JP2010175835A - Camera apparatus - Google Patents

Camera apparatus Download PDFInfo

- Publication number

- JP2010175835A JP2010175835A JP2009018370A JP2009018370A JP2010175835A JP 2010175835 A JP2010175835 A JP 2010175835A JP 2009018370 A JP2009018370 A JP 2009018370A JP 2009018370 A JP2009018370 A JP 2009018370A JP 2010175835 A JP2010175835 A JP 2010175835A

- Authority

- JP

- Japan

- Prior art keywords

- temperature

- camera

- box

- peltier element

- heat radiator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Camera Bodies And Camera Details Or Accessories (AREA)

- Cameras Adapted For Combination With Other Photographic Or Optical Apparatuses (AREA)

- Accessories Of Cameras (AREA)

- Studio Devices (AREA)

Abstract

Description

本発明は、カメラ装置に係り、特に、遠赤外線カメラのカメラ内部を温度を一定に保つことにより、温度変化によるオフセットを補正することなく、映像を取得するのに好適なカメラ装置に関する。 The present invention relates to a camera device, and more particularly, to a camera device suitable for acquiring an image without correcting an offset due to a temperature change by keeping the temperature inside the camera of a far-infrared camera constant.

ボロメータ方式の遠赤外線カメラの場合、カメラ素子周辺の温度が変化すると映像信号が信号レンジを外れてしまう事態に陥る。この対策としては、一般的には、キャリブレーションをおこない、信号レベルを補正して映像信号レベルを安定させているが、キャリブレーションをおこなうときに、画像が0.3〜1秒ほど停止してしまうことがある。特に、屋外で使用する監視カメラの場合は、外気の変化が大きいため、キャリブレーションが頻繁に発生し、その度に映像が一時停止していることになる。 In the case of a bolometer-type far-infrared camera, when the temperature around the camera element changes, the video signal falls outside the signal range. As a countermeasure, generally, calibration is performed and the signal level is corrected to stabilize the video signal level. However, when calibration is performed, the image is stopped for about 0.3 to 1 second. May end up. In particular, in the case of a surveillance camera used outdoors, since the change in outside air is large, calibration frequently occurs, and the video is paused each time.

したがって、カメラの内部では、外気の環境変化によらず一定の温度に保つことが望ましい。一般に、監視用途等に用いられるカメラ装置を冷却するためには、ファンを取り付けて、それによりカメラ装置の内部の空気を循環させる技術やペルチェ素子(Peltier device)などの冷却素子を発熱部分に接触させる技術が知られている。例えば、特許文献1には、ビデオカメラを強制空冷するための構造が開示されており、特許文献2には、撮像素子の温度変化を検出し、ペルチェ素子を制御して、撮像素子の温度変化を一定に保つ監視用の撮像素子が開示されている。

Therefore, it is desirable to maintain a constant temperature inside the camera regardless of changes in the outside air environment. In general, in order to cool a camera device used for surveillance applications, etc., a fan is attached so that the air inside the camera device is circulated and a cooling element such as a Peltier device is brought into contact with the heat generating part. The technology to make it known is known. For example, Patent Document 1 discloses a structure for forced air cooling of a video camera, and

空冷による冷却方法は、実現するための装置の構成も簡易であり、比較的安価に実現できることから、カメラ装置のみならず、さまざまな装置に使われている。しかしながら、カメラ装置が大きいときには、冷却のために流れる風量を大きくしなければならないが、そのためにファンを回転させるためのモータの消費電力が大きくなるという問題点がある。 The cooling method by air cooling has a simple device configuration and can be realized at a relatively low cost. Therefore, it is used not only for camera devices but also for various devices. However, when the camera device is large, it is necessary to increase the amount of air flowing for cooling, which causes a problem that the power consumption of the motor for rotating the fan increases.

また、ペルチェ素子は、二種類の金属の接合部に電流を流すと、片方の金属からもう片方へ熱が移動するというペルチェ効果(Peltier effect)を利用した板状の半導体素子であり、直流電流を流すと、一方の面が吸熱し、反対面に発熱が起こる特性を有する。このペルチェ素子を利用した冷却構造は、基本構成がペルチェ素子と直流電源のみでよく、コンパクトと振動がないシステムを構成できるという利点がある。また、電流の極性を逆転させると、その関係が反転し高精度の温度制御に適しているとされている。 A Peltier element is a plate-like semiconductor element that uses the Peltier effect, in which heat is transferred from one metal to the other when a current is passed through the junction of two types of metal. When flowing, one surface absorbs heat and the opposite surface generates heat. The cooling structure using the Peltier element has the advantage that the basic configuration may be only a Peltier element and a DC power source, and a compact and vibration-free system can be configured. Further, when the polarity of the current is reversed, the relationship is reversed, and it is said that the current polarity is suitable for high-precision temperature control.

しかしながら、移動させる熱以上に、素子自体の放熱量が大きいため、冷却メカニズムとしては電力効率が悪いという問題点がある。 However, since the heat dissipation amount of the element itself is larger than the heat to be moved, there is a problem that power efficiency is poor as a cooling mechanism.

本発明は、上記問題点を解決するためになされたもので、その目的は、カメラ装置の内部に対して、低消費電力で効率よく冷却と暖房をおこない、カメラ装置の内部を一定温度に保つことにより、キャリブレーションの必要をなくすようなカメラ装置を提供することにある。 The present invention has been made to solve the above-described problems, and its purpose is to efficiently cool and heat the inside of the camera device with low power consumption and keep the inside of the camera device at a constant temperature. Accordingly, an object of the present invention is to provide a camera device that eliminates the need for calibration.

本発明のカメラ装置は、レンズ部と、カメラモジュールとを有し、それらを収納するカメラハウジングを備えるカメラ装置で、レンズ部と、カメラモジュールの温度を一定に保つために、カメラハウジングの内部で断熱構造の恒温ボックスで覆うものとする。そして、レンズ部と、カメラモジュールの反対の一面に、ペルチェ素子を設置する。 The camera device of the present invention is a camera device that includes a lens unit and a camera module and includes a camera housing that houses them. In order to keep the temperature of the lens unit and the camera module constant, the camera device is provided inside the camera housing. It shall be covered with a thermostatic box with a heat insulating structure. And a Peltier element is installed in the lens part and one surface opposite to a camera module.

そして、ペルチェ素子に接触するように、恒温ボックスの内部に内部放熱フィンと前記恒温ボックスの外部に外部放熱フィンを取付ける。それぞれの放熱フィンには、FANが取付けられて空気交換を促進するようにする。 Then, an internal radiating fin is attached inside the thermostatic box and an external radiating fin is attached outside the thermostatic box so as to contact the Peltier element. Each radiating fin is provided with a FAN to facilitate air exchange.

このとき、外気温度が高いときには、内部放熱フィンの温度を低く、外部放熱フィンの温度を高く、反対に、外気温度が低いときには、内部放熱フィンの温度を高く、外部放熱フィンの温度を低くするように、ペルチェ素子を制御する。 At this time, when the outside air temperature is high, the temperature of the internal radiating fin is lowered and the temperature of the external radiating fin is raised, and conversely, when the outside air temperature is low, the temperature of the internal radiating fin is raised and the temperature of the external radiating fin is lowered. Thus, the Peltier element is controlled.

本発明によれば、カメラ装置の内部に対して、低消費電力で効率よく冷却と暖房をおこない、カメラ装置の内部を一定温度に保つことにより、キャリブレーションの必要をなくすようなカメラ装置を提供することができる。 According to the present invention, there is provided a camera apparatus that eliminates the need for calibration by efficiently cooling and heating the interior of the camera apparatus with low power consumption and maintaining the interior of the camera apparatus at a constant temperature. can do.

以下、本発明に係る一実施形態を、図1および図2を用いて説明する。

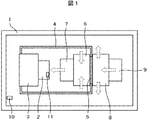

図1は、本発明の一実施形態に係るカメラ装置の断面図である。

図2は、本発明の一実施形態に係るカメラ装置の恒温ボックス4の斜視図である。

Hereinafter, an embodiment according to the present invention will be described with reference to FIGS. 1 and 2.

FIG. 1 is a cross-sectional view of a camera apparatus according to an embodiment of the present invention.

FIG. 2 is a perspective view of the

本実施形態のカメラ装置は、屋外に設置される遠赤外線を利用した監視用カメラ装置などを想定している。本実施形態のカメラ装置の構造としては、屋外用カメラハウジング1の内部に、遠赤外線カメラのカメラモジュール2およびレンズ部3を有している。このカメラモジュール2およびレンズ部3は、断熱性の高い材料で形成された断熱構造の恒温ボックス4で囲われており、カメラハウジング1内部の空気温度とカメラモジュール部2とが遮断されている。したがって、カメラハウジング1内部の温度変化によって、カメラモジュール2内部の温度変化の影響が低減され、温度センサB11には大きな温度変化は検知されない。

The camera device of the present embodiment is assumed to be a monitoring camera device using far infrared rays installed outdoors. As a structure of the camera device of this embodiment, a

また、恒温ボックス4のレンズ部3とカメラモジュール2の反対の壁面には、ペルチェ素子5が配され、恒温ボックス4の内部側には、内部放熱フィン6が、一方の恒温ボックス4の外部側には、外部放熱フィン8が接触するよう取付けられている。また、放熱フィンは、例えば、アルミニウム基板を表面積を大きくなるように積層した構造である。そして、内部放熱フィン6には、FAN7が設置され、外部放熱フィン8には、FAN9が設置され、空気を放熱フィンに送り込むことにより、熱交換を促進している。

In addition, a Peltier

ここで、外気温度(カメラハウジング1の外部の温度)が、高い場合には、ペルチェ素子5を利用して(ペルチェ素子を制御するための直流回路は図示していない)、内部放熱フィン6の温度を低くし、外部放熱フィン8の温度を高くする。恒温ボックス4の内部では、放熱フィン6に取付けられたFAN7から冷却した空気がカメラモジュール2側に送られ、恒温ボックス4の外部では、放熱フィン8に取付けられたFAN9から取り込んだ暖めた空気が放熱フィン8を介して恒温ボックス4の外部に逃がされる。

Here, when the outside air temperature (the temperature outside the camera housing 1) is high, the Peltier

また、反対に、外気温度が、低い場合には、上記の場合のペルチェ素子5に流す電流を逆流させることにより、内部放熱フィン6の温度を高くし、外部放熱フィン8の温度を低くする。上とは逆にこの場合には、恒温ボックス4の内部では、放熱フィン6に取付けられたFAN7から暖めた空気がカメラモジュール2側に送られ、恒温ボックス4の外部では、放熱フィン8に取付けられたFAN9から取り込んだ冷却した空気が放熱フィン8を介して恒温ボックス4の外部に逃がされる。

On the other hand, when the outside air temperature is low, the current flowing through the

外気温度の高低は、カメラハウジング1と恒温ボックス4間に配置された温度センサA10により測定することができる。

The level of the outside air temperature can be measured by a temperature sensor A10 disposed between the camera housing 1 and the

以上のように、恒温ボックス4により、レンズ部3とカメラモジュール2を覆うことににより、レンズ部3とカメラモジュール2に対する外気温度の変化による影響を最小限に保ちつつ、ペルチェ素子5により、外気の温度変化とは逆向きになるように、放熱フィンの温度を制御することにより、レンズ部とカメラモジュールの温度変化を一定に保つことができる。

As described above, by covering the

1…屋外用カメラハウジング、2…カメラモジュール、3…レンズ、4…恒温ボックス、5…ペルチェ素子、6…内部放熱フィン、7…内部FAN、8…外部放熱フィン、9…外部FAN、10…センサA、11…センサB。 DESCRIPTION OF SYMBOLS 1 ... Outdoor camera housing, 2 ... Camera module, 3 ... Lens, 4 ... Constant temperature box, 5 ... Peltier element, 6 ... Internal heat radiation fin, 7 ... Internal heat radiation fin, 8 ... External heat radiation fin, 9 ... External heat radiation fan, 10 ... Sensor A, 11 ... sensor B.

Claims (1)

前記レンズ部と、前記カメラモジュールとは、前記カメラハウジングの内部で断熱構造の恒温ボックスで覆われ、前記恒温ボックスの一面に、ペルチェ素子が設置され、前記ペルチェ素子に接触するように、前記恒温ボックスの内部に内部放熱フィンと前記恒温ボックスの外部に外部放熱フィンが取付けられ、

前記外気温度が高いときには、前記内部放熱フィンの温度を低く、前記外部放熱フィンの温度を高く、

前記外気温度が低いときには、前記内部放熱フィンの温度を高く、前記外部放熱フィンの温度を低くするように、前記ペルチェ素子を制御することを特徴とするカメラ装置。 In a camera device comprising a lens unit and a camera module, and comprising a lens housing and a camera housing for housing the camera module,

The lens unit and the camera module are covered with a thermostat box having a heat insulating structure inside the camera housing, and a Peltier element is installed on one surface of the thermostat box, and the thermostat is in contact with the Peltier element. An internal radiating fin inside the box and an external radiating fin outside the constant temperature box are attached,

When the outside air temperature is high, the temperature of the internal radiating fin is low, the temperature of the external radiating fin is high,

The camera device, wherein the Peltier element is controlled such that when the outside air temperature is low, the temperature of the internal radiating fin is increased and the temperature of the external radiating fin is decreased.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009018370A JP2010175835A (en) | 2009-01-29 | 2009-01-29 | Camera apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009018370A JP2010175835A (en) | 2009-01-29 | 2009-01-29 | Camera apparatus |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010175835A true JP2010175835A (en) | 2010-08-12 |

| JP2010175835A5 JP2010175835A5 (en) | 2012-03-08 |

Family

ID=42706884

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009018370A Pending JP2010175835A (en) | 2009-01-29 | 2009-01-29 | Camera apparatus |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2010175835A (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101642814B1 (en) * | 2015-03-09 | 2016-07-26 | 제일정보통신(주) | Automatic number plate recognition camera system capable of EMP protection under extreme temperatures |

| KR101642810B1 (en) * | 2015-03-09 | 2016-07-26 | 제일정보통신(주) | Automatic number plate recognition camera system capable of EMP protection |

| AT518512A1 (en) * | 2016-03-15 | 2017-10-15 | Efkon Ag | Device for maintaining the temperature of an electrical device |

| DE102017110901A1 (en) * | 2017-05-18 | 2018-11-22 | Eisenmann Se | Device for conditioning a camera |

| JP2019145541A (en) * | 2018-02-16 | 2019-08-29 | パナソニックIpマネジメント株式会社 | Component mounting device |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60177772A (en) * | 1984-02-24 | 1985-09-11 | Hitachi Ltd | Case of television camera |

| JPS61158277A (en) * | 1984-12-29 | 1986-07-17 | Fujitsu Ltd | Infrared-ray image pickup device |

| JPH01117597U (en) * | 1988-02-02 | 1989-08-08 | ||

| JPH01167694U (en) * | 1988-05-17 | 1989-11-24 | ||

| JPH09203950A (en) * | 1996-01-25 | 1997-08-05 | Nippon Avionics Co Ltd | Environmental resistance camera housing |

| JP2001228543A (en) * | 2000-02-15 | 2001-08-24 | Eremakku:Kk | Housing for video equipment |

| JP2003115686A (en) * | 2001-10-05 | 2003-04-18 | Nuclear Fuel Ind Ltd | Overheating controller for operated heat generating component in equipment |

| JP2006331140A (en) * | 2005-05-27 | 2006-12-07 | Olympus Corp | Design method for electronic equipment, electronic equipment design device and program |

-

2009

- 2009-01-29 JP JP2009018370A patent/JP2010175835A/en active Pending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60177772A (en) * | 1984-02-24 | 1985-09-11 | Hitachi Ltd | Case of television camera |

| JPS61158277A (en) * | 1984-12-29 | 1986-07-17 | Fujitsu Ltd | Infrared-ray image pickup device |

| JPH01117597U (en) * | 1988-02-02 | 1989-08-08 | ||

| JPH01167694U (en) * | 1988-05-17 | 1989-11-24 | ||

| JPH09203950A (en) * | 1996-01-25 | 1997-08-05 | Nippon Avionics Co Ltd | Environmental resistance camera housing |

| JP2001228543A (en) * | 2000-02-15 | 2001-08-24 | Eremakku:Kk | Housing for video equipment |

| JP2003115686A (en) * | 2001-10-05 | 2003-04-18 | Nuclear Fuel Ind Ltd | Overheating controller for operated heat generating component in equipment |

| JP2006331140A (en) * | 2005-05-27 | 2006-12-07 | Olympus Corp | Design method for electronic equipment, electronic equipment design device and program |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101642814B1 (en) * | 2015-03-09 | 2016-07-26 | 제일정보통신(주) | Automatic number plate recognition camera system capable of EMP protection under extreme temperatures |

| KR101642810B1 (en) * | 2015-03-09 | 2016-07-26 | 제일정보통신(주) | Automatic number plate recognition camera system capable of EMP protection |

| AT518512A1 (en) * | 2016-03-15 | 2017-10-15 | Efkon Ag | Device for maintaining the temperature of an electrical device |

| AT518512B1 (en) * | 2016-03-15 | 2023-03-15 | Efkon Gmbh | Device for maintaining the temperature of an electrical device |

| DE102017110901A1 (en) * | 2017-05-18 | 2018-11-22 | Eisenmann Se | Device for conditioning a camera |

| JP2019145541A (en) * | 2018-02-16 | 2019-08-29 | パナソニックIpマネジメント株式会社 | Component mounting device |

| JP7178543B2 (en) | 2018-02-16 | 2022-11-28 | パナソニックIpマネジメント株式会社 | Component mounter |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US12093092B2 (en) | Heat transfer apparatus for a computer environment | |

| US9628731B2 (en) | Image capture apparatus | |

| US10795241B2 (en) | IP camera with heat-conducting element for preventing dew condensation | |

| US20110179806A1 (en) | Cooling apparatus | |

| JP4576205B2 (en) | Thermoelectric cooling device and method for adjusting temperature of X-ray detector | |

| US20080173024A1 (en) | Temperature control systems and methods | |

| JPH08178469A (en) | Electronic cooling device | |

| JP2010175835A (en) | Camera apparatus | |

| KR101275721B1 (en) | Multi-purpose heat dissipation enclosure for camera | |

| CN111856856B (en) | Projection device and heat dissipation control method | |

| EP2635017A1 (en) | Monitoring camera | |

| JP2015126128A (en) | Electronic apparatus having forced air cooling | |

| JP2015204422A (en) | Electronic apparatus performing forced air-cooling | |

| JP2008028597A (en) | Monitoring camera | |

| KR102138221B1 (en) | Air cooling heat dissipation system for laser | |

| JP2018180257A (en) | Image monitoring device and temperature control method for the same | |

| JP2010267912A (en) | Cooling device | |

| JP2003283175A (en) | Simplified constant temperature apparatus for electronic device and its control method | |

| JP2010175835A5 (en) | ||

| CN211293575U (en) | Projection device | |

| CN111856857B (en) | Projection device and heat dissipation control method thereof | |

| JP2008177448A (en) | Cooling device and cooling method of semiconductor laser | |

| JP2010283673A (en) | Video camera provided with cooling function | |

| US20080272453A1 (en) | Optical device cooling apparatus and method | |

| JP2017129507A (en) | Temperature controller and temperature-testing device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120125 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120125 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20131015 |