JP4573138B2 - Method for producing silver-containing powder, silver-containing powder and dispersion thereof - Google Patents

Method for producing silver-containing powder, silver-containing powder and dispersion thereof Download PDFInfo

- Publication number

- JP4573138B2 JP4573138B2 JP2008167262A JP2008167262A JP4573138B2 JP 4573138 B2 JP4573138 B2 JP 4573138B2 JP 2008167262 A JP2008167262 A JP 2008167262A JP 2008167262 A JP2008167262 A JP 2008167262A JP 4573138 B2 JP4573138 B2 JP 4573138B2

- Authority

- JP

- Japan

- Prior art keywords

- silver

- compound

- containing powder

- dispersion

- epoxy resin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229910052709 silver Inorganic materials 0.000 title claims description 130

- 239000004332 silver Substances 0.000 title claims description 130

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 title claims description 124

- 239000000843 powder Substances 0.000 title claims description 118

- 238000004519 manufacturing process Methods 0.000 title claims description 21

- 239000006185 dispersion Substances 0.000 title description 83

- 150000001875 compounds Chemical class 0.000 claims description 120

- 239000003822 epoxy resin Substances 0.000 claims description 45

- 229920000647 polyepoxide Polymers 0.000 claims description 45

- FOIXSVOLVBLSDH-UHFFFAOYSA-N Silver ion Chemical compound [Ag+] FOIXSVOLVBLSDH-UHFFFAOYSA-N 0.000 claims description 42

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 38

- 229920002873 Polyethylenimine Polymers 0.000 claims description 34

- 239000003960 organic solvent Substances 0.000 claims description 30

- 239000002202 Polyethylene glycol Substances 0.000 claims description 26

- 239000002245 particle Substances 0.000 claims description 26

- 229920001223 polyethylene glycol Polymers 0.000 claims description 26

- 239000000203 mixture Substances 0.000 claims description 18

- 239000012736 aqueous medium Substances 0.000 claims description 17

- 238000001035 drying Methods 0.000 claims description 17

- 229940100890 silver compound Drugs 0.000 claims description 12

- 150000003379 silver compounds Chemical class 0.000 claims description 12

- 238000004108 freeze drying Methods 0.000 claims description 7

- 125000003277 amino group Chemical group 0.000 claims description 6

- 238000009835 boiling Methods 0.000 claims description 3

- 238000000034 method Methods 0.000 description 58

- 239000007787 solid Substances 0.000 description 32

- 239000002904 solvent Substances 0.000 description 32

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 27

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 27

- 229910052751 metal Inorganic materials 0.000 description 24

- 239000002184 metal Substances 0.000 description 24

- 238000003860 storage Methods 0.000 description 23

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 21

- 230000002829 reductive effect Effects 0.000 description 19

- 239000000047 product Substances 0.000 description 17

- 238000006243 chemical reaction Methods 0.000 description 16

- 239000010408 film Substances 0.000 description 16

- 238000003756 stirring Methods 0.000 description 16

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 15

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 15

- 239000003638 chemical reducing agent Substances 0.000 description 14

- 239000010419 fine particle Substances 0.000 description 14

- 238000006722 reduction reaction Methods 0.000 description 14

- -1 silver ions Chemical class 0.000 description 14

- 239000000243 solution Substances 0.000 description 14

- 238000005259 measurement Methods 0.000 description 13

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 12

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 12

- DNIAPMSPPWPWGF-UHFFFAOYSA-N Propylene glycol Chemical compound CC(O)CO DNIAPMSPPWPWGF-UHFFFAOYSA-N 0.000 description 12

- 239000012046 mixed solvent Substances 0.000 description 12

- 229920000642 polymer Polymers 0.000 description 11

- 239000008139 complexing agent Substances 0.000 description 10

- 230000008569 process Effects 0.000 description 10

- NDVLTYZPCACLMA-UHFFFAOYSA-N silver oxide Chemical compound [O-2].[Ag+].[Ag+] NDVLTYZPCACLMA-UHFFFAOYSA-N 0.000 description 10

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 9

- ZMXDDKWLCZADIW-UHFFFAOYSA-N N,N-Dimethylformamide Chemical compound CN(C)C=O ZMXDDKWLCZADIW-UHFFFAOYSA-N 0.000 description 9

- 238000002156 mixing Methods 0.000 description 9

- 239000000758 substrate Substances 0.000 description 9

- HEDRZPFGACZZDS-UHFFFAOYSA-N Chloroform Chemical compound ClC(Cl)Cl HEDRZPFGACZZDS-UHFFFAOYSA-N 0.000 description 8

- 239000007864 aqueous solution Substances 0.000 description 8

- 230000015572 biosynthetic process Effects 0.000 description 8

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 8

- 239000011248 coating agent Substances 0.000 description 8

- 238000000576 coating method Methods 0.000 description 8

- 125000000524 functional group Chemical group 0.000 description 8

- 239000002082 metal nanoparticle Substances 0.000 description 8

- 239000002994 raw material Substances 0.000 description 8

- 238000005516 engineering process Methods 0.000 description 7

- 239000007788 liquid Substances 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 239000002244 precipitate Substances 0.000 description 7

- 239000000126 substance Substances 0.000 description 7

- 238000003786 synthesis reaction Methods 0.000 description 7

- 238000011282 treatment Methods 0.000 description 7

- 238000005160 1H NMR spectroscopy Methods 0.000 description 6

- NOWKCMXCCJGMRR-UHFFFAOYSA-N Aziridine Chemical group C1CN1 NOWKCMXCCJGMRR-UHFFFAOYSA-N 0.000 description 6

- UFWIBTONFRDIAS-UHFFFAOYSA-N Naphthalene Chemical compound C1=CC=CC2=CC=CC=C21 UFWIBTONFRDIAS-UHFFFAOYSA-N 0.000 description 6

- 238000003917 TEM image Methods 0.000 description 6

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 6

- KRKNYBCHXYNGOX-UHFFFAOYSA-N citric acid Chemical compound OC(=O)CC(O)(C(O)=O)CC(O)=O KRKNYBCHXYNGOX-UHFFFAOYSA-N 0.000 description 6

- 239000012141 concentrate Substances 0.000 description 6

- MTHSVFCYNBDYFN-UHFFFAOYSA-N diethylene glycol Chemical compound OCCOCCO MTHSVFCYNBDYFN-UHFFFAOYSA-N 0.000 description 6

- 238000007710 freezing Methods 0.000 description 6

- 230000008014 freezing Effects 0.000 description 6

- 238000010438 heat treatment Methods 0.000 description 6

- 230000002209 hydrophobic effect Effects 0.000 description 6

- 229920003986 novolac Polymers 0.000 description 6

- 150000003141 primary amines Chemical class 0.000 description 6

- BDERNNFJNOPAEC-UHFFFAOYSA-N propan-1-ol Chemical compound CCCO BDERNNFJNOPAEC-UHFFFAOYSA-N 0.000 description 6

- SQGYOTSLMSWVJD-UHFFFAOYSA-N silver(1+) nitrate Chemical compound [Ag+].[O-]N(=O)=O SQGYOTSLMSWVJD-UHFFFAOYSA-N 0.000 description 6

- 239000010409 thin film Substances 0.000 description 6

- XTHFKEDIFFGKHM-UHFFFAOYSA-N Dimethoxyethane Chemical compound COCCOC XTHFKEDIFFGKHM-UHFFFAOYSA-N 0.000 description 5

- FXHOOIRPVKKKFG-UHFFFAOYSA-N N,N-Dimethylacetamide Chemical compound CN(C)C(C)=O FXHOOIRPVKKKFG-UHFFFAOYSA-N 0.000 description 5

- 238000010521 absorption reaction Methods 0.000 description 5

- 230000000052 comparative effect Effects 0.000 description 5

- 238000000502 dialysis Methods 0.000 description 5

- 239000000428 dust Substances 0.000 description 5

- 239000002105 nanoparticle Substances 0.000 description 5

- 239000003223 protective agent Substances 0.000 description 5

- 230000009467 reduction Effects 0.000 description 5

- 229910001923 silver oxide Inorganic materials 0.000 description 5

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 4

- 238000000862 absorption spectrum Methods 0.000 description 4

- 239000004020 conductor Substances 0.000 description 4

- ZUOUZKKEUPVFJK-UHFFFAOYSA-N diphenyl Chemical compound C1=CC=CC=C1C1=CC=CC=C1 ZUOUZKKEUPVFJK-UHFFFAOYSA-N 0.000 description 4

- 239000002270 dispersing agent Substances 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- 238000009776 industrial production Methods 0.000 description 4

- 230000003993 interaction Effects 0.000 description 4

- 239000002932 luster Substances 0.000 description 4

- 238000002844 melting Methods 0.000 description 4

- 230000008018 melting Effects 0.000 description 4

- 239000000693 micelle Substances 0.000 description 4

- 239000012299 nitrogen atmosphere Substances 0.000 description 4

- 230000003287 optical effect Effects 0.000 description 4

- HHVIBTZHLRERCL-UHFFFAOYSA-N sulfonyldimethane Chemical compound CS(C)(=O)=O HHVIBTZHLRERCL-UHFFFAOYSA-N 0.000 description 4

- 239000006228 supernatant Substances 0.000 description 4

- RYHBNJHYFVUHQT-UHFFFAOYSA-N 1,4-Dioxane Chemical compound C1COCCO1 RYHBNJHYFVUHQT-UHFFFAOYSA-N 0.000 description 3

- WEVYAHXRMPXWCK-UHFFFAOYSA-N Acetonitrile Chemical compound CC#N WEVYAHXRMPXWCK-UHFFFAOYSA-N 0.000 description 3

- CIWBSHSKHKDKBQ-JLAZNSOCSA-N Ascorbic acid Natural products OC[C@H](O)[C@H]1OC(=O)C(O)=C1O CIWBSHSKHKDKBQ-JLAZNSOCSA-N 0.000 description 3

- YMWUJEATGCHHMB-UHFFFAOYSA-N Dichloromethane Chemical compound ClCCl YMWUJEATGCHHMB-UHFFFAOYSA-N 0.000 description 3

- SECXISVLQFMRJM-UHFFFAOYSA-N N-Methylpyrrolidone Chemical compound CN1CCCC1=O SECXISVLQFMRJM-UHFFFAOYSA-N 0.000 description 3

- UEEJHVSXFDXPFK-UHFFFAOYSA-N N-dimethylaminoethanol Chemical compound CN(C)CCO UEEJHVSXFDXPFK-UHFFFAOYSA-N 0.000 description 3

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 3

- ZMANZCXQSJIPKH-UHFFFAOYSA-N Triethylamine Chemical compound CCN(CC)CC ZMANZCXQSJIPKH-UHFFFAOYSA-N 0.000 description 3

- 125000003118 aryl group Chemical group 0.000 description 3

- 239000011668 ascorbic acid Substances 0.000 description 3

- 235000010323 ascorbic acid Nutrition 0.000 description 3

- 229960005070 ascorbic acid Drugs 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 229960002887 deanol Drugs 0.000 description 3

- 238000013461 design Methods 0.000 description 3

- 238000011161 development Methods 0.000 description 3

- 239000012776 electronic material Substances 0.000 description 3

- 125000003700 epoxy group Chemical group 0.000 description 3

- 230000004927 fusion Effects 0.000 description 3

- 229910052739 hydrogen Inorganic materials 0.000 description 3

- 239000001257 hydrogen Substances 0.000 description 3

- 150000002500 ions Chemical class 0.000 description 3

- TYQCGQRIZGCHNB-JLAZNSOCSA-N l-ascorbic acid Chemical compound OC[C@H](O)[C@H]1OC(O)=C(O)C1=O TYQCGQRIZGCHNB-JLAZNSOCSA-N 0.000 description 3

- 230000014759 maintenance of location Effects 0.000 description 3

- 229910021645 metal ion Inorganic materials 0.000 description 3

- 239000011259 mixed solution Substances 0.000 description 3

- 238000001556 precipitation Methods 0.000 description 3

- 238000003672 processing method Methods 0.000 description 3

- 229910001961 silver nitrate Inorganic materials 0.000 description 3

- YLQBMQCUIZJEEH-UHFFFAOYSA-N tetrahydrofuran Natural products C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 3

- 238000009210 therapy by ultrasound Methods 0.000 description 3

- LEEANUDEDHYDTG-UHFFFAOYSA-N 1,2-dimethoxypropane Chemical compound COCC(C)OC LEEANUDEDHYDTG-UHFFFAOYSA-N 0.000 description 2

- CYSGHNMQYZDMIA-UHFFFAOYSA-N 1,3-Dimethyl-2-imidazolidinon Chemical compound CN1CCN(C)C1=O CYSGHNMQYZDMIA-UHFFFAOYSA-N 0.000 description 2

- ARXJGSRGQADJSQ-UHFFFAOYSA-N 1-methoxypropan-2-ol Chemical compound COCC(C)O ARXJGSRGQADJSQ-UHFFFAOYSA-N 0.000 description 2

- HZAXFHJVJLSVMW-UHFFFAOYSA-N 2-Aminoethan-1-ol Chemical compound NCCO HZAXFHJVJLSVMW-UHFFFAOYSA-N 0.000 description 2

- XNWFRZJHXBZDAG-UHFFFAOYSA-N 2-METHOXYETHANOL Chemical compound COCCO XNWFRZJHXBZDAG-UHFFFAOYSA-N 0.000 description 2

- YEJRWHAVMIAJKC-UHFFFAOYSA-N 4-Butyrolactone Chemical compound O=C1CCCO1 YEJRWHAVMIAJKC-UHFFFAOYSA-N 0.000 description 2

- IKHGUXGNUITLKF-UHFFFAOYSA-N Acetaldehyde Chemical compound CC=O IKHGUXGNUITLKF-UHFFFAOYSA-N 0.000 description 2

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 2

- DKPFZGUDAPQIHT-UHFFFAOYSA-N Butyl acetate Natural products CCCCOC(C)=O DKPFZGUDAPQIHT-UHFFFAOYSA-N 0.000 description 2

- OAKJQQAXSVQMHS-UHFFFAOYSA-N Hydrazine Chemical compound NN OAKJQQAXSVQMHS-UHFFFAOYSA-N 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 2

- CSNNHWWHGAXBCP-UHFFFAOYSA-L Magnesium sulfate Chemical compound [Mg+2].[O-][S+2]([O-])([O-])[O-] CSNNHWWHGAXBCP-UHFFFAOYSA-L 0.000 description 2

- XBDQKXXYIPTUBI-UHFFFAOYSA-M Propionate Chemical compound CCC([O-])=O XBDQKXXYIPTUBI-UHFFFAOYSA-M 0.000 description 2

- NBBJYMSMWIIQGU-UHFFFAOYSA-N Propionic aldehyde Chemical compound CCC=O NBBJYMSMWIIQGU-UHFFFAOYSA-N 0.000 description 2

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical compound C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 2

- 229910021607 Silver chloride Inorganic materials 0.000 description 2

- UIIMBOGNXHQVGW-UHFFFAOYSA-M Sodium bicarbonate Chemical compound [Na+].OC([O-])=O UIIMBOGNXHQVGW-UHFFFAOYSA-M 0.000 description 2

- 150000001298 alcohols Chemical class 0.000 description 2

- 235000010290 biphenyl Nutrition 0.000 description 2

- 239000004305 biphenyl Substances 0.000 description 2

- YXVFYQXJAXKLAK-UHFFFAOYSA-N biphenyl-4-ol Chemical compound C1=CC(O)=CC=C1C1=CC=CC=C1 YXVFYQXJAXKLAK-UHFFFAOYSA-N 0.000 description 2

- PXKLMJQFEQBVLD-UHFFFAOYSA-N bisphenol F Chemical compound C1=CC(O)=CC=C1CC1=CC=C(O)C=C1 PXKLMJQFEQBVLD-UHFFFAOYSA-N 0.000 description 2

- HQABUPZFAYXKJW-UHFFFAOYSA-N butan-1-amine Chemical compound CCCCN HQABUPZFAYXKJW-UHFFFAOYSA-N 0.000 description 2

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 2

- 238000005266 casting Methods 0.000 description 2

- 238000005119 centrifugation Methods 0.000 description 2

- 239000013065 commercial product Substances 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- 238000000113 differential scanning calorimetry Methods 0.000 description 2

- 239000012972 dimethylethanolamine Substances 0.000 description 2

- ASQQEOXYFGEFKQ-UHFFFAOYSA-N dioxirane Chemical compound C1OO1 ASQQEOXYFGEFKQ-UHFFFAOYSA-N 0.000 description 2

- 239000012153 distilled water Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000009881 electrostatic interaction Effects 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- XLLIQLLCWZCATF-UHFFFAOYSA-N ethylene glycol monomethyl ether acetate Natural products COCCOC(C)=O XLLIQLLCWZCATF-UHFFFAOYSA-N 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- WSFSSNUMVMOOMR-UHFFFAOYSA-N formaldehyde Natural products O=C WSFSSNUMVMOOMR-UHFFFAOYSA-N 0.000 description 2

- 238000005227 gel permeation chromatography Methods 0.000 description 2

- 235000011187 glycerol Nutrition 0.000 description 2

- 125000003055 glycidyl group Chemical group C(C1CO1)* 0.000 description 2

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 2

- FUZZWVXGSFPDMH-UHFFFAOYSA-M hexanoate Chemical compound CCCCCC([O-])=O FUZZWVXGSFPDMH-UHFFFAOYSA-M 0.000 description 2

- 229920001477 hydrophilic polymer Polymers 0.000 description 2

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 2

- WGCNASOHLSPBMP-UHFFFAOYSA-N hydroxyacetaldehyde Natural products OCC=O WGCNASOHLSPBMP-UHFFFAOYSA-N 0.000 description 2

- IQPQWNKOIGAROB-UHFFFAOYSA-N isocyanate group Chemical group [N-]=C=O IQPQWNKOIGAROB-UHFFFAOYSA-N 0.000 description 2

- 239000002609 medium Substances 0.000 description 2

- 239000000178 monomer Substances 0.000 description 2

- 239000002798 polar solvent Substances 0.000 description 2

- BWHMMNNQKKPAPP-UHFFFAOYSA-L potassium carbonate Chemical compound [K+].[K+].[O-]C([O-])=O BWHMMNNQKKPAPP-UHFFFAOYSA-L 0.000 description 2

- 238000007639 printing Methods 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- WGYKZJWCGVVSQN-UHFFFAOYSA-N propylamine Chemical compound CCCN WGYKZJWCGVVSQN-UHFFFAOYSA-N 0.000 description 2

- 238000000746 purification Methods 0.000 description 2

- 230000035484 reaction time Effects 0.000 description 2

- 230000008707 rearrangement Effects 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- HKZLPVFGJNLROG-UHFFFAOYSA-M silver monochloride Chemical compound [Cl-].[Ag+] HKZLPVFGJNLROG-UHFFFAOYSA-M 0.000 description 2

- 238000004528 spin coating Methods 0.000 description 2

- 150000003512 tertiary amines Chemical class 0.000 description 2

- 125000002088 tosyl group Chemical group [H]C1=C([H])C(=C([H])C([H])=C1C([H])([H])[H])S(*)(=O)=O 0.000 description 2

- XFNJVJPLKCPIBV-UHFFFAOYSA-N trimethylenediamine Chemical compound NCCCN XFNJVJPLKCPIBV-UHFFFAOYSA-N 0.000 description 2

- KGSFMPRFQVLGTJ-UHFFFAOYSA-N 1,1,2-triphenylethylbenzene Chemical compound C=1C=CC=CC=1C(C=1C=CC=CC=1)(C=1C=CC=CC=1)CC1=CC=CC=C1 KGSFMPRFQVLGTJ-UHFFFAOYSA-N 0.000 description 1

- WBODDOZXDKQEFS-UHFFFAOYSA-N 1,2,3,4-tetramethyl-5-phenylbenzene Chemical group CC1=C(C)C(C)=CC(C=2C=CC=CC=2)=C1C WBODDOZXDKQEFS-UHFFFAOYSA-N 0.000 description 1

- ZXSQEZNORDWBGZ-UHFFFAOYSA-N 1,3-dihydropyrrolo[2,3-b]pyridin-2-one Chemical compound C1=CN=C2NC(=O)CC2=C1 ZXSQEZNORDWBGZ-UHFFFAOYSA-N 0.000 description 1

- KJCVRFUGPWSIIH-UHFFFAOYSA-N 1-naphthol Chemical compound C1=CC=C2C(O)=CC=CC2=C1 KJCVRFUGPWSIIH-UHFFFAOYSA-N 0.000 description 1

- VILCJCGEZXAXTO-UHFFFAOYSA-N 2,2,2-tetramine Chemical compound NCCNCCNCCN VILCJCGEZXAXTO-UHFFFAOYSA-N 0.000 description 1

- YFWIACABGHWPLP-UHFFFAOYSA-N 2-(2-hydroxyethoxy)ethanol;propane-1,2,3-triol Chemical compound OCC(O)CO.OCCOCCO YFWIACABGHWPLP-UHFFFAOYSA-N 0.000 description 1

- NGNBDVOYPDDBFK-UHFFFAOYSA-N 2-[2,4-di(pentan-2-yl)phenoxy]acetyl chloride Chemical compound CCCC(C)C1=CC=C(OCC(Cl)=O)C(C(C)CCC)=C1 NGNBDVOYPDDBFK-UHFFFAOYSA-N 0.000 description 1

- JKFYKCYQEWQPTM-UHFFFAOYSA-N 2-azaniumyl-2-(4-fluorophenyl)acetate Chemical compound OC(=O)C(N)C1=CC=C(F)C=C1 JKFYKCYQEWQPTM-UHFFFAOYSA-N 0.000 description 1

- QTWJRLJHJPIABL-UHFFFAOYSA-N 2-methylphenol;3-methylphenol;4-methylphenol Chemical compound CC1=CC=C(O)C=C1.CC1=CC=CC(O)=C1.CC1=CC=CC=C1O QTWJRLJHJPIABL-UHFFFAOYSA-N 0.000 description 1

- GSKNLOOGBYYDHV-UHFFFAOYSA-N 2-methylphenol;naphthalen-1-ol Chemical compound CC1=CC=CC=C1O.C1=CC=C2C(O)=CC=CC2=C1 GSKNLOOGBYYDHV-UHFFFAOYSA-N 0.000 description 1

- PYSGFFTXMUWEOT-UHFFFAOYSA-N 3-(dimethylamino)propan-1-ol Chemical compound CN(C)CCCO PYSGFFTXMUWEOT-UHFFFAOYSA-N 0.000 description 1

- BLFRQYKZFKYQLO-UHFFFAOYSA-N 4-aminobutan-1-ol Chemical compound NCCCCO BLFRQYKZFKYQLO-UHFFFAOYSA-N 0.000 description 1

- YYROPELSRYBVMQ-UHFFFAOYSA-N 4-toluenesulfonyl chloride Chemical compound CC1=CC=C(S(Cl)(=O)=O)C=C1 YYROPELSRYBVMQ-UHFFFAOYSA-N 0.000 description 1

- FVCSARBUZVPSQF-UHFFFAOYSA-N 5-(2,4-dioxooxolan-3-yl)-7-methyl-3a,4,5,7a-tetrahydro-2-benzofuran-1,3-dione Chemical compound C1C(C(OC2=O)=O)C2C(C)=CC1C1C(=O)COC1=O FVCSARBUZVPSQF-UHFFFAOYSA-N 0.000 description 1

- RBWNDBNSJFCLBZ-UHFFFAOYSA-N 7-methyl-5,6,7,8-tetrahydro-3h-[1]benzothiolo[2,3-d]pyrimidine-4-thione Chemical compound N1=CNC(=S)C2=C1SC1=C2CCC(C)C1 RBWNDBNSJFCLBZ-UHFFFAOYSA-N 0.000 description 1

- GJCOSYZMQJWQCA-UHFFFAOYSA-N 9H-xanthene Chemical compound C1=CC=C2CC3=CC=CC=C3OC2=C1 GJCOSYZMQJWQCA-UHFFFAOYSA-N 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- LSNNMFCWUKXFEE-UHFFFAOYSA-M Bisulfite Chemical compound OS([O-])=O LSNNMFCWUKXFEE-UHFFFAOYSA-M 0.000 description 1

- NSPGLQRXIWDSEQ-UHFFFAOYSA-N C(C1=CC=CC=C1)(=O)O.[Ag]=O Chemical compound C(C1=CC=CC=C1)(=O)O.[Ag]=O NSPGLQRXIWDSEQ-UHFFFAOYSA-N 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 1

- IAZDPXIOMUYVGZ-UHFFFAOYSA-N Dimethylsulphoxide Chemical group CS(C)=O IAZDPXIOMUYVGZ-UHFFFAOYSA-N 0.000 description 1

- 239000004593 Epoxy Substances 0.000 description 1

- KMTRUDSVKNLOMY-UHFFFAOYSA-N Ethylene carbonate Chemical compound O=C1OCCO1 KMTRUDSVKNLOMY-UHFFFAOYSA-N 0.000 description 1

- PIICEJLVQHRZGT-UHFFFAOYSA-N Ethylenediamine Chemical compound NCCN PIICEJLVQHRZGT-UHFFFAOYSA-N 0.000 description 1

- 229910001111 Fine metal Inorganic materials 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- KWYHDKDOAIKMQN-UHFFFAOYSA-N N,N,N',N'-tetramethylethylenediamine Chemical compound CN(C)CCN(C)C KWYHDKDOAIKMQN-UHFFFAOYSA-N 0.000 description 1

- OPKOKAMJFNKNAS-UHFFFAOYSA-N N-methylethanolamine Chemical compound CNCCO OPKOKAMJFNKNAS-UHFFFAOYSA-N 0.000 description 1

- 229910002651 NO3 Inorganic materials 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- WUGQZFFCHPXWKQ-UHFFFAOYSA-N Propanolamine Chemical compound NCCCO WUGQZFFCHPXWKQ-UHFFFAOYSA-N 0.000 description 1

- 229910021612 Silver iodide Inorganic materials 0.000 description 1

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical class [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 1

- ZJCCRDAZUWHFQH-UHFFFAOYSA-N Trimethylolpropane Chemical compound CCC(CO)(CO)CO ZJCCRDAZUWHFQH-UHFFFAOYSA-N 0.000 description 1

- 238000005411 Van der Waals force Methods 0.000 description 1

- KXKVLQRXCPHEJC-UHFFFAOYSA-N acetic acid trimethyl ester Natural products COC(C)=O KXKVLQRXCPHEJC-UHFFFAOYSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- 238000007259 addition reaction Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000004220 aggregation Methods 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- 125000003172 aldehyde group Chemical group 0.000 description 1

- 150000001299 aldehydes Chemical class 0.000 description 1

- 150000001408 amides Chemical class 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 238000000149 argon plasma sintering Methods 0.000 description 1

- 239000012298 atmosphere Substances 0.000 description 1

- 125000004429 atom Chemical group 0.000 description 1

- 238000010533 azeotropic distillation Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- VEZXCJBBBCKRPI-UHFFFAOYSA-N beta-propiolactone Chemical compound O=C1CCO1 VEZXCJBBBCKRPI-UHFFFAOYSA-N 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 229920001400 block copolymer Polymers 0.000 description 1

- 150000001639 boron compounds Chemical class 0.000 description 1

- MOOAHMCRPCTRLV-UHFFFAOYSA-N boron sodium Chemical compound [B].[Na] MOOAHMCRPCTRLV-UHFFFAOYSA-N 0.000 description 1

- ZTQSAGDEMFDKMZ-UHFFFAOYSA-N butyric aldehyde Natural products CCCC=O ZTQSAGDEMFDKMZ-UHFFFAOYSA-N 0.000 description 1

- 229930188620 butyrolactone Natural products 0.000 description 1

- PTYMQUSHTAONGW-UHFFFAOYSA-N carbonic acid;hydrazine Chemical compound NN.OC(O)=O PTYMQUSHTAONGW-UHFFFAOYSA-N 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000008199 coating composition Substances 0.000 description 1

- 229930003836 cresol Natural products 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 230000006837 decompression Effects 0.000 description 1

- 230000018044 dehydration Effects 0.000 description 1

- 238000006297 dehydration reaction Methods 0.000 description 1

- ZBCBWPMODOFKDW-UHFFFAOYSA-N diethanolamine Chemical compound OCCNCCO ZBCBWPMODOFKDW-UHFFFAOYSA-N 0.000 description 1

- HPNMFZURTQLUMO-UHFFFAOYSA-N diethylamine Chemical compound CCNCC HPNMFZURTQLUMO-UHFFFAOYSA-N 0.000 description 1

- 238000007598 dipping method Methods 0.000 description 1

- WEHWNAOGRSTTBQ-UHFFFAOYSA-N dipropylamine Chemical compound CCCNCCC WEHWNAOGRSTTBQ-UHFFFAOYSA-N 0.000 description 1

- 239000002612 dispersion medium Substances 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- HZZUMXSLPJFMCB-UHFFFAOYSA-M ethyl(triphenyl)phosphanium;acetate Chemical compound CC([O-])=O.C=1C=CC=CC=1[P+](C=1C=CC=CC=1)(CC)C1=CC=CC=C1 HZZUMXSLPJFMCB-UHFFFAOYSA-M 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- 238000007667 floating Methods 0.000 description 1

- 235000019256 formaldehyde Nutrition 0.000 description 1

- 229960004279 formaldehyde Drugs 0.000 description 1

- WBJINCZRORDGAQ-UHFFFAOYSA-N formic acid ethyl ester Natural products CCOC=O WBJINCZRORDGAQ-UHFFFAOYSA-N 0.000 description 1

- 229920000578 graft copolymer Polymers 0.000 description 1

- 150000008282 halocarbons Chemical class 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- GNOIPBMMFNIUFM-UHFFFAOYSA-N hexamethylphosphoric triamide Chemical compound CN(C)P(=O)(N(C)C)N(C)C GNOIPBMMFNIUFM-UHFFFAOYSA-N 0.000 description 1

- 238000000265 homogenisation Methods 0.000 description 1

- 150000002429 hydrazines Chemical class 0.000 description 1

- 125000004435 hydrogen atom Chemical class [H]* 0.000 description 1

- 238000005984 hydrogenation reaction Methods 0.000 description 1

- 230000003301 hydrolyzing effect Effects 0.000 description 1

- 150000002466 imines Chemical class 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000002608 ionic liquid Substances 0.000 description 1

- GJRQTCIYDGXPES-UHFFFAOYSA-N iso-butyl acetate Natural products CC(C)COC(C)=O GJRQTCIYDGXPES-UHFFFAOYSA-N 0.000 description 1

- FGKJLKRYENPLQH-UHFFFAOYSA-M isocaproate Chemical compound CC(C)CCC([O-])=O FGKJLKRYENPLQH-UHFFFAOYSA-M 0.000 description 1

- ZBKFYXZXZJPWNQ-UHFFFAOYSA-N isothiocyanate group Chemical group [N-]=C=S ZBKFYXZXZJPWNQ-UHFFFAOYSA-N 0.000 description 1

- OQAGVSWESNCJJT-UHFFFAOYSA-N isovaleric acid methyl ester Natural products COC(=O)CC(C)C OQAGVSWESNCJJT-UHFFFAOYSA-N 0.000 description 1

- 150000002576 ketones Chemical class 0.000 description 1

- QDLAGTHXVHQKRE-UHFFFAOYSA-N lichenxanthone Natural products COC1=CC(O)=C2C(=O)C3=C(C)C=C(OC)C=C3OC2=C1 QDLAGTHXVHQKRE-UHFFFAOYSA-N 0.000 description 1

- 238000010550 living polymerization reaction Methods 0.000 description 1

- 229910052943 magnesium sulfate Inorganic materials 0.000 description 1

- 235000019341 magnesium sulphate Nutrition 0.000 description 1

- 239000000696 magnetic material Substances 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 239000002923 metal particle Substances 0.000 description 1

- WSFSSNUMVMOOMR-NJFSPNSNSA-N methanone Chemical compound O=[14CH2] WSFSSNUMVMOOMR-NJFSPNSNSA-N 0.000 description 1

- CRVGTESFCCXCTH-UHFFFAOYSA-N methyl diethanolamine Chemical compound OCCN(C)CCO CRVGTESFCCXCTH-UHFFFAOYSA-N 0.000 description 1

- DMQSHEKGGUOYJS-UHFFFAOYSA-N n,n,n',n'-tetramethylpropane-1,3-diamine Chemical compound CN(C)CCCN(C)C DMQSHEKGGUOYJS-UHFFFAOYSA-N 0.000 description 1

- YKYONYBAUNKHLG-UHFFFAOYSA-N n-Propyl acetate Natural products CCCOC(C)=O YKYONYBAUNKHLG-UHFFFAOYSA-N 0.000 description 1

- XVDBWWRIXBMVJV-UHFFFAOYSA-N n-[bis(dimethylamino)phosphanyl]-n-methylmethanamine Chemical compound CN(C)P(N(C)C)N(C)C XVDBWWRIXBMVJV-UHFFFAOYSA-N 0.000 description 1

- VSWALKINGSNVAR-UHFFFAOYSA-N naphthalen-1-ol;phenol Chemical compound OC1=CC=CC=C1.C1=CC=C2C(O)=CC=CC2=C1 VSWALKINGSNVAR-UHFFFAOYSA-N 0.000 description 1

- 150000002825 nitriles Chemical class 0.000 description 1

- 239000004843 novolac epoxy resin Substances 0.000 description 1

- 238000000879 optical micrograph Methods 0.000 description 1

- 150000002894 organic compounds Chemical class 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920002401 polyacrylamide Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920005862 polyol Polymers 0.000 description 1

- 150000003077 polyols Chemical class 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 1

- 239000001267 polyvinylpyrrolidone Substances 0.000 description 1

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 1

- 229910000027 potassium carbonate Inorganic materials 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 229960000380 propiolactone Drugs 0.000 description 1

- FVSKHRXBFJPNKK-UHFFFAOYSA-N propionitrile Chemical compound CCC#N FVSKHRXBFJPNKK-UHFFFAOYSA-N 0.000 description 1

- 229940090181 propyl acetate Drugs 0.000 description 1

- RUOJZAUFBMNUDX-UHFFFAOYSA-N propylene carbonate Chemical compound CC1COC(=O)O1 RUOJZAUFBMNUDX-UHFFFAOYSA-N 0.000 description 1

- LLHKCFNBLRBOGN-UHFFFAOYSA-N propylene glycol methyl ether acetate Chemical compound COCC(C)OC(C)=O LLHKCFNBLRBOGN-UHFFFAOYSA-N 0.000 description 1

- 238000010298 pulverizing process Methods 0.000 description 1

- UMJSCPRVCHMLSP-UHFFFAOYSA-N pyridine Natural products COC1=CC=CN=C1 UMJSCPRVCHMLSP-UHFFFAOYSA-N 0.000 description 1

- 229920005604 random copolymer Polymers 0.000 description 1

- 239000011541 reaction mixture Substances 0.000 description 1

- 230000009257 reactivity Effects 0.000 description 1

- 238000007761 roller coating Methods 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 239000003566 sealing material Substances 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 150000003378 silver Chemical class 0.000 description 1

- CQLFBEKRDQMJLZ-UHFFFAOYSA-M silver acetate Chemical compound [Ag+].CC([O-])=O CQLFBEKRDQMJLZ-UHFFFAOYSA-M 0.000 description 1

- 229940071536 silver acetate Drugs 0.000 description 1

- ADZWSOLPGZMUMY-UHFFFAOYSA-M silver bromide Chemical compound [Ag]Br ADZWSOLPGZMUMY-UHFFFAOYSA-M 0.000 description 1

- LKZMBDSASOBTPN-UHFFFAOYSA-L silver carbonate Substances [Ag].[O-]C([O-])=O LKZMBDSASOBTPN-UHFFFAOYSA-L 0.000 description 1

- 229910001958 silver carbonate Inorganic materials 0.000 description 1

- 229940071575 silver citrate Drugs 0.000 description 1

- 229940096017 silver fluoride Drugs 0.000 description 1

- 229940045105 silver iodide Drugs 0.000 description 1

- REYHXKZHIMGNSE-UHFFFAOYSA-M silver monofluoride Chemical compound [F-].[Ag+] REYHXKZHIMGNSE-UHFFFAOYSA-M 0.000 description 1

- KKKDGYXNGYJJRX-UHFFFAOYSA-M silver nitrite Chemical compound [Ag+].[O-]N=O KKKDGYXNGYJJRX-UHFFFAOYSA-M 0.000 description 1

- YPNVIBVEFVRZPJ-UHFFFAOYSA-L silver sulfate Chemical compound [Ag+].[Ag+].[O-]S([O-])(=O)=O YPNVIBVEFVRZPJ-UHFFFAOYSA-L 0.000 description 1

- 229910000367 silver sulfate Inorganic materials 0.000 description 1

- WYCFMBAHFPUBDS-UHFFFAOYSA-L silver sulfite Chemical compound [Ag+].[Ag+].[O-]S([O-])=O WYCFMBAHFPUBDS-UHFFFAOYSA-L 0.000 description 1

- 229910001494 silver tetrafluoroborate Inorganic materials 0.000 description 1

- CHACQUSVOVNARW-LNKPDPKZSA-M silver;(z)-4-oxopent-2-en-2-olate Chemical compound [Ag+].C\C([O-])=C\C(C)=O CHACQUSVOVNARW-LNKPDPKZSA-M 0.000 description 1

- KZJPVUDYAMEDRM-UHFFFAOYSA-M silver;2,2,2-trifluoroacetate Chemical compound [Ag+].[O-]C(=O)C(F)(F)F KZJPVUDYAMEDRM-UHFFFAOYSA-M 0.000 description 1

- XAYJXAUUXJTOSI-UHFFFAOYSA-M silver;2,2,3,3,3-pentafluoropropanoate Chemical compound [Ag+].[O-]C(=O)C(F)(F)C(F)(F)F XAYJXAUUXJTOSI-UHFFFAOYSA-M 0.000 description 1

- LMEWRZSPCQHBOB-UHFFFAOYSA-M silver;2-hydroxypropanoate Chemical compound [Ag+].CC(O)C([O-])=O LMEWRZSPCQHBOB-UHFFFAOYSA-M 0.000 description 1

- JUDUFOKGIZUSFP-UHFFFAOYSA-M silver;4-methylbenzenesulfonate Chemical compound [Ag+].CC1=CC=C(S([O-])(=O)=O)C=C1 JUDUFOKGIZUSFP-UHFFFAOYSA-M 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- 229910000030 sodium bicarbonate Inorganic materials 0.000 description 1

- 235000017557 sodium bicarbonate Nutrition 0.000 description 1

- 239000012279 sodium borohydride Substances 0.000 description 1

- 229910000033 sodium borohydride Inorganic materials 0.000 description 1

- 239000001509 sodium citrate Substances 0.000 description 1

- NLJMYIDDQXHKNR-UHFFFAOYSA-K sodium citrate Chemical compound O.O.[Na+].[Na+].[Na+].[O-]C(=O)CC(O)(CC([O-])=O)C([O-])=O NLJMYIDDQXHKNR-UHFFFAOYSA-K 0.000 description 1

- 239000011343 solid material Substances 0.000 description 1

- 239000008247 solid mixture Substances 0.000 description 1

- 239000012265 solid product Substances 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 230000002269 spontaneous effect Effects 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 125000000020 sulfo group Chemical group O=S(=O)([*])O[H] 0.000 description 1

- HXJUTPCZVOIRIF-UHFFFAOYSA-N sulfolane Chemical compound O=S1(=O)CCCC1 HXJUTPCZVOIRIF-UHFFFAOYSA-N 0.000 description 1

- 238000001308 synthesis method Methods 0.000 description 1

- 230000002194 synthesizing effect Effects 0.000 description 1

- AAAQKTZKLRYKHR-UHFFFAOYSA-N triphenylmethane Chemical compound C1=CC=CC=C1C(C=1C=CC=CC=1)C1=CC=CC=C1 AAAQKTZKLRYKHR-UHFFFAOYSA-N 0.000 description 1

- QUTYHQJYVDNJJA-UHFFFAOYSA-K trisilver;2-hydroxypropane-1,2,3-tricarboxylate Chemical compound [Ag+].[Ag+].[Ag+].[O-]C(=O)CC(O)(CC([O-])=O)C([O-])=O QUTYHQJYVDNJJA-UHFFFAOYSA-K 0.000 description 1

- 238000001291 vacuum drying Methods 0.000 description 1

- 238000009777 vacuum freeze-drying Methods 0.000 description 1

- NQPDZGIKBAWPEJ-UHFFFAOYSA-N valeric acid Chemical compound CCCCC(O)=O NQPDZGIKBAWPEJ-UHFFFAOYSA-N 0.000 description 1

- 239000004034 viscosity adjusting agent Substances 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 238000004065 wastewater treatment Methods 0.000 description 1

Images

Landscapes

- Manufacture Of Metal Powder And Suspensions Thereof (AREA)

- Powder Metallurgy (AREA)

- Conductive Materials (AREA)

- Non-Insulated Conductors (AREA)

- Pigments, Carbon Blacks, Or Wood Stains (AREA)

Description

本発明は、平均粒子径が2〜50nmの銀ナノ粒子を含有する粉体とその粉体の分散液に関するものであり、詳しくは、特定の化合物の存在下、銀化合物の還元反応、濃縮、乾燥工程を経ることにより得られる、固体状態で安定な銀含有粉体と、これを溶剤に再分散させて得られる分散液、及びそれらの製造方法に関するものである。 The present invention relates to a powder containing silver nanoparticles having an average particle diameter of 2 to 50 nm and a dispersion of the powder. Specifically, in the presence of a specific compound, the reduction reaction, concentration, The present invention relates to a silver-containing powder that is stable in a solid state, obtained by passing through a drying step, a dispersion obtained by redispersing it in a solvent, and a method for producing the same.

高集積化された高機能で小型・薄型の情報機器の開発には、半導体の微細加工技術の更なる開発と同時に、その微細加工を生かし支える信頼性の高い実装技術が必要である。その実装技術の要素技術には、金属微粒子の製造と、それをペースト化して用いる微細配線・接続技術があり、インクジェット等の印刷技術との組み合わせが注目され、近年各社が競って様々なアプローチで技術開発を行っている(例えば、特許文献1参照。)。 In order to develop highly integrated, highly functional, small, and thin information devices, it is necessary to develop semiconductor microfabrication technology and at the same time have highly reliable mounting technology that supports the microfabrication. The component technology of the mounting technology includes the production of fine metal particles and the fine wiring / connection technology using the paste as a paste. The combination with printing technology such as inkjet has been attracting attention. Technology development is underway (for example, see Patent Document 1).

一般に金属微粒子を製造するには、いわゆるトップダウンと呼ばれる粉砕技術に基づくもの(例えば、特許文献2及び3参照。)と、ボトムアップと呼ばれる分子または原子の化学的・物理的挙動を把握しこれを制御することによって構造を制御する方法(例えば、特許文献4〜6参照。)があり、トップダウン法ではその粒子径をナノメートルオーダーまで均一粉砕することが困難であることから、近年ではボトムアップ法が注目されている。 In general, metal fine particles are produced by grasping the chemical / physical behavior of molecules or atoms based on a so-called top-down pulverization technique (see, for example, Patent Documents 2 and 3) and bottom-up. There is a method for controlling the structure by controlling the thickness (for example, see Patent Documents 4 to 6), and it is difficult to uniformly pulverize the particle diameter to the nanometer order by the top-down method. The up method is attracting attention.

粒子径がナノサイズまで小さくなった金属ナノ粒子は、表面エネルギーが増大するため該粒子表面での融点降下が生じ、その結果、金属ナノ粒子同士の融着が起こりやすく保存安定性が悪くなることが知られている。従って金属ナノ粒子は該融着を防止するための保護剤等で被覆されで、分散溶媒中にコロイド状に分散した分散液としたものが多く提供されている。 Metal nanoparticles whose particle size has been reduced to nano-sizes have increased surface energy, resulting in a melting point drop on the surface of the particles. As a result, metal nanoparticles tend to fuse with each other, resulting in poor storage stability. It has been known. Accordingly, many metal nanoparticles are provided which are coated with a protective agent or the like for preventing the fusion and dispersed in a colloidal form in a dispersion solvent.

それに対して、乾燥状態(固体)の金属ナノ粒子は、それを様々な用途における液状組成物や固体の混合物に容易に配合可能である点から、保護剤で保護された金属ナノ粒子のコロイド状分散液よりもその応用範囲が広く、また、輸送、保管の面からも工業的には有利であると考えられる。例えば、分散溶媒中にコロイド状に安定分散した分散液から分散溶媒を留去、蒸散させて、金属ナノ粒子を含む粉体(固体)を得ようとした場合、隣接した粉体の表面に存在する保護剤同士の粘着や、十分に保護されていない箇所からの金属ナノ粒子同士の融合等により安定に保存することができず、実用的ではない。 In contrast, dried (solid) metal nanoparticles can be easily incorporated into liquid compositions and solid mixtures in various applications, so that the colloidal form of metal nanoparticles protected with a protective agent is used. The application range is wider than that of the dispersion, and it is considered industrially advantageous in terms of transportation and storage. For example, when the dispersion solvent is distilled off from a dispersion that has been stably dispersed in a dispersion solvent and evaporated to obtain a powder (solid) containing metal nanoparticles, it exists on the surface of the adjacent powder. It is not practical because it cannot be stably stored due to adhesion between protective agents to be protected or fusion of metal nanoparticles from a location that is not sufficiently protected.

また、既に本発明者らが前記特許文献6等で提供した技術では、金属イオンの還元によって得られた金属ナノ粒子と高分子化合物とからなる分散体を単離する際に、原料とした金属化合物から発生する対イオン等を除去するために透析法を用いているが、この手法では製造サイクル・コスト的に工業的実施には不向きである。また、該特許文献6等の実施例で記載した、透析した後、乾燥して得られる粉体中における金属含有率はいずれも92質量%未満であり、導電性材料として使用するには高温での処理が必要であった。 Further, in the technique already provided by the present inventors in Patent Document 6 and the like, the metal used as a raw material when isolating a dispersion composed of metal nanoparticles obtained by reduction of metal ions and a polymer compound is used. A dialysis method is used to remove counter ions and the like generated from the compound, but this method is not suitable for industrial implementation in terms of production cycle and cost. In addition, the metal content in the powder obtained by dialysis and drying, as described in the Examples of Patent Document 6 and the like, is less than 92% by mass, and is not suitable for use as a conductive material. It was necessary to process.

金属微粒子の製造方法としては、例えば、アルカリ可溶性ポリマーの存在下で金属イオンを還元して得られる金属微粒子含有液を凍結乾燥法により乾燥する方法が提供されている(例えば、特許文献7参照)。該手法では、アルカリ可溶性ポリマーを完全に溶解させる必要があることから、pHが12程度のアルカリ水溶液を多量に必要とするため、一定量の金属含有粉体を得るためには、使用したアルカリ性水溶液の廃液処理の環境負荷が高く、工業的製法としてふさわしくないものである。更に、前記特許文献7の実施例で得られる金属含有粉体中における金属含有率はいずれも90質量%未満と低いものであり、導電性ペースト等の導電性材料として使用した際には、粉体中の金属以外の固形分が多いことから、導電性発現のために高温での処理が必要と考えられる。また前記特許文献7における安定性は、粉体を得てからすぐに有機溶剤に再分散させた際の分散安定性と該再分散液の経時保存安定性である点から、固体状態(粉体)での保存安定性を保証するものでもない。 As a method for producing metal fine particles, for example, a method of drying a metal fine particle-containing liquid obtained by reducing metal ions in the presence of an alkali-soluble polymer by a freeze-drying method is provided (see, for example, Patent Document 7). . In this method, since it is necessary to completely dissolve the alkali-soluble polymer, a large amount of an alkaline aqueous solution having a pH of about 12 is required. Therefore, in order to obtain a certain amount of metal-containing powder, the alkaline aqueous solution used is used. The wastewater treatment has a high environmental impact and is not suitable as an industrial production method. Further, the metal content in the metal-containing powder obtained in the example of Patent Document 7 is as low as less than 90% by mass, and when used as a conductive material such as a conductive paste, Since there are many solids other than the metal in a body, it is thought that the process at high temperature is required for electroconductivity expression. Further, the stability in Patent Document 7 is the solid state (powder) from the viewpoint of the dispersion stability when redispersed in an organic solvent immediately after obtaining the powder and the storage stability over time of the redispersed liquid. ) Does not guarantee storage stability.

また、金属微粒子の分散液から余剰の分散剤等を除去し、乾燥することによって固体粉末状態の金属微粒子を得る方法も提供されているが(例えば、特許文献8参照。)、その手法は煩雑であり、また再分散可能な溶媒が限定され応用面での制約が大きい。

上記実情に鑑み、本発明が解決しようとする課題は、銀含有粉体中に平均粒子径が2〜50nmの銀ナノ粒子を95質量%以上で含有する、良好な保存安定性と優れた再分散性とを有する乾燥状態の銀含有粉体と、それを各種溶剤に再分散して得られる、低温融着可能な銀含有粉体の分散液、及び工業的生産性に優れるそれらの製造方法を提供することにある。 In view of the above circumstances, the problem to be solved by the present invention is that the silver-containing powder contains silver nanoparticles having an average particle diameter of 2 to 50 nm in an amount of 95% by mass or more, and has excellent storage stability and excellent reproducibility. A silver-containing powder in a dry state having dispersibility, a dispersion of a silver-containing powder that can be fused at low temperature obtained by redispersing it in various solvents, and a method for producing them that is excellent in industrial productivity Is to provide.

本発明者は上記課題を解決するために鋭意検討した結果、高い分散性を発現することに寄与するセグメントと、金属の微粒子を固定化したり、金属イオンを還元したりすることが可能なセグメントの、少なくとも2種のセグメントを有する化合物の存在下で銀化合物を還元した後、濃縮・乾燥工程を経ることにより、平均粒径が小さく、且つ銀含有率が高い銀含有粉体が得られること、得られた銀含有粉体は固体状態での保存安定性に優れ、かつ各種溶剤への再分散が容易で、その他の分散剤を使用しなくても安定性に優れる分散液が得られること、得られた分散液を塗布すると、低温での融着により高い導電性を発現しうることを見出し、本発明を完成するに至った。 As a result of intensive studies to solve the above-mentioned problems, the present inventors have found that a segment that contributes to the development of high dispersibility and a segment that can immobilize metal fine particles or reduce metal ions. In addition, after reducing the silver compound in the presence of a compound having at least two kinds of segments, a silver-containing powder having a small average particle diameter and a high silver content can be obtained by passing through a concentration and drying step. The obtained silver-containing powder is excellent in storage stability in a solid state, can be easily redispersed in various solvents, and a dispersion having excellent stability can be obtained without using other dispersants. When the obtained dispersion was applied, it was found that high conductivity could be expressed by fusion at low temperature, and the present invention was completed.

即ち本発明は、

(1)数平均分子量が500〜50,000のポリエチレンイミン(a)中のアミノ基に数平均分子量が500〜5,000のポリエチレングリコール(b)が結合してなる化合物(X)、または、

数平均分子量が500〜50,000のポリエチレンイミン(a)中のアミノ基に、数平均分子量が500〜5,000のポリエチレングリコール(b)と、エポキシ樹脂(c)とが結合してなる化合物(Y)の存在下、水性媒体中で、銀化合物を銀ナノ粒子(Z)に還元する工程、

(2)(1)で得られた、化合物(X)又は化合物(Y)と、銀ナノ粒子(Z)と、水性媒体との混合物に有機溶剤を加え、その後濃縮する工程、

(3)(2)で得られた濃縮物を乾燥する工程

とを有することを特徴とする銀含有粉体の製造方法、及び該製造方法で得られる平均粒子径が2〜50nmの銀ナノ粒子を95質量%以上で含有する銀含有粉体を提供するものである。

That is, the present invention

(1) Compound (X) obtained by bonding polyethylene glycol (b) having a number average molecular weight of 500 to 5,000 to an amino group in polyethyleneimine (a) having a number average molecular weight of 500 to 50,000, or

A compound in which polyethylene glycol (b) having a number average molecular weight of 500 to 5,000 and an epoxy resin (c) are bonded to an amino group in polyethyleneimine (a) having a number average molecular weight of 500 to 50,000. Reducing the silver compound to silver nanoparticles (Z) in an aqueous medium in the presence of (Y);

(2) A step of adding an organic solvent to the mixture of the compound (X) or the compound (Y) obtained in (1), the silver nanoparticles (Z), and the aqueous medium, and then concentrating the mixture,

(3) A method for producing a silver-containing powder characterized by having a step of drying the concentrate obtained in (2), and silver nanoparticles having an average particle diameter of 2 to 50 nm obtained by the production method The silver containing powder which contains 95 mass% or more is provided.

更に、本発明は、前記銀含有粉体を各種溶剤に再分散して得られる銀含有粉体の分散液及びこれを用いる導電性ペーストを提供するものである。 Furthermore, this invention provides the dispersion liquid of the silver containing powder obtained by re-dispersing the said silver containing powder in various solvents, and the electrically conductive paste using this.

本発明で得られる銀含有粉体は、用いる高分子化合物中のポリエチレンイミン鎖の還元能力、配位結合力や静電的な相互作用等により、銀イオンが銀ナノ粒子に還元された際、その銀ナノ粒子表面に高分子化合物が配位されてなる一定の大きさを有する乾燥状態の粉末であり、保存安定性に優れる。また、この銀含有粉体は水や各種の有機溶剤への再分散性に優れており、分散剤等のその他の化合物を使用することなく、分散液を容易に調製することができる。従って、金属材料、導電材料の各種用途に応じ、粉体そのまま、または分散液に調製してからでも配合に用いることができる。 When the silver-containing powder obtained in the present invention is reduced to silver nanoparticles due to the reducing ability of the polyethyleneimine chain in the polymer compound used, the coordination bond force, electrostatic interaction, etc., It is a dry powder having a certain size obtained by coordination of a polymer compound on the surface of the silver nanoparticles, and is excellent in storage stability. Moreover, this silver-containing powder is excellent in redispersibility in water and various organic solvents, and a dispersion can be easily prepared without using other compounds such as a dispersant. Therefore, according to various uses of the metal material and the conductive material, the powder can be used for blending as it is or after it is prepared into a dispersion.

また、本発明で得られる銀含有粉体の分散液は、該粉体中の銀ナノ粒子を被覆する化合物中の前述のポリエチレンイミン鎖の機能により、銀イオンの還元反応で得られた銀ナノ粒子を安定に保持しており、該化合物中の親水性セグメントや疎水性セグメントが、各種媒体との親和力と、セグメント間の相互作用による強い反発力とをバランスよく発現させることにより、分散性と保存安定性に優れる。 The silver-containing powder dispersion obtained in the present invention is a silver nanoparticle obtained by a silver ion reduction reaction due to the function of the aforementioned polyethyleneimine chain in the compound covering the silver nanoparticles in the powder. The particles are stably held, and the hydrophilic segment and the hydrophobic segment in the compound express a good balance between the affinity with various media and the strong repulsive force due to the interaction between the segments. Excellent storage stability.

また、本発明で得られる銀含有粉体はナノメートルサイズの銀ナノ粒子と有機化合物からなる、一定の構造を有し、且つ銀含有率が高いものである点から、高品位の導電性材料等として好適に用いることができる。更には、比表面積が大きい、表面エネルギーが高い、プラズモン吸収を有する等の金属のナノメートルサイズの微粒子としての特徴を有し、種々の化学的、電気的、磁気的性能を兼備し、多岐にわたる分野、例えば触媒、電子材料、磁気材料、光学材料、各種センサー、色材、医療検査用途等への応用が可能である。また本発明の銀含有粉体及びその分散液の製造方法は、温和な条件下での銀イオンの還元反応に基づくものであり、再現性に優れ、後処理方法も汎用の設備で実施可能であり、工業的製法として優位性が高いものである。 In addition, the silver-containing powder obtained in the present invention is composed of nanometer-sized silver nanoparticles and an organic compound, has a certain structure, and has a high silver content. Etc. can be suitably used. Furthermore, it has the characteristics as nanometer-sized fine particles of metal such as large specific surface area, high surface energy, plasmon absorption, etc., and has various chemical, electrical, and magnetic performances, and has a wide variety Applications to fields such as catalysts, electronic materials, magnetic materials, optical materials, various sensors, color materials, medical examination applications, and the like are possible. In addition, the method for producing the silver-containing powder and the dispersion thereof of the present invention is based on the reduction reaction of silver ions under mild conditions, and is excellent in reproducibility, and the post-treatment method can be performed with general-purpose equipment. It is highly advantageous as an industrial production method.

