JP4688479B2 - 回転機械を評価するための方法及び装置 - Google Patents

回転機械を評価するための方法及び装置 Download PDFInfo

- Publication number

- JP4688479B2 JP4688479B2 JP2004340295A JP2004340295A JP4688479B2 JP 4688479 B2 JP4688479 B2 JP 4688479B2 JP 2004340295 A JP2004340295 A JP 2004340295A JP 2004340295 A JP2004340295 A JP 2004340295A JP 4688479 B2 JP4688479 B2 JP 4688479B2

- Authority

- JP

- Japan

- Prior art keywords

- coating

- component

- laser

- turbine

- computer program

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/62—Systems in which the material investigated is excited whereby it emits light or causes a change in wavelength of the incident light

- G01N21/71—Systems in which the material investigated is excited whereby it emits light or causes a change in wavelength of the incident light thermally excited

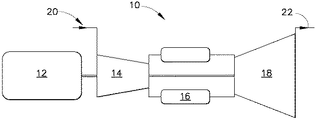

- G01N21/718—Laser microanalysis, i.e. with formation of sample plasma

Landscapes

- Health & Medical Sciences (AREA)

- Physics & Mathematics (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- Optics & Photonics (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Investigating, Analyzing Materials By Fluorescence Or Luminescence (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Investigating Or Analysing Materials By Optical Means (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/722,298 US7064825B2 (en) | 2003-11-25 | 2003-11-25 | Methods and apparatus for evaluating rotary machinery |

| US10/722,298 | 2003-11-25 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005155631A JP2005155631A (ja) | 2005-06-16 |

| JP2005155631A5 JP2005155631A5 (enExample) | 2008-01-17 |

| JP4688479B2 true JP4688479B2 (ja) | 2011-05-25 |

Family

ID=34465682

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004340295A Expired - Fee Related JP4688479B2 (ja) | 2003-11-25 | 2004-11-25 | 回転機械を評価するための方法及び装置 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US7064825B2 (enExample) |

| EP (1) | EP1536222A3 (enExample) |

| JP (1) | JP4688479B2 (enExample) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005027260B4 (de) * | 2005-06-13 | 2007-03-29 | Daimlerchrysler Ag | Verfahren und Vorrichtung zur Qualitätsbestimmung einer Schweißnaht oder einer thermischen Spritzschicht und Verwendung |

| US20070296967A1 (en) * | 2006-06-27 | 2007-12-27 | Bhupendra Kumra Gupta | Analysis of component for presence, composition and/or thickness of coating |

| US7440097B2 (en) * | 2006-06-27 | 2008-10-21 | General Electric Company | Laser plasma spectroscopy apparatus and method for in situ depth profiling |

| US7535565B1 (en) | 2008-01-08 | 2009-05-19 | General Electric Company | System and method for detecting and analyzing compositions |

| WO2014084680A1 (ko) | 2012-11-29 | 2014-06-05 | 주식회사 엘지화학 | 혼합 양극재를 포함하는 이차 전지의 출력 추정 장치 및 방법 |

| JP6119812B2 (ja) * | 2014-08-27 | 2017-04-26 | Jfeスチール株式会社 | スラグ組成の分析方法及び溶融金属の精錬方法 |

| US10232473B2 (en) | 2016-02-26 | 2019-03-19 | General Electric Company | System and method for performing laser induced breakdown spectroscopy during laser ablation coating removal |

| US20210094121A1 (en) * | 2019-09-30 | 2021-04-01 | The Boeing Company | Methods, Systems, and Apparatuses for Laser Ablation Process Control in Real Time |

Family Cites Families (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4677034A (en) | 1982-06-11 | 1987-06-30 | General Electric Company | Coated superalloy gas turbine components |

| US4543486A (en) | 1983-05-20 | 1985-09-24 | The United States Of America As Represented By The Secretary Of The Army | Method and apparatus for using a photoacoustic effect for controlling various processes utilizing laser and ion beams, and the like |

| US4634291A (en) | 1984-11-26 | 1987-01-06 | General Electric Company | Coating thickness measurement |

| US4818118A (en) | 1984-11-26 | 1989-04-04 | General Electric Company | Coating thickness measurement |

| JPH01116433A (ja) * | 1987-10-29 | 1989-05-09 | Agency Of Ind Science & Technol | レーザ発光による微粒子濃度計測法 |

| US5216808A (en) | 1990-11-13 | 1993-06-08 | General Electric Company | Method for making or repairing a gas turbine engine component |

| US6149389A (en) | 1996-03-13 | 2000-11-21 | Forschungszentrum Karlsruhe Gmbh | Protective coating for turbine blades |

| US5742028A (en) | 1996-07-24 | 1998-04-21 | General Electric Company | Preloaded laser shock peening |

| US5730528A (en) | 1996-08-28 | 1998-03-24 | Lockheed Martin Energy Systems, Inc. | High temperature thermometric phosphors for use in a temperature sensor |

| US5847825A (en) | 1996-09-25 | 1998-12-08 | Board Of Regents University Of Nebraska Lincoln | Apparatus and method for detection and concentration measurement of trace metals using laser induced breakdown spectroscopy |

| US5978074A (en) | 1997-07-03 | 1999-11-02 | Therma-Wave, Inc. | Apparatus for evaluating metalized layers on semiconductors |

| US6159619A (en) | 1997-12-18 | 2000-12-12 | General Electric Company | Ripstop laser shock peening |

| US6005219A (en) | 1997-12-18 | 1999-12-21 | General Electric Company | Ripstop laser shock peening |

| US5932120A (en) | 1997-12-18 | 1999-08-03 | General Electric Company | Laser shock peening using low energy laser |

| US6197424B1 (en) | 1998-03-27 | 2001-03-06 | Siemens Westinghouse Power Corporation | Use of high temperature insulation for ceramic matrix composites in gas turbines |

| US6008896A (en) | 1998-07-01 | 1999-12-28 | National Research Council Of Canada | Method and apparatus for spectroscopic analysis of heterogeneous materials |

| AUPP573098A0 (en) * | 1998-09-04 | 1998-10-01 | Generation Technology Research Pty Ltd | Apparatus and method for analyzing material |

| US6075593A (en) * | 1999-08-03 | 2000-06-13 | General Electric Company | Method for monitoring and controlling laser shock peening using temporal light spectrum analysis |

| US6283714B1 (en) | 1999-08-11 | 2001-09-04 | General Electric Company | Protection of internal and external surfaces of gas turbine airfoils |

| US6488986B2 (en) | 2001-01-29 | 2002-12-03 | General Electric Company | Combined coat, heat treat, quench method for gas turbine engine components |

| US6532068B2 (en) | 2001-07-17 | 2003-03-11 | National Research Council Of Canada | Method and apparatus for depth profile analysis by laser induced plasma spectros copy |

| US6629464B2 (en) * | 2001-10-03 | 2003-10-07 | Ui Won Suh | Laser shock peening quality assurance by acoustic analysis |

| US6380512B1 (en) | 2001-10-09 | 2002-04-30 | Chromalloy Gas Turbine Corporation | Method for removing coating material from a cooling hole of a gas turbine engine component |

| US6794602B2 (en) | 2001-10-18 | 2004-09-21 | General Electric Company | Method and apparatus for cleaning generator and turbine components |

| JP2003247943A (ja) * | 2002-02-26 | 2003-09-05 | Mitsubishi Heavy Ind Ltd | セラミックス被覆材の非破壊検査法 |

-

2003

- 2003-11-25 US US10/722,298 patent/US7064825B2/en not_active Expired - Fee Related

-

2004

- 2004-11-24 EP EP04257276A patent/EP1536222A3/en not_active Withdrawn

- 2004-11-25 JP JP2004340295A patent/JP4688479B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US7064825B2 (en) | 2006-06-20 |

| EP1536222A3 (en) | 2005-09-14 |

| EP1536222A2 (en) | 2005-06-01 |

| JP2005155631A (ja) | 2005-06-16 |

| US20050110991A1 (en) | 2005-05-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7535565B1 (en) | System and method for detecting and analyzing compositions | |

| US8656589B2 (en) | Aerofoil assembly and a method of manufacturing an aerofoil assembly | |

| US7925454B1 (en) | Process for determining a remaining life of a deteriorated turbine component | |

| US20070296967A1 (en) | Analysis of component for presence, composition and/or thickness of coating | |

| US11504813B2 (en) | Methods for health monitoring of ceramic matrix composite components in gas turbine engines | |

| US20170247797A1 (en) | System and method for performing laser induced breakdown spectroscopy during laser ablation coating removal | |

| JP5916059B2 (ja) | 波長可変ダイオードレーザを用いたガスタービンの高温ガス温度測定 | |

| JP4688479B2 (ja) | 回転機械を評価するための方法及び装置 | |

| US20160301880A1 (en) | System to prognose gas turbine remaining useful life | |

| JP6010431B2 (ja) | ターボ機械の動作温度を推定するためのシステム及び方法 | |

| US8536544B2 (en) | Apparatus and a method of determining the presence of an alumina layer on a surface of a component | |

| EP1227222B1 (en) | Utilization of pyrometer data to detect oxidation | |

| US11340184B2 (en) | Engine component performance inspection sleeve and method of inspecting engine component | |

| GB2449709A (en) | Method and apparatus for determining a clearance between relatively movable components | |

| US11149581B2 (en) | Turbine engine component with overstress indicator | |

| US20140358452A1 (en) | Method for estimating crack length progressions | |

| JP2009074857A (ja) | ニッケル基合金部品の寿命推定方法 | |

| JP4986730B2 (ja) | 高温用金属製品のコーティング劣化度判定方法 | |

| JP2009074868A (ja) | ニッケル基合金部品の寿命推定方法 | |

| KR20190085031A (ko) | 플래시 서모그래피 보어스코프 | |

| DE MARIA et al. | OPTICAL DEVICE FOR INTEGRITY ASSESSMENT OF THERMAL BARRIER COATINGS |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20071121 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071121 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100406 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20100702 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20100702 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20100702 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20100707 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101005 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110118 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110215 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140225 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |