JP3754287B2 - Portable electronic devices - Google Patents

Portable electronic devices Download PDFInfo

- Publication number

- JP3754287B2 JP3754287B2 JP2000312821A JP2000312821A JP3754287B2 JP 3754287 B2 JP3754287 B2 JP 3754287B2 JP 2000312821 A JP2000312821 A JP 2000312821A JP 2000312821 A JP2000312821 A JP 2000312821A JP 3754287 B2 JP3754287 B2 JP 3754287B2

- Authority

- JP

- Japan

- Prior art keywords

- circuit board

- flexible circuit

- housing

- casing

- board

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Casings For Electric Apparatus (AREA)

- Mounting Of Printed Circuit Boards And The Like (AREA)

- Telephone Set Structure (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、開閉又は折畳み式の携帯電話機や携帯型ビデオカメラ、デジタルカメラ等の携帯型電子機器のヒンジユニットにおけるフレキシブル回路基板の固定及び防水構造に関するものである。

【0002】

【従来の技術】

開閉又は折畳み式(以下「開閉式」という)の携帯電話機や、液晶パネルが開閉する携帯型のビデオカメラ、デジタルカメラなどの携帯型電子機器は、開閉部分がヒンジ接続されている。

以下、携帯電話機を例に挙げて説明する。

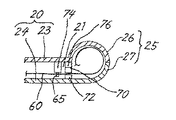

開閉式の携帯電話機(10)は、図1に示すように、操作ボタン(12)、バッテリー(13)、マイク(14)等が配備された第1筐体(20)と、表示部(16)、スピーカ(17)等が配備された第2筐体(40)をヒンジユニット(80)によって接続して構成される。ヒンジユニット(80)は、図8に示すように、第1筐体(20)の基端両側又は片方に形成された円筒型軸受(22)(22)と、第2筐体(40)の基端に同軸に形成された軸受(42)(42)とをヒンジ軸(82)(82)で回動可能に連結しており、軸受(42)(42)間には、第1筐体(20)の内部基板(62)と第2筐体(40)の内部基板(63)とを電気的に接続するフレキシブル回路基板(60)が、ループ状に巻回された状態で円筒状カバー(25)(45)内に収容されている。

【0003】

【発明が解決しようとする課題】

フレキシブル回路基板(60)は、先端の端子(66)(67)を基板(62)(63)に差し込んだり半田付けして、基板(62)(63)どうしを電気的に接続している。

機器の開閉動作を繰り返して行なうと、フレキシブル回路基板(60)が引張りや弛みが生じ、フレキシブル回路基板(60)と基板(62)又は基板(63)との接続が弛んで接触不良を起こしたり、フレキシブル回路基板(60)が基板(62)(63)から抜け落ちて断線することがあった。

【0004】

また、ヒンジユニット(80)は、軸受(22)(42)や円筒状カバー(25)(45)の間に若干の隙間があるため、この隙間から水や湿気が侵入することがある。ヒンジユニット(80)の内部に侵入した水分は、フレキシブル回路基板(60)や筐体(20)(40)の内面を伝って、筐体の内部に入り、基板の腐食やショートなどを起こしてしまうことがあった。

【0005】

本発明の目的は、ヒンジユニットの内部に収容されるフレキシブル回路基板を簡便な方法で固定し、さらに、ヒンジユニットから機器の内部へ水分が侵入しない携帯型電子機器を提供することである。

【0006】

【課題を解決するための手段】

上記課題を解決するために、本発明の携帯型電子機器は、操作ボタン(12)の配された第1筐体(20)と、表示部(16)を具えた第2筐体(40)とがヒンジユニット(80)によって開閉可能に連結され、ヒンジユニット(80)に形成された円筒状カバー(25)(45)の内部を通るフレキシブル回路基板(60)によって、第1筐体(20)の内部基板(62)と第2筐体(40)の内部基板(63)とを電気的に接続した携帯型電子機器において、第1筐体(20)及び/又は第2筐体(40)の内部に、フレキシブル回路基板(60)を挟む挟持部材(70)(72)を配備し、前記第1筐体 (20) 及び/又は前記第2筐体 (40) の内部には、前記挟持部材 (70)(72) に隣接した位置に、前記フレキシブル回路基板 (60) に向けて係止片 (74) が突設され、前記フレキシブル回路基板 (60) には、前記係止片 (74) に嵌まる係止孔 (65) が開設され、前記フレキシブル回路基板 (60) は、前記係止孔 (65) を前記係止片 (74) に嵌めると共に、前記挟持部材 (70)(72) によって挟むことにより、前記第1筺体 (20) 及び/又は前記第2筺体 (40) に固定した。

【0007】

挟持部材(70)(72)は、円筒状カバー(25)(45)の内部と筐体(20)(40)の内部とを連通する基板通路(21)(41)の少なくとも一方を塞ぐように配備され、第1筐体(20)及び/又は第2筐体(40)の内部への水の侵入を防止することが望ましい。

【0009】

【作用及び効果】

フレキシブル回路基板(60)は、挟持部材(70)(72)により上下から挟まれ押さえつけられているから、筐体(20)(40)の開閉に伴って引っ張られたり弛んでも、基板(62)(63)から端子(66)(67)が抜け落ちたることはない。

また、フレキシブル回路基板(60)の係止孔(65)を係止片(74)に嵌めることにより、フレキシブル回路基板(60)の脱落は完全に防止される。

従って、製品の信頼性、耐久性を高めることができる。

【0010】

また、挟持部材(70)(72)は、基板通路(21)(41)と筐体(20)(40)との間を空間的に遮断するから、第1筐体(20)及び第2筐体(40)の内部への水分の侵入が妨げられ、基板(62)(63)やその他の電子部品等の水分による腐食、ショート等を防止でき、製品の信頼性、耐久性を高めることができる。

【0011】

【発明の実施の形態】

以下、本発明を開閉式の携帯電話機(10)に適用した実施例について説明するが、本発明は、携帯電話機に限らず、液晶パネルが開閉するビデオカメラやデジタルカメラ、ノート型パソコン等にも適用できることは勿論である。

また、以下に示す携帯電話機(10)は一例であって、操作ボタン、バッテリー、表示部、アンテナ等の配置、形状及び大きさ等は、下記の実施例に限定されるものではない。

【0012】

開閉式の携帯電話機(10)は、図1に示すように、操作ボタン(12)、バッテリー(13)、マイク(14)等が配された第1筐体(20)と、表示部(16)、スピーカ(17)等が配された第2筐体(40)とを、ヒンジユニット(80)によって相互に回動可能に連結され、折り畳み可能な構成となっている。

第1筐体(20)は、操作ボタン(12)、マイク(14)等が配された第1フロントケース(23)と、その裏面を閉じる第1リアケース(24)から構成され、第1リアケース(24)には、バッテリー(13)等が配備されている。

また、第2筐体(40)は、表示部(16)、スピーカ(17)等が配された第2フロントケース(43)と、その裏面を閉じる第2リアケース(44)から構成される。

【0013】

第1筐体(20)及び第2筐体(40)の内部には、図2に示すように、夫々回路の実装された基板(62)(63)が内蔵され、夫々種々の電子部品が電気的に接続されている。

【0014】

筐体(20)(40)を開閉可能に連結するヒンジユニット(80)は、第1フロントケース(23)の基端両側から斜め上方に向けて突設された第1軸受(22)(22)と、第2フロントケース(43)から突設された第2軸受(42)(42)をヒンジ軸(82)(82)によって回動可能に相互に連結すると共に、第2軸受(42)(42)間に後述するフレキシブル回路基板(60)を収容する第1、第2円筒状カバー(25)(45)を具える。

なお、軸受(22)(42)は、筐体(20)(40)の基端両側でなく、片側だけに設けてもよい。

【0015】

第1円筒状カバー(25)は、第1筐体(20)の基端に形成される。第1円筒状カバー(25)は、第1フロントケース(23)の基端に形成された半円筒体(26)と、第1リアケース(24)の基端から上向きに屈曲し、前記半円筒体(26)と先端が連結する4分の1円弧体(27)から構成され、半円筒体(26)の基端と4分の1円弧体(27)の基端との間には、第1筐体(20)の内部と連通する基板通路(21)が形成されている。第1フロントケース(23)と第1リアケース(24)には、図2乃至図4に示すように、ケース(23)(24)を閉じた状態で、基板通路(21)を通るフレキシブル回路基板(60)を上下に挟み、且つ、第1筐体(20)の内部と第1円筒状カバー(25)の内部との間を空間的に遮断する挟持部材(70)(72)が夫々取り付けられている。挟持部材(70)(72)は、基板通路(21)から第1筐体(20)の内部に水分が侵入するのを防止すると共に、基板通路(21)を通るフレキシブル回路基板(60)のズレや振動、さらには開閉時の引張りや弛みを抑え、基板(62)との接触不良、断線などを防止する。

【0016】

挟持部材(70)(72)は、ウレタン、スポンジ体、ゴム、プラスチックなどの弾性を有する材料から構成することが望ましい。これは、フレキシブル回路基板(60)の断線を防止すると共に、フレキシブル回路基板(60)を挟んだときに、フレキシブル回路基板(60)の形状に倣って、防水効果を高めるためである。

また、挟持部材(70)(72)の幅は、防水効果を高めるために、基板通路(21)の幅以上とすることが望ましい。

さらに、フレキシブル回路基板(60)を円筒状カバー(25)の内径に沿って大きく一周させるように、挟持部材(70)(72)の位置は、図4に示すように、円筒状カバー(25)への侵入側の挟持部材(72)側を低くして、円筒状カバー(25)の内部でのフレキシブル回路基板(60)の折れ曲がり等を防止することが望ましい。

挟持部材(70)(72)は、基板通路(21)又はその近傍に接着等することにより取り付けることができる。

【0017】

さらに、図4に示すように、第1フロントケース(23)には、基板通路(21)の近傍に第1リアケース(24)に向けて係止片(74)が突設されている。係止片(74)は、後述するようにフレキシブル回路基板(60)に開設された係止孔(65)に嵌まって、フレキシブル回路基板(60)の抜止めとなる。なお、係止片(74)の先端を塞いで、フレキシブル回路基板(60)の抜け落ちを防止する受片(図示せず)を第1リアケース(24)に設けてもよい。

上記係止片(74)は、第1リアケース(24)に形成してもよいし、第2筐体(40)側に形成してもよい。また、筐体(20)(40)の両方に設けてもよい。

【0018】

第2円筒状カバー(45)は、第2筐体(40)の基端に形成される。第2円筒状カバー(45)は、第2フロントケース(43)の基端に形成された半円筒体(46)と、第2リアケース(44)の基端から上向きに屈曲し、前記半円筒体(46)と先端が連結する4分の1円弧体(47)から構成され、半円筒体(46)の基端と4分の1円弧体(47)の基端との間には、第2筐体(40)の内部と連通する基板通路(41)が形成されている。図示の実施例では、前述の第2軸受(42)の内側に半円筒体(46)を一体に形成している。

第2フロントケース(43)と第2リアケース(44)には、図2、図3及び図5に示すように、ケース(43)(44)を閉じた状態で、基板通路(41)を通るフレキシブル回路基板(60)を上下に挟み、且つ、第2筐体(40)の内部と第2円筒状カバー(45)の内部との間を空間的に遮断する挟持部材(70)(72)が夫々取り付けられている。挟持部材(70)(72)は、基板通路(41)から第2筐体(40)の内部に水分が侵入するのを防止すると共に、基板通路(41)を通るフレキシブル回路基板(60)のズレや振動、さらには開閉時の引張りや弛みを抑え、基板(63)との接触不良、断線などを防止する。

挟持部材(70)(72)の材質、取付方法等は上述の第1筐体(20)と同様である。

【0019】

フレキシブル回路基板(60)は、図6に示すように、両端に基板(62)(63)へ接続する端子(66)(67)が形成された可撓性の配線基板である。フレキシブル回路基板(60)の第1筐体(20)側には、前述の第1フロントケース(23)に嵌まる係止孔(65)が、係止片(74)と対応した位置に開設されている。

【0020】

なお、図6のフレキシブル回路基板(60)は、基板通路(21)(41)間の幅に合わせて、略中央部を緩く屈曲させている。従って、円筒状カバー(25)(45)内で、フレキシブル回路基板(60)が重なって干渉したり、筐体(20)(40)の開閉に伴い応力が生じて折れ曲がったりすることはない。

【0021】

上記携帯電話機(10)の組立は、例えば、以下の方法により行なうことができる。

《準備工程》

・第1フロントケース(23)と第2フロントケース(43)の軸受(22)(42)をヒンジ軸(82)によって接続するとともに、必要な電子部品、基板(62)(63)を夫々搭載し、電気的に接続しておく。また、フロントケース(23)(43)には、予め基板通路(21)(41)の位置に挟持部材(70)(72)を夫々貼り付けておく。

・第1リアケース(24)及び第2リアケース(44)に、必要な電子部品、基板(62)(63)を搭載し、電気的に接続しておく。リアケース(24)(44)にも、予め基板通路(21)(41)の位置に挟持部材(70)(72)を夫々貼り付けておく。

・フレキシブル回路基板(60)は、略中央位置にて一周のループを形成するように巻回しておく。

【0022】

《フレキシブル回路基板の取付工程》

フロントケース(23)(43)を所定角度開いて、両基板通路(21)(41)が一列に並ぶように調節する。

この状態で、フレキシブル回路基板(60)のループ部分を円筒状カバー(25)(45)に収容する。

次に、図2に示すように、フレキシブル回路基板(60)の一端が、第1フロントケース(23)の基板通路(21)を通り、挟持部材(70)上に載置され、且つ、係止孔(65)が第1フロントケース(23)の係止片(74)に嵌まるように配置して、端子(66)を基板(62)に差し込む。

同様に、フレキシブル回路基板(60)の他端が、第2フロントケース(43)の基板通路(41)を通り、挟持部材(70)上に載置されるように配置して、端子(67)を基板に差し込む。

これにより、フレキシブル回路基板(60)は、基板(62)(63)を電気的に接続すると共に、円筒状カバー(25)(45)の内部で一周するループを形成する。

フレキシブル回路基板(60)は、円筒状カバー(25)(45)内でループを形成しているから、筐体(20)(40)を開閉したときには、フレキシブル回路基板(60)のループ径が大小変化し、フレキシブル回路基板(60)が引っ張られたり弛むのを抑えることができる。

【0023】

《リアケースの取付工程》

第1リアケース(24)を第1フロントケース(23)に嵌め、また、第2リアケース(44)を第2フロントケース(43)に嵌める。このとき、図4及び図5に示すように、両リアケース(24)(44)の挟持部材(72)(72)と、対向する挟持部材(70)(70)によって、フレキシブル回路基板(60)が挟み込まれるようにする。

その後、ネジ止め等により、フロントケース(23)(43)とリアケース(24)(44)を一体に固定して、携帯電話機(10)が組み立てられる。

なお、組立順序等は、上記に限定されるものではない。

【0024】

上記実施例の説明は、本発明を説明するためのものであって、特許請求の範囲に記載の発明を限定し、或は範囲を減縮する様に解すべきではない。又、本発明の各部構成は上記実施例に限らず、特許請求の範囲に記載の技術的範囲内で種々の変形が可能である。

【0025】

例えば、上記実施例では、両方の筐体(20)(40)に挟持部材(70)(72)を配備したが、一方のみに配備してもよい。

また、フレキシブル回路基板(60)の端子は、両方とも基板に差し込むのではなく、予め一方の端子が基板に半田付け等により接続固定されたものや、内部基板(62)又は(63)がフレキシブル回路基板(60)と一体に形成されたものを用いることもできる。

【0026】

さらに、フレキシブル回路基板(60)の折れ曲がり等を防止するために、一方の挟持部材(70)側を高くして、他方の挟持部材(72)側を低くする場合、図7に示すように、フロントケース(23)に高さの差分に相当するリブ(76)を突設しておき、該リブ(76)上に挟持部材(70)を取り付けることもできる。このように、リブ(76)を突設して、挟持部材(70)と挟持部材(72)の部品の共通化を図ることができる。

【図面の簡単な説明】

【図1】携帯電話機の斜視図である。

【図2】携帯電話機のフロントケースとリアケースの分割面に沿って開いたフロントケース側のヒンジユニットの拡大図である。

【図3】携帯電話機のフロントケースとリアケースの分割面に沿って開いたリアケース側のヒンジユニットの拡大図である。

【図4】第1筐体の円筒状カバーの断面図である。

【図5】第2筐体の円筒カバーの断面図である。

【図6】フレキシブル回路基板の平面図である。

【図7】挟持部材の異なる実施例を示す円筒カバーの断面図である。

【図8】従来の携帯電話機を、フロントケースとリアケースの分割面に沿って開いたフロントケース側のヒンジユニットの拡大図である。

【符号の説明】

(10) 携帯電話機

(20) 第1筐体

(40) 第2筐体

(60) フレキシブル回路基板

(65) 係止孔

(70) 挟持部材

(72) 挟持部材

(74) 係止片[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a fixing and waterproofing structure of a flexible circuit board in a hinge unit of a portable electronic device such as an open / close or foldable cellular phone, a portable video camera, or a digital camera.

[0002]

[Prior art]

In portable electronic devices such as an openable / foldable (hereinafter referred to as “openable / closable”) mobile phone, a portable video camera in which a liquid crystal panel is opened and closed, and a digital camera, the opening / closing portion is hinged.

Hereinafter, a mobile phone will be described as an example.

As shown in FIG. 1, the openable mobile phone (10) includes a first housing (20) provided with operation buttons (12), a battery (13), a microphone (14), and the like, and a display unit (16 ), A second housing (40) provided with a speaker (17) and the like is connected by a hinge unit (80). As shown in FIG. 8, the hinge unit (80) includes cylindrical bearings (22) and (22) formed on both sides or one side of the base end of the first casing (20), and a second casing (40). Bearings (42) and (42) formed coaxially at the base end are rotatably connected by hinge shafts (82) and (82), and the first housing is provided between the bearings (42) and (42). The flexible circuit board (60) for electrically connecting the inner board (62) of the (20) and the inner board (63) of the second housing (40) is wound in a loop shape with a cylindrical cover. (25) Contained in (45).

[0003]

[Problems to be solved by the invention]

In the flexible circuit board (60), the terminals (66) and (67) at the tip are inserted into the boards (62) and (63) or soldered to electrically connect the boards (62) and (63).

Repeated opening and closing operation of the device causes the flexible circuit board (60) to be pulled or loosened, and the connection between the flexible circuit board (60) and the board (62) or board (63) is loosened, resulting in poor contact. The flexible circuit board (60) may come off from the boards (62) and (63) and break.

[0004]

Further, since the hinge unit (80) has a slight gap between the bearings (22) and (42) and the cylindrical covers (25) and (45), water and moisture may enter through this gap. Moisture that has entered the hinge unit (80) travels along the inner surfaces of the flexible circuit board (60) and the case (20) (40) and enters the inside of the case, causing substrate corrosion and short circuits. There was a case.

[0005]

An object of the present invention is to provide a portable electronic device in which a flexible circuit board accommodated in a hinge unit is fixed by a simple method and moisture does not enter the device from the hinge unit.

[0006]

[Means for Solving the Problems]

In order to solve the above-described problems, a portable electronic device according to the present invention includes a first housing (20) provided with operation buttons (12) and a second housing (40) including a display unit (16). Are connected to each other by a hinge unit (80) so as to be openable and closable, and a flexible circuit board (60) passing through the inside of a cylindrical cover (25) (45) formed in the hinge unit (80), In the portable electronic device in which the internal board (62) of the second casing (40) and the inner board (63) of the second casing (40) are electrically connected, the first casing (20) and / or the second casing (40) ) Are disposed inside the first casing (20) and / or the second casing (40) , the clamping member (70) (72) sandwiching the flexible circuit board (60). A locking piece (74) protrudes toward the flexible circuit board (60) at a position adjacent to the holding members (70) and (72) , and the flexible circuit board (60) includes the locking piece ( full locking hole fitting 74) (65) is opened, the frame Reluctant circuit substrate (60), together with fitting the locking hole (65) in the locking piece (74), by interposing by the clamping member (70) (72), said first housing (20) and / Or it fixed to the said 2nd housing (40) .

[0007]

The clamping members (70) and (72) block at least one of the substrate passages (21) and (41) that communicate the inside of the cylindrical covers (25) and (45) and the inside of the housings (20) and (40). It is desirable to prevent water from entering the inside of the first housing (20) and / or the second housing (40).

[0009]

[Action and effect]

Since the flexible circuit board (60) is sandwiched and pressed from above and below by the clamping members (70) and (72), even if the flexible circuit board (60) is pulled or loosened as the housing (20) or (40) is opened or closed, the board (62) Terminals (66) and (67) are not dropped from (63).

Further, the flexible circuit board (60) is completely prevented from falling off by fitting the locking hole (65) of the flexible circuit board (60) into the locking piece (74).

Therefore, the reliability and durability of the product can be improved.

[0010]

Further, since the clamping members (70), (72) spatially block the space between the substrate passages (21), (41) and the casings (20), (40), the first casing (20) and the second casing (20). Improves product reliability and durability by preventing moisture from entering the housing (40), preventing corrosion (short circuit) due to moisture on the board (62) (63) and other electronic components. Can do.

[0011]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, an embodiment in which the present invention is applied to an openable / closable mobile phone (10) will be described. Of course, it can be applied.

Further, the cellular phone (10) shown below is an example, and the arrangement, shape, size, and the like of operation buttons, a battery, a display unit, an antenna, and the like are not limited to the following examples.

[0012]

As shown in FIG. 1, the openable mobile phone (10) includes a first casing (20) in which operation buttons (12), a battery (13), a microphone (14) and the like are arranged, and a display unit (16 ), The second housing (40) on which the speaker (17) and the like are arranged, are connected to each other by a hinge unit (80) so as to be rotatable, and can be folded.

The first housing (20) includes a first front case (23) in which an operation button (12), a microphone (14), and the like are arranged, and a first rear case (24) that closes the back surface thereof. A battery (13) and the like are arranged in the rear case (24).

The second housing (40) includes a second front case (43) in which a display unit (16), a speaker (17), and the like are arranged, and a second rear case (44) that closes the back surface thereof. .

[0013]

As shown in FIG. 2, boards (62) and (63) on which circuits are mounted are built in the first casing (20) and the second casing (40), respectively, and various electronic components are provided. Electrically connected.

[0014]

The hinge unit (80) for connecting the casings (20) and (40) so as to be openable and closable is a first bearing (22) (22) projecting obliquely upward from both base ends of the first front case (23). ) And a second bearing (42) (42) projecting from the second front case (43) are connected to each other by hinge shafts (82) and (82) so as to be rotatable, and the second bearing (42) First and second cylindrical covers (25) and (45) for accommodating a flexible circuit board (60) to be described later are provided between (42).

The bearings (22) and (42) may be provided only on one side, not on both sides of the base end of the casing (20) or (40).

[0015]

The first cylindrical cover (25) is formed at the proximal end of the first housing (20). The first cylindrical cover (25) is bent upward from the base end of the first rear case (24) and the semi-cylindrical body (26) formed at the base end of the first front case (23). It consists of a cylindrical body (26) and a quarter-arc body (27) with the tip connected, and between the base end of the semi-cylindrical body (26) and the base end of the quarter-arc body (27) A substrate passage (21) communicating with the inside of the first housing (20) is formed. As shown in FIGS. 2 to 4, the first front case (23) and the first rear case (24) have a flexible circuit passing through the board passage (21) with the case (23) (24) closed. Holding members (70) and (72) sandwiching the substrate (60) up and down and spatially blocking between the inside of the first casing (20) and the inside of the first cylindrical cover (25), respectively. It is attached. The sandwiching members (70), (72) prevent moisture from entering the first housing (20) from the substrate passage (21) and the flexible circuit board (60) passing through the substrate passage (21). Suppresses displacement and vibration, as well as pulling and loosening during opening and closing, and prevents poor contact with the substrate (62) and disconnection.

[0016]

The sandwiching members (70) and (72) are preferably made of an elastic material such as urethane, sponge, rubber, or plastic. This is to prevent disconnection of the flexible circuit board (60) and enhance the waterproof effect following the shape of the flexible circuit board (60) when the flexible circuit board (60) is sandwiched.

Further, the width of the sandwiching members (70), (72) is preferably equal to or greater than the width of the substrate passage (21) in order to enhance the waterproof effect.

Further, as shown in FIG. 4, the positions of the holding members (70) and (72) are such that the flexible circuit board (60) makes one round along the inner diameter of the cylindrical cover (25). It is desirable that the pinching member (72) side on the intrusion side is lowered to prevent the flexible circuit board (60) from being bent inside the cylindrical cover (25).

The clamping members (70) and (72) can be attached by bonding or the like to the substrate passage (21) or the vicinity thereof.

[0017]

Further, as shown in FIG. 4, the first front case (23) is provided with a locking piece (74) projecting toward the first rear case (24) in the vicinity of the substrate passage (21). The locking piece (74) fits into a locking hole (65) formed in the flexible circuit board (60) as will be described later, and prevents the flexible circuit board (60) from being removed. A receiving piece (not shown) that closes the tip of the locking piece (74) and prevents the flexible circuit board (60) from falling off may be provided on the first rear case (24).

The locking piece (74) may be formed on the first rear case (24) or on the second housing (40) side. Moreover, you may provide in both the housing | casing (20) (40).

[0018]

The second cylindrical cover (45) is formed at the proximal end of the second casing (40). The second cylindrical cover (45) is bent upward from the base end of the second rear case (44) and the semi-cylindrical body (46) formed at the base end of the second front case (43). It consists of a cylinder (46) and a quarter arc (47) with the tip connected, and between the base end of the semi-cylinder (46) and the base of the quarter arc (47) A substrate passage (41) communicating with the inside of the second housing (40) is formed. In the illustrated embodiment, a semi-cylindrical body (46) is integrally formed inside the second bearing (42).

As shown in FIGS. 2, 3 and 5, the second front case (43) and the second rear case (44) have the substrate passage (41) with the case (43) (44) closed. A clamping member (70) (72) that sandwiches the flexible circuit board (60) passing therethrough and spatially blocks between the inside of the second casing (40) and the inside of the second cylindrical cover (45). ) Are attached respectively. The clamping members (70) and (72) prevent moisture from entering the inside of the second housing (40) from the board passage (41) and also prevent the flexible circuit board (60) from passing through the board passage (41). Suppresses misalignment and vibration, as well as pulling and loosening during opening and closing, and prevents poor contact with the substrate (63) and disconnection.

The material, attachment method, and the like of the holding members (70) and (72) are the same as those of the first casing (20).

[0019]

As shown in FIG. 6, the flexible circuit board (60) is a flexible wiring board in which terminals (66) and (67) connected to the boards (62) and (63) are formed at both ends. On the first housing (20) side of the flexible circuit board (60), a locking hole (65) that fits into the first front case (23) is opened at a position corresponding to the locking piece (74). Has been.

[0020]

Note that the flexible circuit board (60) of FIG. 6 has its central portion loosely bent according to the width between the board passages (21) and (41). Accordingly, the flexible circuit boards (60) do not overlap and interfere with each other in the cylindrical covers (25) and (45), and are not bent due to stress caused by opening and closing of the casings (20) and (40).

[0021]

The mobile phone (10) can be assembled, for example, by the following method.

<< Preparation process >>

・ The bearings (22) and (42) of the first front case (23) and the second front case (43) are connected by the hinge shaft (82), and necessary electronic components and boards (62) and (63) are mounted respectively. And electrically connected. Further, the holding members (70) and (72) are pasted to the front cases (23) and (43) in advance at the positions of the substrate passages (21) and (41), respectively.

-Necessary electronic components and boards (62) and (63) are mounted on the first rear case (24) and the second rear case (44), and are electrically connected. The clamping members (70) and (72) are also pasted to the rear cases (24) and (44) in advance at the positions of the substrate passages (21) and (41), respectively.

-The flexible circuit board (60) is wound so as to form a loop around the substantially central position.

[0022]

《Flexible circuit board mounting process》

The front cases (23) and (43) are opened by a predetermined angle and adjusted so that both the board passages (21) and (41) are aligned.

In this state, the loop portion of the flexible circuit board (60) is accommodated in the cylindrical covers (25) and (45).

Next, as shown in FIG. 2, one end of the flexible circuit board (60) passes through the board passage (21) of the first front case (23) and is placed on the clamping member (70). The stop hole (65) is disposed so as to fit into the locking piece (74) of the first front case (23), and the terminal (66) is inserted into the board (62).

Similarly, the other end of the flexible circuit board (60) passes through the board passage (41) of the second front case (43) and is placed on the clamping member (70), and the terminal (67 ) Into the board.

As a result, the flexible circuit board (60) electrically connects the boards (62) and (63), and forms a loop that goes around inside the cylindrical covers (25) and (45).

Since the flexible circuit board (60) forms a loop in the cylindrical covers (25) and (45), when the casing (20) (40) is opened and closed, the loop diameter of the flexible circuit board (60) is reduced. It is possible to prevent the flexible circuit board (60) from being pulled or loosened by changing in size.

[0023]

《Rear case mounting process》

The first rear case (24) is fitted into the first front case (23), and the second rear case (44) is fitted into the second front case (43). At this time, as shown in FIGS. 4 and 5, the flexible circuit board (60) is formed by the clamping members (72) and (72) of the rear cases (24) and (44) and the opposing clamping members (70) and (70). ).

Thereafter, the front case (23) (43) and the rear case (24) (44) are fixed together by screwing or the like, and the mobile phone (10) is assembled.

The assembly order and the like are not limited to the above.

[0024]

The above description of the embodiments is for explaining the present invention, and should not be construed as limiting the invention described in the claims or reducing the scope thereof. Moreover, each part structure of this invention is not restricted to the said Example, A various deformation | transformation is possible within the technical scope as described in a claim.

[0025]

For example, in the above embodiment, the clamping members (70), (72) are provided in both the casings (20), (40), but they may be provided in only one of them.

Also, the terminals of the flexible circuit board (60) are not inserted into the board, but one terminal is connected and fixed to the board in advance by soldering or the internal board (62) or (63) is flexible. What was formed integrally with the circuit board (60) can also be used.

[0026]

Further, in order to prevent the flexible circuit board (60) from being bent or the like, when the one holding member (70) side is raised and the other holding member (72) side is lowered, as shown in FIG. It is also possible to project a rib (76) corresponding to the height difference on the front case (23) and attach the clamping member (70) on the rib (76). In this manner, the rib (76) can be protruded so that the parts of the clamping member (70) and the clamping member (72) can be shared.

[Brief description of the drawings]

FIG. 1 is a perspective view of a mobile phone.

FIG. 2 is an enlarged view of a front case side hinge unit opened along a split surface of a front case and a rear case of a mobile phone;

FIG. 3 is an enlarged view of a hinge unit on the rear case side opened along a split surface of the front case and the rear case of the mobile phone.

FIG. 4 is a cross-sectional view of a cylindrical cover of a first housing.

FIG. 5 is a cross-sectional view of a cylindrical cover of a second housing.

FIG. 6 is a plan view of a flexible circuit board.

FIG. 7 is a cross-sectional view of a cylindrical cover showing different embodiments of the holding member.

FIG. 8 is an enlarged view of a hinge unit on the front case side in which a conventional mobile phone is opened along a dividing surface of a front case and a rear case.

[Explanation of symbols]

(10) Mobile phone

(20) First housing

(40) Second housing

(60) Flexible circuit board

(65) Locking hole

(70) Holding member

(72) Holding member

(74) Locking piece

Claims (2)

前記第1筐体(20)及び/又は前記第2筐体(40)の内部には、前記フレキシブル回路基板(60)を挟む挟持部材(70)(72)が配備され、

前記第1筐体 (20) 及び/又は前記第2筐体 (40) の内部には、前記挟持部材 (70)(72) に隣接した位置に、前記フレキシブル回路基板 (60) に向けて係止片 (74) が突設され、前記フレキシブル回路基板 (60) には、前記係止片 (74) に嵌まる係止孔 (65) が開設され、

前記フレキシブル回路基板 (60) は、前記係止孔 (65) を前記係止片 (74) に嵌めると共に、前記挟持部材 (70)(72) によって挟むことにより、前記第1筺体 (20) 及び/又は前記第2筺体 (40) に固定されることを特徴とする携帯型電子機器。A first housing (20) having an operation button (12) and a second housing (40) having a display unit (16) are connected to each other by a hinge unit (80) so as to be opened and closed. 80) A portable circuit in which the internal circuit board (62) of the first housing (20) and the internal circuit board (63) of the second housing (40) are electrically connected to each other by a flexible circuit board (60) passing through the interior of the material (80). In electronic equipment,

Inside the first casing (20) and / or the second casing (40), clamping members (70), (72) that sandwich the flexible circuit board (60) are arranged ,

In the first casing (20) and / or the second casing (40) , a position adjacent to the clamping members (70) (72 ) is directed toward the flexible circuit board (60). A stop piece (74) is projected, and the flexible circuit board (60) is provided with a lock hole (65) that fits into the lock piece (74) .

The flexible circuit board (60) is configured to fit the locking hole (65) into the locking piece (74) and to be sandwiched between the clamping members (70) and (72) , whereby the first casing (20) and / or fixed to the second housing (40) a portable electronic apparatus characterized Rukoto.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000312821A JP3754287B2 (en) | 2000-10-13 | 2000-10-13 | Portable electronic devices |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000312821A JP3754287B2 (en) | 2000-10-13 | 2000-10-13 | Portable electronic devices |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002124779A JP2002124779A (en) | 2002-04-26 |

| JP2002124779A5 JP2002124779A5 (en) | 2005-10-20 |

| JP3754287B2 true JP3754287B2 (en) | 2006-03-08 |

Family

ID=18792335

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000312821A Expired - Fee Related JP3754287B2 (en) | 2000-10-13 | 2000-10-13 | Portable electronic devices |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3754287B2 (en) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3943413B2 (en) | 2002-02-25 | 2007-07-11 | 松下電器産業株式会社 | Foldable electronic device |

| US7251512B2 (en) | 2002-05-13 | 2007-07-31 | Nec Corporation | Water-proof collapsible cellular terminal apparatus |

| KR100466594B1 (en) * | 2002-06-29 | 2005-01-24 | 주식회사 팬택앤큐리텔 | A guide apparatus of flexible printed circuit board and a celluar phone having the same |

| JP3710780B2 (en) | 2002-11-29 | 2005-10-26 | 京セラ株式会社 | Connector connection structure and portable terminal device using the same |

| CN1270502C (en) | 2002-12-25 | 2006-08-16 | 京瓷株式会社 | Portable machine |

| JP4435490B2 (en) * | 2003-02-19 | 2010-03-17 | 株式会社東芝 | Portable wireless communication device and connection member |

| KR100516280B1 (en) * | 2003-04-24 | 2005-09-21 | 주식회사 팬택앤큐리텔 | Mobile phone having hinge apparatus |

| JP2005348341A (en) * | 2004-06-07 | 2005-12-15 | Casio Comput Co Ltd | Portable electronic equipment |

| KR100667523B1 (en) | 2005-01-27 | 2007-01-10 | 엘지전자 주식회사 | Mobile communication terminal having a fpcb with an improved connection structure |

| CN101124806B (en) | 2005-02-18 | 2011-08-03 | 富士通株式会社 | Sliding portable phone set |

| JP4527008B2 (en) * | 2005-06-07 | 2010-08-18 | カルソニックカンセイ株式会社 | Console box structure |

| JP4560793B2 (en) * | 2005-09-16 | 2010-10-13 | 日本電気株式会社 | Portable information terminal |

| JP2008182522A (en) * | 2007-01-25 | 2008-08-07 | Matsushita Electric Ind Co Ltd | Folding electronic equipment |

| JP5250331B2 (en) * | 2008-08-05 | 2013-07-31 | 株式会社電幸社 | Detectors such as wiring boxes |

| JP2011171636A (en) * | 2010-02-22 | 2011-09-01 | Sumitomo Bakelite Co Ltd | Flexible circuit board with waterproof member |

| JP2018019001A (en) * | 2016-07-29 | 2018-02-01 | 株式会社カネカ | Film-like heat conduction member and electronic apparatus enclosure |

| CN115460842A (en) * | 2021-06-08 | 2022-12-09 | 华为技术有限公司 | Foldable electronic equipment |

-

2000

- 2000-10-13 JP JP2000312821A patent/JP3754287B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002124779A (en) | 2002-04-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3754287B2 (en) | Portable electronic devices | |

| US7632025B2 (en) | Mobile communication terminal having rotatable camera | |

| US6256481B1 (en) | Microphone connecting device for flip type portable telephone | |

| JP3718137B2 (en) | Slide type mobile phone with slide module | |

| KR100713536B1 (en) | FlEXIBLE PRINTED CIRCUIT BOARD FOR ELECTRONIC EQUIPMENT | |

| US7386282B2 (en) | Portable communication apparatus | |

| JPH08321370A (en) | Method and equipment for guiding conductor | |

| JPH08186628A (en) | Electronic device with hinge structure | |

| KR100556849B1 (en) | Camera module connecting apparatus of mobile phone | |

| JP3448547B2 (en) | Foldable mobile phone | |

| EP1083623A1 (en) | Antenna device installed in flip cover of flip-up type portable phone | |

| US8422214B2 (en) | Mobile electronic apparatus | |

| JP3397930B2 (en) | Mobile phone equipment | |

| JP3943413B2 (en) | Foldable electronic device | |

| JP2005079452A (en) | Holding structure of external connection terminal | |

| JPH11273780A (en) | Mounting structure of connector protection cover | |

| JP3733016B2 (en) | Portable electronic devices | |

| KR200403684Y1 (en) | Rotary Hinge Module for Cellular Phone | |

| JPH06326425A (en) | Protective structure of flexible printed board | |

| KR200369496Y1 (en) | Fixing device of flexible printed circuit board for mobile phone | |

| KR100630090B1 (en) | Display unit position to convert device of mobile phone | |

| KR200214951Y1 (en) | Detachable hinge arm for portable radiotelephone | |

| JP4284230B2 (en) | Electronics | |

| JP4643732B2 (en) | Mobile terminal device | |

| KR20010103976A (en) | Hinge device for portable radiotelephone |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20050516 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050615 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20050816 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051013 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20051206 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20051215 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20081222 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20081222 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20081222 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20091222 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101222 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101222 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111222 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111222 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121222 Year of fee payment: 7 |

|

| LAPS | Cancellation because of no payment of annual fees |