JP2014506113A - 可変状況で作動するアセンブリ - Google Patents

可変状況で作動するアセンブリ Download PDFInfo

- Publication number

- JP2014506113A JP2014506113A JP2013554043A JP2013554043A JP2014506113A JP 2014506113 A JP2014506113 A JP 2014506113A JP 2013554043 A JP2013554043 A JP 2013554043A JP 2013554043 A JP2013554043 A JP 2013554043A JP 2014506113 A JP2014506113 A JP 2014506113A

- Authority

- JP

- Japan

- Prior art keywords

- voltage

- assembly

- alternator

- power

- commutator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000001360 synchronised effect Effects 0.000 claims abstract description 20

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 24

- 238000004804 winding Methods 0.000 claims description 24

- 230000005284 excitation Effects 0.000 claims description 18

- 229910052742 iron Inorganic materials 0.000 claims description 12

- 230000000694 effects Effects 0.000 claims description 11

- 238000000034 method Methods 0.000 claims description 10

- 230000006870 function Effects 0.000 description 28

- 230000010363 phase shift Effects 0.000 description 15

- 238000010586 diagram Methods 0.000 description 14

- 238000011161 development Methods 0.000 description 10

- 238000005457 optimization Methods 0.000 description 7

- 230000007704 transition Effects 0.000 description 7

- 238000000926 separation method Methods 0.000 description 5

- 230000008901 benefit Effects 0.000 description 4

- 230000008859 change Effects 0.000 description 4

- 238000006243 chemical reaction Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000000712 assembly Effects 0.000 description 3

- 238000000429 assembly Methods 0.000 description 3

- 230000002457 bidirectional effect Effects 0.000 description 3

- 239000003990 capacitor Substances 0.000 description 3

- 230000008878 coupling Effects 0.000 description 3

- 238000010168 coupling process Methods 0.000 description 3

- 238000005859 coupling reaction Methods 0.000 description 3

- 230000007547 defect Effects 0.000 description 3

- 238000013459 approach Methods 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 2

- 210000000078 claw Anatomy 0.000 description 2

- 238000012937 correction Methods 0.000 description 2

- 238000013507 mapping Methods 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 241000555745 Sciuridae Species 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 108091008699 electroreceptors Proteins 0.000 description 1

- 239000000284 extract Substances 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000010248 power generation Methods 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 239000000523 sample Substances 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 230000009897 systematic effect Effects 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02P—CONTROL OR REGULATION OF ELECTRIC MOTORS, ELECTRIC GENERATORS OR DYNAMO-ELECTRIC CONVERTERS; CONTROLLING TRANSFORMERS, REACTORS OR CHOKE COILS

- H02P9/00—Arrangements for controlling electric generators for the purpose of obtaining a desired output

- H02P9/14—Arrangements for controlling electric generators for the purpose of obtaining a desired output by variation of field

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F03—MACHINES OR ENGINES FOR LIQUIDS; WIND, SPRING, OR WEIGHT MOTORS; PRODUCING MECHANICAL POWER OR A REACTIVE PROPULSIVE THRUST, NOT OTHERWISE PROVIDED FOR

- F03D—WIND MOTORS

- F03D7/00—Controlling wind motors

- F03D7/02—Controlling wind motors the wind motors having rotation axis substantially parallel to the air flow entering the rotor

- F03D7/04—Automatic control; Regulation

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K19/00—Synchronous motors or generators

- H02K19/16—Synchronous generators

- H02K19/26—Synchronous generators characterised by the arrangement of exciting windings

- H02K19/28—Synchronous generators characterised by the arrangement of exciting windings for self-excitation

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02P—CONTROL OR REGULATION OF ELECTRIC MOTORS, ELECTRIC GENERATORS OR DYNAMO-ELECTRIC CONVERTERS; CONTROLLING TRANSFORMERS, REACTORS OR CHOKE COILS

- H02P9/00—Arrangements for controlling electric generators for the purpose of obtaining a desired output

- H02P9/08—Control of generator circuit during starting or stopping of driving means, e.g. for initiating excitation

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02P—CONTROL OR REGULATION OF ELECTRIC MOTORS, ELECTRIC GENERATORS OR DYNAMO-ELECTRIC CONVERTERS; CONTROLLING TRANSFORMERS, REACTORS OR CHOKE COILS

- H02P9/00—Arrangements for controlling electric generators for the purpose of obtaining a desired output

- H02P9/14—Arrangements for controlling electric generators for the purpose of obtaining a desired output by variation of field

- H02P9/26—Arrangements for controlling electric generators for the purpose of obtaining a desired output by variation of field using discharge tubes or semiconductor devices

- H02P9/30—Arrangements for controlling electric generators for the purpose of obtaining a desired output by variation of field using discharge tubes or semiconductor devices using semiconductor devices

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02P—CONTROL OR REGULATION OF ELECTRIC MOTORS, ELECTRIC GENERATORS OR DYNAMO-ELECTRIC CONVERTERS; CONTROLLING TRANSFORMERS, REACTORS OR CHOKE COILS

- H02P9/00—Arrangements for controlling electric generators for the purpose of obtaining a desired output

- H02P9/14—Arrangements for controlling electric generators for the purpose of obtaining a desired output by variation of field

- H02P9/26—Arrangements for controlling electric generators for the purpose of obtaining a desired output by variation of field using discharge tubes or semiconductor devices

- H02P9/30—Arrangements for controlling electric generators for the purpose of obtaining a desired output by variation of field using discharge tubes or semiconductor devices using semiconductor devices

- H02P9/305—Arrangements for controlling electric generators for the purpose of obtaining a desired output by variation of field using discharge tubes or semiconductor devices using semiconductor devices controlling voltage

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02P—CONTROL OR REGULATION OF ELECTRIC MOTORS, ELECTRIC GENERATORS OR DYNAMO-ELECTRIC CONVERTERS; CONTROLLING TRANSFORMERS, REACTORS OR CHOKE COILS

- H02P9/00—Arrangements for controlling electric generators for the purpose of obtaining a desired output

- H02P9/48—Arrangements for obtaining a constant output value at varying speed of the generator, e.g. on vehicle

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K7/00—Arrangements for handling mechanical energy structurally associated with dynamo-electric machines, e.g. structural association with mechanical driving motors or auxiliary dynamo-electric machines

- H02K7/18—Structural association of electric generators with mechanical driving motors, e.g. with turbines

- H02K7/1807—Rotary generators

- H02K7/1823—Rotary generators structurally associated with turbines or similar engines

- H02K7/183—Rotary generators structurally associated with turbines or similar engines wherein the turbine is a wind turbine

- H02K7/1838—Generators mounted in a nacelle or similar structure of a horizontal axis wind turbine

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/70—Wind energy

- Y02E10/72—Wind turbines with rotation axis in wind direction

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Control Of Eletrric Generators (AREA)

Abstract

【選択図】 図1

Description

0:開

1:閉

ここで、T1、T2、及びT3は、図7に示すように、補足としてスイッチT4、T5、及びT6をそれぞれ有する3つのスイッチである。この行列MCは、実時間で制御則の関数として推移する。

従って、

従って、次式が得られる。

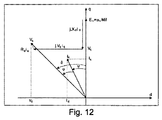

従って、電流Idを用いて内部位相シフト角φを調節することができる。

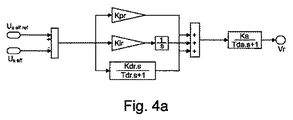

Kpr [0..1500]

Kir [0..200]

Kdr [0..12000]

Tdr [0..0.1]秒

Ka [0..100]

Tda [0..0.05]秒

ここで、

kfは、渦電流による損失に関する係数

kh:ヒステリシスによる損失に関する係数

w:電気角周波数

2 ブレード

6 機械シャフト

20 コンバータ

23 インバータ

Claims (16)

- 可変状況で、特に可変の速度、電力、又は力率で作動する電気機械アセンブリであって、

特に励磁機(11)を用いた電圧(Vf)を通じて又は分割リング及び整流子による直接励磁のDC電流が供給される巻線回転子(15)を有し、かつ出力電圧(US)を送出する1MWよりも大きいか又はそれに等しい電力の同期交流発電機(10)と、

前記交流発電機の前記出力電圧(US)を整流するための場合によってはパルス幅変調又はダイオードベースのものであって任意的にDC/DCコンバータが続く整流子(21)を含むコンバータ(20)と、

を含み、

前記巻線回転子に給電する前記供給電圧(Vf)は、前記交流発電機の前記出力電圧(US)に追従する、

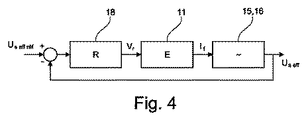

ことを特徴とするアセンブリ。 - 前記交流発電機の前記出力電圧(US)を事前設定値(Us eff ref)に維持するために前記電圧(Vf)に作用するように構成された調整器(18)を含むことを特徴とする請求項1に記載のアセンブリ。

- 前記基準電圧(Us eff ref)は、鉄損、渦電流による損失、ヒステリシスによる損失、前記回転子でのジュール効果を通じた損失、固定子でのジュール効果を通じた損失、前記コンバータでの伝導による損失、該コンバータでのスイッチングによる損失のリストからの損失のうちの少なくとも1つを最小にするように計算されることを特徴とする請求項2に記載のアセンブリ。

- 前記基準電圧Us eff refは、前記速度、前記電力、前記力率、前記機械の熱状態のうちの少なくとも1つに依存することを特徴とする請求項1から請求項3のいずれか1項に記載のアセンブリ。

- 前記基準電圧Us eff refは、アセンブリの前記作動中に実時間で計算されることを特徴とする請求項1から請求項4のいずれか1項に記載のアセンブリ。

- 前記基準電圧Us eff refは、アセンブリの前記作動の前に用途の関数として事前計算されることを特徴とする請求項1から請求項4のいずれか1項に記載のアセンブリ。

- 前記交流発電機は、励磁機(11)を含み、必要な励磁を該励磁機(11)内に発生させることを可能にする電圧(Vr)が、該交流発電機(10)によって供給される有効出力電圧(Us eff)に追従することを特徴とする請求項1から請求項6のいずれか1項に記載のアセンブリ。

- 前記巻線回転子(15)に給電するための少なくとも1つの分割リングと1つの整流子とを含むことを特徴とする請求項1から請求項6のいずれか1項に記載のアセンブリ。

- 前記整流子の出力電流が、DCバス(22)に給電することを特徴とする請求項1から請求項8のいずれか1項に記載のアセンブリ。

- 一定のバス電圧を維持するように前記整流子を制御するための調整器(25)を含むことを特徴とする請求項9に記載のアセンブリ。

- 前記交流発電機の前記出力電圧USを回転速度(回転毎分での)の関数として与える曲線が、該回転速度が公称速度に達した時に捩れを示すことを特徴とする請求項1から請求項10のいずれか1項に記載のアセンブリ。

- 前記交流発電機の前記出力電圧USを回転速度(回転毎分での)の関数として与える曲線が、公称速度よりも小さい回転速度に対して直線とは異なることを特徴とする請求項1から請求項11のいずれか1項に記載のアセンブリ。

- 前記出力電圧USは、公称速度よりも小さい回転速度に対して、該公称速度までの速度範囲の全体にわたって一定のU/fを用いた調整のフレームワーク内で調整電圧よりも低いことを特徴とする請求項1から請求項12のいずれか1項に記載のアセンブリ。

- 発電機、特に風力タービンであって、

請求項1から請求項13のいずれか1項に記載のもののようなアセンブリ、

を含むことを特徴とする発電機。 - 特に請求項1から請求項10のいずれか1項に記載のアセンブリを用いて特に風力ベースの機械エネルギを電気エネルギに変換する方法であって、

巻線回転子(15)を有する同期交流発電機(10)の回転子が、該交流発電機の出力電圧(US)に追従する電圧(Vf)でDC電流を供給される、

ことを特徴とする方法。 - 前記交流発電機の前記出力電圧(US)は、パルス幅変調型整流子を用いて整流されることを特徴とする請求項15に記載の方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1151281A FR2971648B1 (fr) | 2011-02-16 | 2011-02-16 | Ensemble fonctionnant a regime variable, comportant un alternateur synchrone a rotor bobine et un convertisseur |

| FR1151281 | 2011-02-16 | ||

| PCT/IB2012/050717 WO2012110979A1 (fr) | 2011-02-16 | 2012-02-16 | Ensemble fonctionnant a regime variable |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017034049A Division JP2017093296A (ja) | 2011-02-16 | 2017-02-24 | 可変状況で作動するアセンブリ |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2014506113A true JP2014506113A (ja) | 2014-03-06 |

| JP2014506113A5 JP2014506113A5 (ja) | 2019-04-04 |

Family

ID=45774286

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013554043A Pending JP2014506113A (ja) | 2011-02-16 | 2012-02-16 | 可変状況で作動するアセンブリ |

| JP2017034049A Pending JP2017093296A (ja) | 2011-02-16 | 2017-02-24 | 可変状況で作動するアセンブリ |

| JP2019113086A Abandoned JP2019149936A (ja) | 2011-02-16 | 2019-06-18 | 可変状況で作動するアセンブリ |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017034049A Pending JP2017093296A (ja) | 2011-02-16 | 2017-02-24 | 可変状況で作動するアセンブリ |

| JP2019113086A Abandoned JP2019149936A (ja) | 2011-02-16 | 2019-06-18 | 可変状況で作動するアセンブリ |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US9431943B2 (ja) |

| EP (1) | EP2676362A1 (ja) |

| JP (3) | JP2014506113A (ja) |

| KR (1) | KR20140051825A (ja) |

| CN (1) | CN102647139B (ja) |

| FR (1) | FR2971648B1 (ja) |

| WO (1) | WO2012110979A1 (ja) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017180850A1 (en) * | 2016-04-13 | 2017-10-19 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US9819296B2 (en) | 2014-08-01 | 2017-11-14 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US11296638B2 (en) | 2014-08-01 | 2022-04-05 | Falcon Power, LLC | Variable torque motor/generator/transmission |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2491548A (en) * | 2010-09-30 | 2012-12-12 | Vestas Wind Sys As | Over-rating control of a wind turbine power plant |

| CN103378783A (zh) * | 2012-04-16 | 2013-10-30 | 台达电子企业管理(上海)有限公司 | 一种励磁控制电路、控制方法及其电励磁风电系统 |

| EP2741392A3 (en) * | 2012-12-04 | 2016-12-14 | ABB Research Ltd. | Systems and methods for utilizing an active compensator to augment a diode rectifier |

| CN103607154B (zh) * | 2013-11-12 | 2017-02-01 | 北京工业大学 | 一种可电励磁的交流电机控制方法 |

| US20150249417A1 (en) * | 2013-12-30 | 2015-09-03 | Rolls-Royce Corporation | Synchronous generator controller based on flux optimizer |

| FR3022416B1 (fr) * | 2014-06-11 | 2017-08-25 | Valeo Equip Electr Moteur | Boucle de regulation d'un dispositif regulateur numerique de machine electrique tournante a excitation de vehicule automobile |

| JP6269355B2 (ja) * | 2014-07-04 | 2018-01-31 | 株式会社安川電機 | マトリクスコンバータ、発電システムおよび力率制御方法 |

| US9447772B2 (en) * | 2014-12-18 | 2016-09-20 | General Electric Company | Systems and methods for increasing wind turbine power output |

| FR3033458B1 (fr) * | 2015-03-05 | 2018-06-15 | Moteurs Leroy-Somer | Ensemble electromecanique comportant un alternateur |

| JP6559487B2 (ja) * | 2015-07-08 | 2019-08-14 | 株式会社東芝 | 二次励磁装置の制御装置、制御方法、および可変速揚水発電システム |

| FR3040558B1 (fr) * | 2015-08-28 | 2017-08-11 | Valeo Equip Electr Moteur | Circuit d'excitation d'un alternateur de vehicule automobile, regulateur de tension et alternateur l'incorporant |

| CN105201750A (zh) * | 2015-10-16 | 2015-12-30 | 岑益南 | 双风轮直驱风力发电机 |

| DE102017201687A1 (de) * | 2017-02-02 | 2018-08-02 | Siemens Aktiengesellschaft | Regelbare Spannungserzeugungsvorrichtung und Verfahren zum Betreiben einer regelbaren Spannungserzeugungsvorrichtung |

| US10483886B2 (en) * | 2017-09-14 | 2019-11-19 | Hamilton Sundstrand Corportion | Modular electric power generating system with multistage axial flux generator |

| KR102310629B1 (ko) * | 2019-01-24 | 2021-10-07 | 전북대학교산학협력단 | 권선형 회전자 동기 발전기 구동 시스템 및 방법 |

| US11671038B2 (en) * | 2019-08-09 | 2023-06-06 | Hamilton Sundstrand Corporation | Control of a wound field synchronous generator for transient load response |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1187307A2 (de) * | 2000-09-07 | 2002-03-13 | Robert Bosch Gmbh | Reglerstruktur für elektrische Maschinen |

| JP2003143899A (ja) * | 2001-08-24 | 2003-05-16 | Siemens Ag | タービン発電機の加速方法と加速装置 |

| JP2007267586A (ja) * | 2006-02-28 | 2007-10-11 | Hitachi Ltd | 風力発電装置,風力発電システムおよび電力系統制御装置 |

| JP2009065787A (ja) * | 2007-09-06 | 2009-03-26 | Univ Of Ryukyus | 風力発電機に用いる蓄電池設備 |

| JP2009232497A (ja) * | 2008-03-19 | 2009-10-08 | Mitsubishi Electric Corp | 発電機電圧の制御装置 |

| JP2010148336A (ja) * | 2008-12-22 | 2010-07-01 | Hitachi Engineering & Services Co Ltd | 風力発電所とその発電制御方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5083039B1 (en) * | 1991-02-01 | 1999-11-16 | Zond Energy Systems Inc | Variable speed wind turbine |

| DE19845903A1 (de) * | 1998-10-05 | 2000-04-06 | Aloys Wobben | Elektrische Energieübertragungsanlage |

| DE19849889A1 (de) * | 1998-10-29 | 2000-05-04 | Bosch Gmbh Robert | Verfahren zur leistungs- und wirkungsgradoptimierten Regelung von Synchronmaschinen |

| US6346797B1 (en) * | 2000-01-24 | 2002-02-12 | Massachusetts Institute Of Technology | Load matched alternator system |

-

2011

- 2011-02-16 FR FR1151281A patent/FR2971648B1/fr active Active

-

2012

- 2012-02-16 WO PCT/IB2012/050717 patent/WO2012110979A1/fr active Application Filing

- 2012-02-16 CN CN201210035643.0A patent/CN102647139B/zh not_active Expired - Fee Related

- 2012-02-16 EP EP12706701.5A patent/EP2676362A1/fr not_active Withdrawn

- 2012-02-16 KR KR1020137021635A patent/KR20140051825A/ko not_active Application Discontinuation

- 2012-02-16 JP JP2013554043A patent/JP2014506113A/ja active Pending

-

2013

- 2013-07-31 US US13/955,788 patent/US9431943B2/en not_active Expired - Fee Related

-

2017

- 2017-02-24 JP JP2017034049A patent/JP2017093296A/ja active Pending

-

2019

- 2019-06-18 JP JP2019113086A patent/JP2019149936A/ja not_active Abandoned

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1187307A2 (de) * | 2000-09-07 | 2002-03-13 | Robert Bosch Gmbh | Reglerstruktur für elektrische Maschinen |

| JP2003143899A (ja) * | 2001-08-24 | 2003-05-16 | Siemens Ag | タービン発電機の加速方法と加速装置 |

| JP2007267586A (ja) * | 2006-02-28 | 2007-10-11 | Hitachi Ltd | 風力発電装置,風力発電システムおよび電力系統制御装置 |

| JP2009065787A (ja) * | 2007-09-06 | 2009-03-26 | Univ Of Ryukyus | 風力発電機に用いる蓄電池設備 |

| JP2009232497A (ja) * | 2008-03-19 | 2009-10-08 | Mitsubishi Electric Corp | 発電機電圧の制御装置 |

| JP2010148336A (ja) * | 2008-12-22 | 2010-07-01 | Hitachi Engineering & Services Co Ltd | 風力発電所とその発電制御方法 |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9819296B2 (en) | 2014-08-01 | 2017-11-14 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US10084404B2 (en) | 2014-08-01 | 2018-09-25 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US20190013759A1 (en) | 2014-08-01 | 2019-01-10 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US20190068102A1 (en) | 2014-08-01 | 2019-02-28 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US10879828B2 (en) | 2014-08-01 | 2020-12-29 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US10892700B2 (en) | 2014-08-01 | 2021-01-12 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US11296638B2 (en) | 2014-08-01 | 2022-04-05 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US11362611B2 (en) | 2014-08-01 | 2022-06-14 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US11695364B2 (en) | 2014-08-01 | 2023-07-04 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| US11888421B2 (en) | 2014-08-01 | 2024-01-30 | Falcon Power, LLC | Variable torque motor/generator/transmission |

| WO2017180850A1 (en) * | 2016-04-13 | 2017-10-19 | Falcon Power, LLC | Variable torque motor/generator/transmission |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2971648A1 (fr) | 2012-08-17 |

| JP2017093296A (ja) | 2017-05-25 |

| US9431943B2 (en) | 2016-08-30 |

| EP2676362A1 (fr) | 2013-12-25 |

| WO2012110979A1 (fr) | 2012-08-23 |

| US20130313828A1 (en) | 2013-11-28 |

| KR20140051825A (ko) | 2014-05-02 |

| CN102647139B (zh) | 2016-12-07 |

| CN102647139A (zh) | 2012-08-22 |

| FR2971648B1 (fr) | 2016-10-14 |

| JP2019149936A (ja) | 2019-09-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2019149936A (ja) | 可変状況で作動するアセンブリ | |

| US7554302B2 (en) | Slip-controlled, wound-rotor induction machine for wind turbine and other applications | |

| JP5726187B2 (ja) | ウィンドファームおよび風力タービンならびに風力タービンの制御方法ならびにバングバング型コントローラ | |

| Beik et al. | High-voltage hybrid generator and conversion system for wind turbine applications | |

| US10491146B2 (en) | System and method for compensating for generator-induced flicker in a wind turbine | |

| US8546991B2 (en) | Synchronous generator and synchronous generator system for reducing distortion of current waveform | |

| US20090121482A1 (en) | Variable speed power generator having two induction generators on a common shaft | |

| RU2735800C1 (ru) | Способ управления многофазным синхронным генератором с независимым возбуждением в ветряной турбине | |

| US10742149B1 (en) | System and method for reactive power control of a wind turbine by varying switching frequency of rotor side converter | |

| EP3614520B1 (en) | Systems and methods for controlling electrical power systems connected to a power grid | |

| US8432051B2 (en) | Electric generator | |

| Xiang et al. | Switching frequency dynamic control for DFIG wind turbine performance improvement around synchronous speed | |

| Jiang et al. | Analysis and dynamic control of a dual-stator BDFIG-DC system supplying DC grid with minimized torque ripple through harmonic current injection | |

| KR101417509B1 (ko) | 이중 회전자를 갖는 동기 발전기 시스템 | |

| Solomon | The design, control and dynamic performance of an interior permanent magnet synchronous generator for wind power system | |

| CA2824171C (en) | Electrical machine and method for operating such an electrical machine | |

| CN102723739B (zh) | 风力发电系统 | |

| Jung et al. | Control of a synchronous motor with an inverter integrated rotor | |

| Shao et al. | A comparative study on nine-and twelve-phase flux-switching permanent-magnet wind generators | |

| Cho et al. | Self-excitation system using high-efficiency low-power PM generator | |

| Kumar et al. | Speed Control of Brushless Doubly-fed Reluctance Generator under MTPIA and UPPF Conditions for Wind Power Application | |

| Damij | Development of Mechanical Coupling and Exciter System in Synchronous Generators | |

| Merz | Consideration of a variable frequency energy conversion system for marine and onshore wind energy extraction | |

| Bhattacherjee et al. | Brushless and Magnetless Synchronous Generator for Standalone DC Load with Vienna Rectifier | |

| RU2688923C1 (ru) | Аксиальная многофазная двухвходовая электрическая машина-генератор |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150212 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20151214 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20160314 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160527 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20161026 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180402 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20181106 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20190104 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190206 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20190206 |