JP2015073794A - Water extraction coffee and water extraction coffee production device - Google Patents

Water extraction coffee and water extraction coffee production device Download PDFInfo

- Publication number

- JP2015073794A JP2015073794A JP2013213056A JP2013213056A JP2015073794A JP 2015073794 A JP2015073794 A JP 2015073794A JP 2013213056 A JP2013213056 A JP 2013213056A JP 2013213056 A JP2013213056 A JP 2013213056A JP 2015073794 A JP2015073794 A JP 2015073794A

- Authority

- JP

- Japan

- Prior art keywords

- coffee

- container

- drained

- temperature water

- water extraction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Apparatus For Making Beverages (AREA)

Abstract

Description

本発明は、焙煎コーヒー豆を微粉砕してなるコーヒー粉末と常温水との混合液をフィルター部で濾過してコーヒー抽出液として得られる水出しコーヒー、及び、それを製造する水出しコーヒー製造装置に関する。 The present invention relates to a watered coffee obtained as a coffee extract by filtering a mixed liquid of coffee powder obtained by finely pulverizing roasted coffee beans and room temperature water through a filter unit, and a watered coffee manufacture for producing the coffee Relates to the device.

焙煎コーヒー豆を常温水で抽出した水出しコーヒーは、高温の熱水で抽出したものと比べ、抽出時において香り成分の発散が抑制されつつ渋み成分や雑味成分の抽出が抑制されることから、良質な甘みと柔らかい苦みを持ったまろやかな味と豊かな香りが楽しめるものとして愛好家に好まれている。

このような水出しコーヒーを製造する従来の水出しコーヒー製造技術では、焙煎コーヒー豆を微粉砕してなるコーヒー粉末と常温水との混合液をフィルターで濾過して、水出しコーヒーを得るようにしている。更に、水出しコーヒーの抽出には、低温の常温水を利用するため、コーヒー成分を十分に抽出するためには、例えばフィルターで濾過後の抽出液を再度フィルターに循環させるなどのように、コーヒー粉末と抽出液とを長時間にわたって接触させる必要があった(例えば特許文献1を参照。)。

そこで、短時間で水出しコーヒーの抽出を行う従来の水出しコーヒー製造装置として、コーヒー粉末と常温水との混合液を減圧環境下に晒してコーヒー粉末への常温水の浸透を促進させ、その混合液を別途準備したフィルターで濾過してコーヒー成分が十分に抽出された水出しコーヒーを得るものが知られている(例えば特許文献2を参照。)。

Compared with coffee extracted from hot hot water, the drained coffee extracted from roasted coffee beans with room-temperature water has less astringent and savory components extracted during extraction. Therefore, it is preferred by enthusiasts to enjoy a mellow taste and rich aroma with good sweetness and soft bitterness.

In conventional drained coffee manufacturing technology for manufacturing such drained coffee, a mixture of coffee powder obtained by finely pulverizing roasted coffee beans and normal temperature water is filtered through a filter to obtain drained coffee. I have to. Further, since low temperature room temperature water is used for extraction of watered coffee, in order to sufficiently extract coffee components, for example, the extracted liquid after filtering with a filter is circulated through the filter again. It was necessary to contact the powder and the extract for a long time (see, for example, Patent Document 1).

Therefore, as a conventional coffee brewing coffee machine that extracts coffee brewed in a short time, a mixture of coffee powder and room temperature water is exposed to a reduced pressure environment to promote the penetration of room temperature water into the coffee powder. There is known a method in which a mixed liquid is filtered through a separately prepared filter to obtain drained coffee from which coffee components are sufficiently extracted (see, for example, Patent Document 2).

しかしながら、コーヒー粉末と常温水との混合液を減圧環境下に晒す従来の水出しコーヒー製造装置では、混合液を濾過するために別途フィルターを準備する必要があり、更に、混合液をフィルターに移し替えるというような煩雑な作業が必要となる。

本発明は、かかる点に着目してなされたものであり、その目的は、コーヒー成分が十分に抽出された水出しコーヒー、及び、合理的な装置構成を採用しつつ煩雑な作業を必要とすることなく短時間でそのような水出しコーヒーを得ることができる水出しコーヒー製造装置を提供する点にある。

However, in the conventional water-draining coffee manufacturing apparatus that exposes the mixed liquid of coffee powder and normal temperature water to a reduced pressure environment, it is necessary to prepare a separate filter for filtering the mixed liquid, and the mixed liquid is transferred to the filter. A cumbersome work such as replacement is required.

The present invention has been made paying attention to this point, and its purpose is to require a cumbersome operation while adopting a drained coffee from which coffee components are sufficiently extracted and a rational apparatus configuration. The object of the present invention is to provide a drained coffee production apparatus that can obtain such drained coffee in a short time.

この目的を達成するための本発明に係る水出しコーヒー製造装置は、

焙煎コーヒー豆を微粉砕してなるコーヒー粉末と常温水との混合液をフィルター部で濾過してコーヒー抽出液を得る水出しコーヒー製造装置であって、

その特徴構成は、

上部にコーヒー粉末と常温水とが投入される投入口が形成され、底部にコーヒー抽出液を払い出す払出口が形成された筒状の収容容器を備えると共に、前記フィルター部が、前記収容容器内に貯留する混合液に浸漬されて前記投入口と前記払出口とを区画する姿勢で配置され、且つ、

前記投入口及び前記払出口が開閉自在に構成され、

前記収容容器内の空気を吸引する吸引手段と、

運転を制御する運転制御手段とを備え、

前記運転制御手段が、

前記投入口を開放すると共に前記払出口を閉鎖して、前記投入口を介して前記収容容器内へのコーヒー粉末と常温水の投入を受け付ける材料投入処理を実行し、

次に、前記投入口を開放した状態で、前記吸引手段を作動させて、前記収容容器内を減圧させる抽出処理を実行し、

次に、前記吸引手段を停止すると共に、前記払出口を開放する払出処理を実行する点にある。

また、この目的を達成するための本発明に係る水出しコーヒーは、

焙煎コーヒー豆を微粉砕してなるコーヒー粉末と常温水との混合液をフィルター部で濾過してコーヒー抽出液として得られる水出しコーヒーであって、

その特徴構成は、

本発明に係る水出しコーヒー製造装置で製造された点にある。

In order to achieve this object, a water-developing coffee production apparatus according to the present invention comprises:

A water-depositing coffee production apparatus for obtaining a coffee extract by filtering a mixed liquid of coffee powder obtained by finely pulverizing roasted coffee beans and normal temperature water through a filter unit,

Its feature configuration is

The container is provided with a cylindrical storage container in which a charging port for supplying coffee powder and normal temperature water is formed at the top, and a discharge outlet for discharging the coffee extract liquid is formed at the bottom. Placed in a posture so as to divide the inlet and the outlet by being immersed in the liquid mixture stored in

The inlet and the outlet are configured to be openable and closable,

Suction means for sucking air in the container;

An operation control means for controlling the operation,

The operation control means is

Opening the charging port and closing the outlet, performing a material charging process for receiving coffee powder and room temperature water into the container through the charging port,

Next, in a state where the charging port is opened, the suction means is operated to perform an extraction process for reducing the pressure inside the storage container,

Next, the suction means is stopped and a payout process for opening the payout port is executed.

In addition, the watered coffee according to the present invention for achieving this object is:

It is a drained coffee obtained by filtering a mixed liquid of coffee powder obtained by finely pulverizing roasted coffee beans and normal temperature water through a filter unit, and obtaining a coffee extract.

Its feature configuration is

It exists in the point manufactured with the water | moisture-content coffee manufacturing apparatus which concerns on this invention.

本特徴構成によれば、材料投入処理において投入口から収容容器内にコーヒー粉末と常温水とを投入するだけで、抽出処理を実行してそれらコーヒー粉末と常温水との混合液を減圧環境下に晒してコーヒー粉末への常温水の浸透を促進させることができ、更には、排出処理を実行してその混合液を収容容器内に配置したフィルター部で濾過してコーヒー成分が十分に抽出されたコーヒー抽出液を水出しコーヒーとして払出口から払い出すことができる。

即ち、材料投入処理を実行することで、収容容器内に、開放された投入口から、コーヒー粉末と常温水とを投入することができる。すると、収容容器内には、混合液が貯留され、それに浸漬する状態で配置されたフィルター部の上面にコーヒー粉末が堆積することになる。

次に、抽出工程を実行することで、投入口及び排出口の両方が閉鎖され収容容器内が気密に維持された状態で、吸引手段が作動して、収容容器内が減圧される。すると、混合液の溶存空気が除去されると共に、コーヒー粉末の粒子に形成された空隙から空気が除去されることで、常温水のコーヒー粉末の浸透が促進され、結果、常温水に対してコーヒー粉末からコーヒー成分が良好に抽出され、コーヒー成分が十分に抽出されたコーヒー抽出液を短時間で生成することができる。

次に、払出工程を実行することで、払出口が開放されることで、投入口等から収容容器内への空気の導入を伴って、フィルター部により混合液からコーヒー粉末を濾過しつつ、収容容器内のコーヒー抽出液を水出しコーヒーとして払出口から払い出すことができる。

従って、本発明により、コーヒー成分が十分に抽出された水出しコーヒー、及び、合理的な装置構成を採用しつつ煩雑な作業を必要とすることなく短時間でそのような水出しコーヒーを得ることができる水出しコーヒー製造装置を提供することができる。

According to this feature configuration, the coffee powder and the room temperature water are extracted by simply adding the coffee powder and the room temperature water into the storage container from the input port in the material input process, and the mixture of the coffee powder and the room temperature water is reduced in a reduced pressure environment. Exposure to room temperature water can promote the penetration of normal temperature water into the coffee powder.Furthermore, the draining process is carried out and the mixed liquid is filtered through a filter unit placed in the container to sufficiently extract the coffee components. The coffee extract can be dispensed from the dispensing outlet as drained coffee.

That is, by executing the material charging process, coffee powder and room temperature water can be charged into the storage container from the opened charging port. Then, the mixed liquid is stored in the storage container, and the coffee powder is deposited on the upper surface of the filter unit arranged in a state of being immersed therein.

Next, by performing the extraction process, the suction means is operated and the inside of the container is decompressed in a state where both the inlet and the outlet are closed and the container is kept airtight. Then, the dissolved air in the mixed liquid is removed and the air is removed from the voids formed in the coffee powder particles, thereby promoting the penetration of the coffee powder of room temperature water. A coffee extract from which the coffee component is well extracted from the powder and the coffee component is sufficiently extracted can be generated in a short time.

Next, by carrying out the dispensing process, the dispensing outlet is opened, and the air is introduced into the housing container from the inlet or the like, and the coffee powder is filtered from the mixed solution by the filter unit and stored. The coffee extract in the container can be discharged from the outlet as drained coffee.

Therefore, according to the present invention, it is possible to obtain a drained coffee from which coffee components are sufficiently extracted, and such a drained coffee in a short time without using a complicated operation while adopting a rational apparatus configuration. It is possible to provide a drained coffee manufacturing apparatus that can perform the above-described process.

本発明に係る水出しコーヒー製造装置の更なる特徴構成は、

前記収容容器内へ空気を圧送する圧送手段を備え、

前記運転制御手段が、前記払出処理において、前記圧送手段を作動させて、前記収容容器内を昇圧させる点にある。

A further characteristic configuration of the watered coffee production apparatus according to the present invention is as follows:

Comprising pressure feeding means for pumping air into the container;

In the payout process, the operation control means operates the pressure feeding means to increase the pressure in the storage container.

本特徴構成によれば、払出工程を実行することで、投入口及び払出口の両方が開放された状態で、圧送手段が作動して、投入口から収容容器内に強制的に空気が圧送される。すると、収容容器内の液面に係る圧力が増加するため、コーヒー粉末による目詰まりが発生するフィルター部に対するコーヒー抽出液の通過が促進されるので、コーヒー抽出液の収容容器内からの払い出しを迅速に行うことができる。 According to this characteristic configuration, by performing the dispensing process, the pressure feeding unit operates in a state where both the inlet and the outlet are opened, and air is forcibly fed from the inlet into the storage container. The Then, since the pressure related to the liquid level in the storage container increases, the passage of the coffee extract to the filter part where clogging with coffee powder occurs is facilitated, so that the coffee extract can be quickly discharged from the storage container. Can be done.

本発明に係る水出しコーヒー製造装置の更なる特徴構成は、

前記収容容器内において前記フィルター部上面に沿って撹拌翼を回転可能な撹拌手段を備え、

前記運転制御手段が、前記抽出処理において、前記撹拌手段を作動させる点にある。

A further characteristic configuration of the watered coffee production apparatus according to the present invention is as follows:

A stirring means capable of rotating a stirring blade along the upper surface of the filter unit in the container,

The operation control means operates the stirring means in the extraction process.

本特徴構成によれば、抽出工程を実行することで、撹拌手段が作動して、収容容器内に対流が発生するので、収容容器内のフィルター部の上方においてコーヒー粉末と常温水との接触を促進し、コーヒー粉末から常温水へのコーヒー成分の抽出を促進させることができる。

更に、フィルター部の上面においてコーヒー粉末が液相とともに対流するので、コーヒー粉末のフィルター部への目詰まりが抑制される。よって、次の払出工程において、フィルター部に対するコーヒー抽出液の通過が促進されるので、コーヒー抽出液の収容容器内からの払い出しを迅速に行うことができる。

According to this characteristic configuration, by performing the extraction step, the stirring means is activated and convection is generated in the storage container, so that the coffee powder and normal temperature water are brought into contact with each other above the filter portion in the storage container. And can promote the extraction of coffee components from coffee powder to room temperature water.

Furthermore, since the coffee powder convects together with the liquid phase on the upper surface of the filter portion, clogging of the coffee powder into the filter portion is suppressed. Therefore, in the next dispensing step, the passage of the coffee extract to the filter portion is promoted, so that the coffee extract can be quickly dispensed from the storage container.

本発明に係る水出しコーヒー製造装置の更なる特徴構成は、

前記フィルター部を振動可能な振動手段を備え、

前記運転制御手段が、前記抽出処理において、前記振動手段を作動させる点にある。

A further characteristic configuration of the watered coffee production apparatus according to the present invention is as follows:

Comprising vibration means capable of vibrating the filter section;

The operation control means operates the vibration means in the extraction process.

本特徴構成によれば、抽出工程を実行することで、振動手段が作動して、フィルター部が振動するので、コーヒー粉末のフィルター部への目詰まりが抑制される。よって、次の払出工程において、フィルター部に対するコーヒー抽出液の通過が促進されるので、コーヒー抽出液の収容容器内からの払い出しを迅速に行うことができる。 According to this characteristic configuration, by executing the extraction step, the vibration unit is activated and the filter unit vibrates, so that clogging of the coffee powder into the filter unit is suppressed. Therefore, in the next dispensing step, the passage of the coffee extract to the filter portion is promoted, so that the coffee extract can be quickly dispensed from the storage container.

本発明に係る水出しコーヒー製造装置の更なる特徴構成は、

前記コーヒー粉末の平均粒子径が1〜1000μmの範囲内である点にある。

A further characteristic configuration of the watered coffee production apparatus according to the present invention is as follows:

The coffee powder has an average particle size in the range of 1 to 1000 μm.

本特徴構成によれば、コーヒー豆を凍結粉砕などにより細胞レベルまで粉砕して、平均粒子径が1〜1000μm、好ましくは1〜30μmの範囲内のコーヒー粉末を使用することで、コーヒー粉末から常温水へのコーヒー成分の抽出を促進させることができるので、一層短時間でコーヒー成分が十分に抽出されたコーヒー抽出液を得ることができる。 According to this characteristic configuration, coffee beans are ground to the cell level by freeze grinding or the like, and an average particle size of 1 to 1000 μm, preferably 1 to 30 μm, is used. Since the extraction of the coffee component into water can be promoted, a coffee extract in which the coffee component is sufficiently extracted in a shorter time can be obtained.

本発明に係る水出しコーヒー及び水出しコーヒー製造装置の実施形態について、図面に基づいて説明する。

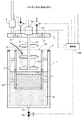

本実施形態の水出しコーヒー製造装置は、図1〜図4、特に図3を参照して、焙煎コーヒー豆を微粉砕してなるコーヒー粉末CPと常温水Wとの混合液MWをフィルター部2で濾過してコーヒー抽出液CWを得るものであって、合理的な装置構成を採用しつつ煩雑な作業を必要とすることなく短時間でコーヒー成分が十分に抽出されたコーヒー抽出液CWを得るものとして構成されている。

DESCRIPTION OF EMBODIMENTS Embodiments of water-deposited coffee and water-deposited coffee manufacturing apparatuses according to the present invention will be described with reference to the drawings.

1 to 4, particularly FIG. 3, the watered coffee manufacturing apparatus of the present embodiment is a filter unit for mixing a liquid MW of coffee powder CP and room temperature water W obtained by finely pulverizing roasted coffee beans. A coffee extract CW obtained by sufficiently filtering coffee components in a short time without requiring a complicated operation while adopting a rational apparatus configuration is obtained. It is configured as a gain.

具体的に、収容容器1とフィルター部2とが設けられ、フィルター部2がその収容容器1内に配置されている。

収容容器1は、有底円筒状に形成された金属製の圧力容器として構成されており、図1及び図2に示すように、その上部にはコーヒー粉末CPと常温水Wとが投入される投入口10が形成され、更に、図4に示すように、底部にはコーヒー抽出液CWを水出しコーヒーとして払い出す払出口15が形成されている。

Specifically, the

The

一方、フィルター部2は、有底円筒状に形成された金属メッシュで構成されており、図3に示すように、収容容器1内において、内壁に固定されたフィルター支持部3により支持されて、収容容器1内に貯留する混合液MWに浸漬されて投入口10と払出口15とを区画する姿勢で配置されている。

ここで、本実施形態の水出しコーヒー製造装置では、コーヒー粉末CPから常温水Wへのコーヒー成分の抽出を促進させるべく、細胞レベルまで粉砕されて平均粒子径が1〜30μmの範囲内となるコーヒー粉末CPが利用される。尚、このような微小粒子径のコーヒー粉末CPは、コーヒー豆を凍結粉砕することにより得ることができる。

そして、フィルター部2は、このような微小粒子径のコーヒー粉末CPを濾過することができる程度の濾過精度(例えば0.8μm〜24μm)を有するものを利用することが望ましい。

尚、コーヒー粉末の平均粒子径やフィルター部2の濾過精度は、コーヒー成分の抽出し易さ許容できる抽出時間等に合わせて適宜変更可能である。例えば、コーヒー粉末の平均粒径を1〜1000μmとしても構わない。

On the other hand, the

Here, in the drained coffee manufacturing apparatus of the present embodiment, in order to promote the extraction of the coffee component from the coffee powder CP to the room temperature water W, it is pulverized to the cell level and the average particle size is in the range of 1 to 30 μm. Coffee powder CP is used. The coffee powder CP having such a fine particle diameter can be obtained by freeze-grinding coffee beans.

And as for the

The average particle diameter of the coffee powder and the filtration accuracy of the

収容容器1の上部の投入口10は、収容容器1の上部開口として構成されており、蓋部開閉用アクチュエータ4により円盤状の蓋部7を上下動作することにより、その投入口10が開閉自在に構成されている。即ち、収容容器1の投入口10の外周縁にはリング状のシール部6が設けられており、図3及び図4に示すように、蓋部開閉用アクチュエータ4により蓋部7を下方に位置させて蓋部7の下面がシール部6に密着すれば、投入口10は気密状態で閉鎖されることになる。また、図1及び図2に示すように、蓋部開閉用アクチュエータ4により蓋部7を上方に位置させて蓋部7の下面がシール部6から離間すれば、投入口10は開放されることになる。

一方、収容容器1の払出口15は、収容容器1の底部に接続された管路として構成されており、その管路に設けられた払出口開閉弁16が開閉動作することにより、開閉自在に構成されている。

The

On the other hand, the

蓋部7には、収容容器1内の空気を吸引する吸引手段としての吸引ポンプ11と、収容容器1内へ空気を圧送する送付手段としての押込みポンプ12とが接続されている。

即ち、投入口10を蓋部7で閉鎖した状態において、図3に示すように、吸引ポンプ11を作動させれば、収容容器1内の空気を吸引して外部へ排出することができ、一方、図4に示すように、押込みポンプ12を作動させれば外部の空気を収容容器1内へ圧送することができる。

Connected to the lid 7 are a

That is, when the

蓋部7には、収容容器1内においてフィルター部2上面に沿って撹拌翼5cを回転可能な撹拌手段5が設けられている。

撹拌手段5は、蓋部7の中心に固定された撹拌用モータ5aと、その撹拌用モータ5aにより回転駆動されて有底円筒状のフィルター部2と同軸上に配置された回転軸5bと、その回転軸5bから放射状に設けられた撹拌翼5cとを備える。

そして、投入口10を蓋部7で閉鎖した状態において、図3及び図4に示すように、撹拌用モータ5aを作動させると、撹拌翼5cが回転軸5bを中心にフィルター部2上面に沿って回転することになる。

The lid portion 7 is provided with stirring means 5 capable of rotating the

The stirring means 5 includes a stirring

When the stirring

蓋部7の下面には、フィルター部2を振動可能な振動手段として、超音波振動子8が設けられている。

即ち、超音波振動子8は、投入口10を蓋部7で閉鎖した状態においてフィルター部2の上方外周縁に接触する位置に配置されており、その状態で作動することで、フィルター部2に対して機械的な振動を付加して、フィルター部2を振動させることができる。

An

That is, the

更に、この水出しコーヒー製造装置には、運転を制御する運転制御手段として、コンピュータからなる制御部20が設けられている。

そして、この制御部20は、吸引ポンプ11、押込みポンプ12、撹拌用モータ5a、蓋部開閉用アクチュエータ4、払出口開閉弁16の作動を制御することで、後述する材料投入処理、抽出処理、及び、払出処理を実行し、水出しコーヒーとなるコーヒー抽出液CWを製造することができる。

以下、この制御部20により実行される処理フローの詳細について説明する。

Further, the water-de-coffee making apparatus is provided with a

And this

The details of the processing flow executed by the

制御部20により実行される材料投入処理では、図1及び図2に示すように、蓋部開閉用アクチュエータ4により蓋部7が上方位置に上昇されて、収容容器1の投入口10が開放され、一方、払出口開閉弁16が閉状態とされて収容容器1の払出口15が閉鎖される。

この状態で、図1に示すように、投入口10から収容容器1内にコーヒー粉末CPが投入されて、そのコーヒー粉末CPがフィルター部2の上面に堆積し、続いて、図2に示すように、投入口10から収容容器1内に常温水Wが投入されて、その常温水Wが収容容器1内に貯留することになる。

In the material charging process executed by the

In this state, as shown in FIG. 1, the coffee powder CP is charged into the

続いて、制御部20により実行される抽出処理では、図3に示すように、先ず、蓋部開閉用アクチュエータ4により蓋部7が下方位置に降下されて、収容容器1の投入口10が閉鎖され、一方、払出口開閉弁16はそのまま閉状態に維持されて収容容器1の払出口15が閉鎖されたままとなり、結果、収容容器1内は気密に維持された状態となる。そして、吸引ポンプ11の作動が開始されて、収容容器1内から空気が吸引されて外部に排出されることで、収容容器1内が減圧される。すると、収容容器1内に貯留されている常温水Wの溶存空気が好適に除去されると共に、コーヒー粉末CPの粒子に形成された空隙から空気が好適に除去されるので、常温水Wのコーヒー粉末CPの浸透が促進される。よって、常温水Wに対してコーヒー粉末CPからコーヒー成分が良好に抽出され、コーヒー成分が十分に抽出されたコーヒー抽出液CWが短時間で生成されることになる。

Subsequently, in the extraction process executed by the

また、この抽出処理では、撹拌用モータ5aの作動が開始されて、収容容器1内に対流が発生される。すると、収容容器1内のフィルター部2の上方においてコーヒー粉末CPと常温水Wとの接触が促進されて、コーヒー粉末CPから常温水Wへのコーヒー成分の抽出が一層促進されることになり、更には、フィルター部2の上面においてコーヒー粉末CPが液相と共に対流するので、コーヒー粉末CPのフィルター部2への目詰まりが抑制される。

更に、この抽出処理では、超音波振動子8の作動が開始されて、フィルター部2が振動される。すると、コーヒー粉末CPのフィルター部2への目詰まりが一層抑制されることになる。

Further, in this extraction process, the operation of the stirring

Furthermore, in this extraction process, the operation of the

続いて、制御部20により実行される払出処理では、図4に示すように、吸引ポンプ11の作動が停止されて、収容容器1内の圧力が大気圧程度に上昇した状態で、蓋部開閉用アクチュエータ4により蓋部7が下方位置に維持されて、収容容器1の投入口10が閉鎖されたまま、払出口開閉弁16が開状態に切り換えられて、収容容器1の払出口15が開放される。すると、払出口15からコーヒー抽出液CWが下方に設けた受け容器(図示省略)に払い出されることになる。

また、この払出処理では、押込みポンプ12の作動が開始されて、外部から収容容器1内へ空気が強制的に圧送されることで、収容容器1内が昇圧される。すると、収容容器1内の液面に係る圧力が増加して、コーヒー粉末CPによる目詰まりが発生するフィルター部2に対するコーヒー抽出液CWの通過が促進されて、コーヒー抽出液CWの払出口15からの払い出しが迅速に行われることになる。

更に、この払出処理でも、撹拌用モータ5aの作動が継続されて、収容容器1内に対流が発生される。すると、フィルター部2の上面においてコーヒー粉末CPの対流が維持された状態となってコーヒー粉末CPのフィルター部2への目詰まりが抑制されるので、結果、フィルター部2に対するコーヒー抽出液CWの通過が一層促進されて、コーヒー抽出液CWの払出口15からの払い出しが一層迅速に行われることになる。

更に、この払出処理でも、超音波振動子8の作動が継続されて、フィルター部2が振動される。すると、コーヒー粉末CPのフィルター部2への目詰まりが一層抑制されるので、結果、コーヒー抽出液CWの払出口15からの払い出しが一層迅速に行われることになる。

Subsequently, in the payout process executed by the

Further, in this dispensing process, the operation of the

Further, even in this payout process, the operation of the stirring

Further, in this payout process, the operation of the

〔その他の実施形態〕

最後に、本発明のその他の実施形態について説明する。尚、以下に説明する各実施形態の構成は、それぞれ単独で適用されるものに限られず、矛盾が生じない限り、他の実施形態の構成と組み合わせて適用することも可能である。

(1)上記実施形態では、払出処理において、圧送手段としての押込みポンプ12を作動させて、収容容器1内を昇圧させて、払出口15からのコーヒー抽出液CWの払出を迅速に行うように構成したが、自然落下によりコーヒー抽出液CWを払い出す場合には、圧送手段としての押込みポンプ12により昇圧する構成を省略しても構わない。

[Other Embodiments]

Finally, other embodiments of the present invention will be described. Note that the configuration of each embodiment described below is not limited to being applied independently, and can be applied in combination with the configuration of other embodiments as long as no contradiction arises.

(1) In the above embodiment, in the dispensing process, the pushing

(2)上記実施形態では、抽出処理及び払出処理において撹拌手段5を作動させる構成を採用したが、別に、このコーヒー成分の抽出促進を行うべく抽出処理でのみ撹拌手段5を作動させたり、当該撹拌手段5を省略しても構わない。 (2) In the above embodiment, the configuration in which the agitation means 5 is activated in the extraction process and the dispensing process is adopted, but separately, the agitation means 5 is activated only in the extraction process to promote the extraction of the coffee component, The stirring means 5 may be omitted.

(3)上記実施形態では、抽出処理及び払出処理において振動手段としての超音波振動子8を作動させる構成を採用したが、別に、抽出処理でのみ超音波振動子8を作動させたり、当該超音波振動子8を省略しても構わない。

(3) In the above-described embodiment, the configuration in which the

本発明は、[焙煎コーヒー豆を微粉砕してなるコーヒー粉末と常温水との混合液をフィルター部で濾過してコーヒー抽出液を得る水出しコーヒー製造装置として好適に利用可能である。 INDUSTRIAL APPLICABILITY The present invention can be suitably used as a drained coffee manufacturing apparatus that obtains a coffee extract by filtering a mixed solution of coffee powder obtained by pulverizing roasted coffee beans and normal temperature water through a filter unit.

1 :収容容器

2 :フィルター部

5 :撹拌手段

5c :撹拌翼

7 :蓋部

8 :超音波振動子(振動手段)

10 :投入口

11 :吸引ポンプ(吸引手段)

12 :押込みポンプ(圧送手段)

15 :払出口

16 :払出口開閉弁

20 :制御部(運転制御手段)

CP :コーヒー粉末

CW :コーヒー抽出液(水出しコーヒー)

MW :混合液

W :常温水

1: Container 2: Filter unit 5: Agitation means 5c: Agitation blade 7: Lid 8: Ultrasonic vibrator (vibration means)

10: Input port 11: Suction pump (suction means)

12: Pushing pump (pressure feeding means)

15: Discharge outlet 16: Discharge opening / closing valve 20: Control unit (operation control means)

CP: Coffee powder CW: Coffee extract (watered coffee)

MW: Mixed liquid W: Normal temperature water

Claims (6)

上部にコーヒー粉末と常温水とが投入される投入口が形成され、底部にコーヒー抽出液を払い出す払出口が形成された筒状の収容容器を備えると共に、前記フィルター部が、前記収容容器内に貯留する混合液に浸漬されて前記投入口と前記払出口とを区画する姿勢で配置され、且つ、

前記投入口及び前記払出口が開閉自在に構成され、

前記収容容器内の空気を吸引する吸引手段と、

運転を制御する運転制御手段とを備え、

前記運転制御手段が、

前記投入口を開放すると共に前記払出口を閉鎖して、前記投入口を介して前記収容容器内へのコーヒー粉末と常温水の投入を受け付ける材料投入処理を実行し、

次に、前記投入口を開放した状態で、前記吸引手段を作動させて、前記収容容器内を減圧させる抽出処理を実行し、

次に、前記吸引手段を停止すると共に、前記払出口を開放する払出処理を実行する水出しコーヒー製造装置。 A water-depositing coffee production apparatus for obtaining a coffee extract by filtering a mixed liquid of coffee powder obtained by finely pulverizing roasted coffee beans and normal temperature water through a filter unit,

The container is provided with a cylindrical storage container in which a charging port for supplying coffee powder and normal temperature water is formed at the top, and a discharge outlet for discharging the coffee extract liquid is formed at the bottom. Placed in a posture so as to divide the inlet and the outlet by being immersed in the liquid mixture stored in

The inlet and the outlet are configured to be openable and closable,

Suction means for sucking air in the container;

An operation control means for controlling the operation,

The operation control means is

Opening the charging port and closing the outlet, performing a material charging process for receiving coffee powder and room temperature water into the container through the charging port,

Next, in a state where the charging port is opened, the suction means is operated to perform an extraction process for reducing the pressure inside the storage container,

Next, the draining coffee manufacturing apparatus that executes a dispensing process for stopping the suction means and opening the dispensing outlet.

前記運転制御手段が、前記払出処理において、前記圧送手段を作動させて、前記収容容器内を昇圧させる請求項1に記載の水出しコーヒー製造装置。 Comprising pressure feeding means for pumping air into the container;

The drained coffee manufacturing apparatus according to claim 1, wherein the operation control unit operates the pressure feeding unit to increase the pressure in the storage container in the dispensing process.

前記運転制御手段が、前記抽出処理において、前記撹拌手段を作動させる請求項1又は2に記載の水出しコーヒー製造装置。 A stirring means capable of rotating a stirring blade along the upper surface of the filter unit in the container,

The drained coffee manufacturing apparatus according to claim 1 or 2, wherein the operation control means activates the stirring means in the extraction process.

前記運転制御手段が、前記抽出処理において、前記振動手段を作動させる請求項1〜3の何れか1項に記載の水出しコーヒー製造装置。 Comprising vibration means capable of vibrating the filter section;

The drained coffee manufacturing apparatus according to any one of claims 1 to 3, wherein the operation control means activates the vibration means in the extraction process.

請求項1〜5の何れか1項に記載の水出しコーヒー製造装置で製造された水出しコーヒー。 It is a drained coffee obtained by filtering a mixed liquid of coffee powder obtained by finely pulverizing roasted coffee beans and normal temperature water through a filter unit, and obtaining a coffee extract.

The drained coffee manufactured with the drained coffee manufacturing apparatus of any one of Claims 1-5.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013213056A JP6207335B2 (en) | 2013-10-10 | 2013-10-10 | Watered coffee and watered coffee production equipment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013213056A JP6207335B2 (en) | 2013-10-10 | 2013-10-10 | Watered coffee and watered coffee production equipment |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015073794A true JP2015073794A (en) | 2015-04-20 |

| JP6207335B2 JP6207335B2 (en) | 2017-10-04 |

Family

ID=52999115

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013213056A Expired - Fee Related JP6207335B2 (en) | 2013-10-10 | 2013-10-10 | Watered coffee and watered coffee production equipment |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6207335B2 (en) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016207846A1 (en) * | 2015-06-24 | 2016-12-29 | Illycaffe' S.P.A. | Brew and dispenser device of a drink and brew method |

| WO2020100898A1 (en) * | 2018-11-13 | 2020-05-22 | サントリーホールディングス株式会社 | Coffee beverage packed in container, and method for producing same |

| US10667644B2 (en) | 2017-01-10 | 2020-06-02 | Haier Us Appliance Solutions, Inc. | Beverage dispenser with a water-resistant vacuum inlet |

| CN111317366A (en) * | 2020-04-27 | 2020-06-23 | 宁波研森电子科技有限公司 | Coffee brewing mechanism and method for making coffee by using same |

| WO2020125644A1 (en) * | 2018-12-19 | 2020-06-25 | 中山市领先电器有限公司 | Coffee cold brew apparatus and method for cold brewing coffee |

| CN111870126A (en) * | 2019-05-03 | 2020-11-03 | 纬创资通股份有限公司 | Extraction device and extraction method |

| JP2020182841A (en) * | 2019-05-03 | 2020-11-12 | 緯創資通股▲ふん▼有限公司Wistron Corporation | Extraction device and extraction method |

| CN112335763A (en) * | 2020-10-20 | 2021-02-09 | 苏州金猫咖啡有限公司 | Preparation method of cold-extracted coffee |

| KR20210110015A (en) * | 2020-02-28 | 2021-09-07 | 한재근 | Coffee extraction system with improved removal performance of foreign substances |

| WO2022098059A1 (en) * | 2020-11-03 | 2022-05-12 | 이강훈 | Coffee beverage brewing extraction method and apparatus using stirring force |

| KR20220099752A (en) * | 2021-01-07 | 2022-07-14 | 주식회사 알시넷 | Leaching method for manufacturing of ice brew coffee |

| JP2022174384A (en) * | 2021-05-11 | 2022-11-24 | 株式会社グリーンハウス | coffee maker |

| CN115777819A (en) * | 2022-11-22 | 2023-03-14 | 福州帅宝生物科技有限公司 | Production process of instant coffee |

| CN115886110A (en) * | 2022-11-21 | 2023-04-04 | 福州帅宝生物科技有限公司 | Coffee extraction process |

| WO2024016685A1 (en) * | 2022-07-19 | 2024-01-25 | 杭州西湖喷泉设备成套有限公司 | Intelligent cold brew coffee device |

| CN119280887A (en) * | 2024-12-16 | 2025-01-10 | 闽榕茶业有限公司 | Cold extraction equipment and cold extraction process of jasmine dew |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5060373A (en) * | 1973-10-01 | 1975-05-24 | ||

| JPS58198247A (en) * | 1982-05-13 | 1983-11-18 | Jietsuto Cafe Kk | Method and apparatus for extraction of coffee |

| JPS6427432A (en) * | 1987-05-07 | 1989-01-30 | Bentz & Sohn Melitta | Method and apparatus for producing aromatic extract from coffee |

| JPH06165640A (en) * | 1992-12-01 | 1994-06-14 | Nippon Sanso Kk | Method and device for producing cold coffee |

| JP2003225054A (en) * | 2001-11-29 | 2003-08-12 | Meiji Milk Prod Co Ltd | Method for extracting and / or squeezing edible food and drink |

| JP2006325662A (en) * | 2005-05-23 | 2006-12-07 | Sanden Corp | Beverage extractor and beverage extraction method |

| JP2008000040A (en) * | 2006-06-21 | 2008-01-10 | Union Coffee Roasters:Kk | Method for producing water drip coffee |

-

2013

- 2013-10-10 JP JP2013213056A patent/JP6207335B2/en not_active Expired - Fee Related

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5060373A (en) * | 1973-10-01 | 1975-05-24 | ||

| JPS58198247A (en) * | 1982-05-13 | 1983-11-18 | Jietsuto Cafe Kk | Method and apparatus for extraction of coffee |

| JPS6427432A (en) * | 1987-05-07 | 1989-01-30 | Bentz & Sohn Melitta | Method and apparatus for producing aromatic extract from coffee |

| JPH06165640A (en) * | 1992-12-01 | 1994-06-14 | Nippon Sanso Kk | Method and device for producing cold coffee |

| JP2003225054A (en) * | 2001-11-29 | 2003-08-12 | Meiji Milk Prod Co Ltd | Method for extracting and / or squeezing edible food and drink |

| JP2006325662A (en) * | 2005-05-23 | 2006-12-07 | Sanden Corp | Beverage extractor and beverage extraction method |

| JP2008000040A (en) * | 2006-06-21 | 2008-01-10 | Union Coffee Roasters:Kk | Method for producing water drip coffee |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016207846A1 (en) * | 2015-06-24 | 2016-12-29 | Illycaffe' S.P.A. | Brew and dispenser device of a drink and brew method |

| US10667644B2 (en) | 2017-01-10 | 2020-06-02 | Haier Us Appliance Solutions, Inc. | Beverage dispenser with a water-resistant vacuum inlet |

| WO2020100898A1 (en) * | 2018-11-13 | 2020-05-22 | サントリーホールディングス株式会社 | Coffee beverage packed in container, and method for producing same |

| WO2020125644A1 (en) * | 2018-12-19 | 2020-06-25 | 中山市领先电器有限公司 | Coffee cold brew apparatus and method for cold brewing coffee |

| US11730305B2 (en) | 2019-05-03 | 2023-08-22 | Wistron Corp. | Extraction device and extracting method |

| CN111870126A (en) * | 2019-05-03 | 2020-11-03 | 纬创资通股份有限公司 | Extraction device and extraction method |

| JP2020182841A (en) * | 2019-05-03 | 2020-11-12 | 緯創資通股▲ふん▼有限公司Wistron Corporation | Extraction device and extraction method |

| KR102345123B1 (en) * | 2020-02-28 | 2021-12-29 | 한재근 | Coffee extraction system with improved removal performance of foreign substances |

| KR20210110015A (en) * | 2020-02-28 | 2021-09-07 | 한재근 | Coffee extraction system with improved removal performance of foreign substances |

| WO2021217965A1 (en) * | 2020-04-27 | 2021-11-04 | 宁波研森电子科技有限公司 | Coffee brewing mechanism and method for making coffee by applying same |

| CN111317366A (en) * | 2020-04-27 | 2020-06-23 | 宁波研森电子科技有限公司 | Coffee brewing mechanism and method for making coffee by using same |

| CN112335763A (en) * | 2020-10-20 | 2021-02-09 | 苏州金猫咖啡有限公司 | Preparation method of cold-extracted coffee |

| CN116437840A (en) * | 2020-11-03 | 2023-07-14 | 李康勋 | Method and device for brewing and extracting coffee beverage using stirring force |

| WO2022098059A1 (en) * | 2020-11-03 | 2022-05-12 | 이강훈 | Coffee beverage brewing extraction method and apparatus using stirring force |

| KR102515492B1 (en) * | 2021-01-07 | 2023-03-29 | 주식회사 알시넷 | Leaching method for manufacturing of ice brew coffee |

| KR20220099752A (en) * | 2021-01-07 | 2022-07-14 | 주식회사 알시넷 | Leaching method for manufacturing of ice brew coffee |

| JP2022174384A (en) * | 2021-05-11 | 2022-11-24 | 株式会社グリーンハウス | coffee maker |

| WO2024016685A1 (en) * | 2022-07-19 | 2024-01-25 | 杭州西湖喷泉设备成套有限公司 | Intelligent cold brew coffee device |

| CN115886110A (en) * | 2022-11-21 | 2023-04-04 | 福州帅宝生物科技有限公司 | Coffee extraction process |

| CN115777819A (en) * | 2022-11-22 | 2023-03-14 | 福州帅宝生物科技有限公司 | Production process of instant coffee |

| CN119280887A (en) * | 2024-12-16 | 2025-01-10 | 闽榕茶业有限公司 | Cold extraction equipment and cold extraction process of jasmine dew |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6207335B2 (en) | 2017-10-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6207335B2 (en) | Watered coffee and watered coffee production equipment | |

| US10791869B2 (en) | System and method for automated coffee grind refinement | |

| CN208599840U (en) | A kind of Experiment of Inorganic Chemstry material grinding agitating device | |

| JP2010528635A5 (en) | ||

| CN113226125B (en) | Device for feeding coffee powder into brewing chamber of coffee machine | |

| CA2960907A1 (en) | Machine for brewing tea | |

| CN107650408B (en) | Cuber | |

| CN111315231A (en) | Coffee brewing device | |

| US20180153335A1 (en) | Beverage preparation apparatus | |

| JP6541419B2 (en) | Solid-liquid extraction device and solid-liquid extraction method | |

| KR101496342B1 (en) | Dutch coffee extraction apparatus | |

| KR101150040B1 (en) | A high viscosity rice fluid production device for a rice noodle manufacturing system and a method thereof | |

| JP2018089382A (en) | Device for removing chaff and fine particle of roasted and crushed coffee bean | |

| JP6482542B2 (en) | Integrated miniaturization device with mill function and blade shear function | |

| JP4334791B2 (en) | Powder filling apparatus and method | |

| US20220354295A1 (en) | System for brewing a liquid | |

| KR102788086B1 (en) | Apparatus manufacturing drip coffee and apparatus manufacturing powder coffee comprising the same | |

| JP2014132981A (en) | Beverage extraction device | |

| CN106578121B (en) | Method for refreshing brain in production of bean products | |

| KR101308902B1 (en) | Apparatus for fabricating food and beverage at low temperature and low pressure | |

| KR20250070311A (en) | Automatic manufacturing apparatus for jelly manufacturing and manufacturing method of jelly using the same | |

| JP2009066289A (en) | Beverage dispenser | |

| RU2566784C1 (en) | Production of viscoelastic mix and device to this end | |

| CN110367845A (en) | A kind of soy bean milk making machine | |

| JP7365606B2 (en) | beverage extraction equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160606 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170317 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170404 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170522 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170808 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170905 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6207335 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |