JP4921913B2 - Substrate cleaning method - Google Patents

Substrate cleaning method Download PDFInfo

- Publication number

- JP4921913B2 JP4921913B2 JP2006271072A JP2006271072A JP4921913B2 JP 4921913 B2 JP4921913 B2 JP 4921913B2 JP 2006271072 A JP2006271072 A JP 2006271072A JP 2006271072 A JP2006271072 A JP 2006271072A JP 4921913 B2 JP4921913 B2 JP 4921913B2

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- cleaning

- nozzle

- cleaning liquid

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/02—Cleaning by the force of jets or sprays

- B08B3/024—Cleaning by means of spray elements moving over the surface to be cleaned

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67017—Apparatus for fluid treatment

- H01L21/67028—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like

- H01L21/6704—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing

- H01L21/67051—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing using mainly spraying means, e.g. nozzles

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Cleaning Or Drying Semiconductors (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

Description

本発明は、基板洗浄方法に関し、特に半導体装置の製造工程のリソグラフィ工程において、液浸型露光装置による露光前もしくは露光後の基板の洗浄方法に関するものである。 The present invention relates to a substrate cleaning method, and more particularly to a substrate cleaning method before or after exposure by an immersion exposure apparatus in a lithography process of a semiconductor device manufacturing process.

半導体リソグラフィ技術における液浸露光装置を用いた微細パターンの露光によって、被処理基板の表面と裏面が液浸液で濡れる場合がある。基板表面が濡れている場合、基板表面上の水滴を取り除く工程が無いと、水滴は基板表面で乾燥し、水滴の乾燥痕跡(水滴痕:Watermark)が基板表面上に残る。 By exposure of a fine pattern using an immersion exposure apparatus in semiconductor lithography technology, the front and back surfaces of the substrate to be processed may be wetted by the immersion liquid. When the substrate surface is wet, if there is no step of removing water droplets on the substrate surface, the water droplets are dried on the substrate surface, and a water droplet drying trace (watermark) remains on the substrate surface.

図9の(a)(b)は、従来例に係る半導体装置の製造工程の断面図である。リソグラフィ工程において、基板表面上には、図9の(a)のように被加工基板91に近い順に反射防止膜92、レジスト93、及び液浸保護膜94を塗布する場合と、図9の(b)のように被加工基板91に近い順に転写膜95、SOG(Spin On Glass)膜96、レジスト93、及び液浸保護膜94を塗布する場合とがある。 FIGS. 9A and 9B are cross-sectional views of a manufacturing process of a semiconductor device according to a conventional example. In the lithography process, an antireflection film 92, a resist 93, and an immersion protection film 94 are applied on the substrate surface in the order of proximity to the substrate 91 as shown in FIG. In some cases, a transfer film 95, an SOG (Spin On Glass) film 96, a resist 93, and an immersion protection film 94 are applied in the order closer to the substrate 91 as shown in FIG.

しかし図9の(a)(b)において、液浸保護膜94上の残留水滴97が乾燥する際に、水滴97は液浸保護膜94を透過してレジスト93に達する。レジスト93に達した水滴は、レジスト93中の酸発生剤、Quencherの膜中の分布を乱し、露光後のベーク(Post Exposure Bake:PEB)工程、液浸保護膜剥離工程、現像工程を経てパターンを形成すると、パターン寸法が所望の寸法から外れる場合や、断面形状が庇形状になる場合や、水滴痕の範囲で全くパターンを形成しない場合などが生じる。これにより、半導体装置製造上の歩留まりを大きく劣化させる。 However, in FIGS. 9A and 9B, when the residual water droplet 97 on the immersion protection film 94 is dried, the water droplet 97 passes through the immersion protection film 94 and reaches the resist 93. The water droplets reaching the resist 93 disturb the distribution of the acid generator and Quencher film in the resist 93, and undergo a post exposure bake (post exposure bake: PEB) process, an immersion protective film peeling process, and a developing process. When a pattern is formed, there are cases where the pattern dimension deviates from a desired dimension, the cross-sectional shape becomes a saddle shape, or the pattern is not formed at all in the range of the water droplet trace. Thereby, the yield in manufacturing the semiconductor device is greatly deteriorated.

また、基板の裏面が濡れている場合は、基板の裏面、エッジ、ベベル部分の汚れが水滴を伝い、PEB工程にてベーカーに汚染物質が付着し、処理される基板の枚数の増加によって蓄積された汚染物質が他の基板の表面に付着することによって欠陥が発生し、それによって歩留まりが低下する可能性がある。 In addition, when the back surface of the substrate is wet, dirt on the back surface, edge, and bevel portion of the substrate travels through the water droplets, and contaminants adhere to the baker in the PEB process, which accumulates due to an increase in the number of substrates to be processed. Defects may be generated by the contaminants adhering to the surface of another substrate, which may reduce the yield.

そこで、液浸露光を用いたリソグラフィ工程において歩留まりを向上させるために、液浸露光後に基板の表面と裏面を洗浄し、基板の表面と裏面の水滴と汚染物質を除去する必要がある。 Therefore, in order to improve the yield in the lithography process using immersion exposure, it is necessary to clean the front and back surfaces of the substrate after the immersion exposure to remove water droplets and contaminants on the front and back surfaces of the substrate.

半導体装置の製造工程において基板を洗浄する技術として、半導体フロントエンドプロセスにおける洗浄装置があるが、洗浄装置の洗浄ユニットは大きく高価であることから、従来の露光装置もしくは塗布現像装置に搭載することは困難である。そこで、以下のような方法が考えられている。 As a technique for cleaning a substrate in the manufacturing process of a semiconductor device, there is a cleaning device in a semiconductor front-end process, but since a cleaning unit of the cleaning device is large and expensive, it can be mounted on a conventional exposure apparatus or coating and developing apparatus. Have difficulty. Therefore, the following method is considered.

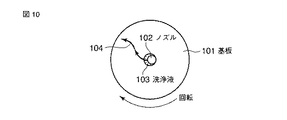

図10は、従来の塗布現像装置に搭載されている現像ユニットを上方から見た図である。図10に示すように、現像後のリンス方法を用いて基板101上にノズル102から洗浄液103を吐出し、毎秒1000〜2000回転で基板をスピン回転させて洗浄液を基板外部へ飛散させる(104)ことによって乾燥する方法で基板を洗浄する。この場合、基板の表面と裏面に微小な水滴痕が数百〜数千個残って基板上に欠陥として生じ、洗浄したのにもかかわらず、欠陥を減らすことはできなかった。

FIG. 10 is a view of a developing unit mounted on a conventional coating and developing apparatus as viewed from above. As shown in FIG. 10, the cleaning liquid 103 is discharged from the

また、現像後のリンス工程にて、基板上の中心部分から外周方向に等速度で洗浄液を吐出しながら基板外に飛散させるスキャンリンス方法を、上記の基板の洗浄に適用した。上述した毎秒1000回転以上で基板を回転させて洗浄液を飛散させる方法では、図10の場合と同様に、基板の表面と裏面に微小な水滴痕が数百〜数千個残って基板上に欠陥として生じた。 Further, in the rinsing process after development, a scan rinsing method in which the cleaning liquid is scattered from the central portion on the substrate to the outside while discharging the cleaning liquid at a constant speed is applied to the cleaning of the substrate. In the above-described method of rotating the substrate at 1000 rpm or more to disperse the cleaning liquid, hundreds to thousands of minute water droplet traces remain on the front and back surfaces of the substrate as in the case of FIG. As a result.

このことから、図11に示すように、洗浄液が飛散しない毎秒500回転以下の回転数で洗浄したが、ノズル102から吐出された洗浄液103が回転する基板101に乗って基板上に滞留し、この滞留した洗浄液が新たに吐出された洗浄液と衝突(105)することによって、洗浄液の流れが乱れて水滴痕が基板上に残る(106)問題が生じた。

Accordingly, as shown in FIG. 11, the cleaning liquid was cleaned at a rotation speed of 500 rotations or less per second so that the cleaning liquid does not scatter, but the cleaning liquid 103 discharged from the

なお特許文献1には、基板洗浄の際、基板中央から外側に向けて走査して基板表面を洗浄する構成が開示されている。

本発明の目的は、安価かつ簡易に、被処理基板上の水滴を残さずに洗浄することができる基板洗浄方法を提供することにある。 An object of the present invention is to provide a substrate cleaning method capable of cleaning at low cost and without leaving water droplets on a substrate to be processed.

本発明の一形態の基板洗浄方法は、被処理基板の上方のノズルから洗浄液を吐出し、前記基板を回転させながら前記基板を洗浄する基板洗浄方法であり、前記ノズルから前記洗浄液を前記基板に吐出しながら、前記ノズルを前記基板の中心から前記基板の外側へ走査し、前記洗浄液を前記基板の外側に散逸させる基板洗浄方法において、前記基板上に滞留している洗浄液が存在する状態で、前記ノズルから吐出された前記洗浄液が前記基板表面に接触した際、前記ノズルから吐出された前記洗浄液が、前記基板上に滞留している前記洗浄液に衝突しないように、前記洗浄液の流量、前記基板の回転数、前記ノズルの走査速度と走査開始位置を制御することを特徴とする。 A substrate cleaning method according to an aspect of the present invention is a substrate cleaning method in which a cleaning liquid is discharged from a nozzle above a substrate to be processed and the substrate is cleaned while rotating the substrate, and the cleaning liquid is applied to the substrate from the nozzle. While discharging, the nozzle is scanned from the center of the substrate to the outside of the substrate, and in the substrate cleaning method for dissipating the cleaning solution to the outside of the substrate, in a state where the cleaning solution staying on the substrate exists, when the cleaning liquid discharged from the nozzle is in contact with the substrate surface, the cleaning liquid discharged from the nozzle, so as not to collide with the cleaning liquid staying on the substrate, of the cleaning solution flow rate, the substrate The number of rotations, the scanning speed of the nozzle and the scanning start position are controlled.

本発明によれば、安価かつ簡易に、被処理基板上の水滴を残さずに洗浄することができる基板洗浄方法を提供できる。 ADVANTAGE OF THE INVENTION According to this invention, the board | substrate cleaning method which can be wash | cleaned cheaply and easily, without leaving the water droplet on a to-be-processed substrate can be provided.

以下、実施の形態を図面を参照して説明する。 Hereinafter, embodiments will be described with reference to the drawings.

(第1の実施の形態)

図1は、第1の実施の形態の基板洗浄方法を示す図である。なお、本基板洗浄方法は、基板洗浄装置内の図示しない制御装置の制御により行われる。図1に示すように、半導体ウエハなどの被処理基板11を洗浄する工程において、被処理基板11上方のノズル12から洗浄液13を吐出し、基板11を回転させながら基板11を洗浄、乾燥する。

(First embodiment)

FIG. 1 is a diagram illustrating a substrate cleaning method according to the first embodiment. This substrate cleaning method is performed under the control of a control device (not shown) in the substrate cleaning apparatus. As shown in FIG. 1, in a process of cleaning a

この工程で、図2に示すように、ノズル12から洗浄液13を基板11に吐出しながら、ノズル12を基板中心から基板の外側へ走査し、基板上の残留水滴14を吸着させながら洗浄液13を基板11外側に散逸させる。これによって、基板11上に水滴を残さずに基板11を洗浄、乾燥する。

In this step, as shown in FIG. 2, while discharging the cleaning liquid 13 from the

ここで、ノズル12から吐出した洗浄液13が基板11の回転に則って基板11上を移動しながら散逸する際に、回転する基板11上に滞留した洗浄液13がノズル12から吐出した洗浄液13と衝突しないように、洗浄液13の流量、基板11の回転数、ノズル12のスキャン(走査)速度とスキャン開始位置を制御する。これによって、基板11上に水滴を残さずに基板11を洗浄、乾燥する。

Here, when the cleaning liquid 13 discharged from the

まず、半導体装置の製造工程における微細パターンを形成するリソグラフィ工程にて、塗布現像装置で被加工基板に反射防止膜ARC29A(日産化学社製)を厚さ77nmで塗布し、205℃で60秒間ベークし、基板を冷却した。その後、レジストAR2014J(JSR社製)を厚さ150nmで塗布し、115℃で60秒間ベークし、基板を冷却した後、保護膜TCX015(JSR社製)を厚さ90nmで塗布し、90℃で60秒間ベークした。この基板を、塗布現像装置とインターフェースユニットを介してインライン接続したArF液浸露光装置に搬送し、液浸露光を行った。 First, in a lithography process for forming a fine pattern in a semiconductor device manufacturing process, an anti-reflection film ARC29A (Nissan Chemical Co., Ltd.) is applied to a substrate to be processed with a coating and developing apparatus at a thickness of 77 nm and baked at 205 ° C. for 60 seconds. And the substrate was cooled. Thereafter, a resist AR2014J (manufactured by JSR) was applied at a thickness of 150 nm, baked at 115 ° C. for 60 seconds, and the substrate was cooled. Then, a protective film TCX015 (manufactured by JSR) was applied at a thickness of 90 nm and at 90 ° C. Bake for 60 seconds. This substrate was transported to an ArF immersion exposure apparatus connected inline with the coating and developing apparatus via an interface unit, and immersion exposure was performed.

液浸露光後、基板表面には直径0.5mmの水滴が5個、直径1mmの水滴が1個残存し、基板裏面には直径2mmの水滴が基板の外周から2mmの位置に2個、直径1mmの水滴が基板の外周から1mmの位置に3個残存した。この基板を、基板表面と裏面の水滴が乾燥して消失しないまでの90秒間のうちに、塗布現像装置中に設置された洗浄ユニットに搬送した。

After immersion exposure, five water droplets with a diameter of 0.5 mm and one water droplet with a diameter of 1 mm remain on the surface of the substrate, and two water droplets with a diameter of 2 mm on the back surface of the substrate at a

保護膜の静的接触角が78度、洗浄液が超純水であり、洗浄液の流量が0.5L/minと設定すると、ノズルから吐出した洗浄液が基板上で跳水現象を起こす。その跳水現象を起こしている領域の半径(跳水半径)が8mmであるので、ノズルのスキャン開始位置Rs0は、跳水半径Rjと比例(Rs0∝Rj)の関係で表される中心から5mmの位置とする。

When the static contact angle of the protective film is 78 degrees, the cleaning liquid is ultrapure water, and the flow rate of the cleaning liquid is set to 0.5 L / min, the cleaning liquid discharged from the nozzle causes a water jump phenomenon on the substrate. Since the radius of the region causing the water jump phenomenon (water jump radius) is 8 mm, the scan start position Rs0 of the nozzle is a

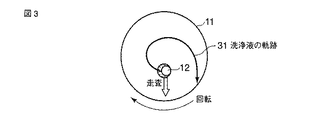

ノズルのスキャン速度Vsは、跳水半径Rjとウエハ(基板)の単位時間あたりの回転数nrevとの積と比例の関係(Vs∝Rj×nrev)で表され、基板の回転数が100rpmである時には、Vs=8.3mm/secで等速にてノズルのスキャンを行いながら基板表面の洗浄処理を行うとよい。この場合、洗浄液は図3で示されるような軌跡(31)を描いて基板の外側へ飛散させた。本工程にて、基板表面に水滴痕がない洗浄、乾燥が行われた。 The nozzle scan speed Vs is expressed by a proportional relationship (Vs∝Rj × nrev) of the product of the water jump radius Rj and the rotation speed nrev per unit time of the wafer (substrate), and when the rotation speed of the substrate is 100 rpm. The substrate surface may be cleaned while scanning the nozzle at a constant speed with Vs = 8.3 mm / sec. In this case, the cleaning liquid was scattered to the outside of the substrate along a locus (31) as shown in FIG. In this step, cleaning and drying were performed with no water mark on the substrate surface.

この場合の各パラメータは以下のように決定される。跳水半径Rj(=Rj(Q))と流量Qの関係は図4のようになり、跳水半径Rjは、本実施の形態のように回転する基板の中心部に吐出しない場合、流量Qにほとんど依存しない。また、図5に示すように、跳水半径Rjは回転数nrevにほぼ関係なく決定され、図6に示すように、スキャン初期位置Rs0と跳水半径Rjは、Rs0=βRj(β〜1)の関係を持つ。 Each parameter in this case is determined as follows. The relationship between the water jump radius Rj (= Rj (Q)) and the flow rate Q is as shown in FIG. 4, and the water jump radius Rj is almost equal to the flow rate Q when not discharged to the center of the rotating substrate as in this embodiment. Do not depend. Further, as shown in FIG. 5, the water jump radius Rj is determined almost regardless of the rotation speed nrev, and as shown in FIG. 6, the scan initial position Rs0 and the water jump radius Rj are in a relationship of Rs0 = βRj (β˜1). have.

また、スキャン速度Vsは以下のように決定される。図7に示すように、基板の回転数nrevが高いとスキャン速度Vsを高くする必要があり、回転数nrevが低いとスキャン速度Vsを低くする必要がある。 The scan speed Vs is determined as follows. As shown in FIG. 7, it is necessary to increase the scanning speed Vs when the rotation speed nrev of the substrate is high, and it is necessary to decrease the scanning speed Vs when the rotation speed nrev is low.

次に基板裏面の洗浄は、基板の外周から30mmの位置に設置した裏面洗浄用のノズルから洗浄液を0.5L/minの流量で基板裏面に向かって吐出し、基板表面の洗浄と同時に行った。

Next, the cleaning of the back surface of the substrate was performed simultaneously with the cleaning of the substrate surface by discharging the cleaning liquid from the back surface cleaning nozzle installed at a

本洗浄によって基板裏面に存在した水滴はすべて除去され、裏面の汚染が無い状態にて基板をPEB工程に搬送した。PEB工程においては、115℃で60秒間ベークした後、基板を冷却し、現像工程に搬送した。現像工程においては、2.38重量%のテトラメチルアンモニウムハイドロオキサイド水溶液(TMAH)を現像液に用い、60秒間現像を行った。以上の工程にて、55nmライン&スペースのパターンを欠陥なく形成した。 All the water droplets present on the back surface of the substrate were removed by the main cleaning, and the substrate was transported to the PEB process with no contamination on the back surface. In the PEB process, after baking at 115 ° C. for 60 seconds, the substrate was cooled and transported to the development process. In the developing step, 2.38 wt% tetramethylammonium hydroxide aqueous solution (TMAH) was used as a developing solution and developed for 60 seconds. Through the above process, a 55 nm line & space pattern was formed without defects.

本第1の実施の形態では、半導体装置の製造工程におけるリソグラフィ工程の液浸露光後の基板の洗浄について説明したが、露光後の洗浄に限るものでも、リソグラフィ工程に限るものでもない。 In the first embodiment, the cleaning of the substrate after the immersion exposure in the lithography process in the manufacturing process of the semiconductor device has been described. However, the cleaning is not limited to the cleaning after the exposure or the lithography process.

(第2の実施の形態)

第2の実施の形態においては、第1の実施の形態と同様の基板に対して同様の材料を積層塗布形成し、ArF液浸露光装置にて液浸露光を行った。

(Second Embodiment)

In the second embodiment, the same material as that in the first embodiment is laminated and formed on the same substrate, and immersion exposure is performed using an ArF immersion exposure apparatus.

液浸露光後、第1の実施の形態と同様に基板の表面と裏面に水滴が残留した。第1の実施の形態と同様の保護膜を塗布形成しているため、保護膜の静的接触角が78度、洗浄液が超純水であり、洗浄液の流量が0.25L/minの場合の跳水半径が6mmであるので、スキャン開始位置Rs0は跳水半径Rjと比例(Rs0∝Rj)の関係で表される位置である中心から4mmの位置とする。

After immersion exposure, water droplets remained on the front and back surfaces of the substrate as in the first embodiment. Since the same protective film as that of the first embodiment is formed by coating, the static contact angle of the protective film is 78 degrees, the cleaning liquid is ultrapure water, and the flow rate of the cleaning liquid is 0.25 L / min. Since the water jump radius is 6 mm, the scan start position Rs0 is set to a

スキャン速度Vsは、跳水半径Rjとウエハ回転数nrevとの積と比例の関係(Vs∝Rj×nrev)で表され、基板の回転数が100rpmである時には、Vs=40mm/secで等速にてノズルのスキャンを行いながら基板表面の洗浄処理を行うとよい。この場合、洗浄液は図8で示されるような軌跡(81)を描いて基板の外側へ飛散させた。本工程にて、基板表面に水滴痕がない洗浄、乾燥が行われた。 The scan speed Vs is expressed by a proportional relationship (Vs∝Rj × nrev) with the product of the water jump radius Rj and the wafer rotation speed nrev. The substrate surface may be cleaned while scanning the nozzle. In this case, the cleaning liquid was scattered on the outside of the substrate along a locus (81) as shown in FIG. In this step, cleaning and drying were performed with no water mark on the substrate surface.

次に基板裏面の洗浄は、第1の実施の形態と同様に基板の外周から30mmの位置に設置した裏面洗浄用のノズルから洗浄液を0.5L/minの流量で基板裏面に向かって吐出し、基板表面の洗浄と同時に行った。 Next, in the cleaning of the back surface of the substrate, the cleaning liquid is discharged toward the back surface of the substrate at a flow rate of 0.5 L / min from the nozzle for back surface cleaning disposed at a position of 30 mm from the outer periphery of the substrate as in the first embodiment. The substrate surface was cleaned at the same time.

本洗浄によって基板裏面に存在した水滴はすべて除去され、裏面の汚染が無い状態にて基板をPEB工程に搬送し、第1の実施の形態と同様の工程を経て、55nmライン&スペースのパターンを欠陥なく形成した。 All water droplets present on the backside of the substrate are removed by this cleaning, and the substrate is transferred to the PEB process with no contamination on the backside. Through the same process as in the first embodiment, a 55 nm line & space pattern is formed. It was formed without defects.

(第3の実施の形態)

第1の実施の形態においては、基板を液浸露光後に洗浄工程を行ったが、本第3の実施の形態においては液浸露光前にも洗浄工程を行う方法を説明する。

(Third embodiment)

In the first embodiment, the cleaning process is performed after the immersion exposure. In the third embodiment, a method for performing the cleaning process before the immersion exposure will be described.

第1の実施の形態と同様に、塗布現像装置で被加工基板に反射防止膜ARC29A(日産化学社製)を厚さ80nmで塗布し、205℃で60秒間ベークし、基板を冷却した。その後、レジストAR2014J(JSR社製)を厚さ150nmで塗布し、115℃で60秒間ベークし、基板を冷却した後、保護膜TCX026(JSR社製)を厚さ90nmで塗布し、90℃で60秒間ベークした。この基板を洗浄ユニットに搬送した。 Similarly to the first embodiment, an antireflection film ARC29A (Nissan Chemical Co., Ltd.) was applied to a substrate to be processed with a thickness of 80 nm by a coating and developing apparatus, baked at 205 ° C. for 60 seconds, and the substrate was cooled. Thereafter, a resist AR2014J (manufactured by JSR) was applied at a thickness of 150 nm, baked at 115 ° C. for 60 seconds, and the substrate was cooled. Then, a protective film TCX026 (manufactured by JSR) was applied at a thickness of 90 nm and at 90 ° C. Bake for 60 seconds. This board | substrate was conveyed to the washing | cleaning unit.

第1の実施の形態と同様の保護膜を塗布形成しているため、保護膜の静的接触角が78度、洗浄液が超純水であり、洗浄液の流量が0.5L/minと設定すると、ノズルから吐出した洗浄液が基板上で跳水現象を起こす。その跳水現象を起こしている領域の半径(跳水半径)が8mmであるので、スキャン開始位置Rs0は跳水半径Rjと比例(Rs0∝Rj)の関係で表される位置である中心から5mmの位置とする。

Since a protective film similar to that of the first embodiment is applied and formed, when the static contact angle of the protective film is 78 degrees, the cleaning liquid is ultrapure water, and the flow rate of the cleaning liquid is set to 0.5 L / min. The cleaning liquid discharged from the nozzle causes a water jump phenomenon on the substrate. Since the radius of the region in which the water jump phenomenon occurs (the water jump radius) is 8 mm, the scan start position Rs0 is a position that is a position expressed by a relationship proportional to the water jump radius Rj (Rs0∝Rj) and a

スキャン速度Vsは、跳水半径Rjとウエハ回転数nrevとの積と比例の関係(Vs∝Rj×nrev)で表され、基板の回転数が150rpmである時には、Vs=12.45mm/secで等速にてノズルのスキャンを行いながら基板表面の洗浄処理を行うとよい。この場合、洗浄液は図3で示されるような軌跡(31)を描いて基板の外側へ飛散させた。 The scanning speed Vs is expressed by a proportional relationship (Vs∝Rj × nrev) with the product of the water jump radius Rj and the wafer rotation speed nrev. When the rotation speed of the substrate is 150 rpm, Vs = 12.45 mm / sec, The substrate surface may be cleaned while scanning the nozzle at high speed. In this case, the cleaning liquid was scattered to the outside of the substrate along a locus (31) as shown in FIG.

本洗浄を行うことによって、ベーカーからの汚染を防止することが可能となる。すなわち、ベーク工程によって保護膜をベークした際の昇華物がベーカーに付着したものが、保護膜上に飛散して基板表面に付着するが、このベーカーからの汚染を防止することができる。 By performing the main cleaning, contamination from the baker can be prevented. That is, although the sublimation product when the protective film is baked by the baking process adheres to the baker, it is scattered on the protective film and adheres to the substrate surface, but contamination from the baker can be prevented.

この基板を、塗布現像装置とインターフェースユニットを介してインライン接続したArF液浸露光装置に搬送し、液浸露光を行い、第1の実施の形態と同様に液浸露光後の洗浄も行い、基板の表面と裏面に水滴痕がない洗浄、乾燥を行った。引き続き、PEB工程、保護膜剥離、現像工程を行い、55nmライン&スペースのパターンを欠陥なく形成した。 The substrate is transported to an ArF immersion exposure apparatus connected in-line with the coating and developing apparatus via an interface unit, subjected to immersion exposure, and cleaned after immersion exposure as in the first embodiment. Washing and drying were performed with no traces of water droplets on the front and back surfaces. Subsequently, a PEB process, a protective film peeling, and a development process were performed to form a 55 nm line & space pattern without defects.

本実施の形態では液浸保護膜がある場合について説明したが、保護膜がなく、液浸露光の際の最表面がレジストである場合でもよい。この場合、水洗によって除くことができる汚染は、ベーク工程の際のレジストの昇華物がベーカーに付着しレジスト上に飛散して基板表面に付着したものである。 In the present embodiment, the case where there is an immersion protective film has been described, but there may be a case where there is no protective film and the outermost surface at the time of immersion exposure is a resist. In this case, the contamination that can be removed by washing with water is that the resist sublimate in the baking process adheres to the baker, scatters on the resist, and adheres to the substrate surface.

(第4の実施の形態)

第4の実施の形態は第1の実施の形態と同様の構成であるが、ノズルのスキャン速度Vsがノズルの位置の基板の角速度ωnzと比例関係(Vs∝ωnz)で表されるよう、ノズルを基板の外周に向かって加速しながら洗浄していく方法である。

(Fourth embodiment)

The fourth embodiment has the same configuration as that of the first embodiment, but the nozzle scan speed Vs is represented by a proportional relationship (Vs∝ωnz) with the angular velocity ωnz of the substrate at the nozzle position. This is a method of cleaning while accelerating toward the outer periphery of the substrate.

保護膜の静的接触角が78度、洗浄液が超純水であり、洗浄液の流量が0.5L/minと設定すると、ノズルから吐出した洗浄液の跳水半径が8mmであるので、スキャン開始位置Rs0は跳水半径Rjと比例(Rs0∝Rj)の関係で表される中心から5mmの位置とする。

If the static contact angle of the protective film is 78 degrees, the cleaning liquid is ultrapure water, and the flow rate of the cleaning liquid is set to 0.5 L / min, the jumping radius of the cleaning liquid discharged from the nozzle is 8 mm, so the scan start position Rs0 Is a

ノズルのスキャン速度Vsは基板の外周から30mmの位置での角速度にてVs=20mm/secで開始し、ノズルのスキャン速度を加速しながら基板表面の洗浄処理を行うとよい。この場合、洗浄液は図3で示されるような軌跡(31)を描いて基板の外側へ飛散させた。 The nozzle scanning speed Vs starts at Vs = 20 mm / sec at an angular speed of 30 mm from the outer periphery of the substrate, and the substrate surface may be cleaned while accelerating the nozzle scanning speed. In this case, the cleaning liquid was scattered to the outside of the substrate along a locus (31) as shown in FIG.

なお、本発明は上記各実施の形態のみに限定されず、要旨を変更しない範囲で適宜変形して実施できる。 In addition, this invention is not limited only to said each embodiment, In the range which does not change a summary, it can deform | transform suitably and can implement.

11…被処理基板 12…ノズル 13…洗浄液 14…残留水滴 11 ... Substrate to be treated 12 ... Nozzle 13 ... Cleaning solution 14 ... Residual water droplets

Claims (5)

前記基板上に滞留している洗浄液が存在する状態で、前記ノズルから吐出された前記洗浄液が前記基板表面に接触した際、前記ノズルから吐出された前記洗浄液が、前記基板上に滞留している前記洗浄液に衝突しないように、前記洗浄液の流量、前記基板の回転数、前記ノズルの走査速度と走査開始位置を制御することを特徴とする基板洗浄方法。 A substrate cleaning method for discharging a cleaning liquid from a nozzle above a substrate to be processed and cleaning the substrate while rotating the substrate, and discharging the cleaning liquid from the nozzle to the substrate while the nozzle is positioned at the center of the substrate. In the substrate cleaning method of scanning from the outside of the substrate to dissipate the cleaning liquid to the outside of the substrate,

The cleaning liquid discharged from the nozzle stays on the substrate when the cleaning liquid discharged from the nozzle comes into contact with the substrate surface in a state where the cleaning liquid stays on the substrate exists . said not to collide with the cleaning liquid, the flow rate of the cleaning solution, the rotational speed of the substrate, the substrate cleaning method characterized by controlling the scanning speed and the scanning start position of the nozzle.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006271072A JP4921913B2 (en) | 2006-10-02 | 2006-10-02 | Substrate cleaning method |

| US11/865,901 US20080078427A1 (en) | 2006-10-02 | 2007-10-02 | Substrate cleaning method and semiconductor device manufacturing method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006271072A JP4921913B2 (en) | 2006-10-02 | 2006-10-02 | Substrate cleaning method |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008091637A JP2008091637A (en) | 2008-04-17 |

| JP2008091637A5 JP2008091637A5 (en) | 2009-10-08 |

| JP4921913B2 true JP4921913B2 (en) | 2012-04-25 |

Family

ID=39259935

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006271072A Expired - Fee Related JP4921913B2 (en) | 2006-10-02 | 2006-10-02 | Substrate cleaning method |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US20080078427A1 (en) |

| JP (1) | JP4921913B2 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4926678B2 (en) * | 2006-12-04 | 2012-05-09 | 東京エレクトロン株式会社 | Immersion exposure cleaning apparatus and cleaning method, and computer program and storage medium |

| JP2009111186A (en) * | 2007-10-30 | 2009-05-21 | Toshiba Corp | Method for treating substrate, method for conveying substrate, and apparatus for conveying substrate |

| JP5159738B2 (en) * | 2009-09-24 | 2013-03-13 | 株式会社東芝 | Semiconductor substrate cleaning method and semiconductor substrate cleaning apparatus |

| US9698062B2 (en) * | 2013-02-28 | 2017-07-04 | Veeco Precision Surface Processing Llc | System and method for performing a wet etching process |

| US10026660B2 (en) | 2014-10-31 | 2018-07-17 | Veeco Precision Surface Processing Llc | Method of etching the back of a wafer to expose TSVs |

| US9870928B2 (en) | 2014-10-31 | 2018-01-16 | Veeco Precision Surface Processing Llc | System and method for updating an arm scan profile through a graphical user interface |

| TWI738757B (en) | 2016-04-05 | 2021-09-11 | 美商維克儀器公司 | An apparatus and method to control etch rate through adaptive spiking of chemistry |

| CN106057710B (en) * | 2016-08-02 | 2019-02-19 | 北京七星华创电子股份有限公司 | Improve the device and method of gas-liquid two-phase atomization cleaning uniformity |

| US10541180B2 (en) | 2017-03-03 | 2020-01-21 | Veeco Precision Surface Processing Llc | Apparatus and method for wafer thinning in advanced packaging applications |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002239434A (en) * | 2001-02-14 | 2002-08-27 | Tokyo Electron Ltd | Apparatus and method for forming coating film |

| JP3655576B2 (en) * | 2001-07-26 | 2005-06-02 | 株式会社東芝 | Liquid film forming method and semiconductor device manufacturing method |

| US20030192570A1 (en) * | 2002-04-11 | 2003-10-16 | Applied Materials, Inc. | Method and apparatus for wafer cleaning |

| JP2004335542A (en) * | 2003-04-30 | 2004-11-25 | Toshiba Corp | Method of cleaning and drying substrate |

| JP2006024715A (en) * | 2004-07-07 | 2006-01-26 | Toshiba Corp | Lithography apparatus and pattern forming method |

| JP4324527B2 (en) * | 2004-09-09 | 2009-09-02 | 東京エレクトロン株式会社 | Substrate cleaning method and developing apparatus |

| JP4459774B2 (en) * | 2004-10-12 | 2010-04-28 | 東京エレクトロン株式会社 | Substrate processing method, substrate processing apparatus, and computer program |

| US7476616B2 (en) * | 2004-12-13 | 2009-01-13 | Fsi International, Inc. | Reagent activator for electroless plating |

-

2006

- 2006-10-02 JP JP2006271072A patent/JP4921913B2/en not_active Expired - Fee Related

-

2007

- 2007-10-02 US US11/865,901 patent/US20080078427A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| US20080078427A1 (en) | 2008-04-03 |

| JP2008091637A (en) | 2008-04-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4921913B2 (en) | Substrate cleaning method | |

| US11367630B2 (en) | Substrate cleaning method, substrate cleaning system, and memory medium | |

| US6864187B2 (en) | Method of washing a semiconductor wafer | |

| TWI619190B (en) | Liquid processing method, memory medium and liquid processing device | |

| US7926439B2 (en) | Substrate processing apparatus | |

| JP5680705B2 (en) | Substrate processing method | |

| JP2021073739A (en) | Substrate cleaning method | |

| JP2006245381A (en) | Device and method for washing and drying substrate | |

| JPH11297652A (en) | Substrate treatment apparatus | |

| JP5276559B2 (en) | Substrate processing method and substrate processing apparatus | |

| JP2008016781A (en) | Substrate processing method and substrate processing apparatus | |

| US6090534A (en) | Device and method of decreasing circular defects and charge buildup integrated circuit fabrication | |

| US10483126B2 (en) | Semiconductor manufacturing apparatus and manufacturing method of semiconductor device | |

| US9937520B2 (en) | Substrate treating method | |

| JP4919409B2 (en) | Semiconductor device manufacturing method | |

| JP2008249854A (en) | Method of cleaning photomask | |

| JP2008258441A (en) | Substrate processing method, and substrate processor | |

| JP2004022783A (en) | Treatment device | |

| JPH1074686A (en) | Chemical liquid treating method and device | |

| WO2021230344A1 (en) | Cleaning device and cleaning method | |

| JP4492931B2 (en) | Method for forming photoresist pattern | |

| JP2008171923A (en) | Wafer cleaning apparatus, and wafer cleaning method | |

| KR102596300B1 (en) | Substrate cleaning apparatus | |

| KR100641540B1 (en) | Resist coater and method for cleaning the same | |

| KR100744277B1 (en) | Apparatus for bead in the edge of a semiconductor wafer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090825 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090825 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110307 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110412 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110613 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120110 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120203 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150210 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |