JP2012024920A - Cmm arm with exoskeleton - Google Patents

Cmm arm with exoskeleton Download PDFInfo

- Publication number

- JP2012024920A JP2012024920A JP2011168620A JP2011168620A JP2012024920A JP 2012024920 A JP2012024920 A JP 2012024920A JP 2011168620 A JP2011168620 A JP 2011168620A JP 2011168620 A JP2011168620 A JP 2011168620A JP 2012024920 A JP2012024920 A JP 2012024920A

- Authority

- JP

- Japan

- Prior art keywords

- probe

- cmm arm

- reporting device

- robot

- movable

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000000523 sample Substances 0.000 claims abstract description 813

- 238000000034 method Methods 0.000 claims abstract description 283

- 230000005540 biological transmission Effects 0.000 claims abstract description 257

- 230000033001 locomotion Effects 0.000 claims description 91

- 210000000707 wrist Anatomy 0.000 claims description 8

- 230000000452 restraining effect Effects 0.000 claims description 3

- 238000005259 measurement Methods 0.000 abstract description 379

- 230000003287 optical effect Effects 0.000 abstract description 168

- 230000008569 process Effects 0.000 description 151

- 238000004519 manufacturing process Methods 0.000 description 83

- HOPMUCXYRNOABF-UHFFFAOYSA-N 1,2,3,4-tetrachloro-5-(2,3,5-trichlorophenyl)benzene Chemical compound ClC1=CC(Cl)=C(Cl)C(C=2C(=C(Cl)C(Cl)=C(Cl)C=2)Cl)=C1 HOPMUCXYRNOABF-UHFFFAOYSA-N 0.000 description 66

- 230000008901 benefit Effects 0.000 description 61

- 230000005484 gravity Effects 0.000 description 55

- 238000013461 design Methods 0.000 description 47

- 239000000463 material Substances 0.000 description 46

- PAYFWJAKKLILIT-UHFFFAOYSA-N 1,2,3,4,5-pentachloro-6-(2,3-dichlorophenyl)benzene Chemical compound ClC1=CC=CC(C=2C(=C(Cl)C(Cl)=C(Cl)C=2Cl)Cl)=C1Cl PAYFWJAKKLILIT-UHFFFAOYSA-N 0.000 description 40

- 238000005452 bending Methods 0.000 description 38

- 238000010586 diagram Methods 0.000 description 38

- 230000036961 partial effect Effects 0.000 description 38

- 230000006870 function Effects 0.000 description 33

- 238000012545 processing Methods 0.000 description 31

- 210000003128 head Anatomy 0.000 description 27

- 238000007689 inspection Methods 0.000 description 25

- 230000001133 acceleration Effects 0.000 description 24

- 239000013013 elastic material Substances 0.000 description 23

- 238000012856 packing Methods 0.000 description 20

- 230000002829 reductive effect Effects 0.000 description 20

- 230000009977 dual effect Effects 0.000 description 19

- 238000005516 engineering process Methods 0.000 description 17

- 238000004891 communication Methods 0.000 description 16

- 239000006260 foam Substances 0.000 description 16

- 230000008859 change Effects 0.000 description 15

- 230000000694 effects Effects 0.000 description 14

- 239000007787 solid Substances 0.000 description 14

- 230000009467 reduction Effects 0.000 description 12

- 230000003068 static effect Effects 0.000 description 12

- 230000001360 synchronised effect Effects 0.000 description 12

- 238000012935 Averaging Methods 0.000 description 11

- 241000350052 Daniellia ogea Species 0.000 description 11

- 238000004458 analytical method Methods 0.000 description 11

- 230000000875 corresponding effect Effects 0.000 description 11

- 229910052751 metal Inorganic materials 0.000 description 11

- 239000002184 metal Substances 0.000 description 11

- 230000006378 damage Effects 0.000 description 10

- 239000002783 friction material Substances 0.000 description 10

- 229920001971 elastomer Polymers 0.000 description 9

- 238000003754 machining Methods 0.000 description 9

- 238000002360 preparation method Methods 0.000 description 9

- 230000004044 response Effects 0.000 description 9

- 230000002441 reversible effect Effects 0.000 description 9

- 238000012546 transfer Methods 0.000 description 9

- 230000004913 activation Effects 0.000 description 8

- 238000009826 distribution Methods 0.000 description 8

- 230000007246 mechanism Effects 0.000 description 8

- 150000003071 polychlorinated biphenyls Chemical class 0.000 description 8

- 238000000926 separation method Methods 0.000 description 8

- 229910052782 aluminium Inorganic materials 0.000 description 7

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 7

- 230000007613 environmental effect Effects 0.000 description 7

- 238000009434 installation Methods 0.000 description 7

- 238000013507 mapping Methods 0.000 description 7

- 238000000691 measurement method Methods 0.000 description 7

- 230000008439 repair process Effects 0.000 description 7

- 230000035939 shock Effects 0.000 description 7

- 230000009471 action Effects 0.000 description 6

- 238000001514 detection method Methods 0.000 description 6

- 239000007789 gas Substances 0.000 description 6

- 238000003780 insertion Methods 0.000 description 6

- 230000037431 insertion Effects 0.000 description 6

- 210000002414 leg Anatomy 0.000 description 6

- 238000003801 milling Methods 0.000 description 6

- 238000012544 monitoring process Methods 0.000 description 6

- 238000012795 verification Methods 0.000 description 6

- 235000011960 Brassica ruvo Nutrition 0.000 description 5

- 239000011248 coating agent Substances 0.000 description 5

- 238000000576 coating method Methods 0.000 description 5

- 230000001276 controlling effect Effects 0.000 description 5

- 230000008878 coupling Effects 0.000 description 5

- 238000010168 coupling process Methods 0.000 description 5

- 238000005859 coupling reaction Methods 0.000 description 5

- 230000007423 decrease Effects 0.000 description 5

- 238000006073 displacement reaction Methods 0.000 description 5

- 238000002372 labelling Methods 0.000 description 5

- 239000004033 plastic Substances 0.000 description 5

- 229920003023 plastic Polymers 0.000 description 5

- 230000001681 protective effect Effects 0.000 description 5

- 238000012360 testing method Methods 0.000 description 5

- 238000012800 visualization Methods 0.000 description 5

- 229920000049 Carbon (fiber) Polymers 0.000 description 4

- 239000000853 adhesive Substances 0.000 description 4

- 230000001070 adhesive effect Effects 0.000 description 4

- 230000009286 beneficial effect Effects 0.000 description 4

- 238000004422 calculation algorithm Methods 0.000 description 4

- 239000004917 carbon fiber Substances 0.000 description 4

- 238000012937 correction Methods 0.000 description 4

- 210000004247 hand Anatomy 0.000 description 4

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 4

- 230000001629 suppression Effects 0.000 description 4

- 238000011144 upstream manufacturing Methods 0.000 description 4

- 239000004593 Epoxy Substances 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 3

- 230000005670 electromagnetic radiation Effects 0.000 description 3

- 230000001788 irregular Effects 0.000 description 3

- 239000003562 lightweight material Substances 0.000 description 3

- 238000009877 rendering Methods 0.000 description 3

- 238000004441 surface measurement Methods 0.000 description 3

- 230000009466 transformation Effects 0.000 description 3

- 230000000007 visual effect Effects 0.000 description 3

- 238000007794 visualization technique Methods 0.000 description 3

- 238000003466 welding Methods 0.000 description 3

- 239000006096 absorbing agent Substances 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 238000003491 array Methods 0.000 description 2

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000000903 blocking effect Effects 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 230000008602 contraction Effects 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 239000003344 environmental pollutant Substances 0.000 description 2

- 230000007274 generation of a signal involved in cell-cell signaling Effects 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 238000002955 isolation Methods 0.000 description 2

- 229910052743 krypton Inorganic materials 0.000 description 2

- DNNSSWSSYDEUBZ-UHFFFAOYSA-N krypton atom Chemical compound [Kr] DNNSSWSSYDEUBZ-UHFFFAOYSA-N 0.000 description 2

- 229910001095 light aluminium alloy Inorganic materials 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 230000013011 mating Effects 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 230000000737 periodic effect Effects 0.000 description 2

- 229920001084 poly(chloroprene) Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 238000013519 translation Methods 0.000 description 2

- RXRLRYZUMSYVLS-UHFFFAOYSA-N 1,2,3,4-tetrachloro-5-(2,4,6-trichlorophenyl)benzene Chemical compound ClC1=CC(Cl)=CC(Cl)=C1C1=CC(Cl)=C(Cl)C(Cl)=C1Cl RXRLRYZUMSYVLS-UHFFFAOYSA-N 0.000 description 1

- MFRCZYUUKMFJQJ-UHFFFAOYSA-N 1,4-dioxane-2,5-dione;1,3-dioxan-2-one Chemical compound O=C1OCCCO1.O=C1COC(=O)CO1 MFRCZYUUKMFJQJ-UHFFFAOYSA-N 0.000 description 1

- 102100029272 5-demethoxyubiquinone hydroxylase, mitochondrial Human genes 0.000 description 1

- 101100024440 Globodera rostochiensis MSP-3 gene Proteins 0.000 description 1

- 101000770593 Homo sapiens 5-demethoxyubiquinone hydroxylase, mitochondrial Proteins 0.000 description 1

- 229910001374 Invar Inorganic materials 0.000 description 1

- 206010061258 Joint lock Diseases 0.000 description 1

- 125000002066 L-histidyl group Chemical group [H]N1C([H])=NC(C([H])([H])[C@](C(=O)[*])([H])N([H])[H])=C1[H] 0.000 description 1

- HCUVEUVIUAJXRB-UHFFFAOYSA-N OC1=C(C=C(CNC(CCCC=2SC=CC=2)=O)C=C1)OC Chemical compound OC1=C(C=C(CNC(CCCC=2SC=CC=2)=O)C=C1)OC HCUVEUVIUAJXRB-UHFFFAOYSA-N 0.000 description 1

- 239000004699 Ultra-high molecular weight polyethylene Substances 0.000 description 1

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 239000003570 air Substances 0.000 description 1

- 230000029777 axis specification Effects 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000004927 clay Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 230000002596 correlated effect Effects 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000013481 data capture Methods 0.000 description 1

- 238000005034 decoration Methods 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 238000012938 design process Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000011143 downstream manufacturing Methods 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 238000005242 forging Methods 0.000 description 1

- 238000007710 freezing Methods 0.000 description 1

- 230000008014 freezing Effects 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000007429 general method Methods 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- 239000010438 granite Substances 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 238000003384 imaging method Methods 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 210000000629 knee joint Anatomy 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000011017 operating method Methods 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

- 238000010422 painting Methods 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 238000007781 pre-processing Methods 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 238000012797 qualification Methods 0.000 description 1

- 238000000275 quality assurance Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 230000002285 radioactive effect Effects 0.000 description 1

- 238000011084 recovery Methods 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 238000002432 robotic surgery Methods 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 230000009528 severe injury Effects 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

- 238000004088 simulation Methods 0.000 description 1

- 230000007480 spreading Effects 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 238000011477 surgical intervention Methods 0.000 description 1

- 230000002195 synergetic effect Effects 0.000 description 1

- 230000009897 systematic effect Effects 0.000 description 1

- 230000002123 temporal effect Effects 0.000 description 1

- 210000003813 thumb Anatomy 0.000 description 1

- 238000000844 transformation Methods 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

- 238000007514 turning Methods 0.000 description 1

- 229920000785 ultra high molecular weight polyethylene Polymers 0.000 description 1

- 238000002604 ultrasonography Methods 0.000 description 1

- 239000013598 vector Substances 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

- 238000005303 weighing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J13/00—Controls for manipulators

- B25J13/08—Controls for manipulators by means of sensing devices, e.g. viewing or touching devices

- B25J13/088—Controls for manipulators by means of sensing devices, e.g. viewing or touching devices with position, velocity or acceleration sensors

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/02—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness

- G01B11/03—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness by measuring coordinates of points

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B5/00—Measuring arrangements characterised by the use of mechanical techniques

- G01B5/004—Measuring arrangements characterised by the use of mechanical techniques for measuring coordinates of points

- G01B5/008—Measuring arrangements characterised by the use of mechanical techniques for measuring coordinates of points using coordinate measuring machines

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/37—Measurements

- G05B2219/37274—Strain gauge

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/40—Robotics, robotics mapping to robotics vision

- G05B2219/40305—Exoskeleton, human robot interaction, extenders

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Human Computer Interaction (AREA)

- Robotics (AREA)

- Mechanical Engineering (AREA)

- Manipulator (AREA)

- A Measuring Device Byusing Mechanical Method (AREA)

- Length Measuring Devices With Unspecified Measuring Means (AREA)

- Testing Or Calibration Of Command Recording Devices (AREA)

- Machine Tool Sensing Apparatuses (AREA)

Abstract

Description

[発明の分野]

本発明は、高精度な測定及び動作を行うための外骨格を有するCMMアームに関する装置及び方法に関する。

[Field of the Invention]

The present invention relates to an apparatus and a method related to a CMM arm having an exoskeleton for performing highly accurate measurement and operation.

