JP4631130B2 - Modified tubular product and manufacturing method thereof - Google Patents

Modified tubular product and manufacturing method thereof Download PDFInfo

- Publication number

- JP4631130B2 JP4631130B2 JP2000154583A JP2000154583A JP4631130B2 JP 4631130 B2 JP4631130 B2 JP 4631130B2 JP 2000154583 A JP2000154583 A JP 2000154583A JP 2000154583 A JP2000154583 A JP 2000154583A JP 4631130 B2 JP4631130 B2 JP 4631130B2

- Authority

- JP

- Japan

- Prior art keywords

- steel pipe

- pipe

- tube

- tubular product

- hydroforming

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、鋼管のハイドロフォーム加工により製造された部分的に強化部を備えた異形管状製品およびその製造方法に関する。

【0002】

【従来の技術】

金属素管(以下、単に素管と記す)を上下一対の金型内にセットし、この素管内に液体を導入し、液体に圧力を負荷するとともに、必要に応じて管端から軸方向に圧縮力を加えることにより素管を膨出させて金型内の形状にならった異形管状製品を得るハイドロフォーム加工(液圧バルジ加工)方法が、自動車部品等の製造に採用されている。

【0003】

このようにして製造された異形管状製品には、その膨出部が部分的に高強度であることが要求される場合がある。その場合肉厚の厚い素管や高強度の素管を用いればよいが、製品の重量が増加したり材料コストが嵩む等の問題がある。

【0004】

ハイドロフォームによる異形管状製品を部分的に強化して前記問題を解消する方法として、異形管状製品の強化が必要な部分に、強度の大きい別部品を溶接等によって接合する方法がある。

【0005】

図2は、溶接により部分強化された異形管状製品斜視図である。

【0006】

ハイドロフォームにより製造された異形管状製品1の一部に補強部材2が溶接部3により接合されている。

【0007】

しかし、このような製品にするには、補強用の別部品を溶接接合するための行程がハイドロフォーム行程とは別に必要となるという問題がある。また、溶接接合した場合、熱ひずみにより製品の寸法精度が低下するという問題に加え、溶接スパッタや溶接ビードと他部品との干渉の問題が生じる。

【0008】

文献「Proceedings of INTERNATIONAL SEMINAR ON RESENT STATUS & TREND OF THBE HYDROFORMING」july 2 1999 p76には、肉厚や強度の異なる短尺金属管を長手方向に接合した組立素管(以下、テラード素管と記す)を用いてハイドロフォームすることにより異形管状製品を製造する方法が開示されている。

【0009】

図3は、テラード素管をハイドロフォーム加工することにより得られる異形管状製品の斜視図である。図3(a)は、断面が長方形の製品例、図3(b)は断面が円形の製品例を示す。これらの異形管状製品1は、その一部に斜線で示す補強金属管2が溶接部3により接合されている。

【0010】

しかし、金属素管を製作するために、金属管同士を溶接するための行程がハイドロフォーム行程とは別に必要となる問題がある。また、金属素管が部分的に強度が異なるため、ハイドロフォーム加工する際、強度の低い部分が強度の高い部分より膨出されやすく、溶接部近傍にしわが発生して満足な製品が得られていないのが現状である。

【0011】

特開平11−5125号公報には、ハイドロフォーム加工を施す金属素管の外側に接着剤を塗布した補強用の中空部材を挿入して、ハイドロフォームをする液圧バルジ加工方法が開示されている。

【0012】

しかし、例えば、自動車用のセンターピラーレインフォースのような複雑な形状の製品をハイドロフォーム加工で成形する場合、プリフォームと呼ばれる予備プレス成形をおこなうのが一般的であり、ハイドロフォームする直前に接着剤を塗布することができない。プリフォーム前に補強用鋼管を挿入するとプリフォーム時に予期せぬ位置で接着されるという問題がある。

【0013】

【発明が解決しようとする課題】

本発明の課題は、溶接や接着剤を使用することなく部分的に補強された異形管状製品およびその製造方法を提供することにある。

【0014】

【課題を解決するための手段】

本発明者らは、上記課題を解消すべく種々実験、検討した結果、鋼管をその外径よりも大きい内径を有する補強用鋼管内に挿入し、その状態で素管内に導入した液体に圧力を負荷して膨出加工することにより鋼管および補強用鋼管を同時に拡管すれば、補強用鋼管は鋼管に強固に締結されるとの知見を得た。

