JP2014185031A5 - - Google Patents

Download PDFInfo

- Publication number

- JP2014185031A5 JP2014185031A5 JP2013062949A JP2013062949A JP2014185031A5 JP 2014185031 A5 JP2014185031 A5 JP 2014185031A5 JP 2013062949 A JP2013062949 A JP 2013062949A JP 2013062949 A JP2013062949 A JP 2013062949A JP 2014185031 A5 JP2014185031 A5 JP 2014185031A5

- Authority

- JP

- Japan

- Prior art keywords

- tension

- dancer

- torque

- arm

- wire

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 230000001629 suppression Effects 0.000 description 3

- 239000003638 reducing agent Substances 0.000 description 1

Images

Description

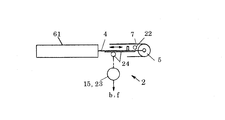

図1は、本発明に係る張力変動抑制方法にもとづく張力変動抑制装置1を示しており、張力変動抑制装置1は、張力付与装置2を前提としている。張力付与装置2は、移動可能なダンサアーム4、すなわちアーム軸3を中心として揺動運動可能なダンサアーム4の先端にダンサローラ5を回転自在に支持し、アーム軸3を回転式のアクチュエータとしてのトルクモータ6の回転力により直接または減速機31により間接的に駆動するとともに、ダンサローラ5にウエブとしてのワイヤ7を巻き掛け、トルクモータ6によってアーム軸3をワイヤ7に対する張力付与方向に付勢することによって、走行中のワイヤ7に目標の張力を付与する。

FIG. 1 shows a tension fluctuation suppressing device 1 based on the tension fluctuation suppressing method according to the present invention. The tension fluctuation suppressing device 1 is based on a

図1および図3の張力付与装置2での揺動運動可能なダンサアーム4によれば、ダンサアーム4が傾くと、トルクの作用方向と張力の方向とが一致しなくなり、トルクモータ6のトルクが目標の張力として正確に作用しなくなる。しかし、図5の張力付与装置2での直線運動可能なダンサアーム4によると、ダンサアーム4のすべての移動位置で直動式のアクチュエータとしてのリニアモータ61による張力付与力とワイヤ7に対する張力の方向とが常時完全に一致しているため、張力制御は精度よく行え、安定する。

According to the

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013062949A JP6124445B2 (en) | 2013-03-25 | 2013-03-25 | Tension fluctuation suppressing method and tension fluctuation suppressing apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013062949A JP6124445B2 (en) | 2013-03-25 | 2013-03-25 | Tension fluctuation suppressing method and tension fluctuation suppressing apparatus |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014185031A JP2014185031A (en) | 2014-10-02 |

| JP2014185031A5 true JP2014185031A5 (en) | 2016-09-15 |

| JP6124445B2 JP6124445B2 (en) | 2017-05-10 |

Family

ID=51832961

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013062949A Active JP6124445B2 (en) | 2013-03-25 | 2013-03-25 | Tension fluctuation suppressing method and tension fluctuation suppressing apparatus |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6124445B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110877839B (en) * | 2018-09-06 | 2022-03-25 | 西门子(中国)有限公司 | Method and equipment for processing broken paper |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6133452A (en) * | 1984-07-24 | 1986-02-17 | Kataoka Kikai Seisakusho:Kk | Tension controller for supply sheet |

| JPH02133197U (en) * | 1989-04-10 | 1990-11-05 | ||

| JPH04265682A (en) * | 1991-02-21 | 1992-09-21 | Fuji Electric Co Ltd | Servo amplifier provided with function for limiting upper limit rotational speed |

| JPH0531943U (en) * | 1991-10-08 | 1993-04-27 | 三菱重工業株式会社 | Tension control device for rotary press |

| JP2513107B2 (en) * | 1992-09-01 | 1996-07-03 | 株式会社ニレコ | Web tension controller |

| JPH09225936A (en) * | 1995-12-20 | 1997-09-02 | Nippei Toyama Corp | Wire saw |

| US6017354A (en) * | 1996-08-15 | 2000-01-25 | Stryker Corporation | Integrated system for powered surgical tools |

| JP4162275B2 (en) * | 1997-02-27 | 2008-10-08 | 大日本印刷株式会社 | Method and apparatus for controlling motor rotation speed ratio of web conveyance system |

| JP2003054800A (en) * | 2001-08-15 | 2003-02-26 | Sony Corp | Tension control device and method |

| JP5728968B2 (en) * | 2011-01-26 | 2015-06-03 | サンケン電気株式会社 | Control device and control method for induction motor |

| JP5155428B2 (en) * | 2011-07-15 | 2013-03-06 | コマツNtc株式会社 | Wire saw |

-

2013

- 2013-03-25 JP JP2013062949A patent/JP6124445B2/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| BR112015002427A2 (en) | skin treatment apparatus for skin surface treatment and skin surface treatment method | |

| JP2013158876A5 (en) | ||

| JP2015512792A5 (en) | ||

| JP2014211612A5 (en) | ||

| JP2012518133A5 (en) | ||

| JP2015112576A5 (en) | ||

| WO2015014970A3 (en) | Machining tool with pivotable tool spindle | |

| EP2682560A3 (en) | Electronic curtain moving device | |

| SG10201402685TA (en) | Robot arm control apparatus, substrate transfer apparatus,substrate processing apparatus, robot arm control method, and program | |

| JP2014527914A5 (en) | ||

| JP2014124741A5 (en) | End effector and robot | |

| CN203664130U (en) | Glue uniformizing mechanism of coating machine | |

| MX2013002083A (en) | Apparatus for sealing an open end of a container. | |

| JP2014185031A5 (en) | ||

| BR112014030754A2 (en) | winder for winding a strip of fabric or sewing or the like on a roller, particularly for circular sewing machines | |

| RU2013131909A (en) | DEVICE AND METHOD FOR ATTACHING TAPE TO CANVAS ON A NONLINEAR TEMPLATE | |

| JP2015034731A5 (en) | ||

| JP2016519599A5 (en) | ||

| WO2016200917A3 (en) | Non-contact magnetic steering | |

| CN104555530A (en) | Wire winding and feeding machine for packer and winding machine | |

| JP2013021137A5 (en) | ||

| JP2015104789A5 (en) | ||

| JP2018187744A5 (en) | Forceps device | |

| JP2017006699A5 (en) | ||

| RU2015101925A (en) | LINEAR MOVEMENT DEVICE WITH CLAMPING CAPACITY, DEPENDING ON LOAD |