JP2009190071A - 溶湯面の不純物除去具 - Google Patents

溶湯面の不純物除去具 Download PDFInfo

- Publication number

- JP2009190071A JP2009190071A JP2008034711A JP2008034711A JP2009190071A JP 2009190071 A JP2009190071 A JP 2009190071A JP 2008034711 A JP2008034711 A JP 2008034711A JP 2008034711 A JP2008034711 A JP 2008034711A JP 2009190071 A JP2009190071 A JP 2009190071A

- Authority

- JP

- Japan

- Prior art keywords

- gas

- molten metal

- handle

- impurity

- scooping

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000012535 impurity Substances 0.000 title claims abstract description 30

- 229910052751 metal Inorganic materials 0.000 title claims abstract description 30

- 239000002184 metal Substances 0.000 title claims abstract description 30

- 239000003963 antioxidant agent Substances 0.000 claims description 6

- 230000003078 antioxidant effect Effects 0.000 claims description 6

- 238000002485 combustion reaction Methods 0.000 abstract description 7

- 230000003647 oxidation Effects 0.000 abstract description 5

- 238000007254 oxidation reaction Methods 0.000 abstract description 5

- 230000002265 prevention Effects 0.000 abstract 4

- 239000007789 gas Substances 0.000 description 34

- 230000008018 melting Effects 0.000 description 10

- 238000002844 melting Methods 0.000 description 10

- 238000002347 injection Methods 0.000 description 4

- 239000007924 injection Substances 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- 229910045601 alloy Inorganic materials 0.000 description 3

- 229910052749 magnesium Inorganic materials 0.000 description 3

- 239000011777 magnesium Substances 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 239000012212 insulator Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 239000007769 metal material Substances 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 150000004767 nitrides Chemical class 0.000 description 2

- 230000001590 oxidative effect Effects 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- RNFJDJUURJAICM-UHFFFAOYSA-N 2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-triene Chemical compound N=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1 RNFJDJUURJAICM-UHFFFAOYSA-N 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 230000001079 digestive effect Effects 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000002000 scavenging effect Effects 0.000 description 1

- 210000000707 wrist Anatomy 0.000 description 1

Images

Landscapes

- Casting Support Devices, Ladles, And Melt Control Thereby (AREA)

Abstract

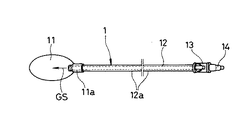

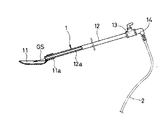

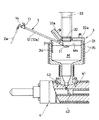

【解決手段】不純物の掬い部と、掬い部に取付けた柄部とからなる。柄部を開閉バルブを設けた管体により中空に形成する。柄部後端にガスホースの接続具を設ける。柄部内をガス通路として先端開口から掬い部に酸化防止ガス又は防燃ガスを噴出できるようにする。

【選択図】図1

Description

11 掬い部

12 柄部

12a 管体

13 開閉バルブ

14 ホース継ぎ口

Claims (2)

- 不純物の掬い部と、その掬い部に取付けた柄部とからなり、その柄部内をガス通路として先端開口から掬い部に酸化防止ガス又は防燃ガスを噴出できるように、該柄部を開閉バルブを設けた管体により中空に形成し、柄部後端にホース継ぎ口を設けてなることを特徴とする溶湯面の不純物除去具。

- 上記掬い部は浅底でスプーンのボールと同様な形態からなり、その後端縁に上向き斜めに突設した柄受けに上記管体の先端部を挿通止着し、柄部の先端開口を掬い部の底面に向けて位置させてなることを特徴とする請求項1記載の溶湯面の不純物除去具。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008034711A JP2009190071A (ja) | 2008-02-15 | 2008-02-15 | 溶湯面の不純物除去具 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008034711A JP2009190071A (ja) | 2008-02-15 | 2008-02-15 | 溶湯面の不純物除去具 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2009190071A true JP2009190071A (ja) | 2009-08-27 |

Family

ID=41072571

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008034711A Pending JP2009190071A (ja) | 2008-02-15 | 2008-02-15 | 溶湯面の不純物除去具 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2009190071A (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101541715B1 (ko) | 2013-12-23 | 2015-08-04 | 주식회사 포스코 | 슬래그 제거 장치 |

| CN110487085A (zh) * | 2019-08-07 | 2019-11-22 | 安徽信息工程学院 | 一种坩埚熔炉捞渣勺 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS53127328A (en) * | 1977-04-14 | 1978-11-07 | Kawasaki Steel Co | Dip up and splash out apparatus for ingot making scum |

| JPS54142333A (en) * | 1978-04-27 | 1979-11-06 | Toyo Boseki | Supporting element for suspension collector |

-

2008

- 2008-02-15 JP JP2008034711A patent/JP2009190071A/ja active Pending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS53127328A (en) * | 1977-04-14 | 1978-11-07 | Kawasaki Steel Co | Dip up and splash out apparatus for ingot making scum |

| JPS54142333A (en) * | 1978-04-27 | 1979-11-06 | Toyo Boseki | Supporting element for suspension collector |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101541715B1 (ko) | 2013-12-23 | 2015-08-04 | 주식회사 포스코 | 슬래그 제거 장치 |

| CN110487085A (zh) * | 2019-08-07 | 2019-11-22 | 安徽信息工程学院 | 一种坩埚熔炉捞渣勺 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| ES2216760T3 (es) | Lanza de varios usos para una camara bajo vacio para desgasificado y procedimiento de utilizacion. | |

| KR20130002325A (ko) | 구리 애노드 정련 시스템 및 방법 | |

| JP2009190071A (ja) | 溶湯面の不純物除去具 | |

| US7563407B2 (en) | Thermal lance assembly | |

| JP2008272815A (ja) | 金属溶湯保持炉の構造 | |

| TWI584889B (zh) | 燃燒裝置及熔融金屬容器之澆道清洗方法 | |

| JP4355581B2 (ja) | 溶融金属用カバーガスの供給方法 | |

| JP6182373B2 (ja) | 消火体験装置 | |

| KR101186577B1 (ko) | 젯트 랜스 점화 및 용융 장치 | |

| JP2005089792A (ja) | スクラップまたは溶銑の転炉あるいは予備処理炉への装入方法、装入装置および装入制御方法 | |

| CN201680713U (zh) | 废杂铜倾动式熔炼炉 | |

| NO158607B (no) | Verktoeyholder, fortrinnsvis for termiske lanser. | |

| JP6358440B2 (ja) | 酸素ガス吹き込み用ランスパイプ | |

| JPH06328232A (ja) | 溶融金属注湯構造 | |

| KR101804670B1 (ko) | 일렉트로 슬래그 재용해로 | |

| KR100768301B1 (ko) | 레들용 필러 투입장치 | |

| KR20190044238A (ko) | 산소랜스의 점화장치 | |

| JP3160108U (ja) | パイプ状消火用具 | |

| KR200346394Y1 (ko) | 원터치 절단기 | |

| FR2467651A1 (fr) | Dispositif pour deboucher l'orifice de coulee d'un recipient metallurgique | |

| KR101907318B1 (ko) | 고로 출선구 굴착용 산소 파이프 착화 장치 | |

| JP4880826B2 (ja) | 酸素吹き込みノズル | |

| JP4214084B2 (ja) | ポーラスプラグの洗浄方法及び装置 | |

| JPH031574B2 (ja) | ||

| JPH07276039A (ja) | 溶融金属注入ノズルの洗浄ノズル |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Effective date: 20090727 Free format text: JAPANESE INTERMEDIATE CODE: A621 |

|

| RD04 | Notification of resignation of power of attorney |

Effective date: 20100131 Free format text: JAPANESE INTERMEDIATE CODE: A7424 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110418 |

|

| A131 | Notification of reasons for refusal |

Effective date: 20110426 Free format text: JAPANESE INTERMEDIATE CODE: A131 |

|

| A02 | Decision of refusal |

Effective date: 20111018 Free format text: JAPANESE INTERMEDIATE CODE: A02 |