【0015】

本発明は、このような知見に基づきなされたもので、その要旨は以下の通りである。

【0016】

(1)鋼管内に液体を注入し、液体に圧力を負荷して鋼管を膨出させるハイドロフォーム加工により異形管状製品を製造する方法において、鋼管の膨出予定部の所定の部位に、鋼管の外径よりも大きい内径を有する補強用鋼管を挿入した状態とし、補強用鋼管の拡管率が0.5%以上となるように、液圧により鋼管および補強用鋼管を拡管して製品形状に成形することを特徴とする部分的に強化部を備えた異形管状製品の製造方法。

【0017】

上記補強用鋼管の拡管率は、10%以下であるのが望ましい。

【0018】

【発明の実施の形態】

以下、本発明について具体的に説明する。

【0019】

図1は、本発明の異形管状製品の製造方法を説明するためのハイドロフォーム用金型部の縦断面図で、図1(a)は鋼管をハイドロフォーム加工する直前の状態、 図1(b)はハイドロフォーム加工が終了した状態、図1(c)は製品の縦断面図を示す。

【0020】

先ず、下記のようにしてハイドロフォーム用素管を用意する。

【0021】

すなわち、鋼管(以下、「素管」という。)の外径よりも大きい内径の補強用鋼管を用意し、素管の膨出予定部の補強すべき所定の部位に補強用鋼管を挿入する。補強用鋼管の長さは、補強したい長さにすればよく、複数カ所の補強が必要であれば、複数の補強用鋼管を挿入すればよい。また、肉厚も目的により任意に選択すればよく、材質も素管と同じでなくとも、より強度の大きい材質であってもよい。

【0022】

図1(a)に示すように、先ず図示しないプレス装置に搭載された上下一対の金型4a、4bの内部に、用意した補強用鋼管6を挿入した素管5をセットし、両管端を軸押し工具7a、7bでシールして加工液の導入口8から液体を導入して素管5内を液体で満たす。液体としては、防錆剤を添加した水が一般的に用いられる。

【0023】

次いで、加工液の圧力を増加させながら、必要に応じて軸押し工具7a、7bを前進させて素管5に軸方向の押圧力を付与して素管5を上下方向に徐々に膨出させる。図1(b)の状態でハイドロフォーム加工は完了する。図1(c)は、金型から取り出された異形管状製品の縦断面図である。上記のように素管5とそれに挿入させた補強用鋼管6とを同時に膨出加工することにより、膨出部5aと補強用鋼管6とは強固に締結着される。

【0024】

本方法に基づいてハイドロフォーム加工した場合、素管(以下、内管と記す場合がある)のみの部分(以下単管部と記す場合がある)と、内管と補強用鋼管(以下、外管と記す場合がある)の2重となっている部分(以下2重管部と記す)とは強度差があるため拡管時に下記のような形状不良が発生する場合がある。図4は、形状不良を説明するための図で、図4(a)は補強用鋼管に挿入した素管をハイドロフォーム加工した際に形状不良11が発生した異形管状製品の縦断面図で、図4(b)は単管と2重管との境界部分の拡大図である。

【0025】

この形状不良11は、2重管部と単管部との強度差が大きく、外管の拡管率が大きい場合に発生する。すなわち、強度差が大きいとハイドロフォーム加工時に、単管部が2重管部よりも膨出し易いので必要以上に膨出し、2重管と金型間の間に単管の膨出部の一部が回り込み、形状不良11が発生するのである。

【0026】

この形状不良は、製品の形状がわるくなるのみでなく、製品に荷重が付加された場合、応力集中により内管のみの場合よりも強度が低下する場合がある。

【0027】

このような形状不良の発生を防止するには、外管の拡菅率は10%以下に押さえることが望ましく、さらに好ましくは5%以下である。なお、拡管率とは管の周長の増加率である。

【0028】

また、製品形状に平坦部があるようなハイドロフォーム加工の場合は、外管の拡菅率が小さいと単管部と2重管部とのフラットネスが出ないため外管の拡菅率は0.2%以上にするのが好ましく、さらに好ましくは0.5%以上である。次に、補強用鋼管の管端部の好ましい形状について説明する。

【0029】

図5は、ハイドロフォーム加工後の外管と内管との境界部を拡大した縦断面図である。図5(a)外管6の端面12が垂直になっている場合、図5(b)は外管端全面において内面面取りが施されている場合、図5(c)は外管端面において一部内面面取りが施されている場合、および図5(d)は(b)の場合にさらに面取りされた面と外管内面と交わる部分を曲面(R)にした場合をそれぞれ示す。

【0030】

図5(a)に示したような外管の端面の場合、外管部の肉厚のため内管に急角度の折れ曲がり部13が生じ、応力集中による強度低下を引き起こす場合がある。したがって、応力の負荷が大きい用途には適していない。

【0031】

そこで、図5(b)に示すように外管端面を予め内面面取り加工を施しておくのが望ましい。面取り角θが大きいと効果が無く、小さすぎると面取り加工の負荷の増大、シャープエッジによる作業者の危険、ハンドリング時の面取り部の変形等の問題が生じるため、5° < θ < 60°とすることが望ましい。

【0032】

図5(c)に示すように一部内面面取り加工しない部分を残しておくと上記問題が解消できる。

【0033】

図5(d)のように、面取り加工を施し、さらに面取りされた面と外管内面と交わる部分を曲面(R)にするとさらによい。

【0034】

【実施例】

図6は、本実施例で用いた金型のダイス溝形を示す。この金型を用いて、表1に示す外管内に内管を挿入し、図1で示した方法でハイドロフォーム加工を施した。外管と内管とは、共に機械構造用炭素鋼鋼管STKM11Aを用いた。外管は、面取りしない管と面取り角度を種々変化させた面取りした管とを用意した。

【0035】

金型のダイス溝寸法は下記の通りであった。

【0036】

D1=73mm

L1:500mm

L2:275mm

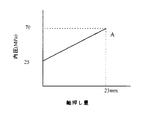

図7は、ハイドロフォーム加工時の内圧、軸押し、ポンチの動作パターンである。ハイドロフォーム加工後、外管と内管との境界部を観察し形状不良の有無を調べた。結果を表1に示す。

【0037】

【表1】

表1から明らかなように、外管が、外径:65mm、肉厚:2.3mmで拡管率が12.3%の場合には、形状がやや不良であったが応力の負荷が小さい用途には使用できる程度であり、それ以外は全て良好であった。

【0038】

図8は、表1の試験No.6のハイドロフォーム加工後の外観写真を示す図である。内管の膨出部5a表面と外管6の表面とが同一面となった状態で圧着されていることが分かる。

【0039】

【発明の効果】

本発明によれば、溶接や接着剤を使用することなく部分的に補強された異形管状製品を最小限の重量増により製造することができる。また、既存の金型を用いて容易にハイドロフォーム加工することができる。

【図面の簡単な説明】

【図1】本発明の異形管状製品の製造方法を説明するためのハイドロフォーム用金型部の縦断面図である。

【図2】溶接により部分強化された異形管状製品斜視図である。

【図3】テラード素管をハイドロフォーム加工することにより得られる異形管状製品の斜視図である。

【図4】形状不良を説明するための製品の縦断面図である。

【図5】ハイドロフォーム加工後の外管と内管との境界部を拡大した縦断面図である。

【図6】本実施例で用いた金型のダイス溝形を示す図である。

【図7】ハイドロフォーム加工時の内圧、軸押し、ポンチの動作パターンを示す図である。

【図8】本発明の製造方法により得られた異形管状製品の外観図である。

【符号の説明】

1 異形管状製品

2 補強材

3 溶接部

4a 上金型

4b 下金型

5 鋼管(素管)

6 補強用鋼管

7a、7b 軸押し工具

8 液体導入口[0001]

BACKGROUND OF THE INVENTION

TECHNICAL FIELD The present invention relates to a modified tubular product having a partially strengthened portion manufactured by hydroforming a steel pipe and a method for manufacturing the same.

[0002]

[Prior art]

A metal pipe (hereinafter simply referred to as a pipe) is set in a pair of upper and lower molds, liquid is introduced into the pipe, pressure is applied to the liquid, and axially from the pipe end as necessary. A hydroforming process (hydraulic bulging process) for obtaining a deformed tubular product having a shape in a mold by expanding a base pipe by applying a compressive force has been adopted for manufacturing automobile parts and the like.

[0003]

The deformed tubular product manufactured in this way may be required to have a partially high bulge portion. In that case, a thick pipe or a high-strength pipe may be used, but there are problems such as an increase in the weight of the product and an increase in material cost.

[0004]

As a method for partially reinforcing a deformed tubular product by hydroforming to solve the above problem, there is a method of joining another part having high strength to a portion where the strengthening of the deformed tubular product is necessary by welding or the like.

[0005]

FIG. 2 is a perspective view of a deformed tubular product partially reinforced by welding.

[0006]

A reinforcing

[0007]

However, in order to obtain such a product, there is a problem that a process for welding and joining another reinforcing component is required separately from the hydroforming process. In addition, when welded, in addition to the problem that the dimensional accuracy of the product decreases due to thermal strain, there arises a problem of interference between weld spatter and weld beads and other parts.

[0008]

In the document "Proceedings of INTERNATIONAL SEMINAR ON RESENT STATUS & TREND OF THBE HYDROFORMING" july 2 1999 p76 A method for producing a deformed tubular product by using and hydroforming is disclosed.

[0009]

FIG. 3 is a perspective view of a deformed tubular product obtained by hydroforming a terrado tube. FIG. 3A shows an example of a product having a rectangular cross section, and FIG. 3B shows an example of a product having a circular cross section. These deformed

[0010]

However, there is a problem that a process for welding the metal pipes is required separately from the hydroforming process in order to manufacture the metal base pipe. In addition, since the metal pipes are partially different in strength, when hydroforming, the low-strength part is more likely to swell than the high-strength part, and wrinkles occur near the weld and a satisfactory product is obtained. There is no current situation.

[0011]

Japanese Patent Application Laid-Open No. 11-5125 discloses a hydraulic bulge processing method in which a reinforcing hollow member coated with an adhesive is inserted on the outside of a metal base tube to be hydroformed to perform hydroforming. .

[0012]

However, for example, when a product with a complicated shape such as a center pillar reinforcement for automobiles is molded by hydroforming, it is common to perform pre-press molding called preform, which is bonded immediately before hydroforming. The agent cannot be applied. When the reinforcing steel pipe is inserted before the preform, there is a problem that it is bonded at an unexpected position during the preform.

[0013]

[Problems to be solved by the invention]

An object of the present invention is to provide a deformed tubular product that is partially reinforced without using welding or an adhesive and a method for manufacturing the deformed tubular product.

[0014]

[Means for Solving the Problems]

The present inventors have various experiments to solve the above problems, studies and as a result, the pressure in the fluid inserted into reinforcing the steel was introduced into the containing tube in that state having an inner diameter larger than the outer diameter of the steel tube It has been found that if the steel pipe and the reinforcing steel pipe are expanded simultaneously by loading and expanding, the reinforcing steel pipe is firmly fastened to the steel pipe .

[0015]

The present invention has been made based on good Una finding this, the gist is as follows.

[0016]

(1) the liquid is injected into the steel pipe, a method for producing a profiled tubular product by hydroforming to bulge the steel pipe loaded with pressure in the liquid, a predetermined portion of the bulging portion to be of steel, the steel tube A steel pipe for reinforcement having an inner diameter larger than the outer diameter is inserted, and the steel pipe and the steel pipe for reinforcement are expanded to form a product shape by liquid pressure so that the expansion ratio of the steel pipe for reinforcement is 0.5% or more. A method for producing a deformed tubular product having a partially reinforced portion.

[0017]

The expansion ratio of the reinforcing steel pipe is desirably 10% or less .

[0018]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, the present invention will be specifically described.

[0019]

FIG. 1 is a longitudinal sectional view of a mold part for hydrofoam for explaining a method for producing a modified tubular product of the present invention, and FIG. 1 (a) is a state immediately before hydroforming a steel pipe , FIG. ) Is a state after hydroforming, and FIG. 1C is a longitudinal sectional view of the product.

[0020]

First, a raw tube for hydrofoam is prepared as follows.

[0021]

That is, a reinforcing steel pipe having an inner diameter larger than the outer diameter of the steel pipe (hereinafter referred to as “element pipe ”) is prepared, and the reinforcing steel pipe is inserted into a predetermined portion to be reinforced in the planned bulge portion of the element pipe . The length of the reinforcing steel pipe may be set to a length to be reinforced, and a plurality of reinforcing steel pipes may be inserted if reinforcement at a plurality of locations is necessary. Further, the thickness may be arbitrarily selected depending on the purpose, and the material may not be the same as that of the raw tube but may be a material having higher strength.

[0022]

As shown in FIG. 1 (a), first, a

[0023]

Then, while increasing the pressure of the working fluid, gradually bulged axial pressing tool 7a, the

[0024]

When hydroforming is performed based on this method, only the raw pipe (hereinafter may be referred to as the inner pipe) only (hereinafter may be referred to as the single pipe section), the inner pipe and the reinforcing steel pipe (hereinafter referred to as the outer pipe ) Since there is a difference in strength from the double part (hereinafter referred to as a double pipe part) of the pipe (which may be referred to as a pipe), the following shape defects may occur during pipe expansion. FIG. 4 is a diagram for explaining the shape defect, and FIG. 4 (a) is a longitudinal sectional view of a deformed tubular product in which the

[0025]

This

[0026]

This defective shape not only makes the shape of the product unclear, but when a load is applied to the product, the strength may be lower than in the case of the inner tube alone due to stress concentration.

[0027]

To prevent good Una defective shape this is拡菅ratio of the outer tube is desirably suppressed to 10% or less, more preferably 5% or less. The tube expansion rate is the rate of increase in tube circumference.

[0028]

In the case of hydroforming such that a flat portion on the product shape processing,拡菅ratio of the outer tube because no out off Rattonesu between the single tube portion拡菅rate is small and the double tube portion of the outer tube The content is preferably 0.2% or more, and more preferably 0.5% or more. Next, the preferable shape of the pipe end part of the reinforcing steel pipe will be described.

[0029]

FIG. 5 is an enlarged longitudinal sectional view of the boundary between the outer tube and the inner tube after hydroforming. 5A, when the end surface 12 of the

[0030]

In the case of the end face of the outer tube as shown in FIG. 5 (a), there is a case where the bent portion 13 having a steep angle is generated in the inner tube due to the thickness of the outer tube portion, and the strength is reduced due to stress concentration. Therefore, it is not suitable for an application with a large stress load.

[0031]

Therefore, it is desirable to chamfer the end surface of the outer tube in advance as shown in FIG. If the chamfering angle θ is large, there is no effect, and if it is too small, problems such as an increase in the load of chamfering processing, danger of workers due to sharp edges, and deformation of the chamfered part during handling occur. It is desirable to do.

[0032]

As shown in FIG. 5 (c), the above problem can be solved by leaving a part of the inner surface that is not chamfered.

[0033]

As shown in FIG. 5D, it is further preferable that chamfering is performed and a portion where the chamfered surface intersects the inner surface of the outer tube is a curved surface (R).

[0034]

【Example】

FIG. 6 shows the die groove shape of the mold used in this example. Using this mold, the inner tube was inserted into the outer tube shown in Table 1, and hydroformed by the method shown in FIG. Both the outer pipe and the inner pipe used the carbon steel pipe STKM11A for mechanical structure. As the outer tube, a tube not chamfered and a chamfered tube with various chamfer angles were prepared.

[0035]

The die groove dimensions of the mold were as follows.

[0036]

D1 = 73mm

L1: 500mm

L2: 275mm

FIG. 7 is an operation pattern of internal pressure, axial push, and punch during hydroforming. After hydroforming, the boundary between the outer tube and the inner tube was observed to check for shape defects. The results are shown in Table 1.

[0037]

[Table 1]

As is apparent from Table 1, when the outer tube has an outer diameter of 65 mm, a wall thickness of 2.3 mm, and a tube expansion ratio of 12.3%, the shape was slightly poor but the stress load was small. In other cases, it was usable, and everything else was good.

[0038]

FIG. 8 is a view showing an appearance photograph after hydroforming of Test No. 6 in Table 1. It can be seen that the inner tube is crimped in a state where the surface of the bulging portion 5a and the surface of the

[0039]

【The invention's effect】

According to the present invention, it is possible to produce a deformed tubular product that is partially reinforced without using welding or an adhesive with a minimum weight increase. Also, hydroforming can be easily performed using an existing mold.

[Brief description of the drawings]

BRIEF DESCRIPTION OF DRAWINGS FIG. 1 is a longitudinal sectional view of a hydroforming mold part for explaining a method for producing a modified tubular product of the present invention.

FIG. 2 is a perspective view of a deformed tubular product partially reinforced by welding.

FIG. 3 is a perspective view of a modified tubular product obtained by hydroforming a terrado element tube.

FIG. 4 is a longitudinal sectional view of a product for explaining a shape defect.

FIG. 5 is an enlarged longitudinal sectional view of a boundary portion between an outer tube and an inner tube after hydroforming.

FIG. 6 is a view showing a die groove shape of a mold used in this example.

FIG. 7 is a diagram showing an operation pattern of internal pressure, shaft pushing and punching during hydroforming.

FIG. 8 is an external view of a modified tubular product obtained by the production method of the present invention.

[Explanation of symbols]

DESCRIPTION OF

6 Reinforcing steel pipes 7a, 7b

Claims (2)

鋼管の膨出予定部の所定の部位に、鋼管の外径よりも大きい内径を有する補強用鋼管を挿入した状態とし、補強用鋼管の拡管率が0.5%以上となるように、液圧により鋼管および補強用鋼管を拡管して製品形状に成形することを特徴とする部分的に強化部を備えた異形管状製品の製造方法。 In a method of manufacturing a deformed tubular product by hydroforming, in which a liquid is injected into a steel pipe and pressure is applied to the liquid to swell the steel pipe ,

In a state where a reinforcing steel pipe having an inner diameter larger than the outer diameter of the steel pipe is inserted into a predetermined portion of the planned expansion portion of the steel pipe , the hydraulic pressure is adjusted so that the expansion ratio of the reinforcing steel pipe is 0.5% or more. A method for producing a deformed tubular product having a partially reinforced portion, characterized in that a steel pipe and a reinforcing steel pipe are expanded and formed into a product shape.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000154583A JP4631130B2 (en) | 2000-05-25 | 2000-05-25 | Modified tubular product and manufacturing method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000154583A JP4631130B2 (en) | 2000-05-25 | 2000-05-25 | Modified tubular product and manufacturing method thereof |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2001334316A JP2001334316A (en) | 2001-12-04 |

| JP2001334316A5 JP2001334316A5 (en) | 2007-04-12 |

| JP4631130B2 true JP4631130B2 (en) | 2011-02-16 |

Family

ID=18659656

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000154583A Expired - Fee Related JP4631130B2 (en) | 2000-05-25 | 2000-05-25 | Modified tubular product and manufacturing method thereof |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4631130B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101357313B1 (en) * | 2012-03-21 | 2014-02-04 | 현대하이스코 주식회사 | Method of manufacturing flanged double-layer water pipe using hydro forming |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1389497A4 (en) | 2001-05-22 | 2009-04-29 | Mitsubishi Motors Corp | Hydroform process, and hydroform product formed by the process |

| JP3455205B2 (en) | 2002-02-18 | 2003-10-14 | 川崎重工業株式会社 | Train formation with energy absorption structure between vehicles |

| JP4473705B2 (en) * | 2003-12-19 | 2010-06-02 | 新日本製鐵株式会社 | Hydroform processing method, hydroform molded article and structure |

| JP4590956B2 (en) * | 2004-07-12 | 2010-12-01 | 日産自動車株式会社 | Hydraulic forming method |

| JP4724429B2 (en) * | 2005-02-03 | 2011-07-13 | 新日本製鐵株式会社 | Axle housing |

| EP1923273B1 (en) * | 2005-09-09 | 2010-12-01 | Toyoda Iron Works Co., Ltd. | Impact absorption member for vehicle |

| KR100889472B1 (en) * | 2007-06-20 | 2009-03-19 | 현대하이스코 주식회사 | High pressure hydroformed multi-layer tube and manufacturing method there of tube using high pressure tube hydroforming |

| KR100878611B1 (en) * | 2007-09-05 | 2009-01-15 | 주식회사 포스코 | Seat back frame |

| CN102164690A (en) | 2008-09-25 | 2011-08-24 | 杰富意钢铁株式会社 | Method for forming deformed cross-section and formed article of quadrilateral cross-section exhibiting excellent spot weldability |

