Well Service & Supply Co | Well pipe string valve |

| US3703913A (en) * | 1971-08-02 | 1972-11-28 | Cvc Co | Automatic rate of flow control valve |

| US3901272A (en) * | 1974-01-04 | 1975-08-26 | Ford Motor Co | Unidirectional flow control valve |

| GB1494319A (en) * | 1974-04-19 | 1977-12-07 | Amalgamated Dental Co Ltd | Dental syringe |

| JPS57179686U (ja) * | 1981-05-09 | 1982-11-13 | ||

| CA1279042C (en) * | 1986-02-11 | 1991-01-15 | Bespak Plc | Gas pressurised dispensing containers |

| JPS63168374U (ja) * | 1987-04-24 | 1988-11-02 | ||

| DE3828811A1 (de) * | 1987-08-28 | 1989-03-09 | Raimund Andris | Dosier- und spraypumpe fuer fluessige und niederviskose stoffe |

| FR2669563B1 (fr) * | 1990-11-23 | 1993-01-08 | Micro Mega Sa | Dispositif de distribution des liquides pour un appareil de nettoyage, de desinfection et de lubrification des pieces a main de dentisterie. |

| WO1995015895A1 (fr) * | 1993-12-06 | 1995-06-15 | Charles Kaeser | Boite d'aerosol rechargeable a propulsion d'air |

| US5542845A (en) * | 1994-08-11 | 1996-08-06 | A.C. Hoffman Engineering, Inc. | Dental syringe safety sheath with modified duckbill valve |

| US5820373A (en) * | 1995-08-29 | 1998-10-13 | Koichi Okano | Cleaning device for periodontal pocket |

| US5878778A (en) * | 1997-10-09 | 1999-03-09 | The United States Of America As Represented By The Secretary Of The Navy | Elastomeric cut-off valve |

| US6378542B1 (en) * | 2000-07-21 | 2002-04-30 | Emerson Electric Co. | Flow control device having a lip seal and compressible bypass pads and associated method for operating an appliance water valve |

| CN2450474Y (zh) * | 2000-11-13 | 2001-09-26 | 陈建湘 | 全自动开闭阀 |

| US6651955B2 (en) * | 2001-07-30 | 2003-11-25 | Hewlett-Packard Development Company, L.P. | Elastomeric valve, and methods |

| US6688323B1 (en) * | 2002-02-26 | 2004-02-10 | Gaap Gas Controls Llc | Gas tank to pressure regulator coupling |

| DE20304172U1 (de) * | 2003-03-15 | 2004-07-29 | Neoperl Gmbh | Einbauteil zum Einsetzen in eine Gas- oder Flüssigkeitsleitung |

| DE20304170U1 (de) * | 2003-03-15 | 2004-07-29 | Neoperl Gmbh | Einbauteil zum Einsetzen in eine Gas- oder Flüssigkeitsleitung |

| EP1622813A4 (en) * | 2003-03-31 | 2009-12-30 | Nick J Manesis | MORE CAN LIQUID SUPPLY ARRANGEMENT |

| KR200325113Y1 (ko) * | 2003-06-16 | 2003-09-02 | 김춘일 | 점적호스용 수압조절밸브 |

| ES2554334T3 (es) * | 2004-01-20 | 2015-12-18 | Koninklijke Philips N.V. | Sistema de chorro de gotitas para limpiar dientes |

-

2006

- 2006-06-30 CN CN2006800236111A patent/CN101213393B/zh not_active Expired - Fee Related

- 2006-06-30 JP JP2008519117A patent/JP5080463B2/ja not_active Expired - Fee Related

- 2006-06-30 AT AT06765977T patent/ATE521835T1/de not_active IP Right Cessation

- 2006-06-30 EP EP20060765977 patent/EP1904774B1/en not_active Not-in-force

- 2006-06-30 WO PCT/IB2006/052213 patent/WO2007004179A2/en not_active Ceased

- 2006-06-30 US US11/993,754 patent/US20100116362A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| WO2007004179A2 (en) | 2007-01-11 |

| US20100116362A1 (en) | 2010-05-13 |

| JP2009500569A (ja) | 2009-01-08 |

| EP1904774B1 (en) | 2011-08-24 |

| WO2007004179A3 (en) | 2007-05-03 |

| ATE521835T1 (de) | 2011-09-15 |

| CN101213393B (zh) | 2010-10-13 |

| CN101213393A (zh) | 2008-07-02 |

| EP1904774A2 (en) | 2008-04-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8454360B2 (en) | Liquid droplet interproximal cleaning apparatus with gas stream protection | |

| JP4918045B2 (ja) | オーラルケアシステムにおける液滴生成のためのガスアシストシステム | |

| US9492244B2 (en) | Liquid jet apparatus and methods for dental treatments | |

| US8573974B2 (en) | Nozzle assembly for liquid droplet based interproximal cleaner | |

| EP2862816A3 (en) | A beverage cartridge | |

| EP1889586A3 (en) | Oral irrigator | |

| JP2012508636A5 (ja) | ||

| JPH02299652A (ja) | 亜歯肉薬剤アプリケーター | |

| WO2011007273A1 (en) | Atomized liquid oral cleaning appliance | |

| JP5080463B2 (ja) | パッシブ制御バルブ | |

| JP2008143345A (ja) | 船体摩擦抵抗低減装置 | |

| JP6829655B2 (ja) | 泡生成部、圧縮気体泡消火器及び圧縮気体泡消火システム | |

| WO2004065750A3 (en) | Multiple dispensing check valve delivery system | |

| KR20120135044A (ko) | 소화제 원액 저장 탱크 및 소화제 혼합 장치 | |

| US779164A (en) | Syringe. | |

| JP5240886B2 (ja) | 微細液滴発生器および微細液滴発生装置、並びに微細液滴発生方法 | |

| JP2008520507A (ja) | エアゾール容器又はスプレー容器用のある角度を成すスプレー流路を有するキャップ | |

| JP2007024421A (ja) | ミスト発生方法及びその装置 | |

| JP2011011699A (ja) | 船体における微細気泡発生装置 | |

| CN101340854A (zh) | 用于清洁液滴冲击区的液滴清洁设备的系统 | |

| EP3711821B1 (en) | Auto-regulating aperture for fire extinguisher discharge | |

| JP6190010B1 (ja) | ガス系消火設備の制御方法およびガス系消火システム | |

| SU1402354A1 (ru) | Порошковый огнетушитель | |

| US1091631A (en) | Sprinkler device for locomotives. | |

| US1048206A (en) | Air-flushing apparatus. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090629 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20111019 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111025 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120125 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20120228 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120627 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20120704 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120807 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120830 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150907 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |