JP4931507B2 - 壁内に形成された冷却流路 - Google Patents

壁内に形成された冷却流路 Download PDFInfo

- Publication number

- JP4931507B2 JP4931507B2 JP2006200296A JP2006200296A JP4931507B2 JP 4931507 B2 JP4931507 B2 JP 4931507B2 JP 2006200296 A JP2006200296 A JP 2006200296A JP 2006200296 A JP2006200296 A JP 2006200296A JP 4931507 B2 JP4931507 B2 JP 4931507B2

- Authority

- JP

- Japan

- Prior art keywords

- wall

- hole

- axis

- orifice

- cone

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000001816 cooling Methods 0.000 title claims description 22

- 238000000034 method Methods 0.000 claims description 22

- 238000009792 diffusion process Methods 0.000 claims description 19

- 238000007373 indentation Methods 0.000 claims 1

- 238000005553 drilling Methods 0.000 description 5

- 239000007789 gas Substances 0.000 description 5

- 240000001549 Ipomoea eriocarpa Species 0.000 description 3

- 235000005146 Ipomoea eriocarpa Nutrition 0.000 description 3

- 230000001154 acute effect Effects 0.000 description 2

- 230000000977 initiatory effect Effects 0.000 description 2

- 238000007429 general method Methods 0.000 description 1

- 230000006698 induction Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000003313 weakening effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23H—WORKING OF METAL BY THE ACTION OF A HIGH CONCENTRATION OF ELECTRIC CURRENT ON A WORKPIECE USING AN ELECTRODE WHICH TAKES THE PLACE OF A TOOL; SUCH WORKING COMBINED WITH OTHER FORMS OF WORKING OF METAL

- B23H1/00—Electrical discharge machining, i.e. removing metal with a series of rapidly recurring electrical discharges between an electrode and a workpiece in the presence of a fluid dielectric

- B23H1/04—Electrodes specially adapted therefor or their manufacture

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23H—WORKING OF METAL BY THE ACTION OF A HIGH CONCENTRATION OF ELECTRIC CURRENT ON A WORKPIECE USING AN ELECTRODE WHICH TAKES THE PLACE OF A TOOL; SUCH WORKING COMBINED WITH OTHER FORMS OF WORKING OF METAL

- B23H9/00—Machining specially adapted for treating particular metal objects or for obtaining special effects or results on metal objects

- B23H9/10—Working turbine blades or nozzles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/02—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by mechanical features, e.g. shape

- B23K35/0211—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by mechanical features, e.g. shape for use in cutting

- B23K35/0216—Rods, electrodes, wires

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

- F01D5/18—Hollow blades, i.e. blades with cooling or heating channels or cavities; Heating, heat-insulating or cooling means on blades

- F01D5/186—Film cooling

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/10—Manufacture by removing material

- F05D2230/12—Manufacture by removing material by spark erosion methods

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/10—Manufacture by removing material

- F05D2230/13—Manufacture by removing material using lasers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2250/00—Geometry

- F05D2250/20—Three-dimensional

- F05D2250/23—Three-dimensional prismatic

- F05D2250/232—Three-dimensional prismatic conical

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/49336—Blade making

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/49336—Blade making

- Y10T29/49339—Hollow blade

- Y10T29/49341—Hollow blade with cooling passage

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Description

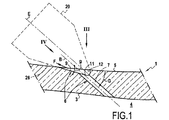

3 内側面

4 内側冷却路

5 壁の外側面

6 流路

7 孔

9 拡散部分

11 オリフィス

12 注ぎ口

13 前端部

15 縁

17 縁端

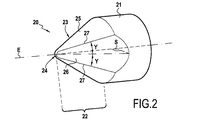

20、21 電極

22 電極の先端

23 円錐

24 端部

25 円錐面

26 平面

27 平面の側縁端

Claims (14)

- 流路(6)を流れる冷気によって冷却されるのに適した内側面(3)と外側面(5)とを呈するタービンブレードの壁(1)に冷却流路(6)を形成する方法であって、前記冷却流路(6)は孔(7)と拡散部(9)とから構成され、前記孔(7)は一方の端部で外に開いて内側面(3)に入り込み、かつ他方の端部でオリフィス(11)を形成する拡散部分(9)に入り込み、前記拡散部(9)は前記オリフィス(11)の周囲にフレア形に広がり、かつ外に開いて外側面(5)に入り込み、前記方法が、前記孔(7)を作るために壁(1)に穴を開けることと、前記電極(20)の先端(22)が端部(24)が丸みを帯びていて、円錐面(25)が平面(26)を呈する円錐形(23)であるエレクトロエロージョン電極(20)を使用することによって、前記拡散部分(9)を形成するために、壁(1)内にくぼみを形成することとの、2つの別個のステップを含むことを特徴とする、方法。

- 壁(1)が前記孔(7)を作るためにレーザによって穴を開けられることを特徴とする、請求項1に記載の方法。

- 前記円錐(23)の軸(E)が前記平面(26)と交差しないことを特徴とする、請求項1または2に記載の方法。

- 前記くぼみが、前記円錐(23)の軸(E)が前記孔(7)の軸(B)に平行となるように前記円錐(23)の軸(E)を向けることによって形成され、孔(7)の軸(B)が好ましくは壁(1)の外側面(5)の方にずらされていることを特徴とする、請求項1から3のいずれか一項に記載の方法。

- 少なくとも1つの冷却流路(6)が形成されるタービンブレードの壁要素(1)であって、流路(6)に沿って流れる冷気によって冷却されるのに適した内側面(3)と外側面(5)とを呈し、前記冷却流路(6)は孔(7)と拡散部(9)とから構成され、前記孔(7)は内側面(3)内の一方の端部、およびオリフィス(11)を形成する拡散部分(9)内の他方の端部で外に開き、前記拡散部(9)は前記オリフィス(11)の周囲でフレア形に開き、かつ外側面(5)内で外に開き、前記壁要素(1)は、拡散部分が実質的に平面であり、壁(1)の厚さで傾斜し、冷気の流れの方向で前記オリフィス(11)から前方へ延在する底の前端部(13)と、オリフィスの後ろ、両側面に沿ってとオリフィス(11)の正面に延在する縁(15)とを有し、前記縁(15)は底の前端部(13)の両側を接合し、前記縁(15)および底の前端部(13)が、丸みを帯びた端部(24)および平面(26)を示す円錐面(25)を有する円錐(23)内で内接することを特徴とする、壁要素。

- 底の前端部(13)の外形が孔(7)を出る冷気の流れ(F)を広げるように、頂点の1つが前記オリフィス(11)の方を向いているほぼ三角形の形状であることを特徴とする、請求項5に記載の壁要素。

- 前端部(13)に垂直な面の底の縁(15)と前端部(13)との間に形成された角度が、厳密に90°より大きいことを特徴とする、請求項5または6に記載の壁要素。

- 前記円錐(23)の軸(E)が孔(7)の軸(B)に平行であり、孔(7)の軸(B)が好ましくは壁(1)の外側面(5)の方へずらされていることを特徴とする、請求項5から7のいずれか一項に記載の壁要素。

- 請求項5から8のいずれか一項に記載の壁要素を含む、中空のターボ機械ブレード。

- 請求項5から8のいずれか一項に記載の壁要素を有する中空ブレードを含む、ターボ機械。

- エレクトロエロージョンによってタービンブレードの壁(1)内に冷却流路(6)の拡散部(9)を形成するための電極であって、先端(22)が丸みを帯びた端部(24)を有する円錐(23)の形状であり、その円錐面(25)が平面(26)を呈することを特徴とする、電極(20)。

- 前記円錐(23)の軸(E)が前記平面(26)と交差しないことを特徴とする、請求項11に記載の電極。

- 前記孔(7)の軸(B)が壁(1)の外側面(5)の方にずらされていることを特徴とする、請求項4に記載の方法。

- 前記孔(7)の軸(B)が壁(1)の外側面(5)の方へずらされていることを特徴とする、請求項8に記載の壁要素。

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0507924A FR2889089B1 (fr) | 2005-07-26 | 2005-07-26 | Canal de refroidissement menage dans une paroi |

| FR0507924 | 2005-07-26 | ||

| FR0650103A FR2895691A1 (fr) | 2006-01-12 | 2006-01-12 | Element de paroi dans lequel est menage un canal de refroidissement |

| FR0650103 | 2006-01-12 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007032567A JP2007032567A (ja) | 2007-02-08 |

| JP2007032567A5 JP2007032567A5 (ja) | 2009-09-10 |

| JP4931507B2 true JP4931507B2 (ja) | 2012-05-16 |

Family

ID=37682465

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006200296A Active JP4931507B2 (ja) | 2005-07-26 | 2006-07-24 | 壁内に形成された冷却流路 |

Country Status (3)

| Country | Link |

|---|---|

| US (3) | US7950902B2 (ja) |

| JP (1) | JP4931507B2 (ja) |

| CA (1) | CA2553860C (ja) |

Families Citing this family (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2926481B1 (fr) * | 2008-01-23 | 2011-09-23 | Snecma | Canal de refroidissement menage dans une paroi |

| JP4898731B2 (ja) * | 2008-03-26 | 2012-03-21 | 三菱重工業株式会社 | ガスタービン冷却構造およびこれを備えたガスタービン |

| DE102009007164A1 (de) * | 2009-02-03 | 2010-08-12 | Rolls-Royce Deutschland Ltd & Co Kg | Verfahren zum Ausbilden einer Kühlluftöffnung in einer Wand einer Gasturbinenbrennkammer sowie nach dem Verfahren hergestellte Brennkammerwand |

| US8168912B1 (en) * | 2009-02-19 | 2012-05-01 | Florida Turbine Technologies, Inc. | Electrode for shaped film cooling hole |

| US20120164376A1 (en) * | 2010-12-23 | 2012-06-28 | General Electric Company | Method of modifying a substrate for passage hole formation therein, and related articles |

| US20120295061A1 (en) * | 2011-05-18 | 2012-11-22 | General Electric Company | Components with precision surface channels and hybrid machining method |

| US8915713B2 (en) * | 2011-09-27 | 2014-12-23 | General Electric Company | Offset counterbore for airfoil cooling hole |

| US9090343B2 (en) * | 2011-10-13 | 2015-07-28 | Sikorsky Aircraft Corporation | Rotor blade component cooling |

| US20130209232A1 (en) | 2012-02-15 | 2013-08-15 | Jinquan Xu | Multi-lobed cooling holes in gas turbine engine components having thermal barrier coatings |

| JP2013167205A (ja) * | 2012-02-15 | 2013-08-29 | Hitachi Ltd | ガスタービン翼、その放電加工用工具及び加工方法 |

| BR112014031176A2 (pt) | 2012-06-13 | 2017-06-27 | Gen Electric | paredes de motor de turbina a gás |

| US9617859B2 (en) * | 2012-10-05 | 2017-04-11 | General Electric Company | Turbine components with passive cooling pathways |

| US9415468B2 (en) * | 2013-08-20 | 2016-08-16 | General Electric Company | Method for manufacturing an airfoil |

| ITCO20130051A1 (it) * | 2013-10-23 | 2015-04-24 | Nuovo Pignone Srl | Metodo per la produzione di uno stadio di una turbina a vapore |

| US9468991B2 (en) | 2014-01-27 | 2016-10-18 | General Electric Company | Method determining hole completion |

| US9662743B2 (en) | 2014-01-27 | 2017-05-30 | General Electric Company | Method for drilling a hole in an airfoil |

| GB201419327D0 (en) | 2014-10-30 | 2014-12-17 | Rolls Royce Plc | A cooled component |

| WO2016074135A1 (zh) | 2014-11-10 | 2016-05-19 | 西门子公司 | 利用激光在工件上加工冷却孔的方法和装置 |

| EP3043023B1 (en) * | 2015-01-06 | 2019-09-18 | Ansaldo Energia IP UK Limited | Method for producing contoured cooling holes |

| CN104668675B (zh) * | 2015-03-05 | 2017-01-04 | 华南理工大学 | 一种具有微锥塔阵列端面的电极及其加工方法与应用 |

| CN105171158B (zh) * | 2015-10-10 | 2017-11-14 | 贵阳中航动力精密铸造有限公司 | 一种涡轮导向叶片锥形气膜孔加工工艺 |

| EP3179040B1 (en) | 2015-11-20 | 2021-07-14 | Raytheon Technologies Corporation | Component for a gas turbine engine and corresponding a method of manufacturing a film-cooled article |

| CN106529069B (zh) * | 2016-11-24 | 2019-06-11 | 中国航发沈阳黎明航空发动机有限责任公司 | 一种过弯叶片锻件叶身余量设计方法 |

| US10927680B2 (en) | 2017-05-31 | 2021-02-23 | General Electric Company | Adaptive cover for cooling pathway by additive manufacture |

| US10760430B2 (en) | 2017-05-31 | 2020-09-01 | General Electric Company | Adaptively opening backup cooling pathway |

| US11041389B2 (en) | 2017-05-31 | 2021-06-22 | General Electric Company | Adaptive cover for cooling pathway by additive manufacture |

| US10704399B2 (en) | 2017-05-31 | 2020-07-07 | General Electric Company | Adaptively opening cooling pathway |

| WO2020246494A1 (ja) * | 2019-06-07 | 2020-12-10 | 株式会社Ihi | フィルム冷却構造及びガスタービンエンジン用タービン翼 |

| US11220917B1 (en) | 2020-09-03 | 2022-01-11 | Raytheon Technologies Corporation | Diffused cooling arrangement for gas turbine engine components |

| CN113182625B (zh) * | 2021-05-07 | 2022-05-20 | 江苏江航智飞机发动机部件研究院有限公司 | 一种多齿涡轮叶片精密电解加工工艺 |

Family Cites Families (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4197443A (en) | 1977-09-19 | 1980-04-08 | General Electric Company | Method and apparatus for forming diffused cooling holes in an airfoil |

| US4650949A (en) * | 1985-12-23 | 1987-03-17 | United Technologies Corporation | Electrode for electrical discharge machining film cooling passages in an airfoil |

| US4738588A (en) | 1985-12-23 | 1988-04-19 | Field Robert E | Film cooling passages with step diffuser |

| US4664597A (en) | 1985-12-23 | 1987-05-12 | United Technologies Corporation | Coolant passages with full coverage film cooling slot |

| US4653983A (en) | 1985-12-23 | 1987-03-31 | United Technologies Corporation | Cross-flow film cooling passages |

| US4672727A (en) | 1985-12-23 | 1987-06-16 | United Technologies Corporation | Method of fabricating film cooling slot in a hollow airfoil |

| US4684323A (en) * | 1985-12-23 | 1987-08-04 | United Technologies Corporation | Film cooling passages with curved corners |

| US4762464A (en) | 1986-11-13 | 1988-08-09 | Chromalloy Gas Turbine Corporation | Airfoil with diffused cooling holes and method and apparatus for making the same |

| US4819325A (en) | 1987-06-01 | 1989-04-11 | Technical Manufacturing Systems, Inc. | Method of forming electro-discharge machining electrode |

| US4803339A (en) * | 1987-09-16 | 1989-02-07 | Rockwell International Corporation | Hollow electrode and arc initiation method |

| GB2227965B (en) * | 1988-10-12 | 1993-02-10 | Rolls Royce Plc | Apparatus for drilling a shaped hole in a workpiece |

| US5368441A (en) | 1992-11-24 | 1994-11-29 | United Technologies Corporation | Turbine airfoil including diffusing trailing edge pedestals |

| US5683600A (en) * | 1993-03-17 | 1997-11-04 | General Electric Company | Gas turbine engine component with compound cooling holes and method for making the same |

| SE509984C2 (sv) * | 1994-03-18 | 1999-03-29 | Sandvik Ab | Chargeringssystem för CVD |

| US5609779A (en) * | 1996-05-15 | 1997-03-11 | General Electric Company | Laser drilling of non-circular apertures |

| US6287075B1 (en) * | 1997-10-22 | 2001-09-11 | General Electric Company | Spanwise fan diffusion hole airfoil |

| EP0950463B1 (de) * | 1998-03-23 | 2002-01-23 | Alstom | Nichtkreisförmige Kühlbohrung und Verfahren zur Herstellung derselben |

| DE59808269D1 (de) * | 1998-03-23 | 2003-06-12 | Alstom Switzerland Ltd | Filmkühlungsbohrung |

| JP2000141069A (ja) * | 1998-11-10 | 2000-05-23 | Toshiba Corp | タービン翼およびその冷却孔加工方法 |

| US6206638B1 (en) | 1999-02-12 | 2001-03-27 | General Electric Company | Low cost airfoil cooling circuit with sidewall impingement cooling chambers |

| DE19960797C1 (de) * | 1999-12-16 | 2001-09-13 | Mtu Aero Engines Gmbh | Verfahren zum Herstellen einer Öffnung in einem metallischen Bauteil |

| US6368060B1 (en) * | 2000-05-23 | 2002-04-09 | General Electric Company | Shaped cooling hole for an airfoil |

| US6573474B1 (en) * | 2000-10-18 | 2003-06-03 | Chromalloy Gas Turbine Corporation | Process for drilling holes through a thermal barrier coating |

| FR2820066B1 (fr) | 2001-02-01 | 2003-03-07 | Snecma Moteurs | Dispositif de centrage et de percage de formes et de trous cylindriques |

| US6554572B2 (en) | 2001-05-17 | 2003-04-29 | General Electric Company | Gas turbine engine blade |

| GB2395157B (en) * | 2002-11-15 | 2005-09-07 | Rolls Royce Plc | Laser driliing shaped holes |

| US6994514B2 (en) * | 2002-11-20 | 2006-02-07 | Mitsubishi Heavy Industries, Ltd. | Turbine blade and gas turbine |

| US7041933B2 (en) * | 2003-04-14 | 2006-05-09 | Meyer Tool, Inc. | Complex hole shaping |

| US6897401B2 (en) * | 2003-07-31 | 2005-05-24 | United Technologies Corporation | Non-separating diffuser for holes produced by a two step process |

| US7008186B2 (en) | 2003-09-17 | 2006-03-07 | General Electric Company | Teardrop film cooled blade |

-

2006

- 2006-07-24 JP JP2006200296A patent/JP4931507B2/ja active Active

- 2006-07-25 CA CA2553860A patent/CA2553860C/fr active Active

- 2006-07-25 US US11/492,110 patent/US7950902B2/en active Active

-

2010

- 2010-05-26 US US12/787,477 patent/US8875393B2/en active Active

-

2014

- 2014-08-18 US US14/462,059 patent/US9114469B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US8875393B2 (en) | 2014-11-04 |

| JP2007032567A (ja) | 2007-02-08 |

| US7950902B2 (en) | 2011-05-31 |

| US20100229388A1 (en) | 2010-09-16 |

| US20070025852A1 (en) | 2007-02-01 |

| CA2553860A1 (fr) | 2007-01-26 |

| CA2553860C (fr) | 2016-01-26 |

| US20140353284A1 (en) | 2014-12-04 |

| US9114469B2 (en) | 2015-08-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4931507B2 (ja) | 壁内に形成された冷却流路 | |

| EP2027963B1 (en) | Composant comprising a percussion drilled shaped through hole providing Coanda effect and method of forming the same using laser percussion driling | |

| US4664597A (en) | Coolant passages with full coverage film cooling slot | |

| US4738588A (en) | Film cooling passages with step diffuser | |

| JP2007032567A5 (ja) | ||

| CA1262689A (en) | Film cooling passages with curved corners | |

| US8057181B1 (en) | Multiple expansion film cooling hole for turbine airfoil | |

| US4726735A (en) | Film cooling slot with metered flow | |

| JP4778754B2 (ja) | タービンバケット翼形部の後縁のための冷却システム | |

| JP4954309B2 (ja) | ダブルジェット式フィルム冷却構造 | |

| JP2008051107A (ja) | 前縁冷却を行うガスタービンの翼 | |

| US4669957A (en) | Film coolant passage with swirl diffuser | |

| JP3367697B2 (ja) | タービン用の動翼 | |

| CN101852099B (zh) | 膜冷却增强装置和结合有膜冷却增强装置的涡轮翼面 | |

| US7530788B2 (en) | Hollow turbomachine blade | |

| JP2009162224A (ja) | 冷却孔を形成する方法及びハイブリッド形成冷却孔を有するタービン翼形部 | |

| US9108282B2 (en) | Method of manufacturing heat exchanger cooling passages in aero propulsion structure | |

| JPS62165503A (ja) | 長手方向に延在する中空エ−ロフオイルの製造方法 | |

| TW200526864A (en) | Cooled rotor blade with vibration damping device | |

| JP2009508038A (ja) | ターボファンの噴射ノイズを軽減させる方法 | |

| BR102016004205A2 (pt) | componente de motor para um motor de turbina a gás | |

| JP2007506017A (ja) | 冷却構造を備えた燃焼室及びかかる燃焼室の製造方法 | |

| JP2020506326A (ja) | ガスタービンのための高温ガス部及び対応する高温ガス部の壁 | |

| WO2013037662A1 (en) | Gas-turbine-component | |

| CN110012640A (zh) | 一种具有开孔间壁的微通道冷板及电子设备 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090723 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090723 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110111 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110408 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110510 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20110808 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20110811 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111109 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120207 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120214 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4931507 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150224 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |