JP4465834B2 - Combine - Google Patents

Combine Download PDFInfo

- Publication number

- JP4465834B2 JP4465834B2 JP2000249562A JP2000249562A JP4465834B2 JP 4465834 B2 JP4465834 B2 JP 4465834B2 JP 2000249562 A JP2000249562 A JP 2000249562A JP 2000249562 A JP2000249562 A JP 2000249562A JP 4465834 B2 JP4465834 B2 JP 4465834B2

- Authority

- JP

- Japan

- Prior art keywords

- transfer cylinder

- transfer

- cylinder

- spiral

- grain

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Threshing Machine Elements (AREA)

Description

【0001】

【発明の属する技術分野】

この発明は、穀粒排出装置を備えたコンバインに関するものである。

【0002】

【従来の技術】

コンバインで立毛穀稈を収穫するときには、このコンバインの前部に設けた刈取機で刈取りした刈取り穀稈は、この刈取機で移送され、後部に設けた脱穀機へ供給され、この脱穀機で脱穀され、脱穀済みの穀粒は、揚穀装置で揚送されて穀粒貯留タンク内へ供給され、この穀粒貯留タンク内で一時貯留される。

【0003】

貯留した穀粒を機外へ排出するときは、穀粒貯留タンク内の穀粒は、この穀粒貯留タンクから縦移送筒内へ供給され、この縦移送筒に内装した縦移送螺旋から後移送筒内へ移送供給され、この後移送筒に内装した後移送螺旋で前移送筒内へ移送供給され、この前移送筒に内装した前移送螺旋で引継ぎされて移送され、この前移送筒の前端部に設けた排出筒の下部の排穀口から機外へ排出される。

【0004】

又、前記コンバインを納屋内へ収納するとき、又は路上走行のとき、及び圃場間を移動走行するときには、作業者が操縦席から一度おりて、前移送筒を回動操作して折り畳み、後移送筒の横側へこの前移送筒を位置させて収納状態にして、納屋への収納、及び収穫作業中以外の時の走行を行う。

【0005】

【発明が解決しようとする課題】

後移送筒の前端部に設けた前移送筒を回動操作して、折り畳み状態、又は作業状態にするときには、操縦席に搭乗した作業者は、一度この操縦席からおりて、回動操作をしないと、折り畳み状態、又は作業状態にすることができなく、このために、これらの操作がめんどうであったが、この発明により、この問題を解決しようとするものである。

【0006】

【課題を解決するための手段】

このために、請求項1記載の発明は、車台(2)の下側に走行装置(3)を設け、該車台(2)の前側に刈取機(13)を昇降自在に設け、該車台(2)の上側に脱穀機(12)を設け、該脱穀機(12)の右側に穀粒貯留タンク(5)を設け、該穀粒貯留タンク(5)の前方の部位に操縦席(18b)を設け、穀粒貯留タンク(5)の底部に穀粒を後方へ移送する底部移送螺旋(14a)を設け、該底部移送螺旋(14a)によって移送された穀粒を引き継いで移送する縦移送筒(6)を穀粒貯留タンク(5)の後側に設け、該縦移送筒(6)の上端部に設けた継手メタル(23)に第1移送螺旋(7)を内装した第1移送筒(8)を取り付け、該第1移送筒(8)の端部に設けた回動受メタル(28)の横側部に第1孔(28b)を設け、第2移送螺旋(9)を内装する第2移送筒(10)の端部に設けた回動メタル(30)の横側部に第2孔(30a)を設け、該第1孔(28b)と第2孔(30a)に支持軸(33)を挿入して第1移送筒(8)と第2移送筒(10)とを折り畳み自在に接続し、第2移送筒(10)の外周部下側の所定位置に前挿入孔(37a)を備えた前側の前受板(37)と後挿入孔(38a)を備えた後側の後受板(38)を固着し、該第2移送筒(10)を折り畳んで第1移送筒(8)の横側に収納する際に操縦席(18b)上から回動操作する丸棒状の回動ハンドル(11)を、前挿入孔(37a)と後挿入孔(38a)に挿入して引き出し状態及び収納状態に前後移動自在に第2移送筒(10)側に支持し、該第2移送筒(10)を折り畳んで第1移送筒(8)の横側に収納した状態において、前記回動ハンドル(11)を収納状態に操作すると該回動ハンドル(11)の握り部(39)が前記回動メタル(30)から突出しない構成とし、前記第1移送筒(8)の外周の横一側部に固着した支持受具(35a)に、下方へ折曲した折曲部(36a)を先端部に有し第2移送筒(10)を折り畳んで第1移送筒(8)の横側に収納するときに該第2移送筒(10)の外周下部を受ける略L字形状の案内ガイド(36)を設けたことを特徴とするコンバインとしたものである。

【0007】

請求項2記載の発明は、前記第2移送筒(10)に結合ピン(10a)を固着し、支持受具(35a)には挿入孔(35c)を設け、第2移送筒(10)を折り畳むときに、該第2移送筒(10)が案内ガイド(36)で案内されて結合ピン(10a)が挿入孔(35c)へ挿入される構成としたことを特徴とする請求項1記載のコンバインとしたものである。

【0008】

【0009】

【0010】

【0011】

【0012】

【発明の効果】

請求項1記載の発明によると、第1移送筒(8)に折り畳み自在に設けた第2移送筒(10)に、該第2移送筒(10)を折り畳んで第1移送筒(8)の横側に収納する際に回動操作する回動ハンドル(11)を、第2移送筒(10)の外周部下側の所定位置に固着した前側の前受板(37)の前挿入孔(37a)と後側の後受板(38)の後挿入孔(38a)に挿入して引き出し状態及び収納状態に前後移動自在に支持したことにより、作業者が操縦席(18b)上から操作可能な操作力の軽い折り畳み用の回動ハンドル(11)を構成することができた。しかも、この回動ハンドル(11)を収納状態に操作すると、回動ハンドル(11)の握り部(39)が第2移送筒(10)の端部に設けた回動メタル(30)から突出しないので、コンバインの機体を覆う機体カバーの着脱時に、この回動ハンドル(11)が障害物になりにくく、この機体カバーの破損を少なくすることができる。

【0013】

また、第1移送筒(8)の外周の横一側部に固着した支持受具(35a)に、下方へ折曲した折曲部(36a)を先端部に有し第2移送筒(10)を折り畳んで第1移送筒(8)の横側に収納するときに該第2移送筒(10)の外周下部を受ける略L字形状の案内ガイド(36)を設けたことにより、第2移送筒(10)の折り畳み操作が容易となる。

【0014】

請求項2記載の発明によると、上記請求項1記載の発明の効果に加えて、第2移送筒(10)が案内ガイド(36)と結合ピン(10a)との両者で支持されるため、該第2移送筒(10)の支持が確実となる。

【0015】

【発明の実施の形態】

以下、本発明の一実施例を図面に基づいて説明する。

コンバイン1の走行装置3の上側に設けた走行車台(車台)2の上側に載置した脱穀機12の右横側に装着した穀粒貯留タンク5内に貯留した穀粒を機外へ排出する穀粒排出装置である縦移送螺旋6aを内装した縦移送筒6の上端部側には、後移送螺旋(第1移送螺旋)7を内装した後移送筒(第1移送筒)8と、この後移送筒8の前端部に前移送螺旋(第2移送螺旋)9を内装した折り畳み自在な前移送筒(第2移送筒)10とを設け、この前移送筒10の下側には、回動ハンドル11を設け、これら前・後移送筒10、8、及び回動ハンドル11等を主に図示して説明する。

【0016】

前記コンバイン1の走行車台2の下側には、図14で示す如く土壌面を走行する左右一対の走行クローラ4を張設した走行装置3を配設し、走行車台2の上側には、脱穀機12を載置した構成である。走行車台2の前側の刈取機13で立毛穀稈を刈取りし、この刈取り穀稈はこの刈取機13で移送され、脱穀機12のフィードチエン12aと挟持杆12bとで引継ぎ挟持移送して脱穀し、脱穀済みで選別済みの穀粒を回収して一時貯留する穀粒貯留タンク5は、脱穀機12の右横側に装着した構成である。穀粒貯留タンク5へ穀粒の供給は、脱穀機12の右横側に設けた揚穀装置27により、供給する構成である。

【0017】

前記脱穀機12の前部で走行車台2の前側には、図14で示す如く前端位置から立毛穀稈を分離するナローガイド15a、及び分草体15bと、この分離された穀稈を引起す引起装置16aと、引起された穀稈を掻込み移送する掻込移送装置17aと、掻込された穀稈を刈取る刈刃装置16bと、刈取り穀稈を移送して、脱穀機12のフィードチエン12aと挟持杆12bとへ受渡しする穀稈移送装置17bとを設けてなる刈取機13は、油圧駆動による伸縮シリンダ13aにより、土壌面に対して昇降自在に作用させる構成である。

【0018】

前記脱穀機12側には、図14で示す如くコンバイン1を始動、停止、及び各部を調節等の操作を行う操作装置18aと、これらの操作を行う作業者が搭乗する操縦席18bとを設け、この操縦席18bの下側で、走行車台2の上側には、エンジン18cを載置すると共に、後方部には、穀粒貯留タンク5を配設する。これら走行装置3と、脱穀機12と、刈取機13と、エンジン18c等により、コンバイン1の機体1aを構成している。

【0019】

前記刈取機13の穀稈移送装置17bによって形成される穀稈移送経路中には、刈取られて移送される穀稈に接触作用することにより、脱穀機12へ穀稈の供給の有無を検出する穀稈センサ13bを設けた構成である。走行車台2の前端部に装架された走行用のミッションケース19aの伝動経路中には、その出力回転数に基づく走行車速を検出する車速センサ19bを設けた構成である。

【0020】

前記穀粒貯留タンク5内の底部には、貯留穀粒を後方部へ移送する前後移送螺旋(底部移送螺旋)14aを前後方向に設けると共に、後方へ移送される穀粒を引継ぎして、継手ケース14bを介して方向変換する縦移送螺旋6aを内装した縦移送筒6を略垂直姿勢で回動可能に、継手ケース14bの上側で穀粒貯留タンク5の後側に設けた構成である。

【0021】

前記縦移送筒6の上端部には、上端部を支点として、その全長がコンバイン1の前後長に亘り折畳み自在、上下回動自在、旋回自在で穀粒を機外へ排出する折畳穀粒移送装置20を設けた構成である。

前記操作装置18aの表面板18dの外側面には、図13で示す如く折畳穀粒移送装置20を主として操作する各種スイッチ、及び各種操作レバー等を図示して説明する。折畳穀粒移送装置20を上下回動、及び左右旋回操作するオーガレバー21aと、エンジン18cの動力をこの折畳穀粒移送装置20へ伝達する籾排出レバー21bとを設け、この籾排出レバー21bを排出位置へ操作すると、穀粒貯留タンク5内の穀粒を機外へ排出できる構成である。

【0022】

又、前記折畳穀粒移送装置20等を始動、及び停止させるときに操作するON−OFFスイッチ方式のスイッチ22aと、旋回させるときに操作するON−OFFスイッチ方式の旋回スイッチ22bと、ON−OFFスイッチ方式のランプスイッチ22cとを設けた構成である。

【0023】

前記縦移送筒6の上端部に設けた継手メタル23の前側には、図2〜図4、及び図6で示す如く後移送螺旋7を内装した後移送筒8を設けた構成である。

前記継手メタル23は、図6で示す如く縦メタル24aと横メタル24bとよりなる構成であり、これら縦・横メタル24a、24b内には、図6で示す如く引継螺旋25と、この引継螺旋25の移送終端に固着した移送羽根25aとを設けると共に、後移送螺旋7の後螺旋軸7aの移送始端部と、後受ブッシュ7fとの間に亘る外径部には、始端螺旋26を固着して設けた構成である。

【0024】

前記縦移送筒6へ供給されて、縦移送螺旋6aで移送される穀粒は、継手メタル23内の引継螺旋25から、始端螺旋26、及び後移送筒8内の後移送螺旋7へと順次引継ぎされて、移送される構成である。

前記筒形状の後移送筒8は、図5、及び図6で示す如くL字形状の継手メタル23の前側に固着して設け、この後移送筒8の前端部には、ベアリング28aを内装した回動受メタル28を固着して設け、この回動受メタル28の一方側の横側部には、受孔28bを設けた構成である。該ベアリング28aの内径部には、先端部にクラッチ爪29aを設け、後側の外径部が六角形状の後螺旋補助軸29を挿入して軸支した構成である。

【0025】

前記後移送筒8内には、図5、及び図6で示す如く後移送螺旋7を内装した構成である。この後移送螺旋7はパイプ形状の後螺旋軸7aの外径部に後螺旋プレート7bを固着すると共に、前端の内径部には、内径が六角形状の受ブッシュ7cを挿入して固着し、後端の内径部には、内径が六角形状の後受ブッシュ7fを挿入して固着した構成である。

【0026】

前記後移送螺旋7の受ブッシュ7cは、回動受メタル28に設けた後螺旋補助軸29へ挿入して軸支すると共に、後受ブッシュ7fは、継手メタル23の横メタル24bの後受軸7dへ挿入して軸支し、この後移送螺旋7を回転自在に軸支した構成である。

【0027】

前記筒形状の前移送筒10は、図1〜図5、及び図7、図8で示す如く後端部に回動メタル30を固着して設けると共に、前端部に排出筒31を装着して設けた構成である。回動メタル30の一方側の横側部には、受孔(第2孔)30aを設け、この受孔30aと回動受メタル28の受孔(第1孔)28bとには、支持軸33を挿入して、この前移送筒10と、後移送筒8とを接続させた構成である。この前移送筒10の固定は後移送筒8の外周部に固着したコ字形状の支持枠32に固定用ハンドル32aを挿入して装着し、この固定用ハンドル32aを回動操作し、前移送筒10の回動メタル30の突出部30bへ結合させて、これら回動メタル30と回動受メタル28とを締付けする構成である。

【0028】

前記回動メタル30には、ベアリング30cを内装して設け、このベアリング30cには、先端部にクラッチ爪34aを設けた前螺旋補助軸34を挿入して軸支した構成である。

前記前移送筒8内には、図5で示す如く前移送螺旋9を内装した構成である。この前移送螺旋9はパイプ形状の前螺旋軸9aの外径部に前螺旋プレート9bを固着すると共に、後端の内径部には、内径が六角形状の受ブッシュ9cを挿入して固着し、又、前端の内径部には、前受軸9dを挿入して固着した構成である。回動受メタル28の後螺旋補助軸29のクラッチ爪29aと、前螺旋補助軸34のクラッチ爪34aとが噛合し、この前移送螺旋9と、後移送螺旋7とが同時に回転駆動する構成である。

【0029】

前記前移送螺旋9の受ブッシュ9cは、回動メタル30に設けた前螺旋補助軸34へ挿入すると共に、前受軸9dは排出筒31の前側壁板31aの内側面に設けた受メタル31cへ挿入し、この前移送螺旋9を回転自在に軸支した構成である。該前移送螺旋9で移送された穀粒は、排出筒31の下部の排穀口31bより、機外へ排出される構成である。

【0030】

前記回動受メタル28と回動メタル30との締付けは、固定用ハンドル32a以外に、図7で示す如く締付用孔28c、30dを設けて、ボルト、及びナット等により装着した構成である。

前記後移送筒8の外径の一方側の横側には、図7、及び図8で示す如く支持装置35を設け、この支持装置35のコ字形状の支持受具35aを固着して設け、この支持受具35aには、ゴム材、又は樹脂材等よりなるクッション部材35bを設けると共に、挿入孔35cを設けた構成である。保持受具35aの先端の下側には、前移送筒10を回動操作して折畳みしたときに、この前移送筒10の外径下部を受ける略L字形状で先端部が下方へ折曲した折曲部36aを設けた案内ガイド36を固着して設けた構成である。

【0031】

前記案内ガイド36は前移送筒10を保持したときは、該前移送筒10の中心位置(イ)から折曲部36aまでの間(L)は、前移送筒10へ固着した結合ピン10aの全長(L1)より、大きくした構成である。この前移送筒10を折畳み操作のときに、この案内ガイド36でこの前移送筒10が案内されて、結合ピン10aが保持受具35の挿入孔35cへ容易に挿入可能な構成であると共に、この前移送筒10を確実に保持する構成であり、又、この結合ピン10aには、抜け止め用のヘヤーピン10bを挿入した構成である。この案内ガイド36には、クッション部材35bを複数個設けた構成である。

【0032】

前記案内ガイド36を設けたことにより、前移送筒10の折畳み操作が容易であり、又、この案内ガイド36と結合ピン10aとの両者で支持されることにより、支持が確実である。更に支持受具35aと案内ガイド36とには、クッション部材35aを設けたことにより、前移送筒10へ傷が付くことを防止できる構成である。

【0033】

前記前移送筒10の外径部には、図1〜図4で示す如くこの前移送筒10を折り畳んで、後移送筒8の横側へ収納状態にするときに、回動操作する回動ハンドル11を設け、低価格で操作力の軽い折り畳み機構にした構成である。

前記回動ハンドル11は丸棒材よりなる構成であり、図1〜図4で示す如く前移送筒10の外周部の下側で、所定位置の前後両側には、前・後受板37、38を固着して設けた構成であり、該前・後受板37、38の前・後挿入孔37a,38aへ挿入して前後移動自在で引き出し状態、及び収納状態に支持した構成である。この回動ハンドル11の前後両端部には、ゴム材、又は樹脂材等よりなる把り39を挿入した構成である。前移送筒10を収納状態に操作したときには、回動ハンドル11も収納状態に操作する構成であり、このときには、この回動ハンドル11の把り39部(握り部39)が前移送筒10の回動メタル30の前側面より突出しない構成である。

【0034】

前記前移送筒10の下側に設けた回動ハンドル11の引出し、及び収納操作は、作業者が操縦席18b上より、操作可能な構成である。

前記回動ハンドル11の外周部には、ゴム材、又は樹脂材等よりなる弾性材の固定装置40を挿入して設けた構成である。該固定装置40には、挿入孔40aを設け、この挿入孔40aは前受板37に固着して設けた固定ピン41の頭部41aの前側へ挿入して、回動ハンドル11の前後操作時以外のときの前後移動を防止する構成である。回動ハンドル11を操作するときには、固定装置40の挿入孔40aを固定ピン41から取り出しする構成である。又、固定装置40の着脱操作は、作業者が操縦席18b上より、操作が可能な構成である。

【0035】

前記回動ハンドル11は前移送筒10の下側に前後移動自在に設けて、作業者が操縦席18bに座ったままで操作できると共に、コンバイン1を圃場へ一時放置するときに、機体1aを覆う機体カバー(図示せず)の着脱時に障害物になることなく、又、この機体カバーの破損を防止する構成である。

【0036】

前記回動ハンドル11に固定装置40を設けて、この回動ハンドル11が自然に前後移動することを防止した構成である。

収納状態の前記前移送筒10を穀粒を排出状態に回動操作するときは、結合ピン10aへ挿入したヘヤーピン10bを抜き、回動受メタル28と回動メタル30とを接合させた固定用ハンドル32aを回動して、結合を解放させると共に、固定装置40を取り外しする。

【0037】

その後に、図4で示す如く前移送筒10を作業者が操縦席18b上より、左外方向へ手で押して、後移送筒8に対して略直角状になるまで回動操作した後に、回動ハンドル11を引き出し、この回動ハンドル11で回動操作して、前移送筒10を後移送筒8へ接合状態に操作する構成であり、その後に固定用ハンドル32aにより、これら前・後移送筒10、8を接合する。その後にヘヤーピン10bを挿入すると共に、回動ハンドル11を収納状態に操作して、固定装置40で固定する構成である。

【0038】

前記穀粒貯留タンク5の後側には、図9〜図12で示す如くこの穀粒貯留タンク5に内装した前後移送螺旋14aの移送終端部を受けて、穀粒の移送方向を上方部へと変更する継手ケース14aを設け、この継手ケース14aの右横側には、複数個の取付ネジ孔42aと、後側には、位置固定ボス42bを設けると共に、継手ケース14aの上側面には、縦移送筒6を回動自在に装着した構成である。この回転により、前・後移送筒10、8が左右に旋回する構成である。

【0039】

前記継手ケース14aには、図12で示す如く取付台43の横側の取付孔43a部は、継手ケース14aの取付ネジ孔42a部へボルト等で装着した構成であり、又、取付台43の後側のボス孔43bは、継手ケース14aの後側の位置固定ボス42b部へ挿入すると共に、後側の取付孔43c部は、走行車台2の上側面へボルト、及びナット等で装着した構成である。

【0040】

モータ受台44は、図12で示す如く下側部に下取付孔44aを設け、この下取付孔44a部は、継手ケース14bの右側で、走行車台2の上側面へボルト、及びナット等で装着した構成である。上側部の左右両側には、モータ取付台45を装着する上取付孔44bを設けた構成である。

【0041】

正逆回転する旋回用モータ46は、図12で示す如くモータ取付台45の上側面へボルト、及びナット等で装着した構成であり、旋回用モータ46の変速用のモータ軸46aの下部の軸端部には、ギヤー46bを軸支した構成である。

前記モータ取付台45の前後両側の取付孔45a,45aと、モータ受台44の上取付孔44b,44bとは、ボルト、及びナット等で装着した構成である。

【0042】

前記縦移送筒6に設けたギヤー6bと、旋回用モータ46のギヤー46bとは、図10で示す如く噛合する構成であり、旋回用モータ46の回転駆動により、縦移送筒6は左、又は右へ回転する構成である。

前記旋回用モータ46の取付部以外の前・後移送筒10、8をユニットとして、他機種に使用することができることにより、コスト低減が可能であり、又、旋回用モータ46は継手ケース14bの右横側に設けたことにより、従来の後側に設けたものに対して、コンバイン1の前後長を大幅に短くすることができて、大幅なコスト低減ができると共に、右側より、旋回用モータ46部のチエックを容易に行うことができる。

【図面の簡単な説明】

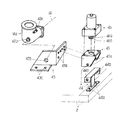

【図1】 回動ハンドル部の拡大側面図

【図2】 前移送筒部の作用拡大平面図

【図3】 前移送筒部の収納状態時の拡大平面図

【図4】 前移送筒部の作用拡大平面図

【図5】 前・後移送筒の接合部の拡大平断面図

【図6】 後移送筒と縦移送筒との接合部の拡大平断面図

【図7】 案内ガイド部の拡大正面図

【図8】 案内ガイド部の拡大平面図

【図9】 旋回用モータ部の拡大平面図

【図10】 旋回用モータ取付部の拡大正面図

【図11】 旋回用モータ取付部の拡大平面図

【図12】 旋回用モータ取付部の拡大背面斜視図

【図13】 操作装置部の拡大背面斜視図

【図14】 コンバインの全体側側面図

【符号の説明】

2 走行車台(車台)

3 走行装置

5 穀粒タンク

6 縦移送筒

7 後移送螺旋(第1移送螺旋)

8 後移送筒(第1移送筒)

9 前移送螺旋(第2移送螺旋)

10 前移送筒(第2移送筒)

10a 結合ピン

11 回動ハンドル

12 脱穀機

13 刈取機

14a 前後移送螺旋(底部移送螺旋)

18b 操縦席

23 継手メタル

28 回動受メタル

28b 受孔(第1孔)

30 回動メタル

30a 受孔(第2孔)

31b 排穀

33 支持軸

35a 支持受具

35c 挿入孔

36 案内ガイド

36a 折曲部

37 前受板

37a 前挿入孔

38 後受板

38a 後挿入孔

39 把り部(握り部)[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a combine equipped with a grain discharging device.

[0002]

[Prior art]

When harvesting napped cereals with a combine, the harvested cereals harvested by a reaper provided at the front of the combine are transported by the reaper, supplied to a threshing machine provided at the rear, and threshed by the thresher. Then, the threshed grain is lifted by the whipping device, supplied into the grain storage tank, and temporarily stored in the grain storage tank.

[0003]

When discharging the stored grain out of the machine, the grain in the grain storage tank is supplied from the grain storage tank into the vertical transfer cylinder, and then transferred from the vertical transfer spiral built in the vertical transfer cylinder. After being transported and supplied into the cylinder, and then transported and supplied into the front transport cylinder by the rear transport spiral installed in the transport cylinder, transferred and transferred by the front transport spiral installed in the front transport cylinder, the front end of the front transport cylinder It is discharged out of the machine through the shed at the bottom of the discharge tube provided in the section.

[0004]

Also, when storing the combine in the storage room, when traveling on the road, and when traveling between fields, the operator is once from the cockpit, and the front transfer cylinder is rotated to be folded and rear transferred. The front transfer cylinder is positioned on the side of the cylinder to be in the storage state, and stored in the barn and travels at times other than during the harvesting operation.

[0005]

[Problems to be solved by the invention]

When turning the front transfer cylinder provided at the front end of the rear transfer cylinder to the folded state or working state, the operator who has boarded the cockpit is once out of this cockpit and performs the rotation operation. Otherwise, it cannot be in the folded state or the working state, and for this reason, these operations have been troublesome. However, the present invention intends to solve this problem.

[0006]

[Means for Solving the Problems]

For this purpose, the invention described in

[0007]

According to the second aspect of the present invention, the coupling pin (10a) is fixed to the second transfer cylinder (10), the support holder (35a) is provided with an insertion hole (35c), and the second transfer cylinder (10) is provided. The second transfer cylinder (10) is guided by a guide guide (36) and the coupling pin (10a) is inserted into the insertion hole (35c) when folded. It is a combine.

[0008]

[0009]

[0010]

[0011]

[0012]

【The invention's effect】

According to the first aspect of the invention, the second transfer cylinder which is provided foldably to the first transfer cylinder (8) (10), first transfer cylinder folded second transfer cylinder (10) (8) A front insertion hole (37a) of a front receiving plate (37) in which a rotation handle ( 11 ) that rotates when stored in the lateral side is fixed to a predetermined position below the outer peripheral portion of the second transfer cylinder (10). ) And the rear receiving plate (38) of the rear side receiving plate (38) and supported so as to be movable back and forth in the pulled out and retracted state, so that the operator can operate from the cockpit ( 18b ). It was possible to construct a folding handle ( 11 ) for folding with a light operating force. Moreover, when the rotating handle (11) is operated to the retracted state, the grip portion (39) of the rotating handle (11) protrudes from the rotating metal (30) provided at the end of the second transfer cylinder (10). Therefore, when the body cover that covers the combine body is attached or detached, the rotating handle ( 11 ) is less likely to become an obstacle, and the damage to the body cover can be reduced.

[0013]

Further, the support holder (35a) fixed to the lateral one side portion of the outer periphery of the first transfer cylinder (8) has a bent portion (36a) bent downward at the distal end portion, and the second transfer cylinder (10). ) Is folded and stored on the side of the first transfer cylinder (8), the second transfer cylinder (10) is provided with a substantially L-shaped guide guide (36) that receives the lower outer periphery of the second transfer cylinder (10). The folding operation of the transfer cylinder (10) is facilitated.

[0014]

According to the invention of

[0015]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

The grain stored in the

[0016]

A

[0017]

As shown in FIG. 14, the

[0018]

On the threshing

[0019]

In the culm transfer path formed by the culm transfer device 17b of the

[0020]

At the bottom of the

[0021]

The upper end of the

On the outer surface of the

[0022]

Further, an ON-OFF switch type switch 22a that is operated when starting and stopping the folding

[0023]

In the front side of the

The

[0024]

The grains supplied to the

The cylindrical

[0025]

The

[0026]

The receiving

[0027]

As shown in FIGS. 1 to 5, 7, and 8, the cylindrical

[0028]

The rotating

The

[0029]

The receiving bush 9c of the

[0030]

The

A

[0031]

When the

[0032]

By providing the

[0033]

As shown in FIG. 1 to FIG. 4, the

The

[0034]

The pull-

An elastic

[0035]

The

[0036]

The rotation handle 11 is provided with a fixing

When the

[0037]

Thereafter, as shown in FIG. 4, the operator manually pushes the

[0038]

On the rear side of the

[0039]

As shown in FIG. 12, the

[0040]

As shown in FIG. 12, the

[0041]

As shown in FIG. 12, the turning

The mounting

[0042]

The gear 6b provided on the

Since the front and

[Brief description of the drawings]

[Fig. 1] Enlarged side view of the rotating handle portion [Fig. 2] Enlarged plan view of the action of the front transfer cylinder portion [Fig. 3] Enlarged plan view of the front transfer cylinder portion in the storage state [Fig. Action enlarged plan view [Fig. 5] Enlarged plan sectional view of the junction between the front and rear transfer cylinders [Fig. 6] Enlarged plan sectional view of the junction between the rear and vertical transfer cylinders [Fig. 7] Enlargement of the guide guide Front view [Fig. 8] Enlarged plan view of the guide guide unit [Fig. 9] Enlarged plan view of the turning motor unit [Fig. 10] Enlarged front view of the turning motor mounting unit [Fig. 11] Enlarged plan view of the turning motor mounting unit FIG. 12 is an enlarged rear perspective view of the turning motor mounting portion. FIG. 13 is an enlarged rear perspective view of the operating device portion. FIG. 14 is an overall side view of the combine.

2 Running chassis (chassis)

3 traveling

8 Rear transfer cylinder (first transfer cylinder)

9 Front transfer spiral (second transfer spiral)

10 Front transfer tube (second transfer tube)

30 Rotating metal 30a Receiving hole (second hole)

31b threshing 33 support shaft

35a support bracket

35c insertion hole

36 guide

36a bent part

37 front backing plate

37a front insertion hole

38 back plate

38a

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000249562A JP4465834B2 (en) | 2000-08-21 | 2000-08-21 | Combine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000249562A JP4465834B2 (en) | 2000-08-21 | 2000-08-21 | Combine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002058330A JP2002058330A (en) | 2002-02-26 |

| JP2002058330A5 JP2002058330A5 (en) | 2007-06-14 |

| JP4465834B2 true JP4465834B2 (en) | 2010-05-26 |

Family

ID=18739286

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000249562A Expired - Fee Related JP4465834B2 (en) | 2000-08-21 | 2000-08-21 | Combine |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4465834B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4901502B2 (en) * | 2007-01-24 | 2012-03-21 | 三菱農機株式会社 | Combine grain discharging device |

-

2000

- 2000-08-21 JP JP2000249562A patent/JP4465834B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002058330A (en) | 2002-02-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4465834B2 (en) | Combine | |

| JP4670155B2 (en) | Combine | |

| JP2006094775A (en) | Grain storage tank device of combine harvester | |

| JPH1189417A (en) | Threshed grain storing part structure in combine harvester | |

| JP4466221B2 (en) | Combine | |

| JP4158305B2 (en) | Combine | |

| JP4622390B2 (en) | Combine | |

| JP3956580B2 (en) | Combine | |

| JP4138450B2 (en) | Combine | |

| JP3486932B2 (en) | Combine | |

| JP4039312B2 (en) | Combine | |

| JP2001224237A (en) | Grain recovering apparatus in combine harvester | |

| JP4466180B2 (en) | Combine | |

| JP3829328B2 (en) | Combine | |

| JP4670945B2 (en) | Combine | |

| JP2008237159A (en) | Combine harvester | |

| JP2006094778A (en) | Grain discharge device of combine harvester | |

| JPH0636666Y2 (en) | Storage structure of culm conveying and discharging device in combine | |

| JP2887912B2 (en) | Combine harvester attachment / detachment device | |

| JP4670982B2 (en) | Combine | |

| JP2004049018A (en) | Narrow guide apparatus of combine harvester | |

| JP4179027B2 (en) | Combine | |

| JP3353587B2 (en) | Combine Glen Tank | |

| JP2007006815A (en) | Combine harvester | |

| JP2005210943A (en) | Stretchable grain-discharging device of combine harvester, or the like |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070426 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070426 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090304 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090519 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090713 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100202 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100215 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130305 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160305 Year of fee payment: 6 |

|

| LAPS | Cancellation because of no payment of annual fees |