JP2017224826A - 抗折強度の高い薄型チップの形成方法及び形成システム - Google Patents

抗折強度の高い薄型チップの形成方法及び形成システム Download PDFInfo

- Publication number

- JP2017224826A JP2017224826A JP2017125526A JP2017125526A JP2017224826A JP 2017224826 A JP2017224826 A JP 2017224826A JP 2017125526 A JP2017125526 A JP 2017125526A JP 2017125526 A JP2017125526 A JP 2017125526A JP 2017224826 A JP2017224826 A JP 2017224826A

- Authority

- JP

- Japan

- Prior art keywords

- wafer

- grinding

- tape

- polishing

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034 method Methods 0.000 title claims abstract description 81

- 238000005452 bending Methods 0.000 title claims description 12

- 238000000227 grinding Methods 0.000 claims abstract description 146

- 239000000758 substrate Substances 0.000 claims abstract description 89

- 239000004065 semiconductor Substances 0.000 abstract description 26

- 235000012431 wafers Nutrition 0.000 description 283

- 238000005498 polishing Methods 0.000 description 137

- 238000005520 cutting process Methods 0.000 description 89

- 230000008569 process Effects 0.000 description 53

- 239000000126 substance Substances 0.000 description 39

- 238000003825 pressing Methods 0.000 description 38

- 230000035882 stress Effects 0.000 description 33

- 238000005530 etching Methods 0.000 description 30

- 239000004744 fabric Substances 0.000 description 29

- 230000033001 locomotion Effects 0.000 description 26

- 238000012545 processing Methods 0.000 description 26

- 238000009833 condensation Methods 0.000 description 15

- 230000005494 condensation Effects 0.000 description 15

- 239000013078 crystal Substances 0.000 description 15

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 13

- 230000009471 action Effects 0.000 description 13

- 238000004140 cleaning Methods 0.000 description 13

- 238000010586 diagram Methods 0.000 description 11

- 230000003287 optical effect Effects 0.000 description 11

- 239000000853 adhesive Substances 0.000 description 10

- 230000001070 adhesive effect Effects 0.000 description 10

- 230000007246 mechanism Effects 0.000 description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 10

- 238000005192 partition Methods 0.000 description 9

- 238000011156 evaluation Methods 0.000 description 8

- 238000005259 measurement Methods 0.000 description 8

- 238000007517 polishing process Methods 0.000 description 8

- 230000002829 reductive effect Effects 0.000 description 8

- 238000012546 transfer Methods 0.000 description 8

- 238000003486 chemical etching Methods 0.000 description 7

- 239000000428 dust Substances 0.000 description 7

- 239000007788 liquid Substances 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 230000000644 propagated effect Effects 0.000 description 7

- 239000002002 slurry Substances 0.000 description 7

- 239000012141 concentrate Substances 0.000 description 6

- 229910052710 silicon Inorganic materials 0.000 description 6

- 238000004804 winding Methods 0.000 description 6

- 230000002411 adverse Effects 0.000 description 5

- 230000007547 defect Effects 0.000 description 5

- 239000012530 fluid Substances 0.000 description 5

- 230000008646 thermal stress Effects 0.000 description 5

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 4

- 239000006061 abrasive grain Substances 0.000 description 4

- 230000006835 compression Effects 0.000 description 4

- 238000007906 compression Methods 0.000 description 4

- 238000006073 displacement reaction Methods 0.000 description 4

- 230000006870 function Effects 0.000 description 4

- 230000002093 peripheral effect Effects 0.000 description 4

- 239000010703 silicon Substances 0.000 description 4

- 239000000377 silicon dioxide Substances 0.000 description 4

- 238000001179 sorption measurement Methods 0.000 description 4

- 229920005830 Polyurethane Foam Polymers 0.000 description 3

- 229910020175 SiOH Inorganic materials 0.000 description 3

- 238000005336 cracking Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 230000036961 partial effect Effects 0.000 description 3

- 239000011496 polyurethane foam Substances 0.000 description 3

- RMAQACBXLXPBSY-UHFFFAOYSA-N silicic acid Chemical compound O[Si](O)(O)O RMAQACBXLXPBSY-UHFFFAOYSA-N 0.000 description 3

- 229920000459 Nitrile rubber Polymers 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 231100000989 no adverse effect Toxicity 0.000 description 2

- 239000004745 nonwoven fabric Substances 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 238000010008 shearing Methods 0.000 description 2

- 229920003048 styrene butadiene rubber Polymers 0.000 description 2

- 239000002174 Styrene-butadiene Substances 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000001311 chemical methods and process Methods 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 229910052681 coesite Inorganic materials 0.000 description 1

- 239000008119 colloidal silica Substances 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 229910052906 cristobalite Inorganic materials 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000001962 electrophoresis Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 238000001502 gel electrophoresis Methods 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 238000005286 illumination Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000012466 permeate Substances 0.000 description 1

- 230000010287 polarization Effects 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- 230000007480 spreading Effects 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 229910052682 stishovite Inorganic materials 0.000 description 1

- 238000002834 transmittance Methods 0.000 description 1

- 229910052905 tridymite Inorganic materials 0.000 description 1

- 239000011800 void material Substances 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 230000037303 wrinkles Effects 0.000 description 1

Images

Landscapes

- Laser Beam Processing (AREA)

- Dicing (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017125526A JP2017224826A (ja) | 2017-06-27 | 2017-06-27 | 抗折強度の高い薄型チップの形成方法及び形成システム |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017125526A JP2017224826A (ja) | 2017-06-27 | 2017-06-27 | 抗折強度の高い薄型チップの形成方法及び形成システム |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017026939A Division JP6276437B2 (ja) | 2017-02-16 | 2017-02-16 | 抗折強度の高い薄型チップの形成方法及び形成システム |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018097877A Division JP2018133593A (ja) | 2018-05-22 | 2018-05-22 | ウェハ加工方法及びウェハ加工システム |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2017224826A true JP2017224826A (ja) | 2017-12-21 |

| JP2017224826A5 JP2017224826A5 (enExample) | 2018-02-15 |

Family

ID=60688371

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017125526A Pending JP2017224826A (ja) | 2017-06-27 | 2017-06-27 | 抗折強度の高い薄型チップの形成方法及び形成システム |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2017224826A (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2019181656A (ja) * | 2018-04-17 | 2019-10-24 | 株式会社ディスコ | 切削ブレードの整形方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003077295A1 (fr) * | 2002-03-12 | 2003-09-18 | Hamamatsu Photonics K.K. | Procede permettant de decouper un substrat en puces |

| JP2007235069A (ja) * | 2006-03-03 | 2007-09-13 | Tokyo Seimitsu Co Ltd | ウェーハ加工方法 |

| JP2017224391A (ja) * | 2016-06-13 | 2017-12-21 | 三菱電機株式会社 | 光源ユニット及び照明装置 |

-

2017

- 2017-06-27 JP JP2017125526A patent/JP2017224826A/ja active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003077295A1 (fr) * | 2002-03-12 | 2003-09-18 | Hamamatsu Photonics K.K. | Procede permettant de decouper un substrat en puces |

| JP2007235069A (ja) * | 2006-03-03 | 2007-09-13 | Tokyo Seimitsu Co Ltd | ウェーハ加工方法 |

| JP2017224391A (ja) * | 2016-06-13 | 2017-12-21 | 三菱電機株式会社 | 光源ユニット及び照明装置 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2019181656A (ja) * | 2018-04-17 | 2019-10-24 | 株式会社ディスコ | 切削ブレードの整形方法 |

| JP7033485B2 (ja) | 2018-04-17 | 2022-03-10 | 株式会社ディスコ | 切削ブレードの整形方法 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5825511B2 (ja) | 半導体基板の切断方法 | |

| JP2012109357A (ja) | 半導体基板の切断方法及び半導体基板の切断装置 | |

| JP5803049B2 (ja) | 半導体基板の切断方法 | |

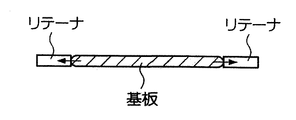

| JP6081006B2 (ja) | ウェハ割断方法及びウェハ割断装置 | |

| JP2019161232A (ja) | レーザ加工システム | |

| JP6128666B2 (ja) | 半導体基板の割断方法及び割断装置 | |

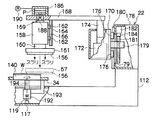

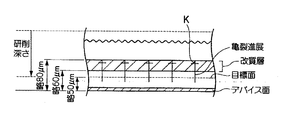

| JP6081005B2 (ja) | 研削・研磨装置及び研削・研磨方法 | |

| JP2019012848A (ja) | ウェハ加工方法及びウェハ加工システム | |

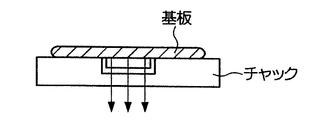

| JP6276437B2 (ja) | 抗折強度の高い薄型チップの形成方法及び形成システム | |

| JP2018142717A (ja) | ウェハ加工方法及びウェハ加工システム | |

| JP6276357B2 (ja) | ウェーハ加工方法 | |

| JP5995023B2 (ja) | 半導体基板の割断方法 | |

| JP6593663B2 (ja) | ウェハ加工方法及びウェハ加工システム | |

| JP2017123475A (ja) | 抗折強度の高い薄型チップの製造システム及び製造方法 | |

| JP2017038092A (ja) | ウェハ加工装置及びウェハ加工方法 | |

| JP2020074414A (ja) | 抗折強度の高いチップを得る半導体ウェーハのレーザ加工装置 | |

| JP2020074454A (ja) | チップ強度の向上を図るレーザ加工システム及びレーザ加工方法 | |

| JP2017224826A (ja) | 抗折強度の高い薄型チップの形成方法及び形成システム | |

| JP2019096911A (ja) | レーザ加工システム | |

| JP2019071476A (ja) | レーザ光学部 | |

| JP2019071475A (ja) | レーザ光学部 | |

| JP6276356B2 (ja) | ウェーハ加工方法 | |

| JP6276347B2 (ja) | ウェーハ加工システム | |

| JP6276332B2 (ja) | ウェーハ加工システム | |

| JP6197970B2 (ja) | 分割起点形成方法及び分割起点形成装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171228 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20171228 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20180110 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180112 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180213 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20180223 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180814 |