| KR101132891B1 (en) | 2008-12-19 | 2012-04-03 | 현대하이스코 주식회사 | High pressure hydroformed multi-layer tube and manufacturing method there of tube using high pressure tube hydroforming |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62237015A (en) * | 1986-04-08 | 1987-10-17 | Musashi Seimitsu Ind Co Ltd | Assembbly cam shaft |

| JPS63119937A (en) * | 1986-10-01 | 1988-05-24 | エミテック・ゲゼルシャフト・フュア・エミッシオンステクノロジー・ミット・ベシュレンクテル・ハフツング | Manufacture of shaft with projection and shaft with projection consisting of shaft pipe and fitted element |

| JPH0738796U (en) * | 1991-04-27 | 1995-07-14 | 武蔵精密工業株式会社 | Assembly camshaft |

| JPH115125A (en) * | 1997-06-13 | 1999-01-12 | Nissan Motor Co Ltd | Forming method for bulge with oil pressure |

-

2000

- 2000-05-25 JP JP2000154583A patent/JP4631130B2/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62237015A (en) * | 1986-04-08 | 1987-10-17 | Musashi Seimitsu Ind Co Ltd | Assembbly cam shaft |

| JPS63119937A (en) * | 1986-10-01 | 1988-05-24 | エミテック・ゲゼルシャフト・フュア・エミッシオンステクノロジー・ミット・ベシュレンクテル・ハフツング | Manufacture of shaft with projection and shaft with projection consisting of shaft pipe and fitted element |

| JPH0738796U (en) * | 1991-04-27 | 1995-07-14 | 武蔵精密工業株式会社 | Assembly camshaft |

| JPH115125A (en) * | 1997-06-13 | 1999-01-12 | Nissan Motor Co Ltd | Forming method for bulge with oil pressure |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101357313B1 (en) * | 2012-03-21 | 2014-02-04 | 현대하이스코 주식회사 | Method of manufacturing flanged double-layer water pipe using hydro forming |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2001334316A (en) | 2001-12-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4478200B2 (en) | Hydroform processing method and hydroformed parts | |

| CA2383851C (en) | Reinforced hydroformed members and methods of making the same | |

| JP4631130B2 (en) | Modified tubular product and manufacturing method thereof | |

| JP5136998B2 (en) | Hydraulic bulge method and hydraulic bulge product | |

| US20070234771A1 (en) | Method of Hydraulic bulging and shaft pressing profile element pipe to make hydraulically bulged product | |

| US7293442B1 (en) | Method for hydroforming a ring-shaped tubular structure | |

| JP3820885B2 (en) | Molding method, mold and hydraulic bulge processed parts for hydraulic bulge parts | |

| JPH10175026A (en) | Hydroforming method of tube | |

| JPH10175027A (en) | Metallic tube for hydro-form | |

| JPH10175028A (en) | Highly accurate forming method of metallic tube by hydro-forming method | |

| WO2011099592A1 (en) | Hydroforming method and hydroforming device | |

| JP2001321844A (en) | Method for hydroforming metal tube and die | |

| JPH10249459A (en) | Method for reducing tube made of metal | |

| JP4906849B2 (en) | Steel pipe expansion forming method and steel pipe expansion forming apparatus | |

| JP3642232B2 (en) | Fluid pressure molding method, fluid pressure molding apparatus, and body member | |

| JP3794680B2 (en) | Hydroforming method | |

| JP4060723B2 (en) | Hydraulic bulge processing apparatus and hydraulic bulge processing method | |

| JP2002113524A (en) | Core for working metal tube and method for working metal tube | |

| JP4730164B2 (en) | Hydraulic bulge parts with flange | |

| JP5037020B2 (en) | Manufacturing method of metal pipe parts | |

| JPH0230336A (en) | Method for expanding metallic tube | |

| JP4288100B2 (en) | Suspension member | |

| JP2001225114A (en) | Hydraulic forming method | |

| JP4676594B2 (en) | Hydroform processing method | |

| JP2011115817A (en) | Welding member and method for manufacturing the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070227 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070227 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20070227 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090902 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090909 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091102 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100511 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100709 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20101019 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101101 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4631130 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131126 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131126 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131126 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |