JP2015024876A - Drying and preservation facility - Google Patents

Drying and preservation facility Download PDFInfo

- Publication number

- JP2015024876A JP2015024876A JP2013153857A JP2013153857A JP2015024876A JP 2015024876 A JP2015024876 A JP 2015024876A JP 2013153857 A JP2013153857 A JP 2013153857A JP 2013153857 A JP2013153857 A JP 2013153857A JP 2015024876 A JP2015024876 A JP 2015024876A

- Authority

- JP

- Japan

- Prior art keywords

- warehouse

- storage

- drying

- dry

- long

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000001035 drying Methods 0.000 title claims abstract description 175

- 238000004321 preservation Methods 0.000 title claims abstract description 28

- 238000003860 storage Methods 0.000 claims abstract description 313

- 238000010981 drying operation Methods 0.000 claims abstract description 8

- 238000000034 method Methods 0.000 claims abstract description 6

- 230000007774 longterm Effects 0.000 claims description 63

- 238000003306 harvesting Methods 0.000 claims description 51

- 239000000463 material Substances 0.000 claims description 40

- 238000012546 transfer Methods 0.000 claims description 20

- 238000012545 processing Methods 0.000 abstract description 27

- 230000014759 maintenance of location Effects 0.000 abstract 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 36

- 238000005192 partition Methods 0.000 description 18

- 244000061456 Solanum tuberosum Species 0.000 description 8

- 235000002595 Solanum tuberosum Nutrition 0.000 description 8

- 239000003507 refrigerant Substances 0.000 description 8

- 238000004891 communication Methods 0.000 description 6

- 241000234282 Allium Species 0.000 description 5

- 235000002732 Allium cepa var. cepa Nutrition 0.000 description 5

- 238000004378 air conditioning Methods 0.000 description 4

- 238000001816 cooling Methods 0.000 description 4

- 235000012015 potatoes Nutrition 0.000 description 4

- 230000006866 deterioration Effects 0.000 description 3

- 238000009792 diffusion process Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 235000013305 food Nutrition 0.000 description 2

- 238000005057 refrigeration Methods 0.000 description 2

- 239000012141 concentrate Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000007726 management method Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 235000013372 meat Nutrition 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

Images

Landscapes

- Storage Of Harvested Produce (AREA)

- Warehouses Or Storage Devices (AREA)

Abstract

Description

本発明は、処理物を乾燥用温度にて乾燥させる乾燥装置を備えた乾燥倉庫と、乾燥後の処理物を前記乾燥用温度より低温の保存用温度にて保存する保存装置を備えた保存倉庫と、を有する乾燥保存設備に関する。 The present invention relates to a drying warehouse provided with a drying device for drying a processed product at a drying temperature, and a storage warehouse provided with a storage device for storing the dried processed product at a storage temperature lower than the drying temperature. And a dry storage facility.

このような、乾燥保存設備に関連する従来技術として、圃場で収穫されたジャガイモやタマネギ等の収穫物を乾燥させる乾燥倉庫を備えた乾燥設備が特許文献1に記載され、生鮮食品や化成品などを低温で冷蔵保存する冷蔵倉庫を備えた冷蔵設備が特許文献2に記載されている。このような設備の能力を向上させる場合、一般に、倉庫の大型化や複数化といったように設備規模を大きくすることで処理能力の向上が行われる。

As a conventional technique related to such a dry storage facility, a drying facility provided with a drying warehouse for drying a harvested product such as potato or onion harvested in a field is described in

ところで、特許文献1の乾燥倉庫や特許文献2の冷蔵倉庫は、処理物に対していずれも単独の処理を行う倉庫であるが、例えば、収穫されたジャガイモやタマネギを冷蔵保存する場合は、品質保持のために、冷蔵保存前に一旦余分な水分を乾燥させてから冷蔵保存するので、乾燥倉庫と冷蔵倉庫の2つの異なる機能の倉庫が必要となる。

上記のように乾燥機能と冷蔵保存機能の双方の機能を備えた乾燥保存設備を従来の乾燥倉庫や冷蔵倉庫を使って構成すると、それぞれの機能毎に倉庫を設けることになるため、乾燥保存設備が大型化することになる。特に、乾燥処理能力や冷蔵保存能力が高い乾燥保存設備を構成しようとした場合、乾燥倉庫と冷蔵倉庫のそれぞれの大型化や複数化により対応することになるため、設備の大型化の問題が顕著となる。

特に、ジャガイモやタマネギ等の自然栽培により収穫される収穫物を処理対象とする場合、収穫時期には大量の収穫物が集中して発生するため、小規模の乾燥倉庫では、処理が追いつかず、収穫物の品質が維持できない。そのため、収穫時期に備えて、一時に多くの収穫物を乾燥処理できるように、乾燥処理能力の高い乾燥保管設備が好ましい。

一方で、市場に対してジャガイモやタマネギ等の収穫物を収穫時期以外にも継続的に安定供給するためには、できるだけ多くの収穫物を保存しておくことが必要となる。そのため、処理物の安定供給の観点からは、保存能力の高い、規模の大きな乾燥保管設備が好ましい。

このように、収穫時期に必要となる高い乾燥処理能力と安定供給のために必要となる高い保存能力とを従来の乾燥倉庫や冷蔵倉庫を使って実現すると乾燥保管設備は大型化する。

By the way, the dry warehouse of

As described above, if a dry storage facility having both a drying function and a refrigerated storage function is configured using a conventional drying warehouse or refrigerated warehouse, a warehouse is provided for each function. Will become larger. In particular, when trying to construct a dry storage facility with high drying processing capacity and refrigerated storage capacity, the problem of increasing the size of the equipment is prominent because each of the drying warehouses and refrigerated warehouses will be dealt with by increasing the size and number of them. It becomes.

In particular, when harvesting harvested by natural cultivation, such as potatoes and onions, is the target of processing, a large amount of harvest is concentrated during the harvesting period. The quality of the harvest cannot be maintained. Therefore, a dry storage facility with a high drying processing capacity is preferable so that many harvested products can be dried at a time in preparation for the harvest time.

On the other hand, in order to continuously and stably supply harvests such as potatoes and onions other than the harvest time to the market, it is necessary to preserve as many harvests as possible. Therefore, from the viewpoint of stable supply of processed products, a large-scale dry storage facility with high storage capacity is preferable.

As described above, when a high drying capacity required for harvesting time and a high storage capacity required for stable supply are realized by using a conventional drying warehouse or refrigerated warehouse, the drying storage equipment becomes larger.

そこで、設備の大型化を回避しながら収穫物の乾燥処理能力及び保存能力の双方を高めることができる乾燥保管設備が望まれる。 Therefore, a dry storage facility that can increase both the drying processing capacity and the storage capacity of the harvested product while avoiding an increase in the size of the equipment is desired.

本発明に係る乾燥保管設備の特徴構成は、処理物を乾燥用温度にて乾燥させる乾燥装置を備えた乾燥倉庫と、乾燥後の処理物を前記乾燥用温度より低温の保存用温度にて保存する保存装置を備えた保存倉庫と、を有する乾燥保存設備であって、

前記乾燥倉庫の少なくとも一部は、前記保存装置を備えた乾燥保存兼用倉庫であり、前記乾燥保存兼用倉庫は、前記乾燥装置により処理物を乾燥させる乾燥運転と前記保存装置により処理物を保存する保存運転とに切り換え自在に構成されている点にある。

The characteristic configuration of the dry storage facility according to the present invention includes a drying warehouse equipped with a drying device for drying a processed product at a drying temperature, and storing the dried processed product at a storage temperature lower than the drying temperature. A dry storage facility having a storage warehouse with a storage device to perform,

At least a part of the drying warehouse is a dry storage combined warehouse equipped with the storage device, and the dry storage combined warehouse stores a processed product by a drying operation for drying the processed product by the drying device and the storage device. The point is that it can be switched to a storage operation.

この特徴構成によれば、乾燥倉庫において処理物を乾燥用温度にて乾燥させることで、処理物に付着あるいは含有される水分量を保存時に適した量まで乾燥させて、その後、保存倉庫において処理物を乾燥用温度より低温の保存用温度にて保存することができる。これにより処理物を良好な保存状態で保存することができる。

そして、乾燥倉庫にて乾燥させるべき処理物が多く発生した場合は、乾燥保存兼用倉庫を乾燥運転すれば、設備の乾燥処理能力を高くなるので、発生した処理物を比較的高能力で乾燥させることができる。一方、乾燥倉庫にて乾燥させるべき処理物の発生が少ない場合は、乾燥保存兼用倉庫を保存運転すれば、設備の保存能力が高くなるので、それまでに乾燥させた処理物が多くても、それらの処理物を適切に保存することができる。

そのため、収穫時期に集中するジャガイモ等の乾燥処理のように、乾燥処理の要求のピーク時期が存在するような場合には、その乾燥処理の要求のピーク時期には乾燥保存兼用倉庫を乾燥運転し、ピーク時期が過ぎたら乾燥保存兼用倉庫を保存運転することで、乾燥処理の要求のピーク時期に必要な乾燥倉庫の能力と、乾燥処理の要求のピーク時期が過ぎた後の保存要求に必要な保存倉庫の能力との双方を備えながらも、これらの能力に応じた乾燥倉庫と保存倉庫とのそれぞれを単純に設けた乾燥保存設備に比べて、乾燥保存兼用倉庫が同じスペースでも双方の機能を担っている分だけ、設備の大型化を抑制できる。

このように、設備の大型化を回避しながら収穫物の乾燥処理能力及び保存能力の双方を高めることができる。

According to this characteristic configuration, the amount of water adhering to or contained in the processed product is dried to an amount suitable for storage by drying the processed product in a drying warehouse at a drying temperature, and then processed in the storage warehouse. The product can be stored at a storage temperature lower than the drying temperature. Thereby, a processed material can be preserve | saved in a favorable preservation | save state.

And if there are many processed items to be dried in the drying warehouse, the drying processing capacity of the equipment will be increased if the drying storage warehouse is operated for drying, so that the generated processed products are dried with a relatively high capacity. be able to. On the other hand, if there is little occurrence of processed material to be dried in the dry warehouse, the storage capacity of the equipment will be increased if the dry storage combined warehouse is operated, so even if there are many processed products that have been dried so far, Those processed products can be appropriately stored.

For this reason, when there is a peak demand for drying treatment, such as drying processing for potatoes, etc., which concentrates on the harvesting season, the dry storage warehouse is operated for drying at the peak demand for the drying treatment. When the peak time has passed, the dry storage combined warehouse is stored and operated, so that the drying warehouse capacity required at the peak time of the drying process request and the storage request after the peak time of the drying process request have passed. Compared to a dry storage facility that simply has a dry warehouse and a storage warehouse according to these capacities, while having both of the capabilities of a storage warehouse, both functions can be performed even in the same storage space. The size of the equipment can be suppressed by the amount that it bears.

Thus, it is possible to increase both the drying processing capacity and the storage capacity of the harvested product while avoiding an increase in the size of the equipment.

ここで、前記処理物が、圃場から収穫された収穫物であり、前記保存用温度よりも低温の長期保存用温度にて保存する長期保存装置を備えた長期保存倉庫をさらに有し、前記長期保存倉庫は、前記保存倉庫にて前記乾燥用温度から前記保存用温度まで冷却された収穫物を前記長期保存用温度にて保存し、前記長期保存倉庫の少なくとも一部は、前記保存装置を備えた兼用保存倉庫であり、前記兼用保存倉庫は、前記保存装置により処理物を保存する保存運転と前記長期保存装置により処理物を長期保存する長期保存運転とに切り換え自在に構成されていると好適である。 Here, the processed product is a crop harvested from a field, and further includes a long-term storage warehouse including a long-term storage device for storing at a long-term storage temperature lower than the storage temperature. The storage warehouse stores the harvested product cooled from the drying temperature to the storage temperature at the storage warehouse at the long-term storage temperature, and at least a part of the long-term storage warehouse includes the storage device. It is preferable that the dual-purpose storage warehouse is configured to be switchable between a storage operation for storing the processed material by the storage device and a long-term storage operation for storing the processed material for a long time by the long-term storage device. It is.

この構成によれば、処理物が、圃場から収穫された例えばジャガイモやタマネギ等の収穫物であるので、長期間保存する場合には、収穫物の品質の劣化が極力進行しない状態で保存するのが好ましい。生鮮品を長期保存する場合、一般に氷温保存(摂氏0度付近での保存)が行われるが、収穫物の場合は、保存前に乾燥処理を行うので、収穫物が比較的高温になり、その状態からいきなり氷温保存すると、急激な温度変化が発生するため、収穫物にダメージを与えることになり、品質保持の面で問題がある。その点、上記構成によれば、乾燥処理後の収穫物は、長期保存倉庫にて保存される前に、保存倉庫にて一旦乾燥用温度から保存用温度まで冷却された後に、長期保存倉庫にて保存される。したがって、乾燥後の収穫物に発生する温度変化を緩やかにすることができるため、収穫物に与えるダメージを小さくできる。このように、収穫物の高品質保存が可能となる。

しかも、長期保存倉庫の一部を時期に応じて、上記のような収穫物の温度変化の緩和に必要となる保管倉庫として利用できるので、収穫時期の初期など、収穫物の備蓄量が比較的少ないときには使用することのない長期保存倉庫を有効に活用できるので、保存倉庫の設置数を抑制することができ、設備の大型化を回避できる。

したがって、設備の大型化を回避しながら収穫物の高品質保存が可能となる。

According to this configuration, since the processed product is a harvested product such as potato or onion harvested from the field, when the product is stored for a long period of time, it is stored in a state where deterioration of the quality of the product does not proceed as much as possible. Is preferred. When storing fresh products for a long period of time, ice temperature storage (storage near 0 degrees Celsius) is generally performed, but in the case of harvested products, the drying process is performed before storage, so the harvested products become relatively hot, If the ice temperature is suddenly preserved from that state, a sudden temperature change occurs, resulting in damage to the harvest, and there is a problem in terms of quality maintenance. In that respect, according to the above configuration, the harvested product after the drying treatment is once cooled in the storage warehouse from the drying temperature to the storage temperature before being stored in the long-term storage warehouse, and then stored in the long-term storage warehouse. Saved. Therefore, since the temperature change generated in the dried crop can be moderated, damage to the harvest can be reduced. In this way, high quality preservation of the harvest is possible.

Moreover, since a part of the long-term storage warehouse can be used as a storage warehouse that is necessary for alleviating the temperature change of the harvest as described above, the amount of harvest stored is relatively low, such as at the beginning of the harvest period. Since it is possible to effectively use a long-term storage warehouse that is not used when there are few, it is possible to suppress the number of storage warehouses installed and avoid an increase in the size of the equipment.

Therefore, it is possible to preserve the harvested product with high quality while avoiding the enlargement of the equipment.

また、前記保存倉庫は、前記保存装置による処理物の保存を行う場合は、前記乾燥倉庫により乾燥された処理物と、前記乾燥倉庫により乾燥される前の処理物とを、区分けされた異なる保管領域に保存すると好適である。 In addition, when storing the processed product by the storage device, the storage warehouse separates the processed product dried by the drying warehouse from the processed product before being dried by the drying warehouse. It is preferable to store in the area.

例えば、乾燥処理待ちの処理物と乾燥後の処理物を同じ保存倉庫に保管する場合に、乾燥前の処理物から発生する水蒸気が乾燥後の処理物の保管領域に拡散すると、せっかくの乾燥処理の効果が低下してしまい乾燥後の処理物の品質劣化に繋がるおそれがある。この点、この構成によれば、仕切体等を設けて区分けされた異なる保管領域を形成することで、これらの2つの保管領域の間で水蒸気の拡散を阻止して、2つの保管領域での湿度差があっても、2つの保管領域の間で湿度が平衡しないようにすることができる。つまり、乾燥前の処理物と乾燥後の処理物とを同じ保存倉庫に保存する場合に、乾燥後の処理物が乾燥前の処理物から発生する水蒸気の影響を極力受けないようにすることができる。したがって、保存倉庫の大規模化を回避しつつ処理物の品質保持を図ることができる。 For example, when the processed product waiting for drying processing and the processed product after drying are stored in the same storage warehouse, if water vapor generated from the processed product before drying diffuses into the storage area of the processed product after drying, the precious drying process is performed. This may reduce the quality of the processed product after drying. In this regard, according to this configuration, by forming different storage areas that are partitioned by providing a partition body or the like, diffusion of water vapor between these two storage areas is prevented, and the two storage areas Even if there is a difference in humidity, it is possible to prevent the humidity from being balanced between the two storage areas. In other words, when the processed product before drying and the processed product after drying are stored in the same storage warehouse, the processed product after drying should not be affected as much as possible by the water vapor generated from the processed product before drying. it can. Therefore, it is possible to maintain the quality of the processed product while avoiding the enlargement of the storage warehouse.

本発明に係る乾燥保存設備の更なる特徴構成は、前記乾燥倉庫、前記保存倉庫、及び、前記長期保存倉庫のそれぞれが、処理物を収納する収納棚に対する入出庫処理を行う搬送装置を備えた自動倉庫にて構成され、前記乾燥倉庫、前記保存倉庫、及び、前記長期保存倉庫のそれぞれについての前記搬送装置の相互間で処理物を搬送自在な連絡用搬送装置が設けられている点にある。 A further characteristic configuration of the dry storage facility according to the present invention includes a transport device that performs a loading / unloading process on a storage shelf in which each of the dry warehouse, the storage warehouse, and the long-term storage warehouse stores a processed product. It is constituted by an automatic warehouse, and is characterized in that there is provided a communication conveying device that can convey a processed material between the conveying devices for each of the drying warehouse, the storage warehouse, and the long-term storage warehouse. .

この特徴構成によれば、乾燥倉庫、保存倉庫、及び、長期保存倉庫のそれぞれにおいて搬送装置による入出庫作業が行われ、しかも、各倉庫で入出庫される処理物は、連絡用搬送装置により搬送されるので、処理物の乾燥・保存・長期保存といった一連の処理を実行するに当たり、作業者による処理物の搬送作業の負荷が軽減され、使い勝手のよい乾燥保存設備となる。 According to this feature configuration, the loading / unloading work is performed by the transfer device in each of the dry warehouse, the storage warehouse, and the long-term storage warehouse, and the processed material that is loaded / unloaded in each warehouse is transferred by the communication transfer device. Therefore, when performing a series of processes such as drying, storage, and long-term storage of the processed material, the load of the work transfer operation by the operator is reduced, and the dry storage facility is easy to use.

また、前記長期保存温度は、摂氏−0.5度〜摂氏0.5度の範囲で設定され、前記保存温度は、摂氏5度〜15度の範囲で設定されると好適である。 The long-term storage temperature is preferably set in a range of −0.5 degrees Celsius to 0.5 degrees Celsius, and the storage temperature is preferably set in a range of 5 degrees Celsius to 15 degrees Celsius.

この特徴構成によれば、収穫物の品質の劣化が極力進行しない氷温保存状態で収穫物を長期保存できる。しかも、乾燥後の収穫物を、摂氏5度〜15度の範囲で設定される保存温度にて馴染ませるため、乾燥後の収穫物に急激な温度変化が発生することを防止でき、収穫物に与えるダメージを小さくできる。したがって、処理物の品質を適切に維持できる。 According to this characteristic configuration, the harvest can be stored for a long period of time in an ice temperature storage state where deterioration of the quality of the harvest does not proceed as much as possible. Moreover, since the dried crop is acclimatized at a storage temperature set in the range of 5 to 15 degrees Celsius, it is possible to prevent a sudden temperature change from occurring in the dried crop. The damage done can be reduced. Therefore, the quality of the processed product can be appropriately maintained.

本発明に係る乾燥保存設備の実施形態を図面に基づいて説明する。 An embodiment of a dry storage facility according to the present invention will be described with reference to the drawings.

1.設備概略

本実施形態の乾燥保存設備100は,乾燥空調装置11(本発明の「乾燥装置」に相等)により処理物を乾燥させる乾燥倉庫A、低温空調装置12(本発明の「保存装置」に相当)により処理物を低温保存する保存倉庫B、及び、氷温空調装置13(本発明の「長期保存装置」に相当)により処理物を氷温保存する長期保存倉庫Cを備えている。乾燥保存設備100は,圃場で収穫された収穫物(例えば、ジャガイモ)が処理物として搬入されると、乾燥倉庫Aにおいて処理物の保存に適した水分含有状態になるまで乾燥用温度である約30℃の空調環境で所定の乾燥時間(例えば、約30時間)だけ乾燥させた後、保存倉庫Bにおいて低温に馴染むまで保存用温度である約10℃の空調環境で所定の予冷時間(例えば、約24時間)だけ冷蔵保存し、その後、長期保存倉庫Cにおいて保存用温度よりも低温の長期保存用温度である約0℃の空調環境で氷温保存する。なお、所定の乾燥時間は処理物の初期水分含有率と目標水分含有率とに基づいて設定される。

1. Outline of Equipment The

これにより、乾燥保存設備100は、氷温保存による鮮度維持効果だけでなく、氷温保存前に乾燥させることで保存に適した水分含有状態で氷温保存できる。しかも、乾燥処理後にいきなり氷温保存するのではなく、乾燥処理後に比較的高温となっている処理物を予冷期間だけ一旦冷蔵保存することで、乾燥後の急激な温度変化により処理物にストレスが生じることを回避し、処理物の品質保持を図っている。長期保存倉庫Cにおいて約0℃で氷温保存している処理物を出荷する場合は、処理物を長期保存倉庫Cから保存倉庫Bに移し替えて約10℃まで温度回復させ、その後、結露により処理物に付着した水分を乾燥倉庫Aにて約30℃で乾燥させた上で、図外の選別処理部による選別処理を経て出荷する。

As a result, the

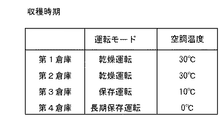

図1に示すように、乾燥保存設備100は、第1倉庫1から第4倉庫4までの4つの倉庫を備えている。第1倉庫1及び第2倉庫2は何れも、乾燥空調装置11及び低温空調装置12の双方を備えており、乾燥空調装置11を作動させて乾燥倉庫Aとしての運転(乾燥運転)と低温空調装置12を作動させて保存倉庫Bとしての運転(保存運転)とに切り換えて使用できる。つまり、乾燥倉庫Aとしての第1倉庫1及び第2倉庫2の何れもが、保存装置としての低温空調装置を備えた乾燥保存兼用倉庫となっている。

As shown in FIG. 1, the

第3倉庫は、低温空調装置12及び氷温空調装置13の双方を備えており、低温空調装置12を作動させて保存倉庫Bとしての運転(保存運転)と氷温空調装置13を作動させて長期保存倉庫Cとしての運転(保存運転)とに切り換えて使用できる。第4倉庫は、氷温空調装置13を備えており、氷温空調装置13を作動させて長期保存倉庫Cとしての運転(保存運転)だけが可能である。

つまり、長期保存倉庫Cとして第3倉庫3及び第4倉庫4の一部である第3倉庫3が、保存装置としての低温空調装置を備えた乾燥保存兼用倉庫となっている。

The third warehouse includes both the low

That is, the

乾燥保存設備100は、第1倉庫1及び第2倉庫2を乾燥保存兼用倉庫とし、第3倉庫3を乾燥保存兼用倉庫とし、これらの運転を適宜切り替えることで、収穫時期に大量に乾燥処理すべき処理物に対応できるだけの乾燥処理能力と、収穫時期に収穫される処理物を長期間に亘って出荷して、処理物を市場に安定的に供給できるだけの保存能力を備えている。以下、乾燥保存設備100の構成と運用について説明する。

The

2.設備構成

図1に示すように、乾燥保存設備100は、第1棟Z1と第2棟Z2とを備えており、これらは、渡り廊下Z3により連結されている。第1棟Z1には、第1倉庫1及び第2倉庫2が配設され、第2棟Z2には、第3倉庫3及び第4倉庫4が配設されている。このように、乾燥保存設備100では、複数の倉庫が複数の棟に分散配置されており、これにより棟毎に設備の管理ができるとともに、複数の倉庫を設置する際の、倉庫規模やレイアウトの選択の自由度を高めている。

2. Facility Configuration As shown in FIG. 1, the

第1棟Z1及び第2棟Z2の夫々は、外周部に配置された断熱性の区画壁5により外部と区画され、内部に配置された同じく断熱性の区画壁5により、空調管理単位の倉庫空間SSが2個形成されている。すなわち、第1棟Z1及び第2棟Z2において、合計4個の倉庫空間SSが形成されている。

そして、第1倉庫空間SS1に、第1倉庫1の収納棚1a及び搬送装置1bが設けられ、第1倉庫空間SS2に、第2倉庫2の収納棚2a及び搬送装置2bが設けられ、第1倉庫空間SS3に、第3倉庫3の収納棚3a及び搬送装置3bが設けられ、第1倉庫空間SS4に、第4倉庫4の収納棚4a及び搬送装置4bが設けられている。

Each of the first building Z1 and the second building Z2 is partitioned from the outside by a heat-insulating

In the first warehouse space SS1, the

各倉庫の収納棚1a〜4aは、処理物をパレット単位で収納する収納部6を上下左右に配列した棚を、搬送用通路を隔てて対向配置して構成されている。第1倉庫1〜第3倉庫3の収納棚1a〜3aは、1対の棚体で構成され、第4倉庫4の収納棚4aは、氷温保存容量の確保のため2対の棚体で構成されている。1つの収納部6は、少なくとも1つのパレットを載置支持自在に構成されている。処理物はメッシュ状の側面を有する樹脂製のコンテナに収容されており、複数のコンテナがパレット上に載置支持されている。収納部6としては、このようにパレットを載置支持自在なものに限らず、側壁を備えたボックスパレットを収納するものでもよい。この場合、処理物は、ボックスパレットに直接収容される。なお、収納部6としては、収納物の出し入れ方向に並ぶ状態で複数のパレット又はボックスパレット、或いはこれらの双方を収納自在に構成してもよい。

The

各倉庫の搬送装置1b〜4bは、処理物をパレット単位で搬送して収納棚1a〜4aに対する入出庫処理を行うスタッカークレーンにて構成される。スタッカークレーンは、搬送用通路を走行自在な走行台車と、走行台車に立設された昇降マストに沿って昇降自在な昇降台と、昇降台に設けられて出退式のフォーク装置とを備えている。第4倉庫4は、2対の棚体のそれぞれの搬送用空間に対して搬送装置4bが設けられている。

The transfer devices 1b to 4b in each warehouse are configured by stacker cranes that transfer processed objects in units of pallets and perform loading / unloading processing on the

第1棟Z1には第1荷捌き空間ST1が設けられ、第2棟Z2には第2荷捌き空間ST2が設けられている。第1荷捌き空間ST1は、第1倉庫空間SS1及び第2倉庫空間SS2と隣接しており、これらの倉庫空間SS1・SS2との連通部である入出庫用開口を開閉する自動シャッター8が設けられている。第2荷捌き空間ST2は、第3倉庫空間SS3及び第4倉庫空間SS4と隣接しており、これらの倉庫空間SS3・SS4との連通部である入出庫用開口を開閉する自動シャッター8が設けられている。

The first building Z1 is provided with a first handling space ST1, and the second building Z2 is provided with a second handling space ST2. The first unloading space ST1 is adjacent to the first warehouse space SS1 and the second warehouse space SS2, and an

第1荷捌き空間ST1及び第2荷捌き空間ST2は、渡り廊下Z3により連通しており、第1荷捌き空間ST1及び第2荷捌き空間ST2に亘って、連絡用搬送装置としての搬送台車9が設けられている。乾燥保存設備100で処理される処理物は、開閉扉を備えた搬出入口7から第1荷捌き空間ST1及び第2荷捌き空間ST2に搬出入される。

The first cargo handling space ST1 and the second cargo handling space ST2 are communicated with each other by a passage corridor Z3, and a

搬送台車9は、各倉庫の搬送装置1b〜4bについて設けられた入庫コンベヤ10a及び出庫コンベヤ10bや、荷捌き箇所に設けられた搬出入コンベヤを経由するように設定された直線状の走行経路に沿って往復移動自在となっており、第1倉庫1〜第4倉庫4のそれぞれについての搬送装置1b〜4bと搬出入コンベヤ14との間、並びに搬送装置1b〜4bの相互間で入庫コンベヤ10a及び出庫コンベヤ10bを介して処理物を搬送する。

The

第1倉庫1は、乾燥空調装置11及び低温空調装置12を備えている。詳細な図示は省略するが、乾燥空調装置11は、第1棟Z1の外部に設けられた乾燥送風機及び第1倉庫空間SS1に接続された温風ダクト及び吸気ダクトを備えている。第1倉庫1の低温空調装置12は、第1倉庫空間SS1の天井部に設けられる図示しない複数の室内機と、これら複数の室内機のそれぞれに各別に冷媒を循環させる複数の冷媒供給管とを備えている。

The

乾燥空調装置11の温風ダクトは、複数に分岐して複数の収納部6に温風を供給する。吸気ダクトは、複数に分岐して収納部6の背面に設けられた吸気ファン6aに接続されている。乾燥空調装置11は、乾燥対象の処理物が収納された収納部6を通過した高湿空気を吸引し棟外に排出する。なお、乾燥空調装置11は、収納棚1aを複数のゾーンに分割して乾燥処理を管理しており、ゾーン別に乾燥空気の供給を制御して対応するゾーンに属する複数の収納部6についての各ファン6bの作動を制御するようになっている。

The hot air duct of the drying

本実施形態では、第1倉庫1の収納棚1aを構成する一対の棚体には、その前面を覆うシートカーテンが設けられている。シートカーテンは、処理物の入庫作業及び出庫作業を搬送装置1bにより行う際は、折り畳まれて搬送用空間の端部に退避され、乾燥処理を行う際には棚の前面の全体に展開される。シートカーテンには、展開状態において各収納部における処理物が存在する領域に対応する箇所に、多数の通気口が形成されており、収納部6の背面に設けられたファン6bの吸引作用により、棚全面側から高温乾燥空気が該複数の通気口を通過して乾燥対象の処理物に当たることで、処理物を効率的に乾燥させることができるようになっている。

In the present embodiment, a pair of shelves constituting the

第1倉庫1では、図外の指令操作部を作業者が設定指令操作することで、乾燥空調装置11及び低温空調装置12の何れかが選択的に作動する。乾燥運転指令が指令され、乾燥空調装置11が作動すると、乾燥用温度にて処理物を乾燥させる乾燥運転が実行され、保存運転指令が指令され、低温空調装置12が作動すると、乾燥用温度より低温の保存用温度にて処理物を保存する保存運転が実行される。

本実施形態では、第1倉庫1での乾燥温度は、摂氏25度〜35度の範囲で設定され、好ましくは、摂氏30度に設定される。第1倉庫1での保存温度は、摂氏5度〜15度の範囲で設定され、好ましくは、摂氏10度に設定される。

In the

In the present embodiment, the drying temperature in the

このように、第1倉庫1は、乾燥空調装置11及び低温空調装置12を備えた乾燥保存兼用倉庫であり、処理物を乾燥用温度にて乾燥させる乾燥空調装置11により処理物を乾燥させる乾燥運転と、乾燥用温度より低温の保存用温度にて保存する低温空調装置12により処理物を保存する保存運転とに切り換え自在に構成されている。第2倉庫2も第1倉庫1と同様に、乾燥空調装置11及び低温空調装置12を備えた乾燥保存兼用倉庫であり、乾燥運転と保存運転とに切り換え自在に構成されている。

As described above, the

第3倉庫3は、低温空調装置12及び氷温空調装置13を備えている。詳細な図示は省略するが、低温空調装置12は、第3倉庫空間SS3の天井部に設けられる図示しない複数の室内機と、これら複数の室内機のそれぞれに各別に冷媒を循環接続される複数の冷媒供給管とを備えている。氷温空調装置13も同様に、第3倉庫空間SS3の天井部に設けられる図示しない複数の室内機と、これら複数の室内機のそれぞれに各別に冷媒を循環接続される複数の冷媒供給管とを備えている。なお、低温空調装置12と氷温空調装置13との双方の機能を有する空調装置にて兼用してもよい。

The

第3倉庫3では、図外の指令操作部を作業者が設定指令操作することで、低温空調装置12及び氷温空調装置13の何れかが選択的に作動する。保存運転指令が指令され、低温空調装置12が作動すると、保存用温度にて処理物を保存する保存運転が実行され、長期保存運転指令が指令され、氷温空調装置13が作動すると、保存用温度よりも低温の長期保存用温度にて処理物を保存する長期保存運転が実行される。

本実施形態では、第3倉庫3での保存温度は、第1倉庫1及び第2倉庫2での保存温度と同様に、摂氏5度〜15度の範囲で設定され、好ましくは、摂氏10度に設定される。第3倉庫3での長期保存温度は、摂氏−0.5度〜摂氏0.5度の範囲で設定され、好ましくは、摂氏0度に設定される。

In the

In the present embodiment, the storage temperature in the

このように、第3倉庫3は、低温空調装置12及び氷温空調装置13を備えた兼用保存倉庫であり、処理物を保存用温度にて保存する低温空調装置12により、処理物を保存する保存運転と、処理物を保存用温度より低温の長期保存用温度にて保存する氷温空調装置13により、処理物を保存する長期保存運転とに切り換え自在に構成されている。

As described above, the

第3倉庫3の第3倉庫空間SS3は、収納棚3aにおける倉庫長手方向の中間位置に設けられた仕切体15により区分けされており、異なる2つの保管領域が隣接している。仕切体15は、収納棚3aを構成する一対の棚体の仕切箇所において夫々に床から天井まで閉鎖する仕切パネル15aと、当該仕切箇所において、搬送用通路を床から天井まで閉鎖する仕切扉15bとで構成されている。

The third warehouse space SS3 of the

第3倉庫3が保存運転される場合、第3倉庫空間SS3に形成される2つの保管領域

は、処理段階の異なる処理物を保存するように使い分けがされる。すなわち、第3倉庫空間SS3に形成される2つの保管領域のうち荷捌き空間ST2に近い側の領域は、乾燥保存設備100に搬入される処理物が乾燥倉庫Aでの乾燥処理能力を超えて、乾燥処理待ちの処理物が発生した場合に、乾燥処理前の処理物が保存される乾燥前保管領域となっている。一方、荷捌き空間ST2に遠い側の領域は、乾燥倉庫Aでの乾燥処理後の処理物が保存される乾燥前後保管領域となっている。

When the

このように、兼用保存倉庫である第3倉庫3は、低温空調装置12による処理物の保存を行う場合は、乾燥倉庫Aにより乾燥された処理物と、乾燥倉庫Aにより乾燥される前の収穫物とを、区分けされた異なる保管領域に保存する。ちなみに、本実施形態では、第3倉庫3に入庫される処理物は、当該処理物の処理進捗情報に基づき搬送装置3bにより自動的に2つの保管領域に振り分け入庫される。もちろん、入庫対象の処理物が該当する保管領域を、作業者が指定してもよい。

As described above, the

第3倉庫3が保存運転される場合、第3倉庫空間SS3には、乾燥処理待ちの処理物と乾燥後の処理物が保管されることになるが、その場合、乾燥前の処理物から発生する水蒸気が乾燥後の処理物の保管領域に拡散すると、せっかくの乾燥処理の効果が低下してしまい乾燥後の処理物の品質劣化に繋がるおそれがある。そこで、仕切体15を設けることにより乾燥前保管領域と乾燥前後保管領域との2つの保管領域の間で水蒸気の拡散を阻止して、当該2つの保管領域での湿度差があっても、当該2つの保管領域の間で湿度が平衡しないようにしている。

When the

なお、乾燥処理待ちの処理物の発生程度は、収穫時期での乾燥処理周期における処理物の発生量と、乾燥倉庫Aの収容能力によって異なるため、仕切体15の倉庫長手方向の設置位置は、収穫時期での乾燥処理周期における処理物の発生量と、乾燥倉庫Aの収容能力に基づいて決定するのが好ましい。

In addition, since the generation | occurrence | production degree of the processed material waiting for a drying process changes with the generation amount of the processed material in the drying process cycle in a harvest time, and the storage capacity of the drying warehouse A, the installation position of the

第4倉庫4は、氷温空調装置13を備えている。詳細な図示は省略するが、氷温空調装置13は、第4倉庫空間SS4の天井部に設けられる図示しない複数の室内機と、これら複数の室内機のそれぞれに各別に冷媒を循環接続される複数の冷媒供給管とを備えている。第4倉庫4では、図外の指令操作部を作業者が設定指令操作することで、氷温空調装置13が作動する。長期保存運転指令が指令され、氷温空調装置13が作動すると、保存用温度よりも低温の長期保存用温度にて処理物を保存する長期保存運転が実行される。

The

このように、第4倉庫4は、氷温空調装置13を備え、保存用温度より低温の長期保存用温度にて処理物を保存する長期保存運転とを行うように構成されている。本実施形態では、第4倉庫4での長期用保存温度は、第3倉庫3での長期保存温度と同様に、摂氏−0.5度〜摂氏0.5度の範囲で設定され、好ましくは、摂氏0度に設定される。

Thus, the

5.設備運用

乾燥保存設備100は、時期によって乾燥保存兼用倉庫である第2倉庫と、兼用保存倉庫である第3倉庫の運転モードを切り換えて、乾燥処理対象の処理物の物量変動や、氷温保管対象の処理物の物量変動に対応している。

5. Facility operation The

まず、処理物である収穫物の収穫時期(例えば、6月〜7月)における乾燥保存設備100の運用について説明する。収穫時期は、生産者から処理物乾燥保存設備100に次々に持ち込まれる収穫物を次々に乾燥処理する必要がある。そこで、収穫時期は、図6に示すように、乾燥保存兼用倉庫の第1倉庫1及び第2倉庫2の双方を乾燥モードにて運転し、図2に示すように、第1倉庫1及び第2倉庫2の両倉庫を乾燥倉庫Aとする。第1倉庫1及び第2倉庫2で乾燥処理後の収穫物は、低温に馴染むませるため、第3倉庫3で保存用温度にて一時的に保存される。したがって、第3倉庫3は、図6に示すように、保存モードにて運転される。

First, the operation of the

本実施形態では、第3倉庫3が保存モードにて運転される場合は、仕切体15によって区切られる2つの保管領域の夫々に乾燥前の収穫物と乾燥後の収穫物とを振り分けて保管するため、仕切体15における一対の仕切扉15bは通常時は閉じられている。これにより両保管領域の間で水蒸気の移動が阻止される。なお、搬送装置3bであるスタッカークレーンが乾燥後処理物の入出庫のために倉庫奥側(荷捌き空間Z2から遠い方)の保管領域まで走行するときは、一対の仕切扉15bが開き状態(図3参照)に自動的に切り換わって、仕切箇所におけるスタッカークレーンの走行が許容される。

In the present embodiment, when the

次に、処理物であるジャガイモの収穫後の時期(例えば、8月〜3月)における乾燥保存設備100の運用について説明する。収穫後の時期は、生産者から処理物乾燥保存設備100に処理物が持ち込まれなくなるので、収穫物の乾燥処理は後述するように出荷対象の処理物を乾燥処理すれば済むことになり、乾燥保存設備100の乾燥処理能力を落とすことができる。そこで、収穫後の時期は、図7に示すように、乾燥保存兼用倉庫のうち第1倉庫1のみを乾燥モードにて運転し、第2倉庫2は保存運転モードにて運転する。これにより、図3に示すように、第1倉庫1が乾燥倉庫Aとなり、第2倉庫が保存倉庫Bとなる。収穫後の時期のうち、収穫時期直後は、収穫時期に収穫された処理物の備蓄量が最も多くなるため、これらの処理物を氷温保存するべく、長期保存倉庫Cの容量を極力大きくする。したがって、第3倉庫3は、図7に示すように、長期保存モードにて運転される。

Next, the operation of the

本実施形態では、第3倉庫3が長期保存モードにて運転される場合は、仕切体15における一対の仕切扉15bは図7に示すように、常時開き状態としているが、保存モードにて運転される場合と同様に、通常時は閉じ状態とし、搬送装置3bのスタッカークレーンが通過する必要がある場合に一時的に開き状態に自動的に切り換えるようにしてもよい。

In the present embodiment, when the

以下、収穫時期と収穫後の時期における処理物の処理内容について、図4及び図5に基づき説明する。 Hereinafter, the processing content of the processed material in the harvest time and the time after harvest will be described with reference to FIGS. 4 and 5.

収穫時期は、前述のとおり、図4に示すように、第1倉庫1及び第2倉庫2が乾燥運転され双方が乾燥倉庫Aとなっており、第3倉庫3が保存運転され保存倉庫Bとなっており、第4倉庫4が長期保存運転され長期保存倉庫Cとなっている。図4の矢印S1〜S3は搬入された収穫物の動きを示しており、具体的には、搬送台車9と各倉庫の搬送装置1b〜4bにより処理される。

As described above, as shown in FIG. 4, the harvesting time is such that the

収穫物が搬入されると、乾燥倉庫Aが乾燥対象の収穫物が受入れ可能であれば、収穫物は乾燥倉庫Aに入庫され(矢印S1及びS1m)乾燥処理が行われる。既に乾燥倉庫Aに入庫されている先行する収穫物の乾燥処理により乾燥倉庫Aの受入れ可能容量が低下していて、今回搬入された収穫物の一部又は全部を受入れ不可の場合は、その受入れ不可の収穫物は、一旦保存倉庫Bの乾燥前保管領域に入庫され(矢印S1及びS1s)、乾燥倉庫Aに空きができるまで低温保存され、乾燥倉庫Aに空きができれば、保存倉庫Bの乾燥前保管領域から出庫され、乾燥倉庫Aに入庫される(矢印S1及びS1m)。これにより、乾燥処理待ちの期間に品質が劣化することが極力防止できる。 When the harvest is carried in, if the drying warehouse A can accept the harvest to be dried, the harvest is received in the drying warehouse A (arrows S1 and S1m) and the drying process is performed. If the available capacity of the dry warehouse A has decreased due to the drying process of the preceding harvest that has already been received in the dry warehouse A, and if some or all of the harvest that has been carried in this time cannot be accepted, accept it Unacceptable crops are temporarily stored in the storage area before storage in storage warehouse B (arrows S1 and S1s) and stored at low temperature until there is an empty space in drying warehouse A. The goods are taken out from the previous storage area and are put into the dry warehouse A (arrows S1 and S1m). Thereby, it can prevent as much as possible that quality deteriorates during the period of waiting for a drying process.

乾燥倉庫Aでの乾燥処理が完了すると、乾燥倉庫Aから出庫され、保存倉庫Bの乾燥後保管領域に入庫される(矢印S2)。保存倉庫Bで予冷期間だけ保存することにより保存用温度に馴染ませ後、保存倉庫Bから出庫して長期保存倉庫Cに入庫する(矢印S3)。収穫時期であっても、出荷は行われるが、その場合、長期保存倉庫Cから出庫した収穫物を出荷しても良いが、乾燥倉庫Aから出庫した収穫物をそのまま、又は、保存倉庫Bの乾燥後保管領域から収穫物を出庫してそのまま、出荷用の収穫物としてもよい。 When the drying process in the drying warehouse A is completed, the cargo is discharged from the drying warehouse A and is stored in the storage area after drying in the storage warehouse B (arrow S2). After storing in the storage warehouse B only for the pre-cooling period, the storage warehouse B gets used to the storage temperature, and then leaves the storage warehouse B and enters the long-term storage warehouse C (arrow S3). Although the shipment is carried out even at the harvest time, the harvested product from the long-term storage warehouse C may be shipped, but the harvested product from the dry warehouse A is used as it is or in the storage warehouse B. The harvested product may be taken out from the storage area after drying and used as a harvested product for shipping.

出荷時期は、前述のとおり、図5に示すように、第1倉庫1が乾燥運転され乾燥倉庫Aとなっており、第2倉庫2が保存運転され保存倉庫Bとなっており、第3倉庫3及び第4倉庫4の双方が長期保存運転され長期保存倉庫Cとなっている。そして、出荷要求に応じた量の収穫物が、長期保存倉庫Cから出庫され、氷温保存で0度に冷えている収穫物をいきなり乾燥倉庫Aで乾燥用温度に温めるのではなく、一旦保存倉庫Bに入庫して(矢印R1)、保存用温度に馴染ませる。保存倉庫Bにて出荷用予冷期間だけ保存したら、保存倉庫Bから出庫して、結露を除去するために、乾燥倉庫Aに入庫する(矢印R2)。乾燥倉庫Aに入庫後、出荷用乾燥期間が経過したら、当該収穫物が乾燥倉庫Aから出庫されて(矢印R3)、出荷される。

As described above, the shipping time is as follows. As shown in FIG. 5, the

〔その他の実施形態〕

最後に、本発明のその他の実施形態について説明する。なお、以下に説明する各実施形態の構成は、それぞれ単独で適用されるものに限られず、矛盾が生じない限り、他の実施形態の構成と組み合わせて適用することも可能である。

[Other Embodiments]

Finally, other embodiments of the present invention will be described. Note that the configuration of each embodiment described below is not limited to being applied independently, and can be applied in combination with the configuration of other embodiments as long as no contradiction arises.

(1)上記実施形態では、処理物が、圃場から収穫された収穫物であるものを例示したが、処理物としては、食肉等の他の食材でもよく、また、乾燥及び冷蔵保存を要する対象であれば、食材に限らず工業生産品等でもよい。 (1) In the above embodiment, the processed product is exemplified as a harvested product harvested from the field. However, the processed product may be other ingredients such as meat, and also needs to be dried and refrigerated. As long as it is not limited to food, it may be an industrial product.

(2)上記実施形態では、乾燥倉庫、保存倉庫、長期保存倉庫の全てが搬送装置を備えた構成を例示したが、これらの倉庫のうちの何れか又は全てが搬送装置を備えなくてもよい。例えば、乾燥倉庫だけに搬送装置を備える、又は、乾燥倉庫及び保存倉庫に搬送装置を備える等、どの倉庫を自動倉庫にて構成するかは適宜選択できる。なお、搬送装置を備えない倉庫についての入庫作業及び出庫作業は、作業者が運転するフォークリフト等の荷役装置を用いることになる。 (2) In the embodiment described above, the dry warehouse, the storage warehouse, and the long-term storage warehouse are all provided with the transport device. However, any or all of these warehouses may not include the transport device. . For example, it is possible to appropriately select which warehouse is configured in the automatic warehouse, such as including a transport device only in a dry warehouse, or including a transport device in a dry warehouse and a storage warehouse. In addition, a loading / unloading operation for a warehouse that does not include a transfer device uses a cargo handling device such as a forklift that is operated by an operator.

(3)上記実施形態では、複数の倉庫が複数の棟に分散配置されたものを例示したが、一つの建屋に集約配置してもよい。 (3) In the above-described embodiment, an example in which a plurality of warehouses are distributed and arranged in a plurality of ridges is illustrated, but they may be collectively arranged in one building.

(4)上記実施形態では、連絡用搬送装置が、直線状の搬送経路に沿って走行自在な搬送台車にて構成されたものを例示したが、環状の搬送経路に沿って走行自在な搬送台車にて構成してもよい。また、搬送台車ではなく、ローラコンベアやベルトコンベヤにて連絡用搬送装置を構成してもよい。 (4) In the above-described embodiment, the communication transport device is exemplified by the transport cart that can travel along the linear transport path. However, the transport cart that can travel along the annular transport path. You may comprise. Moreover, you may comprise the conveying apparatus for connection not with a conveyance trolley but with a roller conveyor or a belt conveyor.

(5)上記実施形態では、乾燥保存兼用倉庫である第1倉庫1及び第2倉庫のうち、第2倉庫の運転モードを、時期によって乾燥運転と保存運転とに切り換えるものを例示したが、乾燥保存兼用倉庫である第1倉庫1及び第2倉庫の双方の運転モードを乾燥運転と保存運転とに切り換えてもよい。

(5) In the above embodiment, the

(6)上記実施形態では、乾燥倉庫及び保存倉庫に加え、長期保存倉庫をさらに備えている乾燥保存設備を例示したが、長期保存倉庫を備えずに、乾燥倉庫及び保存倉庫を備えた乾燥保存設備であってもよい。 (6) In the above embodiment, the dry storage facility further provided with the long-term storage warehouse in addition to the dry warehouse and the storage warehouse is illustrated, but the dry storage with the dry warehouse and the storage warehouse is provided without the long-term storage warehouse. It may be equipment.

(7)上記実施形態では、兼用保存倉庫は、保存装置による処理物の保存を行う場合は、乾燥倉庫により乾燥された処理物と、乾燥倉庫により乾燥される前の処理物とを、区分けされた異なる保管領域に保存するものを例示したが、兼用保存倉庫が異なる保管領域に区分けされず、単一の保管領域にて専ら乾燥倉庫により乾燥された処理物を保存するように構成されたものでもよい。この場合、乾燥倉庫により乾燥される前の処理物を保存する低温倉庫を別途設けてもよいし、設けなくてもよい。 (7) In the above embodiment, the combined storage warehouse separates the processed product dried by the drying warehouse and the processed product before being dried by the drying warehouse when storing the processed product by the storage device. However, the dual-purpose storage warehouse is not divided into different storage areas, but is configured to store the processed material that has been dried exclusively by the dry warehouse in a single storage area. But you can. In this case, a low-temperature warehouse for storing the processed material before being dried by the drying warehouse may be provided separately, or may not be provided.

(8)上記実施形態では、出荷時期において乾燥保存兼用倉庫の全てを乾燥運転にするものを例示したが、出荷時期において乾燥保存兼用倉庫の一部だけを乾燥運転にし、残り乾燥保存兼用倉庫を保存運転にするものでもよい。 (8) In the above embodiment, the dry storage / commercial warehouse is all dry-dried at the shipping time, but only a part of the dry / storage warehouse is dry-dried at the shipping time, and the remaining dry / storage warehouse is used. It may be a storage operation.

1 乾燥倉庫・乾燥保存兼用倉庫

2 乾燥倉庫・乾燥保存兼用倉庫

3 保存倉庫・兼用保存倉庫

1a・2a・3a・4a 収納棚

1b・2b・3b・4b 搬送装置

9 連絡用搬送装置

11 乾燥装置

12 保存装置

13 長期保存装置

DESCRIPTION OF

Claims (5)

乾燥後の処理物を前記乾燥用温度より低温の保存用温度にて保存する保存装置を備えた保存倉庫と、を有する乾燥保存設備であって、

前記乾燥倉庫の少なくとも一部は、前記保存装置を備えた乾燥保存兼用倉庫であり、

前記乾燥保存兼用倉庫は、前記乾燥装置により処理物を乾燥させる乾燥運転と前記保存装置により処理物を保存する保存運転とに切り換え自在に構成されている乾燥保存設備。 A drying warehouse equipped with a drying device for drying the processed material at a drying temperature;

A storage warehouse equipped with a storage device for storing the processed product after drying at a storage temperature lower than the drying temperature,

At least a part of the dry warehouse is a dry storage combined warehouse equipped with the storage device,

The dry storage warehouse is a dry storage facility configured to be switchable between a drying operation for drying a processed material by the drying device and a storage operation for storing the processed material by the storage device.

前記保存用温度よりも低温の長期保存用温度にて保存する長期保存装置を備えた長期保存倉庫をさらに有し、

前記長期保存倉庫は、前記保存倉庫にて前記保存用温度で保存されていた収穫物を前記長期保存用温度にて保存し、

前記長期保存倉庫の少なくとも一部は、前記保存装置を備えた兼用保存倉庫であり、

前記兼用保存倉庫は、前記保存装置により処理物を保存する保存運転と前記長期保存装置により処理物を長期保存する長期保存運転とに切り換え自在に構成されている請求項1に記載の乾燥保存設備。 The treated product is a harvested product from a farm;

A long-term storage warehouse equipped with a long-term storage device for storing at a temperature for long-term storage lower than the temperature for storage;

The long-term storage warehouse stores the harvest stored at the storage temperature in the storage warehouse at the long-term storage temperature,

At least a part of the long-term storage warehouse is a combined storage warehouse including the storage device,

2. The dry storage facility according to claim 1, wherein the combined storage warehouse is configured to be switchable between a storage operation for storing a processed product by the storage device and a long-term storage operation for storing the processed material for a long time by the long-term storage device. .

前記乾燥倉庫、前記保存倉庫、及び、前記長期保存倉庫のそれぞれについての前記搬送装置の相互間で処理物を搬送自在な連絡用搬送装置が設けられている請求項2又は3に記載の乾燥保存設備。 Each of the drying warehouse, the storage warehouse, and the long-term storage warehouse is configured by an automatic warehouse including a transfer device that performs a loading / unloading process with respect to a storage shelf that stores a processed product,

4. The dry storage according to claim 2, wherein a contact transfer device capable of transferring a processed material between the transfer devices for each of the dry warehouse, the storage warehouse, and the long-term storage warehouse is provided. Facility.

前記保存温度は、摂氏5度〜15度の範囲で設定される請求項2〜4の何れか1項に記載の乾燥保存設備。 The long-term storage temperature is set in a range of -0.5 degrees Celsius to 0.5 degrees Celsius,

The dry storage facility according to any one of claims 2 to 4, wherein the storage temperature is set in a range of 5 to 15 degrees Celsius.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013153857A JP2015024876A (en) | 2013-07-24 | 2013-07-24 | Drying and preservation facility |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013153857A JP2015024876A (en) | 2013-07-24 | 2013-07-24 | Drying and preservation facility |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015024876A true JP2015024876A (en) | 2015-02-05 |

| JP2015024876A5 JP2015024876A5 (en) | 2016-08-12 |

Family

ID=52489863

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013153857A Pending JP2015024876A (en) | 2013-07-24 | 2013-07-24 | Drying and preservation facility |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2015024876A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6152216B1 (en) * | 2016-12-27 | 2017-06-21 | 株式会社園田総合ホールディングス | Food storage method and food storage warehouse |

| JP2020005589A (en) * | 2018-07-10 | 2020-01-16 | 株式会社前川製作所 | Storage system and method of using storage system |

| JP2020065531A (en) * | 2018-10-22 | 2020-04-30 | 株式会社前川製作所 | Storage unit |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05118757A (en) * | 1991-10-30 | 1993-05-14 | Yanmar Agricult Equip Co Ltd | Crop storing facility |

| JPH0682120A (en) * | 1992-09-01 | 1994-03-22 | Kubota Corp | Drying storage method for agricultural and fishery product |

| JPH11187760A (en) * | 1997-12-26 | 1999-07-13 | Mitsubishi Agricult Mach Co Ltd | Assimilation of grain stored at low temperature and assimilating apparatus therefor |

| JP2002098420A (en) * | 2000-09-25 | 2002-04-05 | Gac Corp | Cooling device with drying function and cold insulation warehouse with drying function |

| JP2003061594A (en) * | 2001-08-28 | 2003-03-04 | Nagano Pref Gov Nouson Kogyo Kenkyusho | Rice with improved taste and method for improving the taste |

| JP2004166610A (en) * | 2002-11-20 | 2004-06-17 | Jinichi Fujiya | Method for preserving perishable food at low temperature and refrigerating apparatus |

| JP2007292378A (en) * | 2006-04-25 | 2007-11-08 | Fukushima Industries Corp | Low temperature storage |

| JP2009041887A (en) * | 2007-08-10 | 2009-02-26 | Satake Corp | Joint dry storage facility for grain |

| JP2010203674A (en) * | 2009-03-03 | 2010-09-16 | Fuji Plant Kk | Drying storage system |

| JP2011200259A (en) * | 2011-07-15 | 2011-10-13 | Iseki & Co Ltd | Grain housing facility |

-

2013

- 2013-07-24 JP JP2013153857A patent/JP2015024876A/en active Pending

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05118757A (en) * | 1991-10-30 | 1993-05-14 | Yanmar Agricult Equip Co Ltd | Crop storing facility |

| JPH0682120A (en) * | 1992-09-01 | 1994-03-22 | Kubota Corp | Drying storage method for agricultural and fishery product |

| JPH11187760A (en) * | 1997-12-26 | 1999-07-13 | Mitsubishi Agricult Mach Co Ltd | Assimilation of grain stored at low temperature and assimilating apparatus therefor |

| JP2002098420A (en) * | 2000-09-25 | 2002-04-05 | Gac Corp | Cooling device with drying function and cold insulation warehouse with drying function |

| JP2003061594A (en) * | 2001-08-28 | 2003-03-04 | Nagano Pref Gov Nouson Kogyo Kenkyusho | Rice with improved taste and method for improving the taste |

| JP2004166610A (en) * | 2002-11-20 | 2004-06-17 | Jinichi Fujiya | Method for preserving perishable food at low temperature and refrigerating apparatus |

| JP2007292378A (en) * | 2006-04-25 | 2007-11-08 | Fukushima Industries Corp | Low temperature storage |

| JP2009041887A (en) * | 2007-08-10 | 2009-02-26 | Satake Corp | Joint dry storage facility for grain |

| JP2010203674A (en) * | 2009-03-03 | 2010-09-16 | Fuji Plant Kk | Drying storage system |

| JP2011200259A (en) * | 2011-07-15 | 2011-10-13 | Iseki & Co Ltd | Grain housing facility |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6152216B1 (en) * | 2016-12-27 | 2017-06-21 | 株式会社園田総合ホールディングス | Food storage method and food storage warehouse |

| JP2020005589A (en) * | 2018-07-10 | 2020-01-16 | 株式会社前川製作所 | Storage system and method of using storage system |

| JP2020065531A (en) * | 2018-10-22 | 2020-04-30 | 株式会社前川製作所 | Storage unit |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2012056659A (en) | Automated storage and retrieval warehouse and container of the same | |

| US5054291A (en) | Multi-bay system for the forced air postharvest conditioning of agricultural crops | |

| JP2015024876A (en) | Drying and preservation facility | |

| EP2837293B1 (en) | Produce ripening chamber | |

| US20160107561A1 (en) | Storage racking system for cold chain logistics | |

| KR101866613B1 (en) | Container capable of air conditioning | |

| US3621672A (en) | Pressure cooling apparatus | |

| JP5725066B2 (en) | Automatic transfer system | |

| SE1450444A1 (en) | Freight storage arrangement in several floors | |

| JP3826708B2 (en) | Warehouse equipment | |

| JP2004299800A (en) | Low-temperature warehouse, and method for shipping material stored therein | |

| JP5983823B2 (en) | Automatic freezing warehouse | |

| JP4967255B2 (en) | Low temperature insecticidal method and low temperature insecticidal equipment | |

| CN112349020A (en) | Integrated refrigeration house for storing and selling by self | |

| JP2001315906A (en) | Thawing system | |

| JP3596656B2 (en) | Agriculture and marine products processing system | |

| CN105501782A (en) | Warehousing system equipment and application thereof | |

| JP3625641B2 (en) | Low temperature sorting system | |

| JP5910314B2 (en) | Automatic freezing warehouse | |

| JP3083611B2 (en) | Pre-cooling facility | |

| KR20230168432A (en) | Fulfillment center system | |

| KR102249429B1 (en) | Control apparatus and system of refrigerating/freezing and method thereof | |

| JP5169211B2 (en) | Grain rack shelf dryer | |

| Polvonov | MODERN VEGETABLE STORAGE TECHNOLOGIES | |

| JPH0641321B2 (en) | Logistics equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160621 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160621 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170327 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170404 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170605 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20171128 |