JP2009534177A - 酸素還元性触媒層の製造方法 - Google Patents

酸素還元性触媒層の製造方法 Download PDFInfo

- Publication number

- JP2009534177A JP2009534177A JP2009506681A JP2009506681A JP2009534177A JP 2009534177 A JP2009534177 A JP 2009534177A JP 2009506681 A JP2009506681 A JP 2009506681A JP 2009506681 A JP2009506681 A JP 2009506681A JP 2009534177 A JP2009534177 A JP 2009534177A

- Authority

- JP

- Japan

- Prior art keywords

- carbon

- substrate

- catalyst layer

- transition metal

- nitrogen

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000003054 catalyst Substances 0.000 title claims abstract description 124

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 16

- 239000000758 substrate Substances 0.000 claims abstract description 74

- 239000000463 material Substances 0.000 claims abstract description 69

- 238000010438 heat treatment Methods 0.000 claims abstract description 65

- 239000007789 gas Substances 0.000 claims abstract description 62

- 238000005240 physical vapour deposition Methods 0.000 claims abstract description 59

- 230000003197 catalytic effect Effects 0.000 claims abstract description 53

- 238000012545 processing Methods 0.000 claims abstract description 53

- 150000003624 transition metals Chemical class 0.000 claims abstract description 52

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 claims abstract description 44

- 229910052723 transition metal Inorganic materials 0.000 claims abstract description 43

- 229910052697 platinum Inorganic materials 0.000 claims abstract description 21

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 claims abstract description 13

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 71

- 238000000034 method Methods 0.000 claims description 65

- 229910052799 carbon Inorganic materials 0.000 claims description 64

- 239000012528 membrane Substances 0.000 claims description 51

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 47

- 239000010408 film Substances 0.000 claims description 45

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 39

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 35

- 239000001301 oxygen Substances 0.000 claims description 35

- 229910052760 oxygen Inorganic materials 0.000 claims description 35

- 229910052757 nitrogen Inorganic materials 0.000 claims description 22

- 229910052742 iron Inorganic materials 0.000 claims description 17

- 239000002245 particle Substances 0.000 claims description 17

- 229910017052 cobalt Inorganic materials 0.000 claims description 12

- 239000010941 cobalt Substances 0.000 claims description 12

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 claims description 12

- 239000002131 composite material Substances 0.000 claims description 11

- 238000011282 treatment Methods 0.000 claims description 10

- WEVYAHXRMPXWCK-UHFFFAOYSA-N Acetonitrile Chemical compound CC#N WEVYAHXRMPXWCK-UHFFFAOYSA-N 0.000 claims description 9

- 238000005260 corrosion Methods 0.000 claims description 9

- 230000007797 corrosion Effects 0.000 claims description 9

- 239000000843 powder Substances 0.000 claims description 9

- -1 ammonia, aromatic nitrogen compounds Chemical class 0.000 claims description 6

- 239000011248 coating agent Substances 0.000 claims description 6

- 238000000576 coating method Methods 0.000 claims description 6

- 238000000151 deposition Methods 0.000 claims description 6

- 229910000510 noble metal Inorganic materials 0.000 claims description 6

- 239000010409 thin film Substances 0.000 claims description 6

- 239000004745 nonwoven fabric Substances 0.000 claims description 4

- 239000002759 woven fabric Substances 0.000 claims description 4

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 3

- 239000000919 ceramic Substances 0.000 claims description 3

- 239000000835 fiber Substances 0.000 claims description 3

- 239000010936 titanium Substances 0.000 claims description 3

- 229910052719 titanium Inorganic materials 0.000 claims description 3

- 229910017464 nitrogen compound Inorganic materials 0.000 claims 2

- 238000005229 chemical vapour deposition Methods 0.000 claims 1

- 239000010410 layer Substances 0.000 description 103

- 239000000446 fuel Substances 0.000 description 28

- 210000004027 cell Anatomy 0.000 description 26

- 230000008569 process Effects 0.000 description 23

- 230000000052 comparative effect Effects 0.000 description 22

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 21

- 238000009792 diffusion process Methods 0.000 description 21

- 238000005259 measurement Methods 0.000 description 16

- 239000003792 electrolyte Substances 0.000 description 14

- 239000001257 hydrogen Substances 0.000 description 14

- 229910052739 hydrogen Inorganic materials 0.000 description 14

- 230000010287 polarization Effects 0.000 description 13

- 102100025532 Male-enhanced antigen 1 Human genes 0.000 description 12

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 11

- 125000004429 atom Chemical group 0.000 description 11

- 239000000203 mixture Substances 0.000 description 11

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 10

- 229910021529 ammonia Inorganic materials 0.000 description 10

- 238000004544 sputter deposition Methods 0.000 description 10

- 229910002804 graphite Inorganic materials 0.000 description 9

- 239000010439 graphite Substances 0.000 description 9

- 239000000523 sample Substances 0.000 description 9

- 239000006185 dispersion Substances 0.000 description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 7

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 6

- 125000004432 carbon atom Chemical group C* 0.000 description 6

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 6

- 229920000049 Carbon (fiber) Polymers 0.000 description 5

- 229920000557 Nafion® Polymers 0.000 description 5

- 239000002253 acid Substances 0.000 description 5

- 229910052786 argon Inorganic materials 0.000 description 5

- 150000001721 carbon Chemical group 0.000 description 5

- 239000004917 carbon fiber Substances 0.000 description 5

- 238000000691 measurement method Methods 0.000 description 5

- 125000004433 nitrogen atom Chemical group N* 0.000 description 5

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 5

- 238000010586 diagram Methods 0.000 description 4

- 210000002381 plasma Anatomy 0.000 description 4

- 239000010453 quartz Substances 0.000 description 4

- 238000012360 testing method Methods 0.000 description 4

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 3

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- RWRDLPDLKQPQOW-UHFFFAOYSA-N Pyrrolidine Chemical compound C1CCNC1 RWRDLPDLKQPQOW-UHFFFAOYSA-N 0.000 description 3

- 239000006230 acetylene black Substances 0.000 description 3

- 230000002378 acidificating effect Effects 0.000 description 3

- 238000002485 combustion reaction Methods 0.000 description 3

- 238000002484 cyclic voltammetry Methods 0.000 description 3

- 238000005137 deposition process Methods 0.000 description 3

- 229910001873 dinitrogen Inorganic materials 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 238000001755 magnetron sputter deposition Methods 0.000 description 3

- 239000010970 precious metal Substances 0.000 description 3

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 2

- 235000005018 Pinus echinata Nutrition 0.000 description 2

- 241001236219 Pinus echinata Species 0.000 description 2

- 235000017339 Pinus palustris Nutrition 0.000 description 2

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical compound C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 2

- KAESVJOAVNADME-UHFFFAOYSA-N Pyrrole Chemical compound C=1C=CNC=1 KAESVJOAVNADME-UHFFFAOYSA-N 0.000 description 2

- SMWDFEZZVXVKRB-UHFFFAOYSA-N Quinoline Chemical compound N1=CC=CC2=CC=CC=C21 SMWDFEZZVXVKRB-UHFFFAOYSA-N 0.000 description 2

- 238000013019 agitation Methods 0.000 description 2

- 238000012512 characterization method Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 238000010891 electric arc Methods 0.000 description 2

- 230000005611 electricity Effects 0.000 description 2

- 229920002313 fluoropolymer Polymers 0.000 description 2

- 239000004811 fluoropolymer Substances 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 238000002847 impedance measurement Methods 0.000 description 2

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 2

- 229910052753 mercury Inorganic materials 0.000 description 2

- BDAGIHXWWSANSR-UHFFFAOYSA-N methanoic acid Natural products OC=O BDAGIHXWWSANSR-UHFFFAOYSA-N 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- JMANVNJQNLATNU-UHFFFAOYSA-N oxalonitrile Chemical compound N#CC#N JMANVNJQNLATNU-UHFFFAOYSA-N 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 238000010926 purge Methods 0.000 description 2

- 239000012925 reference material Substances 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 230000004580 weight loss Effects 0.000 description 2

- DOBUSJIVSSJEDA-UHFFFAOYSA-L 1,3-dioxa-2$l^{6}-thia-4-mercuracyclobutane 2,2-dioxide Chemical compound [Hg+2].[O-]S([O-])(=O)=O DOBUSJIVSSJEDA-UHFFFAOYSA-L 0.000 description 1

- OSWFIVFLDKOXQC-UHFFFAOYSA-N 4-(3-methoxyphenyl)aniline Chemical compound COC1=CC=CC(C=2C=CC(N)=CC=2)=C1 OSWFIVFLDKOXQC-UHFFFAOYSA-N 0.000 description 1

- 241000208140 Acer Species 0.000 description 1

- 229910052582 BN Inorganic materials 0.000 description 1

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 description 1

- MYMOFIZGZYHOMD-UHFFFAOYSA-N Dioxygen Chemical compound O=O MYMOFIZGZYHOMD-UHFFFAOYSA-N 0.000 description 1

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- 102100034256 Mucin-1 Human genes 0.000 description 1

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 102220522310 THAP domain-containing protein 1_Y50A_mutation Human genes 0.000 description 1

- CODVACFVSVNQPY-UHFFFAOYSA-N [Co].[C] Chemical compound [Co].[C] CODVACFVSVNQPY-UHFFFAOYSA-N 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 239000012300 argon atmosphere Substances 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 239000012298 atmosphere Substances 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000003153 chemical reaction reagent Substances 0.000 description 1

- 239000012612 commercial material Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 239000008367 deionised water Substances 0.000 description 1

- 229910021641 deionized water Inorganic materials 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 229910001882 dioxygen Inorganic materials 0.000 description 1

- 230000005684 electric field Effects 0.000 description 1

- 239000002001 electrolyte material Substances 0.000 description 1

- 238000004146 energy storage Methods 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 235000019253 formic acid Nutrition 0.000 description 1

- 229910021397 glassy carbon Inorganic materials 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 239000008240 homogeneous mixture Substances 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 230000002706 hydrostatic effect Effects 0.000 description 1

- QWPPOHNGKGFGJK-UHFFFAOYSA-N hypochlorous acid Chemical compound ClO QWPPOHNGKGFGJK-UHFFFAOYSA-N 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 229910052741 iridium Inorganic materials 0.000 description 1

- GKOZUEZYRPOHIO-UHFFFAOYSA-N iridium atom Chemical compound [Ir] GKOZUEZYRPOHIO-UHFFFAOYSA-N 0.000 description 1

- SZVJSHCCFOBDDC-UHFFFAOYSA-N iron(II,III) oxide Inorganic materials O=[Fe]O[Fe]O[Fe]=O SZVJSHCCFOBDDC-UHFFFAOYSA-N 0.000 description 1

- 239000006166 lysate Substances 0.000 description 1

- 229910000370 mercury sulfate Inorganic materials 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000002923 metal particle Substances 0.000 description 1

- 238000001465 metallisation Methods 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 239000002105 nanoparticle Substances 0.000 description 1

- 229910052762 osmium Inorganic materials 0.000 description 1

- SYQBFIAQOQZEGI-UHFFFAOYSA-N osmium atom Chemical compound [Os] SYQBFIAQOQZEGI-UHFFFAOYSA-N 0.000 description 1

- 239000007800 oxidant agent Substances 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 238000002047 photoemission electron microscopy Methods 0.000 description 1

- 229920001483 poly(ethyl methacrylate) polymer Polymers 0.000 description 1

- UMJSCPRVCHMLSP-UHFFFAOYSA-N pyridine Natural products COC1=CC=CN=C1 UMJSCPRVCHMLSP-UHFFFAOYSA-N 0.000 description 1

- 230000009257 reactivity Effects 0.000 description 1

- 238000006722 reduction reaction Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 229910052703 rhodium Inorganic materials 0.000 description 1

- 239000010948 rhodium Substances 0.000 description 1

- MHOVAHRLVXNVSD-UHFFFAOYSA-N rhodium atom Chemical compound [Rh] MHOVAHRLVXNVSD-UHFFFAOYSA-N 0.000 description 1

- 229910052707 ruthenium Inorganic materials 0.000 description 1

- 238000001507 sample dispersion Methods 0.000 description 1

- 239000012047 saturated solution Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000000527 sonication Methods 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- BFKJFAAPBSQJPD-UHFFFAOYSA-N tetrafluoroethene Chemical group FC(F)=C(F)F BFKJFAAPBSQJPD-UHFFFAOYSA-N 0.000 description 1

- 229910001887 tin oxide Inorganic materials 0.000 description 1

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

- 239000012808 vapor phase Substances 0.000 description 1

- 239000012855 volatile organic compound Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/0664—Carbonitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/24—Vacuum evaporation

- C23C14/32—Vacuum evaporation by explosion; by evaporation and subsequent ionisation of the vapours, e.g. ion-plating

- C23C14/325—Electric arc evaporation

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

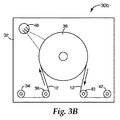

- C23C14/56—Apparatus specially adapted for continuous coating; Arrangements for maintaining the vacuum, e.g. vacuum locks

- C23C14/562—Apparatus specially adapted for continuous coating; Arrangements for maintaining the vacuum, e.g. vacuum locks for coating elongated substrates

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/58—After-treatment

- C23C14/5846—Reactive treatment

- C23C14/586—Nitriding

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Catalysts (AREA)

- Inert Electrodes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/379,518 US7740902B2 (en) | 2006-04-20 | 2006-04-20 | Method for making oxygen-reducing catalyst layers |

| PCT/US2007/066247 WO2007140051A2 (en) | 2006-04-20 | 2007-04-09 | Method for making oxygen-reducing catalyst layers |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009534177A true JP2009534177A (ja) | 2009-09-24 |

| JP2009534177A5 JP2009534177A5 (enExample) | 2010-05-27 |

Family

ID=38619788

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009506681A Withdrawn JP2009534177A (ja) | 2006-04-20 | 2007-04-09 | 酸素還元性触媒層の製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7740902B2 (enExample) |

| EP (1) | EP2011181A2 (enExample) |

| JP (1) | JP2009534177A (enExample) |

| CN (1) | CN101427405A (enExample) |

| WO (1) | WO2007140051A2 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012146670A (ja) * | 2010-07-15 | 2012-08-02 | Showa Denko Kk | 燃料電池用触媒およびその用途 |

| JP2012221735A (ja) * | 2011-04-08 | 2012-11-12 | Kumamoto Univ | 燃料電池用電極触媒 |

| JP2014015345A (ja) * | 2012-07-06 | 2014-01-30 | Panasonic Corp | 炭素系材料、電極触媒、電極、ガス拡散電極、電気化学装置、燃料電池、並びに炭素系材料の製造方法 |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA2597290A1 (en) * | 2005-02-16 | 2006-08-24 | 3M Innovative Properties Company | Fuel cell catalyst |

| US9287568B2 (en) | 2007-04-12 | 2016-03-15 | 3M Innovative Properties Company | High performance, high durability non-precious metal fuel cell catalysts |

| US20080280164A1 (en) * | 2007-05-11 | 2008-11-13 | 3M Innovative Properties Company | Microporous carbon catalyst support material |

| US20100048380A1 (en) * | 2008-08-21 | 2010-02-25 | Board Of Trustees Of Michigan State University | Novel catalyst for oxygen reduction reaction in fuel cells |

| US20110287174A1 (en) | 2008-08-21 | 2011-11-24 | Board Of Trustees Of Michigan State University | Novel catalyst for oxygen reduction reaction in fuel cells |

| CN102498239B (zh) | 2009-08-04 | 2016-01-20 | 金泰克斯公司 | 用于电化学传感器中的阴极材料和相关的装置、以及其制造方法 |

| CN102386429B (zh) * | 2011-10-24 | 2013-01-23 | 沈阳建筑大学 | 一种单室无膜微生物燃料电池的空气阴极催化剂层制作方法 |

| US9350026B2 (en) | 2012-09-28 | 2016-05-24 | Uchicago Argonne, Llc | Nanofibrous electrocatalysts |

| CN103736513B (zh) * | 2014-01-03 | 2016-03-02 | 北京工业大学 | 一种TiO2(B)@g-C3N4复合纳米片光催化剂的制备方法 |

| DE102021107865A1 (de) | 2021-03-29 | 2022-09-29 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung eingetragener Verein | Bauteile aus einem keramischen Werkstoffverbund und Verfahren zu seiner Herstellung |

| CN116651437A (zh) * | 2023-05-19 | 2023-08-29 | 北京邮电大学 | 一种制备杂原子修饰金属负载商业碳基材料方法 |

| EP4667614A1 (de) * | 2024-06-21 | 2025-12-24 | voestalpine Stahl GmbH | Verfahren und vorrichtung zum dreidimensionalen beschichten eines porösen materials |

Family Cites Families (57)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4340276A (en) | 1978-11-01 | 1982-07-20 | Minnesota Mining And Manufacturing Company | Method of producing a microstructured surface and the article produced thereby |

| JPS589764B2 (ja) | 1980-04-18 | 1983-02-22 | 宇部興産株式会社 | 金属炭窒化物の製法 |

| JPS59181466A (ja) * | 1983-03-31 | 1984-10-15 | Toshiba Corp | 電解質マトリツクスの製造方法 |

| US5079107A (en) | 1984-06-07 | 1992-01-07 | Giner, Inc. | Cathode alloy electrocatalysts |

| US4568598A (en) | 1984-10-30 | 1986-02-04 | Minnesota Mining And Manufacturing Company | Article with reduced friction polymer sheet support |

| US4812352A (en) | 1986-08-25 | 1989-03-14 | Minnesota Mining And Manufacturing Company | Article having surface layer of uniformly oriented, crystalline, organic microstructures |

| US5039561A (en) | 1986-08-25 | 1991-08-13 | Minnesota Mining And Manufacturing Company | Method for preparing an article having surface layer of uniformly oriented, crystalline, organic microstructures |

| JPH01210035A (ja) | 1988-02-18 | 1989-08-23 | Tanaka Kikinzoku Kogyo Kk | 白金触媒とその製造方法 |

| US5176786A (en) | 1988-07-13 | 1993-01-05 | Minnesota Mining And Manufacturing Company | Organic thin film controlled molecular epitaxy |

| US4958386A (en) * | 1988-07-14 | 1990-09-25 | Louis Jeune Marc Henri | Aerobic pants |

| US5336558A (en) | 1991-06-24 | 1994-08-09 | Minnesota Mining And Manufacturing Company | Composite article comprising oriented microstructures |

| DK0564796T3 (da) | 1992-03-13 | 2000-07-10 | Binsmaier Hannelore | Fremgangsmåde til fremstilling af elektrisk energi ud fra bioråstoffer |

| US5240893A (en) | 1992-06-05 | 1993-08-31 | General Motors Corporation | Method of preparing metal-heterocarbon-nitrogen catalyst for electrochemical cells |

| US5338430A (en) | 1992-12-23 | 1994-08-16 | Minnesota Mining And Manufacturing Company | Nanostructured electrode membranes |

| US5643343A (en) | 1993-11-23 | 1997-07-01 | Selifanov; Oleg Vladimirovich | Abrasive material for precision surface treatment and a method for the manufacturing thereof |

| US5593934A (en) | 1993-12-14 | 1997-01-14 | Tanaka Kikinzoku Kogyo K.K. | Platinum alloy catalyst |

| US5711773A (en) | 1994-11-17 | 1998-01-27 | Plasmoteg Engineering Center | Abrasive material for precision surface treatment and a method for the manufacturing thereof |

| US5872074A (en) | 1997-01-24 | 1999-02-16 | Hydro-Quebec | Leached nanocrystalline materials process for manufacture of the same, and use thereof in the energetic field |

| US6475653B1 (en) | 1997-09-01 | 2002-11-05 | Rmg Services Pty Ltd | Non diffusion fuel cell and a process of using the fuel cell |

| US5879828A (en) | 1997-10-10 | 1999-03-09 | Minnesota Mining And Manufacturing Company | Membrane electrode assembly |

| US5879827A (en) | 1997-10-10 | 1999-03-09 | Minnesota Mining And Manufacturing Company | Catalyst for membrane electrode assembly and method of making |

| US6136412A (en) | 1997-10-10 | 2000-10-24 | 3M Innovative Properties Company | Microtextured catalyst transfer substrate |

| US6042959A (en) | 1997-10-10 | 2000-03-28 | 3M Innovative Properties Company | Membrane electrode assembly and method of its manufacture |

| DE19802013A1 (de) | 1998-01-21 | 1999-07-22 | Huels Chemische Werke Ag | Verfahren zur Herstellung niederer und höherer Alkalialkoholate, insbesondere Kaliumtertiärbutylat, durch mikroheterogene Katalyse |

| US6967183B2 (en) * | 1998-08-27 | 2005-11-22 | Cabot Corporation | Electrocatalyst powders, methods for producing powders and devices fabricated from same |

| US6610436B1 (en) | 1998-09-11 | 2003-08-26 | Gore Enterprise Holdings | Catalytic coatings and fuel cell electrodes and membrane electrode assemblies made therefrom |

| US6403245B1 (en) | 1999-05-21 | 2002-06-11 | Microcoating Technologies, Inc. | Materials and processes for providing fuel cells and active membranes |

| US6482763B2 (en) | 1999-12-29 | 2002-11-19 | 3M Innovative Properties Company | Suboxide fuel cell catalyst for enhanced reformate tolerance |

| US6749892B2 (en) | 2000-03-22 | 2004-06-15 | Samsung Electronics Co., Ltd. | Method for fabricating membrane-electrode assembly and fuel cell adopting the membrane-electrode assembly |

| WO2002005371A1 (en) * | 2000-07-06 | 2002-01-17 | Matsushita Electric Industrial Co., Ltd. | Method for producing film electrode jointed product and method for producing solid polymer type fuel cell |

| DE10038800A1 (de) | 2000-08-09 | 2002-06-20 | Cornelia Repenning | Vorrichtung zur Herstellung katalytisch wirksamer Schichten |

| US6835489B2 (en) * | 2002-08-15 | 2004-12-28 | Texaco Ovonic Fuel Cell Llc | Double layer oxygen electrode and method of making |

| US7157068B2 (en) * | 2001-05-21 | 2007-01-02 | The Trustees Of Boston College | Varied morphology carbon nanotubes and method for their manufacture |

| US20030124717A1 (en) * | 2001-11-26 | 2003-07-03 | Yuji Awano | Method of manufacturing carbon cylindrical structures and biopolymer detection device |

| US7390920B2 (en) | 2002-02-14 | 2008-06-24 | Monsanto Technology Llc | Oxidation catalyst and process |

| CN1260842C (zh) | 2002-07-09 | 2006-06-21 | 中国科学院长春应用化学研究所 | 燃料电池阴极非铂复合催化剂的制备方法 |

| US6946362B2 (en) | 2002-09-06 | 2005-09-20 | Hewlett-Packard Development Company, L.P. | Method and apparatus for forming high surface area material films and membranes |

| US7645543B2 (en) * | 2002-10-15 | 2010-01-12 | Polyplus Battery Company | Active metal/aqueous electrochemical cells and systems |

| EP1570539A2 (en) | 2002-10-31 | 2005-09-07 | Carbon Nanotechnologies, Inc. | Fuel cell electrode comprising carbon nanotubes |

| US7108939B2 (en) | 2002-12-12 | 2006-09-19 | Hitachi, Ltd. | Covalently bonded catalyst carrier and catalytic component |

| US20040116742A1 (en) | 2002-12-17 | 2004-06-17 | 3M Innovative Properties Company | Selective reaction of hexafluoropropylene oxide with perfluoroacyl fluorides |

| US6624328B1 (en) | 2002-12-17 | 2003-09-23 | 3M Innovative Properties Company | Preparation of perfluorinated vinyl ethers having a sulfonyl fluoride end-group |

| US7348088B2 (en) | 2002-12-19 | 2008-03-25 | 3M Innovative Properties Company | Polymer electrolyte membrane |

| JP4150789B2 (ja) | 2003-01-14 | 2008-09-17 | 独立行政法人産業技術総合研究所 | 非晶質窒化炭素膜及びその製造方法 |

| US20050031921A1 (en) * | 2003-08-07 | 2005-02-10 | Ovshinsky Stanford R. | Hybrid fuel cell |

| AU2004275787B2 (en) | 2003-09-26 | 2010-06-17 | 3M Innovative Properties Company | Nanoscale gold catalysts, activating agents, support media, and related methodologies useful for making such catalyst systems especially when the gold is deposited onto the support media using physical vapor deposition |

| US7419741B2 (en) | 2003-09-29 | 2008-09-02 | 3M Innovative Properties Company | Fuel cell cathode catalyst |

| US8057847B2 (en) * | 2003-10-31 | 2011-11-15 | Utc Fuel Cells, Llc | Method for preparing membranes and membrane electrode assemblies with hydrogen peroxide decomposition catalyst |

| US20050200040A1 (en) * | 2004-03-15 | 2005-09-15 | Hara Hiroaki S. | Method of preparing membrane electrode assemblies with aerogel supported catalyst |

| US7067217B2 (en) * | 2004-04-06 | 2006-06-27 | Angstrom Power | Compact fuel cell layer |

| US20060088739A1 (en) * | 2004-10-26 | 2006-04-27 | Energy Conversion Devices, Inc. | Power generation and supply system |

| CA2597290A1 (en) | 2005-02-16 | 2006-08-24 | 3M Innovative Properties Company | Fuel cell catalyst |

| US7674549B2 (en) * | 2005-02-28 | 2010-03-09 | Sanyo Electric Co., Ltd. | Fuel cell power generation apparatus, fuel cartridge, and fuel cell system using the same |

| JP2006253147A (ja) * | 2005-03-09 | 2006-09-21 | Samsung Sdi Co Ltd | 陽イオン交換膜燃料電池用の電極触媒の製造方法 |

| US20070082814A1 (en) | 2005-10-12 | 2007-04-12 | 3M Innovative Properties Company | Ternary nanocatalyst and method of making |

| US7906251B2 (en) * | 2006-04-20 | 2011-03-15 | 3M Innovative Properties Company | Oxygen-reducing catalyst layer |

| US20080274391A1 (en) * | 2007-03-05 | 2008-11-06 | Bose Rathindra N | Multifunctional tunable metal-phosphate composite electrocatalyst for efficient oxygen reduction and methanol oxidation for applications in fuel cells and electrolysis |

-

2006

- 2006-04-20 US US11/379,518 patent/US7740902B2/en not_active Expired - Fee Related

-

2007

- 2007-04-09 WO PCT/US2007/066247 patent/WO2007140051A2/en not_active Ceased

- 2007-04-09 EP EP07811838A patent/EP2011181A2/en not_active Withdrawn

- 2007-04-09 CN CNA2007800142000A patent/CN101427405A/zh active Pending

- 2007-04-09 JP JP2009506681A patent/JP2009534177A/ja not_active Withdrawn

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012146670A (ja) * | 2010-07-15 | 2012-08-02 | Showa Denko Kk | 燃料電池用触媒およびその用途 |

| JP2012221735A (ja) * | 2011-04-08 | 2012-11-12 | Kumamoto Univ | 燃料電池用電極触媒 |

| JP2014015345A (ja) * | 2012-07-06 | 2014-01-30 | Panasonic Corp | 炭素系材料、電極触媒、電極、ガス拡散電極、電気化学装置、燃料電池、並びに炭素系材料の製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101427405A (zh) | 2009-05-06 |

| US7740902B2 (en) | 2010-06-22 |

| WO2007140051A3 (en) | 2008-03-20 |

| WO2007140051A2 (en) | 2007-12-06 |

| EP2011181A2 (en) | 2009-01-07 |

| US20070248752A1 (en) | 2007-10-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2009534177A (ja) | 酸素還元性触媒層の製造方法 | |

| JP2009534175A (ja) | 酸素還元触媒層 | |

| US8221934B2 (en) | Method to enhance the durability of conductive carbon coating of PEM fuel cell bipolar plates | |

| EP3776702B1 (en) | Catalyst comprising pt, ni, and ta | |

| CA2909743A1 (en) | Catalyst electrodes and method of making it | |

| WO1999013128A1 (en) | A method of depositing an electrocatalyst and electrodes formed by such method | |

| US11973232B2 (en) | Catalyst | |

| EP3533099B1 (en) | Pt-ni-ir catalyst for fuel cell | |

| EP3533097B1 (en) | Catalyst | |

| EP3533096B1 (en) | Catalyst | |

| US20220115675A1 (en) | Pt-ni-ir catalyst for fuel cell | |

| US11404702B2 (en) | Catalyst comprising Pt, Ni, and Cr | |

| US20210008528A1 (en) | Catalyst comprising pt, ni, and ru | |

| CN101120467A (zh) | 燃料电池催化剂 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100409 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100409 |

|

| A761 | Written withdrawal of application |

Free format text: JAPANESE INTERMEDIATE CODE: A761 Effective date: 20100520 |