[発明の背景]

既存の自動測定法

中型から大型のサイズの物体を自動測定するには、0.05mm(+/−2シグマ)、通常は0.025mm(+/−2シグマ)以上の測定機精度が必要である。「シグマ」とは、1標準偏差を意味する。自動測定は現在、主に2つの方法、(i)3つ以上の軸を有する大型で高価な従来のコンピュータ数値制御座標測定機(CNC CMM)、(ii)自動車生産ラインの終端にある専用セルに通常は位置付けられる、静的光学プローブの剛性構造、で行われている。従来のCMMでは、光学プローブが静止物体の周りを極めて制御された方法で移動して、正確なデータを生成する。第2の場合では、光学プローブ及び物体の両方が静止しており、位置決めが較正されることにより正確なデータが可能になる。従来のCMMのほとんどは、移動ブリッジ又は水平アームの構造であり、Zeiss(ドイツ)、Hexagon Brown&Sharpe(スウェーデン)、及びLK(英国)を含む企業がこれらを生産している。従来のCMMに取り付けられる機械式タッチプローブは、Renishaw(英国)を含む企業により供給されている。従来のCMMに取り付けられる光学プローブは、Metris(ベルギー)を含む企業により供給されている。Renishaw Autojoint等の自動プローブマウントは、高精度まで再現可能であり、自動プローブ交換のためのプローブラックとともに供給される。静的光学プローブの剛構造は、Perceptron(米国)により供給されている。従来のCMM及び静的光学プローブの両方が、以下の欠点を有する。すなわち、従来のCMM及び静的光学プローブは、生産ラインにおいて、通常は測定のためだけに用いられて生産作業には用いられないセル空間を使い切り、通常はラインの終端に設置され、下流のプロセスにデータを供給することができず、高価であり、投資回収を考えても正当化し難い。さらに、光学プローブの剛構造は、生産ラインにおいて急速に変化するモデルに対応する柔軟性がない。既存の高精度測定システムの欠点により、今日では、従来のプロセスよりも高速、高性能、且つ安価であるが高精度位置決めを必要とするロボットを用いる効率的な生産プロセスを、生産ラインで利用することはできない。

[Background of the invention]

Existing automatic measurement method Automatic measurement of medium to large size objects requires a measuring machine accuracy of 0.05mm (+/- 2 sigma), usually 0.025mm (+/- 2 sigma) or higher. is there. “Sigma” means one standard deviation. Automatic measurement currently has two main methods: (i) a large and expensive conventional computer numerical control coordinate measuring machine (CNC CMM) with more than two axes; (ii) a dedicated cell at the end of the automobile production line It is usually done with a rigid structure of a static optical probe, which is positioned. In a conventional CMM, an optical probe moves around a stationary object in a highly controlled manner to generate accurate data. In the second case, both the optical probe and the object are stationary and the positioning is calibrated to allow accurate data. Most conventional CMMs are moving bridge or horizontal arm structures, which are produced by companies including Zeiss (Germany), Hexagon Brown & Sharpe (Sweden), and LK (UK). Mechanical touch probes attached to conventional CMMs are supplied by companies including Renishaw (UK). Optical probes attached to conventional CMMs are supplied by companies including Metris (Belgium). Automatic probe mounts such as Renishaw Autojoin are reproducible to high precision and are supplied with a probe rack for automatic probe replacement. The rigid structure of the static optical probe is supplied by Perceptron (USA). Both conventional CMM and static optical probes have the following disadvantages. In other words, conventional CMMs and static optical probes use up cell space that is normally used only for measurement and not for production work in the production line, and is usually installed at the end of the line, downstream processes. Data cannot be supplied to the network, it is expensive, and it is difficult to justify it even considering investment recovery. Furthermore, the rigid structure of the optical probe is not flexible to accommodate rapidly changing models in the production line. Due to the shortcomings of existing high-precision measurement systems, today, the production line uses an efficient production process that uses robots that are faster, perform better, and cheaper than conventional processes but require high-precision positioning. It is not possible.

ロボット自動測定

1960年代以来、各企業により、短いサイクルタイム及び再現性を必要とする用途のために、重いロボットアームが開発されてきた。しかしながら、主に温度、磨耗、及び振動の問題から、これらのロボットアームの精度は低い。ロボットは、自動測定用のプローブを担持するために用いられてきた。ロボットアームは、特に自動車産業において、ほとんどの自動測定の厳しい要件を満たすのに十分な精度を有さない。ロボットアームの高い再現性により、「準静的な」測定は自動車産業が少なからず取り入れる解決手段となった。「準静的な」測定では、プローブは或る位置から次の位置へ移動し、静止しているかゆっくりと移動している場合にのみデータを取る。測定は、接触プローブ又は非接触プローブのいずれでも行うことができる。ロボットアームの測定プローブは、通常は10mm/秒〜200mm/秒(但し、それよりも速くても遅くてもよい)の速度で移動しながら、物体の表面から3次元データを取るが、精度は低い。ロボットアームを生産する企業には、Fanuc(日本)及びKuka(ドイツ)が含まれる。Perceptron及びLMI-Diffracto(米国)は、ロボットアーム及び光学プローブを用いる解決手段を提供している。3D Scanners及びKukaは、フランクフルトでのユーロモールド(Euromold)2001見本市において、リアルタイム光学検査による解決手段を示したが、その精度は0.5〜1mmのオーダであった。標準的な産業ロボットの熱成長は、リーチ1メートル当たり1℃の温度上昇につき約10ミクロンであり、500ミクロンを超える誤差は、生産ライン状態で記録され得る。LMI-Diffractoは、Kukaにより供給されている、それぞれが光学プローブを担持する標準的な産業ロボットを4つ備える自動生産ライン設備を有し、このロボットは熱成長が補償されるため、生産ライン状態の熱誤差が100ミクロン未満に減る可能性がある。Perceptronに譲渡されたGreerによる米国特許第6,078,846号では、ロボットの熱成長の補償は、光学プローブにより固定アーチファクトを測定することにより実行される。光学プローブは、ロボットが移動間で静止している間に測定を行う。誤差マッピングがロボットの精度を高めた。Krypton(オランダ)製又はNorthern Digital(カナダ)製のもの等の写真測量システムを用いて測定を行いながら、計画的な移動のプログラムの間ロボットを揺動させる(dancing)ことを含む、いくつかの手法がある。続いて、測定値を用いて誤差マップが作成される。荷重の誤差補償は、サーボにより用いられる電力を測定して、アームにかかる荷重を自動的に計算することにより、すでに行われている。複数のタイプの誤差補償を用いた場合でも、自動車生産ラインで多く見られるタイプ及びリーチのロボットでは0.2mm(+/−2シグマ)の精度しか得られなかった。走査中にプローブと物体との間で相対移動が行われる走査プローブを担持するロボットアームに関する問題は、システムが有用となるのに十分な精度を有さないことである。

Automatic Robot Measurement Since the 1960s, companies have developed heavy robot arms for applications that require short cycle times and repeatability. However, the accuracy of these robot arms is low, mainly due to temperature, wear, and vibration problems. Robots have been used to carry probes for automatic measurement. Robot arms do not have sufficient accuracy to meet the stringent requirements of most automatic measurements, especially in the automotive industry. Due to the high reproducibility of the robotic arm, “quasi-static” measurements have become a solution that is more or less adopted by the automotive industry. In a “quasi-static” measurement, the probe moves from one position to the next and takes data only when it is stationary or moving slowly. The measurement can be performed with either a contact probe or a non-contact probe. The measurement probe of the robot arm usually takes 3D data from the surface of the object while moving at a speed of 10 mm / sec to 200 mm / sec (however, it may be faster or slower). Low. Companies that produce robot arms include Fanuc (Japan) and Kuka (Germany). Perceptron and LMI-Diffracto (USA) provide solutions using robotic arms and optical probes. 3D Scanners and Kuka showed solutions by real-time optical inspection at the Euromold 2001 trade show in Frankfurt, but the accuracy was on the order of 0.5-1 mm. Typical industrial robot thermal growth is about 10 microns for a 1 ° C. temperature rise per meter reach, and errors over 500 microns can be recorded in production line conditions. LMI-Diffracto has an automatic production line facility supplied by Kuka with four standard industrial robots each carrying an optical probe, which is compensated for thermal growth so that the production line condition Can be reduced to less than 100 microns. In US Pat. No. 6,078,846 to Greer, assigned to Perceptron, compensation for robot thermal growth is performed by measuring fixed artifacts with an optical probe. The optical probe performs measurements while the robot is stationary between movements. Error mapping increases the accuracy of the robot. Several measures, including dancing the robot during a planned movement program while taking measurements using a photogrammetry system such as those from Krypton (Netherlands) or Northern Digital (Canada) There is a technique. Subsequently, an error map is created using the measured values. Load error compensation has already been performed by measuring the power used by the servo and automatically calculating the load on the arm. Even when multiple types of error compensation were used, only 0.2 mm (+/− 2 sigma) accuracy was obtained with the type and reach robots often found in automobile production lines. A problem with a robotic arm carrying a scanning probe in which relative movement between the probe and object occurs during scanning is that the system is not accurate enough to be useful.

追跡

Long他による米国特許第6,166,811号では、プローブに取り付けられた写真測量標的を写真測量システムによりリアルタイムで追跡する、物体の走査の精度を高めるための写真測量システムが開示されている。この方法には多くの欠点がある。第1に、プローブと写真測量用カメラとの間に、複数の明瞭な視線が維持される必要がある。実際には、写真測量用カメラからプローブ上の写真測量標的までの視線は、プログラムされたロボットの移動及び/又は物体の走査に必要なプローブの向きのプログラムされた変化により、遮られる場合が多い。これにより、システムの適用性は大きな制約を受けるため、システムは多くの用途で役に立たなくなってしまう。第2に、環境照明状態をほぼ理想的な状態に保たなければならず、そうしなければ写真測量システムの精度が低下するか、又はシステムの機能が停止する。実際には、これは設定が困難であり、その場所での他の照明要件と相容れない場合が多い。第3に、写真測量システムは、この用途で十分な精度を提供するのに必要な分解能及び速度の両方を有さない場合が多い。第4に、写真測量用カメラ及びロボットは、互いに対してしっかりと取り付けられなければならない。これには、所望の精度を得るために寸法の大きい剛構造が必要となる場合が多い。写真測定技術をロボット測定システムに組み込むことに関する主な問題は、得られるシステムが有用となるほど十分に小型且つ堅牢ではないことである。

Pursuit

US Pat. No. 6,166,811 by Long et al. Discloses a photogrammetry system for improving the accuracy of object scanning by tracking a photogrammetry target attached to a probe in real time by a photogrammetry system. This method has many drawbacks. First, it is necessary to maintain a plurality of clear lines of sight between the probe and the photogrammetry camera. In practice, the line of sight from the photogrammetric camera to the photogrammetric target on the probe is often obstructed by programmed changes in probe orientation required for programmed robot movement and / or object scanning. . This limits the applicability of the system, making the system useless for many applications. Second, the ambient lighting conditions must be kept approximately ideal, otherwise the photogrammetry system will be less accurate or the system will stop functioning. In practice, this is difficult to set up and is often incompatible with other lighting requirements at that location. Third, photogrammetry systems often do not have both the resolution and speed necessary to provide sufficient accuracy for this application. Fourth, the photogrammetry camera and robot must be securely attached to each other. This often requires a rigid structure with large dimensions to obtain the desired accuracy. The main problem with incorporating photographic measurement technology into robotic measurement systems is that the resulting system is not small and robust enough to be useful.

Leica Geosystemsは、6自由度のレーザトラッカLTD800を供給している。これは、1秒間に最高1000回の測定で、1つの視線で35mの範囲にわたって位置及び向きを測定することができる。その精度は、ゆっくりと移動する標的の場合は50ミクロンのオーダである。その価格は、130,000USドルを超える。ロボット測定に関するその制限の多くは、写真測量の制限と同様である。レーザトラッカ技術をロボット測定システムに組み込むことに関する主な問題は、高価であり、追跡されるプローブの向きが制限され、得られるシステムが有用となるほど十分に小型且つ堅牢ではないことである。 Leica Geosystems supplies the 6 degree of freedom laser tracker LTD800. This can measure the position and orientation over a range of 35 m with a single line of sight, with up to 1000 measurements per second. Its accuracy is on the order of 50 microns for a slowly moving target. Its price is over US $ 130,000. Many of the restrictions on robotic measurements are similar to those of photogrammetry. The main problem with incorporating laser tracker technology into a robotic measurement system is that it is expensive, the orientation of the probe being tracked is limited, and the resulting system is not small and robust enough to be useful.

ロボットコントローラ及びプログラミング

ロボットアームのコントローラは、当業者には十分に理解されている。標準的な参考文献は、Richard P Paulによる「Robot Manipulators, Mathematics Programming and Control」である。Adept Technologies(米国)は、6軸ロボットコントローラを8,500USドルの価格から供給している。動きのシーケンスをオフラインで生成し、続いてそれを後で実行するためにロボットコントローラに伝達するロボットのプログラミングに利用可能な製品は数多くあるが、一例はTenomatix(米国)のEmWorkplaceである。HA Shlatter AG(スイス)に譲渡されたRichterによる特許出願GB2036376Aでは、ロボットに取り付けられたデバイスをユーザが保持してロボットを手動でガイドすることにより、プログラミングが行われ、デバイスはユーザが意図したロボットの方向を検知する歪みゲージを備える。

Robot Controller and Programming Robot arm controllers are well understood by those skilled in the art. The standard reference is “Robot Manipulators, Mathematics Programming and Control” by Richard P Paul. Adept Technologies (USA) supplies a 6-axis robot controller starting at a price of US $ 8,500. There are many products available for robot programming that generate a sequence of movements offline and subsequently communicate them to a robot controller for later execution, one example being EmWorkplace from Tenomaxix (USA). In patent application GB2036376A by Richter, assigned to HA Shlatter AG (Switzerland), programming is performed by manually holding the device while the device is attached to the robot, and the device is the robot intended by the user. A strain gauge that detects the direction of

手動CMMアーム

1970年代以来、各企業は手動操作可能なCMMアームを製造しており、これは、主に手動CMMアームのリーチに応じて0.025mm(+/−2シグマ)〜0.005mm(+/−2シグマ)の測定精度を、接触プローブを用いて近年達成している。手動CMMアームの精度は、さらなる開発によりさらに高まると予測される。これらの手動CMMアームはすでに、多くの測定要件を満たすのに十分な精度を有しており、測定市場における成長部門である。手動CMMアームは、アクセスが困難な領域に到達することができる柔軟性を有する。手動CMMアームは、多くの用途で満足できる精度を有するが、自動化はされず、特に半熟練の作業者が必要であるため操作費用が高く、人間の作業者では人的ミスが起こりやすい。手動CMMアームを生産する企業としては、Cimcore(米国)、Faro Technologies(米国)、Romer(フランス)、Zett Mess Technik(ドイツ)、及びOGP(英国)が挙げられる。例として、Eatonによる米国特許第3,994,798号、Faro Technologiesに譲渡されたRaabによる米国特許第5,402,582号、Eatonによる米国特許第5,829,148号、及びFaro Technologiesに譲渡されたRaabによる米国特許第6,366,831号は、手動CMMアームに関する背景情報を開示している。手動CMMアームの継手に軸受を設けることは既知であり、Faro Technologiesに譲渡されたRaabによる米国特許出願第2002/0087233号は、軸受に関する背景情報を開示している。手動CMMアームの設計は、通常、継手1の中心からプローブ先端までのリーチが約2メートルに制限されるが、これは、それよりも長いとアームを用いるのに2人の作業者が必要だからである。手動CMMアームは、長くなるほど精度が低下する。概して、モジュール式の手動CMMアーム設計で、他の全ての要素が同じである場合、精度はやはり長さに反比例する。Raabによる米国特許第6,366,831号では、現場において、手動CMMアームは通常、ロボットアームの10倍以上の絶対位置精度を有すると開示されている。ロボットにおいて継手の位置ずれを含む不正確を引き起こす要因のいくつかが、米国特許第6,366,831号で言及されている。Faro Technologies及びRomerにより製造されるもの等の手動CMMアームは、概して、1人の人間が両手で操作する。作業者の手はそれぞれ、手で把持される手動CMMアームの部分に、異なる6自由度の作用を与える。用途によっては、片手しか必要としない熟練作業者もいる。手動CMMアームは、作業者がループを完結させる、閉ループ式で制御される機構である。このような制御は熟練を要する作業であり、作業者は、2つの手のみを用いて、重力の影響下で様々な異なる空間レイアウトで6つ又は7つのアーム自由軸を制御する必要がある。作業者が手動CMMアームの操作を誤り、手動CMMアームの一部又は全部が、衝突するか又は作業者が押さえるまで重力により加速することはよくある。データの取り込み中に、作業者が手動CMMアームに可変の、場合によっては過剰な力及びトルクを加えることにより、手動CMMアームが出力する測定データの精度が低下することもある。

Manual CMM Arms Since the 1970s, companies have been manufacturing manually operable CMM arms, mainly depending on the reach of manual CMM arms, from 0.025mm (+/- 2 sigma) to 0.005mm ( Measurement accuracy of (+/- 2 sigma) has recently been achieved using a contact probe. The accuracy of the Manual CMM Arm is expected to increase further with further development. These manual CMM arms already have sufficient accuracy to meet many measurement requirements and are a growing sector in the measurement market. The Manual CMM Arm has the flexibility to reach areas that are difficult to access. Manual CMM Arms have satisfactory accuracy for many applications, but are not automated, are particularly expensive because they require semi-skilled workers, and human workers are prone to human error. Companies that produce manual CMM arms include Cimcore (USA), Faro Technologies (USA), Romer (France), Zett Mess Technik (Germany), and OGP (UK). Examples include U.S. Pat. No. 3,994,798 to Eaton, U.S. Pat. No. 5,402,582 to Rab assigned to Faro Technologies, U.S. Pat. No. 5,829,148 to Eaton, and assigned to Faro Technologies. Raab, US Pat. No. 6,366,831, discloses background information on manual CMM arms. It is known to provide a bearing on the joint of a manual CMM arm, and US Patent Application No. 2002/0087233 by Raab assigned to Faro Technologies discloses background information on bearings. Manual CMM arm designs are typically limited to a reach of about 2 meters from the center of fitting 1 to the probe tip, because longer than that requires two workers to use the arm. It is. The accuracy of the manual CMM arm decreases with increasing length. In general, in a modular manual CMM arm design, if all other elements are the same, the accuracy is also inversely proportional to the length. US Pat. No. 6,366,831 by Raab discloses that in the field, a manual CMM arm typically has an absolute positional accuracy of more than 10 times that of a robot arm. Some of the factors that cause inaccuracies including joint misalignment in robots are mentioned in US Pat. No. 6,366,831. Manual CMM arms, such as those manufactured by Faro Technologies and Romer, are generally operated by one person with both hands. Each of the operator's hands exerts six different degrees of freedom on the portion of the Manual CMM Arm that is gripped by the hand. Some skilled workers require only one hand, depending on the application. The manual CMM arm is a closed-loop controlled mechanism that allows the operator to complete the loop. Such control is a skillful task and requires the operator to control six or seven arm free axes in a variety of different spatial layouts under the influence of gravity using only two hands. Often, an operator misoperates the Manual CMM Arm and some or all of the Manual CMM Arm is accelerated by gravity until it collides or is pressed by the operator. During data capture, the operator may apply variable and possibly excessive force and torque to the Manual CMM Arm, reducing the accuracy of the measurement data output by the Manual CMM Arm.

補償デバイス及び保持デバイス

手動CMMアームは通常、上腕に持ち上げ力を与えて釣り合いを取る傾向があるトルクを上腕に与える、第2の継手に内蔵される補償デバイスを有する。手動CMMアームの補償デバイスは、Raab他による米国特許第6,298,569号、Raab他による米国特許第6,253,458号、及びRaab他による米国特許出願第2003/0167647号に開示されており、これらはすべてFaro Technologiesに譲渡されている。これは、アームが軽く作業者にとって持ち上げやすくなっているため、使用時の疲労が少ないことを意味する。これは、手動CMMアームを介して伝達されるトルクがより大きいことも意味し、要件として、手動CMMアームは、必要な精度を得るためにこのような補償デバイスを有さない場合よりも重く設計されなければならない。ロボットの消費電力並びにモータのパワー、サイズ、及び重量を減らすために、ロボットを補償することが標準的な慣行である。第2003/0167647号では、垂下した向きで用いる場合、加工ばね補償デバイスを取り外し、反転させ、再び配置して、アームを補償することができるが、この手順は、工場内で行われなければならないため、ユーザにとって不都合である。手動CMMアームの中には、アームの1つ又は複数の軸を任意の空間的向きにロックする保持デバイスを有するものがあり、このような保持デバイスは、測定セットごとにアームを下に置く必要をなくす。Cimcore(米国)製の3000シリーズ手動CMMアームでは、軸2(第1の直交ヒンジ軸)にある補償デバイスに摺動ペグ固定具(sliding peg fixing)が取り付けられており、ペグが穴に滑り込むと、軸2が通る補償デバイスがロックされる。複数の軸上の空気ブレーキは、Zett Mess Technik GmbHに譲渡されたNietzによるPCT/EP01/01570に開示されており、Zett MessのAMPG−P手動CMMアーム製品の軸1〜4に設けられている。空気ブレーキは、無線遠隔制御スイッチにより解除することができ、空気ブレーキはディスクに作用する。空気ブレーキ及びディスクは、手動CMMアームに直接取り付けられ、手動CMMアームの重量を増し、手動CMMアームの軸受にモーメントを伝えることにより、その精度及び有用性を低下させる。

Compensation Device and Holding Device Manual CMM Arms typically have a compensation device built into the second joint that provides the upper arm with a torque that tends to counterbalance by lifting the upper arm. Manual CMM Arm compensation devices are disclosed in US Pat. No. 6,298,569 by Raab et al., US Pat. No. 6,253,458 by Raab et al. And US Patent Application No. 2003/0167647 by Raab et al. All of which have been transferred to Faro Technologies. This means that the arm is light and easy to lift for the operator, so there is less fatigue during use. This also means that the torque transmitted through the Manual CMM Arm is greater, and as a requirement, the Manual CMM Arm is designed to be heavier than without such a compensation device to obtain the required accuracy. It must be. It is standard practice to compensate for robots to reduce robot power consumption and motor power, size, and weight. In 2003/0167647, when used in a suspended orientation, the processing spring compensation device can be removed, flipped and repositioned to compensate the arm, but this procedure must be performed in the factory This is inconvenient for the user. Some manual CMM arms have a holding device that locks one or more axes of the arm in any spatial orientation, and such holding devices require the arm to be down for each measurement set. Is lost. In the 3000 Series Manual CMM Arm made by Cimcore (USA), a sliding peg fixing is attached to the compensation device on axis 2 (first orthogonal hinge axis) and when the peg slides into the hole , The compensation device through which

手動CMMアームの光学プローブ

手動CMMアームの光学プローブは、本発明の発明者であるCramptonにより、WO9705449を含むいくつかの特許出願に開示された。手動CMMアームの光学プローブは、特に、3D Scanners、Romer、Faro Technologies、Perceptron、Steinbichler(ドイツ)、Pulstec(日本)、及びKreon(フランス)により提供又は開発されている。光学プローブは、概して、手動CMMアームの側部にずらして取り付けられるか、又は手動CMMアームのプローブ端に取り付けられる。大別すると3つのタイプの光学プローブ、すなわちポイント光学プローブ、ライン光学プローブ、及びエリア光学プローブがある。今のところ、ポイント光学プローブ、ライン光学プローブ、及びエリア光学プローブに関する精度を測定すべき方法を規定する測定精度標準はない。市場は、実用的な方法で精度を確かめて光学プローブのタイプ間を比較することを可能にする標準試験を行うことができないという状況にある。光学プローブは、主にその測定範囲が短いことから、高精度になってきている。概して、光学プローブは、20〜40mmのオーダの測定範囲にわたって測定データを収集する。これは、手動CMMアームの端から離れている場合が多い。最も優れた手動CMMアームを最も優れた光学プローブと組み合わせた場合の精度は、すでに0.050mm(+/−2シグマ)よりも高精度であり、測定範囲が短ければ0.010mm(+/−2シグマ)よりも、さらには0.002mm(+/−2シグマ)よりも高精度になり得る。

Manual CMM Arm Optical Probes Manual CMM Arm optical probes have been disclosed in several patent applications including WO 9705449 by the inventor of the present invention, Crampton. Optical probes for manual CMM arms are provided or developed by 3D Scanners, Romer, Faro Technologies, Perceptron, Steinbichler (Germany), Pulstec (Japan), and Kreon (France), among others. The optical probe is generally mounted off the side of the manual CMM arm or attached to the probe end of the manual CMM arm. Broadly speaking, there are three types of optical probes: point optical probes, line optical probes, and area optical probes. At present, there is no measurement accuracy standard that defines how accuracy should be measured for point optical probes, line optical probes, and area optical probes. The market is in a situation where it is not possible to carry out standard tests that make it possible to compare accuracy between optical probe types in a practical way. Optical probes have become highly accurate mainly due to their short measurement range. In general, an optical probe collects measurement data over a measurement range on the order of 20-40 mm. This is often away from the end of the manual CMM arm. The accuracy when combining the best manual CMM arm with the best optical probe is already higher than 0.050 mm (+/- 2 sigma), and 0.010 mm (+/-) if the measurement range is short 2 sigma) and even higher than 0.002 mm (+/- 2 sigma).

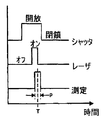

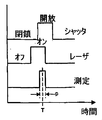

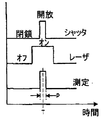

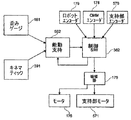

手動CMMアームの光学プローブの同期化及び補間

手動CMMアーム及び光学プローブを備えるシステムでは、それぞれからの測定値が合成されて、出力測定データが与えられる。本発明の発明者であるCramptonによるWO9705449に開示されているように、手動CMMアーム及び光学プローブを備えるシステムの測定精度は、手動CMMアームからの測定と光学プローブからの測定のタイミングを同期させることにより高まる。代替的に、WO9705449にさらに開示されているように、手動CMMアーム及び光学プローブを備えるシステムの測定精度は、手動CMMアームからの各測定値にタイムスタンプし、光学プローブからの各測定値にタイムスタンプし、その後、2つの測定値セットを補間して組み合わせた測定値セットを提供するプロセスを用いることにより高まる。しかしながら、場合によっては、システムに混乱が起こり、いずれかのデバイスからの1つ又は複数の測定値が失われる。この状況では、後半の補間プロセスが複雑になり得る。

Manual CMM Arm Optical Probe Synchronization and Interpolation In systems with a manual CMM arm and optical probe, measurements from each are combined to provide output measurement data. As disclosed in WO 9705449 by Crampton, the inventor of the present invention, the measurement accuracy of a system comprising a manual CMM arm and an optical probe synchronizes the timing of the measurement from the manual CMM arm and the measurement from the optical probe. Will increase. Alternatively, as further disclosed in WO 9705449, the measurement accuracy of a system comprising a manual CMM arm and an optical probe is time stamped on each measurement from the manual CMM arm and timed on each measurement from the optical probe. It is enhanced by using a process that stamps and then interpolates the two measurement sets to provide a combined measurement set. However, in some cases, the system is confused and one or more measurements from any device are lost. In this situation, the later interpolation process can be complicated.

ロボット及び手動CMMアームの較正及び位置合わせ

Shellによる米国特許第5,687,293号に開示されているように、ロボットは、基準球体と、ロボットに取り付けられている先端が球状のプローブとを用いて、種々のロボット空間レイアウトで先端が球状のプローブを基準球体に複数回接触させることにより、較正することができる。6軸ロボットの実施形態の39パラメータキネマティックモデルが開示されている。ロボットに対する光学プローブの位置合わせは、De Smetによる米国特許第6,321,137号(B1)に開示されている。手動CMMアームを手動で較正する方法は、Faro Technologiesに譲渡されたRaabによる米国特許第5,402,582号に開示されている。手動CMMアームは、出荷前に製造業者により較正される。Faro Technologiesを含むいくつかの供給業者は、手動CMMアームの較正は同じまま、ユーザがプローブを交換するたびに簡単にプローブ較正を行うことができるようにしている。OGP UKは、極性(Polar)手動CMMアームを供給し、ユーザが簡単な手順で極性アーム及びプローブを合わせて完全に較正することができるようにしており、この手順は、アームを様々な空間レイアウトで動かしながら、極性アームの球状プローブが置かれる複数の円錐を有する基準アーチファクトを用いて行われる。これらの6軸極性アームには39パラメータ運動力学(kinematic)モデルが用いられる。手動CMMアームの完全且つ高精度な手動較正は、通常は500の別個のポイントが数時間かかるプロセスで記録される、骨の折れるプロセスである。各ポイントで人的ミスが起こりやすい。異なる作業者が異なる場所で手動CMMアームを保持し、異なるグリップを介して異なるトルクを付与し、異なるパターンの荷重及び曲げモーメントをアームに加えるため、異なる撓み及び端部傾斜が生じる。手動で較正される手動CMMアームは、各作業者の持ち方及び使用の仕方に応じて異なった機能をすることになる。各空間的向きでどのような持ち方をしても、再現可能なパターンの荷重及び曲げモーメント下にあるような手動CMMアームが必要である。異なる作業者が用いる場合に生じる荷重及び曲げモーメントが同じパターンであるような、手動CMMアームを手動で較正する方法が必要である。その較正の再現性及び精度を高め、特に現在の手動プロセスで実用的又は費用効果的であるよりも多くのポイントを記録することを可能にする、手動CMMアームを自動で較正する方法が必要である。手動CMMアームに対する光学プローブの位置合わせ(較正又は適格化(qualification)としても知られる)は、本発明の発明者であるCramptonによるWO9705449号に開示されている。

Calibration and alignment of robots and manual CMM arms

As disclosed in US Pat. No. 5,687,293 by Shell, the robot uses a reference sphere and a probe with a spherical tip attached to the robot, and the tip is arranged in various robot space layouts. Calibration can be done by bringing the spherical probe into contact with the reference sphere multiple times. A 39-parameter kinematic model of a 6-axis robot embodiment is disclosed. The alignment of the optical probe with respect to the robot is disclosed in US Pat. No. 6,321,137 (B1) by De Smet. A method for manually calibrating a manual CMM arm is disclosed in US Pat. No. 5,402,582 by Raab assigned to Faro Technologies. The Manual CMM Arm is calibrated by the manufacturer before shipping. Several suppliers, including Faro Technologies, allow manual probe calibration to be easily performed each time the user changes the probe while the calibration of the manual CMM arm remains the same. OGP UK supplies Polar manual CMM arms, allowing users to fully calibrate polar arms and probes together in a simple procedure, which allows the arm to be placed in various spatial layouts. This is done using a reference artifact having a plurality of cones on which the spherical probe of the polar arm is placed. A 39-parameter kinematic model is used for these 6-axis polar arms. Full and accurate manual calibration of a Manual CMM Arm is a laborious process, typically 500 separate points are recorded in a process that takes several hours. Human error is likely to occur at each point. Different workers hold the Manual CMM Arm at different locations, apply different torques through different grips, and apply different patterns of loads and bending moments to the arms, resulting in different flexures and end tilts. A manual CMM arm that is manually calibrated will function differently depending on how each operator holds and uses. Whatever way you hold in each spatial orientation, you need a manual CMM arm that is under a reproducible pattern of loads and bending moments. There is a need for a method of manually calibrating a manual CMM arm such that the loads and bending moments that occur when used by different workers are in the same pattern. There is a need for a method of automatically calibrating a manual CMM Arm that increases the reproducibility and accuracy of its calibration and allows more points to be recorded than is practical or cost effective, especially with current manual processes. is there. The alignment of the optical probe to the manual CMM arm (also known as calibration or qualification) is disclosed in WO 9705449 by Crampton, the inventor of the present invention.

ロボット及び測定デバイスの取り付け

Tounai他による米国特許第5,392,384に開示されているように、6軸関節測定デバイスの先端は、ロボットを較正するためにロボットの先端に取り付けられる。Faro Technologiesに譲渡されたRaabによる米国特許第6,535,794号に開示されているように、6軸関節測定デバイスの先端は、誤差マップを生成するためにロボットの先端に取り付けられる。Bieg他による米国特許第6,519,860号に開示されているように、3軸関節測定デバイスの先端は、ロボット又は機械の空間性能を測定するためにロボット又は機械の先端に取り付けられる。これらの開示はいずれも、物体を測定するためには用いられていない。WahrburgによるWO98/27887に開示されているように、外科ロボット及び多継手センサアームがベースに取り付けられる。多継手センサアームを手動で用いて患者の測定が行われ、これらの測定に基づいてロボットプログラムが生成され、ロボットが外科的介入を実行する。この開示では、測定は自動化されていない。従来技術の2つのアイテムが、曲げによる撓み及び/又は熱膨張を受けやすいロボットアームの端点の位置及び/又は向きを測定するデバイスを開示している。Flemmingによる米国特許第4,119,212号に開示されているように、両端にしっかりと取り付けられた平面ゴニオメータを有する単純な膝継手を用いて、移動セグメントの端の場所が監視される。このデバイスは、平面での動作に制限され、面外の曲げは測定されない。したがって、このデバイスは、3D空間での位置及び向きを測定することができない。Slocumによる米国特許第4,606,696号に開示されているように、ロボットアームの端の位置及び向きを測定するデバイスは、回転軸受及びリニア軸受により繋がれる多数の測定リンクと、回転角及び直線移動を測定する測定デバイスとを備える。測定リンクは、ロボットアームの両端点にピン留めされるだけでなく、少なくとも1つの中間ヒンジ継手でロボットアームにしっかりとピン留めされる。この手法には、6軸ロボットに対して12個の高精度な回転及び直線測定デバイスが必要である。12個の測定デバイスからの誤差が積み重なるため、この手法を6軸ロボットの高精度な3D測定デバイスに発展させることが果たしてできるかどうかは疑わしくなる。付加的な回転及び直線測定デバイスが必要なく、それらに関連する誤差が積み重ならない、より単純でより堅牢なシステムが必要である。米国特許第4,119,212号及び米国特許第4,606,696号はいずれも、ロボットアームの各端に測定デバイスをしっかりと取り付けることを必要とする。プローブ端へのしっかりとした取り付けは、ロボットアームの端の位置を正確に測定するのに必須である。ロボットアームを用いてCMMアームを位置決めする場合、プローブ端へのしっかりとした取り付けは必要なく、望ましくもない。米国特許第4,119,212号及び米国特許第4,606,696号はいずれも、デバイスにおいて較正情報を用いる手段を提供していない。これらはいずれも、デバイスを座標測定機として用いることを提案していない。較正情報を用いなければ、デバイスが現在の用途で必要とされるほど高精度になり得るかどうかは疑わしい。

Installation of robot and measuring device

As disclosed in US Pat. No. 5,392,384 to Tounai et al., The tip of the six-axis articulation measurement device is attached to the tip of the robot to calibrate the robot. As disclosed in US Pat. No. 6,535,794 by Raab assigned to Faro Technologies, the tip of the six-axis articulation device is attached to the tip of the robot to generate an error map. As disclosed in US Pat. No. 6,519,860 to Bieg et al., The tip of the three-axis articulating device is attached to the tip of the robot or machine to measure the spatial performance of the robot or machine. None of these disclosures are used to measure objects. A surgical robot and a multi-joint sensor arm are attached to the base as disclosed in WO 98/27887 by Wahrburg. Patient measurements are made manually using the multi-joint sensor arm, a robot program is generated based on these measurements, and the robot performs the surgical intervention. In this disclosure, the measurement is not automated. Two items of the prior art disclose devices that measure the position and / or orientation of the end points of robotic arms that are susceptible to bending deflection and / or thermal expansion. As disclosed in U.S. Pat. No. 4,119,212 by Flemming, the location of the end of the moving segment is monitored using a simple knee joint having a planar goniometer securely attached to both ends. This device is limited to operation in a plane and no out-of-plane bending is measured. Therefore, this device cannot measure the position and orientation in 3D space. As disclosed in U.S. Pat. No. 4,606,696 to Slocum, a device for measuring the position and orientation of the end of a robot arm comprises a number of measurement links connected by rotary and linear bearings, a rotation angle and A measuring device for measuring linear movement. The measurement link is not only pinned to the end points of the robot arm, but is also firmly pinned to the robot arm with at least one intermediate hinge joint. This technique requires twelve highly accurate rotation and linear measurement devices for a 6-axis robot. Since the errors from the twelve measuring devices accumulate, it is questionable whether this technique can be developed into a highly accurate 3D measuring device for a 6-axis robot. There is a need for a simpler and more robust system that does not require additional rotational and linear measurement devices and does not accumulate the errors associated with them. U.S. Pat. No. 4,119,212 and U.S. Pat. No. 4,606,696 both require a measurement device to be securely attached to each end of the robot arm. Secure attachment to the probe end is essential to accurately measure the position of the end of the robot arm. When positioning a CMM arm using a robotic arm, a secure attachment to the probe end is not necessary or desirable. Neither US Pat. No. 4,119,212 and US Pat. No. 4,606,696 provide a means for using calibration information in the device. None of these suggests using the device as a coordinate measuring machine. Without calibration information, it is questionable whether the device can be as accurate as needed in current applications.

他の背景

GoochによるPCT/GB01/01590に開示されているように、ロボットのプローブ端に光学プローブ及び工具の両方が取り付けられるロボットが示され、このロボットを用いて、光学プローブでの測定及び工具での作業を選択的に行うことができる。しかしながら、測定精度を得るために、上述の欠点の全てを有する光学追跡システムが用いられる。GoochによるPCT/GB01/01590にさらに開示されているように、ロボットは、移動式であり、例えばレール上に取り付けられて、測定中の大きな物体の周りにアクセスできるようにする。このさらなる開示も、光学追跡の欠点を有する。Faroのアームを利用する手動罫書き(marking out)システム及びKuka製の産業ロボットを利用するロボット罫書きシステムが、GoochによるPCT/GB01/03865に開示されている。これら2つのシステムは、高精度であるか又は自動化されているが、両方を兼ね備えてはいない。手動CMMアームに取り付けられた非接触センサによる、回転テーブル上の物体の手動走査は、本発明の発明者であるCramptonにより、WO9705449に開示されている。大きな物体のフライス削り(milling)は、標準的な5軸又は6軸の産業ロボットにより実行されているが、得られる物体は、標準的な産業ロボットの精度が限られているため高精度ではなく、通常は、種々の向きからの切削が行われる手仕上げが必要である。大きな物体のフライス削りは、Mecof spa(イタリア)により製造されるもの等の大型の5軸マシニングセンターと、Zeiss製及びLK Tool製のもの等の大型の5軸水平アームCMMとで、正確に行われることが普通である。加工され得る物体の種類は、直交座標型機械(Cartesian machine type)により制限され、例えば、水平アームはコーナの周りを曲がることができない。Delcam(英国)は、5軸及び6軸の産業ロボット用のフライス削りプログラムを生成することが可能な、PowerShapeと呼ばれるソフトウェアを提供している。

Other background

As disclosed in PCT / GB01 / 01590 by Gooch, a robot is shown in which both an optical probe and a tool are attached to the probe end of the robot, using this robot to measure with an optical probe and work with a tool Can be selectively performed. However, to obtain measurement accuracy, an optical tracking system having all of the above-mentioned drawbacks is used. As further disclosed in PCT / GB01 / 01590 by Gooch, the robot is mobile, for example mounted on a rail, allowing access around a large object being measured. This further disclosure also has the disadvantage of optical tracking. A manual marking out system using Faro's arm and a robot marking system using an industrial robot made by Kuka are disclosed in PCT / GB01 / 03865 by Gooch. These two systems are either highly accurate or automated, but not both. Manual scanning of an object on a rotary table by a non-contact sensor attached to a manual CMM arm is disclosed in WO 9705449 by Crampton, the inventor of the present invention. Large object milling is performed by standard 5-axis or 6-axis industrial robots, but the resulting object is not highly accurate due to the limited accuracy of standard industrial robots. Usually, hand finishing is required in which cutting is performed from various directions. Milling of large objects is performed accurately with large 5-axis machining centers such as those manufactured by Mecof spa (Italy) and large 5-axis horizontal arms CMM such as those made by Zeiss and LK Tool. It is normal. The types of objects that can be machined are limited by Cartesian machine types, for example, horizontal arms cannot bend around corners. Delcam (UK) offers software called PowerShape that can generate milling programs for 5-axis and 6-axis industrial robots.

精度の必要性

ユーザは、自身の手動CMMアームからさらに高い精度を得ることを望んでいる。作業者が手動CMMアームに過大な応力を加えること、種々のハンドグリップ位置からアームに加わるモーメントにばらつきがあること、及び組み込まれている釣合い重りが軸受にモーメントを与えることから、手動CMMアームにおいてかなりの誤差が生じる。CMMアームに対する荷重が持ち方の影響を受けず、かなり精度が高い、より再現性が高い手動CMMアームが必要である。人的ミスをなくすように自動化された、より精度が高い較正プロセスがさらに必要である。

Need for accuracy Users want to get even higher accuracy from their manual CMM Arm. In manual CMM arms, the operator applies excessive stress to the manual CMM arm, there are variations in the moment applied to the arm from various handgrip positions, and the built-in counterweight gives moment to the bearing. A considerable error occurs. There is a need for a manual CMM arm that is highly reproducible and highly reproducible, with the load on the CMM arm being unaffected by how it is held. There is a further need for a more accurate calibration process that is automated to eliminate human error.

自動化の必要性

光学プローブを有する手動CMMアームは、通常は連続で長時間用いられる。この時間の大半の間、作業者は、自身から離れた場所にある、多くの場合は不便な場所にある手動CMMアームを保持する。離れて支持される重量は、長い手動CMMアームの場合は数キログラムであり得る。これは重労働であり、多くの作業者を、特に体が小さい人ほど疲労させる。作業者の疲労は一般的な問題であり、これは、病気、機能喪失、又は傷害に至る可能性がある。手動CMMアームを用いて行われる作業の大半は、一度しか光学検査を必要としない独特な構成部品に対するものである。多くの場合、検査される表面は、直接アクセス可能ではなく、アームを操作できるように作業者が上る一時的なガントリが必要である。走査中にプローブと物体との間で相対移動が行われる、走査プローブを担持する手動CMMアームに関する問題は、これらが十分な精度を有していても、システムは自動的に動作することができないため、システムの使用に疲労が伴い、作業者のミス又は手動CMMアームへの過大な応力により、不正確なデータが出力され得ることである。

The need for automation Manual CMM arms with optical probes are usually used continuously for extended periods of time. During most of this time, the operator holds a manual CMM arm that is remote from him, often in an inconvenient location. The remotely supported weight can be several kilograms for a long manual CMM arm. This is hard work and fatigues many workers, especially those with a small body. Worker fatigue is a common problem, which can lead to illness, loss of function, or injury. Most of the work done with the Manual CMM Arm is for unique components that only require optical inspection once. In many cases, the surface to be inspected is not directly accessible, but requires a temporary gantry that allows the operator to climb up to operate the arm. The problem with manual CMM arms carrying scanning probes where relative movement occurs between the probe and the object during scanning is that the system cannot operate automatically even if they have sufficient accuracy Thus, the use of the system is fatigued and incorrect data can be output due to operator error or excessive stress on the manual CMM arm.

アクセス性の必要性

測定すべき物体の形状と、可動部材上のプローブへのそのアクセス性は、用途ごとに異なる。物体の形状のより大きな範囲にアクセスするのに十分な柔軟性を有するCMMほど、有用性が高い。実際には、硬質セグメントにより隔てられた一連の好ましくは6つ又は7つの継手を備える関節アームCMMは、直交軸構成のCMMよりも柔軟性が高いことが、一般的に分かっている。技術の現状では、直交軸構成の自動CMMは、自動関節ロボットアームよりも精度が数オーダ高いことも、一般的に分かっている。直交軸構成の自動CMMは、自動関節アームロボットよりも組み立てライン等の製造環境への配置に適していないことも、一般的に分かっている。問題は、関節式であり十分な精度を有する自動CMM機が利用可能ではないことである。

Necessity of accessibility The shape of the object to be measured and its accessibility to the probe on the movable member vary from application to application. A CMM that is flexible enough to access a larger range of object shapes is more useful. In practice, it has generally been found that articulated arm CMMs with a series of preferably six or seven joints separated by rigid segments are more flexible than orthogonal configuration CMMs. In the current state of the art, it is also generally known that an automatic CMM with orthogonal axis configuration is several orders of magnitude more accurate than an automatic articulated robot arm. It has also been generally found that an orthogonal CMM automatic CMM is less suitable for placement in a manufacturing environment such as an assembly line than an automatic articulated arm robot. The problem is that automatic CMM machines that are articulated and have sufficient accuracy are not available.

可搬性の必要性

1990年代半ばに十分な精度を有するようになって以来、約5,000程度の可搬式手動CMMアームが購入されていることが示すように、可搬式手動CMMアームに対する需要は大きい。それに対応して、可搬式自動CMMアームも必要とされているが、現在は存在していない。

The need for portability As shown by the fact that around 5,000 portable manual CMM arms have been purchased since becoming sufficiently accurate in the mid-1990s, the demand for portable manual CMM arms is large. Correspondingly, a portable automatic CMM arm is also required, but currently does not exist.

堅牢性の必要性

手動CMMアームは、より高精度になるとともに堅牢性が低下してきている。手動CMMアームの既存の設計は、使用及び輸送の際に衝撃、モーメント、及び酷使(abuse:手荒な扱い)を受けやすい、精密測定システムを有する。輸送ケースの既存の設計は単純であるため、手動CMMアームは、特に衝撃により損傷を受ける。堅牢な可搬式手動CMMアームと、輸送時の衝撃から手動CMMアームに加わる力及びモーメントを最小限に抑える輸送ケースとが必要である。

The need for robustness Manual CMM arms have become more accurate and less robust. Existing designs of Manual CMM Arms have precision measurement systems that are susceptible to shock, moments, and abuse during use and transportation. Since the existing design of the transport case is simple, the manual CMM arm is particularly damaged by impact. There is a need for a robust, portable manual CMM arm and a transport case that minimizes the forces and moments applied to the manual CMM arm from impacts during transport.

[発明の概要]

従来技術では、Flemmingが、平面内でのみ使用可能であり面外の曲げを考慮に入れていない、測定アームが取り付けられたロボットアームを開示している。Slocumは、3D空間内で動作するロボットアームのための測定デバイスを開示している。これは、6軸ロボットに対して12個の回転及び直線測定デバイスを必要とし、複雑であり、製造費用が高く、誤差の積み重ねにより精度が制限される。

[Summary of Invention]

In the prior art, Flemming discloses a robot arm fitted with a measuring arm that can only be used in a plane and does not take into account out-of-plane bending. Slocum discloses a measuring device for a robotic arm that operates in 3D space. This requires 12 rotational and linear measuring devices for a 6-axis robot, is complex, expensive to manufacture, and accuracy is limited by error stackup.

したがって、本発明の目的の1つは、3D空間で動作し、且つ軸ごとに1つの測定デバイスしか必要としない、すなわち、6軸CMMアームには6つの角度エンコーダ、7軸CMMアームには7つの角度エンコーダしか必要としない、外骨格及び伝達手段を有するCMMアームを提供することである。これにより、Slocumのデバイスよりも著しく堅牢且つ高精度であり、Flemmingのデバイスでの制限である3D空間で動作することができる、外骨格を有するCMMアームが得られる。手動動作及び自動の両方の実施形態を有する、外骨格を有するCMMアームを提供することが、本発明のさらなる目的である。別の目的は、データを収集できる外骨格を有するCMMアームを提供することである。さらに別の目的は、作業を行うことができる外骨格を有するCMMアームを提供することである。

Thus, one of the objectives of the present invention operates in 3D space and requires only one measurement device per axis,

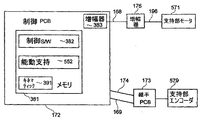

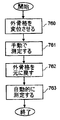

本発明の第1の実施形態では、可搬式ロボットCMMアームが、物体の測定を実行することができるように伝達手段を介して内部CMMアームを支持及び操作する、自動外骨格を備える。ロボットCMMアーム及び内部CMMアームは、ベースにしっかりと取り付けられる。外骨格及び内部CMMアームは、同じ数の軸と、ほぼ同じ継手軸の向き及び継手中心とを有する。ロボットCMMアームは、6つ又は7つの軸を有することが好ましい。外骨格が内部CMMアームの駆動及び支持の両方を行うように、外骨格と内部CMMアームとの間には伝達手段がある。伝達手段は、非硬質であり、内部CMMアームのプローブ端は、外骨格のプローブ端に対してわずかに移動することができる。この第1の実施形態は、ロボットアームのプローブ端と測定デバイスのプローブ端とをしっかりと取り付ける必要があるSlocum及びFlemmingのデバイスとは基本的に異なる。内部CMMアームのプローブ端には、少なくとも1つのプローブが取り付けられる。内部CMMアームからの位置及びプローブからの測定値が組み合わせられ、その組み合わせの曖昧性による精度不良を回避するために、新規の体系的に変化する同期ラベル及び同期方法が提案される。ロボットCMMアームのベースには、制御ボックスが組み込まれる。スリップリングが、軸方向の軸(axial axes)上での無限回転を可能にする。ロボットCMMアームは通常、20〜30kgの重量があり、可搬式であるため、測定される物体の方へ移動させることができる。物体のデータを測定するためにロボットCMMアームを位置決めする方法を提供することが、この第1の実施形態のさらなる目的である。このロボットCMMアームの発明は、新規の構造と、いずれのロボット、手動CMMアーム、又は従来のCMMも可能ではない新規の能力を有する。 In a first embodiment of the invention, the portable Robot CMM Arm comprises an automatic exoskeleton that supports and manipulates the Internal CMM Arm via a transmission means so that object measurements can be performed. The Robot CMM Arm and the Internal CMM Arm are securely attached to the base. The exoskeleton and the internal CMM arms have the same number of axes and approximately the same joint axis orientation and joint center. The Robot CMM Arm preferably has 6 or 7 axes. There is a transmission means between the exoskeleton and the internal CMM arm so that the exoskeleton both drives and supports the internal CMM arm. The transmission means is non-rigid and the probe end of the internal CMM arm can move slightly relative to the probe end of the exoskeleton. This first embodiment is fundamentally different from the Slocum and Flemming devices that require a secure attachment of the probe end of the robot arm and the probe end of the measurement device. At least one probe is attached to the probe end of the internal CMM arm. In order to combine the position from the internal CMM arm and the measurements from the probe and avoid inaccuracies due to the ambiguity of the combination, a new systematically changing synchronization label and synchronization method is proposed. A control box is incorporated in the base of the Robot CMM Arm. A slip ring allows infinite rotation on the axial axes. The Robot CMM Arm usually weighs 20-30 kg and is portable so it can be moved towards the object to be measured. It is a further object of this first embodiment to provide a method for positioning a Robot CMM Arm to measure object data. This Robot CMM Arm invention has a new structure and new capabilities that are not possible with any robot, manual CMM arm, or conventional CMM.

本発明の第2の実施形態では、産業ロボットCMMアームが、内部CMMアームを囲む外骨格を備える。産業ロボットCMMアームには、フライス削り等の作業を行うための工具を取り付けることができる。外骨格及び内部CMMアームは、プローブ端でしっかりと取り付けられることにより、内部CMMアームが工具の位置を測定して、以前のロボットのいずれよりも高精度に空間内で工具をガイドすることができる。 In the second embodiment of the present invention, the Industrial Robot CMM Arm comprises an exoskeleton surrounding the Internal CMM Arm. Tools for performing operations such as milling can be attached to the Industrial Robot CMM Arm. The exoskeleton and the internal CMM arm are securely attached at the probe end, allowing the internal CMM arm to measure the position of the tool and guide the tool in space with greater accuracy than any of the previous robots. .

第3の実施形態では、能動支持ロボットCMMアームが、正確な測定のために外骨格から内部CMMアームを支持し且つ移動させる、能動伝達手段を備える。外骨格は、内部CMMアームを揺動させて、内部CMMアームの重量を減らすとともに、内部CMMアームに対する力及びモーメントを大幅に減らす。伝達手段は非硬質であり、内部CMMアームのプローブ端は、外骨格のプローブ端に対してわずかに移動することができる。これは、能動支持ロボットCMMアームが、他のタイプのロボットCMMアームよりも高精度であることを意味する。さらなる変更形態では、内部CMMアームと外骨格との間に空気軸受が設けられる。 In a third embodiment, the active support Robot CMM Arm comprises active transmission means that support and move the Internal CMM Arm from the exoskeleton for accurate measurement. The exoskeleton swings the Internal CMM Arm, reducing the weight of the Internal CMM Arm and greatly reducing the forces and moments on the Internal CMM Arm. The transmission means is non-rigid and the probe end of the internal CMM arm can move slightly relative to the probe end of the exoskeleton. This means that the Active Support Robot CMM Arm is more accurate than other types of Robot CMM Arm. In a further modification, an air bearing is provided between the internal CMM arm and the exoskeleton.

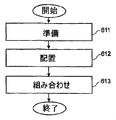

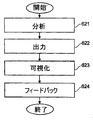

第4の実施形態では、量を計測する方法、量をモデリングする方法、量を分析する方法、量を可視化する方法、及び結果を製造プロセスにフィードバックする方法が開示される。量測定プローブが、ロボットCMMアームのプローブ端に取り付けられる。測定された量を測定中の物体のCADモデルと組み合わせる手段が設けられる。 In a fourth embodiment, a method for measuring quantities, a method for modeling quantities, a method for analyzing quantities, a method for visualizing quantities, and a method for feeding back results to a manufacturing process are disclosed. A quantity measuring probe is attached to the probe end of the Robot CMM Arm. Means are provided for combining the measured quantity with the CAD model of the object being measured.

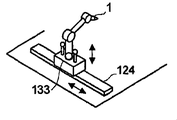

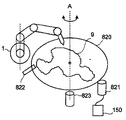

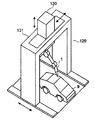

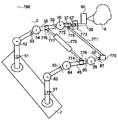

第5の実施形態では、移動式ロボットCMMアームに関する方法及び装置が開示される。ロボットCMMアームが、電気車両に組み込まれた格納可能な足を有する三脚に取り付けられ、或る測定位置から次の測定位置へ移動させられる。これは、車両又は航空機等の大きな物体を自動的に走査するために通常は用いられ、現在用いられている大型の水平タイプ又はブリッジタイプのCMMよりも低価格で柔軟性が高い代替物となる。 In a fifth embodiment, a method and apparatus for a Mobile Robot CMM Arm is disclosed. A Robot CMM Arm is attached to a tripod with retractable legs built into an electric vehicle and moved from one measurement position to the next measurement position. This is typically used to automatically scan large objects such as vehicles or aircraft, and is a cheaper and more flexible alternative to the currently used large horizontal or bridge type CMMs .

第6の実施形態では、変位可能な外骨格を有するロボットCMMアームの実施形態が開示される。内部CMMアームは、外骨格から変位し、ロボットプログラムを生成するために手動で用いられる。内部CMMアームが外骨格に戻されると、ロボットがロボットプログラムを自動的に実行する。ロボットプログラムを生成するための内部CMMアームの手動操作は、教示ペンダントの使用等の従来の方法よりも高速且つ有用であるという利点を有する。 In a sixth embodiment, an embodiment of a Robot CMM Arm having a displaceable exoskeleton is disclosed. The Internal CMM Arm is displaced from the exoskeleton and used manually to generate a robot program. When the Internal CMM Arm is returned to the exoskeleton, the robot automatically executes the robot program. Manual operation of the Internal CMM Arm to generate the robot program has the advantage of being faster and more useful than conventional methods such as using a teaching pendant.

第7の実施形態では、結合されたCMMアーム及びロボットを備えるロボットCMMアームが開示される。CMMアームは、少なくとも2つの位置、すなわちプローブ端と中間位置とにおいて、ロボットにより支持される。この実施形態は、CMMアーム付近からの熱源を移動させるという利点を有する。 In a seventh embodiment, a Robot CMM Arm comprising a coupled CMM Arm and Robot is disclosed. The CMM arm is supported by the robot in at least two positions: a probe end and an intermediate position. This embodiment has the advantage of moving the heat source from near the CMM arm.

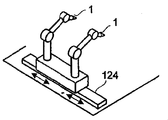

第8の実施形態では、外骨格を有する手動CMMアームが開示される。内部CMMアームは、外骨格により支持及び駆動され、外骨格はさらに作業者により支持及び移動される。現在の手動CMMアームは、作業者が同じアームで操作するように、測定機能、自立機能、及び堅牢性機能を組み合わせる。この第8の実施形態は、測定機能を内部CMMアームに与え、作業者が操作するための支持機能及び堅牢性機能を外骨格に与える。どのような方法で作業者が外骨格を持っても、内部CMMアームは各空間位置で常に全く同じように支持されるため、内部CMMアームに対する荷重が再現可能であり、較正プロセス中の荷重と同じである。この荷重パターンの再現性は、外骨格を有する手動CMMアームが、いかなる既存の手動CMMアームデバイスよりも高精度なデバイスであることを意味する。作業者が無線送信機を有するボタンユニットを外骨格の好都合な場所に取り付けるように、可撓性ボタン手段が設けられ、無線受信機がシステムに組み込まれる。望ましくない衝撃及び荷重から内部CMMアームを守るために、バンプストップ手段が外骨格に設けられる。打撃からプローブを保護し、接触プローブに対する荷重の一部を補償するために、プローブカバーが設けられる。外骨格を有する手動CMMアームと比較して、より小型であり、特に手首及びプローブ領域における操作が改善されているが、依然として著しく高い精度を有する、部分外骨格を有する複数の手動CMMアームが開示される。外骨格と複数の異なる接触プローブ及び非接触プローブとを有する手動CMMアームを用いるための、測定方法が提供される。外骨格を有する手動CMMアームのための自動較正装置及び方法が開示される。輸送中に外骨格を有する手動CMMアームに加わる衝撃荷重の大きさを最小にするために、荷重分散機構を有する輸送ケースが提供される。 In an eighth embodiment, a manual CMM arm having an exoskeleton is disclosed. The internal CMM arm is supported and driven by the exoskeleton, which is further supported and moved by the operator. Current manual CMM arms combine measurement, self-supporting, and ruggedness features so that an operator operates with the same arm. This eighth embodiment provides a measurement function to the internal CMM arm and a support function and a robust function for the operator to operate on the exoskeleton. Whatever way the operator holds the exoskeleton, the internal CMM arm is always supported in exactly the same way at each spatial position, so the load on the internal CMM arm is reproducible, and the load during the calibration process The same. This reproducibility of the load pattern means that a manual CMM arm with an exoskeleton is a more accurate device than any existing manual CMM arm device. Flexible button means are provided and a wireless receiver is incorporated into the system so that the operator can attach the button unit with the wireless transmitter to a convenient location on the exoskeleton. Bump stop means are provided on the exoskeleton to protect the internal CMM Arm from unwanted impacts and loads. A probe cover is provided to protect the probe from hitting and to compensate for some of the load on the contact probe. Disclosed are multiple manual CMM arms with partial exoskeletons that are smaller and have improved maneuverability, especially in the wrist and probe areas, but still have significantly higher accuracy compared to manual CMM arms with exoskeletons Is done. A measurement method is provided for using a manual CMM arm having an exoskeleton and a plurality of different contact and non-contact probes. An automatic calibration apparatus and method for a manual CMM arm having an exoskeleton is disclosed. In order to minimize the magnitude of the impact load applied to the manual CMM arm with the exoskeleton during transport, a transport case with a load distribution mechanism is provided.

第9の実施形態では、保持外骨格を有する手動CMMアームが開示される。外骨格における1つ又は複数の継手は、ブレーキによりロックすることができる。これは、作業者が動作の途中で中断する必要がある場合に、アームがどの位置にあってもロックすることができるため、アームを停止位置に戻す必要がなくなることを意味する。以前のブレーキシステムは、CMMアームに対して作用し、CMMアームに荷重を加えていたが、この実施形態は、内部CMMアームにいかなる荷重も加えずに、外骨格に対して作用するという利点を有する。 In a ninth embodiment, a manual CMM arm having a holding exoskeleton is disclosed. One or more joints in the exoskeleton can be locked by a brake. This means that when the operator needs to be interrupted in the middle of the operation, the arm can be locked at any position, so that it is not necessary to return the arm to the stop position. Previous brake systems acted on the CMM arm and applied a load to the CMM arm, but this embodiment has the advantage of acting on the exoskeleton without applying any load to the internal CMM arm. Have.

第10の実施形態では、本発明の内骨格を有する手動CMMアームの実施形態が開示される。CMMアームは、支持内骨格の外部にある。以前のデバイスでは、カウンターバランス機能は、Romer及びCimcoreのデバイスのようにアームと平行でアームの外部にあったか、又はアームに曲げモーメントが加わるようにアームに埋め込まれていた。本発明は、CMMアームの内側に補償機能を隠すとともに、アームに曲げモーメントを加えずに補償する。 In a tenth embodiment, an embodiment of a manual CMM arm having an endoskeleton of the present invention is disclosed. The CMM arm is outside the supporting endoskeleton. In previous devices, the counterbalance function was either parallel to the arm, like the Romer and Cimcore devices, or external to the arm, or embedded in the arm so that a bending moment was applied to the arm. The present invention hides the compensation function inside the CMM arm and compensates without applying a bending moment to the arm.

第11の実施形態では、内骨格を有するロボットCMMアームが開示される。このCMMアームは、支持及び駆動ロボット内骨格の外部にある。第1の利点は、外部CMMアームが全てのドライブ(drives:駆動機構)を隠すため、アクセスが限られている用途に適したアームが提供されることである。第2の利点は、外部CMMアームがより大きな断面を有し、且つあまり曲がらないため、より高精度になることである。 In an eleventh embodiment, a Robot CMM Arm having an endoskeleton is disclosed. This CMM arm is outside the support and drive robot endoskeleton. The first advantage is that an external CMM arm hides all the drives, thus providing an arm suitable for limited access applications. The second advantage is that the external CMM arm has a larger cross section and does not bend very much, resulting in higher accuracy.

次に、本発明の実施形態を、添付図面を参照して例としてのみ説明する。 Embodiments of the present invention will now be described by way of example only with reference to the accompanying drawings.

[好ましい実施形態の形態]

[第1の実施形態]

可搬式ロボットCMMアーム

本発明の外骨格を有するCMMアームの第1の実施形態は、可搬式ロボットCMMアームである。この可搬式ロボットCMMアームの実施形態は、外骨格によりガイドされる内部CMMアームを備える。外骨格は、高精度な測定ができるように、伝達手段を介して内部CMMアームを支持及び操作する。本発明は、多くのロボットCMMアームの関節アームレイアウトで具現することができる。本発明の第1の実施形態によるロボットCMMアームには、2つの好ましいレイアウト、すなわち、6つの継手を有する6軸型及び7つの継手を有する7軸型がある。

[Preferred Embodiment]

[First Embodiment]

Portable Robot CMM Arm A first embodiment of a CMM arm having an exoskeleton of the present invention is a portable Robot CMM Arm. This embodiment of the portable Robot CMM Arm comprises an Internal CMM Arm guided by an exoskeleton. The exoskeleton supports and manipulates the internal CMM arm via a transmission means so that highly accurate measurements can be made. The present invention can be implemented in the articulated arm layout of many Robot CMM Arms. There are two preferred layouts for the Robot CMM Arm according to the first embodiment of the invention: a 6-axis type with 6 joints and a 7-axis type with 7 joints.

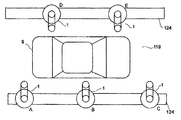

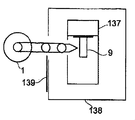

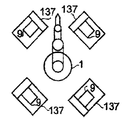

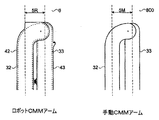

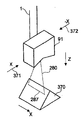

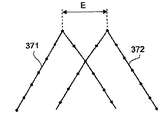

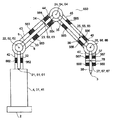

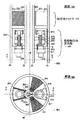

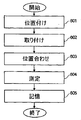

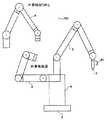

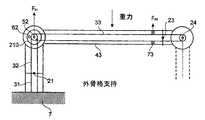

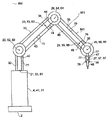

ロボットCMMアームの継手及びセグメントのレイアウト

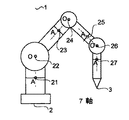

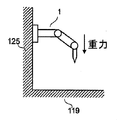

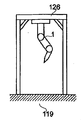

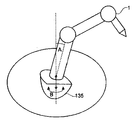

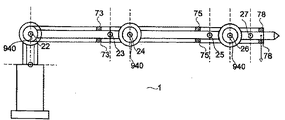

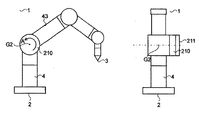

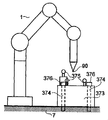

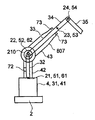

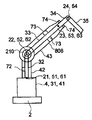

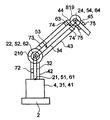

図1A及び図1Bは、本発明の第1の実施形態によるロボットCMMアーム1の好ましい6軸レイアウト及び7軸レイアウトそれぞれを示す図である。関節ロボットCMMアーム1は、ベース端2及びプローブ端3を有し、2端間に一連のセグメント及び回転継手を備える。2つのタイプの継手、軸方向継手及び直交継手がある。軸方向継手(図1A、図1Bでは「A」と記す)は、その2つの隣接するセグメントの共通軸を中心に回転する。直交継手(図1A及び図1Bでは「O」と記す)は、その2つの隣接するセグメント間のヒンジとして回転する。図1Aでは、継手のタイプは、ベース端2からプローブ端3まで順に、AOOAOAであり、これらはそれぞれ継手中心21、22、24、25、26、及び27を指す。図1Bでは、継手のタイプは、ベース端2からプローブ端3まで順に、AOAOAOAであり、これらはそれぞれ継手中心21、22、23、24、25、26、及び27を指す。6軸レイアウトは、7軸レイアウトよりも低費用であるという利点を有する。7軸レイアウトは、6軸レイアウトよりも複雑な物体へのアクセスの柔軟性が高いという利点を有する。

Robot CMM Arm Joint and Segment Layout FIGS. 1A and 1B are diagrams illustrating a preferred 6-axis layout and 7-axis layout of the

図1Bの好ましい7軸ロボットCMMアーム1は、本発明のロボットCMMアーム1のこの第1の実施形態で説明されているが、本発明は、この継手レイアウト又は図1Aの好ましい6軸レイアウトに限定されず、軸受は7つよりも多くても少なくてもよい。単純な用途では、3つの継手で十分であり得る。本発明は、回転移動軸のみに限定されない。以下で開示されるように、本発明は、ベース端2を取り付けることが好ましい1つ又は複数の直線移動軸を備えていてもよい。

Although the preferred 7-axis

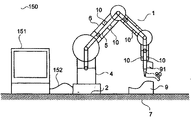

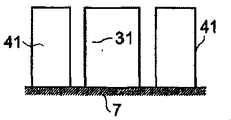

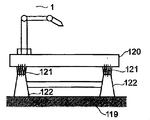

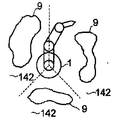

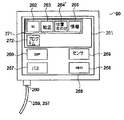

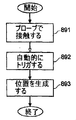

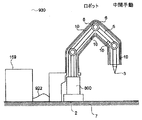

図1cは、ケーブル152によりラップトップコンピュータ151に接続されるロボットCMMアーム1を備える、ロボットCMMアームシステム150を示す。ロボットCMMアーム1は、ベース端2及びプローブ端3を有する。ロボットCMMアーム1は表面7に取り付けられる。ロボットCMMアーム1のプローブ端3には、プローブ90が取り付けられる。ロボットCMMアーム1のプローブ端3付近には、光学プローブ91も取り付けられる。ロボットCMMアーム1は、ベース4、内部CMMアーム5、外骨格6、及び伝達手段10を備える。測定される物体9は、表面7に配置される。

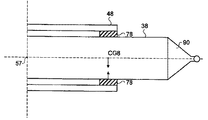

FIG. 1 c shows a Robot

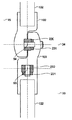

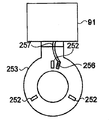

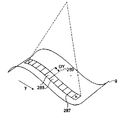

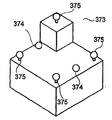

図2は、ロボットCMMアーム1の2つの主要部品、すなわち、内部CMMアーム5及び外骨格6を示し、これらは、共通のベース4と、共通の継手中心21、22、23、24、25、26、及び27とを共有する。内部CMMアーム5は、本明細書中でそれぞれCMMセグメント2〜8と呼ばれる、セグメント32、33、34、35、36、37、及び38を備える。CMMセグメント8 38は、ロボットCMMアーム1のプローブ端3に達する。共通のベース4は、CMMセグメント31とも呼ばれる。内部CMMアーム5はさらに、本明細書中でそれぞれCMM継手1〜7と呼ばれる、継手51、52、53、54、55、56、57を備える。外骨格6は、本明細書中でそれぞれ外骨格セグメント2〜8と呼ばれる、セグメント42、43、44、45、46、47、及び48を備える。外骨格セグメント8 48は、ロボットCMMアーム1のプローブ端3まで達しない。共通のベース4は、外骨格セグメント41とも呼ばれる。外骨格6はさらに、本明細書中でそれぞれ外骨格継手1〜7と呼ばれる、継手61、62、63、64、65、66、及び67を備える。ロボットCMMアーム1はさらに、本明細書中でそれぞれ伝達手段2〜8と呼ばれる、伝達手段72、73、74、75、76、77、及び78を備え、これらは内部CMMアーム5を外骨格6に取り付ける。伝達手段2 72は、CMMセグメント2 32を外骨格セグメント2 42に取り付ける。伝達手段3 73は、CMMセグメント3 33を外骨格セグメント3 43に取り付け、伝達手段4 74、5 75、6 76、7 77、及び8 78に関しても同様である。

FIG. 2 shows two main parts of a

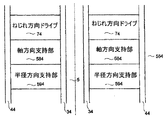

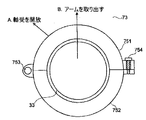

内部CMMアームの継手及びセグメントのレイアウト

ロボットCMMアーム1の内部CMMアーム5のセグメント及び継手は、概して以下のように命名及びレイアウトされる。

Inner CMM Arm Joint and Segment Layout The segments and joints of the

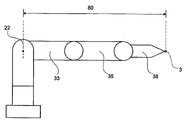

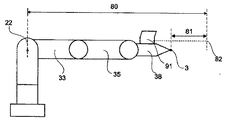

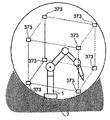

次に図3を参照すると、ロボットCMMアーム1のリーチ80は、CMM継手3〜7がこの距離を最大にするように回転する場合の、継手中心2 22からCMMセグメント8 38のプローブ端3までであると定義される。ロボットCMMアーム1のリーチ80の大部分は、CMMセグメント3 33の長さ及びCMMセグメント5 35の長さの和から成る。

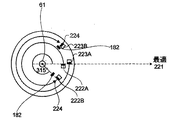

Referring now to FIG. 3, the

次に図4を参照すると、光学プローブ91がCMMセグメント8 38に取り付けられている場合、リーチ80は、CMMセグメント8 38のプローブ端3と測定が行われ得る測定深さの光学測定中点82との間の距離である仮想リーチ81だけ増加する。

Referring now to FIG. 4, when the

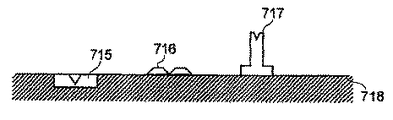

各CMMセグメントは高い剛性を有する。内部CMMアーム5に対して少しでも荷重があると、セグメントの曲げ又はねじれが生じ、内部CMMアーム5の精度を低下させることになる。重力は持続的な荷重源であり、重力の影響は、ロボットCMMアーム1の空間的向きが異なれば異なる。通常の使用時におけるロボットCMMアームの長いCMMセグメントの典型的な最大角度ねじれ傾斜(maximum angular torsional slope)は0.25秒角であるが、特にCMMセグメントの長さに応じて、それよりも大きくても小さくてもよい。通常の使用時におけるロボットCMMアームの長いCMMセグメントの典型的な最大角度曲げ傾斜(maximum angular bending slope)は0.5秒角であるが、長いCMMセグメントの材料、長さ、及び直径に応じて、それよりも大きくても小さくてもよい。

Each CMM segment is highly rigid. If any load is applied to the

各CMMセグメントは、1つ又は複数の重要なアイテムを備える。 Each CMM segment comprises one or more important items.

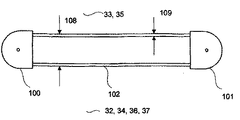

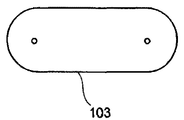

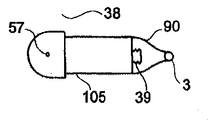

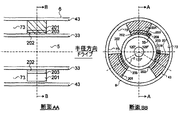

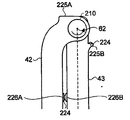

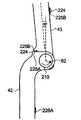

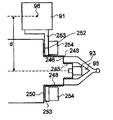

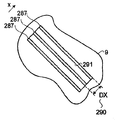

次に図5Aを参照すると、CMMセグメント3 33、5 35は、それぞれ1つの継手を収容する2つの端ハウジング100と101との間に、直径108及び肉厚109を有するリンク部材102を備える。次に図5Bを参照すると、CMMセグメント2 32、4 34、6 36、及び7 37は、各端に1つずつ2つの継手を収容するダブルハウジング103を備える。次に図5C1を参照すると、CMMセグメント8 38は、一端にCMM継手7 57を収容するプローブ端ハウジング105を備え、他端には、プローブ端3で終端するプローブ90が取り付けられるCMMプローブ取り付け手段39がある。CMM継手2 52、4 54、6 56に直交継手を設ける種々のオプションがあることが理解されるであろう。次に図5C2を参照すると、カンチレバーオプション及びインラインオプションが、CMM継手2 52に関して示される。CMM継手2 52、4 54、6 56の好ましいオプションはインライン(in-line:直列)である。ロボットCMMアーム1の範囲は、これらの継手オプションのいずれにも限定されず、任意の他の設計の直交継手を含むことができる。

Referring now to FIG. 5A,

外骨格の継手及びセグメントのレイアウト

ロボットCMMアーム1の外骨格6のセグメント及び継手は、概して以下のように命名及びレイアウトされる。

Exoskeleton Joint and Segment Layout The segments and joints of the

各外骨格セグメントは、1つ又は複数の重要なアイテムを備える。 Each exoskeleton segment comprises one or more important items.

ベースのレイアウト

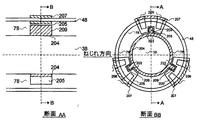

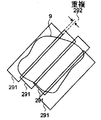

次に図5Dを参照すると、ベース4は、標準3.5インチの強力ねじ(heavy duty thread)116によって取り付け板8に螺入される、軸受中心21を有するCMM継手1 51を収容するCMMセグメント1 31と、ボルト106によってCMMセグメント 31にしっかりと取り付けられる、継手中心21を有する外骨格継手1 61を収容する外骨格セグメント1 41とを備える。取り付け板8は、取り付けボルト107等の取り付け手段104によって表面7に取り付けられる。内部CMMアーム5及び外骨格6の両方が、ベースセグメント31、41をそれぞれ有する。この第1の実施形態では、外骨格セグメント1 41は、座ぐり穴用ボルト(counter-bored bolts)106によりCMMセグメント1 31にしっかりと取り付けられる。次に図5Eを参照すると、本発明のロボットCMMアーム1の別の実施形態では、CMMセグメント1 31が外骨格セグメント1 41に取り付けられないように、CMMセグメント1 31は第1の表面7aに取り付けることができ、外骨格セグメント1 41は第2の表面7bに取り付けることができる。次に図5Fを参照すると、本発明のロボットCMMアーム1のさらなる実施形態では、CMMセグメント1 31及び外骨格セグメント1 41の両方を、同じ表面7に独立して取り付けることができる。表面7とベース2との間にベース延長セクションを設けることにより、CMM継手1 51を表面7からさらに高い位置に上昇させることができる。このようなベース延長セクションは、通常は0.075ppm/℃という低い熱膨張率を有する炭素繊維織物から成る軽量管に基づいていることが好ましい。これは、表面7に対するベース延長管を有するロボットCMMアーム1の測定が、温度の変化に大きな影響を受けないことを意味する。次に図5Gを参照すると、本発明のロボットCMMアーム1のさらなる実施形態では、CMMセグメント1 31を、表面7に取り付けられた外骨格セグメント1 41にしっかりと、又は移動可能に(flexibly)取り付けることができる。次に図5Hを参照すると、本発明のロボットCMMアームのさらなる実施形態では、CMMセグメント1 31及び外骨格セグメント1 41は、表面7に取り付けられた同じベースアイテム4であってもよく、CMMセグメント2 32及び外骨格セグメント2 42の両方が、それぞれCMM継手1 51及び外骨格継手1 61を介してこれに取り付けられる。いかなるベース取り付け形態があってもよいことが、本発明のロボットCMMアームの目的である。

Base Layout Referring now to FIG. 5D, the base 4 houses a CMM joint 151 having a bearing

ロボットCMMアームのリーチ

本発明のロボットCMMアーム1は、この第1の実施形態では、種々のリーチを有する或る範囲の可搬式ロボットCMMアームとして提供される。可搬式ロボットCMMアームのリーチ80は、0.6mから3mまで様々である。本発明の範囲は、この範囲内のリーチに限定されず、リーチ80は、0.6mよりも短くてもよく、又は3mよりも長くてもよい。

Reach of Robot CMM Arm The

内部CMMアームの構造

剛性及び質量

本発明の目的の1つは、内部CMMアーム5の質量を最小にすることである。これによりさらに、剛性が低くてよく、内部CMMアーム5を動かす原動力も少なくてよいため、可搬式ロボットCMMアーム1の質量を最小にすることができ、それによりロボットCMMアーム1の可搬性がより高まる。有益な相乗効果があり、内部CMMアーム5から質量を100g除去するごとに、ロボットCMMアーム1の設計から約250〜400gを除去することができることが、経験により示されている。中程度のリーチを有する内部CMMアーム5の移動部品の典型的な重量は、2.5〜4kgである。内部CMMアーム5に対する、特に内部CMMアームの継手51〜57に対する応力を最小にするために、外骨格6が内部CMMアーム5を支持及び駆動する。使用時には、外骨格6に対する荷重は、重力及び伝達手段10を介して伝達される荷重だけであるべきである。外骨格6は、内部CMMアーム5を常に同じ場所で支持するため、同じ空間的向きで再現可能に荷重が与えられる。比較すると、技術水準の手動CMMアームは、付加的な応力が作業者により加えられるような設計になっており、この応力は、内部CMMアーム5に対する応力よりも著しく高い上に、作業者が把持する位置及び把持の仕方に応じて、異なる荷重場所及び荷重方向で加えられる。これは、内部CMMアーム5が、同様のリーチを有する手動CMMアームほど高い剛性を必要とせず、より軽量であることを意味する。

Internal CMM Arm Structure Rigidity and Mass One of the purposes of the present invention is to minimize the mass of the

リンク部材の直径及び厚さ