本発明の銀ナノ粒子粉体の製造方法は

(1)数平均分子量が500〜50,000のポリエチレンイミン(a)中のアミノ基に数平均分子量が500〜5,000のポリエチレングリコール(b)が結合してなる化合物(X)、または、

数平均分子量が500〜50,000のポリエチレンイミン(a)中のアミノ基に、数平均分子量が500〜5,000のポリエチレングリコール(b)と、エポキシ樹脂(c)とが結合してなる化合物(Y)の存在下、水性媒体中で、銀化合物を銀ナノ粒子(Z)に還元する工程、

(2)(1)で得られた、化合物(X)又は化合物(Y)と、銀ナノ粒子(Z)と、水性媒体との混合物に有機溶剤を加え、その後濃縮する工程、

(3)(2)で得られた濃縮物を乾燥する工程

とを有することを特徴とする。

The method for producing silver nanoparticle powder of the present invention is as follows: (1) Polyethylene glycol (b) having a number average molecular weight of 500 to 5,000 in the amino group in polyethyleneimine (a) having a number average molecular weight of 500 to 50,000 Or a compound (X) formed by binding, or

A compound in which polyethylene glycol (b) having a number average molecular weight of 500 to 5,000 and an epoxy resin (c) are bonded to an amino group in polyethyleneimine (a) having a number average molecular weight of 500 to 50,000. Reducing the silver compound to silver nanoparticles (Z) in an aqueous medium in the presence of (Y);

(2) A step of adding an organic solvent to the mixture of the compound (X) or the compound (Y) obtained in (1), the silver nanoparticles (Z), and the aqueous medium, and then concentrating the mixture,

(3) A step of drying the concentrate obtained in (2).

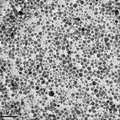

本発明における銀ナノ粒子とは、透過型電子顕微鏡写真で観測される粒子径がナノメートルオーダーであることを意味するものであり、その形が完全な球体であることを必要としない。又、化合物(X)又は化合物(Y)を構成する各セグメントの数平均分子量は、ゲルパーミュエーションクロマトグラフィー(GPC)によって測定した、ポリスチレン換算値である。 The silver nanoparticle in the present invention means that the particle diameter observed in a transmission electron micrograph is on the order of nanometers, and the shape does not need to be a perfect sphere. Moreover, the number average molecular weight of each segment which comprises a compound (X) or a compound (Y) is a polystyrene conversion value measured by gel permeation chromatography (GPC).

本発明において使用する化合物(X)および化合物(Y)を構成するポリエチレンイミン鎖(a)は、該鎖中のエチレンイミン単位が銀およびそのイオンと配位結合可能であり、更に銀イオンの還元を促して銀ナノ粒子(Z)とし、該銀ナノ粒子(Z)を安定化し保持する高分子鎖である。その構造はエチレンイミン単位を主な繰り返し単位とし、直鎖状、分岐状のいずれであっても良く、市販品・合成品のいずれでも良い。 In the polyethyleneimine chain (a) constituting the compound (X) and the compound (Y) used in the present invention, the ethyleneimine unit in the chain can be coordinated with silver and its ions, and further reduction of silver ions Is a polymer chain that stabilizes and holds silver nanoparticles (Z). The structure has an ethyleneimine unit as the main repeating unit, and may be linear or branched, and may be either a commercial product or a synthetic product.

本発明で得られる銀含有粉体の大きさは、用いる化合物(X)または化合物(Y)の分子量やポリエチレンイミン(a)の分子量だけではなく、該化合物(X)または化合物(Y)を構成する各成分、即ち、ポリエチレンミン(a)、後述する親水性セグメント(b)、化合物(Y)であっては更に後述のエポキシ樹脂(c)の構造や組成比、また原料として用いる銀の種類によっても影響を受ける。また、銀含有粉体における銀ナノ粒子(Z)の含有率を上げるためには、分岐状のポリエチレンイミン鎖を用いることが好ましい。 The size of the silver-containing powder obtained in the present invention is not limited to the molecular weight of the compound (X) or compound (Y) used or the molecular weight of the polyethyleneimine (a), but constitutes the compound (X) or compound (Y). In the case of each component to be processed, that is, polyethylenemin (a), hydrophilic segment (b) described later, compound (Y), the structure and composition ratio of epoxy resin (c) described later, and the kind of silver used as a raw material Also affected by. In order to increase the content of silver nanoparticles (Z) in the silver-containing powder, it is preferable to use a branched polyethyleneimine chain.

一般に市販されている分岐状ポリエチレンイミンは3級アミンによって分岐状となっており、本発明で使用する化合物(X)または化合物(Y)の原料として用いることができる。保存安定性に優れる銀含有粉体やその分散液が得られる、好ましい粒径の銀含有粉体が得られる点からは、分岐度を(3級アミン)/(全てのアミン)のモル比で示すと(1〜49)/(100)の範囲の分岐度であることが好ましく、工業的な製造面、入手のし易さ等も鑑みるとより好ましい分岐度の範囲は(15〜40)/(100)である。 A commercially available branched polyethyleneimine is branched by a tertiary amine and can be used as a raw material for the compound (X) or the compound (Y) used in the present invention. From the viewpoint of obtaining a silver-containing powder having a preferable particle diameter, which can provide a silver-containing powder having excellent storage stability and a dispersion thereof, the degree of branching is expressed as a molar ratio of (tertiary amine) / (all amines). When it shows, it is preferable that it is a branching degree of the range of (1-49) / (100), and the range of a more preferable branching degree is (15-40) / in view of an industrial manufacture surface, availability, etc. (100).

前記ポリエチレンイミン(a)部分の平均分子量としては、低すぎると、化合物(X)または化合物(Y)による銀ナノ粒子(Z)の保持能力が低下しやすく、保存安定性が不十分になることがあり、高すぎると銀含有粉体が巨大化しやすく、該分散液の保存安定性に支障をきたすことがある。従って、得られる銀含有粉体およびその分散液の保存安定性がより優れたものであり、該粉体中の銀ナノ粒子(Z)の含有率を高くすることができる観点から数平均分子量としては500〜50,000の範囲であり、1,000〜40,000の範囲であることが好ましく、1,800〜30,000の範囲であることが最も好ましい。 If the average molecular weight of the polyethyleneimine (a) portion is too low, the retention ability of the silver nanoparticles (Z) by the compound (X) or the compound (Y) tends to be lowered, and the storage stability becomes insufficient. If it is too high, the silver-containing powder tends to become enormous and the storage stability of the dispersion may be hindered. Therefore, the storage stability of the obtained silver-containing powder and its dispersion is more excellent, and the number average molecular weight is from the viewpoint of increasing the content of silver nanoparticles (Z) in the powder. Is in the range of 500 to 50,000, preferably in the range of 1,000 to 40,000, and most preferably in the range of 1,800 to 30,000.

ポリエチレングリコール(b)の分子量としては、親水性有機溶剤に分散させる場合は、分子量が低すぎると分散安定性が悪化し、高すぎると分散体同士が凝集してしまう可能性が考えられる。また、銀含有粉体においては、固体状態における凝集のない保存安定性と、銀含有率を高くすることとのバランスをとることが必要である点から、ポリエチレングリコール(b)部分の数平均分子量としては500〜5,000であり、1,000〜3,000であることがより好ましい。 When the molecular weight of polyethylene glycol (b) is dispersed in a hydrophilic organic solvent, the dispersion stability may be deteriorated if the molecular weight is too low, and the dispersion may be aggregated if the molecular weight is too high. Further, in the silver-containing powder, it is necessary to balance the storage stability without aggregation in the solid state and the increase in the silver content, so that the number average molecular weight of the polyethylene glycol (b) portion. Is 500 to 5,000, more preferably 1,000 to 3,000.

ポリエチレングリコール(b)は一般的に市販品でも、合成品でも良い。また、他の親水性ポリマーとの共重合体等であっても良い。このとき使用できる親水性ポリマーとしては、例えば、ポリビニルアルコール、ポリアクリルアミド、ポリイソプロピルアクリルアミド、ポリビニルピロリドン等が挙げられる。得られる銀含有粉体中の銀含有率を高める点から、共重合体を使用する場合においても、全体の分子量が500〜5,000の範囲であることが好ましい。 Polyethylene glycol (b) may generally be a commercial product or a synthetic product. Further, it may be a copolymer with other hydrophilic polymer. Examples of the hydrophilic polymer that can be used at this time include polyvinyl alcohol, polyacrylamide, polyisopropylacrylamide, and polyvinylpyrrolidone. From the viewpoint of increasing the silver content in the resulting silver-containing powder, even when a copolymer is used, the overall molecular weight is preferably in the range of 500 to 5,000.

本発明において使用する化合物(Y)中には、更に疎水性セグメントとしてエポキシ樹脂(c)を結合してなるものである。化合物(Y)中にエポキシ樹脂(c)由来の構造を含有させることにより、該化合物(Y)を水または親水性溶媒中に再分散した場合には、分子内又は分子間相互の強い会合力により、ミセルのコアを形成し、安定なミセルを形成してその中に銀ナノ粒子(Z)を取り込んで安定な分散液を得ることができる。また疎水性有機溶媒中に再分散させる場合には、該溶剤との高い親和性を有することで、分散安定性に優れたものにすることが可能となる。 In the compound (Y) used in the present invention, an epoxy resin (c) is further bonded as a hydrophobic segment. By incorporating a structure derived from the epoxy resin (c) into the compound (Y), when the compound (Y) is redispersed in water or a hydrophilic solvent, a strong associative force within the molecule or between the molecules. By forming a micelle core, a stable micelle can be formed, and silver nanoparticles (Z) can be taken therein to obtain a stable dispersion. Further, when redispersed in a hydrophobic organic solvent, it has a high affinity with the solvent, so that the dispersion stability can be improved.

エポキシ樹脂(c)は一般的に市販、又は合成可能な構造であれば特に限定されることなく使用することができる。例えば、ビスフェノールA型エポキシ樹脂、ビスフェノールF型エポキシ樹脂、ビフェニル型エポキシ樹脂、ナフタレン型エポキシ樹脂、ナフタレン型4官能エポキシ樹脂、テトラメチルビフェニル型エポキシ樹脂、フェノールノボラック型エポキシ樹脂、クレゾールノボラック型エポキシ樹脂、ビスフェノールAノボラック型エポキシ樹脂、トリフェニルメタン型エポキシ樹脂、テトラフェニルエタン型エポキシ樹脂、ジシクロペンタジエン−フェノール付加反応型エポキシ樹脂、フェノールアラルキル型エポキシ樹脂、ナフトールノボラック型エポキシ樹脂、ナフトールアラルキル型エポキシ樹脂、ナフトール−フェノール共縮ノボラック型エポキシ樹脂、ナフトール−クレゾール共縮ノボラック型エポキシ樹脂、芳香族炭化水素ホルムアルデヒド樹脂変性フェノール樹脂型エポキシ樹脂、ビフェニルノボラック型エポキシ樹脂、特開2003−201333号記載のキサンテン型エポキシ樹脂等が挙げられ、単独で用いてもよく、2種以上を混合してもよい。これらの中でも、得られる銀含有粉体またはその分散液を導電性ペーストとして用いる際に、基板との密着性に優れる等の観点から、ビスフェノールA型エポキシ樹脂を用いることが好ましく、親水性有機溶剤中での会合力が強く、分散安定性・保存安定性に優れる銀含有粉体の分散液が得られる点から、ナフタレン型4官能エポキシ樹脂等の3官能以上のエポキシ樹脂を用いることが好ましい。また、これらのエポキシ樹脂は、そのまま化合物(Y)の原料としても良く、更には目的とする化合物(Y)の構造等に応じて、種々の変性を加えたものであっても良い。例えば、エポキシ樹脂(c)中のエポキシ基の一部を、金属との相互作用を有する芳香環を有する化合物で予め開環させて、より安定な銀含有粉体とすることもできる。 The epoxy resin (c) can be used without particular limitation as long as it is generally commercially available or can be synthesized. For example, bisphenol A type epoxy resin, bisphenol F type epoxy resin, biphenyl type epoxy resin, naphthalene type epoxy resin, naphthalene type tetrafunctional epoxy resin, tetramethylbiphenyl type epoxy resin, phenol novolac type epoxy resin, cresol novolac type epoxy resin, Bisphenol A novolac type epoxy resin, triphenylmethane type epoxy resin, tetraphenylethane type epoxy resin, dicyclopentadiene-phenol addition reaction type epoxy resin, phenol aralkyl type epoxy resin, naphthol novolak type epoxy resin, naphthol aralkyl type epoxy resin, Naphthol-phenol co-condensed novolak epoxy resin, Naphthol-cresol co-condensed novolac epoxy resin, Aromatic hydrocarbon form Aldehyde resin modified phenol resin type epoxy resin, a biphenyl novolak type epoxy resin, a xanthene type epoxy resins described in JP-2003-201333, may be used alone, or may be a mixture of two or more. Among these, when using the obtained silver-containing powder or dispersion thereof as a conductive paste, it is preferable to use a bisphenol A type epoxy resin from the viewpoint of excellent adhesion to a substrate, etc., and a hydrophilic organic solvent It is preferable to use a trifunctional or higher functional epoxy resin such as a naphthalene type tetrafunctional epoxy resin from the viewpoint of obtaining a dispersion of a silver-containing powder having a strong associative force and excellent dispersion stability and storage stability. In addition, these epoxy resins may be used as the raw material of the compound (Y) as they are, and further may be those modified in various ways according to the structure of the target compound (Y). For example, a part of the epoxy group in the epoxy resin (c) can be ring-opened in advance with a compound having an aromatic ring having an interaction with a metal to obtain a more stable silver-containing powder.

また、エポキシ樹脂(c)の分子量としては特に限定されるものではないが、親水性有機溶剤中に再分散させる場合は、低すぎると分散安定性が悪化し、高すぎるとミセル同士が凝集してしまう可能性が考えられ、また疎水性有機溶剤中に分散させる場合は、低すぎるとミセルの分散性が乏しくなり、高すぎると溶媒との親和性が保持できなくなる。これらの観点、および銀含有粉体の固形分中における銀含有率を容易に高めることができる点から、エポキシ樹脂(c)の数平均分子量としては通常100〜200,000であることが好ましく、特に300〜100,000であることが好ましい。 Further, the molecular weight of the epoxy resin (c) is not particularly limited, but when redispersed in a hydrophilic organic solvent, the dispersion stability is deteriorated if it is too low, and the micelles are aggregated if it is too high. In the case of dispersing in a hydrophobic organic solvent, if it is too low, the dispersibility of micelles is poor, and if it is too high, the affinity with the solvent cannot be maintained. From these viewpoints and the point that the silver content in the solid content of the silver-containing powder can be easily increased, the number average molecular weight of the epoxy resin (c) is usually preferably 100 to 200,000, In particular, it is preferably 300 to 100,000.

本発明で用いる化合物(X)および化合物(Y)の製造方法としては、特に限定されるものではないが、設計どおりの化合物を容易に合成可能である点から、下記の方法によるものが好ましい。 Although it does not specifically limit as a manufacturing method of compound (X) and compound (Y) used by this invention, The thing by the following method is preferable from the point which can synthesize | combine a compound as designed easily.

ポリエチレンイミン(a)は前述したとおり、市販又は合成したものを好適に用いることができる。まず、分岐状ポリエチレンイミン鎖を用いる場合について説明する。 As described above, a commercially available or synthesized polyethyleneimine (a) can be suitably used. First, the case where a branched polyethyleneimine chain is used will be described.

分岐状ポリエチレンイミンの末端は1級アミンとなっているため、ポリエチレングリコール(b)の末端を1級アミンと反応する官能基に予め変性させて、反応させることによって、本発明で用いる事ができる化合物(X)を合成することができる。1級アミンと反応する官能基としては、特に限定されるものではなく、例えば、アルデヒド基、カルボキシ基、イソシアネート基、トシル基、エポキシ基、グリシジル基、イソチオシアネート基、ハロゲン、酸クロライド、スルホン酸クロライド等が挙げられる。なかでもカルボキシ基、イソシアネート基、トシル基、エポキシ基、グリシジル基は反応性、取扱い易さ等、製法上有利であり、好ましい官能基である。 Since the terminal of the branched polyethyleneimine is a primary amine, the terminal of polyethylene glycol (b) can be used in the present invention by pre-modifying and reacting with a functional group that reacts with the primary amine. Compound (X) can be synthesized. The functional group that reacts with the primary amine is not particularly limited. For example, aldehyde group, carboxy group, isocyanate group, tosyl group, epoxy group, glycidyl group, isothiocyanate group, halogen, acid chloride, sulfonic acid Examples include chloride. Among them, a carboxy group, an isocyanate group, a tosyl group, an epoxy group, and a glycidyl group are advantageous in terms of production methods such as reactivity and ease of handling, and are preferable functional groups.

また1級アミンと直接反応する官能基でなくとも、種々の処理を行うことによって1級アミンと反応可能な官能基にできるものであれば良く、例えば、ヒドロキシ基を有するポリエチレングリコールを用いるのであれば、これをグリシジル化する等の手法でポリエチレンイミン鎖と反応させても良い。更には、分岐状ポリエチレンイミン鎖の1級アミンを、官能基を有するポリエチレングリコールと反応可能な他の官能基に変換する処理を施した後、これらを反応させて化合物(X)を合成することも可能である。 In addition, the functional group may not be a functional group that directly reacts with the primary amine, but may be any functional group that can be reacted with the primary amine by various treatments. For example, polyethylene glycol having a hydroxy group may be used. For example, it may be reacted with a polyethyleneimine chain by a technique such as glycidylation. Furthermore, after performing the process which converts the primary amine of a branched polyethyleneimine chain | strand into the other functional group which can react with the polyethylene glycol which has a functional group, these are made to react and synthesize | combine a compound (X). Is also possible.

ポリエチレンイミン鎖(a)が直鎖状ポリエチレンイミン鎖の場合は、リビング重合によって、まずポリアシル化エチレンイミン鎖を合成し、引き続き、ポリエチレングリコールを導入することによって高分子化合物を得た後、ポリアシル化エチレンイミン鎖を加水分解して直鎖状ポリエチレンイミン鎖とする方法が挙げられる。 When the polyethyleneimine chain (a) is a linear polyethyleneimine chain, a polymer compound is obtained by first synthesizing a polyacylated ethyleneimine chain by living polymerization, and subsequently introducing polyethylene glycol. Examples include a method of hydrolyzing an ethyleneimine chain to form a linear polyethyleneimine chain.

また、本発明で用いる化合物(Y)に合成方法については、前記特許文献6や、特開2006−213887号公報、特許第4026662号、特許第4026664号等にて、既に本発明者により提供しているので、それを参照すれば良い。 In addition, the synthesis method for the compound (Y) used in the present invention has already been provided by the present inventor in Patent Document 6, Japanese Patent Application Laid-Open No. 2006-213877, Japanese Patent No. 4026662, Japanese Patent No. 4026664, and the like. You can refer to it.

本発明で用いる化合物(X)および化合物(Y)中のポリエチレンイミン(a)とポリエチレングリコール(b)の各成分の鎖を構成するポリマーのモル比(a):(b)としては特に限定されるものではないが、得られる銀含有粉体の保存安定性、その分散液の分散安定性及び保存安定性に優れる点から、通常(a):(b)=1:1〜100の範囲であり、特に1:1〜30になるように設計することが好ましい。 The molar ratio (a) :( b) of the polymer constituting the chain of each component of polyethyleneimine (a) and polyethylene glycol (b) in compound (X) and compound (Y) used in the present invention is particularly limited. Although it is not a thing, from the point which is excellent in the storage stability of the obtained silver containing powder, the dispersion stability of the dispersion liquid, and storage stability, Usually in the range of (a) :( b) = 1: 1-100. In particular, it is preferable to design such that the ratio is 1: 1 to 30.

また、化合物(Y)を用いる場合、ポリエチレンイミン(a)とポリエチレングリコール(b)、エポキシ樹脂(c)の各成分の鎖を構成するポリマーのモル比(a):(b):(c)としては特に限定されるものではないが、得られる銀含有粉体の保存安定性、その分散液の分散安定性及び保存安定性に優れる点から、通常(a):(b):(c)=1:1〜100:1〜100の範囲であり、特に1:1〜30:1〜30になるよう設計することが好ましい。 Moreover, when using a compound (Y), the molar ratio (a) :( b) :( c) of the polymer which comprises the chain | strand of each component of a polyethyleneimine (a), polyethyleneglycol (b), and an epoxy resin (c) Is not particularly limited, but is usually (a) :( b) :( c) from the viewpoint of excellent storage stability of the resulting silver-containing powder, dispersion stability of the dispersion, and storage stability. = 1: 1 to 100: 1 to 100, and it is particularly preferable that the design is 1: 1 to 30: 1 to 30.

本発明に使用する化合物(X)および化合物(Y)は、銀ナノ粒子(Z)を安定に存在させることが出来るポリエチレンイミン(a)とは別に、ポリエチレングリコール(b)、又は、更にエポキシ樹脂(c)に由来する構造を有する。上記したように、ポリエチレングリコール(b)の部分は、親水性有機溶剤中では溶媒と高い親和性を示し、また、エポキシ樹脂(c)の部分は親水性有機溶剤中で強い会合力を示す。さらには、エポキシ樹脂(c)中に芳香環を有する場合には、該芳香環の有するπ電子が銀と相互作用することによって、さらに銀含有粉体を安定化することに寄与するとも考えられる。 The compound (X) and the compound (Y) used in the present invention include polyethylene glycol (b), or further an epoxy resin, separately from the polyethyleneimine (a) capable of stably presenting silver nanoparticles (Z). It has a structure derived from (c). As described above, the polyethylene glycol (b) portion exhibits a high affinity with the solvent in the hydrophilic organic solvent, and the epoxy resin (c) portion exhibits a strong associating force in the hydrophilic organic solvent. Furthermore, when the epoxy resin (c) has an aromatic ring, it is considered that the π electrons of the aromatic ring interact with silver to further contribute to stabilizing the silver-containing powder. .

また、化合物(X)および化合物(Y)中に存在するポリエチレングリコール(b)由来構造部分は、後の精製工程において、一度濃縮した後、水または水と親水性有機溶剤との混合溶剤に再分散させる際、該化合物(X)または化合物(Y)と銀ナノ粒子(Z)との効率的な再配置を行なうことに寄与すると考えられる。即ち、ポリエチレングリコール(b)由来構造が再分散のときに溶剤側へ偏在することによって、化合物中のポリエチレンイミン(a)由来構造の全てが銀ナノ粒子(Z)の安定的な保持に関与するようになると考えられ、このことが、必要最低限の化合物(X)又は化合物(Y)で銀ナノ粒子(X)を安定化することになり、得られる銀含有粉体中の銀含有率を高くすることができるものと推察できる。従って、この様にして得られる銀含有粉体はその最表面がポリエチレングリコール(b)由来構造で覆われた状態になっていると考えられ、該粉体を再分散させて分散液を調製する際に、新たな分散剤を使用しなくても最分散が容易でかつ安定性に優れたものとなる要因であると考えられる。 Further, the polyethylene glycol (b) -derived structural portion present in the compound (X) and the compound (Y) is once concentrated in a subsequent purification step, and then reconstituted in water or a mixed solvent of water and a hydrophilic organic solvent. When dispersed, the compound (X) or the compound (Y) and the silver nanoparticles (Z) are considered to contribute to efficient rearrangement. That is, since the polyethylene glycol (b) -derived structure is unevenly distributed to the solvent side during redispersion, all of the polyethyleneimine (a) -derived structures in the compound are involved in the stable retention of the silver nanoparticles (Z). This will stabilize the silver nanoparticles (X) with the minimum necessary compound (X) or compound (Y), and the silver content in the resulting silver-containing powder will be reduced. It can be inferred that it can be increased. Therefore, it is considered that the silver-containing powder obtained in this manner is in a state where the outermost surface is covered with a structure derived from polyethylene glycol (b), and a dispersion is prepared by redispersing the powder. In this case, it is considered that this is a factor that facilitates the most dispersion and has excellent stability without using a new dispersant.

本発明の製造方法における第一工程は、前述の化合物(X)又は化合物(Y)を水性媒体、即ち水又は水と親水性有機溶剤との混合溶剤に溶解又は分散させる工程である。ポリエチレンイミン(a)とポリエチレングリコール(b)と、更に化合物(Y)である場合には、エポキシ樹脂(c)との組合せにより、水性媒体への溶解性・分散性が異なるが、均一に溶解または分散させることが必要となる。ここで用いることができる親水性有機溶剤としては、25〜35℃で、水100質量部に対して、少なくとも5質量部混和し、均一な混合溶剤が得られるものであればよく、例えば、メタノール、エタノール、イソプロピルアルコール、n−プロピルアルコール、テトラヒドロフラン、ジオキサン、アセトン、メチルエチルケトン、ジメチルアセトアミド、ジメチルホルムアミド、エチレングリコール、プロピレングリコール、エチレングリコールモノメチルエーテル、プロピレングリコールモノメチルエーテル、エチレングリコールジメチルエーテル、プロピレングリコールジメチルエーテル、ジエチレングリコール、グリセリン、ジメチルスルフォンオキシド、ジオキシラン、N−メチルピロリドン、ジメチルイミダゾリジノン、スルホラン等を挙げることができ、単独でも、2種以上を混合して用いても良い。また、各種イオン液体を用いても良い。 The first step in the production method of the present invention is a step of dissolving or dispersing the aforementioned compound (X) or compound (Y) in an aqueous medium, that is, water or a mixed solvent of water and a hydrophilic organic solvent. In the case of polyethyleneimine (a), polyethylene glycol (b), and further compound (Y), the solubility and dispersibility in aqueous media differ depending on the combination of epoxy resin (c), but it dissolves uniformly. Or it is necessary to disperse. The hydrophilic organic solvent that can be used here may be any one that can be mixed at least 5 parts by mass with respect to 100 parts by mass of water at 25 to 35 ° C. to obtain a uniform mixed solvent. , Ethanol, isopropyl alcohol, n-propyl alcohol, tetrahydrofuran, dioxane, acetone, methyl ethyl ketone, dimethylacetamide, dimethylformamide, ethylene glycol, propylene glycol, ethylene glycol monomethyl ether, propylene glycol monomethyl ether, ethylene glycol dimethyl ether, propylene glycol dimethyl ether, diethylene glycol Glycerin, dimethylsulfone oxide, dioxirane, N-methylpyrrolidone, dimethylimidazolidinone, sulfo Can be exemplified emissions etc., may be used individually or as a mixture of two or more. Various ionic liquids may be used.

前記化合物(X)又は化合物(Y)と、水性媒体との使用割合としては、取り扱い上の容易性と、銀イオンの還元反応の容易性の観点、得られる銀含有粉体の銀含有率の向上の観点から、化合物(X)又は化合物(Y)の濃度が1〜20質量%になるように用いることが好ましく、2〜15質量%であることがより好ましい。この時、化合物(X)又は化合物(Y)の溶解性・分散性が不足する場合には、例えば、酢酸エチル、酢酸プロピル、酢酸ブチル、酢酸イソブチル、エチレングリコールモノメチルエーテルアセテート、プロピレングリコールモノメチルエーテルアセテート等を併用した混合溶剤を用いることで溶解性・分散性を調整することができる。化合物(X)又は化合物(Y)を溶解または分散させるには、通常、室温で静置、又は攪拌を行えばよく、必要に応じて超音波処理、加熱処理等を行ってもよい。また化合物(X)又は化合物(Y)の結晶性等により、水性媒体とのなじみが低い場合には、例えば、化合物(X)又は化合物(Y)を少量の良溶媒で、溶解又は膨潤させた後、目的とする水性媒体中へ分散させる方法でもよい。このとき、超音波処理又は加熱処理を行うとより効果的である。 As the use ratio of the compound (X) or the compound (Y) and the aqueous medium, the silver content of the silver-containing powder obtained from the viewpoint of easy handling and ease of silver ion reduction reaction. From the viewpoint of improvement, the concentration of the compound (X) or the compound (Y) is preferably 1 to 20% by mass, and more preferably 2 to 15% by mass. At this time, when the solubility / dispersibility of compound (X) or compound (Y) is insufficient, for example, ethyl acetate, propyl acetate, butyl acetate, isobutyl acetate, ethylene glycol monomethyl ether acetate, propylene glycol monomethyl ether acetate Solubility and dispersibility can be adjusted by using a mixed solvent in combination. In order to dissolve or disperse the compound (X) or the compound (Y), usually, the compound (X) or the compound (Y) may be left standing or stirred at room temperature, and may be subjected to ultrasonic treatment, heat treatment or the like as necessary. Further, when the familiarity with the aqueous medium is low due to the crystallinity of the compound (X) or the compound (Y), for example, the compound (X) or the compound (Y) is dissolved or swollen with a small amount of a good solvent. Thereafter, it may be dispersed in a target aqueous medium. At this time, it is more effective to perform ultrasonic treatment or heat treatment.

化合物(X)または化合物(Y)の溶液または分散液を調製した後、銀化合物を混合するが、このとき、得られる銀含有粉体中の銀含有率を高める観点から、化合物(X)又は化合物(Y)100質量部に対して、銀として400〜9900質量部になるよう用いることが好ましい。さらに水性媒体の使用量を削減することによって生産性を高めることと、還元反応の制御を容易に行なうことができる観点から、不揮発分として2〜80質量%になるよう混合することが好ましい。より好ましくは、化合物(X)又は化合物(Y)100質量部に対して、銀として900〜9900質量部、不揮発分として3〜50質量%となるように用いることである。 After preparing a solution or dispersion of compound (X) or compound (Y), a silver compound is mixed. At this time, from the viewpoint of increasing the silver content in the obtained silver-containing powder, compound (X) or It is preferable to use it so that it may become 400-9900 mass parts as silver with respect to 100 mass parts of compounds (Y). Furthermore, it is preferable to mix so that it may become 2-80 mass% as a non volatile matter from a viewpoint which improves productivity by reducing the usage-amount of an aqueous medium, and can control a reductive reaction easily. More preferably, it is used so that it may become 900-9900 mass parts as silver and 3-50 mass% as a non volatile matter with respect to 100 mass parts of compound (X) or compound (Y).

この時、用いることができる銀化合物としては、還元反応によって銀ナノ粒子(Z)が得られるものであればよく、例えば、硝酸銀、酸化銀、酢酸銀、フッ化銀、銀アセチルアセトナート、安息香酸銀、炭酸銀、クエン酸銀、銀ヘキサフルオロフォスフェート、乳酸銀、亜硝酸銀、ペンタフルオロプロピオン酸銀、過塩素酸銀、硫酸銀、塩化銀、臭化銀、ヨウ化銀、亜硫酸銀、銀テトラフルオロボレート、p−トルエンスルホン酸銀、トリフルオロ酢酸銀、等が挙げられ、取り扱い容易性、工業的入手容易性の観点から、硝酸銀または酸化銀を用いることが好ましい。 At this time, as a silver compound that can be used, any silver compound (Z) can be obtained by a reduction reaction. For example, silver nitrate, silver oxide, silver acetate, silver fluoride, silver acetylacetonate, benzoic acid Silver oxide, silver carbonate, silver citrate, silver hexafluorophosphate, silver lactate, silver nitrite, silver pentafluoropropionate, silver perchlorate, silver sulfate, silver chloride, silver bromide, silver iodide, silver sulfite, Examples thereof include silver tetrafluoroborate, silver p-toluenesulfonate, and silver trifluoroacetate. From the viewpoint of easy handling and industrial availability, it is preferable to use silver nitrate or silver oxide.

前記工程において、化合物(X)又は化合物(Y)が溶解または分散している水性媒体と銀化合物とを混合する方法としては、特に限定されるものではなく、該化合物(X)又は化合物(Y)が溶解または分散している媒体に銀化合物を加える方法、その逆の方法、或いは別の容器に同時に投入しながら混合する方法でもよい。攪拌等の混合方法についても、特に限定されない。 In the step, the method of mixing the silver compound with the aqueous medium in which the compound (X) or the compound (Y) is dissolved or dispersed is not particularly limited, and the compound (X) or the compound (Y ) May be a method in which a silver compound is added to a medium in which the solution is dissolved or dispersed, or vice versa, or a method in which mixing is performed while simultaneously charging in another container. A mixing method such as stirring is not particularly limited.

この時、還元反応を早めるために、必要に応じて30〜70℃程度に加温しても良く、また、還元剤を併用しても良い。 At this time, in order to accelerate the reduction reaction, it may be heated to about 30 to 70 ° C. as necessary, or a reducing agent may be used in combination.

前記還元剤としては、特に限定されるものではないが、還元反応を容易にコントロールすることができるとともに、後の精製工程で容易に反応系から除去可能である点から、例えば、水素、水素化ホウ素ナトリウム、水素化ホウ素アンモニウム等のホウ素化合物、メタノール、エタノール、プロパノール、イソプロピルアルコール、エチレングリコール、プロピレングリコール等のアルコール類、ホルムアルデヒド、アセトアルデヒド、プロピオンアルデヒド等のアルデヒド類、アスコルビン酸、クエン酸、クエン酸ナトリウム等の酸類、ヒドラジン、炭酸ヒドラジン等のヒドラジン類等を用いることが好ましい。これらの中でも、工業的入手のし易さ、取扱い面等からより好ましいものとしては、水素化ホウ素ナトリウム、アスコルビン酸、クエン酸ナトリウム等である。 The reducing agent is not particularly limited. For example, hydrogen, hydrogenation can be performed because the reduction reaction can be easily controlled and can be easily removed from the reaction system in a subsequent purification step. Boron compounds such as sodium boron and ammonium borohydride, alcohols such as methanol, ethanol, propanol, isopropyl alcohol, ethylene glycol and propylene glycol, aldehydes such as formaldehyde, acetaldehyde and propionaldehyde, ascorbic acid, citric acid and citric acid It is preferable to use acids such as sodium and hydrazines such as hydrazine and hydrazine carbonate. Among these, sodium borohydride, ascorbic acid, sodium citrate and the like are more preferable from the viewpoint of industrial availability and handling.