JP4994101B2 - LED illumination lamp and lamp fixture using the LED illumination lamp - Google Patents

LED illumination lamp and lamp fixture using the LED illumination lamp Download PDFInfo

- Publication number

- JP4994101B2 JP4994101B2 JP2007121065A JP2007121065A JP4994101B2 JP 4994101 B2 JP4994101 B2 JP 4994101B2 JP 2007121065 A JP2007121065 A JP 2007121065A JP 2007121065 A JP2007121065 A JP 2007121065A JP 4994101 B2 JP4994101 B2 JP 4994101B2

- Authority

- JP

- Japan

- Prior art keywords

- led

- fluorescent lamp

- terminal

- resistor

- capacitor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Circuit Arrangement For Electric Light Sources In General (AREA)

- Arrangement Of Elements, Cooling, Sealing, Or The Like Of Lighting Devices (AREA)

Description

本発明は、発光ダイオード(以下、LEDと略す)を備えるLED照明灯及び該LED照明灯を用いた灯器具に関する。 The present invention relates to an LED illumination lamp including a light emitting diode (hereinafter abbreviated as LED) and a lamp fixture using the LED illumination lamp.

フィラメントの電極を有する蛍光ランプが使用される蛍光灯器具はグロースタータ式、ラピッドスタート式及びインバータ式に大別される。グロースタータ式においては点灯回路が、一般に安定器とグロースタータにより構成されている。電源が入った場合、前記安定器、一方のフィラメント、グロースタータ、他方のフィラメントの順に電流が流れ、両フィラメントが加熱される。次いで、グロースタータが動作し、前記回路が切れる。この際、蛍光ランプの両フィラメントの間に高い電圧(千数百ボルト)のパルス電圧が発生し、放電(蛍光ランプが点灯)する。この放電により流れる電流は、安定器により規制される。 Fluorescent lamp fixtures using fluorescent lamps having filament electrodes are roughly classified into a glow starter type, a rapid start type, and an inverter type. In the glow starter type, the lighting circuit is generally composed of a ballast and a glow starter. When the power is turned on, current flows in the order of the ballast, one filament, the glow starter, and the other filament, and both filaments are heated. The glow starter then operates and the circuit is turned off. At this time, a high voltage (thousands of volts) pulse voltage is generated between both filaments of the fluorescent lamp, and discharge (fluorescent lamp is lit). The current flowing by this discharge is regulated by the ballast.

ラピッドスタート式は、グロースタータがなくても蛍光ランプが始動(放電)できるよう点灯回路と蛍光ランプに工夫がされている。点灯回路には蛍光ランプの両フィラメントを加熱するための加熱電流を流す回路が設けられている。また、例えば、40形蛍光ランプでは両フィラメントの間に200V以上の電圧が供給されるように設計されている。電源が入った場合、両フィラメントが加熱(予熱)され、両フィラメントに200V以上の電圧が供給される。一方、ラピッドスタート式に対応する蛍光ランプは主にガラス管内面に導電性被膜を形成しているので、グロースタータ式より低い電圧で始動(放電)を開始することが出来る。 In the rapid start type, the lighting circuit and the fluorescent lamp are devised so that the fluorescent lamp can be started (discharged) without a glow starter. The lighting circuit is provided with a circuit for supplying a heating current for heating both filaments of the fluorescent lamp. For example, the 40-type fluorescent lamp is designed so that a voltage of 200 V or more is supplied between both filaments. When the power is turned on, both filaments are heated (preheated), and a voltage of 200 V or more is supplied to both filaments. On the other hand, since the fluorescent lamp corresponding to the rapid start type has a conductive film formed mainly on the inner surface of the glass tube, it can start (discharge) at a lower voltage than the glow starter type.

また、インバータ式は、商用の交流電源を整流及び平滑し、20000‐100000Hzの高周波の交流に変換して蛍光灯を点灯させるものである。従って、安定器の小型軽量化、電力損の低減、蛍光ランプの電極損失低下に伴う効率向上、光のフリッカ減少等の特徴を有することから、近年、その需要は増加している。また、メーカによって多少の違いはあるものの、前記フィラメントを流れる電流を検知し、前記電流値が一定以上の場合に光源へ電圧を印加するなどの制御を行う場合が多い。 The inverter type rectifies and smoothes a commercial AC power source, converts it into a high frequency AC of 20000-100000 Hz, and turns on a fluorescent lamp. Accordingly, the demand has been increasing in recent years because it has features such as reduction in the size and weight of the ballast, reduction in power loss, improvement in efficiency accompanying reduction in electrode loss in fluorescent lamps, and reduction in light flicker. In addition, although there are some differences depending on the manufacturer, in many cases, control is performed such as detecting the current flowing through the filament and applying a voltage to the light source when the current value is a certain value or more.

一方、青色LEDの開発により、青色LEDと、青色の光に励起され黄色に発光する蛍光体とから構成されるシングルチップ方式の白色LED、2色以上のLEDによる混光を利用するマルチチップ方式の白色LED等の白色LEDが商用化されている。最近は、小型、省電力というLEDの特徴から、特に照明の光源としてのLEDの使用が急増している。 On the other hand, with the development of blue LEDs, a single-chip white LED composed of a blue LED and a phosphor that emits yellow light when excited by blue light, a multi-chip method that utilizes mixed light of two or more LEDs White LEDs such as white LEDs have been commercialized. Recently, the use of LEDs as a light source for illumination has been increasing rapidly due to the characteristics of LEDs that are small and power-saving.

上述のようなLEDの照明への適用の一例としては、既存の蛍光ランプの外見を維持させ、既存の蛍光灯器具の活用を可能としたLED照明灯が挙げられる。 As an example of application of the LED as described above, there is an LED illumination lamp that maintains the appearance of an existing fluorescent lamp and enables the use of an existing fluorescent lamp apparatus.

このように既存の蛍光ランプに代えてLED照明灯を蛍光灯器具に備える場合は、既存の蛍光ランプにおいては放電のために必要であった口金のフィラメント、該フィラメントを加熱する加熱電流の回路(例えばグロースタータ)等が不要になり、口金の端子ピン対の内でグロースタータと接続される何れか一方の端子ピンも不要である。この場合、簡単に端子ピン対をショートしてLEDの光源へ接続する構成にしても良いが、端子ピン対をショートした場合、LEDの光源に印加される高電圧がグロースタータにもそのまま印加され、グロースタータの故障を招くうえ、以降の既存蛍光ランプの使用に支障をもたらすといった問題があった。 In this way, when an LED illumination lamp is provided in a fluorescent lamp fixture in place of an existing fluorescent lamp, a filament of a base that is necessary for discharge in the existing fluorescent lamp, and a heating current circuit for heating the filament ( For example, a glow starter is not necessary, and any terminal pin connected to the glow starter in the terminal pin pair of the base is not necessary. In this case, the terminal pin pair may be simply shorted and connected to the LED light source. However, when the terminal pin pair is shorted, the high voltage applied to the LED light source is also applied to the glow starter as it is. In addition to the failure of the glow starter, there were problems that would hinder the subsequent use of the existing fluorescent lamp.

このような問題に対し、例えば特許文献1では、蛍光ランプ点灯のためのフィラメントの加熱回路(電気要素)を備えた既存の蛍光灯器具に対応できる回路構成を有するLED照明装置を提案している。

For example,

また、蛍光ランプの端子ピン対の内、何れか一本のみが電源と接続されるが、何れの方が電源と接続されるのかがメーカによって異なるといった現状を考慮し、特許文献2では、何れか一方の口金にワイヤードOR回路を備えることにより、既存の蛍光灯器具のソケットへ取り付ける際、取り付け方向に影響されること無く安全に点灯するLED照光装置を提案している。

しかしながら、特許文献1のLED照明装置及び特許文献2のLED照光装置は、グロースタータ式蛍光灯器具及びラピッドスタート式蛍光灯器具には対応できるが、インバータ式蛍光灯器具に対応することが出来ない。

However, the LED illumination device of

つまり、特許文献1のLED照明装置はフィラメントがなく、端子ピン対の間が開いている状態であるので、インバータ式蛍光灯器具に使用された場合、前記フィラメントを流れる電流を検知することが出来ず、LED照明装置に印加されるべき電圧が印加されなくなる等の使用上の障害が生じるといった問題がある。

That is, since the LED lighting device of

また、特許文献2のLED照光装置においては、何れか一方の口金にのみワイヤードOR回路が設けられショートされているので、前記端子ピン間の電流検知はできるものの、口金の2つの端子ピンは夫々電源及び電子安定器と接続しているので、電源から蛍光灯互換LED照明管に印加される高電圧が電子安定器の前記加熱回路にもそのまま印加され、前記電子安定器の故障を招く虞があった。

Further, in the LED illumination device of

本発明は斯かる事情に鑑みてなされたものであり、その目的とするところは、グロースタータ式蛍光灯器具、インバータ式蛍光灯器具、ラピッドスタート式蛍光灯器具等の何れの蛍光灯器具に対しても支障が生じず、何れの蛍光灯器具にも対応することが出来るLED照明灯を提供することにある。 The present invention has been made in view of such circumstances, and the object of the present invention is to any fluorescent lamp apparatus such as a glow starter type fluorescent lamp apparatus, an inverter type fluorescent lamp apparatus, and a rapid start type fluorescent lamp apparatus. However, it is to provide an LED illumination lamp that does not cause any trouble and can be applied to any fluorescent lamp apparatus.

また、本発明の他の目的とするところは、グロースタータ式蛍光灯器具に対しては、フィラメントを加熱するための電気要素であるグロースタータへの電源からの大電流(過電流)の流入を防止し、インバータ式蛍光灯器具に対しては口金の2つの端子ピン間の電流検知を可能とし、ラピッドスタート式蛍光灯器具に対しても支障が生じず、何れの蛍光灯器具にも対応することが出来るLED照明灯を提供することにある。 In addition, another object of the present invention is that for a glow starter type fluorescent lamp fixture, an inflow of a large current (overcurrent) from a power source to a glow starter which is an electric element for heating a filament is performed. It can prevent current detection between the two terminal pins of the base for inverter type fluorescent lamp fixtures, and does not cause any trouble for rapid start type fluorescent lamp fixtures. It is in providing the LED lighting which can do.

さらに、本発明のもう一つの他の目的は、LEDのチラツキ減少及び、交流から直流への変換効率の向上を図ることが出来るLED照明灯を提供することにある。 Furthermore, another object of the present invention is to provide an LED illuminating lamp capable of reducing flickering of the LED and improving the conversion efficiency from AC to DC.

さらにまた、本発明のもう一つの他の目的は、上述のLED照明灯を備えた灯器具を提供することにある。 Still another object of the present invention is to provide a lamp fixture including the above-mentioned LED illumination lamp.

本発明に係るLED照明灯は、LEDを備えたLED照明灯において、グロースタータ式蛍光灯器具、インバータ式蛍光灯器具及びラピッドスタート式蛍光灯器具の何れに対しても使用可能とするためのインピーダンス素子を備え、前記インピーダンス素子は、インピーダンスの値が10Ωから100Ωの範囲に含まれることを特徴とする。 LED lighting according to the present invention, the LED lighting lamp having a L ED, glow starter type fluorescent lamp fixture, inverter type fluorescent lamp fixture and rapid start type to also be able to use for any of the fluorescent lamp fixture An impedance element is provided , and the impedance element has an impedance value in a range of 10Ω to 100Ω .

本発明に係るLED照明灯は、LEDを備えており、始動回路を有する蛍光灯器具に使用されるLED照明灯において、前記始動回路の短絡を防止するインピーダンス素子を備え、前記インピーダンス素子は、インピーダンスの値が10Ωから100Ωの範囲に含まれることを特徴とする。 LED lighting according to the present invention includes a LED, the LED lighting lamp used in fluorescent light fixtures that have a starting circuit includes an impedance element to prevent shorting of the starting circuit, said impedance element Is characterized in that the impedance value falls within the range of 10Ω to 100Ω .

本発明に係るLED照明灯は、一対の端子を有する2つの口金を介して電源に接続されるLEDを備えるLED照明灯において、各口金の一対の端子間に、インピーダンス素子を接続してあり、前記インピーダンス素子は、インピーダンスの値が10Ωから100Ωの範囲に含まれることを特徴とする。 LED lighting according to the present invention, the LED lighting lamp comprising a LED connected to the power supply via two die having a pair of terminals, between a pair of terminals of the mouthpiece, Ri tare connect the impedance element The impedance element includes an impedance value in a range of 10Ω to 100Ω .

本発明に係るLED照明灯は、フィラメントを加熱するための電気要素を備えた蛍光灯器具に使用され、電源及び前記電気要素に夫々接続される一対の端子を有する2つの口金並びに該口金を介して前記電源に接続されるLEDを備えるLED照明灯において、各口金の一対の端子間の接続を行い、かつ該接続によって前記電気要素に流れる電源からの電流を制限するインピーダンス素子を夫々備え、前記インピーダンス素子は、インピーダンスの値が10Ωから100Ωの範囲に含まれることを特徴とする。 The LED illuminating lamp according to the present invention is used in a fluorescent lamp apparatus having an electrical element for heating a filament, and includes a power source, two bases each having a pair of terminals connected to the electrical element, and the base. An LED illuminating lamp including an LED connected to the power source, each of which includes an impedance element that performs a connection between a pair of terminals of each base and restricts a current from the power source flowing through the electrical element by the connection , The impedance element is characterized in that an impedance value is included in a range of 10Ω to 100Ω .

本発明にあっては、グロースタータ式蛍光灯器具に使用された場合は、電源からの大電流(過電流)が前記インピーダンス素子によって制限されてからグロースタータへ供給され、グロースタータへの大電流(過電流)の供給が防止される。また、インバータ式蛍光灯器具に使用された場合は、口金の2つのピン間の電流が検知でき、前記LEDへの電圧の印加が正常に行われる。ラピッドスタート式蛍光灯器具に使用された場合は、電子安定器からの加熱のための電流が前記インピーダンス素子へ流れて消費されるだけでLEDの点灯等に支障を起こさない。 In the present invention, when used in a glow starter type fluorescent lamp apparatus, a large current (overcurrent) from a power source is limited by the impedance element and then supplied to the glow starter, and a large current to the glow starter Supply of (overcurrent) is prevented. Moreover, when used for an inverter type fluorescent lamp apparatus, the current between the two pins of the base can be detected, and the voltage is normally applied to the LED. When used in a rapid start type fluorescent lamp apparatus, the current for heating from the electronic ballast flows to the impedance element and is consumed, so that the lighting of the LED is not hindered.

本発明に係るLED照明灯は、前記インピーダンス素子は、インピーダンスの値が10Ω〜100Ωであることを特徴とする。 The LED illumination lamp according to the present invention is characterized in that the impedance element has an impedance value of 10Ω to 100Ω.

本発明にあっては、インピーダンスの値が10Ω〜100Ωであるインピーダンス素子を用いて各口金の一対の端子間を接続し、インピーダンスの値が高すぎる場合の電流検知の不能並びに、インピーダンス値が低すぎる場合のグロースタータ等のフィラメント加熱のための電気要素への大電流(過電流)の流入に備える。 In the present invention, an impedance element having an impedance value of 10Ω to 100Ω is used to connect between a pair of terminals of each base. When the impedance value is too high, the current cannot be detected and the impedance value is low. To prepare for inflow of a large current (overcurrent) to an electrical element for heating a filament such as a glow starter when it is too high.

本発明に係るLED照明灯は、前記一対の端子に並列接続する全波整流回路部を設けてあることを特徴とする。 The LED illuminating lamp according to the present invention is characterized in that a full-wave rectifier circuit portion connected in parallel to the pair of terminals is provided.

本発明にあっては、前記一対の端子に並列接続する前記全波電流回路部を設け、交流で点灯する場合よりLEDのチラツキを減少させると共に、交流から直流への変換効率を向上させる。 In the present invention, the full-wave current circuit unit connected in parallel to the pair of terminals is provided to reduce flickering of the LED and improve the conversion efficiency from alternating current to direct current as compared with the case of lighting with alternating current.

本発明に係るLED照明灯は、前記インピーダンス素子は、抵抗及びコンデンサを並列に接続してなることを特徴とする。

また、本発明に係るLED照明灯は、一面に前記LEDが取り付けられた基板を有する光源部と、該光源部を収容する保護筒と、前記基板の他面に設けられ、商用電源の交流を直流に変換して前記LEDに供給する回路部とを備えることを特徴とする。

The LED illumination lamp according to the present invention is characterized in that the impedance element is formed by connecting a resistor and a capacitor in parallel .

In addition, the LED illumination lamp according to the present invention is provided on the other surface of the light source unit having a substrate on which the LED is mounted on one surface, a protective cylinder that accommodates the light source unit, and provides AC power for a commercial power source And a circuit unit that converts the current into a direct current and supplies it to the LED.

本発明にあっては、前記抵抗又はコンデンサーを前記インピーダンス素子として使用することによって、グロースタータ式蛍光灯器具への使用の場合は、グロースタータへ供給される電源からの大電流(過電流)を前記抵抗又はコンデンサーに経由させて制限し、グロースタータを保護する。また、インバータ式蛍光灯器具への使用の場合は、前記抵抗又はコンデンサーに流れる電流を検知でき、前記LEDへの電圧の印加が正常に行われる。ラピッドスタート式蛍光灯器具に使用された場合は、電子安定器からの加熱のための電流が前記抵抗又はコンデンサーへ流れて消費されるだけであり、LEDの点灯等に支障を起こさない。 In the present invention, by using the resistor or the capacitor as the impedance element, a large current (overcurrent) from a power source supplied to the glow starter is used in the case of a glow starter type fluorescent lamp fixture. The glow starter is protected by limiting via the resistor or capacitor. In the case of use in an inverter type fluorescent lamp fixture, the current flowing through the resistor or the capacitor can be detected, and the voltage is normally applied to the LED. When used in a rapid start type fluorescent lamp fixture, the current for heating from the electronic ballast flows only to the resistor or the capacitor and is consumed, and does not hinder the lighting of the LED.

本発明に係る灯器具は、上述のいずれか一つのLED照明灯と、該LED照明灯に電力を供給する回路とを備えることを特徴とする。 A lamp fixture according to the present invention includes any one of the above-described LED illumination lamps and a circuit for supplying electric power to the LED illumination lamps.

本発明にあっては、前記回路を介して電源からの電力が前記LED照明灯に供給され、LED照明灯が点灯する。 In this invention, the electric power from a power supply is supplied to the said LED illumination light via the said circuit, and an LED illumination lamp lights.

本発明に係る灯器具は、グロースタータ式蛍光灯器具又はインバータ式蛍光灯器具若しくはラピッドスタート式蛍光灯器具のいずれか一つを備えることを特徴とする。 The lamp fixture according to the present invention includes any one of a glow starter type fluorescent lamp fixture, an inverter type fluorescent lamp fixture, or a rapid start type fluorescent lamp fixture.

本発明によれば、フィラメントを加熱するための電気要素を備える例えば、グロースタータ式蛍光灯器具、インバータ式蛍光灯器具、ラピッドスタート式蛍光灯器具等の何れの蛍光灯器具に対しても支障が生じず、何れの蛍光灯器具にも対応することが出来るLED照明灯を得ることができる。 According to the present invention, there is no problem for any fluorescent lamp apparatus including an electrical element for heating the filament, such as a glow starter type fluorescent lamp apparatus, an inverter type fluorescent lamp apparatus, and a rapid start type fluorescent lamp apparatus. It does not occur, and an LED illuminating lamp that can be applied to any fluorescent lamp fixture can be obtained.

本発明によれば、グロースタータ式蛍光灯器具に対しては、フィラメントを加熱するための電気要素であるグロースタータへの大電流(過電流)の流入を防止し、インバータ式蛍光灯器具に対しては口金の2つの端子ピン間の電流検知を可能とし、ラピッドスタート式蛍光灯器具に対しても支障が生じず、何れの蛍光灯器具にも対応することが出来る。 According to the present invention, for a glow starter type fluorescent lamp apparatus, a large current (overcurrent) is prevented from flowing into the glow starter, which is an electrical element for heating the filament. Therefore, it is possible to detect the current between the two terminal pins of the base, and there is no problem with the rapid start type fluorescent lamp apparatus, and any fluorescent lamp apparatus can be supported.

さらに、本発明によれば、前記一対の端子に並列接続する全波整流回路部を備えているので、LEDのチラツキが減少し、交流から直流への変換効率が向上する。 Further, according to the present invention, since the full-wave rectifier circuit unit connected in parallel to the pair of terminals is provided, the flicker of the LED is reduced, and the conversion efficiency from AC to DC is improved.

(実施の形態1)

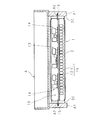

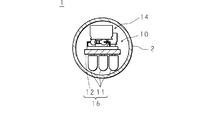

以下、本発明の実施の形態1に係るLED照明灯を天井に配設されたグロースタータ式蛍光灯器具に取り付けた場合を、本発明の実施の形態1に係る灯器具の例として詳述する。図1は本発明の実施の形態1に係るLED照明灯1が蛍光灯器具Aに取り付けられた状態を示す縦断面図であり、図2は本発明の実施の形態1に係るLED照明灯1の破断面図、図3は、図2のIII‐III 線による拡大断面図である。

(Embodiment 1)

Hereinafter, the case where the LED illumination lamp according to the first embodiment of the present invention is attached to a glow starter type fluorescent lamp fixture arranged on the ceiling will be described in detail as an example of the lamp fixture according to the first embodiment of the present invention. . FIG. 1 is a longitudinal sectional view showing a state in which an

実施の形態1に係るLED照明灯1は、円筒状をなす保護筒2と、保護筒2内に収容される光源部10と、保護筒2の両端を蓋する口金30,30とを備えている。保護筒2は乳白色のアクリル製であり、口金30,30はアルミニウム製である。

The

光源部10は、一面に複数の白色LED11,11,11,…が半田付けされている回路基板12とからなるLEDモジュール16を備えている。LEDモジュール16には白色LED11,11,11,…の直列回路が複数並列接続している。回路基板12は、各口金30,30の対向方向を長さ方向とする矩形をなしており、保護筒2の長さより少し短い長さ及び保護筒2の内径より小さい幅を有している。一方、天井と対向する回路基板12の他面には定電流回路13、全波整流器14,14を備えている。各口金30,30からの商用電源の交流を直流に変換する全波整流器14,14及び、全波整流器14,14と接続されて白色LED11,11,11,…に供給する電流を一定電流に制御する定電流回路13が接続されている。全波整流器14,14は後述の全波整流回路141a,141bを備えている。保護筒2の両端部は夫々先端に向けて縮径しており、口金30,30により覆われている。

The

口金30,30は保護筒2の端部に倣う円筒状をなしており、一端側に底を有して保護筒2の端部を夫々覆っている。口金30,30は、光源部10を商用電源に接続させるための2つの端子ピン対15,15を夫々備えている。端子ピン対15,15は保護筒2の内側から外側に向けて前記底を貫通しており、端子ピン対15,15の一端は後述の抵抗17a,17bを通じて全波整流器14,14と接続しており、全波整流器14,14は定電流回路13と接続している。端子ピン対15,15の他端は後述のソケット部A1,A1に接続されている。端子ピン対15,15の2つの端子の内、何れか一方はソケット部A1,A1を介してグロースタータ(図示せず)と接続しており、他方はソケット部A1,A1及び安定器(図示せず)を通じて商用電源と接続している。

The

蛍光灯器具Aは、口金30,30の端子ピン対15,15と接続するソケット部A1,A1を備えている。ソケット部A1,A1は端子ピン対15,15に対応する位置に、端子ピン対15,15が嵌合されるソケット側端子A2,A2を備えている。ソケット側端子A2,A2は、端子ピン対15,15に倣う形状の電気的及び機械的接続のための嵌合穴である。

The fluorescent lamp fixture A includes socket portions A1 and A1 that are connected to the terminal pin pairs 15 and 15 of the

図4は実施の形態1に係るLED照明灯1がグロースタータ式蛍光灯器具に取り付けられた場合の概略回路図である。図中一点鎖線により囲まれた部分は実施の形態1に係るLED照明灯1を示す。

FIG. 4 is a schematic circuit diagram when the

実施の形態1に係るLED照明灯1は、LEDモジュール16、定電流回路13、第1全波整流器14a、第2全波整流器14b、第1抵抗17a、第2抵抗17b、第1口金30a、第2口金30bを備えている。第1端子ピン対15aの端子152a及び、第2端子ピン対15bの端子152bはグロースタータA3に接続されおり、端子151a及び端子151bは商用電源Pと接続しているが、第1口金30aの端子151aは安定器A4を通じて商用電源Pと接続している。実施の形態1に係るLED照明灯1のLEDモジュール16は、蛍光灯器具へ取り付ける際に取り付け方向に影響されずに点灯できるように、第1端子ピン対15a及び第2端子ピン対15bに対してOR回路を構成している。

The

第1口金30aの端子151a及び端子152aはインピーダンス素子としての例えば、10Ωのインピーダンスを有する第1抵抗17aにより接続されており、第1抵抗17aに第1全波整流器14aの入力側端子が接続されている。また、第2口金30bの端子151b及び端子152bも10Ωのインピーダンスを有する第2抵抗17bにより接続されており、第2抵抗17bに第2全波整流器14bの入力側端子が接続されている。第1全波整流器14aの出力側の正側端子には、定電流回路13を通じてLEDモジュール16のアノード側端子が接続されており、LEDモジュール16のカソード側端子は第2全波整流器14b出力側の負側端子に接続されている。第1全波整流器14a及び第2全波整流器14bの出力側の各正側端子は相互接続されており、該出力側の各負側端子も相互接続されている。

The terminal 151a and the terminal 152a of the

図5は、図4に係るLED照明灯1の具体的な例を示す回路図である。図5のLED照明灯1は、369個の白色LED11,11,11,…を備えるLEDモジュール16と、ヒューズ19(又は遮断・接合を繰り返すプロテクタ等)とを備えており、インピーダンス素子としての例えば、第1抵抗171a及び第1コンデンサー172a並びに第2抵抗171b及び第2コンデンサー172bを更に備えている。第1抵抗171a及び第1コンデンサー172a並びに第2抵抗171b及び第2コンデンサー172bのインピーダンスは夫々10Ωである。その他、図4と同一の部分には同一の符号を付し、その詳細な説明は省略する。

FIG. 5 is a circuit diagram showing a specific example of the

以下、図4に基づき、本発明の実施の形態1に係るLED照明灯1の点灯について説明する。スイッチ(図示せず)をオンにした場合、商用電源Pからの交流電流が安定器A4を通じて第1端子ピン対15aの端子151aに流れる。交流電流は端子151aを経由して第1全波整流器14aに流れ、第1全波整流器14aにて全波整流されて直流電流に変換される。変換された直流電流は定電流回路13に流れ、定電流回路13にて電流が適宜調整される。調整された電流はLEDモジュール16に流れ、白色LED11,11,11,…が白色に発光する。

Hereinafter, based on FIG. 4, lighting of the

一方、第1端子ピン対15aの端子151a及び端子152a並びに、第2端子ピン対15bの端子151b及び端子152bは、夫々第1抵抗17a及び第2抵抗17bを通じて相互接続されているので、端子151a又は端子151bに流入される商用電源Pからの大電流(過電流)は第1抵抗17a及び第2抵抗17bを通じて端子152a又は152bにも流れ、ひいては端子152a,152bと接続しているグロースタータA3に流れることとなる。つまり、商用電源Pからの大電流(過電流)が直接グロースタータA3に流れないで、第1抵抗17a及び第2抵抗17bを通じて流れることにより制限され、大電流(過電流)によるグロースタータA3の故障が未然に防止される。

On the other hand, the terminal 151a and the terminal 152a of the first

上述の実施の形態1においては、第1抵抗17a及び第2抵抗17bのインピーダンスが10Ωである場合を例として説明したがこれに限るものでなく、既存蛍光ランプのフィラメントのインピーダンスに近似する10Ωから100Ωまでの範囲のインピーダンスであれば良い。 In the first embodiment described above, the case where the impedance of the first resistor 17a and the second resistor 17b is 10Ω has been described as an example. However, the present invention is not limited to this, and from 10Ω that approximates the impedance of the filament of the existing fluorescent lamp. Any impedance in the range up to 100Ω may be used.

上述の実施の形態1においては、LED照明灯1をグロースタータ式蛍光灯器具に取り付ける場合を例として説明したが、これに限るものでない。例えば、ラピッドスタート式蛍光灯器具に取り付けられた場合は、電子安定器からの加熱電流が第1端子ピン対15aの何れかの端子に流れても、第2端子ピン対15bの何れかの端子に流れても、第1抵抗17a及び第2抵抗17bにて前記加熱電流が消費されるたけであり、LED照明灯は支障を起こすことなく点灯される。

In the first embodiment described above, the case where the

上述の実施の形態1においては、LED照明灯1をグロースタータ式蛍光灯器具に取り付ける場合を例として説明したがこれに限るものでない。例えば、インバータ式蛍光灯器具に取り付けられた場合は、第1端子ピン対15aの何れか一方の端子及び、第2端子ピン対15bの何れか一方の端子に流れる電子安定器からの加熱電流が、第1抵抗17a及び第2抵抗17bを通じて夫々他方の端子に流れる。従って、第1端子ピン対15a及び第2端子ピン対15bの何れに対しても、2つの端子の間の電流の検知が可能であり、電子安定器の放電電圧の印加が続けられ、LED照明灯が点灯される。

In

(実施の形態2)

以下、本発明の実施の形態2に係るLED照明灯1をインバータ式蛍光灯器具に取り付けた場合を、本発明の実施の形態2に係る灯器具の例として説明する。なお、実施の形態1と同一の部分については同一の符号を付している。

(Embodiment 2)

Hereinafter, the case where the

図6は実施の形態2に係るLED照明灯1がインバータ式蛍光灯器具に取り付けられた場合の概略回路図である。図中一点鎖線により囲まれた部分は実施の形態2に係るLED照明灯1を示す。

FIG. 6 is a schematic circuit diagram when the

実施の形態2に係るLED照明灯1は、LEDモジュール16、定電流回路13、第1全波整流器14a、第2全波整流器14b、第1抵抗171a、第2抵抗171b、第1コンデンサー172a、第2コンデンサー172b、第1口金30a及び第2口金30bを備えており、LEDモジュール16は第1端子ピン対15a及び第2端子ピン対15bに対してOR回路を構成している。

The

第1端子ピン対15aの端子151a及び端子152b並びに、第2端子ピン対15bの端子151b及び端子152bは共に電子安定器A5を通じて商用電源Pと接続している。インバータ式蛍光灯器具においては、電子安定器A5がフィラメントを加熱する加熱回路(図示せず)及び蛍光灯の放電のための電圧印加回路(図示せず)を共に備えているからである。また、インバータ式蛍光灯器具においては、電子安定器A5が、第1端子ピン対15a又は第2端子ピン対15bの何れか一方の2つの端子間の電流を検知し、一定以上である場合のみ放電のための電圧(以下、放電電圧)を印加し、一定以下である場合、つまりフィラメントが切れている場合は放電電圧の印加を中止する制御等を行っていた。

The

第1口金30aの端子151a及び152aには第1抵抗171a及び第1コンデンサー172aが並列接続されており、第1抵抗171a及び第1コンデンサー172aには、第1全波整流器14aの入力側端子が接続している。第1抵抗171a及び第1コンデンサー172aのインピーダンスは10Ωである。また、第2口金30bの端子151b及び152bも第2抵抗171b及び第2コンデンサー172bが並列接続されており、第2抵抗171b及び第2コンデンサー172bには、第2全波整流器14bの入力側端子が接続されている。第2抵抗171b及び第2コンデンサー172bのインピーダンスは10Ωである。第1全波整流器14aの出力側の正側端子には、定電流回路13を通じてLEDモジュール16のアノード側端子が接続されており、LEDモジュール16のカソード側端子は第2全波整流器14b出力側の負側端子に接続されている。第1全波整流器14a及び第2全波整流器14bの出力側の各正側端子は相互接続されており、該出力側の各負側端子も相互接続されている。

A

以下、本発明の実施の形態2に係るLED照明灯1の点灯について説明する。スイッチ(図示せず)をオンにした場合、電子安定器A5の働きにより、加熱のための加熱電流が第1端子ピン対15aの端子152a又は第2端子ピン対15bの端子152bに流れると共に、放電電圧が印加され、端子151a又は端子151bに流れる。端子151a又は端子151bを経由した交流電流は、第1全波整流器14a又は第2全波整流器14bに流れ、第1全波整流器14a又は第2全波整流器14bにて全波整流されて直流電流に変換される。変換された直流電流は定電流回路13に流れ、定電流回路13にて電流が適宜調整される。調整された電流はLEDモジュール16に流れ、白色LED11,11,11,…が白色に発光する。

Hereinafter, lighting of the

一方、第1端子ピン対15aの端子151a及び端子152aは、第1抵抗171a及び第1コンデンサー172aを通じて相互接続されており、第2端子ピン対15bの端子151b及び端子152bは、第2抵抗171b及び第2コンデンサー172bを通じて相互接続されている。例えば電子安定器A5から加熱電流が端子152a又は端子152b流れる場合、前記加熱電流は、第1抵抗171a及び第1コンデンサー172aを通じて或いは、第2抵抗171b及び第2コンデンサー172bを通じて、端子151a又は端子151bに流れ、ひいては端子151a及び端子151bを接続している電子安定器A5に流れることとなる。従って、第1端子ピン対15a及び第2端子ピン対15bの何れに対しても、2つの端子の間の電流の検知が可能である。この際、第1抵抗171a及び第1コンデンサー172a並びに、第2抵抗171b及び第2コンデンサー172bのインピーダンスは既存の蛍光灯のフィラメントに近似する10Ωであるので、電子安定器A5は放電電圧の印加を続ける。また、商用電源Pからの大電流(過電流)が直接電子安定器A5の加熱回路に流れないで、第1抵抗171a及び第1コンデンサー172a(又は第2抵抗171b及び第2コンデンサー172b)を通じて流れることにより制限され、大電流(過電流)による電子安定器A5の加熱回路の故障が未然に防止される。

Meanwhile, the terminal 151a and the terminal 152a of the first

上述の実施の形態2においては、第1抵抗171a及び第1コンデンサー172a(又は第2抵抗171b及び第2コンデンサー172b)のインピーダンスが10Ωである場合を例として説明したがこれに限るものでなく、既存蛍光ランプのフィラメントのインピーダンスに近似する10Ωから、第1端子ピン対15aの端子151a及び端子152aの間或いは、第2端子ピン対15bの端子151b及び端子152bの間の電流検知が可能である100Ωまでの範囲のインピーダンスであれば良い。

In the second embodiment, the case where the impedance of the

また、実施の形態2においては、第1端子ピン対15a(又は第2端子ピン対15b)の間を、第1抵抗171a及び第1コンデンサー172a(又は第2抵抗171b及び第2コンデンサー172b)が並列に接続している場合を例として説明したが、これに限るものでなく、直列に設けても良い。

In the second embodiment, the

上述の実施の形態2においては、LED照明灯1をインバータ式蛍光灯器具に取り付ける場合を例として説明したがこれに限るものでない。例えば、ラピッドスタート式蛍光灯器具に取り付けられた場合は、電子安定器からの加熱電流が第1端子ピン対15aの何れかの端子に流れても、第2端子ピン対15bの何れかの端子に流れても、第1抵抗171a及び第1コンデンサー172a並びに、第2抵抗171b及び第2コンデンサー172bにて前記加熱電流が消費されるだけであり、LED照明灯は支障を起こすことなく点灯される。

In above-mentioned

上述の実施の形態2においては、LED照明灯1をインバータ式蛍光灯器具に取り付ける場合を例として説明したが、これに限るものでない。例えば、グロースタータ式蛍光灯器具に取り付けられた場合は、第1端子ピン対15aの何れかの一方の端子又は、第2端子ピン対15bの何れかの一方の端子に流れる商用電源Pからの大電流(過電流)が直接グロースタータに流れないで、第1抵抗171a及び第1コンデンサー172a或いは、第2抵抗171b及び第2コンデンサー172bを通じてグロースタータに流れることとなる。従って、第1抵抗171a及び第1コンデンサー172a或いは、第2抵抗171b及び第2コンデンサー172bにより大電流(過電流)が制限され、大電流(過電流)によるグロースタータの故障が未然に防止できる上、LED照明灯は支障を起こすことなく点灯される。

In above-mentioned

(実施の形態3)

以下、本発明の実施の形態3に係るLED照明灯をインバータ式蛍光灯器具に取り付けた場合を、本発明の実施の形態3に係る灯器具の例として説明する。なお、実施の形態1及び実施の形態2と同一の部分については同一の符号を付している。

(Embodiment 3)

Hereinafter, the case where the LED illumination lamp according to

図7は実施の形態3に係るLED照明灯1がインバータ式蛍光灯器具に取り付けられた場合の概略回路図である。図中一点鎖線により囲まれた部分は実施の形態3に係るLED照明灯1を示す。

FIG. 7 is a schematic circuit diagram when the

実施の形態3に係るLED照明灯1は、LEDモジュール16、定電流回路13、第1半波整流器18a、第2半波整流器18b、第1抵抗171a、第2抵抗171b、第1コンデンサー172a、第2コンデンサー172b、第1口金30a及び第2口金30bを備えている。第1半波整流器18a及び第2半波整流器18bには半波整流回路181a及び181bが夫々内装され、交流の半サイクルのみを使って直流を得る。

The

第1端子ピン対15aの端子151a及び端子152b並びに、第2端子ピン対15bの端子151b及び端子152bは共に電子安定器A5を通じて商用電源Pと接続している。第1口金30aの端子151a及び152aには第1抵抗171a及びコンデンサー172aが並列接続されており、第1抵抗171a及び第1コンデンサー172aには、第1半波整流器18aの入力側端子が接続している。第1抵抗171a及び第1コンデンサー172aのインピーダンスは10Ωである。また、第2口金30bの端子151b及び152bにも第2抵抗171b及び第2コンデンサー172bが並列接続されており、第2抵抗171b及び第2コンデンサー172bには、第2半波整流器18bの出力側端子が接続されている。第2抵抗171b及び第2コンデンサー172bのインピーダンスは10Ωである。第1半波整流器18aの出力側は、定電流回路13を通じてLEDモジュール16のアノード側端子が接続されており、LEDモジュール16のカソード側端子は第2半波整流器18bの入力側の端子に接続されている。

The

以下、本発明の実施の形態3に係るLED照明灯1の点灯について説明する。スイッチ(図示せず)をオンにした場合、電子安定器A5の働きにより、加熱のための加熱電流が第1端子ピン対15aの端子152aに流れると共に、放電電圧が印加される。端子151aを経由した商用電源Pからの交流電流は、第1半波整流器18aに流れ、第1半波整流器18aで半波整流されて直流電流に変換される。変換された直流電流は定電流回路13に流れ、定電流回路13にて電流が適宜調整される。調整された電流はLEDモジュール16に流れ、白色LED11,11,11,…が白色に発光する。以降、電流は第2半波整流器18b、端子151b及び152bに流れる。

Hereinafter, lighting of the

一方、第1端子ピン対15aの端子151a及び端子152aは、第1抵抗171a及び第1コンデンサー172aを通じて相互接続されており、第2端子ピン対15bの端子151b及び端子152bは、第2抵抗171b及び第2コンデンサー172bを通じて相互接続されている。例えば電子安定器A5から加熱電流が端子152a又は端子152b流れる場合、前記加熱電流は、第1抵抗171a及び第1コンデンサー172aを通じて或いは、第2抵抗171b及び第2コンデンサー172bを通じて、端子151a又は端子151bに流れ、ひいては端子151a及び端子151b接続している電子安定器A5に流れることとなる。従って、第1端子ピン対15a及び第2端子ピン対15bの何れに対しても、2つの端子の間の電流の検知が可能である。この際、第1抵抗171a及び第1コンデンサー172a並びに、第2抵抗171b及び第2コンデンサー172bのインピーダンスは既存の蛍光灯のフィラメントに近似する10Ωであり、電子安定器A5は放電電圧の印加を続ける。また、商用電源Pからの大電流(過電流)が直接電子安定器A5の加熱回路に流れないで、第1抵抗171a及び第1コンデンサー172a(又は第2抵抗171b及び第2コンデンサー172b)を通じて流れることにより制限され、大電流(過電流)による電子安定器A5の加熱回路の故障が未然に防止される。

Meanwhile, the terminal 151a and the terminal 152a of the first

上述の実施の形態3においては、第1抵抗171a及び第1コンデンサー172a(又は第2抵抗171b及び第2コンデンサー172b)のインピーダンスが10Ωである場合を例として説明したがこれに限るものでなく、既存蛍光ランプのフィラメントのインピーダンスに近似する10Ωから、第1端子ピン対15aの端子151a及び端子152aの間或いは、第2端子ピン対15bの端子151b及び端子152bの間の電流検知が可能である100Ωまでの範囲のインピーダンスであれば良い。

In the above-described third embodiment, the case where the impedance of the

また、実施の形態3においては、第1端子ピン対15a(又は第2端子ピン対15b)の間を、第1抵抗171a及び第1コンデンサー172a(又は第2抵抗171b及び第2コンデンサー172b)が並列に接続している場合を例として説明したが、これに限るものでなく、直列に設けても良い。

In the third embodiment, the

上述の実施の形態3においては、LED照明灯1をインバータ式蛍光灯器具に取り付ける場合を例として説明したが、これに限るものでない。例えば、ラピッドスタート式蛍光灯器具に取り付けられた場合は、電子安定器A5からの加熱電流が第1端子ピン対15aの何れかの端子に流れても、第2端子ピン対15bの何れかの端子に流れても、第1抵抗171a及び第1コンデンサー172a並びに、第2抵抗171b及び第2コンデンサー172bにて前記加熱電流が消費されるだけであり、LED照明灯は支障を起こすことなく点灯される。

In above-mentioned

上述の実施の形態3においては、LED照明灯1をインバータ式蛍光灯器具に取り付ける場合を例として説明したがこれに限るものでない。例えば、グロースタータ式蛍光灯器具に取り付けられた場合は、第1端子ピン対15aの何れかの一方の端子に流れる商用電源Pからの大電流(過電流)が直接グロースタータに流れないで、第1抵抗171a及び第1コンデンサー172aを通じてグロースタータに流れることとなる。従って、大電流(過電流)が第1抵抗171a及び第1コンデンサー172aにより制限され、大電流(過電流)によるグロースタータの故障が未然に防止できる上、LED照明灯は支障を起こすことなく点灯される。

In above-mentioned

上述の実施の形態1乃至3においては、インピーダンス素子として抵抗及びコンデンサーが用いられた場合を例として説明したが、これに限るものでなく、インピーダンス素子としてコイルを用いても良い。なお、抵抗、コンデンサー及びコイル夫々の単独使用であっても良く、インピーダンスの範囲が10Ω−100Ωであれば、これらを並列又は直列に接続した組み合わせであっても良い。 In the first to third embodiments described above, the case where a resistor and a capacitor are used as the impedance element has been described as an example. However, the present invention is not limited to this, and a coil may be used as the impedance element. In addition, each of a resistance, a capacitor | condenser, and a coil may be used individually, and if the impedance range is 10ohm-100ohm, the combination which connected these in parallel or in series may be sufficient.

1 LED照明灯

11 LED

15 端子ピン対

15a 第1端子ピン対

15b 第2端子ピン対

151a,152a,151b,152b 端子

17a 第1抵抗

17b 第2抵抗

171a 第1抵抗

172a 第1コンデンサー

171b 第2抵抗

172b 第2コンデンサー

14 全波整流器

14a 第1全波整流器

14b 第2全波整流器

141a,141b 全波整流回路

18a 第1半波整流器

18b 第2半波整流器

181a,181b 半波整流回路

30 口金

30a 第1口金

30b 第2口金

A 蛍光灯器具

A3 グロースタータ

A5 電子安定器

1

15

Claims (7)

グロースタータ式蛍光灯器具、インバータ式蛍光灯器具及びラピッドスタート式蛍光灯器具の何れに対しても使用可能とするためのインピーダンス素子を備え、

前記インピーダンス素子は、インピーダンスの値が10Ωから100Ωの範囲に含まれることを特徴とするLED照明灯。 In LED lighting with LED

It includes an impedance element for enabling use with any of a glow starter type fluorescent lamp fixture, an inverter type fluorescent fixture, and a rapid start type fluorescent fixture ,

The LED illumination lamp according to claim 1, wherein the impedance element includes an impedance value in a range of 10Ω to 100Ω .

前記始動回路の短絡を防止するインピーダンス素子を備え、

前記インピーダンス素子は、インピーダンスの値が10Ωから100Ωの範囲に含まれることを特徴とするLED照明灯。 In an LED illuminating lamp having an LED and used in a fluorescent lamp fixture having a starting circuit,

Comprising an impedance element for preventing a short circuit of the starting circuit ;

The LED illumination lamp according to claim 1, wherein the impedance element includes an impedance value in a range of 10Ω to 100Ω .

各口金の一対の端子間に、インピーダンス素子を接続してあり、

前記インピーダンス素子は、インピーダンスの値が10Ωから100Ωの範囲に含まれることを特徴とするLED照明灯。 In an LED illuminating lamp comprising an LED connected to a power source via two caps having a pair of terminals,

Between a pair of terminals of the mouthpiece, Ri tare connect the impedance element,

The LED illumination lamp according to claim 1, wherein the impedance element includes an impedance value in a range of 10Ω to 100Ω .

各口金の一対の端子間の接続を行い、かつ該接続によって前記電気要素に流れる電源からの電流を制限するインピーダンス素子を夫々備え、

前記インピーダンス素子は、インピーダンスの値が10Ωから100Ωの範囲に含まれることを特徴とするLED照明灯。 A fluorescent lamp apparatus having an electrical element for heating a filament, and a power source and two bases each having a pair of terminals connected to the electrical element, and an LED connected to the power source via the base. In the LED lighting with which

Each of the caps is provided with an impedance element for making a connection between a pair of terminals and limiting a current from a power source flowing through the electrical element by the connection ,

The LED illumination lamp according to claim 1, wherein the impedance element includes an impedance value in a range of 10Ω to 100Ω .

該光源部を収容する保護筒と、 A protective cylinder for housing the light source unit;

前記基板の他面に設けられ、商用電源の交流を直流に変換して前記LEDに供給する回路部とA circuit unit provided on the other surface of the substrate, which converts AC of commercial power to DC and supplies the LED to the LED;

を備えることを特徴とする請求項1から5のいずれか一つに記載のLED照明灯。The LED illumination lamp according to any one of claims 1 to 5, further comprising:

グロースタータ式蛍光灯器具、インバータ式蛍光灯器具又はラピッドスタート式蛍光灯器具のいずれか一つと

を備えることを特徴とする灯器具。 LED lighting according to any one of claims 1 to 6 ;

One of a glow starter type fluorescent lamp fixture, an inverter type fluorescent lamp fixture, and a rapid start type fluorescent lamp fixture.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007121065A JP4994101B2 (en) | 2007-05-01 | 2007-05-01 | LED illumination lamp and lamp fixture using the LED illumination lamp |

| PCT/JP2008/058194 WO2008136458A1 (en) | 2007-05-01 | 2008-04-28 | Illumination device and lamp using the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007121065A JP4994101B2 (en) | 2007-05-01 | 2007-05-01 | LED illumination lamp and lamp fixture using the LED illumination lamp |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008277188A JP2008277188A (en) | 2008-11-13 |

| JP2008277188A5 JP2008277188A5 (en) | 2009-12-03 |

| JP4994101B2 true JP4994101B2 (en) | 2012-08-08 |

Family

ID=40054897

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007121065A Expired - Fee Related JP4994101B2 (en) | 2007-05-01 | 2007-05-01 | LED illumination lamp and lamp fixture using the LED illumination lamp |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4994101B2 (en) |

Families Citing this family (39)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9253830B2 (en) | 2008-10-16 | 2016-02-02 | Kumho Electric, Inc. | LED fluorescent lamp |

| US9732915B2 (en) | 2008-10-16 | 2017-08-15 | Kumho Electric Inc. | LED fluorescent lamp |

| US8358056B2 (en) * | 2008-10-16 | 2013-01-22 | Kumho Electric Inc. | LED fluorescent lamp |

| US9078309B2 (en) | 2008-10-16 | 2015-07-07 | Kumho Electric Inc. | LED fluorescent lamp |

| EP2222134A3 (en) * | 2009-02-05 | 2015-12-30 | Myung Koo Park | LED fluorescent lamp |

| KR100933076B1 (en) * | 2009-02-05 | 2009-12-21 | 금호전기주식회사 | LED fluorescent lamp |

| JP5503164B2 (en) * | 2009-03-10 | 2014-05-28 | 東神電気株式会社 | Fluorescent lamp type LED lighting tube and fluorescent lamp type LED lighting apparatus equipped with the lighting tube |

| JP2011044316A (en) * | 2009-08-20 | 2011-03-03 | Panasonic Electric Works Co Ltd | Lighting deice |

| JP2011076919A (en) * | 2009-09-30 | 2011-04-14 | World Wide Engineering Kk | Led array lighting unit, and planar indirect lighting fixture using this unit |

| JP5437054B2 (en) * | 2009-12-25 | 2014-03-12 | 三菱電機照明株式会社 | LED lamp, LED lighting device, LED lamp lighting apparatus, and LED lighting system |

| JP2012004093A (en) * | 2010-05-15 | 2012-01-05 | Saka Techno Science Co Ltd | Straight tube type lighting system and manufacturing method |

| JP5732072B2 (en) * | 2010-11-17 | 2015-06-10 | アイリスオーヤマ株式会社 | LED lighting |

| WO2012070277A1 (en) * | 2010-11-25 | 2012-05-31 | アイリスオーヤマ株式会社 | Led illumination |

| CN102155647A (en) * | 2010-12-07 | 2011-08-17 | 刘昌贵 | LED (light emitting diode) fluorescent lamp and fluorescent lamp connecting circuit |

| CN102155648A (en) * | 2010-12-07 | 2011-08-17 | 刘昌贵 | LED (light-emitting diode) fluorescent lamp and fluorescent lamp connecting circuit |

| CN102155645B (en) * | 2010-12-07 | 2013-02-27 | 刘昌贵 | LED (light emitting diode) fluorescent lamp and fluorescent lamp connecting circuit |

| TW201251502A (en) * | 2011-06-08 | 2012-12-16 | Gio Optoelectronics Corp | Light emitting apparatus |

| JP5830986B2 (en) * | 2011-07-06 | 2015-12-09 | 株式会社リコー | Lighting control circuit, illumination lamp using the lighting control circuit, and luminaire using the illumination lamp |

| KR20130030712A (en) * | 2011-09-17 | 2013-03-27 | 이상범 | Power saving led lighting |

| CN103260290B (en) * | 2012-02-15 | 2015-04-08 | 杨振声 | LED fluorescent lamp and its circuit module |

| TWI401991B (en) * | 2012-07-17 | 2013-07-11 | Geometek Applic Engineering Co Ltd | Power transformation apparatus between dc lighting element and ballast |

| JP6007680B2 (en) | 2012-08-31 | 2016-10-12 | 株式会社リコー | Lighting control circuit, illumination lamp using the lighting control circuit, and control method of the lighting control circuit |

| JP6069993B2 (en) * | 2012-09-13 | 2017-02-01 | 株式会社リコー | Lighting |

| EP2907365B1 (en) | 2013-06-27 | 2016-09-21 | Philips Lighting Holding B.V. | Retrofit light emitting diode tube |

| EP3017657A1 (en) * | 2013-07-05 | 2016-05-11 | Koninklijke Philips N.V. | Connection circuit for connecting a driver device to an external power supply for driving a load, in particular an led unit |

| ES2625004T3 (en) * | 2013-07-30 | 2017-07-18 | Philips Lighting Holding B.V. | LED replacement lamp for safe operation with electromagnetic ballast |

| JP5871889B2 (en) * | 2013-12-11 | 2016-03-01 | 三菱電機照明株式会社 | LED lamp and LED lighting system |

| JP5855077B2 (en) * | 2013-12-11 | 2016-02-09 | 三菱電機照明株式会社 | LED lamp, LED lighting device, LED lamp lighting apparatus, and LED lighting system |

| JP6340878B2 (en) * | 2014-02-26 | 2018-06-13 | 株式会社リコー | Lighting lamp and lighting device |

| JP6432147B2 (en) * | 2014-02-26 | 2018-12-05 | 株式会社リコー | Illumination lamp and illumination device |

| KR200482510Y1 (en) * | 2014-03-24 | 2017-02-03 | 추앙, 밍-채 | Led lamp |

| DK3167225T3 (en) | 2014-07-08 | 2018-01-29 | Philips Lighting Holding Bv | LED TUBE |

| JP2016085813A (en) | 2014-10-23 | 2016-05-19 | 株式会社リコー | Lighting lamp and lighting device |

| JP2016212966A (en) * | 2015-04-30 | 2016-12-15 | 株式会社リコー | Lighting lamp, lighting device, and lighting control circuit |

| JP2017004611A (en) * | 2015-06-04 | 2017-01-05 | 株式会社リコー | Illumination lamp, illumination apparatus, lighting control circuit, and drive method for illumination lamp |

| JP2016029666A (en) * | 2015-10-27 | 2016-03-03 | 株式会社リコー | Lighting control circuit, floodlight using lighting control circuit, and lighting device using floodlight |

| JP6109915B2 (en) * | 2015-12-09 | 2017-04-05 | 三菱電機照明株式会社 | LED lighting device, LED lamp lighting apparatus, and LED lighting system |

| CN110140426B (en) * | 2017-01-03 | 2022-04-15 | 昕诺飞控股有限公司 | Modified light-emitting diode (LED) lamp tube for replacing fluorescent lamp tube |

| JP7117862B2 (en) * | 2018-02-23 | 2022-08-15 | 株式会社Mass | Construction method of LED light replacement work |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3965419B1 (en) * | 2006-08-23 | 2007-08-29 | 株式会社モモ・アライアンス | Lighting device |

| JP3972056B1 (en) * | 2006-10-24 | 2007-09-05 | 株式会社モモ・アライアンス | Lighting device |

-

2007

- 2007-05-01 JP JP2007121065A patent/JP4994101B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008277188A (en) | 2008-11-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4994101B2 (en) | LED illumination lamp and lamp fixture using the LED illumination lamp | |

| TWI645741B (en) | Straight tube led light | |

| JP6330431B2 (en) | Illumination lamp and illumination device | |

| KR100844538B1 (en) | LED lighting which can be used for fluorescent lamp socket with ballast | |

| CN102474958B (en) | Led turn-on circuit, lamp, and illumination apparatus | |

| CN102348314B (en) | LED lamp power supply unit and LED lamp system | |

| JP2010511971A (en) | LED lighting for fluorescent lamps with ballast | |

| JP5384964B2 (en) | LED lighting device | |

| CN100466878C (en) | Discharge lamp lighting device | |

| JP2010140827A (en) | Lighting device and illumination fixture using the same | |

| US20090289561A1 (en) | Flicker-free led lamp and led string lamp | |

| JP6075749B2 (en) | LED lamp | |

| JP6614315B2 (en) | Illumination lamp and illumination device | |

| KR100893906B1 (en) | LED lighting and LED lighting | |

| JP5924437B1 (en) | Lighting lamp, lighting device, and lighting control circuit | |

| JP6011676B1 (en) | Lighting lamp, lighting device, and lighting control circuit | |

| US20190191526A1 (en) | Led lamp protection circuit | |

| JP6354265B2 (en) | Illumination lamp, illumination device, and connection method of illumination lamp | |

| JP5745494B2 (en) | Fluorescent LED lamp | |

| JP2019194962A (en) | Power supply device for led illumination lamp of discharge lamp stabilizer compatible type | |

| KR101446836B1 (en) | Fluorescent lamp compatible LED lamps with status monitoring function | |

| JP2016212966A (en) | Lighting lamp, lighting device, and lighting control circuit | |

| JP2006092943A (en) | Filament breakage detection method, filament breakage detection device, discharge lamp lighting device and lighting fixture | |

| JP2006092940A (en) | Discharge lamp lighting device and lighting apparatus | |

| JP2009272180A (en) | Compact self-ballasted fluorescent lamp |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091021 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20091021 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111122 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120120 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120417 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120508 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150518 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |