JP4427770B2 - Method and apparatus for compressing foundry sand - Google Patents

Method and apparatus for compressing foundry sand Download PDFInfo

- Publication number

- JP4427770B2 JP4427770B2 JP2000120567A JP2000120567A JP4427770B2 JP 4427770 B2 JP4427770 B2 JP 4427770B2 JP 2000120567 A JP2000120567 A JP 2000120567A JP 2000120567 A JP2000120567 A JP 2000120567A JP 4427770 B2 JP4427770 B2 JP 4427770B2

- Authority

- JP

- Japan

- Prior art keywords

- compressing

- auxiliary frame

- foundry sand

- lower auxiliary

- frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Casting Devices For Molds (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、鋳型造型空間の鋳物砂を圧縮するのに好適な方法およびその装置に関する。

【0002】

【従来技術と課題】

従来、模型板と鋳枠とで画成された鋳型造型空間に充填された鋳物砂を圧縮する方法の一つとして、模型板と圧縮手段とを相互に接近させて行なうようにしたものがある。しかし、この方法では模型板を昇降させるための大型の油圧シリンダが必要になり、その結果、鋳型造型機は、高さの高いものになり、設置に当たってはピットを設ける必要があるなどの問題があった。

【0003】

本発明は上記の事情に鑑みてなされたもので、その目的は、ピットを必要とする模型板昇降用の大型の油圧シリンダを設けることなく、模型板と枠部材とで画成された鋳型造型空間の鋳物砂を、ほぼ全体にわたって所要の硬度に圧縮することが可能な方法およびその装置を提供することにある。

【0004】

【課題を解決するのための手段】

上記の目的を達成するために請求項1の発明における鋳物砂の圧縮方法は、水平状にして固定された模型板と、この模型板に上下摺動自在に環装されて昇降可能に配設された下補助枠と、

この下補助枠の上方に昇降可能に配設された枠部材と

によって画成された鋳型造型空間の鋳物砂を圧縮する方法であって、前記鋳型造型空間に鋳物砂を投入する工程と、少なくとも前記下補助枠が下降不可能な状態の下に前記鋳型造型空間の鋳物砂をこれの上方から圧縮手段によって圧縮する第1圧縮工程と、前記下補助枠および前記枠部材が下降可能な状態の下に前記鋳型造型空間の鋳物砂を前記圧縮手段によってさらに圧縮する第2圧縮工程と、を有することを特徴とする。

【0005】

【発明の実施の形態】

なお、本発明において、枠部材とは、造型される鋳型が鋳枠付きの場合には鋳枠であり、また鋳枠無しの場合には型枠を意味する。またなお、造型される鋳型は、鋳枠付きの場合と、鋳物砂が型枠内で固化された後型枠から抜き出された鋳枠無しの場合とを含む。さらになお、第2圧縮工程における圧縮手段による圧縮力は、第1圧縮工程におけるそれとほぼ同じでもよいが、より大きくすることにより、本発明の効果を高めることができる。またなお、本発明において圧縮手段としては、各種の構造のものがあって、鋳物砂を圧縮する部分が一体的なもの、複数に分割されたもの、さらに背面に圧力流体が作用する可撓性膜を備えて柔軟性を高めたものがある。なお、模型板、下補助枠および下補助枠昇降機構を搬入出手段に装着することにより、各種の模型板を使用することができる。

【0006】

【実施例1】

本発明を適用した鋳型造型機の一実施例について図面に基づき詳細に説明する。本鋳型造型機は、水平状にして固定された模型板1と、この模型板1に上下摺動自在に環装されて昇降可能に配設された下補助枠2と、この下補助枠2の上方に昇降可能に配設された枠部材としての鋳枠3と、この鋳枠3の上方に昇降可能に配設された上補助枠4と、前記鋳枠3の上方に昇降可能に配設され下部が少なくとも前記上補助枠4に進入可能な圧縮手段5と、で構成してある。

【0007】

そして、前記模型板1は、後述のターンテーブル19の上面に取り付けてあり、さらに模型板1の上面には模型の形状によってはベントプラグ(図示せず)が埋設してある。後述のターンテーブル19の上面に取り付けて前記下補助枠2は後述のターンテーブル19に装着された下補助枠昇降機構としての複数の油圧シリンダ6・6によって昇降するようになっている。また、前記鋳枠3は、複数のつば付きローラ7・7を前後方向に適宜の間隔をおいてフレーム8・8に軸支して成る搬送機構9によって前後方向へ移動できるようにしてあり、搬送機構9は昇降フレーム10に装着してある。昇降フレーム10は、定盤状の機台11の左右両側に立設された2本の油圧シリンダ12・13のピストンロッドの上端間に架設してあって、油圧シリンダ12・13の伸縮作動により昇降するようになっている。

【0008】

また、前記上補助枠4は前記フレーム8・8に装着された下向きの油圧シリンダ14・14のピストンロッドの下端間に架設してある。また、前記圧縮手段5は、前記フレーム8・8に装着された前後方向へ延びるレール20・20上に、側面に軸支された複数のつば付きローラ21・21を介して前後方向へ走行可能にして架装してあって、昇降可能な複数の直方体状の圧縮部材18・18を有している。また、前記レール20・20上には鋳物砂の計量ホッパ22が前後方向へ走行可能にして架装してある。また、前記2本の油圧シリンダ12・13のうち左側の油圧シリンダ12には、左右方向へ延びる搬入出手段としての回転テーブル19の中央が間欠的に水平回転可能に環装して装着してある。

【0009】

次に、所定の鋳型造型空間に鋳物砂を投入し、圧縮する手順について説明する。まず、油圧シリンダ6・6を伸長作動して下補助枠2を上昇させた状態の下に、油圧シリンダ12・13を所要長さ収縮作動して昇降フレーム10を下降させ下補助枠2上に鋳枠3を載置し、続いて、油圧シリンダ14・14を伸長作動して鋳枠3上に上補助枠4を重ね合わせて鋳型造型空間を画成する。

【0010】

次いで、計量ホッパ22から鋳型造型空間に所要量の鋳物砂を投入し、続いて、計量ホッパ22を搬出するとともに圧縮手段5を上補助枠4の真上に搬入する。次いで、油圧シリンダ6・6の収縮時に油排出側から排油できないようにして下補助枠2を下降不可能にし、かつ油圧シリンダ14・14の収縮時に油排出側から排油できるようにした状態の下に、圧縮手段5の圧縮部材18・18をそれぞれ独立して下降させて鋳物砂を圧縮するとともに、油圧シリンダ12・13を収縮作動して昇降フレーム10を介して圧縮手段5を適宜の長さ下降させる。これにより、鋳型造型空間の鋳物砂は第1圧縮される(図参照)。

【0011】

次いで、油圧シリンダ6・6の収縮時に油排出側から排油できるようにして下補助枠2を下降可能にし、かつ油圧シリンダ14・14を伸長作動した状態の下に、油圧シリンダ12・13をさらに収縮作動して圧縮手段5と、鋳枠3および上補助枠4をさらに下降させる。すると、下補助枠2は、鋳枠3、上補助枠4および油圧シリンダ14・14を介して押し下げられ、これに伴って、鋳物砂が鋳枠3と一体となって下降されて模型板1に押し付けられ、この結果、鋳物砂はさらに圧縮されることになる。この場合、鋳枠4内の鋳物砂の下面(合わせ面)が鋳枠4の下面レベルとほぼ一致するのが望ましい。

【0012】

鋳物砂の圧縮完了後、圧縮部材18・18を上昇させるとともに、油圧シリンダ6・6を伸長作動させながら油圧シリンダ12・13を伸長作動して圧縮手段5、上補助枠4等を上昇させ、造型された鋳型を内蔵した鋳枠3をつば付きローラ7・7に係止させて吊り上げ、模型板1から分離する。その後、ターンテーブル19を180度水平回転させて別の模型板1を圧縮手段5の真下に移動させ、計量ホッパ22に鋳物砂を補充し、さらに搬送機構9上に別の空状の鋳枠3を搬入して一サイクルを終了する。

【0013】

なお、上記の実施例では造型された鋳型は、鋳枠3付きであるが、型枠から押し出された状態の枠無しでもよい。この場合には、第1圧縮工程において、圧縮部材18・18を任意のレベルまで上補助枠4および型枠内に進入させることができ、しかも上補助枠4を省略してもよい。

【0014】

【発明の効果】

上記の説明から明らかなように請求項1の発明は、水平状にして固定された模型板と、この模型板に上下摺動自在に環装されて昇降可能に配設された下補助枠と、

この下補助枠の上方に昇降可能に配設された枠部材と、

によって画成された鋳型造型空間の鋳物砂を圧縮する方法であって、前記鋳型造型空間に鋳物砂を投入する工程と、少なくとも前記下補助枠が下降不可能な状態の下に前記鋳型造型空間の鋳物砂をこれの上方から圧縮手段によって圧縮する第1圧縮工程と、前記下補助枠および前記枠部材が下降可能な状態の下に前記鋳型造型空間の鋳物砂を前記圧縮手段によってさらに圧縮する第2圧縮工程と、を有するから、ピットを必要とする模型板昇降用の大型の油圧シリンダを設けることなく、模型板と鋳枠とで画成された鋳型造型空間の鋳物砂を、ほぼ全体にわたって確実に所要の硬度に圧縮することが可能になるなどの優れた実用的効果を奏する。

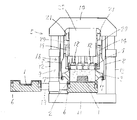

【図面の簡単な説明】

【図1】本発明を適用した鋳型造型機の一実施例を示す概略縦断面図である。

【符号の説明】

1 模型板

2 下補助枠

3 鋳枠

5 圧縮手段

19 ターンテーブル[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a method and apparatus suitable for compressing foundry sand in a mold making space.

[0002]

[Prior art and issues]

Conventionally, as one method for compressing foundry sand filled in a mold forming space defined by a model plate and a casting frame, there is one in which the model plate and the compression means are brought close to each other. . However, this method requires a large hydraulic cylinder for raising and lowering the model plate, and as a result, the mold making machine has a high height, and it is necessary to provide a pit for installation. there were.

[0003]

The present invention has been made in view of the above circumstances, and its purpose is to mold a mold defined by a model plate and a frame member without providing a large hydraulic cylinder for lifting the model plate that requires a pit. It is an object of the present invention to provide a method and an apparatus capable of compressing a foundry sand in a space to a required hardness almost entirely.

[0004]

[Means for solving the problems]

In order to achieve the above object, the method for compressing foundry sand according to the invention of claim 1 includes a model plate fixed in a horizontal shape, and is mounted on the model plate so as to be slidable up and down so as to be movable up and down. Lower auxiliary frame,

A method of compressing foundry sand in a mold making space defined by a frame member disposed so as to be able to move up and down above the lower auxiliary frame, the step of throwing foundry sand into the mold making space, and at least A first compression step of compressing the molding sand of the mold making space from above the lower auxiliary frame under a state in which the lower auxiliary frame cannot be lowered; and a state in which the lower auxiliary frame and the frame member can be lowered. And a second compression step of further compressing the foundry sand in the mold making space by the compression means.

[0005]

DETAILED DESCRIPTION OF THE INVENTION

In the present invention, the frame member means a cast frame when the mold to be molded has a cast frame, and means a mold frame when there is no cast frame. The mold to be molded includes a case with a cast frame and a case without a cast frame extracted from the mold after the foundry sand is solidified in the mold. Furthermore, although the compression force by the compression means in the second compression step may be substantially the same as that in the first compression step, the effect of the present invention can be enhanced by increasing the compression force. Further, in the present invention, the compression means has various structures, the one that compresses the foundry sand is integrated, the one that is divided into a plurality of parts, and the flexibility that the pressure fluid acts on the back surface. Some have increased flexibility with a membrane. Various model plates can be used by mounting the model plate, the lower auxiliary frame, and the lower auxiliary frame lifting mechanism on the carry-in / out means.

[0006]

[Example 1]

An embodiment of a mold making machine to which the present invention is applied will be described in detail with reference to the drawings. The mold making machine includes a model plate 1 that is horizontally fixed, a lower

[0007]

And the said model board 1 is attached to the upper surface of the below-mentioned turntable 19, Furthermore, the vent plug (not shown) is embed | buried under the upper surface of the model board 1 depending on the shape of a model. The lower

[0008]

The upper auxiliary frame 4 is installed between the lower ends of piston rods of downward hydraulic cylinders 14 and 14 mounted on the frames 8 and 8. The compression means 5 can run in the front-rear direction on the

[0009]

Next, a procedure for putting casting sand into a predetermined mold making space and compressing it will be described. First, under the state where the

[0010]

Next, a required amount of foundry sand is put into the mold making space from the weighing hopper 22, and then the weighing hopper 22 is unloaded and the compression means 5 is loaded directly above the upper auxiliary frame 4. Next, the lower

[0011]

Next, when the

[0012]

After the compression of the foundry sand, the compression members 18 and 18 are raised, the hydraulic cylinders 12 and 13 are extended while the

[0013]

In the above-described embodiment, the molded mold is provided with the casting frame 3, but it may be without the frame extruded from the molding frame. In this case, in the first compression step, the compression members 18 and 18 can enter the upper auxiliary frame 4 and the mold to an arbitrary level, and the upper auxiliary frame 4 may be omitted.

[0014]

【The invention's effect】

As is apparent from the above description, the invention of claim 1 includes a model plate that is horizontally fixed, and a lower auxiliary frame that is mounted on the model plate so as to be slidable up and down and arranged to be movable up and down. ,

A frame member arranged to be movable up and down above the lower auxiliary frame;

A method of compressing foundry sand in a mold making space defined by the step of throwing the foundry sand into the mold making space; A first compression step of compressing the foundry sand from above by a compressing means, and further compressing the foundry sand in the mold making space by the compressing means under a state in which the lower auxiliary frame and the frame member can be lowered. A second compression step, so that almost all of the molding sand in the mold molding space defined by the model plate and the cast frame is provided without providing a large hydraulic cylinder for lifting the model plate that requires pits. Excellent practical effects such as being able to be reliably compressed to the required hardness.

[Brief description of the drawings]

FIG. 1 is a schematic longitudinal sectional view showing an embodiment of a mold making machine to which the present invention is applied.

[Explanation of symbols]

DESCRIPTION OF SYMBOLS 1

Claims (5)

この下補助枠の上方に昇降可能に配設された枠部材と、

によって画成された鋳型造型空間の鋳物砂を圧縮する方法であって、

前記鋳型造型空間に鋳物砂を投入する工程と、

少なくとも前記下補助枠が下降不可能な状態の下に前記鋳型造型空間の鋳物砂をこれの上方から圧縮手段によって圧縮する第1圧縮工程と、

前記下補助枠および前記枠部材が下降可能な状態の下に前記鋳型造型空間の鋳物砂を前記圧縮手段によってさらに圧縮する第2圧縮工程と、

を有することを特徴とする鋳物砂の圧縮方法。A model plate that is horizontally fixed, and a lower auxiliary frame that is mounted on the model plate so as to be slidable up and down and arranged to be movable up and down;

A frame member arranged to be movable up and down above the lower auxiliary frame;

A method of compressing foundry sand in a mold making space defined by

Introducing casting sand into the mold making space;

A first compression step of compressing the foundry sand in the mold making space from above by a compression means under a state where at least the lower auxiliary frame cannot be lowered;

A second compression step of further compressing the foundry sand in the mold making space under the state in which the lower auxiliary frame and the frame member can be lowered;

A method for compressing foundry sand, comprising:

前記第2圧縮工程における前記圧縮手段による圧縮力が、前記第1圧縮工程のときよりも大きいことを特徴とする鋳物砂の圧縮方法。In the molding sand compression method according to claim 1,

The method for compressing foundry sand, wherein a compressive force by the compressing means in the second compressing step is larger than that in the first compressing step.

相互に独立して下降可能な複数の圧縮部材または背面に圧力流体が作用する可撓性膜を備えた圧縮手段によって前記鋳型造型空間の鋳物砂を圧縮することを特徴とする鋳物砂の圧縮方法。The method for compressing foundry sand according to claim 1 and 2,

A method for compressing foundry sand, characterized by compressing the foundry sand in the mold molding space by a plurality of compressing members that can descend independently of each other or a compressing means having a flexible film on which a pressure fluid acts on the back surface. .

水平状にして固定された模型板と、

この模型板に上下摺動自在に環装されて昇降可能に配設された下補助枠と、

この下補助枠を昇降させる下補助枠昇降機構と、

前記下補助枠の上方に昇降可能に配設された枠部材と、

この枠部材の上方に昇降可能に配設され下部が少なくとも枠部材に進入可能な圧縮手段と、

を備えたことを特徴とする鋳物砂の圧縮装置。A device that compresses casting sand in a mold making space defined by a model plate, a frame member, and an auxiliary frame over two stages,

A horizontal and fixed model board;

A lower auxiliary frame that is mounted on the model plate so as to be slidable up and down and arranged to be movable up and down;

A lower auxiliary frame elevating mechanism for elevating and lowering the lower auxiliary frame;

A frame member disposed so as to be movable up and down above the lower auxiliary frame;

A compression means disposed so as to be movable up and down above the frame member and having a lower part capable of entering at least the frame member;

A foundry sand compression apparatus characterized by comprising:

前記模型板、前記下補助枠および前記下補助枠昇降機構は、搬入出手段によって前記圧縮手段の真下位置に入出可能であることを特徴とする鋳物砂の圧縮装置。In the molding sand compression apparatus according to claim 4,

The molding sand compression apparatus, wherein the model plate, the lower auxiliary frame, and the lower auxiliary frame elevating mechanism can be moved into and out of the compression unit by a loading / unloading unit.

Priority Applications (13)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000120567A JP4427770B2 (en) | 2000-04-21 | 2000-04-21 | Method and apparatus for compressing foundry sand |

| CNB200510004635XA CN100376344C (en) | 2000-04-21 | 2001-04-17 | Molding machine and a pattern carrier used therefor |

| EP01921854.4A EP1208928B1 (en) | 2000-04-21 | 2001-04-17 | Die molding machine and pattern carrier |

| CNB2005100046364A CN1311934C (en) | 2000-04-21 | 2001-04-17 | Molding machine and a pattern carrier used therefor |

| BR0106085-6A BR0106085A (en) | 2000-04-21 | 2001-04-17 | Molding machine and mold conveyor used for the same |

| CNB018010342A CN1214880C (en) | 2000-04-21 | 2001-04-17 | Mold molding method and device |

| CNB2005100046379A CN1311935C (en) | 2000-04-21 | 2001-04-17 | Molding machine and a pattern carrier used therefor |

| PCT/JP2001/003262 WO2001081025A1 (en) | 2000-04-21 | 2001-04-17 | Die molding machine and pattern carrier |

| MXPA01012791A MXPA01012791A (en) | 2000-04-21 | 2001-04-17 | Die molding machine and pattern carrier. |

| KR1020017016346A KR100838875B1 (en) | 2000-04-21 | 2001-04-17 | Mold Molding Machine and Pattern Carrier |

| US10/018,569 US6823929B2 (en) | 2000-04-21 | 2001-04-17 | Die molding machine and pattern carrier |

| TW090109345A TW555600B (en) | 2000-04-21 | 2001-04-19 | Die molding machine and pattern carrier |

| US10/968,999 US7237593B2 (en) | 2000-04-21 | 2004-10-21 | Molding machine and a pattern carrier used therefor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000120567A JP4427770B2 (en) | 2000-04-21 | 2000-04-21 | Method and apparatus for compressing foundry sand |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2001300692A JP2001300692A (en) | 2001-10-30 |

| JP4427770B2 true JP4427770B2 (en) | 2010-03-10 |

Family

ID=18631354

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000120567A Expired - Fee Related JP4427770B2 (en) | 2000-04-21 | 2000-04-21 | Method and apparatus for compressing foundry sand |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4427770B2 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102078917B (en) * | 2010-12-21 | 2013-05-08 | 四川海科机械制造有限公司 | Semi-modular forming manufacturing method and application template thereof |

| CN102294740B (en) * | 2011-09-02 | 2013-06-19 | 王本淼 | Die for making combined cavity member in machine |

| CN102371611B (en) * | 2011-09-02 | 2013-09-18 | 王本淼 | Method for manufacturing cavity component by using automatic system of mechanical mould |

| CN103831408B (en) * | 2014-03-07 | 2016-03-30 | 南京亚力电气有限公司 | Horizontal parting removable flask molding machine |

| CN103831406B (en) * | 2014-03-07 | 2016-03-30 | 南京亚力电气有限公司 | Structure is simple, pick and place mould labour-saving horizontal parting removable flask molding machine |

| CN103831404B (en) * | 2014-03-07 | 2016-03-30 | 南京亚力电气有限公司 | The horizontal parting removable flask molding machine of stable action |

| CN106863584B (en) * | 2017-03-21 | 2023-08-01 | 贵州大学 | Automatic making dragon fruit tray-supporting mechanism |

| CN110355335B (en) * | 2019-08-19 | 2020-11-20 | 闻喜县博盛金属制品有限公司 | Cast sand die assembly for alloy casting |

-

2000

- 2000-04-21 JP JP2000120567A patent/JP4427770B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2001300692A (en) | 2001-10-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TW555600B (en) | Die molding machine and pattern carrier | |

| CN102834200B (en) | Mold molding device and mold molding method | |

| US6684933B2 (en) | Method and apparatus for compacting molding sand | |

| KR100721633B1 (en) | Molding machine for producing the death penalty and the method of manufacturing the death penalty | |

| TW424015B (en) | Automatic vibration molding machine for green mold | |

| JP4427770B2 (en) | Method and apparatus for compressing foundry sand | |

| GB2043507A (en) | Moulding apparatus | |

| KR100778162B1 (en) | Compression method of foundry sand and its device | |

| JP3407879B2 (en) | Method and apparatus for filling and compressing molding sand | |

| JP3802358B2 (en) | Casting sand compression method and casting sand molding method | |

| JP2002336936A (en) | Sand molding device with frame, pattern carrier, pattern exchange device, pattern carrier setting device, and molding method of sand mold with frame | |

| JP4203839B2 (en) | Mold making method and apparatus | |

| JP3835667B2 (en) | Method and apparatus for forming sand mold with frame | |

| JP3441063B2 (en) | Molding method and apparatus for sand mold with frame | |

| JP4096314B2 (en) | Molding method of sand mold with frame | |

| JP4078640B2 (en) | Method of pouring mold with cast frame | |

| JP3407882B2 (en) | Mold removal method | |

| US3519058A (en) | Molding method | |

| JPS60145245A (en) | Mold forming device | |

| CN216632508U (en) | Horizontal parting molding machine for efficient exhaust watchcase molding line | |

| JPS60158949A (en) | Method and device for forming casting mold | |

| MXPA06012488A (en) | Method of squeezing foundry sand, match plate, and upper and lower flasks. | |

| JP3431571B2 (en) | Molding apparatus and pattern carrier for sand mold with frame | |

| JP2002346697A5 (en) | ||

| JP3441065B2 (en) | Mold molding method and molding apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060901 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090727 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20091120 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20091203 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121225 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4427770 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131225 Year of fee payment: 4 |

|

| LAPS | Cancellation because of no payment of annual fees |