JP2015152265A5 - - Google Patents

Download PDFInfo

- Publication number

- JP2015152265A5 JP2015152265A5 JP2014027797A JP2014027797A JP2015152265A5 JP 2015152265 A5 JP2015152265 A5 JP 2015152265A5 JP 2014027797 A JP2014027797 A JP 2014027797A JP 2014027797 A JP2014027797 A JP 2014027797A JP 2015152265 A5 JP2015152265 A5 JP 2015152265A5

- Authority

- JP

- Japan

- Prior art keywords

- heat

- heat exchanger

- heat exchange

- flow path

- primary

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000012530 fluid Substances 0.000 claims description 11

- 238000011144 upstream manufacturing Methods 0.000 claims 2

- 230000001629 suppression Effects 0.000 description 4

- 238000001816 cooling Methods 0.000 description 3

- 239000002737 fuel gas Substances 0.000 description 3

- 239000006227 byproduct Substances 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- 239000000470 constituent Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- GNVXPFBEZCSHQZ-UHFFFAOYSA-N iron(2+);sulfide Chemical compound [S-2].[Fe+2] GNVXPFBEZCSHQZ-UHFFFAOYSA-N 0.000 description 1

- MBMLMWLHJBBADN-UHFFFAOYSA-N iron-sulfur Chemical compound [Fe]=S MBMLMWLHJBBADN-UHFFFAOYSA-N 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

Images

Description

第1実施形態において、図1に示すように、ガスタービン10は、圧縮機11と燃焼器12とタービン13により構成されている。このガスタービン10は、発電機14が連結されており、発電可能となっている。 In the first embodiment , as illustrated in FIG. 1, the gas turbine 10 includes a compressor 11, a combustor 12, and a turbine 13. The gas turbine 10 is connected to a generator 14 and can generate power.

ここで、第2熱交換器33,33Aの作用を従来の熱交換器と比較して説明する。図5は、従来の熱交換器の作用を表す概略図、図6は、第1実施形態の熱交換器の作用を表す概略図である。

Here, the operation of the

そして、燃料ガスLの過熱が抑制されることで、熱交換部42の構成部材(例えば、伝熱管など)に大きな熱負荷が作用することはなく、板厚の増加などを不要として製造コストの増加を抑制することができる。また、燃料ガスLの過熱が抑制されることから、副生物(例えば、硫化鉄:FeS)が生成されることはなく、この副生物による熱交換器33,33Aへの悪影響を防止することができる。

In addition, since the overheating of the fuel gas L is suppressed, a large heat load does not act on the constituent members (for example, heat transfer tubes) of the

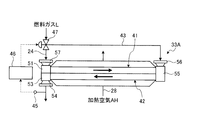

第2熱交換器33Bの構成は、上述したものに限定されるものではない。図8に示すように、第2熱交換器33Cは、燃料ガス供給ライン24と、冷却空気ライン28と、第1熱交換部41及び第2熱交換部42と、バイパス流路43と、流量調整弁47と、温度センサ45と、制御部46とを有している。

The configuration of the second heat exchanger 33B is not limited to that described above. As shown in FIG. 8, the second heat exchanger 33C includes a fuel

また、上述した実施形態では、二次流体により一次流体を加熱する熱交換器としたが、二次流体により一次流体を冷却する熱交換器としてもよく、この場合、熱交換器による過冷却を抑制することができる。 Further, in the above embodiment, although the heat exchanger for heating the primary fluid by the secondary fluid may be a heat exchanger for cooling the primary fluid by the secondary fluid, in this case, over-cooling by the heat exchanger Can be suppressed.

Claims (5)

前記一次流路内で二次流体が流れる二次流路と、

一次流体と二次流体とで熱交換を行う複数の熱交換部と、

前記複数の熱交換部のうち少なくとも1つの熱交換部をバイパスするバイパス流路と、

前記バイパス流路を流れる一次流体の流量を調整する流量調整弁と、

前記複数の熱交換部の出口側における一次流体の温度を計測する温度センサと、

前記温度センサが検出した一次流体の温度に応じて前記流量調整弁の開度を調整する制御部と、

を有し、

前記複数の熱交換部は、直列に接続された第1熱交換部と第2熱交換部を有し、前記バイパス流路は、一端部が前記第1熱交換部の入口に接続され、他端部が前記第1熱交換部と前記第2熱交換部の接続部に接続され、

前記第1熱交換部と前記第2熱交換部は、平行をなして配置され、一端部に前記第1熱交換部の入口部と前記第2熱交換部の出口部が配置され、他端部に前記接続部が配置される、

ことを特徴とする熱交換器。 A primary flow path through which the primary fluid flows;

A secondary channel through which a secondary fluid flows in the primary channel;

A plurality of heat exchanging units for exchanging heat between the primary fluid and the secondary fluid;

A bypass flow path that bypasses at least one heat exchange section among the plurality of heat exchange sections;

A flow rate adjustment valve for adjusting the flow rate of the primary fluid flowing through the bypass flow path;

A temperature sensor for measuring the temperature of the primary fluid on the outlet side of the plurality of heat exchange units;

A controller that adjusts the opening of the flow rate adjusting valve according to the temperature of the primary fluid detected by the temperature sensor;

I have a,

The plurality of heat exchanging units include a first heat exchanging unit and a second heat exchanging unit connected in series, and one end of the bypass channel is connected to an inlet of the first heat exchanging unit, An end is connected to a connection part of the first heat exchange part and the second heat exchange part,

The first heat exchange part and the second heat exchange part are arranged in parallel, and an inlet part of the first heat exchange part and an outlet part of the second heat exchange part are arranged at one end, and the other end The connection part is arranged in the part,

A heat exchanger characterized by that.

The heat exchanger according to any one of claims 1 to 3 , wherein the flow rate adjustment valve is a three-way valve provided at a branch portion between the primary flow path and the bypass flow path.

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014027797A JP6262013B2 (en) | 2014-02-17 | 2014-02-17 | Heat exchanger |

| US15/110,849 US20160341497A1 (en) | 2014-02-17 | 2015-01-20 | Heat exchanger |

| CN201580004366.9A CN105899907B (en) | 2014-02-17 | 2015-01-20 | Heat exchanger |

| KR1020167018819A KR20160099624A (en) | 2014-02-17 | 2015-01-20 | Heat exchanger |

| PCT/JP2015/051370 WO2015122244A1 (en) | 2014-02-17 | 2015-01-20 | Heat exchanger |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014027797A JP6262013B2 (en) | 2014-02-17 | 2014-02-17 | Heat exchanger |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015152265A JP2015152265A (en) | 2015-08-24 |

| JP2015152265A5 true JP2015152265A5 (en) | 2016-12-28 |

| JP6262013B2 JP6262013B2 (en) | 2018-01-17 |

Family

ID=53894715

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014027797A Active JP6262013B2 (en) | 2014-02-17 | 2014-02-17 | Heat exchanger |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6262013B2 (en) |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5113002A (en) * | 1974-07-24 | 1976-02-02 | Hitachi Ltd | KAHENSETSURYUSUGATANETSUKOKANKI |

| JPS52123541A (en) * | 1976-04-09 | 1977-10-17 | Taisei Corp | Method of piping of cooling water duct in room cooling system |

| JPS5849519Y2 (en) * | 1979-07-16 | 1983-11-11 | 株式会社荏原製作所 | Shell-and-tube heat exchanger |

| JPS5812997A (en) * | 1981-07-16 | 1983-01-25 | Mitsubishi Heavy Ind Ltd | Heat exchanger |

| JPS62160170U (en) * | 1986-04-01 | 1987-10-12 | ||

| JPS63134292U (en) * | 1987-02-24 | 1988-09-02 | ||

| JPS648087U (en) * | 1987-06-26 | 1989-01-17 | ||

| JPH04309765A (en) * | 1991-04-04 | 1992-11-02 | Nippondenso Co Ltd | Heat exchanger |

| JP2001091099A (en) * | 1999-09-17 | 2001-04-06 | Sanyo Electric Co Ltd | Heat exchanger |

| JP2002129979A (en) * | 2000-10-20 | 2002-05-09 | Mitsubishi Heavy Ind Ltd | Regenerator for gas turbine |

| JP2009127888A (en) * | 2007-11-20 | 2009-06-11 | Toyota Motor Corp | Heat exchanger and engine |

| US20090183867A1 (en) * | 2008-01-23 | 2009-07-23 | Compressor Systems Inc. | Varying ambient heat exchanger for a compressor |

-

2014

- 2014-02-17 JP JP2014027797A patent/JP6262013B2/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2015122244A1 (en) | Heat exchanger | |

| JP5522950B2 (en) | Multi-tube heat exchanger | |

| RU2013106154A (en) | WASTE HEAT DISPOSAL SYSTEM WITH PARTIAL RECOVERY | |

| WO2014079247A1 (en) | Power station boiler economizer | |

| JP2013199925A5 (en) | ||

| JP2010216692A5 (en) | ||

| JP5790973B2 (en) | Water heater | |

| JP2015206359A (en) | Fuel heating system for use with combined cycle gas turbine | |

| JP6504525B2 (en) | Overheater | |

| JP2020029994A5 (en) | ||

| JP5822487B2 (en) | Gas turbine plant and control method thereof | |

| JP2015152265A5 (en) | ||

| JP2017114179A5 (en) | ||

| JP6407612B2 (en) | Decompression energy recovery device in gas pipeline | |

| JP6262012B2 (en) | Heat exchanger | |

| JP2013044327A (en) | Temperature variable chiller coil | |

| JP2020024814A5 (en) | ||

| JP6180845B2 (en) | Heat exchanger and heat pump type water heater using the same | |

| JP2015152264A5 (en) | ||

| CN203719239U (en) | Condensation heat recovery system of refrigerating unit | |

| JP2008170042A5 (en) | ||

| JP2017155736A (en) | Intake heater and gas turbine | |

| JP2016217272A (en) | Gas turbine suction device | |

| JP6262013B2 (en) | Heat exchanger | |

| JP6268984B2 (en) | Heat source machine |