JP4648570B2 - Fur fabric and products using it - Google Patents

Fur fabric and products using it Download PDFInfo

- Publication number

- JP4648570B2 JP4648570B2 JP2001151035A JP2001151035A JP4648570B2 JP 4648570 B2 JP4648570 B2 JP 4648570B2 JP 2001151035 A JP2001151035 A JP 2001151035A JP 2001151035 A JP2001151035 A JP 2001151035A JP 4648570 B2 JP4648570 B2 JP 4648570B2

- Authority

- JP

- Japan

- Prior art keywords

- fur

- string

- net

- base

- fabric

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D5/00—Fur garments; Garments of fur substitutes

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D23/00—General weaving methods not special to the production of any particular woven fabric or the use of any particular loom; Weaves not provided for in any other single group

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41H—APPLIANCES OR METHODS FOR MAKING CLOTHES, e.g. FOR DRESS-MAKING OR FOR TAILORING, NOT OTHERWISE PROVIDED FOR

- A41H41/00—Machines or appliances for making garments from natural or artificial fur

Description

【0001】

【発明の属する技術分野】

本願発明は、ネット状ベースに紐状毛皮又は毛付き紐状人造物を取付けて成る毛皮生地及びこれを使用した製品に関するものである。

【0002】

【従来の技術】

毛皮製品において、ファッション性の向上や軽量化、原皮の有効利用などの観点から、原皮を細い紐状に裁断し、この紐状毛皮を素材として生地を製造することが提案されている。

【0003】

その例として、実開昭61−155384号公報、特開昭64-45836号公報、特開平1-213432号公報には、紐状毛皮を縦糸(経糸)と横糸(緯糸)として織ることによって生地となすか、又は、紐状毛皮と他の糸とを織って生地となすことが開示されている。また、実用新案登録第3027596 号公報には、紐状毛皮と毛糸とをニット編みして生地と成すことが開示されている。

【0004】

また、特開平5-171551号公報、特開平6- 81000号公報、実用新案登録第3008585 号公報には、ネット状のベースに紐状毛皮を絡ませて生地と成すことが記載されている。

【0005】

更に、実開昭57-74953号公報には、多数の帯状毛皮と多数の帯状伸縮性布とを交互に並べて、隣合った帯状毛皮と帯状伸縮性布とを縫い合わせて生地と成すこと、及び、小さな四角形に裁断された角形毛皮と角形伸縮性布とを縦横に交互に整列して並べ、隣合った角形毛皮と角形伸縮性布とを互いに縫い合わせて生地と成すことが記載されている。

【0006】

【発明が解決しようとする課題】

実開昭57-74953号公報を除いた各従来技術は、生地が殆ど伸縮しないため身体へのフィット性に欠けるという問題があった。他方、実開昭57-74953号公報の場合は生地を伸縮させることはできるが、生地に作用した引っ張り力が縫い目の部分にそのまま作用するため、破れ易くて実用性に乏しいという問題があった。

【0007】

そこで、本願出願人は、特願2000−130077号において、一連に広がる伸縮性のベースに紐状毛皮又はその類似物を取付けて成る伸縮性の毛皮生地又は毛皮状生地を提案した。本願発明は、この先願と同様であり、強度に優れた伸縮性毛皮生地と製品を提供せんとするものである。

【0033】

【課題を解決するための手段】

請求項1の発明は生地に係るもので、この生地は、伸縮性糸の群と非伸縮性糸の群とが交叉したネット状ベースと、紐状毛皮又は毛付き紐状人造物とから成り、前記ネット状ベースには前記紐状毛皮又は毛付き紐状人造物を通し得る網目の群が空いており、前記網目に前記紐状毛皮又は毛付き紐状人造物を通すことにより、前記非伸縮性糸に前記紐状毛皮又は毛付き紐状人造物を巻き付けている。

【0034】

本願発明は、請求項2に記載したように、請求項1に記載した毛皮生地を使用している製品も含んでいる。

【0038】

【発明の作用・効果】

【0041】

本願発明では、生地に作用した外力(主として引張り力)が紐状毛皮又は毛付き紐状人造物に直接に作用することは殆どないか又は少ないため、生地の強度は著しく高い。

【0042】

従って本願発明では、ネット状ベースと紐状毛皮又は毛付き紐状人造物とから成る伸縮性の生地を、強度を向上した状態で提供できる。

【0043】

例えばスカートに適用した場合、人の身体へのフィット性には主として横糸が寄与しているので、スカートを例にとると、横糸のみを伸縮性の弾性糸で構成して縦糸は伸縮しない非弾性糸を使用して、非弾性の縦糸に紐状毛皮又は毛付き紐状人造物を巻き付けることにより、製品の保形機能を向上できる。

【0045】

【発明の実施形態】

次に、本発明の参考例及び実施形態を図面に基づいて説明する。

【0046】

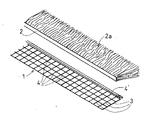

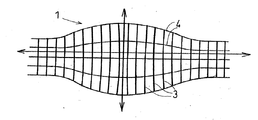

(1).第1参考例(図1〜図3)

図1〜図3で示す第1参考例では、縦横に大きく伸縮するネット状ベース1を使用している。図1は分離斜視図、図2はネット状ベース1を伸ばした状態の平面図、図3は紐状毛皮2の巻き付け状態を示す一部破断平面図である。ネット状ベース1は、ゴムのように大きく伸縮する縦糸3の群と横糸4の群とから成っており、端部に位置した横糸4に紐状毛皮2を巻き付けている。

【0047】

端部に位置した横糸4には太い補強糸4′が重なっている。また、紐状毛皮2は、毛2aが外側に位置する状態で(スキン面が横糸4に重なる状態で)横糸4に巻き付けている。紐状毛皮2は、全ての横糸4に巻き付けても良いし、一つ飛びや二つ飛びの状態で巻き付けても良い。図3では、紐状毛皮2の毛2aの部分は一部省略している。

【0048】

衣類のフードのように衣服本体に着脱自在に取付けるものの場合は、紐状毛皮2が通っていない網目の群を少なくとも1列残しておくと、その網目の部分を引き延ばしてボタンに嵌め込むことにより、フードなどを衣服本体に簡単にしかも外れ落ちない状態に取付けることができる。

【0049】

なお、ネット状ベース1を構成する縦糸3と横糸4との区別は便宜的なものであり、区別すること自体には大きな意味はない。1つのネット状ベース1において、ある部分では紐状毛皮2を横糸4に巻き付け、ある部分では縦糸3に紐状毛皮2を巻き付けるということも可能である。

【0050】

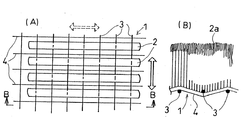

(2).第1実施形態(図4)

図4では第1実施形態を示しており、(A)は一部省略平面図、(B)は(A)のB−B視図である。この例は、ネット状ベース1の周囲に伸縮性布地からなる縁布5を縫い付けている。これは、生地同士の縫い合わせや、衣服本体への縫い付け等の便宜のためである。この例では、縦糸3は弾性糸からなっていて横糸4は非弾性糸からなっており、紐状毛皮2は1列飛ばしの状態で横糸4に巻き付けている。

【0050】

(3).第2参考例(図5)

図5では第2参考例を示している。(A)は一部省略平面図、(B)は(A)のB−B視図である。この例では、ネット状ベース1の隣合った網目に紐状毛皮2を交互に通している。

【0051】

従って、紐状毛皮2の毛2aはネット状ベース1の片面だけに露出している。この例の場合、紐状毛皮2を張った状態でネット状ベース1の目に通している場合は、生地は紐状毛皮2の長手方向には殆ど伸びないので、ネット状ベース1は縦糸3だけが伸縮する構造でも良い。

【0052】

他方、両糸3,4を伸縮性のあるもので製造すると共に、紐状毛皮2を、ある程度の余裕をもった状態で(すなわち、後述の図8と同様に、紐状毛皮2の長さをネット状ベース1の長さよりも長くして)ネット状ベース1 の目に通すと、生地は縦横の両方向に伸縮させることができる。

【0053】

(4).第3参考例(図6)

図6に示す第3参考例も紐状毛皮2をネット状ベース1の網目に通しただけのものであるが、この例では、紐状毛皮2をゴム紐のような弾性芯6に巻き付けておき、これをネット状ベース1に通している。

【0054】

従って、ネット状ベース1の両面に紐状毛皮2の毛2aが露出している。弾性芯6の存在により、紐状毛皮2はその長手方向に伸びることができ、かつ、ずれ動きがない利点がある。

【0055】

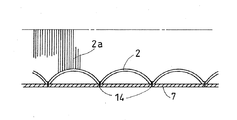

(5).第4参考例(図7〜図8)

図7〜8に示すのは第4参考例であり、図7は平面図、図8は図7の VIII-VIII視断面図である。この第4参考例では、伸縮性ベースとして、弾性糸で織られた布状ベース7を使用しており、適当な間隔で平行に並べた多数本の紐状毛皮2を布状ベース7に縫い付け固定している。布状ベース7に裏地の役割を持たせることができる利点がある。

【0056】

この場合、紐状毛皮2は、長手方向に沿って飛び飛びの状態で布状ベース7に糸14で縫着しており、かつ、隣合った縫い付け箇所の間の部位がアーチ状になるように設定している。このため、生地は紐状毛皮2の長手方向にも多少は伸縮させることができる。

【0057】

(6).第5参考例(図9)

図9に示す第5参考例では、上ネット状ベース1aと下ネット状ベース1bとで紐状毛皮2の群をサンドイッチ状に挟み、両ネット状ベース1a,1bを糸などの適宜手段で離反不能に固定している。この場合、紐状毛皮2の側に位置した上ネット状ベース1はできるだけ細い糸で構成するのが好ましい。両ネット状ベース1とも、紐状毛皮2と交叉した方向のみに伸縮すれば足りる。

【0058】

(7).第2実施形態(図10〜図13)

図10〜図13では、製品に適用した第2実施形態を示している。図10(A)の第1製品例は、伸縮性毛皮生地で製造されたキャップ状の帽子8である。帽子8は大きく伸び変形するため、頭のサイズが異なる人が被ってもぴったりとフィットする。

【0059】

図10(B)の第2製品例は、伸縮性毛皮生地によって製造されたループ状のマフラー9である。マフラー9はその長手方向に伸びるため、幾重かに巻いて首にピッタリとフィットさせることができる。ループ状又は筒状に形成される他の製品としては、例えばリストバンド、レッグウォーマー、ハンドウォーマー、腹巻などが挙げられる。

【0060】

図10(C)では、第3製品例として、通常の帽子10に着脱自在に取付ける飾り11を表示している。この場合、帽子10が飾り11でが締め付けられているため、飾り11が風で簡単に外れることはない。従って、ホックなどを使用しなくても、ユーザーは、天候や好みなどに応じて、飾り11を取付けたり外したりする選択をすることができる。

【0061】

図11〜図12では第4製品例としてマフラー9を表示しており、このマフラー9は、一端寄り部位の箇所にスリット12を設けている。そして、図12に示すように、スリット12にマフラー9の他端部を挿入すると、マフラー9は環状になる。図11で4条の平行斜線を表示しているが、これは模様や色彩の違いを表示したものである。

【0061】

図13では、第5製品例としてスカート13を表示している。この場合、ネット状ベース1は、横糸4のみが伸び変形する。また、紐状毛皮2は縦糸3に巻き付けている。

【0062】

人の身体へのフィット性には主として横糸4が寄与しているので、横糸4のみを弾性糸で構成し、縦糸3は非弾性糸を使用している(これにより、製品の保形機能を向上できる)。

【0108】

なお、紐状毛皮に代えて人造の類似物(すなわち毛付き紐状人造物)を使用できる。類似物としては、帯状部に毛を植毛又は起毛した構造のものや、芯材の周囲に毛を植毛したものなど、様々の構造のものがある。

【0109】

【図面の簡単な説明】

【図1】第1参考例の分離斜視図である。

【図2】第1参考例に使用するネット状ベースの平面図である。

【図3】第1参考例の一部破断図である。

【図4】第1実施形態を示す図である。

【図5】第2参考例を示す図である。

【図6】第3参考例を示す図である。

【図7】第4参考例の一部省略平面図である。

【図8】図7の VIII-VIII視断面図である。

【図9】第6参考例を示す図である。

【図10】第2実施形態に係る第1〜第3製品例を示す図である。

【図11】第2実施形態に係る第4製品例の一部破断平面図である。

【図12】第2実施形態に係る第4製品例の使用状態を示す図である。

【図13】第2実施形態に係る第5製品例の一部破断斜視図である。

【符号の簡単な説明】

1 ネット状ベース

2 紐状毛皮

3 ネット状ベースを構成する縦糸

4 ネット状ベースを構成する横糸

8 製品の一例としての帽子

9 製品の一例としてのマフラー

11 製品の一例として帽子用飾り

13 製品の一例としてスカート[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a fur fabric formed by attaching a string-like fur or a hair-like string-like artificial object to a net-like base, and a product using the same.

[0002]

[Prior art]

For fur products, from the viewpoint of improving fashionability, weight reduction, and effective use of raw leather, it has been proposed to cut the raw leather into a thin string shape, and to produce a fabric using the string-shaped fur as a material.

[0003]

As an example, Japanese Utility Model Laid-Open No. 61-155384, Japanese Patent Laid-Open No. 64-45836, and Japanese Patent Laid-Open No. 1-213432 describe fabrics by weaving string-like fur as warp (warp) and weft (weft). It is disclosed that a fabric is made by weaving a string-like fur and another thread. Japanese Utility Model Registration No. 3027596 discloses knit knitting of string-like fur and yarn to form a fabric.

[0004]

Japanese Patent Application Laid-Open Nos. H5-171551, H6-81000, and Utility Model Registration No. 3008585 describe that a string-like fur is entangled with a net-like base to form a fabric.

[0005]

Furthermore, Japanese Utility Model Publication No. 57-74953 discloses that a large number of strip-shaped furs and a large number of strip-shaped stretchable fabrics are alternately arranged, and the adjacent strip-shaped fur and strip-shaped stretchable fabrics are stitched together to form a fabric, and In addition, it is described that square fur and square elastic cloth cut into small squares are alternately arranged vertically and horizontally, and adjacent square fur and square elastic cloth are sewn together to form a fabric.

[0006]

[Problems to be solved by the invention]

Each of the conventional techniques except Japanese Utility Model Publication No. 57-74953 has a problem that the fabric is hardly stretched and thus lacks fit to the body. On the other hand, in the case of Japanese Utility Model Publication No. 57-74953, the fabric can be expanded and contracted, but the tensile force acting on the fabric acts on the seam as it is, so there is a problem that it is easy to break and is not practical. .

[0007]

Accordingly, the applicant of the present application has proposed a stretchable fur fabric or a furlike fabric in which a string-like fur or the like is attached to a series of stretchable bases in Japanese Patent Application No. 2000-130077. The present invention is similar to this prior application, and intends to provide a stretchable fur fabric and a product excellent in strength.

[0033]

[Means for Solving the Problems]

The invention of

[0034]

The present invention includes a product using the fur fabric according to

[0038]

[Operation and effect of the invention]

[0041]

In the present invention, since the external force (mainly tensile force) acting on the fabric hardly or hardly acts directly on the string-like fur or the hair-like string-like artificial object, the strength of the fabric is remarkably high.

[0042]

Therefore, in this invention, the stretchable cloth which consists of a net-like base and a string-like fur or a string-like artificial object with hair can be provided in the state which improved the intensity | strength.

[0043]

For example, when applied to a skirt, wefts mainly contribute to the human body's fit. Therefore, taking the skirt as an example, only the wefts are made of elastic elastic yarns, and the warp yarns are not elastic. use yarn, the string-like fur or the inelastic warp yarns by winding flocked string-like artificial material, it is possible to improve the shape retention capability of the product.

[0045]

DETAILED DESCRIPTION OF THE INVENTION

Next, reference examples and embodiments of the present invention will be described with reference to the drawings.

[0046]

(1). First reference example (Figs. 1-3)

In the first reference example shown in FIGS. 1 to 3, a net-

[0047]

A thick reinforcing thread 4 'overlaps the

[0048]

In the case of clothes that are detachably attached to the garment body, such as a hood of clothing, if at least one row of meshes that the string-

[0049]

Note that the distinction between the

[0050]

(2). First embodiment (FIG. 4)

FIG. 4 shows the first embodiment, where (A) is a partially omitted plan view, and (B) is a BB view of (A). In this example, an

[0050]

(3). Second reference example (Fig. 5)

FIG. 5 shows a second reference example. (A) is a partially omitted plan view, (B) is a BB view of (A). In this example, the string-

[0051]

Accordingly, the

[0052]

On the other hand, both the

[0053]

(4) Third reference example (Fig. 6)

The third reference example shown in FIG. 6 is also the one in which the string-

[0054]

Therefore, the

[0055]

(5). Fourth reference example (FIGS. 7 to 8)

7 to 8 show a fourth reference example, FIG. 7 is a plan view, and FIG. 8 is a sectional view taken along the line VIII-VIII in FIG. In this fourth reference example, a cloth-

[0056]

In this case, the string-

[0057]

(6). Fifth reference example (Fig. 9)

In the fifth reference example shown in FIG. 9, a group of string-

[0058]

(7). Second embodiment (FIGS. 10 to 13)

10 to 13 show a second embodiment applied to a product. The first product example in FIG. 10A is a cap-shaped cap 8 made of stretchable fur fabric. Since the hat 8 stretches and deforms greatly, it fits snugly even when worn by people with different head sizes.

[0059]

The second product example in FIG. 10B is a loop-shaped

[0060]

In FIG. 10C, as a third product example, a

[0061]

11 to 12, a

[0061]

In FIG. 13, a

[0062]

Since mainly the

[0108]

In addition, it can replace with a string-like fur and can use the similar thing (namely, hair-like string-like artificial object ). As similar substances, there are various structures such as a structure in which hair is planted or raised in a band-shaped portion and a structure in which hair is implanted around a core material.

[0109]

[Brief description of the drawings]

FIG. 1 is an exploded perspective view of a first reference example.

FIG. 2 is a plan view of a net-like base used in the first reference example.

FIG. 3 is a partially cutaway view of a first reference example.

FIG. 4 is a diagram showing a first embodiment.

FIG. 5 is a diagram illustrating a second reference example.

FIG. 6 is a diagram illustrating a third reference example.

FIG. 7 is a partially omitted plan view of a fourth reference example.

8 is a cross-sectional view taken along the line VIII-VIII in FIG.

FIG. 9 is a diagram illustrating a sixth reference example.

FIG. 10 is a diagram illustrating first to third product examples according to the second embodiment.

FIG. 11 is a partially broken plan view of a fourth product example according to the second embodiment.

FIG. 12 is a diagram illustrating a usage state of a fourth product example according to the second embodiment.

FIG. 13 is a partially broken perspective view of a fifth product example according to the second embodiment.

[Brief description of symbols]

DESCRIPTION OF

Claims (2)

毛皮生地。And the group of stretchable yarns and net-like base and a group of non-elastic yarn is cross consists of a string-like fur or hair with cord-like man-made, in the net-like base the cord-like fur or hair with cord-like and empty the group of mesh capable through man-made, by passing the said mesh cord-like fur or hair with cord-like man-made, the string-like fur or hair with cord-like man made structures on the non-stretchable yarn Winding,

Fur fabric.

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001151035A JP4648570B2 (en) | 2001-05-21 | 2001-05-21 | Fur fabric and products using it |

| RU2002134753/12A RU2225697C1 (en) | 2001-05-21 | 2001-10-03 | Materials and articles from strips of natural or artificial fur |

| KR10-2002-7017821A KR100487440B1 (en) | 2001-05-21 | 2001-10-03 | Fur materials and clothings and the accessory for clothing |

| CA002413159A CA2413159C (en) | 2001-05-21 | 2001-10-03 | Materials and products using strip of real or artificial fur |

| CNB018122639A CN1187000C (en) | 2001-05-21 | 2001-10-03 | Materials and products using strip of real or artificial |

| PCT/JP2001/008730 WO2002094045A1 (en) | 2001-05-21 | 2001-10-03 | Materials and products using strip of real or artificial fur |

| HK03107366A HK1054847A1 (en) | 2001-05-21 | 2003-10-14 | Materials and products using strip of real or artificial fur. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001151035A JP4648570B2 (en) | 2001-05-21 | 2001-05-21 | Fur fabric and products using it |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002339192A JP2002339192A (en) | 2002-11-27 |

| JP2002339192A5 JP2002339192A5 (en) | 2008-07-31 |

| JP4648570B2 true JP4648570B2 (en) | 2011-03-09 |

Family

ID=18995960

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001151035A Expired - Fee Related JP4648570B2 (en) | 2001-05-21 | 2001-05-21 | Fur fabric and products using it |

Country Status (7)

| Country | Link |

|---|---|

| JP (1) | JP4648570B2 (en) |

| KR (1) | KR100487440B1 (en) |

| CN (1) | CN1187000C (en) |

| CA (1) | CA2413159C (en) |

| HK (1) | HK1054847A1 (en) |

| RU (1) | RU2225697C1 (en) |

| WO (1) | WO2002094045A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100608513B1 (en) * | 2005-08-02 | 2006-08-03 | 김영호 | Functional fabric manufacture method and functional fabric |

| DE102010032121A1 (en) * | 2010-07-24 | 2012-01-26 | Christine Becker-Weber | Elastic leather clothing |

| CA2949312C (en) | 2016-03-24 | 2021-03-16 | Wolfie Furs Inc. | Garment accessory attachment mechanism |

| CN106108187B (en) * | 2016-08-31 | 2018-06-01 | 深圳歌力思服饰股份有限公司 | A kind of overturning hair neck |

| KR200485385Y1 (en) * | 2016-11-14 | 2017-12-29 | 하선경 | Functional a fur comforter |

| CN113046893A (en) * | 2019-12-27 | 2021-06-29 | 杨一山 | Human weaving machine device |

| CN112195294B (en) * | 2020-10-24 | 2022-02-11 | 故城县民夕毛皮制品有限公司 | Method for making high-end-quality mink clothes without cutter marks on rough surface |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR10199E (en) * | 1909-05-12 | Celestine Rubens Nee Suss | New kind of hygienic clothing intended to preserve the cold and to avoid excess heat | |

| US2112036A (en) * | 1936-12-23 | 1938-03-22 | Loscher Lily | Garment |

| KR870003852Y1 (en) * | 1986-04-09 | 1987-12-05 | 삼양모피 주식회사 | Wool-fabric shawl |

| JPH0681000A (en) * | 1992-09-04 | 1994-03-22 | Kinoshita Bussan Kk | Production of fur plate |

| JPH0742641B2 (en) * | 1992-12-08 | 1995-05-10 | 株式会社ロザソン | Method of manufacturing fur fabric |

| JP3220125B1 (en) * | 2000-04-28 | 2001-10-22 | 剛氏有限公司 | Fabric using string-like fur or fur-like material and products using the same |

-

2001

- 2001-05-21 JP JP2001151035A patent/JP4648570B2/en not_active Expired - Fee Related

- 2001-10-03 KR KR10-2002-7017821A patent/KR100487440B1/en not_active IP Right Cessation

- 2001-10-03 CN CNB018122639A patent/CN1187000C/en not_active Expired - Lifetime

- 2001-10-03 WO PCT/JP2001/008730 patent/WO2002094045A1/en active IP Right Grant

- 2001-10-03 RU RU2002134753/12A patent/RU2225697C1/en not_active IP Right Cessation

- 2001-10-03 CA CA002413159A patent/CA2413159C/en not_active Expired - Lifetime

-

2003

- 2003-10-14 HK HK03107366A patent/HK1054847A1/en not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| KR100487440B1 (en) | 2005-05-04 |

| CN1187000C (en) | 2005-02-02 |

| JP2002339192A (en) | 2002-11-27 |

| RU2225697C1 (en) | 2004-03-20 |

| KR20030040227A (en) | 2003-05-22 |

| WO2002094045A1 (en) | 2002-11-28 |

| HK1054847A1 (en) | 2003-12-19 |

| CA2413159C (en) | 2006-05-30 |

| CN1440245A (en) | 2003-09-03 |

| CA2413159A1 (en) | 2002-11-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3165353U (en) | Wearable towel | |

| JPH0768642B2 (en) | wig | |

| JP4648570B2 (en) | Fur fabric and products using it | |

| EP1221870B1 (en) | Materials and products using strip of real or artificial fur | |

| US20060048275A1 (en) | Headwear having exposed stitches to fix a lower hem thereof | |

| JP2002339192A5 (en) | ||

| RU2002134753A (en) | MATERIALS AND ARTICLES FROM STRIPES OF NATURAL OR ARTIFICIAL FUR | |

| JP4032100B2 (en) | Inner wear | |

| JP4284032B2 (en) | Clothing with sleeves | |

| JP3145373U (en) | Cylindrical personal items | |

| JPS62141107A (en) | Hexagonal knitting type artificial hair increasing method | |

| JP3227382U (en) | mask | |

| JP2012122172A (en) | Multifunctional clothing | |

| CN108716053B (en) | Stretchable knitted fabric | |

| KR200402409Y1 (en) | Shawl to use in muffler | |

| JP3564473B1 (en) | Annular band | |

| JP3091217U (en) | Stretchy lace knitting structure | |

| JP2022067217A (en) | Clothing fabric made by using three-dimensionally structured knitted fabric, and clothing | |

| JP2003138403A (en) | Short or girdle | |

| JP3117458U (en) | Multifunctional band for jewelry | |

| AU2001100184A4 (en) | Sweat-absorbing headgear | |

| JP3107606U (en) | Towel muffler | |

| JP2023063806A (en) | Waist nipper | |

| JP3574650B1 (en) | Band with length adjustment function | |

| JP2008174862A (en) | Knitted cap |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080521 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080618 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090520 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090820 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20090916 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100118 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20100122 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20100212 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101210 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131217 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4648570 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |