JP3208073U - Multi-layer glass mounting frame - Google Patents

Multi-layer glass mounting frame Download PDFInfo

- Publication number

- JP3208073U JP3208073U JP2016005038U JP2016005038U JP3208073U JP 3208073 U JP3208073 U JP 3208073U JP 2016005038 U JP2016005038 U JP 2016005038U JP 2016005038 U JP2016005038 U JP 2016005038U JP 3208073 U JP3208073 U JP 3208073U

- Authority

- JP

- Japan

- Prior art keywords

- frame

- attachment

- male

- female

- cover

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Securing Of Glass Panes Or The Like (AREA)

- Door And Window Frames Mounted To Openings (AREA)

Abstract

【課題】アタッチメント付き複層ガラスを用い、既設の単板ガラスサッシ窓のいかなる部材も除去することなく、容易に複層ガラス化できる複層ガラス据え付け用フレームを提供する。【解決手段】アタッチメント付き複層ガラス据え付け用フレームとして、上枠、下枠、及び左右の縦枠より構成され、かつ上枠、下枠、及び縦枠は、各々ベース(メス)部材31とカバー(オス)部材32の対よりなる構成とし、ベース(メス)部材はその中央長手方向に沿って断面略コ状の嵌合溝を備える構造とし、カバー(オス)部材はその長手方向に沿うアタッチメント押え部321、及び一対の爪付きリブを有する嵌合部322になる構成とし、カバー(オス)部材のベース(メス)部材への押し込み操作により、上記カバー(オス)部材と上記ベース(メス)部材とがスナップフィットする仕組みのフレームとした。【選択図】図7To provide a double-glazed glass mounting frame that uses a double-glazed glass with an attachment and can be easily made into multi-layer glass without removing any members of an existing single-plate glass sash window. A multi-layer glass mounting frame with an attachment is composed of an upper frame, a lower frame, and left and right vertical frames, and each of the upper frame, the lower frame, and the vertical frame includes a base (female) member 31 and a cover. (Male) member 32 is configured, and the base (female) member has a structure having a substantially U-shaped fitting groove along the central longitudinal direction, and the cover (male) member is an attachment along the longitudinal direction. It is set as the structure which becomes the fitting part 322 which has a holding part 321 and a pair of rib with a nail | claw, and the said cover (male) member and the said base (female) by pushing operation to the base (female) member of a cover (male) member The frame has a mechanism that snap fits with the member. [Selection] Figure 7

Description

本考案は複層ガラス据え付け用フレームに関する。さらに詳しくは、既設の単板ガラスサッシ窓への複層ガラスの据え付けに適した、複層ガラス据え付け用フレームに関する。 The present invention relates to a double-glazed frame. More specifically, the present invention relates to a double-glazed glass frame suitable for mounting double-glazed glass on an existing single glass sash window.

近年、省エネルギーや生活空間の改善のため、新築建物に、断熱性、防音性、防露性に優れる複層ガラスを使用するケースが定着している。

また、建物の既設の単板ガラスサッシ窓を複層ガラスの窓にリフォームする需要も年々高まっている。しかし、複層ガラスは単板ガラスの数倍の厚さを有しているため、単板ガラス仕様のサッシそのままでは複層ガラス仕様に転用することはできず、結果改装には、多額の工事費(材料費、人件費)を要していた。そこで、最近では、既設の単板ガラス仕様サッシにも据え付けできるよう、特定形状のアタッチメントを付設した複層ガラスも提案されている(例えば特許文献1)。これらのアタッチメントは、広幅の複層ガラスを既設の単板ガラス仕様サッシに据え付けできるよう、断面略U字状の保持枠部と、その保持枠部端部に連なりかつその保持枠部より幅の狭い脚部より構成されている。In recent years, cases of using double-glazed glass with excellent heat insulation, soundproofing, and dewproofing properties have been established in new buildings in order to save energy and improve living spaces.

In addition, the demand for renovating existing single-panel glass sash windows in buildings to double-glazed windows is increasing year by year. However, double-glazed glass is several times thicker than single-glazed glass, so it cannot be diverted to single-glazed glass sashes as they are. Material costs, labor costs). Therefore, recently, a multi-layer glass provided with an attachment of a specific shape so as to be installed on an existing single plate glass sash has also been proposed (for example, Patent Document 1). These attachments are connected to the holding frame portion having a substantially U-shaped cross section and the end portion of the holding frame portion so as to be able to install a wide-width multilayer glass on an existing single plate glass specification sash, and are narrower than the holding frame portion. It consists of legs.

しかし、アタッチメント付き複層ガラスを単板ガラス仕様サッシに据え付けするにしても、

イ)二枚ガラスの重量を支えながらサッシへ据え付けるには複数の作業者を要し、特に建物外側の高所作業の場合には足場の設置も必要となるため、依然として人件費又は工賃がかかり、

ロ)既存の単板ガラスは廃材として処理せねばならない、という問題があった。However, even if the double-glazed glass with attachments is installed on a single glass sash,

B) Multiple workers are required to install on the sash while supporting the weight of the double-glazed glass. In particular, in the case of working at high places outside the building, it is also necessary to install scaffolding, which still requires labor costs or labor costs. ,

B) There was a problem that existing single plate glass had to be treated as waste material.

そこで、アタッチメント付き複層ガラスを用い、既設の単板ガラスサッシ窓のいかなる部材も除去することなく、容易に複層ガラス化する方策について鋭意検討した結果、本考案者は、特定構造の複層ガラス据え付け用フレームが上記課題を同時に解決することを見出し、本考案に到達した。 Therefore, as a result of diligent research on a method for easily converting to a multi-layer glass without removing any members of the existing single-panel glass sash window using the multi-layer glass with an attachment, the present inventor The inventors found that an installation frame can solve the above-mentioned problems at the same time, and reached the present invention.

すなわち、本考案は、アタッチメント付き複層ガラス据え付け用フレームであって、当該複層ガラス据え付け用フレームは、

上枠、下枠、及び左右の縦枠より構成され、

上記上枠、下枠、及び縦枠は、各々ベース(メス)部材とカバー(オス)部材の対より構成されており、

上記ベース(メス)部材は、その中央長手方向に沿って断面略コ状の嵌合溝を備え、

上記カバー(オス)部材は、その長手方向に沿う、

アタッチメント押え部と、一対の爪付きリブを有する嵌合部にて構成されており、

上記カバー(オス)部材の上記ベース(メス)部材への押し込み操作により、上記カバー(オス)部材と上記ベース(メス)部材とがスナップフィットする、

ことを特徴とするアタッチメント付き複層ガラス据え付け用フレームである(以下、本考案のアタッチメント付き複層ガラス据え付け用フレームを単に「本考案フレーム」と略称することがある。)。That is, the present invention is a multi-layer glass installation frame with an attachment, the multi-layer glass installation frame,

It consists of an upper frame, a lower frame, and left and right vertical frames,

The upper frame, the lower frame, and the vertical frame are each composed of a pair of a base (female) member and a cover (male) member,

The base (female) member includes a fitting groove having a substantially U-shaped cross section along the central longitudinal direction thereof.

The cover (male) member is along its longitudinal direction,

It consists of an attachment presser and a fitting part with a pair of ribs with claws,

By pressing the cover (male) member into the base (female) member, the cover (male) member and the base (female) member snap fit.

A double-glazed glass mounting frame with an attachment characterized by the above (hereinafter, the double-glazed glass mounting frame with an attachment of the present invention may be simply referred to as “the inventive frame”).

本考案フレームは、アタッチメント付き複層ガラスであって、当該アタッチメントが、断面略U字状の保持枠部とその保持枠部端部に連なりかつその端部より幅の狭い脚部より構成されている、アタッチメント付き複層ガラスの据え付けに適している。

本考案フレームは、既設の単板ガラスサッシ窓の内側へのアタッチメント付き複層ガラスの据え付けを可能にするもので、既設の単板ガラスの撤去は不要となる。

本考案フレームは、任意寸法のサッシ窓に使用できるので汎用性に富む。

後に詳述するように、本考案フレームを採用することにより、あらかじめ既設のサッシの所定の位置に上記の上枠、下枠、及び左右の縦枠の、各々のベース(メス)部材をビス止め等により固定しておき、その後、既設アルミサッシ天面上にアタッチメントの保持枠部端部を載置するか、又はアルミサッシに固定済みのベース(メス)部材天面上にアタッチメントの脚部端部を載置して複層ガラスの位置決めをし、その後、各々のベース(メス)部材の対をなすカバー(オス)部材を押し付けスナップフィットすれば、一気に据え付けが完了するので、据え付け時間が著しく短縮される。加えて、カバー(オス)部材がベース(メス)部材の固定に用いたビスを覆うので、美観を損なうこともない。

据え付け後は、上記上枠、下枠、縦枠は、各々複層ガラス窓の上框、下框、縦框を形成する。The frame of the present invention is a multi-layer glass with an attachment, and the attachment is composed of a holding frame portion having a substantially U-shaped cross section and a leg portion that is continuous with the end portion of the holding frame portion and narrower than the end portion. Suitable for installation of double-glazed glass with attachments.

The frame of the present invention makes it possible to install a double-glazed glass with an attachment to the inside of an existing single glass sash window, and it is not necessary to remove the existing single glass.

The frame of the present invention is versatile because it can be used for a sash window of any size.

As will be described in detail later, by adopting the frame of the present invention, the base (female) members of the upper frame, the lower frame, and the left and right vertical frames are screwed to predetermined positions of an existing sash in advance. Then, place the attachment frame end of the attachment on the top of the existing aluminum sash, or attach the leg end of the attachment to the top of the base (female) member that has already been fixed to the aluminum sash. Place the part and position the multi-layer glass, then press the cover (male) member that forms a pair of each base (female) member and snap fit, so installation is completed at once, so installation time is remarkably Shortened. In addition, since the cover (male) member covers the screw used for fixing the base (female) member, the aesthetic appearance is not impaired.

After installation, the upper frame, the lower frame, and the vertical frame form the upper, lower, and vertical walls of the multi-layer glass window, respectively.

本考案の複層ガラス据え付け用フレームは、任意寸法の既存アルミサッシに適用できるので汎用性が高い。また複層ガラスの据付に際し、重量のある複層ガラスを支えたままビス止め固定する工程がないので、据付作業が格段に楽になる。更に、据付に際し、既存の単板ガラスの撤去が不要のため、廃棄物が発生しない。 The multi-layer glass mounting frame of the present invention is highly versatile because it can be applied to existing aluminum sashes of arbitrary dimensions. In addition, when installing the double-glazed glass, there is no process of fixing and fixing the heavy double-glazed glass while supporting it, so that the installation work becomes much easier. Furthermore, no waste is generated because it is not necessary to remove the existing single plate glass during installation.

以下、本考案フレーム(複層ガラス据え付け用フレーム(1))について、図を用いて説明し、その効用を明らかにする。

本考案フレーム(1)がその使用の前提とする単板ガラス仕様サッシ(5)は、ガラス板(51)、アルミサッシ(52)、及びグレージングチャンネル(53)を基本構成とするものである(図7)。本考案フレームはアルミサッシ窓への適用を主目的とするが、外枠が木製のフィックス窓にも適用可能である。Hereinafter, the frame of the present invention (multi-layer glass mounting frame (1)) will be described with reference to the drawings, and its utility will be clarified.

A single glass sash (5) that the frame (1) of the present invention is premised on is based on a glass plate (51), an aluminum sash (52), and a glazing channel (53) (see FIG. 7). The frame of the present invention is mainly applied to an aluminum sash window, but can also be applied to a fixed window with a wooden outer frame.

本考案フレーム(1)の使用に適するアタッチメント付き複合ガラス(6)は、二枚のガラス板(6a)を、その周縁にスペーサー(6b)を介在させて重ね複層ガラスとし、その外縁にアタッチメント(7)を付設したものである(図7)。なお、密封性を高めるため、ガラス板(6a),スペーサー(6b)とアタッチメント(7)の間に封止材(6c)を介在させるのが通例である。

アタッチメント(7)は、断面略U字形状の保持枠部(71)と当該保持枠部(71)に連なる脚部(72)より構成される。保持枠部(71)はガラス板(6a)を保持する。他方脚部(72)は本来複合ガラスを既設の単板ガラス仕様アルミサッシ(52)へ据え付けるのを目的に形成されているもので、その幅は保持枠部(71)の幅より狭く設計されている。The composite glass (6) with an attachment suitable for the use of the frame (1) of the present invention has two glass plates (6a) laminated with a spacer (6b) at the periphery thereof, and is attached to the outer edge thereof. (7) is attached (FIG. 7). In addition, in order to improve sealing performance, it is usual to interpose a sealing material (6c) between a glass plate (6a), a spacer (6b), and an attachment (7).

The attachment (7) includes a holding frame portion (71) having a substantially U-shaped cross section and a leg portion (72) connected to the holding frame portion (71). The holding frame portion (71) holds the glass plate (6a). The other leg portion (72) is originally formed for the purpose of installing the composite glass on the existing single plate glass specification aluminum sash (52), and its width is designed to be narrower than the width of the holding frame portion (71). Yes.

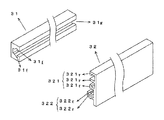

本考案フレーム(1)は、上枠(2)、下枠(3)、及び左右の縦枠(3,4)を基本構成とし、上記上枠(2)、下枠(3)、及び縦枠(3,4)は、各々ベース(メス)部材(21,31,41)とカバー(オス)部材(22,32,42)の対より構成されていることが最大の特色である。図1は本考案フレームの下枠(3)を例に、ベース(メス)部材(31)とカバー(オス)部材(32)の構造を示すものである。 The frame (1) of the present invention basically comprises an upper frame (2), a lower frame (3), and left and right vertical frames (3, 4). The upper frame (2), the lower frame (3), and the vertical frame The greatest feature of the frames (3, 4) is that they are each composed of a pair of base (female) members (21, 31, 41) and cover (male) members (22, 32, 42). FIG. 1 shows the structure of a base (female) member (31) and a cover (male) member (32) taking the lower frame (3) of the present invention frame as an example.

図1に示すように、上記ベース(メス)部材(31)はその長手方向に沿って断面略コ状の嵌合溝(31g)が形成されているとともに、カバー(オス)部材(32)の爪を係り止めする一対の爪係り止め部(31f)が備わっている。 As shown in FIG. 1, the base (female) member (31) is formed with a fitting groove (31g) having a substantially U-shaped cross section along its longitudinal direction, and the cover (male) member (32). A pair of claw locking portions (31f) for locking the claw is provided.

他方上記カバー(オス)部材(32)は、その長手方向に沿って、アタッチメント押え部(321)と、上記ベース(メス)部材(31)の嵌合溝(31g)にスナップフィットする一対の爪付きリブ(322r)と、を備えている。必要に応じ、ベース(メス)部材(31)には、ビス(8)の貫通孔(図示していない)を設けてある。 On the other hand, the cover (male) member (32) has a pair of claws that snap fit into the attachment pressing portion (321) and the fitting groove (31g) of the base (female) member (31) along the longitudinal direction thereof. And a rib (322r). The base (female) member (31) is provided with a through hole (not shown) for the screw (8) as required.

上記カバー(オス)部材(32)を、上記ベース(メス)部材(31)への押し込むことにより、カバー(オス)部材(32)と上記ベース(メス)部材(31)とがスナップフィットする構造となっている(図2)。スナップフィットされた両部材は複合ガラスのアタッチメント(7)を挟んで複合ガラス(6)を固定する。

なお、アタッチメント押え部(321)の短手方向の高さは、対応するアタッチメント脚部(72)の高さと略同等である。A structure in which the cover (male) member (32) and the base (female) member (31) snap fit by pushing the cover (male) member (32) into the base (female) member (31). (Fig. 2). The snap-fitted members fix the composite glass (6) with the composite glass attachment (7) interposed therebetween.

Note that the height of the attachment pressing portion (321) in the short direction is substantially the same as the height of the corresponding attachment leg (72).

本考案フレーム(1)は、スナップフィット機能を発揮するよう、弾性樹脂材料にて構成される。弾性樹脂材料としては、熱可塑性樹脂が好ましく、ポリ塩化ビニルがコストパフォーマンスの観点からより好ましいが、必要に応じ強度、耐クリープ性に優れるエンジニアリング樹脂を採用することもできる。上記弾性樹脂材料は成形コスト面から、押出し形材のものが適している。 The inventive frame (1) is made of an elastic resin material so as to exhibit a snap-fit function. As the elastic resin material, a thermoplastic resin is preferable, and polyvinyl chloride is more preferable from the viewpoint of cost performance. However, an engineering resin excellent in strength and creep resistance can be used as necessary. From the viewpoint of molding cost, an extruded shape material is suitable for the elastic resin material.

以下では、本考案フレーム(1)を使用して、アタッチメント付き複合ガラスを既設の単板ガラス仕様アルミサッシ窓に据え付ける手順について説明し、その利点を述べる。

先ず、アタッチメント付き複層ガラスの外形寸法を実測し、上枠(2)、下枠(3)、縦枠(4)の据付位置を決め、これらをアルミサッシ(52)に接合する。接合には接着、ビス止め等の手段があるが、堅固な接合とするにはビス止めが好ましい。Below, the procedure which installs the composite glass with an attachment to the existing single plate glass specification aluminum sash window using this invention frame (1) is demonstrated, and the advantage is described.

First, the external dimensions of the multilayer glass with attachment are measured, the installation positions of the upper frame (2), the lower frame (3), and the vertical frame (4) are determined, and these are joined to the aluminum sash (52). Bonding includes means such as adhesion and screwing, but screwing is preferable for firm bonding.

次いで、複合ガラス(6)をそのアタッチメント(7)の脚部に(72)をアルミサッシ(52)にあてがい、直ちにカバー(オス)部材(22,32,42)を、それらのアタッチメント押え部(221,321,421)が窓中心に向くようにあてがい、対応するベース(メス)部材(21,31,41)に向けて押し込み、嵌合させる(図2、図3)。カバー(オス)部材には一対の爪付きリブが備わっているため、両者を容易にスナップフィットさせることができる。なお、作業の安定性の観点から、カバー部材の嵌合順序は、上枠(2)、下枠(3)、次いで縦枠(4)の順に行うのが好ましい。 Next, the composite glass (6) is applied to the legs of the attachment (7) (72) to the aluminum sash (52), and the cover (male) member (22, 32, 42) is immediately attached to the attachment presser ( 221, 321, 421) are directed toward the center of the window and pushed into the corresponding base (female) members (21, 31, 41) to be fitted (FIGS. 2 and 3). Since the cover (male) member is provided with a pair of ribs with claws, both can be snap-fitted easily. From the viewpoint of work stability, the cover member is preferably fitted in the order of the upper frame (2), the lower frame (3), and then the vertical frame (4).

上記嵌合作業に先立ち、あらかじめ、アタッチメント(7)の脚部(72)の面であってアルミサッシ(52)と相対する側の面に、両面テープを貼るか、または接着剤を塗布するかして複層ガラス(6)を仮止めしておくことが作業を容易にする。 Prior to the mating operation, a double-sided tape or adhesive is applied to the surface of the leg (72) of the attachment (7) opposite to the aluminum sash (52) in advance. Then, temporarily fixing the multilayer glass (6) facilitates the work.

また、アタッチメント(7)とアルミサッシ(52)の間、アタッチメント(52)とカバー(オス)部材((22,32,42)の間の密封性を高め、かつガタ無く嵌合できるよう、緩衝材又は封止材(図示していない)をそれらの間に挿入しても良い。 In addition, a buffer is provided so as to improve sealing between the attachment (7) and the aluminum sash (52), between the attachment (52) and the cover (male) member ((22, 32, 42), and without any looseness. A material or sealant (not shown) may be inserted between them.

嵌合した後は、アタッチメント(7)脚部(72)、及び上(下、縦)枠のベース(メス)部材(21,31,41)の固定に用いたビス(8)は、共にカバー(オス)部材(22,32,42)の背面に隠れるので、見栄えがよい(図5)。また、カバー(オス)部材(22,32,42)の表面を木目調とすることで 意匠性を高めることもできる。 After fitting, the screws (8) used for fixing the attachment (7) legs (72) and the base (female) members (21, 31, 41) of the upper (lower, vertical) frame are both covered. Since it is hidden behind the (male) member (22, 32, 42), it looks good (FIG. 5). Moreover, the design property can also be improved by making the surface of the cover (male) member (22, 32, 42) into a wood grain.

1 複層ガラス据え付け用フレーム

2 上枠

3 下枠

4 縦枠

21,31,41 上(下、縦)枠のベース(メス)部材

21g,31g,41g ベース(メス)部材の溝

21f,31f,41f 爪係り止め部

22,32,42 カバー(オス)部材

221,321,421 カバー(オス)部材のアタッチメント押え部

221r,321r,421r アタッチメント押え部のリブ

222,322,422 カバー(オス)部材の嵌合部

222r,322r,422r 嵌合部の爪付きリブ

5 単板ガラスサッシ窓

51 ガラス板

52 アルミサッシ

53 グレージングチャンネル

6 複層ガラス

6a ガラス板

6b スペーサー

6c 封止材

7 アタッチメント

71 保持枠部

71b 保持枠部端部

72 脚部

72b 脚部端部

8 ビスDESCRIPTION OF

Claims (3)

上枠、下枠、及び左右の縦枠より構成され、

前記上枠、下枠、及び左右の縦枠は、各々ベース(メス)部材とカバー(オス)部材の対より構成されており、

前記ベース(メス)部材はその中央長手方向に沿って断面略コ状の嵌合溝が形成されており、

前記カバー(オス)部材は、その長手方向に沿う、

アタッチメント押え部と、一対の爪付きリブを有する嵌合部にて構成されており、

前記カバー(オス)部材の上記ベース(メス)部材への押し込み操作により、前記カバー(オス)部材と前記ベース(メス)部材とがスナップフィットする、

ことを特徴とするアタッチメント付き複層ガラス据え付け用フレーム。A multi-layer glass mounting frame with an attachment, wherein the multi-layer glass mounting frame is:

It consists of an upper frame, a lower frame, and left and right vertical frames,

The upper frame, the lower frame, and the left and right vertical frames are each composed of a pair of a base (female) member and a cover (male) member,

The base (female) member is formed with a fitting groove having a substantially U-shaped cross section along its central longitudinal direction.

The cover (male) member is along its longitudinal direction,

It consists of an attachment presser and a fitting part with a pair of ribs with claws,

By pressing the cover (male) member into the base (female) member, the cover (male) member and the base (female) member snap fit.

A double-glazed glass installation frame with an attachment.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016005038U JP3208073U (en) | 2016-09-30 | 2016-09-30 | Multi-layer glass mounting frame |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016005038U JP3208073U (en) | 2016-09-30 | 2016-09-30 | Multi-layer glass mounting frame |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP3208073U true JP3208073U (en) | 2016-12-22 |

| JP3208073U7 JP3208073U7 (en) | 2018-02-08 |

Family

ID=57572529

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016005038U Expired - Fee Related JP3208073U (en) | 2016-09-30 | 2016-09-30 | Multi-layer glass mounting frame |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3208073U (en) |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS57150192U (en) * | 1981-03-17 | 1982-09-21 | ||

| WO1997041329A1 (en) * | 1996-04-26 | 1997-11-06 | Kaneka Corporation | Light-controllable heat insulating window |

-

2016

- 2016-09-30 JP JP2016005038U patent/JP3208073U/en not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS57150192U (en) * | 1981-03-17 | 1982-09-21 | ||

| WO1997041329A1 (en) * | 1996-04-26 | 1997-11-06 | Kaneka Corporation | Light-controllable heat insulating window |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6679013B2 (en) | Window assembly with hinged components | |

| US10871024B2 (en) | Frame system | |

| JP5946869B2 (en) | Outer wall mounting member and outer wall structure | |

| US4875316A (en) | Combination metal and wood window frame assembly | |

| US10267082B2 (en) | Profile for fastening panes | |

| CA2863237C (en) | Manufactures, methods and structures to reduce energy transfer in buildings | |

| KR101527875B1 (en) | Composite sliding window using PVC and aluminum | |

| CA2448373C (en) | Muntin clip | |

| JP3208073U (en) | Multi-layer glass mounting frame | |

| JP3208073U7 (en) | ||

| RU176748U1 (en) | The design of the wooden window and balcony block | |

| KR101527874B1 (en) | Composite sliding window using PVC and aluminum | |

| KR101855998B1 (en) | The system includes a heat-insulating windows and structure of the window sash | |

| KR102018425B1 (en) | Window fram dividing bar set being easy to install and adjust position and dividing window prepared therefrom | |

| KR102018426B1 (en) | Dividing window being easy to adjust and assemble | |

| CN107780759A (en) | Aluminum alloy doors and windows overall assembled sash profile component | |

| AU2017228710B2 (en) | An auxiliary framing system | |

| JP5597658B2 (en) | Frame material and additional windows | |

| CN219587452U (en) | Profile door leaf structure | |

| RU89582U1 (en) | WINDOW AND DOOR FINISHING SYSTEM | |

| CN206128991U (en) | Two horizontal nodes of sliding door of aluminum alloy | |

| JP6892336B2 (en) | Sash frame mounting structure | |

| EP3721039B1 (en) | Heat-insulating door or window | |

| CN206035218U (en) | Al -alloy door & window unit -installment window fan -type material subassembly | |

| KR102041522B1 (en) | system window having attaching type installation structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 3208073 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| A623 | Registrability report |

Free format text: JAPANESE INTERMEDIATE CODE: A623 Effective date: 20170616 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20170616 |

|

| A623 | Registrability report |

Free format text: JAPANESE INTERMEDIATE CODE: A623 Effective date: 20170929 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171004 |

|

| R231 | Written correction (descriptions, etc.) |

Free format text: JAPANESE INTERMEDIATE CODE: R231 |

|

| R157 | Certificate of patent or utility model (correction) |

Free format text: JAPANESE INTERMEDIATE CODE: R157 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |